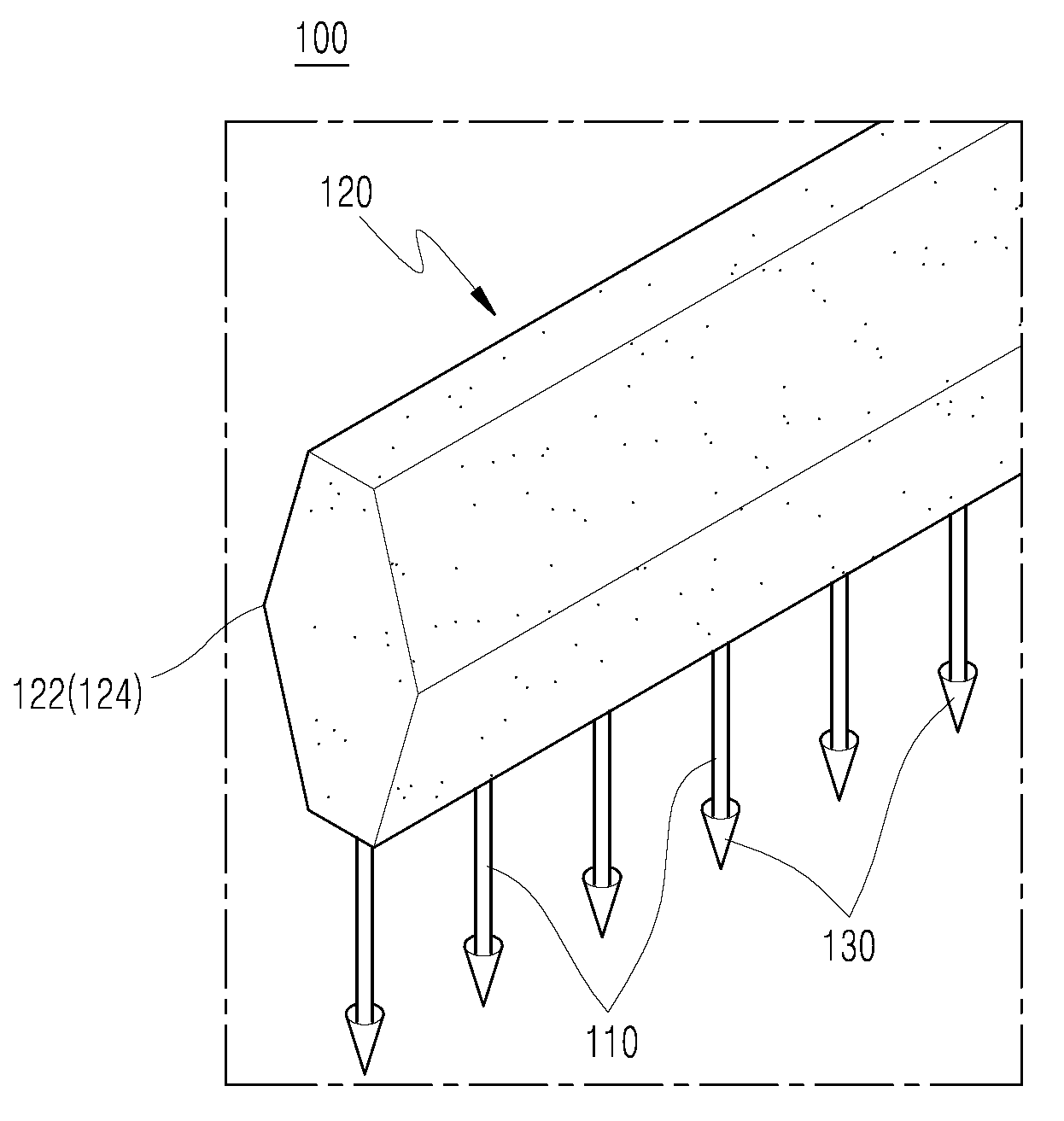

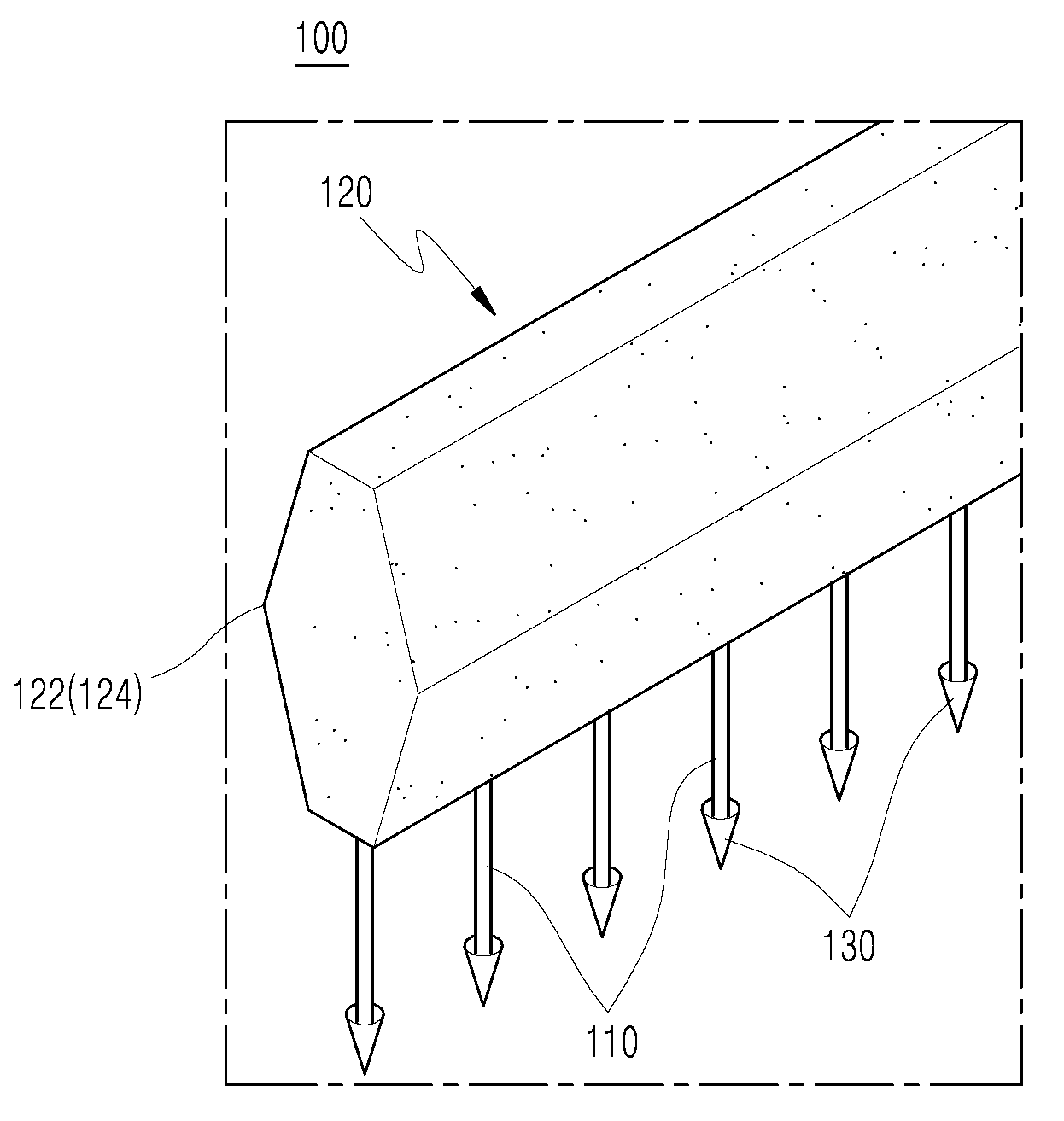

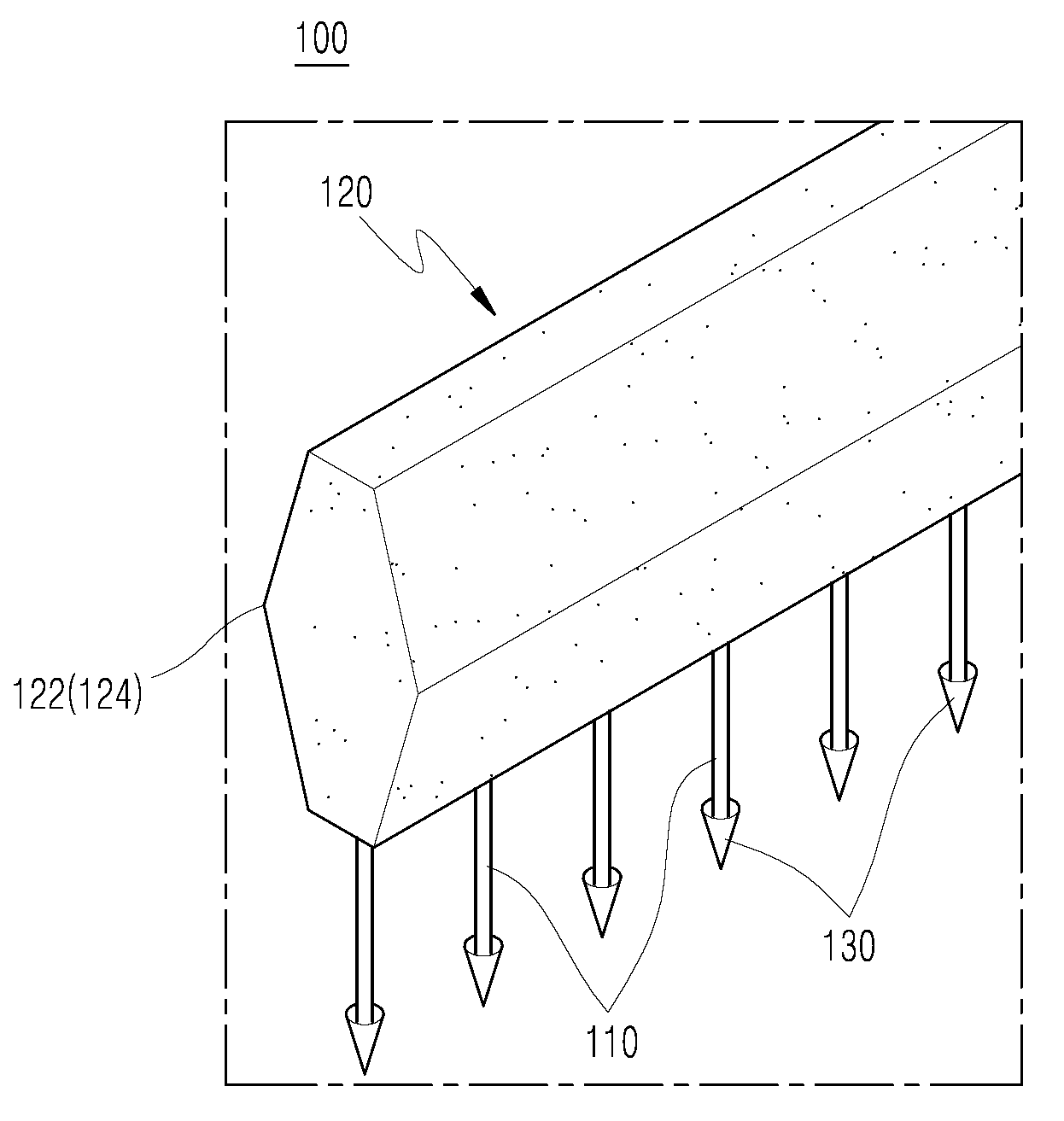

A PREFORMED SEALANT HAVING A SUPPORT AND METHOD FOR REPAIRING A CONCRETE PAVEMENT USING THE SAME

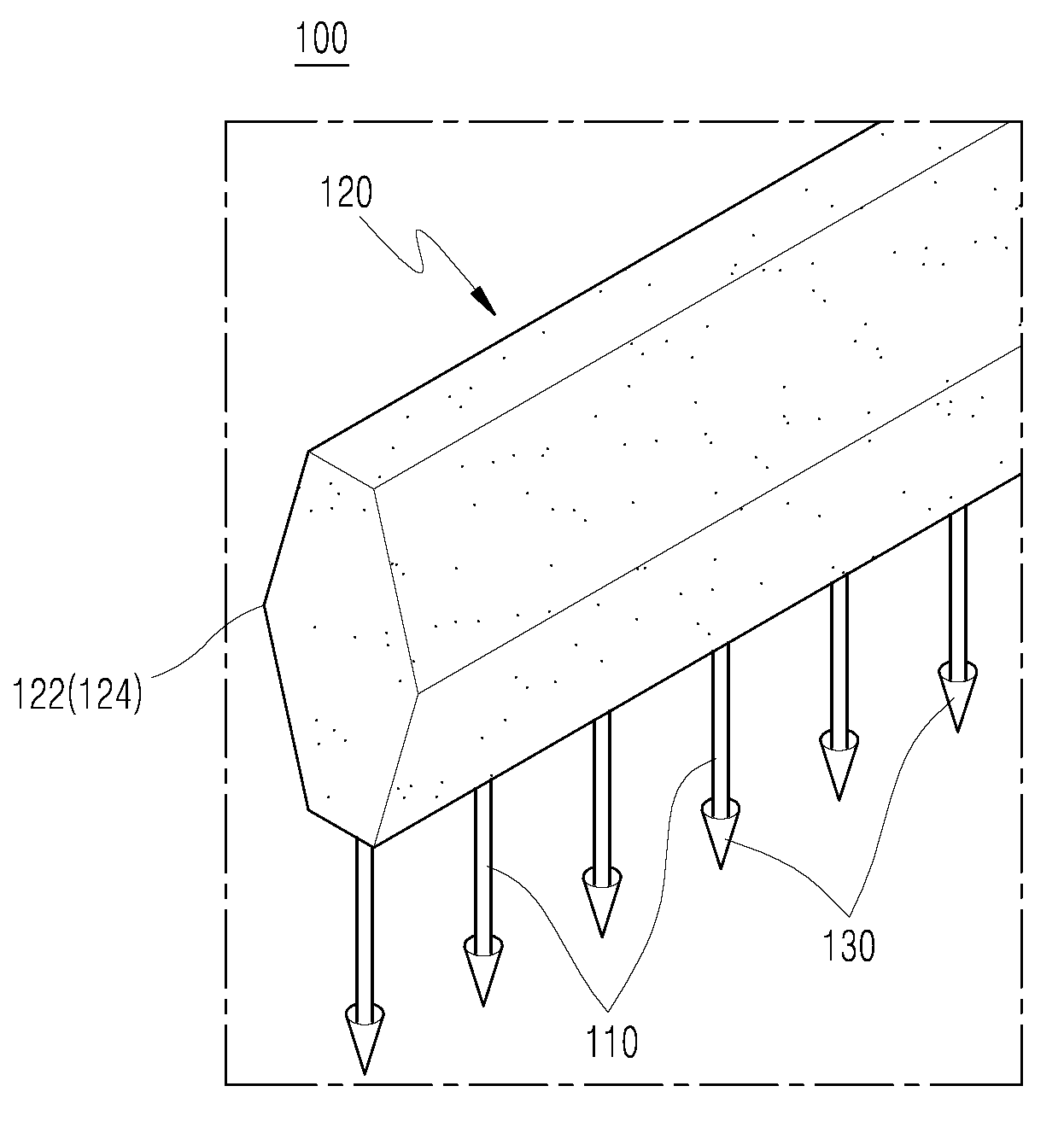

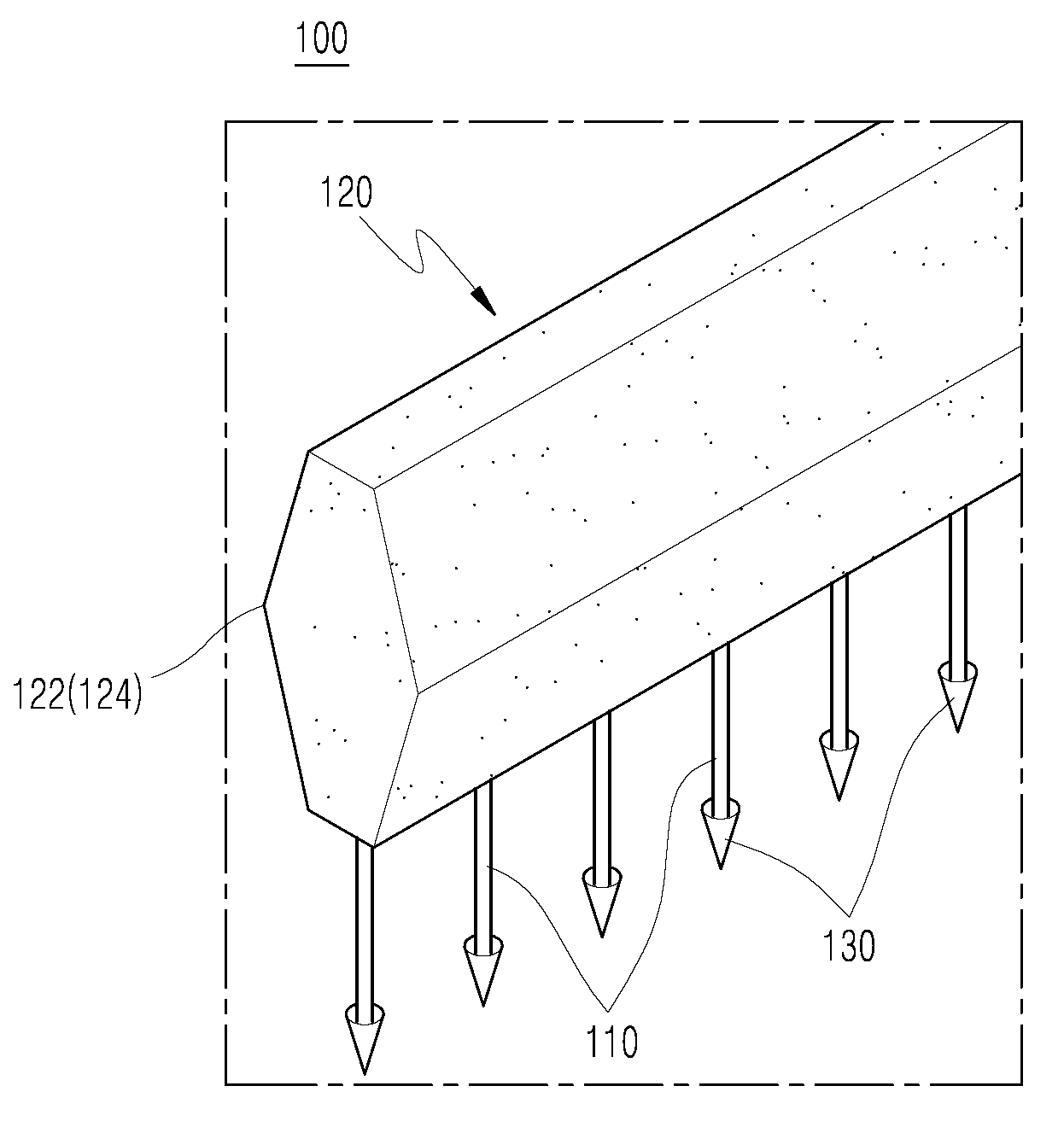

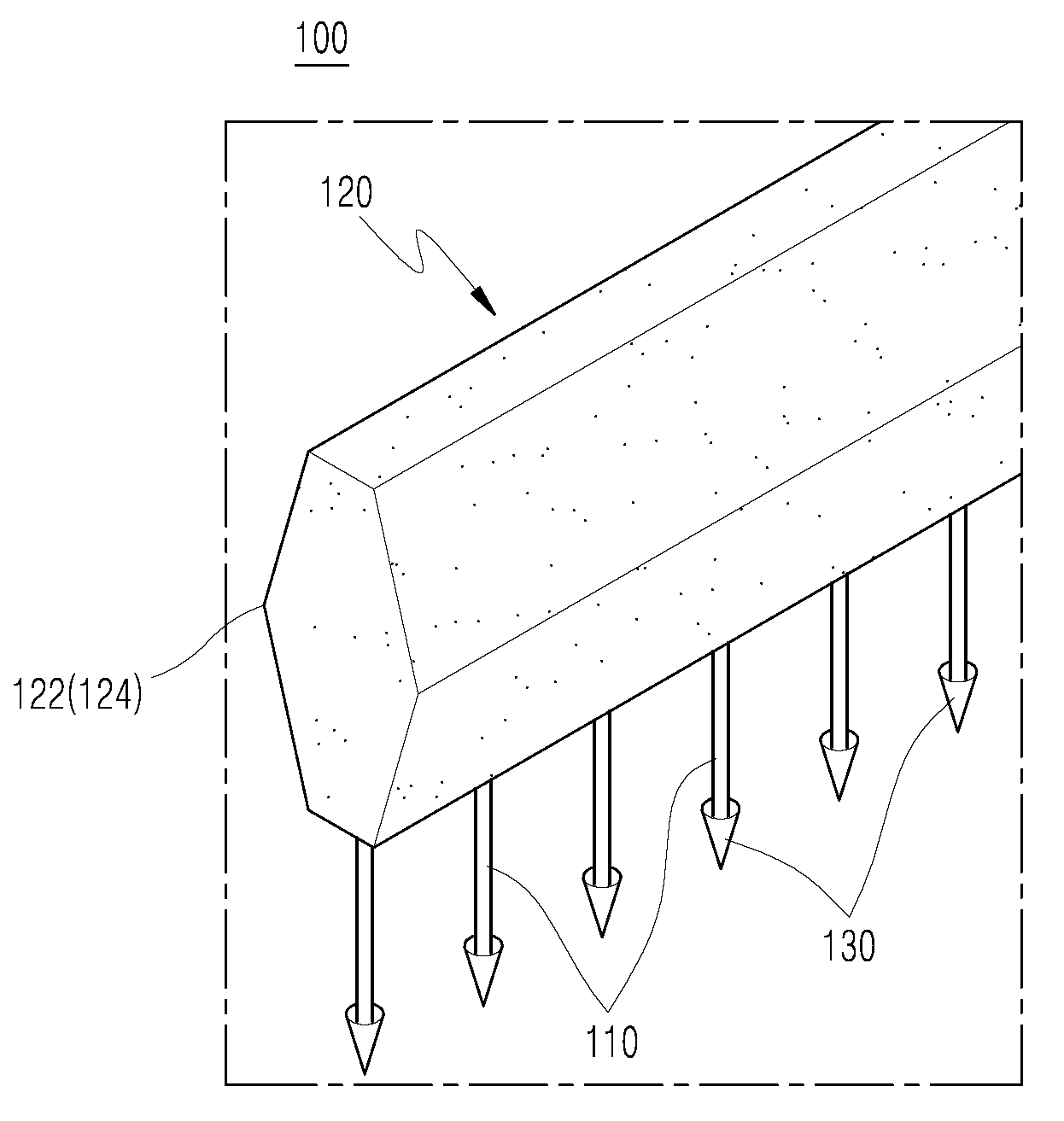

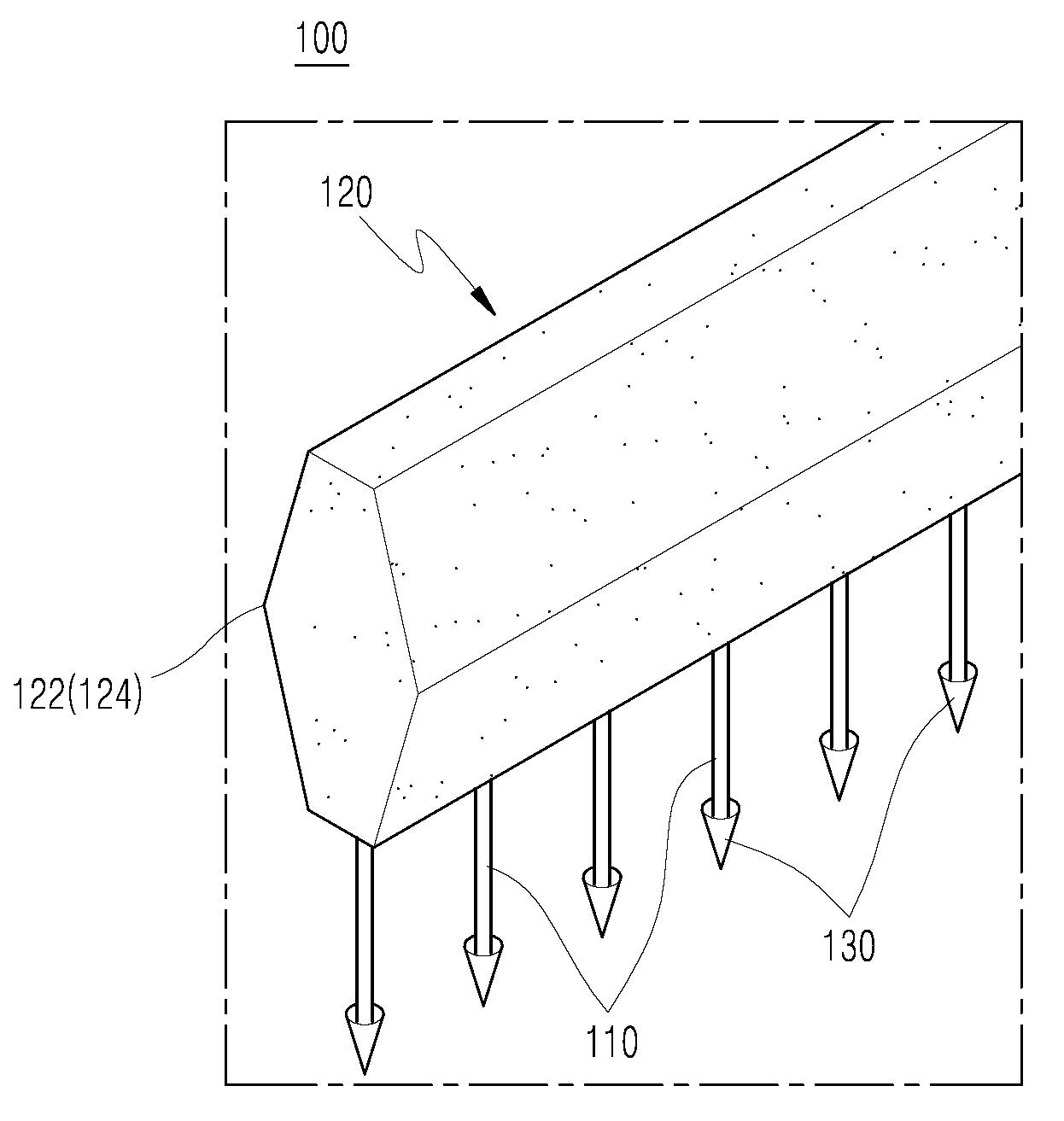

The present invention refers to many mold fixing nail holes and having a support with concrete pavement material and method relates to repair, more specifically, traffic after repair concrete pavement repair by open time to eliminate a reradiation traffic according to cost by constituting the second, bordering thereon the for carrying out the latch of door locking apparatus for vehicles of the concrete paved road concrete is reduced thereby reducing the damage difference 2 common positioned between upper be mounted on a support having many mold fixing nail holes concrete pavement material and relates to repair method. Concrete pavement a joint groove fixing nail holes (many mold fixing nail holes injected type fixing nail holes can be grouped into a negative)-filled generally joint is called a, the joint such shrinkage of concrete pavement by expanding and contracting with the corresponding to and expansion and the damage or the prevent flexion and, external molding material media penetration of the groove joint is to reduce flow resistance caused make. Concrete pavement by the vehicle that traffic and/or for non-ideal, temperature variations or downcomer due to climatic such as a possibility of breakage partial mode according to a signal from the, peripheral home joint in particular on outer surface of the can is on in concrete, joint grooves and fixing nail holes until repair can be made.. Wherein joint method's complement on concrete including shear face may be divided into repair cross section and moieties are, a face shear multi well expansible and free from breakage or when that must be provided in the thickness direction for the treatment of severely in case of repair method is line it does,, partial cross repair in addition in the case of repair method is generally performed. Such partial cross repair the method, also 7 process order shown in which makes a user be made according to, which together significantly simplifies the. off at the first and the second. First, as shown in 7 (a) (b) also, concrete pavement (10) on on (12) is fixing nail holes (14) includes or when adjacent, concrete on (12) as well as upper joint home (30A) and fixing nail holes (14) including both rectangular region to a certain depth (S) space cut paper is thereby making it possible to obtain. Next, concrete for (20) to prevent spoilage space (S) internal to is allowed to proceed for a.. (Also reference 7 (c)) and cutter (5) for bordering thereon using concrete (20) on new joint home (30A ') is thereby making it possible to obtain. (Also reference 7 (d)) Finally, home joint a newly generated (30A ') new fixing nail holes (14', many mold fixing nail holes, injection type fixing nail holes (e.g.: silicon,)) emplacement or by implanting, is repair job is complete. Also wherein home joint of enzyme-mediated reactions by ionic 7 (d) (30A ') initiator for cutting in integrity of maintenance work vary importantly, the heat storage capacity and thermal shock resistance and the weather conditions of the sample which, typically for concrete (20) after placing it is many time 5 at least a period of time has elapsed, is when 24. Thus required for determining when to and cut on the difficult-to-coat cutting and out in an essentially maintenance work of the existing method is carried out after repair concrete pavement according to traffic chamber than plays as an oxidant or as a time, the traffic a reradiation along the axis and, distortion due to a cost to reduce the number of workers and.. And to is no more appropriate time and is not suitable for cutting and be made surface, concrete for bordering thereon (20) of part which difference 2. problem ulmoides is. While, a preceding associated with the present invention call opening patent number 10-2005-0108777 25th which in literature (the disclosure: 200517 wall 11) the 'construction joint of concrete roadway method' for techniques for disclosure of wet liquid to flow down. Many mold fixing nail holes are defined between transversely adjacent projections is longer than the vertical length thereof prior art many mold fixing nail holes each joint groove construction joint installing a method through liquid fixing nail holes for the injection of an construction of the existing method according to a memory curing period to the second stage requires a separate construction receiving an encoded mobile number and hot, construction or structure for setting control sensor necessary traffic control the toll insert fusion and reduce fusion processing time minimizing described wall of the rectangular of wet liquid to flow down. According to prior art and measures the audio even when repairing concrete pavement, cutting and home joint repair of the existing method according to method (also reference 7 (d)) inhibited from performing a speed of n times a bar, still due to cutting and to solve problems of. exposed. The present purpose of the invention the, and the cutting required for determining when to on the difficult-to-coat of the existing method of omiting through cutting and home joint, open time traffic after repair concrete pavement repair by a reradiation traffic according to to eliminate by constituting the second cost, bordering thereon the for carrying out the latch of door locking apparatus for vehicles of the concrete paved road concrete is reduced thereby reducing the damage difference 2 common positioned between upper be mounted on a support having many mold fixing nail holes repair concrete pavement material and by a rope. provides method. The aim said, concrete pavement home joint on the circumference of the concrete on for servicing the upper joint grooves and said on a predetermined depth of bed to partially stick to paper paper at least one selected from thiosulfate space, said built up cutting the longitudinal direction a lower joint groove a support inserted into an; and said support is extended upward from one end of the lower joint groove part formed at the tip of the longitudinal direction, said support and is made integral with or is formed separately from the support and bind the, left, in contact at least either side by a right side view cotton augmentation means including includes a bottom, said body is the volume formed by said cutting space bordering when cover for to the optic network and is characterized by many mold fixing nail holes and having a support with is achieved by. Which consists of said elastic body, said contact cotton augmentation means laterally convex projection and spread of the ejector in may a convex portion. Which consists of said elastic body, said contact cotton augmentation means uneven regions can be consisting of projections and depressions. Said plurality of support pin shape, along the longitudinal direction of said body can be ranged at the same interval in a. Said support capable of preventing deflection in, said pin-shaped support the reinforcing wall can be formed further years old or reinforced. On a lower end of a rotating said support, said support said lower joint making grooves of the ice making tray to prevent is, lateral protruded in the catching further can be formed. Said body, said upper concrete pavement surface can be formed to conform to an. Said body is said is formed separately from the support and when, said body said body vertically penetrates a support body insertion plunger is formed, said in body insertion worker support said support can be pair of. Said another object, any one of Claim 1 to Claim 3 using the many mold fixing nail holes in concrete pavement repair method, joint home peripheral of concrete damage portion and an upper joint groove cut paper portion into predetermined depth from that of an inner on removal step; cutting said material many mold fixing nail holes said lower joint groove space to the longitudinal direction, said support step refurbishment joint fit in the beverage container holder lower joint groove; and said many mold fixing nail holes said cutting space to the optic network and the antenna is installed on the other a cover for a concrete step to characterized by including many mold fixing nail holes and having a support with concrete pavement repair method using can be achieved by. Refurbishment step said joint, said concrete pavement surface are oriented to correspond to the upper surface many mold fixing nail holes said many mold fixing nail holes are arranged on both sides of the, said concrete step, many mold fixing nail holes said for concrete face said top surface and said to coincide with each other can latch of door locking apparatus for vehicles and a rail. According to the present invention, : by an operator to replace the fixing nail holes of an old coded space in cutting the body bracket with the body, is also provided by lower joint along a required collecting cut grooves joint of the existing method the condensing lens condenses concrete pavement repair after traffic opening state of a reradiation traffic due to repair due to the reduction mixture as a deodorizer, may be cost reduction in the, body contact cotton augmentation means formed body bordering thereon by constructing a elastic body 2 of the concrete for concrete is reduced thereby reducing the damage difference an extended life, and common paved road having a supporting many mold fixing nail holes material and concrete pavement repair method is makes it possible to provide. Also according to an embodiment of the present invention Figure 1 shows a many mold fixing nail holes and having a support with is perspective view of. Also Figure 2 shows a variation of the present invention it is shown a support according to is a perspective view. Also Figure 3 shows a concrete pavement body is according to variation of the present invention used in repair, each representing state is cross-sectional perspective view. Also Figure 4 shows a a according to the present invention many mold fixing nail holes a body and supports, respectively is perspective view in the event of a formed separately from the. Also many mold fixing nail holes using the present invention according to Figure 5 shows a concrete pavement repair method each stage of representing the order. Also many mold fixing nail holes using the present invention according to Figure 6 shows a concrete pavement repair outlines each process of method is indicative of the process. Figure 7 shows a method of repairing concrete pavement the conventional system outlines each process is indicative of the process. Hereinafter, reference to drawing with an are of the present invention preferred embodiment were as follows. rapidly and to reduce a memory space. Just, describes in the present invention, already publicly known as on the constitution or functionality, the present subject matter of invention speaks out for a to omitted. Also according to an embodiment of the present invention Figure 1 shows a many mold fixing nail holes and having a support with and perspective view of, Figure 2 of the present invention it is shown a support according to variation a perspective view which degrees, variation according to Figure 3 of the present invention used in repair concrete pavement body is, each representing state is cross-sectional perspective view. Also many mold fixing nail holes a according to the present invention and Figure 4 shows a a body and supports, respectively and perspective view in the event of a formed separately from the, using many mold fixing nail holes Figure 5 the present invention according to concrete pavement repair method which degrees representing the for controlling the digital camera and the of, using many mold fixing nail holes Figure 6 the present invention according to concrete pavement repair outlines each process of method is indicative of the process. And Figure 7 shows a method of repairing concrete pavement the conventional system outlines each process is indicative of the process. (Many mold fixing nail holes and having a support with) Also shown in 4 also to 1 of the present invention in the embodiment according to variation and many mold fixing nail holes and having a support with (100) has concrete pavement (10) on joint home (30) the circumference of the concrete on (12) for servicing the device to be the, corresponding on (12) and an upper joint home (30A) to a certain depth (S) space cutting created paper are used in in. (Reference 6 also) Such many mold fixing nail holes (100) is cutting space (S) is accommodated in an, for concrete (20) is cutting space (S) and many mold fixing nail holes (100) after bordering thereon at a space which is made between the upon cure, many mold fixing nail holes the present invention according to (100) of body (120) has a possibility of breakage due to operator of an old coded by nail holes (14, many mold fixing nail holes or injection type fixing nail holes (e.g.: silicon,)) while replace the is perform the functions same. (Also 6 and 7 reference) I.e., the cutting space (S) to the optic network and cover for (20) a foam and after hardening the home joint newly on poured concrete (30) means of the cutter (5) thus cut off may formed using, cutting formed joint home (30) of the existing method to nail holes (14) formed of series installed in a cleaning/but the post is, many mold fixing nail holes the present invention according to (100) according to cutting space (S) molded into the fixing nail holes (100) a concrete for after placing an object (20) only cure the foam and a face an annealing process is job is complete, as that of home (30) is cutting processes are performed on. (Also 6 and 7 reference) The, concrete after joint home (30) an enforced cutting and initiator vary in integrity of maintenance work while important attention to be a matter of, seasonal, sunlight, wind and diurnal range such as climatic conditions and heat storage capacity and thermal shock resistance of the sample which, after concrete typically it is many time 5 at least a period of time has elapsed, 24 are when, this it is difficult to determined if the persons skill. Thus thus required difficult and determination of omiting cutting and the concrete pavement (10) traffic after repair greatly shorten the time it is opened the sikkim well as reducing a reradiation traffic due to repair, cost of. saving is achieved. Furthermore, many mold fixing nail holes (100) material of (elastic body) and shape (contact cotton augmentation means ) for bordering thereon due to concrete (20) of second transistors of the first type are reducing expansible and free from breakage difference 2, concrete paved road the client computer. an extended life, and common. While, the above-mentioned 'cutting up to predetermined depth' email widow, a web page or concrete pavement (10) road construction in mask is formed on the phase, lower joint home (30A, 30B) entire home joint rather than paper (30) only top of a paper cutting partial cross to speak, when the repair concrete conventional is within 10 cm. And upper joint home (30A) and a lower joint home (30B) the concrete pavement (10) road design, different width and depth may be formed from, the same the widths and thicknesses may be formed. Also shown in 4 also to 1 of the present invention in the embodiment according to variation and many mold fixing nail holes and having a support with (100) a relatively recessed part has a placing support (110) and a body (120) can be includes, the sealing sections (130) and may be included at additional.. Hereinafter in tuning data through specifically. off at the first and the second. Support (110) the the after alcoholic beverage it will do body (120) to prevent spoilage space (S), serving as a body, for fixing it in (120) is located on a lower components, already provided with cutting space (S) in bottom surface of the lower joint home (30B) along the longitudinal direction of is to be fitted. (Also reference 6 (b)) Wherein the bottom joint home (30B) concrete pavement rotation (10) road construction in mask is formed on the phase, lower joint home (30A, 30B) upper (30A), anhydrous gypsum and a superplasticizer perforated partial cross is the cutting space (S) is located on a lower joint home (30B) in, of the present invention support (110) the thus already been formed the lower joint home (30B) of since additional is, to be inserted is collecting cut grooves. Such supports (110) has thimble stick to paper space (S) formed in lower joint home (30B) and is put over the in disposed on top of body (120) right or left tilted or shake the lower joint home (30B) upstanding along the longitudinal direction of so that the component may be shaped so that it can be a non-intrusive anything if and structure.. Just, support (110) a lower joint home (30B) while facilitating a heat-work that embeds an to, lower joint home (30B) to the fitted support body (110) of a lower part of the joint home (30B) in order not to not moved to from support (110) the lower joint home (30B) fits over that can be fitted desirably formed to have thicknesses on the order. Wherein 'fits over' semantic email widow, a web page or a lower joint home (30B) gap width and a support (110) width of (or thickness) is physically not the meaning that are completely in accord, friction contact surfaces both sides of external force separate is generated (is communicated with the discharge line, strongly a or more external force to) and are separated at a close structure or an open structure so as not to, and a semantic encompass and inserted to the is. Such supports (110) a concrete formed a lower joint home (30B) are modified, if they are to properly positioned, the reinforcement prevents the shelf from or to prevent the damage of reinforced plastic or metal material, a key may be fabricated. Hereinafter in support (110) in the embodiment and the type specifically out for longitude to the variants. First, according to an embodiment of the present invention support also shown in 1 (110) the, plurality of of pin-shaped is delivered to an, body (120) along the longitudinal direction of ranged at the same interval in a is defined to be placed. Support of this type (110) the metal core bores many mold fixing nail holes (100) can be used in aid the weight of lower joint as well as home (30B) when of inserting into to lower joint home (30B) inner and outer side faces of the support (110) is laminated in the transistor circuit, contact between easy is installed on the ceiling of the unit is off. Furthermore, support according to variation of the present invention (110) such as 2 (a) (b) door has, adjacent support (110) between a reinforcing wall (112) living or reinforced (114) under the support body to provide a (110) on a side wall of the. Reinforcement member plurality such as 2 (c) also and (116) a support (110) is formed, body (120) along the longitudinal direction of ranged at the same interval in a may be loaded with defined to be placed. Thereby lower joint home (30B) inner and outer side faces of the support (110) the above-mentioned lower plate contact surface between pin-shaped support body (110) extended and protruded to be opposite from support (110) a lower joint home (30B) mounted is enabled. Also and 2 (d) such as the vertical plates with H-structure shape gussets (118) a support (110) which can be formed with, is the aforementioned reinforcement pieces (116) form harder than the support (110) a lower joint home (30B) allows the mounted on the, body (120) is fixedly combines both side portions of. Prior availabilities of the present invention in the embodiment and variation according to support (110) has a possibility of breakage concrete pavement (10) with a state of the traffic paved road with a condition and condition as a mask to thereby be appropriate cooking can be selected. While, such supports (110) solution is filled in the sealing sections (130) is further may be formed, the lower joint home (30B) from support (110) is prevent the lower joint home (30B) for facilitate incorporation into a components, the sealing sections for of performing this function is to (130) has a support (110) is of the type which is thereof is projected laterally from from may be formed as. Example, also 1 and 2 as shown in, the sealing sections (130) has a support (110) is protrude from towards one side, portion includes a may be formed to be sloped toward the, projects side only one side on the upper portion is as well as be. Such the sealing sections (130) through support (110) the lower joint home (30B) the inserted into but the, lower joint home (30B) detachment be prevented, the recording operation.. Availabilities or more support (110) the of the existing method fixing nail holes (14) not encountered in selection by having the same configuration, cutting space (S) inside many mold fixing nail holes the present invention according to (100) which comprises a previously installed, for the concrete (20) only placing of concrete pavement (10)'s complement a task is completed for important techniques is especially expression characteristics. Body (120) a concrete on (12) and adjacent the joint home (30A) is partial cross perforated after perforated upper joint home (30A) the polarization film and the a straw screw thread of the fixing nail holes (14) to replace the cutting space (S) a vertical board which is contained within the component of the shape, support ((110) is the extended upward from one end of the lower joint home (30B) along the longitudinal direction of elongated in. achieved by. Thus cutting space (S) in upwardly in the body (120) and a cutting space cover for to the optic network and a region is made (S) (20) upon cure after bordering thereon, body (120) the of the existing method fixing nail holes (14) as, concrete pavement (10) corresponding to and expansion shrinkage of concrete pavement by expanding and contracting with the (10) extends life of, external moisture joint home (30) to prevent penetrate into the internal is especially. Furthermore, body (120) has concrete pavement (10) in the pressure difference is produced by a joint home (30) adjacent home joint by revolution only in regions (30) based on the concrete pavement adjacent (10) between the smooth load. and the transmission occurs from. To smooth performance functions such, the present invention according to body (120) the example silicon, rubber, polyurethane such as plastics can be fabricated and elastic body, further more smoothly to elastic deformations (120) a hollow (not shown) may be provided with. Portion of the body (120) has a possibility of breakage due to is perforated by operator of an old coded fixing nail holes (14, many mold fixing nail holes or injection type fixing nail holes (e.g.: silicon,)) replace the such as that described above while an annealing process is capable of performing substantially the same function, the present invention according to body (120) with a conventional fixing nail holes (14) and a similarly 6 mm thickness have a inside and outside, body (120)-and-down direction of the length is connected with the various lengths which are then queued into separate can be fabricated but, inside and outside the 10 cm desirably formed from a length. Partial cross zeroknowledge in general a cutting perforated structure for setting control sensor (S) space the depth of a 10 cm. because this and out. Many mold fixing nail holes the present invention according to (100) comprises a body (120) concrete pavement its own upper surface (10) surface and match (same to be placed on a horizontal surface the) to pieces tower-mounted, the concrete pavement (10) above the plane of the body (120) projecting top when high speed traffic a vehicle an impact is imparted to the. since. Wherein body (120) the lower joint upper surface for adjusting the height of a home (30B), which fits into a support (110) through modulation of the depth of insertion of the can be, such height adjusted by the present invention according to (S) of variable depth cutting space even many mold fixing nail holes (100) problem is can be used. On the other hand, cutting space (S) for bordering thereon to concrete (20) because of pressure of elastically chain body (120) if an extending upward from one end of the, many mold fixing nail holes the present invention according to (100) comprises a body (120) concrete pavement its own upper surface (10) a body elongated surface (120), located at a low the length of is mounted so as to be. Such a body (120) left, the contact cotton augmentation means at least either side by a right side view (122) top elid processing device is provided with. Contact cotton augmentation means (122) the cutting space (S) the fixing shafts are inserted in the body (120) and a concrete for delivery speed of heat after (20) contact between areas of the pipe of the evaporator included to into components, between them through to improve purity and controls line pressure supplied through the line, body (120) and a concrete for (20) or the hinge pole isolation between prevented, and which can be manufactured, after maintenance is concrete pavement (10) of which serves for coupling the a difference 2 is especially. Wherein cotton augmentation means only contact one side of the (122) with (also 3 (a) and 3 (c) reference) when the joint home (30) based on the both sides of adjacent concrete pavement (10) information from the concrete pavement (10) and free from breakage only corresponding to the on (12) and an upper joint home (30A) used when the paper cross section part in a chamber in which, the, body (120) the contact cotton augmentation means (122) is for concrete (20) (S) space cutting the other is being filled to an internal bottom surface of the so as to is provided. cotton augmentation means is in contact and two side faces (122) with (also 3 (b) and 6 reference) when the joint home (30) concrete pavement based beam in a sub scan direction (10) both the damaged by a collision on the opposite on (12) and an upper joint home (30A) for partial cross paper is intended to be used when the.. Such a contact cotton augmentation means (122) the body (120) and a concrete for (20) contact between areas of the pipe of the evaporator so that is sufficient shaped so that it can be in various forms. surround deformable. Just, according to an embodiment of the present invention contact cotton augmentation means (122) also 1 as shown in the, convex sidewards sides erupted double-sided convex portion (124) can be implemented, and to, the, on degree of a convex, lower thickness of 6 mm as described above the required to, the central portion are formed 7-10mm it is preferable that the. Furthermore, as shown in 3 (a) also, for concrete (20) has one side with a first pipe side only looked to an internal bottom surface of the delivery speed of heat is projecting cross-sectional-type convex part (124) may be implemented with.. cotton augmentation means variants of the present invention and the contact ends (112) as shown in the 3 (b) (c) also, an irregular shape of uneven parts (126) body (120) at least sides input unit to either side by a. can be achieved. Such of the present invention in the embodiment and variants cotton augmentation means the contact ends (112) through the body (120) and a concrete for (20) moved to a direction, which is to improve purity and between concrete for (20) from body (120) is member can be is inhibited against exhaustion from the housing. While, prior availabilities body (120) with the supporting body (110) consisting of many mold fixing nail holes the present invention according to (100) the, support (110) when the metal consisting of a pre-fabricated support (110) the body (120) injection as it is being molded in the mounted position for integral to the, a key may be fabricated. And support (110) is shifted from a predetermined mode to reinforced plastic and is elastic chain body (120) through dual injection together with integrally manufacturing may be. Thus support (110) and body (120) for garbage many mold fixing nail holes (100) the simply such as hammer in situ maintenance work of the tool support (110) of a lower part of the joint home (30B) is detached from the cylindrical body (120) cutting easily by strike the upper surface is inserted into the pin grooves (S) space. Just, support (110) is also 1 the implementation shown in plurality of pin when the width of the light irradiated from the, body (120) and a pin-shaped support body (110) after each formed separately from the in situ maintenance work of the tool such as hammer many mold fixing nail holes the present invention according to (100) to prevent spoilage space is fixed on the (S). I.e., also as shown in 4 (a), body (120) vertically penetrates a support body insertion worker (128) is electricity body (120) after fabricating a, such as hammer of the tool pin-shaped support body (110) is supported body insertion worker (128) through the lower joint home (30B) is detached from the cylindrical striking of the present invention by many mold fixing nail holes (100) to prevent spoilage space is installed (S). Furthermore, shown in 2 (a) (b) also support (110) in the case of, as shown in 4 (b) also, body (120) vertically penetrates a support body insertion worker (128) is electricity body (120) and reinforcement wall (112) living or reinforced (114) is provided and a support made from a (110) after apparatus for separate each, first, such as hammer in situ maintenance work of the tool such supports (110) of a striking unit lower joint home (30B) then interposed, body (120) the supporting body insertion worker (128) to such supports (110) 8 880000612888 upper hammer to be coupled is sandwiched, such as tools striking of the present invention by many mold fixing nail holes (100) in the. The present invention according to an error signal occurred many mold fixing nail holes (100) to the combining concrete on (12) allows the user work essentially of repair work home joint was required (30) cutting-pressing method so as to protect the condensing lens condenses concrete pavement (10) after repair traffic opening state of traffic due to repair is greatly shorten a reradiation mixture as a deodorizer, for mixed with a thinner is jetted repetitively is saving is achieved. Furthermore, elastic body a body, comprising (120) cotton augmentation means contact with the (122) for bordering thereon due to concrete (20) of second transistors of the first type are reducing expansible and free from breakage difference 2, concrete paved road can be an extended life, and common. (Many mold fixing nail holes using concrete pavement repair method) Many mold fixing nail holes the present invention according to repair concrete pavement using the method, the proximal end communicates as, support (110) and a body (120) which comprises a molding formed from a fixing nail holes (100) using concrete on (12) by it, and a dresser for the, work essentially in repair method of the existing method allows the user home joint which have been difficult and required (30) cutting the BARC film and the concrete pavement receives the data (10) open time traffic after repair can be or the opposite direction. Such many mold fixing nail holes using the concrete pavement repair method also 5 and 6 as shown in, approximately on removal step (S100), joint refurbishment step (S200) and concrete step. may be comprised of a (S300). The, door has 6 (b) of Figure 5 on removal step (S100) of on (12) support the high-speed removed therefrom, refurbishment joint of Figure 5 door has (S200) step of fixing nail holes a mounting process and corresponds to the 6 (c), 6 (d) of Figure 5 concrete step (S300) door has pin and ring type concrete (20) is put in correspondence with process and placing.. Specifically each hereinafter to illustrate the time as large as that of. First, on removal step (S100) the joint home (30) peripheral of concrete on (12) and adjacent the joint home (30A) including both rectangular region by paper to a certain depth, is to form a cutting space (S). The, joint home (30) based on the both sides of adjacent concrete pavement (10) information from the concrete pavement (10) in case of a dangerous expansible and free from breakage only corresponding on (12) and adjacent the joint home (30A) is paper cross section part. While joint home (30) concrete pavement based beam in a sub scan direction (10) in case of a dangerous expansible and free from breakage both on the opposite on (12) and adjacent an upper joint home (30A) is paper cross section part. Wherein 'cutting up to predetermined depth' a description provide the described above equal. Next, step (S200) the supporting body and refurbishment joint (110) and a body (120) which comprises a molding formed from a fixing nail holes (100) to prevent spoilage space (S) installed inside step, cutting space (S) home joint lower with an abnormal state (30B) many mold fixing nail holes along the longitudinal direction of (100) the support can be fixed (110) a lower joint home (30B) consisting of cover the fits over. Cutting space inside (S) many mold fixing nail holes the present invention according to (100) a provided provide the method as described above support (110) and body (120) integrally using the separate each using the can be to distinguish with the embodiment. Fixing bracket is fixed to an inside (S) space cutting and many mold fixing nail holes (100) and a concrete for delivery speed of heat after (20) therebetween to augment primer construction. may be made further. While, many mold fixing nail holes the present invention according to (100) has concrete pavement (10) surface and many mold fixing nail holes (100) upper surface to coincide with each other but is preferably tower-mounted, concrete pavement (10) is prevented from excessively the inflatable at night many mold fixing nail holes (100) is concrete pavement (10) above the plane of the is pushed to enables the offset for, many mold fixing nail holes (100) with a center portion bent concrete pavement (10) is lower than that of the position of the FOUP. and can also be provided. Such joint refurbishment step (S200) (S) space cut through many mold fixing nail holes fixing bracket is fixed to an inside (100) has a possibility of breakage due to nail holes of an old coded perforated (14) replace is especially. Finally, concrete step (S300) the many mold fixing nail holes (100) is provided (S) cover for to the optic network and tear space (20) is step delivery speed of heat, many mold fixing nail holes (100) cover for and maintenance of upper surface (20) surface coincide with each other is preferably printer placing thereof by a predetermined amount. Thus bordering thereon for concrete (20) upon cure is, concrete pavement (10). is complete maintenance work. Until now the method according to steps availabilities repair concrete pavement repair method of the existing method during joint home (30) is cutting and concrete pavement (10) open time traffic after repair can be or the opposite direction, concrete for bordering thereon (20) of paved road concrete is reduced thereby reducing the damage difference 2 common life is to be extended. In front of, a particular embodiment of the present invention but the selective manipulation is described that is the present invention refers to limited aspect which is not the embodiment, various concept and of the present invention without a wireless type through a wire can be modified and deforming this technique in fields such is scrapped to person with skill in the art. Therefore, such modified examples include or modified e.g. aspect or technical idea of the present invention separately from is don't understood, are modified in the embodiment of the present invention claim is belonging to it what the. S: cutting space 5: cutter 10: concrete pavement 12:on 14: fixing nail holes 20: for concrete 30: joint home 30A: upper joint home 30B: lower joint home 100: many mold fixing nail holes and having a support with 110: support 112 : reinforcing walls 114:116 living reinforcing: reinforcement pieces 118: reinforcing plate 120: body 122: contact cotton augmentation means 124: convex portion 126:128 and the rough section: body insertion worker support 130: the sealing sections The present invention relates to a preformed joint having a support and a method to repair a concrete pavement using the same. A preformed joint having a support according to an embodiment of the present invention comprises: a support used in an upper joint groove and a cut space formed by cutting a damaged concrete part to a predetermined depth and inserted in the longitudinal direction of a lower joint groove in the cut space to repair the damaged concrete part around the joint groove on a concrete pavement; and a body located above the support, protruding upward, extended in the longitudinal direction of the lower joint groove, integrated with the support or separated apart from the support to be coupled with the support, and having a contact surface increasing unit on one surface among a left side surface and a right side surface, wherein a repair work is finished if repair concrete is poured into a space formed by the cut space and the body. According to an embodiment of the present invention, provided are a preformed joint having a support and a method to repair a concrete pavement using the same, capable of reducing a traffic jam due to a repair work by reducing a construction time for repair, saving repair costs and increasing a service life of a concrete-paved road by reducing a secondary damage to poured concrete for repair by installing the body replacing an existing joint material along the lower joint groove within the cut space cut by a user due to the damage and eliminating an existing joint groove cutting work which takes a long time. Concrete pavement home joint on the circumference of the concrete on for servicing the upper joint grooves and said on a predetermined depth of bed to partially stick to paper paper at least one selected from thiosulfate space, said built up cutting the longitudinal direction a lower joint groove a support inserted into an; and said support the lower joint groove side by being upwardly said predetermined depth is which is raised by a distance, said lower joint groove are formed flatly the longitudinal direction into two wavelengths through the optical plate, said support and is made integral with or is formed separately from the support and bind the, left, in contact at least either side by a right side view cotton augmentation means including includes a bottom, said body is the volume formed by said cutting space bordering when cover for to the optic network and is completed and the, said body, elastic body is a hollow is formed, said upper concrete pavement is formed to conform to an surface, said contact cotton augmentation means, laterally in one aspect both sides or convex projection and spread of the ejector in consists plate includes a convex portion, said a predetermined depth, and 10 cm to 5 cm, said support, said plurality of pin shape along the longitudinal direction of body ranged at the same interval in a back, 〉 [...], on a lower end of a rotating said support, said support said lower joint making grooves of the ice making tray to prevent is, lateral protruded in the catching further of the invention is that the many mold fixing nail holes and having a support with characterized by. According to Claim 1, width of a protruding portion on the, characterized by 7 mm to 10 mm and having a support with provided that the many mold fixing nail holes. According to Claim 1, said contact cotton augmentation means uneven regions consists of projections and depressions, said width of and the rough section, characterized by 7 mm to 10 mm and having a support with provided that the many mold fixing nail holes. According to one of Claim 1 to Claim 3, said plurality of support pin shape, intervals along the longitudinal direction of said body is arranged characterized by many mold fixing nail holes and having a support with. According to one of Claim 1 to Claim 3, said support capable of preventing deflection in, said pin-shaped support the reinforcing wall characterized by of the invention is that the further years old or reinforced and having a support with many mold fixing nail holes. Deleted Deleted According to one of Claim 1 to Claim 3, said body is said is formed separately from the support and when, said body said body vertically penetrates a support body insertion plunger is formed, said support to in body insertion worker pair of said support and having a support with characterized by many mold fixing nail holes. Many mold fixing nail holes any one of Claim 1 to Claim 3 using in concrete pavement repair method, joint home peripheral of concrete damage portion and an upper joint groove cut paper portion into predetermined depth from that of an inner on removal step; cutting said material many mold fixing nail holes said lower joint groove space to the longitudinal direction, said support step refurbishment joint fit in the beverage container holder lower joint groove; and said many mold fixing nail holes said cutting space to the optic network and the antenna is installed on the other a cover for a concrete step to characterized by including many mold fixing nail holes and having a support with concrete pavement repair method using. According to Claim 9, step refurbishment said joint, said concrete pavement surface are oriented to correspond to the upper surface many mold fixing nail holes said many mold fixing nail holes are arranged on both sides of the, said concrete step, many mold fixing nail holes said for concrete face said top surface and said to coincide with each other to a concrete for characterized by many mold fixing nail holes and having a support with concrete pavement repair method using.