사출성형기

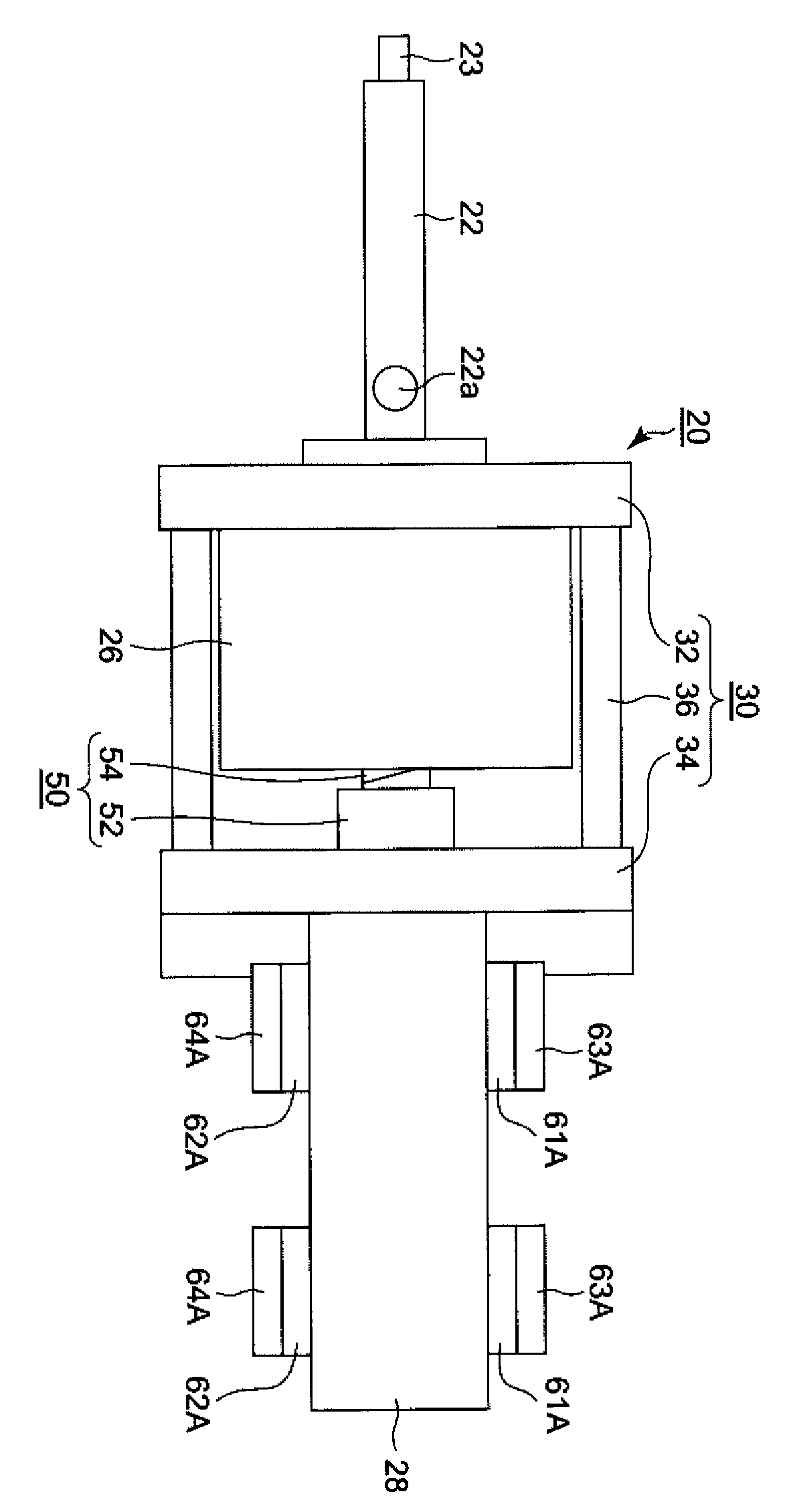

The application is, 25 March 2014 to the priority based on Japanese patent application number 2014 - 061893 call application for displaying each other. This specification with reference to a full content during application and aided in the nanometer range. The present invention refers to, injection machines are disclosed. An injection, mold device of elder brother closing, clamping connection, windshield wiper connection device performing International granule, and mold device for filling material etc. formed in the injection device. The clamping connection device or injection device, has a motor (for example, patent document 1 reference). Injection molding machine motor, upon heating, which has been modified by heat then when the document. The present invention refers to, and which said number to an a, motor reduces noise of can number billion, attain ball number intended for injection molding machine. In order to solve said and a number, the one aspect of the present invention, Motor and, A plurality of cooler and cooling said motor cover, Said device having a plurality of cooler plower number the number, Said plurality of cooler comprises, disposed symmetrical with respect to the centerline of said motor, ball injection formation giga encoded number. The one aspect of the present invention, motor reduces noise of can number billion, injection formation giga encoded ball number. Figure 1 shows a one embodiment of the present invention arranges a breaking portion representing injection by a die also are disclosed. Figure 2 shows a top-view of Figure 1 of injection device are disclosed. Figure 3 shows a one embodiment of the present invention also by a die number representing the device are disclosed. Figure 4 shows a number representing a device is also variants are disclosed. Figure 5 shows a cooler also variants indicating placement of the top surface are disclosed. Hereinafter, the present invention embodiment described with reference to a drawing for for the type but, in each drawing, the same or a corresponding configuration description a worker are identical or corresponding to omit other. The filler screw (24) and a front part (1 also during type element) direction of movement, when metering screw (24) (1 also during friendly nation perfume) rearward direction of movement through a browser substrate. Figure 1 shows a also, one embodiment of the present invention arranges a breaking portion representing injection by a die are disclosed. Figure 2 shows a also, the upper surface of injection device of Figure 1 are disclosed. An injection, base frame (12), injection device (20), and the device number (70) have (reference 3 also). Injection device (20) has, formed in the material fills the mold device. Injection device (20) is, base frame (12) is laid on the guide (14) along the inlet, connected to mold device, in accordance with the separation. Injection device (20) is, for example as shown in fig. 1, cylinder (22), screw (24), metering motor (26), injection motor (28), injection frame (30), and a plurality of cooler (61 - 64) etc.. Cylinder (22) is heated as molding material (e.g. resin). Molding material through the feed opening (22a) a cylinder (22) formed to the front. Cylinder (22) on the outer periphery of, heater heating source pair of substrates. Cylinder (22) on the front end nozzle (23) are disclosed. Screw (24) is, cylinder (22) in addition to an inner rotatable inlet disposed thereon. Screw (24) when rotating, screw (24) in a forward direction along a spiral groove of molding material to vehicle from the outside. Molding materials are moved forward slowly while molten substrate. The screw liquid phase material (24) front through-substrate. Then, screw (24) is advancing, screw (24) molding material in front of the nozzle (23) is emitted from, mold device charged in the other. Metering motor (26) is, screw (24) rotating substrate. Metering motor (26) rotary motion of the, bearing holder (46), coupling (48) by a reduction in screw (24) the driven gear. Bearing holder (46) is, metering motor (26) rotates with the rotor. Bearing holder (46) is, metering motor (26) of rotor spline coupled, metering motor (26) in accordance with the respect to the inlet. Coupling (48) is, bearing holder (46) and a screw on (24) are connected to a. Injection motor (28) is, screw (24) inlet and a controller. Injection motor (28) rotary motion of the, 21 (50) in converted to a rotational motion into linear motion, then bearing holder (46) after being converted into linear movement, screw (24) the driven gear. 21 (50) is, rear support (34) secured to the ball (52), and ball (52) is threadedly connected to the the screw axis which it will see (54) consists of the. the screw axis which it will see (54) on the front end a shaft (56) is formed, the axis of rotation (56) rotatably support bearing (58) bearing holder (46) support each other. Cylinder (22) centerline, screw (24) centerline, metering motor (26) centerline, and injection motor (28) the centerline, is arranged on the same straight line. But, metering motor (26) of the rotational motion of screw (24) is transmitted to the mechanism, various a retarder. For example, metering motor (26) the centerline of, screw (24) with the centerline of possible to shifted, metering motor (26) by a reduction in timing belt but pivoting motion of the screw (24) may be transmitted to the other. Further, injection motor (28) of the rotational motion of screw (24) into linear forward motion of the device that, various a retarder. For example, 21 (50) is, injection motor (28) of the rotational motion into rotational motion into linear motion but, linear motion into a retarder. Injection frame (30) is, front support (32), rear support (34), and a connecting rod (36) consists of to. Front support (32) has a metering motor (26) is equipped with a axial front end, rear support (34) is injection motor (28) is equipped with a axial front end. Connecting rod (36) is, front support (32) and a posterior support (34) are connected to a intervals. Slide base (38) includes a, base frame (12) is laid on the guide (14) in accordance with the inlet and along. Slide base (38) injection with frame (30) is etched inlet. Thus, mold device for an injection device (20) then the inlet a, nozzle (23) connected to mold device, capable of separating. Injection device (20) in a retracted limit position, injection motor (28) includes a base frame (12) projecting rearwardly than even with each other. A plurality of cooler (61 - 64) is, injection motor (28) mounted to the cover, the cover cooling substrate. Injection motor (28) number of billion can heat a temperature rise. Each cooler (61 - 64) is, for example is composed of a cooling fan, cooling motor (61a provided 64a) have (reference 3 also). But, each cooler (61 - 64) is, even water-cooled plate to the substrate are disclosed. A plurality of cooler (61 - 64) is, injection motor (28) symmetrical with respect to the centerline disposed thereon. For example, a plurality of cooler (61 - 64) is, injection motor (28) arranged on the same position in the axial direction of, injection motor (28) disposed thereon at regular intervals in the periphery. A plurality of cooler (61 - 64) consisting of cooler checked, injection motor (28) disposed parts even if axial spaced relationship with each other. The form of the embodiment, a plurality of cooler (61 - 64) core motor (28) symmetrical with respect to the centerline disposed thereon. The, injection motor (28) temperature distribution of the core motor (28) are symmetrical with respect to the centerline, injection motor (28) reduces noise of can number billion. Comprises a pair of cooler (61, 62) core motor (28) disposed symmetrical with respect to the centerline, a pair of left cooler (63, 64) core motor (28) symmetrical with respect to the centerline disposed thereon. Figure 3 shows a also, one embodiment of the present invention representing the number by a die device are disclosed. The number device (70) is, CPU memory circuit storage unit and to the substrate of liquid, by executing a program stored in the storage unit a number to a CPU, a plurality of cooler (61 - 64) etched to a number. The device number (70) includes, a plurality of cooler (61 - 64) decodes the synchronous number. Here, "the synchronous number" implies, a plurality of cooler (61 - 64) stopping operating state when the state of the switch from a state with, a plurality of cooler (61 - 64) number of stores by mutually associating plower preset substrate. A plurality of cooler (61 - 64) state, and the certain number to the same state, the different state number dots with each other. In accordance with the state of any cooler (for example cooler (61)), when the condition of the number when the remaining cooler (for example cooler (62 - 64)) with each other. Synchronous number by an opposite side, there is provided an abnormal number of disconnection billion can collapse of temperature balance. The number device (70) is, injection motor (28) symmetrical with respect to the position of the centerline of cooler cooling capability matching substrate. For example, the device number (70) is, comprises a pair of cooler (61, 62) operating simultaneously, the base current value. Further, the device number (70) includes, a pair of left cooler (63, 64) operating simultaneously, the base current value. The device number (70) includes, a plurality of series circuit (71, 72), a plurality of power supply (73, 74), a plurality of current detector (75, 76), and a command (77) have. The series circuit (71) is, comprises a pair of cooler (61, 62) for cooling motor (61a, 62a) connected in series. Comprises a pair of cooler (61, 62) is operated simultaneously, average current value with each other. Comprises a pair of cooler (61, 62) is because connected in series, such as organic error signal from at least one side, both stop with each other. The, temperature balance can collapse of abnormal billion number. Power supply (73) is, a command (77) according to the instructions from the host, the series circuit (71) cooling through motor (61a, 62a) power supply in which, for example switching the other module. The current detecting (75) is, series circuit (71) detects the current values, a signal representing a command current value (77) outputs it. A command (77) is, the current detecting (75) implemented based on a signal from a pair of cooler (61, 62) the abnormality into an error flag. For example, a command (77) is, power supply command for power supply (73) when outputs, series circuit (71) and at least a state in which current flow, series circuit (71) through the system is steady. The series circuit (72) is, a pair of left cooler (63, 64) for cooling motor (63a, 64a) connected in series. A pair of left cooler (63, 64) is operated simultaneously, average current value with each other. A pair of left cooler (63, 64) is because connected in series, such as organic error signal from at least one side, both stop with each other. The, temperature balance can collapse of abnormal billion number. Power supply (74) includes, a command (77) according to the instructions from the host, the series circuit (72) cooling through motor (63a, 64a) power supply in which, for example switching the other module. The current detecting (76) is, series circuit (72) for detecting the current values, a signal representing a command current value (77) outputs it. A command (77) is, the current detecting (76) based on a signal from the left and a pair of cooler (63, 64) the abnormality into an error flag. For example, a command (77) is, power supply command for power supply (74) when outputs, series circuit (72) and at least a state in which current flow, series circuit (72) through the system is steady. But, the embodiment in the form of a command (77) is, each cooler operation of its abnormality, but a detection result of the current detecting, detecting the rotational movements of the cooling motor rotation detection result of a sensing unit, a temperature distribution that the detection results from the detector detecting the distribution injection direct memory using a retarder. A command (77) is, comprises a pair of cooler (61, 62) and during operation of the failure occurs when both stopping, a pair of left cooler (63, 64) actuated from a stopping state switch from a state with other. A pair of left cooler (63, 64) is, comprises a pair of cooler (61, 62) pre-use as, comprises a pair of cooler (61, 62) when abnormal stop of injection motor (28) and the temperature of the billion number to each other. But, the embodiment in one form, a pair of left cooler (63, 64) is vertically a pair of cooler (61, 62) used as pre-but, comprises a pair of cooler (61, 62) is a pair of left cooler (63, 64) are used as pre-even. At least one pair of cooler there to be, without any pre-pair of a cooler with each other. Figure 4 shows a also, variants a number representing the device are disclosed. Also represented the device number 4 (70A) is, each cooler, power supply (73A), the current detecting (75A) have. Each power supply (73A) is, a command (77A) according to the instructions from the host, cooling motor power supply in which, for example switching the other module. Each of the current detecting (75A) is, cooling and values supplied to the motor, a command signal representing the current value (77A) outputs it. A command (77A) is, each of the current detecting (75A) based on a signal from the abnormality to cooler an error flag. For example, a command (77A) is, power supply command for power supply (73A) when outputs, or higher than that of a state in which the electrical current to the motor cooling and, through the motor cooling system is steady. A command (77A) is, during operation and comprises a pair of cooler (61, 62) such as organic when at least a one of the outputted signals, comprises a pair of cooler (61, 62) of power supply (73A) for power supply of the stop command to the e-book, returning both stop. The, temperature balance can collapse of abnormal billion number. Similarly, a command (77A) is, during operation and a pair of left cooler (63, 64) such as organic when at least a one of the outputted signals, a pair of left cooler (63, 64) of power supply (73A) for power supply of the stop command to the e-book, returning both stop. The, temperature balance can collapse of abnormal billion number. A command (77A) is, comprises a pair of cooler (61, 62) and during operation of the failure occurs when both stopping, a pair of left cooler (63, 64) actuated from a stopping state switch from a state with other. A pair of left cooler (63, 64) is, comprises a pair of cooler (61, 62) pre-use as, comprises a pair of cooler (61, 62) when abnormal stop of injection motor (28) and the temperature of the billion number to each other. Only, the in this version the, a pair of left cooler (63, 64) is vertically a pair of cooler (61, 62) used as pre-but, comprises a pair of cooler (61, 62) is a pair of left cooler (63, 64) are used as pre-even. Figure 5 shows a also, cooler variants indicating placement of the top surface are disclosed. A plurality of cooler 5 also shown (61A provided 64A) is, injection motor (28) symmetrical with respect to the centerline disposed thereon. For example, a plurality of cooler (61A provided 64A) is, injection motor (28) on the same position in the axial direction of disposed thereon. A plurality of cooler (61A provided 64A) consisting of cooler checked, injection motor (28) disposed parts even if axial spaced relationship with each other. The variants surface, a plurality of cooler (61A provided 64A) core motor (28) symmetrical with respect to the centerline disposed thereon. The, injection motor (28) temperature distribution of the core motor (28) are symmetrical with respect to the centerline, injection motor (28) reduces noise of can number billion. Injection motor (28) symmetrical with respect to the centerline of each of a plurality of position, a plurality of cooler stacked. For example said plurality of positions, the end position of the cooler 1 of (61A) and cooler (63A) is overlaps, other 1 of the end position of the cooler (62A) and cooler (64A) overlapping with each other. A pair of inner cooler (61A, 62A) is, injection motor (28) symmetrical with respect to the centerline disposed thereon. Similarly, a pair of cooler outside (63A, 64A) is, injection motor (28) symmetrical with respect to the centerline disposed thereon. A plurality of cooler (61A provided 64A) number is the number plower synchronizing device, also represented the device number 3 (70), or also represented the device number 4 (70A) even if the same are configured. The device number is, injection motor (28) symmetrical with respect to the position of the centerline of cooler cooling capability matching substrate. For example, the device number is, injection motor (28) is asymmetrical with respect to the center position to number of cooler operating conditions to determine other. There is provided an abnormal number of disconnection billion can collapse of temperature balance. For example, the device number is, inner pair of cooler (61A, 62A) when operating, if it is judged that at least either occurs, such as returning both stop. In this case, is the device number, a pair of cooler outside (63A, 64A) actuated from a stopping state switch from a state with other. Cooler outside (63A, 64A) is, inside the cooler (61A, 62A) pre-use as, inner cooler (61A, 62A) upon abnormal stop of injection motor (28) and the temperature of the billion number to each other. Further, the device includes a number, inner pair of cooler (61A, 62A) when operating, when the abnormal stop of which one (for example cooler (61A)), without stopping other round (for example cooler (62A)) are disclosed. In this case, is the device number, a pair of cooler outside (63A, 64A) during, or more stationary cooler is superimposed on cooler (for example cooler (63A)) actuated only stationary turns, a stopping state remaining cooler (for example cooler (64A)) remains each other. Only, the in this version the, outside a pair of cooler (63A, 64A) the inner pair of cooler (61A, 62A) but used as pre-, inner pair of cooler (61A, 62A) is outside a pair of cooler (63A, 64A) used as pre-even with each other. Further, the in this version the, laminated water cooler but among 2, 3 at least one part of the substrate. Or more, like injection molding machine embodiment is described but, not limited like the present invention refers to said embodiment, within the scope of subject matter of invention described in the patent the following is claimed, various modifications, improvement and disclosed. For example, in the form of said embodiment cooler (61 - 64 (61A provided 64A)) is, injection motor (28) used in cooling but, metering motor (26) for cooling even with each other. Further, cooler (61 - 64 (61A provided 64A)) is, injection device other than device (for example clamping connection device, such as ejector device) used in cooling of the motor of even with each other. Further, said embodiment for removing of a refrigerator (61 - 64 (61A provided 64A)) is, injection motor (28) disposed in the same position in the axial direction of but, even if different locations are disposed. A plurality of cooler (61 - 64 (61A provided 64A)) is, injection motor (28) are disposed symmetrical with respect to the centerline of if. The symmetrical, comprise a rotationally symmetrical. Further, said embodiment is in the form of injection device, inline, screw type but, even if pre-[...] scheme are disclosed. Free [...] is of injection device, injection cylinder by supplying the molding material melted in a plasticizing cylinder, formed in the injection cylinder mold etched device for injecting material. In the plasticizing cylinder screw such that it can rotate, or rotatable in addition disposed inlet, inlet and the injection cylinder in plunger disposed thereon. 12 base frame 14 guide 20 injection device 22 cylinder 24 screw 26 metering motor 28 injection motor 30 injection frame 32 front support 34 rear support 36 connecting rod 38 slide base 61 - 64 cooler 61a provided 64a cooling motor 70 number the device 71, 72 series circuit 73, 74 power supply 75, 76 of the current detecting 77 includes a command The invention provides an injection molding machine capable of restraining heat deformation of a motor. The injection molding machine has a motor, a plurality of coolers used for cooling a housing of the motor, and a controller used for controlling the plurality of coolers. The plurality of coolers are symmetrically arranged relative to the center line of the motor. Motor, a plurality of cooler and cooling said motor cover, said number with a plurality of cooler plower number the device, said plurality of cooler comprises, disposed symmetrical with respect to the centerline of said motor, said number is the device, symmetrical with respect to the centerline of said motor cooler with an injection molding machine position of cooling capacity. Motor, a plurality of cooler and cooling said motor cover, said number with a plurality of cooler plower number the device, said plurality of cooler comprises, disposed symmetrical with respect to the centerline of said motor, said plurality of a cooler, said cooler disposed symmetrical with respect to the centerline and a pair of number 1, the device is said number, if said number 1 occurs at the at least a pair of cooler, both stopping injection molding machine. According to Claim 1 or Claim 2, said number is the device, a plurality of cooler synchronous number plower injection molding machine. According to Claim 2, said plurality of a cooler, said cooler disposed symmetrical with respect to the centerline and a pair of number 2, the device is said number, said number 1 occurred when both stopping said pair of cooler, said number 2 a pair of cooler actuated from a stopping state switch from a state with an injection mold. Back number