Hydraulic fluid and transmission oil on vegetable oil basis.

[0001] The invention concerns the use of a vegetable oil with a specific composition as hydraulic fluid and Getriebeöl.

By a hydraulic fluid one generally understands a fluid, which is needed for the transmission of energy in hydraulic systems. Hydraulic fluids must fulfill a multiplicity of requirements. So they should show a good lubrication behavior and a small compressibility, apart from a high resistance to aging should the influence of the temperature on the viscosity as small as possible sein.

Admit are hydraulic fluids as hydraulic oils based on mineral oil. These wise usually a viscosity index of approx. 100 up. Additives are added to the mineral oil, in order to ensure a corrosion protection and increase its resistance to aging. Additionally frequently viscosity index-better is added to them. By it langkettige hydrocarbon connections are to be understood, which work in more or less cold oils only little viscosity-increasing, however with higher operatings temperature by a Entknäulen in the oil separate and thus its volume increase. The oil thickens thereby and the viscosity index increases in the desired Weise.

Such viscosity index-better have however the disadvantage that the langkettigen hydrocarbon connections are split under load into smaller fragments, whereby their original thickening effect changes partly drastically. This effect is in the professional world as so-called permanent Scherverlust bekannt.

In addition synthetic hydraulic fluids are well-known, are e.g. developed from phosphatic esters or water-free chlorinated hydrocarbons. Also mixtures from both components are used as hydraulic fluids. Their viscosity index is for instance with 150.

In contrast to this in the meantime also biologically degradable hydraulic fluids on vegetable oil basis are become known. Here in particular rapeseel oil is to be called as a well-known hydraulic fluid. The viscosity index of such hydraulic fluids on the basis of vegetable oils usually lies above it with 200 and. With rapeseel oil however it showed up that it itself due to its unfavorable Alterungsund hydrolysis characteristics only badly as hydraulic fluid eignet.

Of importance for the economy of a hydraulic fluid is among other things the viscosity index. A higher viscosity index leads to the fact that the hydraulic fluid is thinner at small temperatures and therefore can be more easily pumped, but at the same time at the very high work temperatures in a pump thicker remains. Losses by internal leakages are from there geringer.

In order to increase this viscosity index artificially, e.g. the Evonik raw max of additive GmbH introduced special polymer additives developed, which are added to the hydraulic fluid, and under the designation “Dynavis” into the market. Own attempts showed however that these polymers after longer service lives cut werden.

This has the consequence that the viscosity index itself during the enterprise again reduced and thus also desired saving clearly reduces wird.

On the basis of this conditions of the technology the available invention the task was the basis to make a hydraulic fluid available even after longer to long service life invariably high viscosity index of larger or directly 200 exhibits and with which that the vegetable oils well-known problem unfavorable Alterungsund hydrolysis features little to not at all auftritt.

This task is solved by the use of vegetable oil with a natural viscosity index (VI) of larger or directly 200, a portion of simply insatiated fatty acid of at least 80%, a portion of doubly insatiated fatty acids of maximally 1 -10% and a portion of three-way insatiated fatty acids of smaller 1%, preferably smaller 0.5% and particularly prefers smaller or directly 0,1% exhibits, than hydraulic fluid and/or Getriebeöl.

By the term “natural viscosity index” is understood thereby in the context of the available invention a viscosity index, that itself without additive of any viscosity index-better ergibt.

In the case of this use according to invention the composition of the hydraulic fluid or the transmission oil is optimized again particularly in such a way that the portion to three-way or if necessary prefers still more highly insatiated fatty acids with smaller 1%, preferably smaller 0.5% and particularly smaller or directly 0,1% is kept extremely small. Thus do not become an amazing, up to then well-known stability of the hydraulic fluid according to invention or the transmission oil also with very long service lives erreicht.

The advantage also with long service lives continuously high viscosity index was already initially represented. The hydraulic fluid or the transmission oil is thinner at small temperatures and can be thus more easily pumped, while it remains thicker at the very high work temperatures in a pump. It is to be still mentioned that the energy balance does not increase linear with rising viscosity index. The effect shows up more strongly with increasing viscosity index, i.e. the difference in the interval between 150 and 200 is larger e.g. than between 100 and 150.

A further advantage, which admitted itself opposite with the hydraulic fluid according to invention or the transmission oil that so far of mineral or synthetic hydraulic fluids showed, is a clearly improved KornCH 699,659 Al press ion module. In attempts it was determined that a piston in the hydraulic cylinder must put one back with employment of the hydraulic fluid according to invention around approx. 10% smaller distance, around the same pressure aufzubauen.

This leads on the one hand to shorter cycle times and on the other hand arises a smaller power requirement, what today in the industry due to the high energy costs and ever the profit margin calculations a very much meaning value more scarcely becoming in the market hat.

Opposite the well-known mineral or synthetic hydraulic fluids also the lubrication properties of the hydraulic fluid according to invention or the transmission oil are improved. By it we the friction reduced and thus the energy consumption affects favorably. Also the pump wear is geringer.

As the latter still the printing viscosity behavior is to be called. The hydraulic fluid according to invention bzw.

the transmission oil shows a clearly smaller viscosity increase under pressure than the well-known mineral or synthetic hydraulic fluids. This effect can be recognized already in usual hydraulic systems. Usual hydraulic systems thereby such systems are called, those for instance with pressures from 100 to 300 bar arbeiten.

This effect becomes still clearer however regarding the use than transmission oil, there here the pressures clearly more largely sind.

It can be also intended that a part of the vegetable oil is used in form of an insatiated ester of this vegetable oil. That proves as meaningful if the viscosity is to be changed due to the application requirements. When using the pure vegetable oil this exhibits a viscosity of 40 Pas (pascal second) with 40oC. Attempts showed that by the replacement of approximately 10% of the vegetable oil by the appropriate insatiated ester the viscosity can be reduced to 32 Pas with 40oC. The insatiated ester serves thus quasi for diluting the hydraulic fluid which is based on vegetable oil and extends the spectrum of the Anwendungen. thus in a simple manner

In the vegetable oil alternatively also at least an additive can be contained, that is selected from Antioxidantien, corrosion protection agents, copper Deaktivatoren, wear protective agents and/or Antischaummitteln.

That at least an additive serves thereby for it, the actually already existing positive characteristics of the vegetable oil, also in accordance with one of the arrangements according to invention, diez. B. by the additive of a portion of an insatiated ester to be given knows to strengthen still and/or unwanted characteristics at least too minimieren.

The quantity of added additive depends on the targeted application and can of few ppm (parts by million) up to 2%, possibly even up to 5% betragen.

As an additive Antioxidantien can be used, which cause a ageing protection as antioxidants. As Antioxidantien in the sense of the available invention can both primary ageing protective agents in the form of Radikalfängernals also secondary ageing protective agents as Peroxidzersetzer and liabilities gates and/or metal ion the activators assigned werden.

As a further additive corrosion protection agents are to be called, which cover also rust inhibitors. As such additives are suitable prefer boundary surface-active additives, which both ash-free and ash-giving its können.

In addition anti-wear additives are to be called, which will call also EP/AW additives (extreme pressure/antiwear). Here such are to be particularly called on the basis from sulfur and phosphorus to. While in former times gladly elementary sulfur was used, one prefers today rather boundary surface-active materials, which contain zinc, phosphorus and/or sulfur in the polar group. A well-known representative is here Zinkdithiophosphat (ZnDTP). ZnDTP works thereby in all other respects at the same time as Alterungsund Korrosionsschutzmittel.

Beside copper Deaktivatoren as further additive also non-foaming agents can be added. Silicone oils are as non-foaming agents bevorzugt. after today's state of the art

In different large-scale test studies when using according to invention or the vegetable oils in each case in one of the arrangements according to invention a outstanding shearing strength, measured over hours, resulted from 0,7% or under it. In some attempts a shearing strength of -0,7%. resulted

In the following the invention is on the basis of remark examples in connection with the beige-joined Fig. more near describes werden.

Show:

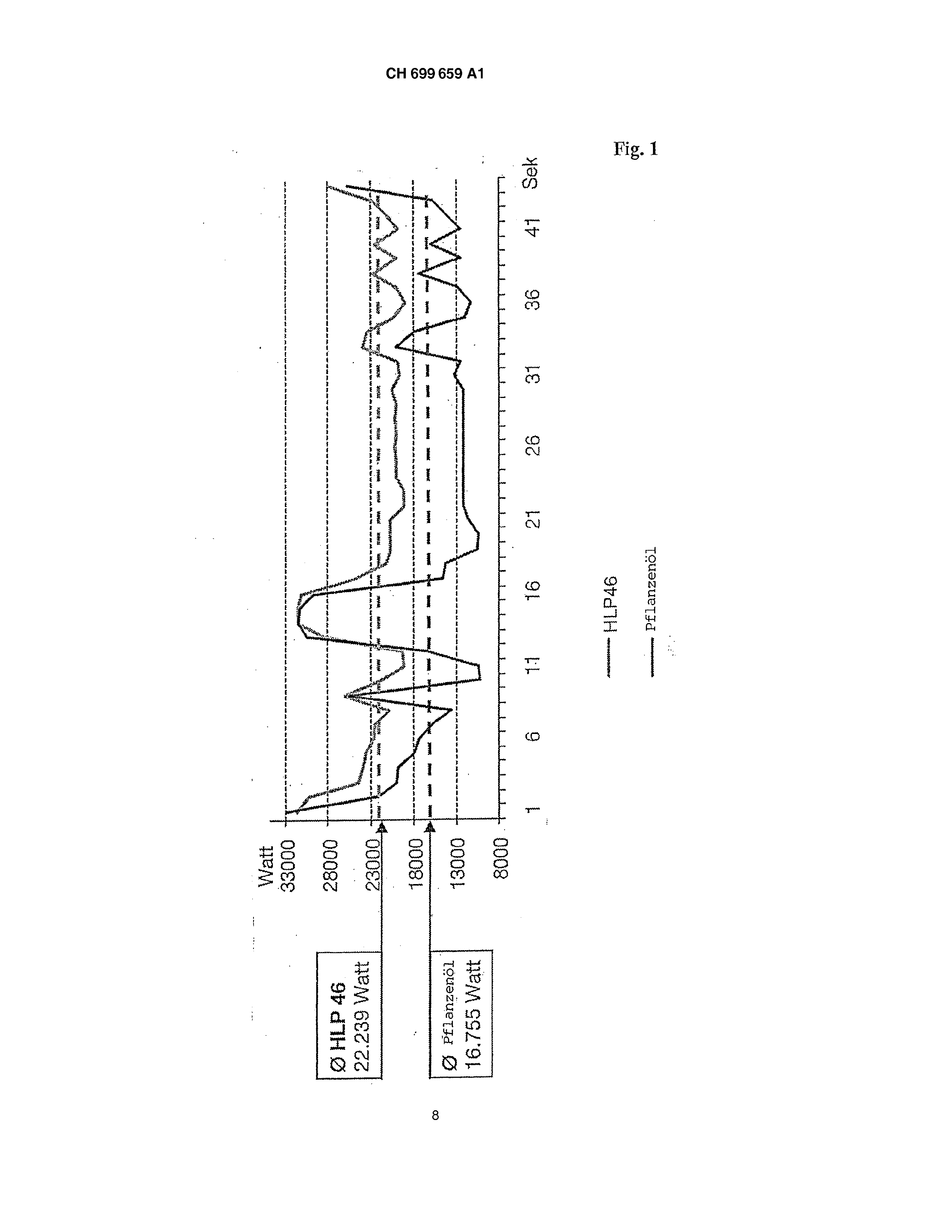

Fig. 1: Energy consumption of the hydraulic fluid according to invention compared with a well-known product with use as hydraulic fluid in an injection moulding machine during a duty cycle, and Fig. 2: Determined cycle times of the hydraulic fluid according to invention compared with a well-known product with use as hydraulic fluid in an injection moulding machine during a Arbeitszyklus.

CH 699,659 Al Ith output product for application as hydraulic fluid:

When a sunflower nuclear oil used basis for a hydraulic fluid, its oleic acid content, d.h.

the content of simply insatiated fatty acids, is particularly optimized and with 90,92% lies. In addition the sunflower nuclear oil points doubly insatiated fatty acids auf.

With this remark example became in particular the content of three-way insatiated fatty acid kontrolliert.

Newer investigations surprisingly resulted in the fact that the characteristics as hydraulic fluid in addition, when completely particularly on this characteristic depends transmission oil. Already very small constituent amount at three-way insatiated fatty acid affects the total behavior of the hydraulic fluid and/or the transmission oil already unfavorably. Here the content of three-way insatiated fatty acid was reduced to a portion, smaller than 0.1% ist.

The hydraulic fluid according to invention is fast and completely biological abbaubar.

II. Application as hydraulic fluid in an injection moulding machine: Criterion: Energy consumption under Ith more closely specified hydraulic fluid was used in central hydraulics (hydraulic pump) of a 2K SPM Arburg 520 C-injection moulding machine. As comparison a hydraulic oil of the SAE class HLP 46 was used. HLP 46 contains additives for the increase of the resistance to aging, the corrosion protection and the EP-Eigenschaften.

The measuring period amounted to 81 cycles, with 44 sec. per single-sequence. As material 2K plastic ABS was processed in each case black Norodur. The Watt nominal value of the hydraulic pump amounts to 37.000.

As criterion for the efficiency of the two used hydraulic fluids here the energy consumption became gewählt.

However by the use of the hydraulic fluid according to invention opposite the HLP 46 an energy saving was reached by 5484 Watts, what for instance a portion of 25% entspricht.

While the average energy consumption amounted to when using HLP 46 altogether 22,239 Watts, in contrast to this with the hydraulic fluid according to invention a consumption of 16.755 Watts was measured. The different energy balance during a duty cycle is closer in Fig.1 dargestellt.

IN. Application as hydraulic fluid in an injection moulding machine: Criterion: Cycle time under Ith more closely specified hydraulic fluid was used in central hydraulics (hydraulic pump) of a SPM Arburg 420 C-injection moulding machine. As comparison hydraulic oil of the SAE class HLP 46 was used, that likewise already under IITH additives specified for the increase of the resistance to aging, the corrosion protection and the EP-characteristics enthält.

As criterion for the efficiency of the two used hydraulic fluids the cycle time was selected here. The measuring period amounted to 59 cycles, with 62,10 sec. per single-sequence for the hydraulic oil of the SAE class HLP 46, opposite 58,32 sec. for the hydraulic fluid according to invention. That corresponds to a cycle time taktzeitverkürzung of 6,08% for the hydraulic fluid according to invention. As material thereby a thermoplastic elastomer was processed in each case. The Watt nominal value of the hydraulic pump amounts to 30.000. Fig. 2 places the differences descriptive dar.

Besides by the use of the hydraulic fluid according to invention opposite the HLP 46 an energy saving was reached of approximately 6.33%. In addition a clearly reduced CCVAusstoss could determined werden.

IV fairs of the wear values of the hydraulic fluid according to invention in the enriching balance the hydraulic fluid according to invention, as under I. more near defines, without any additive additive one uses and one tests in the enriching balance. The wear plane lies with only 12.61 mm compared with approx. 50 mm with Mineralölen.

V. Printing stability test of the hydraulic fluid according to invention opposite mineral oils in the accomplished printing stability test resulted for the hydraulic fluid according to invention (dimensionless) a value of approximately 10, during itself for the tested mineral oil a value of approximately 7 ergab.

From the results of the investigations, like under IV. and V. indicated, it follows that the hydraulic fluid according to invention fulfills all requirements, which the appreciative DIN 51525 demands regarding the lubrication behavior as such, i.e. without any additive of otherwise usual additives, already. It does not require in principle the further, otherwise usual additives. These can improve, the extremely positive results, in particular regarding the long-term stability, already obtained, but again. As an additive, which can be added alternatively, an ageing protecting agent is in the form of Antioxidantien too nennen.

VI. Example of use for hydraulic applications with small temperature distribution is accomplished the test in hydraulic actuator for a control drive for the control of Durchgangsund three-way valves with long-distance heatings. In particular with long-distance heatings regulating valves are needed, which master high DiffeCH 699,659 Al renzdrücke. The drive is to e.g. cause that with through-way valves, in particular with large nominal sizes, masters high differential pressures werden.

The temperature distribution is with approx. 30oC to 50oC. The hydraulic fluid according to invention is used without additives. It is particularly suitable due to the larger bulk modulus and the better printing viscosity behavior opposite the well-known lubricants for this employment. A higher accuracy of the rule mechanism and a smaller thickening of the medium under high Druck. result

VII. Example of use in a high pressure test stand to the examination of injection nozzles so-called high pressure test stands are needed, in order to control the function of the nozzles first. Modern injection nozzles work with pressures up to 6.000 bar. The hydraulic device for the examination of the nozzles is usually equipped with a hydraulic fluid. Mineral oil-based hydraulic oils became with these new test stands problems prepare, since them under high pressure very viscous and in frontiers to become firm to be able. The employment of a medium on the basis of the hydraulic fluid according to invention offers an ideal solution of this problem, since the hydraulic fluid according to invention is sufficiently age stable on the one hand and on the other hand a normal lubrication due to the liquid medium ensured. An overview of the viscosities of the hydraulic fluid according to invention compared with the hydraulic oil of the SAE class HLP 46, determined in the attempt, shows table 1.

Table 1:

Substance:

Temp. Pressure The invention concerns the use of vegetable oil with a natural viscosity index (VI) of larger or directly 200, a portion of simply insatiated fatty acid of at least 80%, a portion of doubly insatiated fatty acids of maximally 1-10% and a portion of three-way insatiated fatty acid of smaller 1%, preferably smaller 0.5% and particularly prefers smaller or directly 0,1% exhibits, than hydraulic fluid in hydraulic systems and/or than transmission oil. A part of the vegetable oil can be used in form of an insatiated ester of the vegetable oil. It knows also at least an additive in a portion of maximally 2-5 Gew. - is % contained its, that selected from Antioxidantien, copper Deaktivatoren, corrosion protection agents, wear protective agents and/or non-foaming agents. The shearing strength according to invention used of the vegetable oil, measured over 20 hours, amounts to 0.7% or under it. 1. Use of pure vegetable oil with a natural viscosity index (VI) of larger or directly 200, a portion of simply insatiated fatty acid of at least 80%, a portion of doubly insatiated fatty acids of maximally 1-10% and a portion of three-way insatiated fatty acid of smaller 1%, preferably smaller 0.5% and particularly prefers smaller or directly 0,1% exhibits, and its shearing strength, over 20 hours, 0.7% or among them amounts to measured, than hydraulic fluid in hydraulic systems and/or than transmission oil. 2. Use according to requirement 1, by the fact characterized that a part of the vegetable oil is used in form of an insatiated ester of the vegetable oil. 3. Use according to requirement 1 or 2, by it characterized that at least an additive is contained, that selected is from Antioxidantien, copper Deaktivatoren, corrosion protection agents, wear protective agents and/or non-foaming agents. 4. Use after requirements 3, by the fact characterized that the additive in a portion of maximally 2-5 Gew. - is contained %, related to the total composition.