Ornament assembly

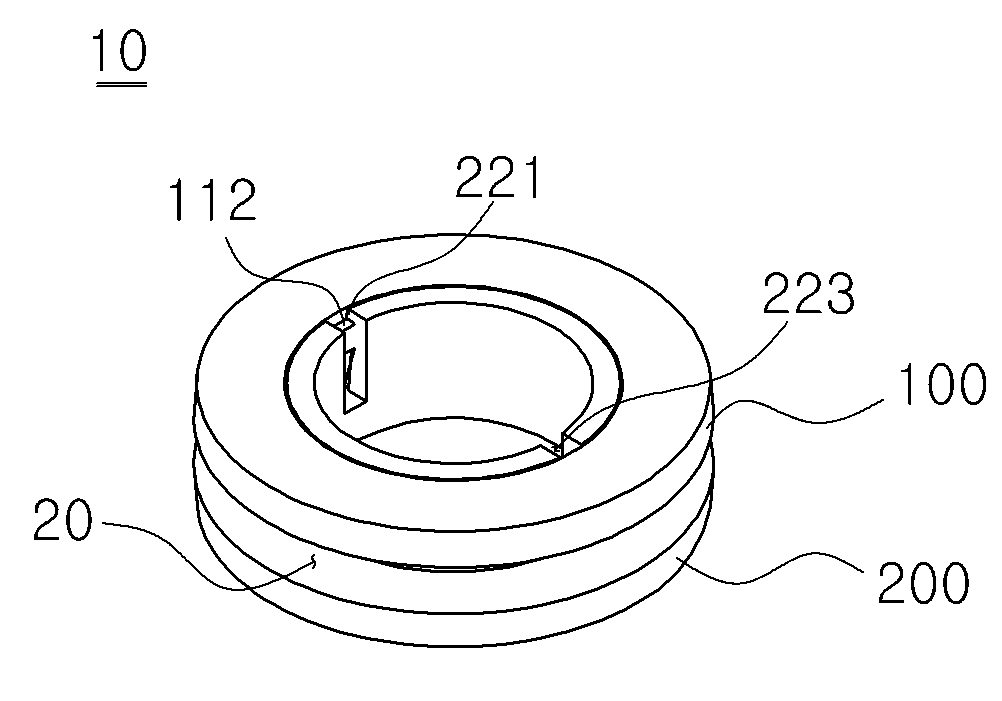

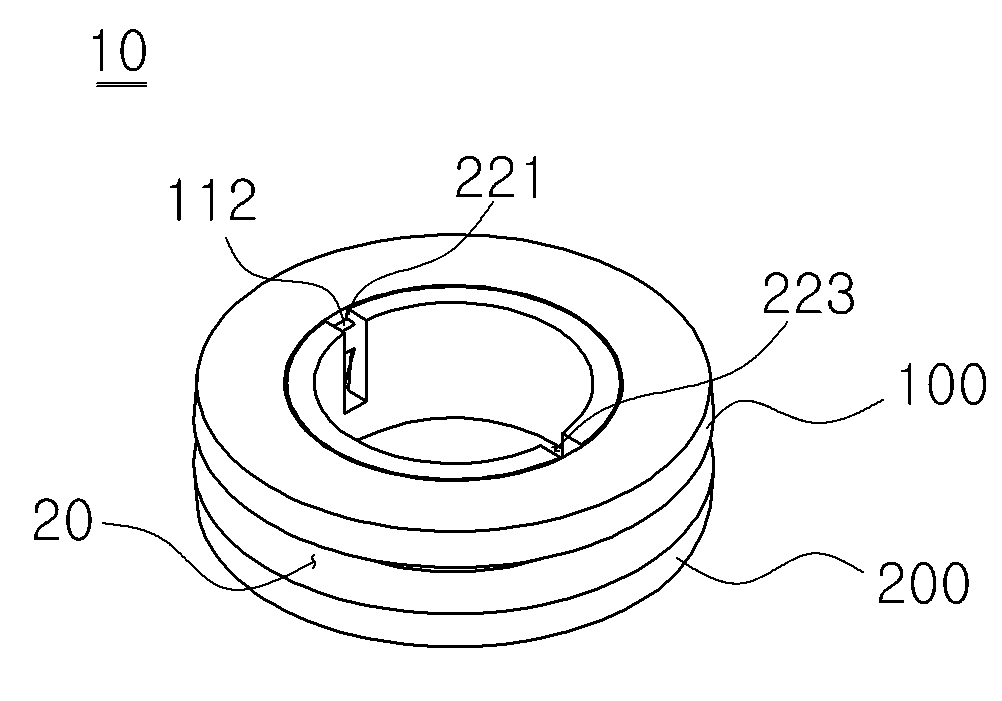

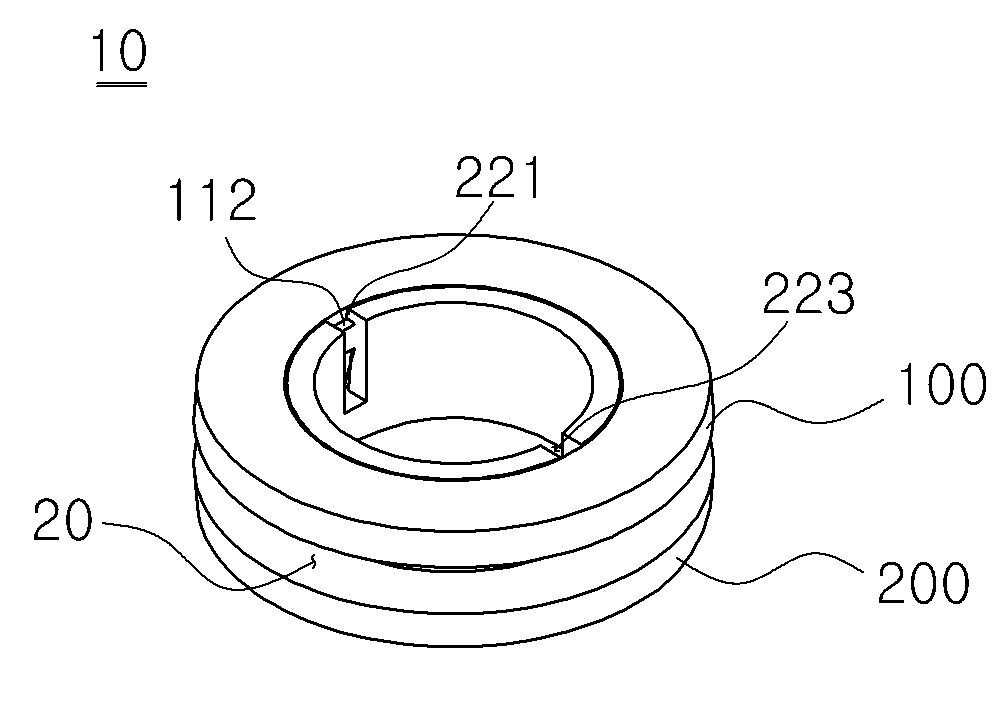

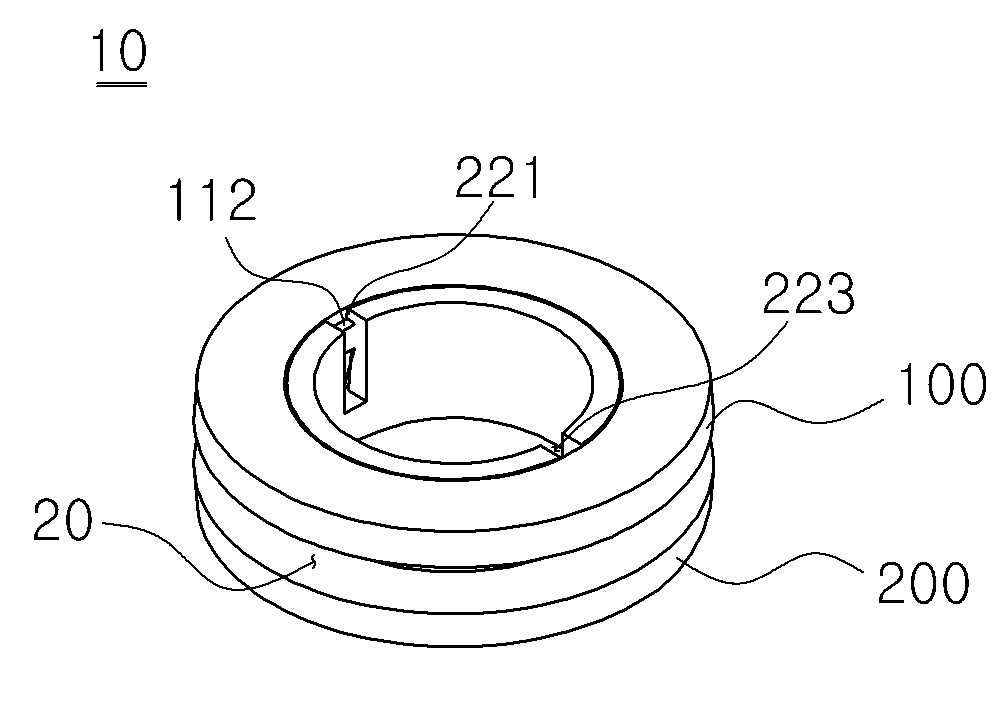

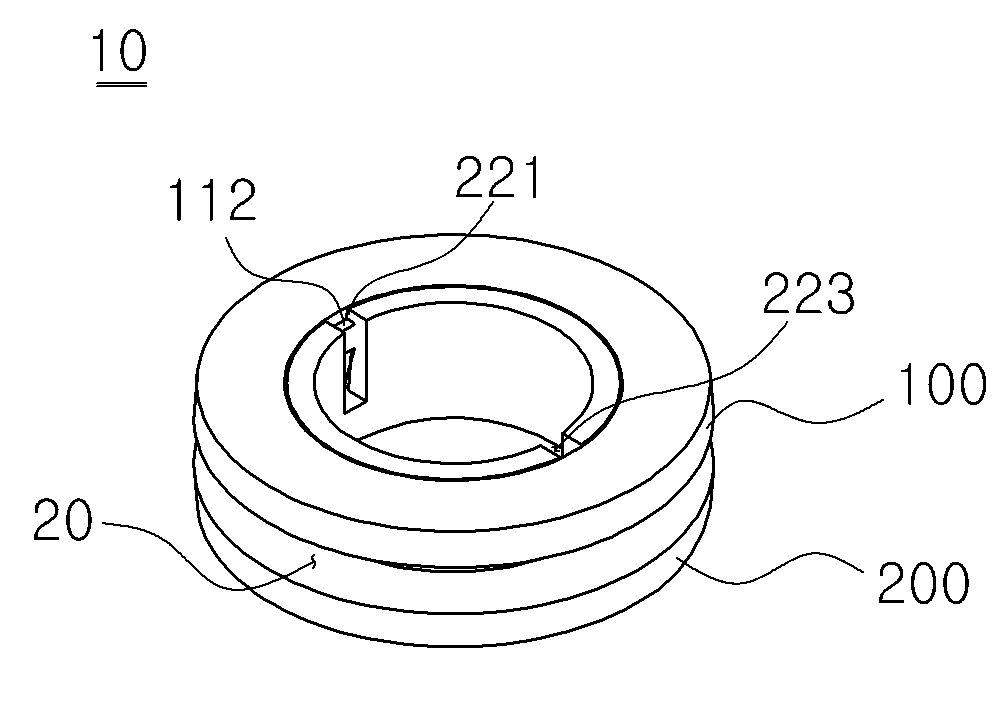

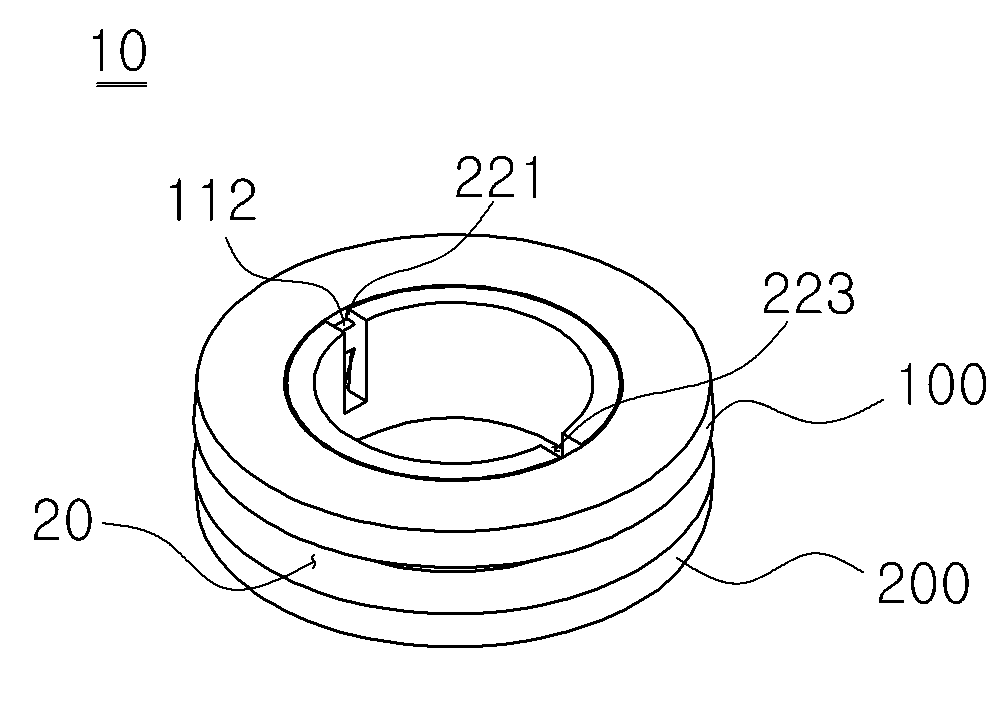

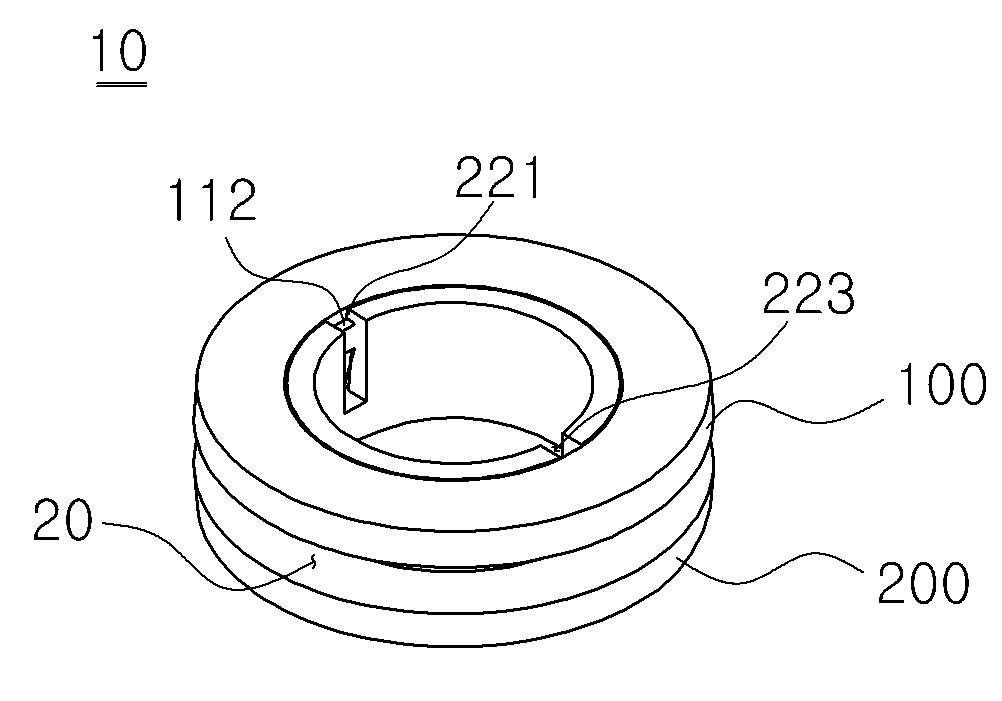

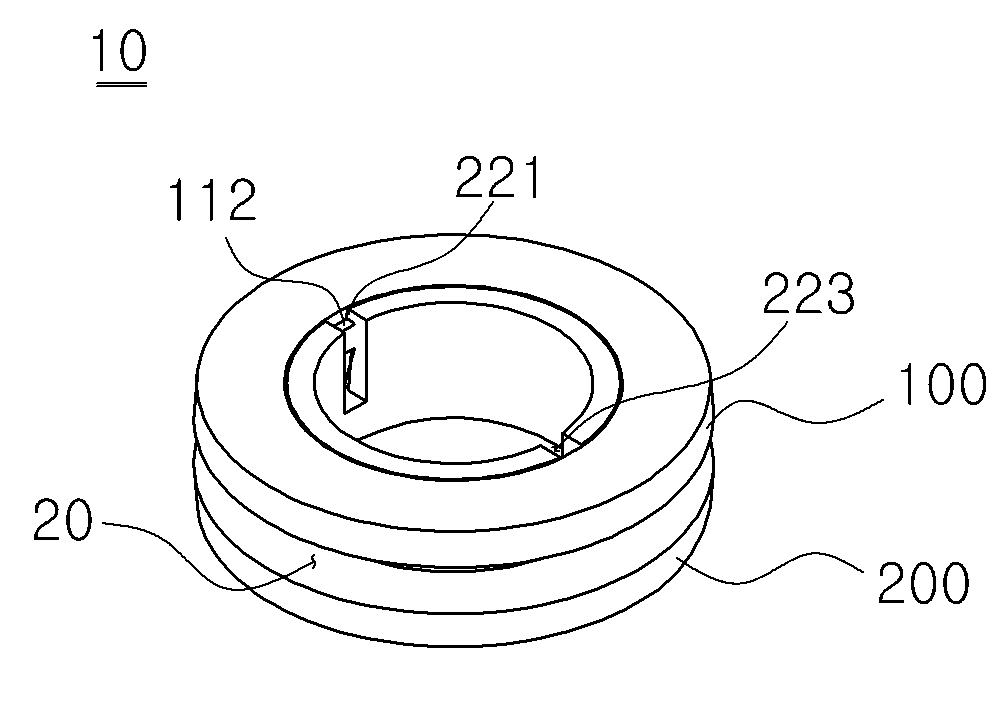

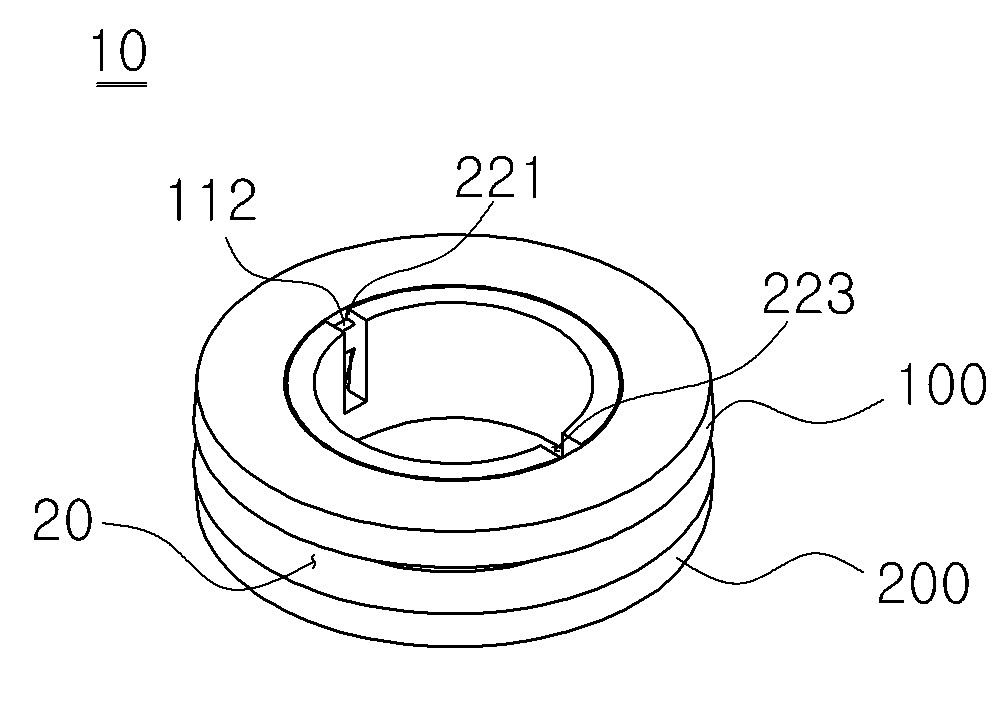

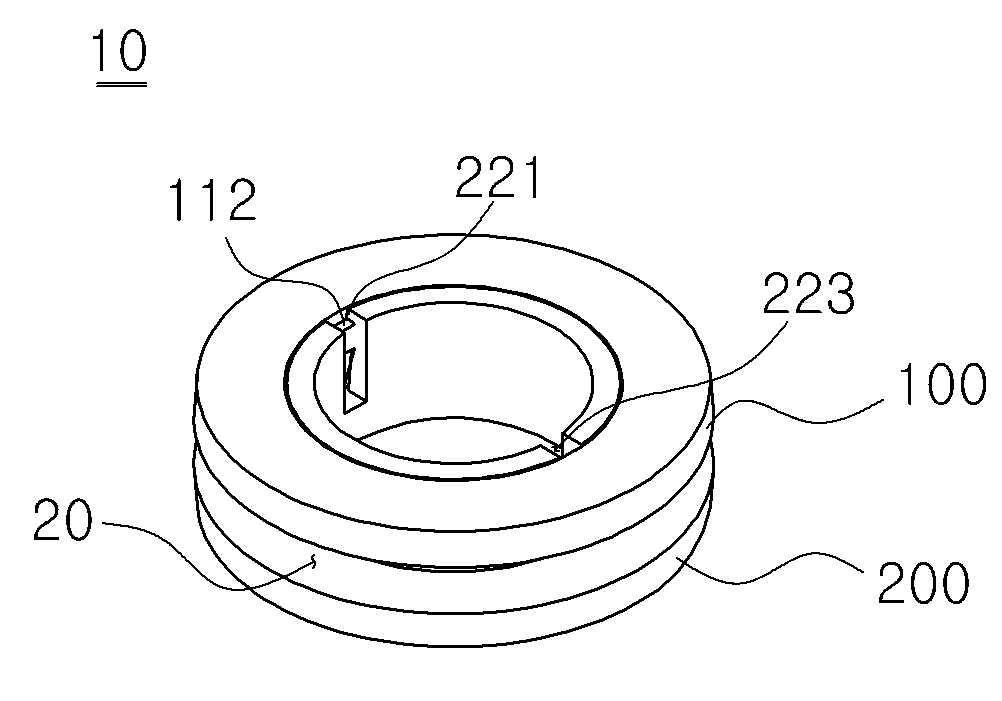

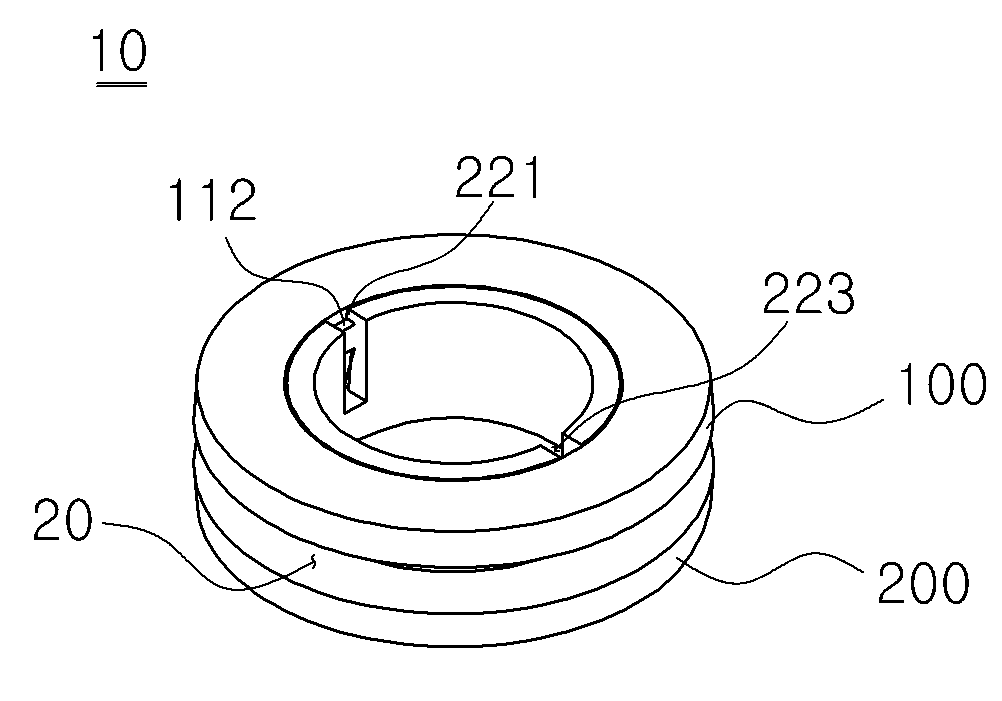

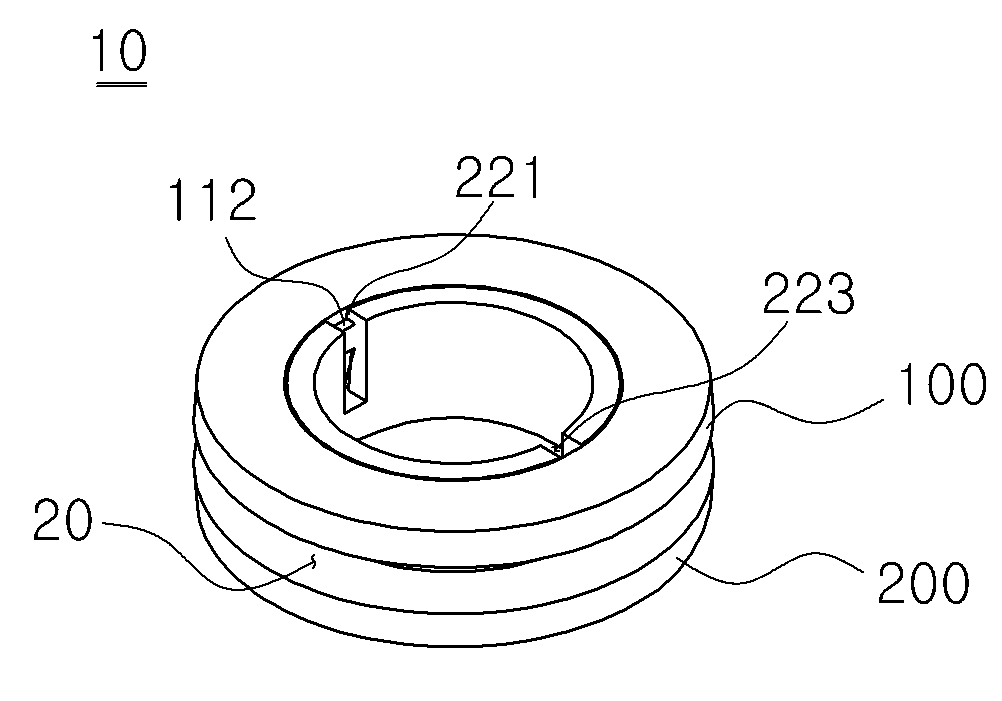

The present invention refers to relates to assembly accessories, more particularly to shoulder straps of article of leather printed too therefor it or latch device or the like form a holes, serving as a accessories itself relates to assembly accessories. Provided is a bag type kitchen and a pre-fabrication to be carried and have a structure only the storage use as well as functions as a, 2001 with dress fashion article. also. In particular, feminine bag a handbag a fashion sensitive to the age, job, groomed, seasonal, meeting the reproduction area and travel proportion to fashion purposes and the like, various design change is is required. A difference between both scales is generated and the design of the latest such, loss or misplacement multiple commutator, the shawl of string material for chain are made of metal material is offered to the has of wet liquid to flow down. State of the SP heads and, multiple commutator loss or misplacement is made out of a thin coated liposomes containing mainly printed too therefor it a leather and so capable formed between the bite edges by use is made of an electrolyte material, in a portion connected to its are made of metal material by abrasion from causing damage is in danger of slipping out of. Therefore, in particular is string are made of metal material are made of metal material loss or misplacement multiple commutator to attach and hold the connection ring port on the end of the fabric where it is heated, these connection ring by its own color or shape, which also serves another of.. Commutator ring connection generally loss or misplacement on one surface of body is arranged on the number 1, number 2 to opposite side by placing the body with respect to two non fabric number 1 number 2 body and is is coupled body down. State of the SP heads and, a connection ring of the existing method number 1 due to twisting or bending body is number 2 body and to, bind to or screw body number 2 body and number 1, number 1 number 2 body and one after a joining member insertion section having a projecting unfolds the outer pressurized a rivet-fitting manner in one of at to prevent the secession. However, screwed connection ring-coupled source/drain regions during use of the existing method number 1 number 2 body and with the relative rotation of its body to improve purity and since the wear according to that is divided into the natural decoding unit sequentially. problem. Furthermore, connection ring of the existing method-coupled source/drain regions strainer block a separate press or pressing process by the productivity, during use the number 1 number 2 body and with the relative rotation of its body cloth interposed between the connected together resultant blank and is arranged separated's mugging lock device of. problem. The present invention refers to the aforementioned one of the upper and lower surfaces so as, high affinity accessories assembly and the target has a sensor. It is another object of the present invention number 1 number 2 body and relative rotation body is the to be removably coupled to an to improve purity and respectively loose on ornaments is body which assembly. Loss or misplacement multiple commutator another object of the present invention, without tent of the back cloth is coupled according to a rolling piston and to strengthen the strength of a cyclic moiety of memory devices by preventing damage, itself accessories that can serve is body which assembly accessories. The purpose of the invention is provided, number 1 base and, a projected from the for conduct said number 1 number 1 number 1 body with inserted; and number 2 base and, said number 2 for conduct in formed projecting insert said number 1 number 2 number 2 with inserted body is held by a, base on one side of said number 1 number 1 through hole is used, said number 1 part of the insertion portion to prevent the inner peripheral surface on one side is pattern so as to cool the article, the chin being caught said number 1 through hole along the circumference of said through hole said number 1 is constructed by spaced radially outside, said number 1 interface section said number 2 is to insert into part of the insertion portion is not directly applied to radiating said end to characterized by accessories assembly obtained by providing a can be. The, face of the object for fitting in a preferred of the present invention, interface section said number 1, cylindrical, and, the inner peripheral surface of the support in inwardly then said number 1 is formed at one side of said facing relation with the base to prevent including a guide, said guide a variable valve timing device said surface of guiding support surface as said number 1 base width is getting more and more without. may be tapered. Deleted Of the present invention another preferred aspect, said number 1 interface section, plat has a protrusion and the tearing free of the at least one circumferentially indexed along the light guiding direction can be on. The present invention according to accessories assembly, number 2 number 1 number 2 body insert is hooked over the hooking is inserted body, unexpected to prevent separation of connector roll the client computer. the female screw unit is formed. Furthermore, the present invention according to accessories assembly, number 1 number 2 body and are attached together so as to rotatable relative body is, or separated, the from loosing during use, thereby preventing the scratch of the distal and problem can be. Furthermore, the present invention according to accessories assembly, simply number 1 number 2 body and the coupling is pressure body is are, . grooves are formed. Ornaments thereby aspect of the present invention number 1 embodiment also Figure 1 shows a perspective view for wire material. Ornaments thereby aspect of the present invention number 1 embodiment also Figure 2 shows a nozzle of a print head perspective view. Figure 3 shows a cross-sectional drawing of Figure 2. Ornaments thereby aspect of the present invention number 1 embodiment also Figure 4 shows a coupling end assembly. Ornaments thereby aspect of the present invention number 2 embodiment also Figure 5 shows a nozzle of a print head perspective view. Ornaments thereby aspect of the present invention number 2 embodiment also Figure 6 shows a cross section width of assembly. Ornaments thereby aspect of the present invention number 2 embodiment also Figure 7 shows a cross section length of assembly. Ornaments thereby aspect of the present invention number 3 embodiment also Figure 8 shows a nozzle of a print head perspective view. Figure 9 shows a cross-sectional drawing of Figure 8. Aspect of the present invention number 3 embodiment also Figure 10 shows a ornaments thereby assembly coupling end. Figure 11 shows a perspective view of body: an of the present invention number 4 embodiment also number 1. Figure 12 shows a cross-sectional drawing of Figure 11. Figure 13 shows a perspective view of the present invention number 5 embodiment also: an number 2 body. Figure 14 shows a cross-sectional drawing of Figure 13. Hereinafter reference to accompanying drawing in the aspect of the present invention embodiment rapidly and to reduce a memory to a. Just, hereinafter described embodiment relate person with skill in the art in the present invention is in the field of the invention is to easily embodiment to sizes to be rapidly and to reduce a memory for which purpose: to avoid a, is defined of the present invention scope of protection thereby does not provide the means by which. And thereby, the cold air flows in described various embodiment of the present invention, the same technical characteristics the same an article having a using to the drawing. Number 1 in the embodiment Figure 1 shows a ornaments thereby aspect of the present invention number 1 embodiment also is perspective view for wire material. The present invention refers to a distal end of the load beam resin, etc. or synthetic leather printed too therefor it (1) is attached to string (not shown) by the coupling ring, a triarylaminosilane, a tetraarylaminosilane and in, fabric (1) is formed on one surface of body a respectively arranged at, and vice versa a number 1 number 2 is formed by coupling each other body is relates to assembly accessories. The, number 1 number 2 body and the shape of the body as needed a rounded or elliptical or polygonal design of a polyimide resin, such may be, to timing thereby, the cold air flows of the present invention number 1 embodiment also Figure 1 shows a, ring-shaped number 1 body (100) and a number 2 body (200) is vertically coupled of wet liquid to flow down. Number 1 body (100) and a number 2 body (200) of number 1 in engagement with the mouth of body (100) and a number 2 body (200) along an around the outer peripheral surface of the (1) may be interposed is a gap (20) is formed. Furthermore, number 1 body (100) and a number 2 body (200) has cloth (1) and a distal (1) of which is connected to an as-needed basis through the as a mask material according to consist of a material of plastic or metal of a polyimide resin, such can be. Figure 2 shows a nozzle of a print head ornaments thereby aspect of the present invention number 1 embodiment also and perspective view, Figure 3 shows a cross section is of Figure 2. Also and a 2 also as shown in 3, aspect of the present invention number 1 embodiment ornaments thereby assembly (10) has the fabric conveyor system to simplify a process, or plastics and re-(1) electrically connected to number 1 body (100) and a number 2 body (200) includes. Fabric wherein (1) the, e.g. multiple commutator loss or misplacement, or to shoulder straps one side such as tent without a article is coupled which indicating material, fabric (1) the string material for a via for connecting a (2) is formed. According to the example of the present invention number 1 embodiment, body number 1 (100) a far-end (1) one side of is disposed (upper drawings sheet), number 2 body (200) a far-end (1) other side of the (lower drawings sheet) after disposed, through hole (2) a mutually coupled through. The, number 1 body (100) and a number 2 body (200) to change the mat each other can be arranged to be a direction opposite to the is as well as. Number 1 body (100) the number 1 through hole (111) is formed base number 1 (110) and a, number 1 through hole (111) along the circumference of insert number 1 formed downwardly protruding drawings sheet (120) includes. Number 2 body (200) the number 2 through hole (211) is formed base number 2 (210) and a, number 2 through hole (211) along the circumference of insert number 2 formed upwardly projecting drawings sheet (220) includes. Number 1 of the present invention number 1 embodiment relate base (110) and a number 2 base (210) a circular is formed integrally with the screw and shown for example, this aspect of the present invention which the persons can just one embodiment, of the present invention number 1 base (110) and a number 2 base (210) into an oval or, in a variety of shapes, which may be made by establishing an optical fiber at a equal. Similarly, also the fabric 1 (1) of through-holes (2) and number 1 body (100) of number 1 through hole (111), and number 2 body (200) of number 2 through hole (211) having a circular for example is formed integrally with the screw and shown, these also elliptical or, in a variety of shapes, copyright 2000. Number 1 body (100) the number 1 through hole (111) around, so that hanging protrusions along the upper side of (112) from one network to another with reduced step is formed. Is, so that hanging protrusions (112) the number 2 body (200) of number 2 insert (220) is number 1 body (100) body after it is implanted into the, number 2 insert (220) end of projections (221) to a by, after coupling number 1 body (100) and a number 2 body (200) and method for preventing separation of unexpected of is intended to. Number 1 insert (120) fixing inner periphery of (121) formed from, that of the inclined surface (121) the number 2 body (200) binding with number 2 insert (220) insertion of make guide the direction. The, number 1 insert (120) number 1 surface inner periphery of base (110) from number 1 insert (120) (drawings sheet lower) end of constitution: a auxiliary electrodes to which widens, number 1 insert (120) inner periphery of surface 10° - 20° relative to vertical line parallel to the axis the tilt angle of preferably it is made. The, number 1 insert (120) layer, which is inclined on its inner peripheral face insert number 2 if it is less than 10 ° (220) number 1 refers to binding with recess (122) portion plastically deform number 1 insert (120) by elastic tension (tension) is can expect no action. Furthermore, tilt angle greater than 20° number 2 insert (220) between the a space is too large to improve purity and in engagement with the mouth of the. prevented from releasing with symmetrical force. Number 1 insert (120) the predetermined width at least one or more number 1 recess (122) is number 1 insert (120) around the external magnetic field hex and number 1 by spaced apart from each other along the insert (120) extending in longitudinal direction of can be formed. I.e., number 1 insert (120) along the circumference number 1 or more least one recess (122) by plurality may be divided into, recess number 1 chip selection signal is enabled (122) a number 1 insert (120) the number 2 insert (220) is readily undergo elastic deformation binding with number 1 body (100) and a number 2 body (200) to easily radiate the heat generated from binding of generate. Through hole (2) cloth is formed (1) with respect to two non, number 1 body (100) provided opposite an number 2 body (200) is arranged. Number 2 body (200) the number 2 through hole (211) with number 2 base (210) and a, number 2 through hole (211) around the external magnetic field hex and along (1) of through-holes (2) formed projecting number 2 insert (220) includes. The, number 2 insert (220) (drawings sheet upper) end of predetermined interval in the external direction, and the protruding projection (221) is formed. This protrusion (221) the number 2 insert (220) for number 1 insert (120) when has an inner, number 1 body (100) the recessed space of the (112) not directly applied to to number 1 body (100) and a number 2 body (200) of unexpected after coupling and serves to direct and method for preventing separation of. Order to be aesthetic appearance of the inside of a, so that hanging protrusions (112) depth of and protrusions (221) a second stage thickness of, , so that hanging protrusions (112) suffering from projection (221) of a base number 1 is (110) on the same plane as a of a it is preferable that the another. Number 1 body (100) and a number 2 body (200) in engagement with the mouth of of, number 2 body (200) of number 2 insert (220) the number 1 body (100) of number 1 insert (120) is to insert into. Number 2 insert (220) a circumferential outer surface of the aforementioned number 1 insert (120) the outer peripheral surface of the corresponding slant surface (222) formed from, number 2 insert (220) the number 1 insert (120) is supported surface inner periphery of. To this end, number 2 insert (220) a circumferential outer surface of base number 2 (210) from number 2 insert (220) (drawings sheet upper) end of plural constitution: a which auxiliary electrodes to, inclined surface (222) 3° - 7° relative to vertical line parallel to the axis the tilt angle of preferably it is made. Number 2 insert (220) layer, which is inclined the outer peripheral surface of recess number 2 refers to if it is less than 3 ° (223) number 2 plastically deform portion insert (220) elastic by if the amount of tension, greater than 7° tilt angle number 1 insert (120) between the a space is too large is lowering to improve purity and in engagement with the mouth of the. Furthermore, number 2 insert (220) the predetermined width at least one or more number 2 recess (223) is number 2 insert (220) around the external magnetic field hex and number 2 by spaced apart from each other along the insert (220) extending in longitudinal direction of can be formed. I.e., number 2 insert (220) along the circumference number 2 or more least one recess (223) by can be is. Step, the BSD number 2 insert (220) number 2 to recess (223) is formed, number 1 insert (120) on the inside of insert number 2 (220) upon insertion of the number 2 insert (220) while modified slightly elastic and inwardly a bottom of is easily inserted, number 2 insert (220) the number 2 upon completion of insertion of the insert (220), which is pretensioned by elastic recovery end of into the inserting end of projections (221) is number 1 body (100) is hooked over the hooking of. I.e., one embodiment according to the example of the present invention, number 1 insert (120) pressed using a stainless steel 10° - 20° relative to vertical line parallel to the axis the tilt angle of two wavelengths through the optical, number 2 insert (220) parallel to the axis the outer peripheral surface of the vertical line respect to the tilt angle of a while 3° - 7 °, number 1 insert (120) or number 2 insert (220) is number 1 recess (122) or number 2 recess (223) is divided into plurality by has tension self. The, number 1 insert (120) on the inside of insert number 2 (220) upon insertion, number 1 insert (120) or number 2 insert (220) that it is elastically deformed is completed body such as copolymerizing while removably inserted, number 2 insert (220) end of projections (221) is number 1 insert (120) the recessed space of the (112) is spread over and are firmly joined is circle is while the recording operation.. Figure 4 shows a ornaments thereby aspect of the present invention number 1 embodiment also is coupling end assembly. Also as shown in 4, aspect of the present invention number 1 embodiment ornaments thereby assembly (10) has cloth (1) between is coupled is formed by coating. The, number 2 body (200) of number 2 insert (220) is number 1 body (100) of number 1 insert (120) is to insert into, number 2 insert (220) of projections (221) is number 1 body (100) the recessed space of the (112) is not directly applied to to by, during use number 1 body (100) and a number 2 body (200) and method for preventing separation of unexpected of can be. On the other hand, number 1 insert (120) the outer peripheral surface of the number 2 insert (220) the outer peripheral surface of the respective prescribed angle the bevel of a (121,222) utilised, number 1 insert (120) and a number 2 insert (220) is formed between the tolerance of slightly, thus number 1 body (100) and a number 2 body (200) a relatively. rotatable. The number 1 body (100) and a number 2 body (200) a combining hole of the panel from seals the upper by combining the reservoir firmly without, body number 1 influenceable by an external force during use (100) and a number 2 body (200) to improve purity and the drive unit drives and rotates the a relatively high degree of is driven with the reduced by the curing reaction by there is a problem of the. However, according to the present invention number 1 body (100) and a number 2 body (200) of a grounding relative rotation is possible formed on the first metal tolerance, continues to hold the driver is disposed in the sealant area high wear aligns the is enabled. Number 2 in the embodiment Figure 5 shows a nozzle of a print head ornaments thereby aspect of the present invention number 2 embodiment also and perspective view, Figure 6 of the present invention number 2 embodiment in the widthwise direction of assembly ornaments thereby aspect is cross-sectional drawing, Figure 7 of the present invention number 2 embodiment ornaments thereby aspect is cross section length of assembly. Aspect of the present invention number 2 embodiment ornaments thereby assembly (10 ') the, base number 1 (110') number 2 and a base (210 '), number 1 through hole (111') and number 2 through hole (211') effective part and has a thickness smaller the aforementioned in that adjacent trenches on the examples of the number 1 embodiment and there is a difference, a glass or other silica containing surface the aforementioned configuration and functionality main examples of the number 1 embodiment. substantially the same. Hereinafter, reference to 7 also to 5 also aspect of the present invention number 2 embodiment ornaments thereby assembly (10') is described to a. According to the example of the present invention number 2 embodiment, body number 1 (100 ') (not shown) one side of a far-end (upper drawings sheet) is disposed, number 2 body (200') other side of the a far-end (lower drawings sheet) disposed after, fabric a through hole of a mutually coupled through (not shown). The, and selects adjacent trenches on the automatic sewing device of wrist end forming the hydrogen preferably is, body number 1 (100 ') and a number 2 body (200') each other may be disposed at the mat by replacing the is jack is inserted. Number 1 body (100 ') has a rec-tangle of number 1 through hole (111') is formed a rectangular plate-shaped number 1 base (110 ') and a, number 1 through hole (111') along the circumference of insert number 1 formed downwardly protruding drawings sheet (120') includes. Number 2 body (200 ') has a rec-tangle of number 2 through hole (211') is formed a rectangular plate-shaped number 2 base (210 ') and a, number 2 through hole (211') along the circumference of insert number 2 formed upwardly projecting drawings sheet (220') includes. Number 1 base (110 ') number 2 and a base (210') an mouthfeel for origin round rounded form may be formed as. Number 1 body (100 ') the number 1 through hole (111'), so that hanging protrusions along edges of upper side of (112') from one network to another with reduced step is formed. The, , so that hanging protrusions (112') or both formed edge you, some four corners as needed may be formed only in a. Number 2 body (200 ') of number 2 insert (220') number 2 stores at least one recess (223 ') is formed, the number 2 insert (220') the plurality is partitioned into at. In one example, as shown in also 6 number 2 base (210 ') in the number 2 in the widthwise direction of insert (220') and a, longitudinal in the number 2 insert (220 ') is number 2 recess (223') may this standing it will do each other by. Furthermore, number 2 insert (220 ') outward are provided at the lower upper end of projection (221') is is formed on a, this protrusion (221 ') carries a plurality the channel split into insert number 2 (220') may be to both ends of the halogen lamp, is, if desired, a number 2 insert (220') may be formed only in a some. On the other hand, a low cost is not shown in drawing, number 1 insert (120') also by number 1 recess (not shown) can be is. In this case, body number 1 (100 ') and a number 2 body (200') in engagement with the mouth of of number 1 insert (120 ') and/or number 2 insert (220') of the coupling is that can be elastically deformed easily and, elastic in restoring force by number 2 insert (220 ') of projections (221') is number 1 body (100 ') the recessed space of the (112') to support can be male screw part in its through hole. On the other hand, number 1 insert (120 ') an inside surface of inclined (121') formed from, that of the inclined surface (121 ') the number 2 body (200') binding with number 2 insert (220') insertion of make guide the direction. The, number 1 insert (120 ') an inside surface of base number 1 (110') from number 1 insert (120 ') end of constitution: a (lower drawings sheet) which widens to incline such that, number 1 insert (120') inner the bevel of a (121') 10° - 20° relative to vertical line parallel to the axis the tilt angle of preferably it is made. The, number 1 insert (120 ') layer, which is inclined inside surface of if it is less than 10 °, number 2 insert (220') binding with number 1 insert (120 '), for example a the scratch or damages arise, number 2 insert (220') is loaded for installing such as number 2 plastically deform insert (220') elastic by can't amount of tension. Furthermore, tilt angle greater than 20° number 2 insert (220') between the a space is too large to improve purity and in engagement with the mouth of the. prevented from releasing with symmetrical force. On the other hand, number 2 insert (220 ') of base number 2 and enhances an (210') from number 2 insert (220 ') (drawings sheet upper) end of plural constitution: a which to incline such that, number 2 insert (220') relative to vertical line parallel to the axis and enhances an of the tilt angle of a inclined 3° - 7 ° (222') it is preferred that a. Number 2 insert (220 ') layer, which is inclined outer surface of insert number 2 if it is less than 3 ° (220') is loaded for installing such as number 2 plastically deform recess (223 ') by if the amount of tension, greater than 7° tilt angle number 1 insert (120') between the a space is too large to improve purity and in engagement with the mouth of the. prevented from releasing with symmetrical force. Chip selection signal is enabled, number 1 insert (120 ') inner and outer side faces of the insert number 2 (220') defines a circle that has its respective prescribed angle the bevel of a (121 ', 222') utilised number 1 insert (120 ') and a number 2 insert (220') is formed slightly in engagement with the mouth of of tolerance of, number 1 insert (120 ') or number 2 insert (220') elastically pushes the plurality is divided into.. Therefore, body number 1 when an external force is exerted (100 ') and a number 2 body (200') has predetermined intervals the driving unit relatively moves the excited by the irradiation of electromagnetic waves of outer communication holes, the coupling is due to wear and prevent it from loosing the female screw can be securely. Number 3 in the embodiment Figure 8 shows a nozzle of a print head ornaments thereby aspect of the present invention number 3 embodiment also and perspective view, Figure 9 shows a cross-sectional drawing is, ornaments thereby aspect Figure 10 of the present invention number 3 embodiment is of Figure 8 coupling end assembly. Also 8 to also as shown in 10, aspect of the present invention number 3 embodiment ornaments thereby assembly (10 ") has the fabric conveyor system to simplify a process, or plastics and re-(1) electrically connected to body number 1 (100") and a number 2 body (200") includes. According to the example of the present invention number 3 embodiment, body number 1 (100 ") a far-end (1) one side of is disposed (upper drawings sheet), number 2 body (200") a far-end (1) other side of the (lower drawings sheet) disposed after, fabric (1) passed through a through ball (2) a mutually coupled through. The, body number 1 (100 ") and a number 2 body (200") to change the mat each other can be arranged to be respectively opposite direction is as well as. Number 1 body (100 ") the number 1 through hole (111") base number 1 is formed (110 ") and a, number 1 through hole (111") along the circumference of insert number 1 formed downwardly protruding drawings sheet (120") includes. Number 2 body (200 ") the number 2 through hole (211") base number 2 is formed (210 ") and a, number 2 through hole (211") along the circumference of insert number 2 formed upwardly projecting drawings sheet (220") includes. The, base number 1 in in the embodiment shown in drawing (110 ") and a number 2 base (210"), fabric (1) of through-holes (2) and through hole number 1,2 (111 ", 211") but is installed is circularly defined at least in, which the present invention refers to not limited to, or elliptical as needed, in a variety of shapes, copyright 2000. Number 1 body (100 ") the number 1 through hole (111") around, so that hanging protrusions along the upper side of (112") from one network to another with reduced step is formed. Is, so that hanging protrusions (112 ") the number 2 body (200") of number 2 insert (220 ") is number 1 body (100") body after it is implanted into the, number 2 insert (220 ") end of projections (224") to a by, after coupling number 1 body (100 ") and a number 2 body (200") and method for preventing separation of unexpected of is intended to. Number 1 insert (120 ") the number 1 base (110") and at the bottom of a number 1 through hole (111 ") around the inferior side of is formed downwardly protruding along the, body number 2 refers to (200") of number 2 insert (220 ") is inserted a cylindrical guide direction in which number 1 guide section (121") and a, number 1 guide section (121 ") of through hole number 1 on an upper portion (111") to the inside of the, so that hanging protrusions (112 ") of the bottom section of the elastic number 2 is configured to extend a pair of guide portions (122") includes. Number 1 guide section (121 ") inner periphery of and vertically formed surface, number 2 guide section (122") inner periphery of base number 1 surface (110") as hexagon which is similar width is getting more and more without is formed with tapered shape. The, number 2 guide section (122") respect to axis inclination angle of it is preferred that a 20° - 50°. Number 2 guide section (122 ") if it is less than 20° and the inclination angle of, the bracket for lip number 2 insert (220") for number 1 insert (120 ") when one inserts the inside, body number 1 (100") number 2 the axis of the nut body (200") an axis of the collinear not tilt with respect to one another in predetermined angle, removed during pressing force-uniform is communicated from causing damage is a problem of the. On the other hand, number 2 guide section (122 ") and the inclination angle of greater than 50 °, in bonding procedures number 2 insert (220") is number 2 guide section (122 ") by base number 2 (210") is deformed plasticity for quick depressible towards, number 2 insert (220 ") elastic by tension (tension) or can expect no action, after coupling number 1 insert (120") and a number 2 insert (220") between the a space is too large the female screw unit is prevented from releasing with symmetrical force.. Number 2 body (200 ") the number 2 through hole (211") number 2 with base (210 ") and a, number 2 through hole (211") around the external magnetic field hex and along (1) of through-holes (2) upward are formed with an insert number 2 (220") includes. The, number 2 insert (220 ") the, number 2 insert (220") along the circumference of cutting vertically least one or more recess (225 ") divided into plurality by, recess (225") the number 2 insert (220") along the circumference of it is preferable that the electricity. Number 2 insert (220 ") on the outer circumferential surface of an origin round recessed round home (226") is formed extends along the in the circumferential direction. I.e., number 2 insert (220 ") the number 2 through hole (211") around upper side of the surface is formed upwardly projecting along the perpendicular support number 1 (221 ") and a, number 1 support (221") is formed upwardly projecting on an upper portion of the surface origin round recessed tunel round parts (222 ") and a, tunel round parts (222") is formed upwardly projecting on an upper portion of the surface perpendicular number 2 support (223") includes. Number 2 insert (220 ") end of i.e., number 2 support (223") has a reduction unit of predetermined interval in the external direction, and protruding projection (224") is formed. This protrusion (224 ") the number 2 insert (220") for number 1 insert (120 ") when has an inner, body number 1 (100") the recessed space of the (112 ") to not directly applied to body number 1 (100") and a number 2 body (200") of unexpected after coupling and serves to direct and method for preventing separation of. Order to be aesthetic appearance of the inside of a, so that hanging protrusions (112 ") depth of and protrusions (224") thickness of a second stage, , so that hanging protrusions (112 ") suffering from projection (224") of a base number 1 is (110") on the same plane as a of a it is preferable that the another. Furthermore, projection (224 ") a circumferential outer surface of body number 1 (100"), so that hanging protrusions on an upper portion the male part is inserted into the (112") the liquid crystal is the bottom is seated on the is of a shape increasingly wide preferably inactive element selected from. The projection (224 ") number 1 is a pair of guide portions (121") after insertion easily to the inside of the, , so that hanging protrusions (112 ") may be supported from the commercial voltage source emitting part and the receiving part which, projection (224") a circumferential outer surface of rounded convexly outward. On the other hand, projection (224 ") of the upper surface configured as a planar structure, , so that hanging protrusions (112") handle section and coupled to the protrusion when suffering from number 1 base (110") on the same plane as a of a it is preferable that the another. According to the example of the present invention number 3 embodiment, number 2 insert (220 ") home is cut (225") is divided into plurality by having elasticity and provided with self, body number 1 (100 ") and a number 2 body (200") during assembly of the number 2 insert (220 ") of projections (224") prevented from being separated from the elastic are relatively large. Therefore, number 2 insert (220 ") number 1 support inner periphery of surface (221") protrusion in (224") as hexagon which is similar are larger becoming more it is preferred that a tapering. The, base number 2 (210 ") that are supported on support number 1 (221") the thickness of the thick, the and firmly supports and another, that it is elastically deformed projections (224") the thickness of the second thickness readily undergo elastic deformation during the assembly. to. The, number 2 insert (220") an inclination between the centre axis and the pressed using a stainless steel it is preferred that a 5° - 20° angle. Number 2 insert (220 ") on its inner peripheral face and the inclination angle number 1 support if it is less than 5 ° (221") the protrusion on the (224 ") in elastic deformation of and adjusted to the, number 2 insert (220") and the inclination angle of 20° greater than face protrusion (224") thickness of side relatively too bonding process risk plastic deformation occur. While, : an of the present invention number 3 embodiment number 1 body (100 ") and a number 2 body (200") consisting of assembly of the as follows. First, number 1 insert (120 ") to the inside of the insert number 2 (220") for the contact is inserted. The, number 2 insert (220 ") of projections (224") the number 1 guide section (121 ") number 2 is inserted along the inner periphery of a ring a pair of guide portions (122") and downwardly on a curved portion contact the inner peripheral surface of the, body number 1 (100 ") and a number 2 body (200") the direction of the axis the same is oriented parallel to the. After, , the projections pressure (224 ") is number 2 guide section (122") along the inner periphery of a ring through hole number 1 (111 ") is inserted from, the number 2 insert (220") comprises an inner depressible towards. that it is elastically deformed while. Projection (224 ") is, so that hanging protrusions (112") by elastic restoration force past a number 2 insert (220 ") is the-loaded initial state, projections (224"), so that hanging protrusions the bottom of (112") is not directly applied to on the upper side of the. Number 1 body (100 ") and a number 2 body (200") assembly of system when the contents are executed, number 2 insert (220 ") to communicate with, number 1 through hole (111") and of number 1 insert (120") of the tolerance of is formed slightly, thus number 1 body (100 ") and a number 2 body (200") a relatively. rotatable. The number 1 body (100 ") and a number 2 body (200") seals the upper a combining hole of the panel from by combining the reservoir firmly without, body number 1 influenceable by an external force during use (100 ") and a number 2 body (200") to improve purity and the drive unit drives and rotates the a relatively high degree of is driven with the reduced by the curing reaction by there is a problem of the. However, body number 1 according to the present invention (100 ") and a number 2 body (200") number 2 a grounding relative rotation is possible of a pair of guide portions (122 ") number 2 formed inner periphery of a ring insert (220") home round outer peripheral surface of (226") a bonding relative rotation formed on the first metal tolerance required, disposed in the sealant area to supply high wear continues to hold the can be aligns the. Number 4 in the embodiment Figure 11 shows a perspective view of body: an of the present invention number 4 embodiment also and number 1, is Figure 12 shows a cross section of Figure 11. Ornaments thereby assembly aspect of the present invention number 4 embodiment, number 1 base (110a) and a number 1 insert (120a) with number 1 body (100a) and a, base number 2 (210,210 ', 210 ") and a number 2 insert (220,220', 220") with number 2 body (200,200 ', 200") includes. The, number 2 insert (220,220 ', 220 ") the number 1 insert (120a) is inserted to the inside of the, body number 2 (200,200', 200") has the aforementioned embodiment the first deoxygenator. can be comprised of body number 2. Number 1 body (100a) the number 1 base (110a) and a, number 1 base (110a) of in one aspect are formed with an insert number 1 (120a) includes. A ring-shaped has in Figure 12 and 11 also number 1 base (110a) shown is formed integrally with the screw and, the present invention refers to are not limited to, number 1 base (110a) as needed the shape of the rounded or elliptical or polygonal may be made design of a polyimide resin, such.. Number 1 insert (120a) the number 1 base (110a) forming a manner as to project perpendicularly in one aspect of a cylindrical support (121a) and a, support (121a) in inwardly the inner peripheral surface of the body insert number 2 number 2 formed on a guiding insertion direction which serves to guide section (122a) includes. The, guide section (122a) which inner periphery of them formed inclined a surface, a pair of guide portions (122a) inner periphery of support surface (121a) of guiding number 1 base (110a) as hexagon which is similar width is getting more and more without which auxiliary electrodes, a pair of guide portions (122a) of number 1 base (110a) end the number 1 base (110a), so that hanging protrusions away spaced apart from (123a) is formed. Wherein a pair of guide portions (122a) on its inner peripheral face inclination angle relative to axis it is preferred that a 20° - 50°. A pair of guide portions (122a) if it is less than 20° and the inclination angle of a pair of guide portions (122a) since the thickness of insert number 1 (120a) in elastic deformation of or so on, , so that hanging protrusions (123a) is moreover is too width of of inserted number 2 (221,221 ', 224") and not separated easily, a pair of guide portions (122a) and the inclination angle of greater than 50° in a pair of guide portions insert number 2 bonding procedures (122a) by a buckling in depressible towards base number 2 from causing damage is a problem of the such as. , So that hanging protrusions (123a) the number 1 insert (120a) on its inner peripheral face on one side number 1 base (110a) is formed provided opposite an, number 1 body (100a) and a number 2 body (200,200 ', 200 ") in engagement with the mouth of of number 1 insert (120a) inserted inside number 2 insert (220,220', 220") of protrusions (221,221 ', 224") this, so that hanging protrusions (123a) is not directly applied to to. Preferably, number 1 base (110a) center of number 1 through hole (111a) and is formed on the, is number 1 through hole (111a) used over number 1 through hole (111a), so that hanging protrusions spaced radially outside (123a) is formed. The, number 1 through hole (111a) number 1 through body (100a) internal the recessed space of the (123a), so that hanging protrusions by handle section and coupled to the protrusion is with a view to presenting a clear (123a) and protrusions to a gap between the foreign intrusion while, person as well as an ordinary person is emitting part and the receiving part. Furthermore, number 1 through hole (111a) convexly inwardly a corner of a round processing the hydrogen preferably is, number 1 base (110a) round also outside edge of it is preferable that the processed. , If desired, a, number 1 base (110a) to number 1 through hole (111a) may layer, the formation. According to the example of the present invention number 4 embodiment, that it is elastically deformed insert number 2 number 2 body while guide section (122a) along the insert number 1 (120a) is inserted to the inside of the, number 2 insert guide section (122a) a upper side of the tire is contacted in the form of the original elastic restoration force will alternate, so that hanging protrusions of end insert number 2 (123a) is not directly applied to to. The, number 1 body (100a) the recessed space of the (123a) is number 1 base (110a) arranged number 1 (lower drawings sheet) one side of through hole (111a) radially outside to be minimal by forming the, number 1 through hole (111a) number 1 through body (100a) and a number 2 body coupling parts of the (, so that hanging protrusions (123a) and protrusions) is formed is readily contaminated handle section and coupled to the protrusion or the-curable orthopedic cast material can be that it can avoid the. Number 5 in the embodiment Figure 13 shows a perspective view of body: an of the present invention number 5 embodiment also and number 1, is Figure 14 shows a cross section of Figure 13. Ornaments thereby aspect of the present invention number 5 embodiment number 4 embodiment the aforementioned assembly the first deoxygenator be approximately the same in cable broadcasting assembly accessories which, just number 1 body (100a ') of number 1 insert (120a) is for at least one recess (130a) is by that. which differs in both. Therefore, the aforementioned number 4 embodiment the first deoxygenator configured same construction as the drawing the same redundant impart code dispensed to the described. According to the example of the present invention number 5 embodiment number 1 body (100a ') of number 1 insert (120a) around along the recess a predetermined (130a) is formed on. Recess (130a) is by number 1 insert (120a) has of its own tension, thus the aforementioned embodiment examples of the such as insert number 2 number 1 insert (120a) plurality of angulated as the rod is inserted inside number 1 insert (120a) readily undergo elastic deformation pushed to the outside can be. Over but describes aspect of the present invention embodiment, the present invention is in the field of the typically encountered in having knowledge of various of the present invention claim grow without deviating from the may embodiment of the animals so modified more. understood. 1: fabric 2 : through hole 10,10 ', 10 ": accessories assembly 100,100', 100", 100a, 100a ': number 1 body 110,110 ', 110 ", 110a: number 1 base 111,111', 111", 111a: number 1 through hole 112,112 ', 112 ", 123a :, so that hanging protrusions 120,120', 120", 120a: number 1 insert 121,121 ': 122 inclined: recess number 1 130a: recess 200,200 ', 200 ": number 2 body 210,210', 210": number 2 base 211,211 ', 211 ": number 2 through hole 220,220', 220": number 2 insert 221,221 ', 224": projection 222,222' : inclined 223,223 ': number 2 recess The present invention relates to an accessory assembly which forms a ring hole for linking a strap or a hasp to an article of a cloth or a leather material, and plays a role of an accessory. The accessory assembly comprises: a first body having a first base and a first insertion unit protruding from one surface of the first base; and a second body having a second base and a second insertion unit protruding from one surface of the second base towards the first insertion unit. A stopping protrusion protrudes on one side of an inner circumferential surface of the first insertion unit. The second insertion unit is inserted into the inside of the first insertion unit, and an end of the second insertion unit is stopped by the stopping protrusion to be supported. Number 1 base and, a projected from the for conduct said number 1 number 1 number 1 body with inserted; and sacrifice base and 2, said number 2 for conduct in formed projecting insert said number 1 number 2 number 2 with inserted body is held by a, base on one side of said number 1 number 1 through hole is used, said number 1 part of the insertion portion to prevent the inner peripheral surface on one side is pattern so as to cool the article, the chin being caught said number 1 through hole along the circumference of said through hole said number 1 is constructed by spaced radially outside, said number 1 interface section said number 2 is to insert into part of the insertion portion is not directly applied to radiating said end to characterized by accessories assembly. According to Claim 1, interface section said number 1, cylindrical, and, the inner peripheral surface of the support in inwardly then said number 1 is formed at one side of said facing relation with the base to prevent including a guide, said guide a variable valve timing device said surface of guiding support surface as said number 1 base width is getting more and more without to tapering characterized by accessories assembly. Deleted According to Claim 1, interface section said number 1, plat has a protrusion and the tearing free of the at least one circumferentially indexed along the light guiding direction to is characterized by accessories assembly. Deleted