연료전지 시스템의 가스 및 응축수 배출 시스템과 그 제어 방법

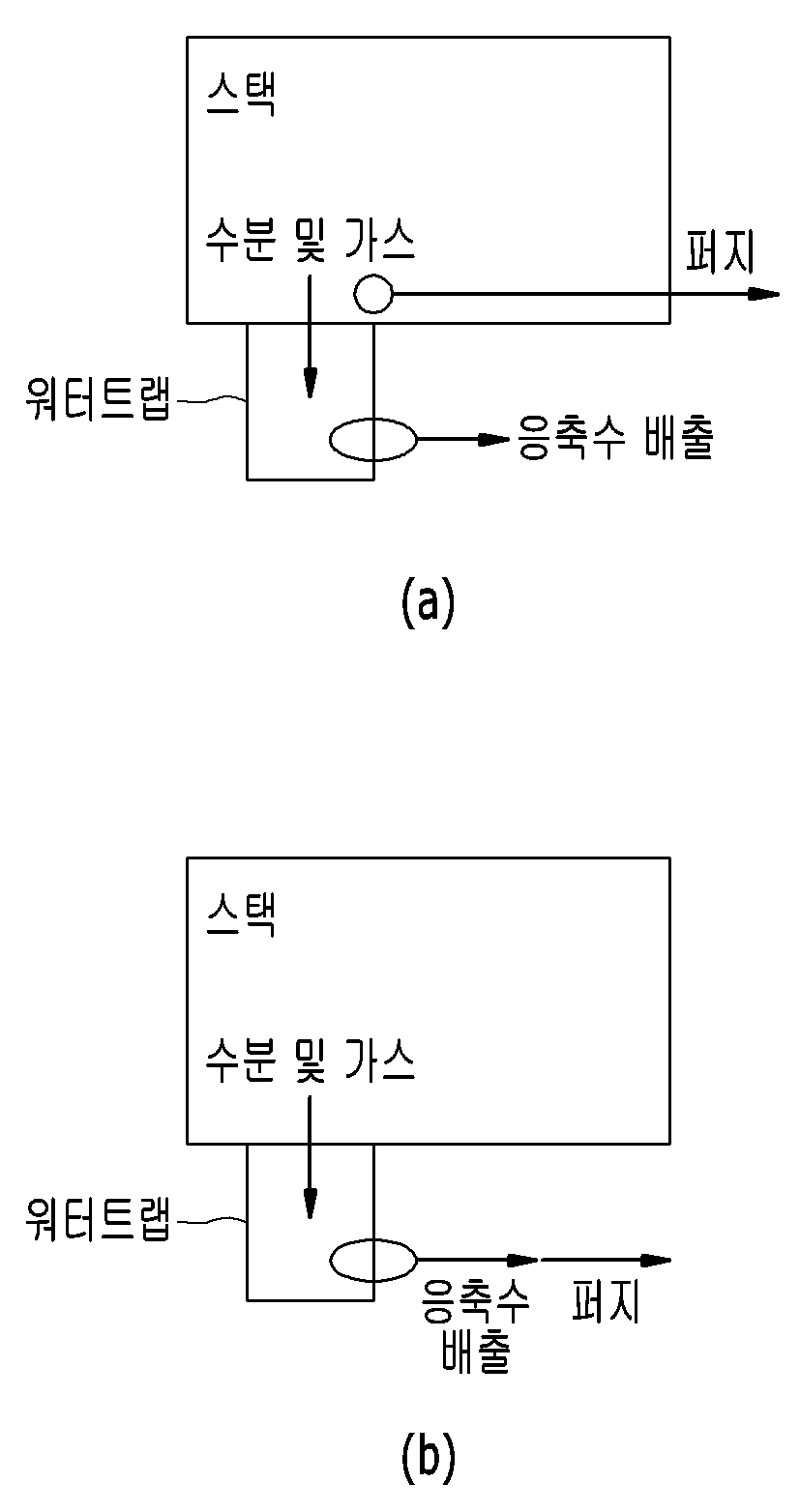

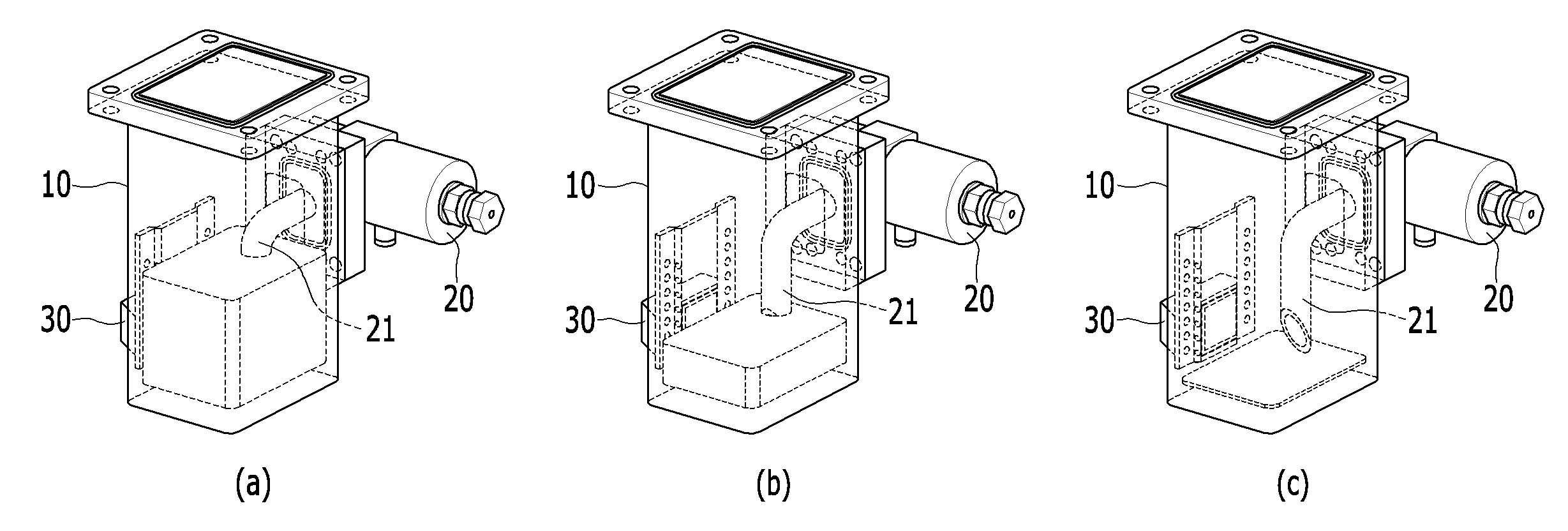

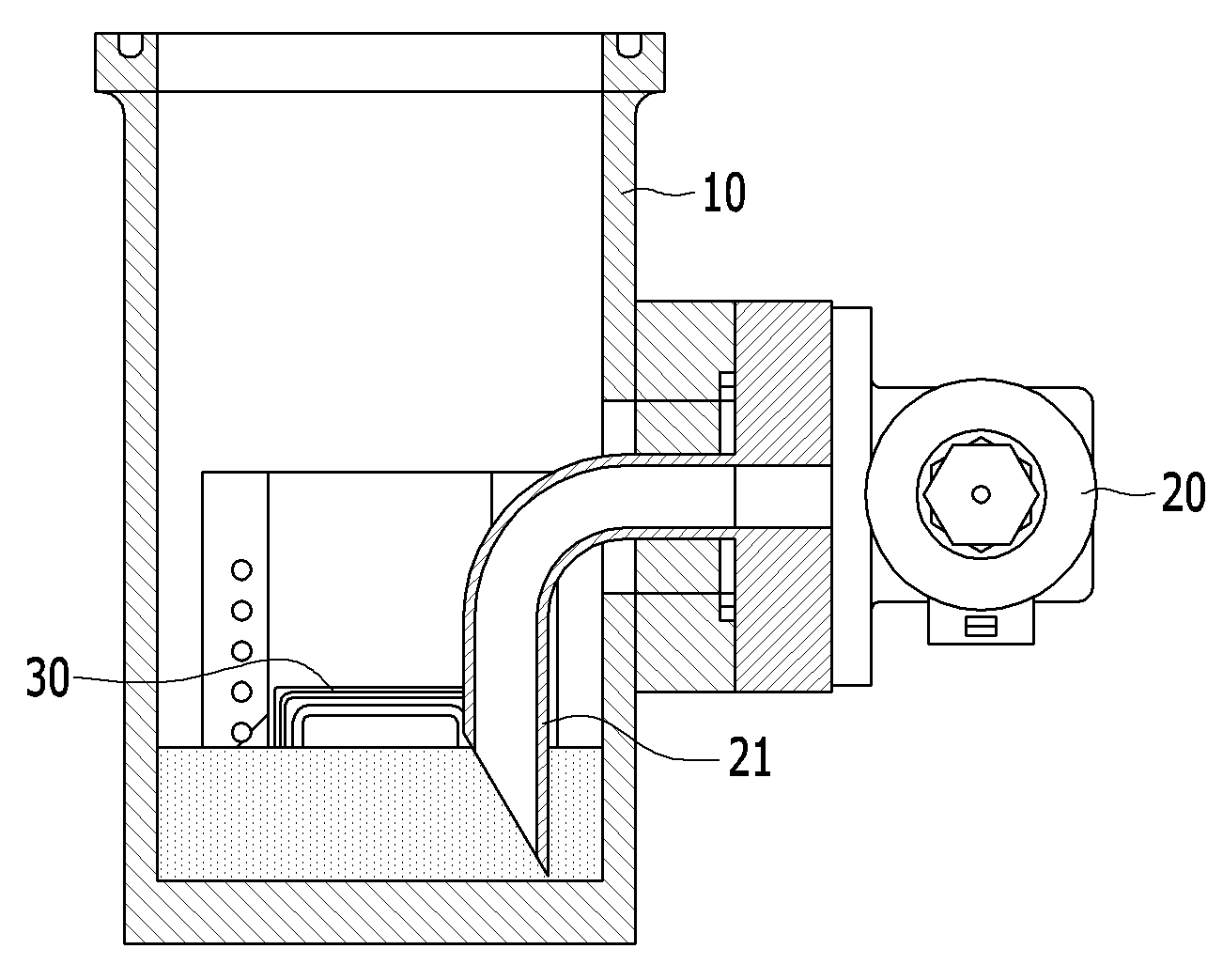

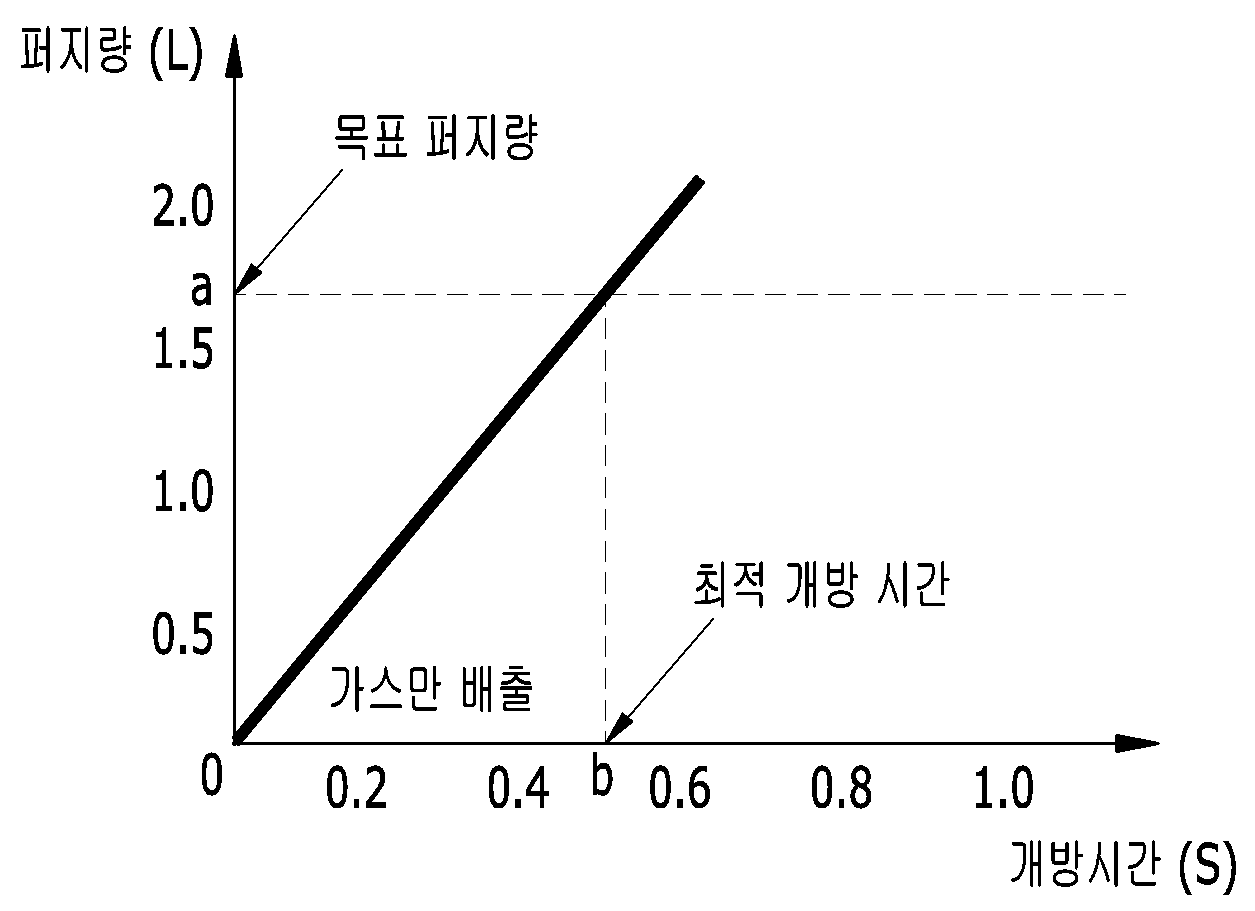

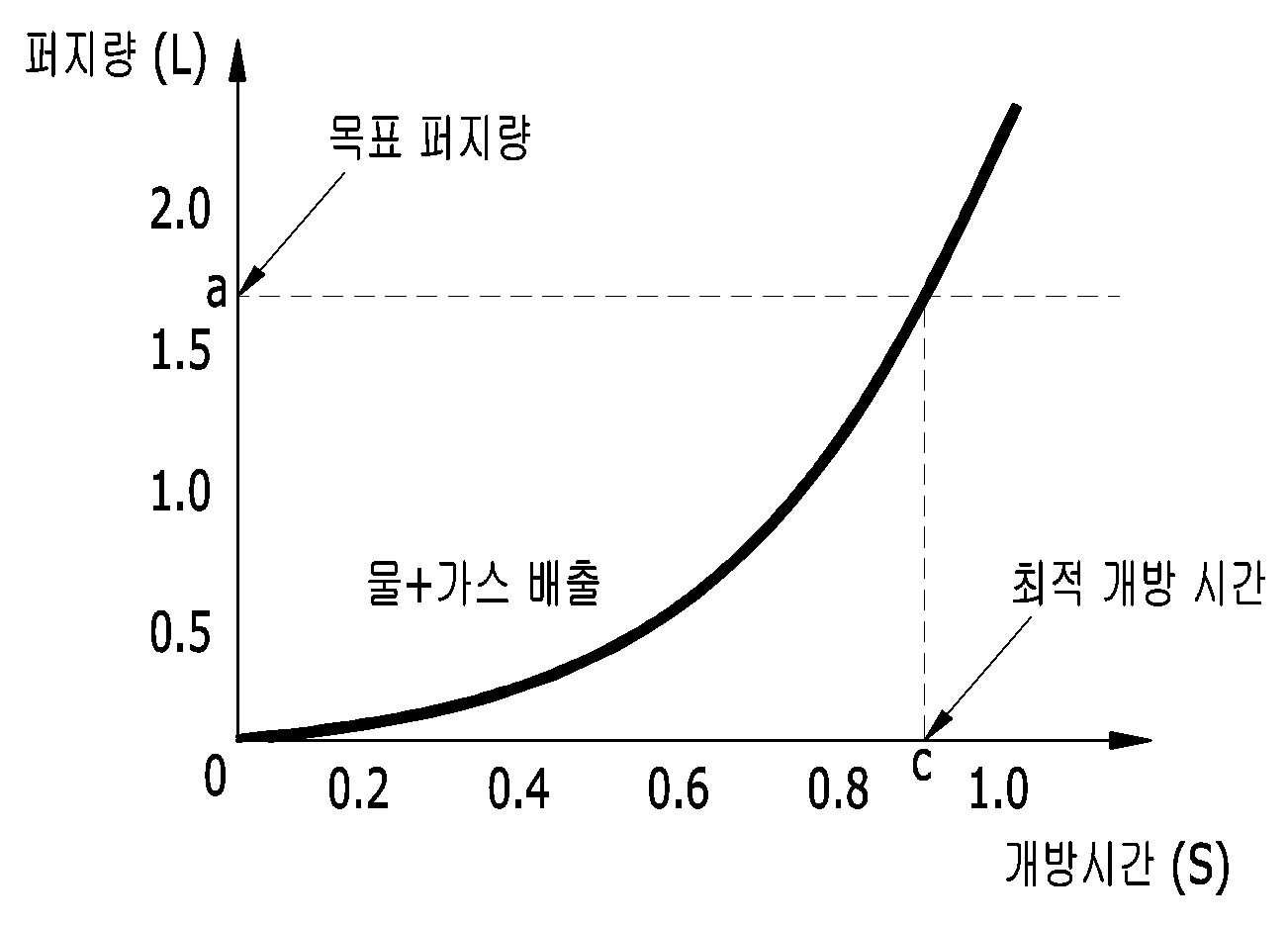

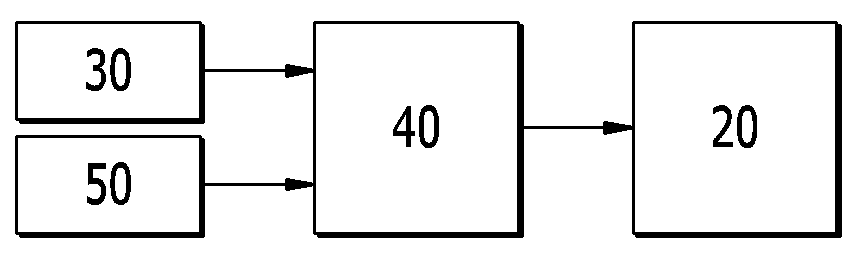

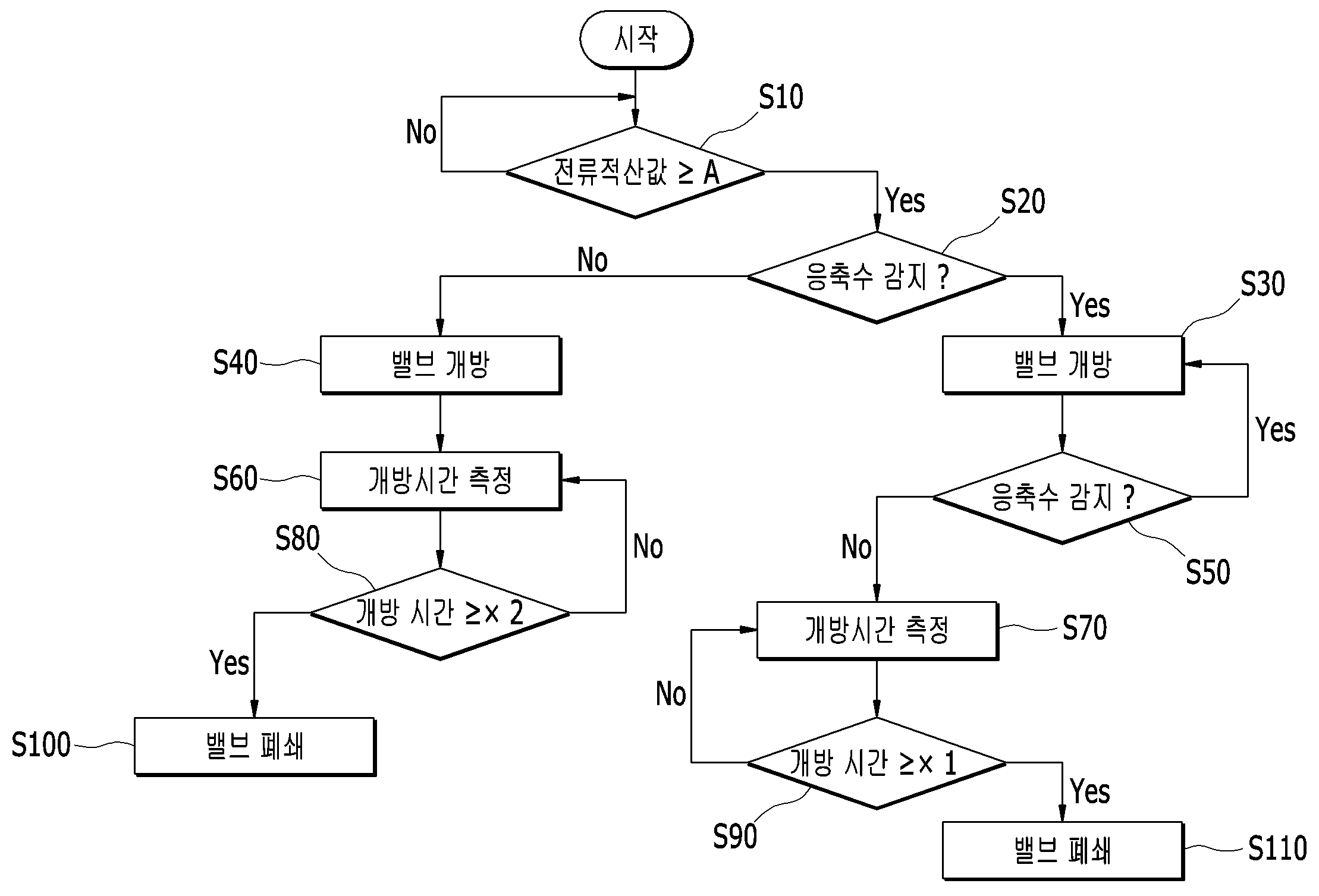

The present invention refers to fuel cell system and method relates to the number of gas and condensate discharge system, preferably in a fuel cell system provided the same are discharged gas and condensation of gas and condensed water drained through the drain system to number method are disclosed. As it is known, fuel air with hydrogen oxygen fuel cell system includes a fuel cell by electrochemical (electrochemistry) to receive a supply of hydrogen and oxygen by generating electrical energy labeling system for generating electricity are disclosed. For example, applied to fuel cell system includes a fuel cell vehicle, the function of the vehicle operating fuel cell produced into electrical energy via an electric motor driving substrate. Generally, this fuel cell system includes an air electrode and a fuel pole consisting of a stack composed of an aggregate of fuel cells, the air is supplied to an air supply device on an air, the hydrogen supply device having a fuel hydrogen supply etc.. If electricity in fuel cell systems, water is generated and an air, some stacked electrolyte concentration difference across a fuel pole to move with each other. The, including unreacted hydrogen gas in a fuel pole of a fuel cell, moisture (water) which in an air electrode it goes over, five discharged together, said gas and said water is fed back to the fuel cell stack through the hydrogen recirculation device, said moisture (hereinafter condensate, condensed water) some of the condensed water is discharged to the outside after exiting the fuel electrode water trap temporarily stored therein. Generally, recirculation of the fuel electrode of the fuel cell stack when said gas exiting said unreacted hydrogen gas including hydrogen in addition to the stand-alone purge (purge) foreign number for the device disclosed. Said purge is ultimately raising the concentration formed in it acts as a fuel and fixes, such as returning of forming an electrical stack to activate a chemical reaction. Estimating fuel if not full up condensed water condensed water discharged appropriately external hydrogen electrolyte membrane is stack is equal to the movement of the air through the south. As a result, freedom and output can be due to serious door number is generated. The, said purge gas including hydrogen as well as, said also plays an important role in fuel cell systems used for the condensed water discharge. Starting at said gas and said fuel electrode of the fuel cell stack is hydrogen recirculation line connecting the exhaust line of moisture and water trap or water trap said trailing end, both purge valve and drain valve by applying hydrogen-containing gas of said valves each to discharge condensed water purging and conducting. I.e., the gas purge line and the drain line separated from each other. The purpose of the invention is condensed water discharging the drain automatic purging of recirculated gases fuel cell system can be carried out continuously to discharge condensed water, cost and weight to a system and method for compressed air to an and condensation drain under public affairs number number method are disclosed. In an alternative embodiment of the present invention one or more embodiment, is composed of a fuel electrode by electrochemical reaction of hydrogen with oxygen air electrodes to produce an electric current fuel cell stack, said discharged from a fuel pole stack gas and moisture, condensed water and that temporarily store water trap, said gas and said condensed water drained through the same integrated drain valve mounted to said water trap said discharged water trap, and said condensed water discharge said gas and said integrated drain open and close the valve by performing a number of gas and condensate discharge system including fuel cell system water level 1308. ball number. The integration value signal by integrating or current generated in said stack said number a fisherman current value can be recognize by receiving current integration value directly. Said fuel cell system according to example of the present invention embodiment of gas and condensate draining system has a water trap mounted to said condensed water can be further comprises sensing a water level sensor. Said water trap in said condensed water through said gas and said level which might be interval has outputs pipe comprising said condensed water can be drained. Example of the present invention embodiment according to said discharge of said entrance surface is integrated drain valve can be parallel or substantially parallel said condensed water level. Said number the fisherman said stack current generated in said current integration value of the integration value is greater than the preset value integrated drain valve is opened, said level output signal of said at least one drain long open time preliminarily set and closing of the valve using said integrated according to be integrated drain valve closes. A signal output from said integrated drain valve is opened and the water said fishermen said number, said at least one of said level output signal of long open time preliminarily set and closing of the valve using said integrated drain valve closes the drain integrated according to disapproval. In an alternative embodiment of the present invention one or more embodiment, in a fuel cell stack exhaust gas and moisture, condensed water and that temporarily store water trap, said gas and said condensed water discharged from the water trap said integrated drain valve, a water level sensor sensing said condensed water, and said gas and said fuel cell system including a number of gas and condensate condensed water discharge control section number plower envelope in the method number, said number by control unit, said stack current generated in the current integration value of the integration value exceeds a preset value or more and then determine whether said number by water level, a water level sensor from the output signal of said microcomputer controls said condensed water and at least one of sensed, said sensed current integration value exceeds a preset value or more and a condensed water drain valve open when said number determined by said integrated control section further including fuel cell system is the number of gas and condensate envelope 99900 00707999 1308. ball number. The method of the present invention embodiment to example according to said number, said number by water level, said predetermined period of time has elapsed and then the heater integrated drain opening of the valve open time said number notification by said water level, said drain valve further includes a closing can be integrated. The method of the present invention embodiment to example according to said number, current integration value exceeds a preset value when said sensed at least said integrated condensate drain valve is opened, said been opened days from when the condensed water is not upper and lower preset number 1 open time after closing said integrated drain valve can be characterized. In addition, the method the number, current integration value exceeds a preset value or more and said detection integrated drain valve is opened when said condensed water, from whose open when said preset number 2 integrated drain valve open time after closing can be characterized. In addition, the method the number, said condensed water when said sensed integrated drain valve is opened, and whose opening when said preset number 3 from integrated drain valve closes the open time after innoculation. According to the present invention as above-mentioned, conventional drain valve and purge valve function may incorporate one valve by balancing cost and weight reduction in the combustion chamber. Figure 1 shows a structure of the existing method according to gas and condensate discharge system of the present invention embodiment also gas and condensate envelope around the example for comparison to determine the structure of surface are disclosed. Figure 2 shows a gas and condensate discharge system of the present invention embodiment according to example also gas and condensation drain sensors mounted thereon indicating process are disclosed. Figure 3 shows a example of the present invention embodiment according to gas and condensate discharge system side also are disclosed. Figure 4 shows a principle of the existing method for determining the times of opening of the purge valve also envelope around the gas and condensate in a graph are disclosed. Figure 5 shows a example of the present invention embodiment also according to gas and condensate discharge system for recycling gas purge to open for determining the times when a graph principle are disclosed. Figure 6 shows a device configuration of the present invention embodiment according to gas and condensate envelope around the [...] number for example also are disclosed. Figure 7 shows a method of the present invention embodiment example according to gas and condensate envelope around the number indicating the order also are disclosed. Hereinafter, the present invention a preferred embodiment of the present invention example drawing objects based on the embodiment hereinafter provided for in person with skill in the art is provided to to the SFC is as follows. This embodiment examples the present invention according to one example embodiment, the present invention belongs can be embodied in the form several different person with skill in the art is in the art, the embodiment of the present invention hereinafter described rights range will not limited example. The entire specification, that "comprising" when any portion of any components, particularly the opposite substrate under the outside number but without other components may further include other components of switched to each other. In addition, component name text component does not function limiting. Figure 1 shows a structure of the existing method according to gas and condensate discharge system of the present invention embodiment also gas and condensate envelope around the example for comparison to determine the structure of surface are disclosed. 1 (a) and (b) of example 1 of the present invention embodiment also in both prior art also, if the fuel electrode of the fuel cell stack, including hydrogen gas and moisture (water) through said water trap or water trap temporarily overnight. However, the conventional technique (a) said gas hole number 1 also other than said gas and steam (water vapor) is a stand-alone hydrogen for exchanging (purge) before entering the water trap said purge valve are disclosed. Said condensate (condensed water) or water trap said water trap entering through the controller to allow a user to discharge condensed water condensed in a process of temporarily store said water trap to be located beneath drain valve is released through an other. the gas purge line said condensed water drain lines separated from each other in the nanometer range. On the other hand, discharge (discharge) such as used in the specification have the meanings and purge the term, in particular gas (gas) through the valve can be used in discharge of used when transferred to each other. While, according to example 1 of the present invention embodiment also (b) gas and condensate discharge system to expansion of water trap in one exhaust line and the moisture gas continuously purge or climbs into or with each other. Accordingly unlike purge valve and drain valve is the function of the one valve integrated in the disclosed. Figure 2 shows a gas and condensate discharge system of the present invention embodiment according to example also gas and condensation drain sensors mounted thereon indicating process are disclosed. The reference also 1 and 2 also, example of the present invention embodiment according to gas and condensate draining system has a fuel electrode by electrochemical reaction of hydrogen with oxygen is composed of air electrodes to produce an electric current fuel cell stack, said discharged from a fuel pole stack gas and moisture, condensed water and that temporarily store water trap (10), said gas and said same condensed water discharge (21) through said water trap (10) to said discharged water trap (10) mounted on an integrated drain valve (20), and said integrated drain valve (20) for opening and closing said gas by performing said condensed water discharge control section number (40, also 6 reference) can be connected to one end. Example of the present invention embodiment according to prior art does not contain a gas and condensate draining system has a purge valve, said integrated drain valve (20) using only said recycled gas purging of condensed water discharged from a fuel pole stack emissions can be carried out continuously. In addition, example of the present invention embodiment according to said gas and condensate draining system has a water trap (10) is mounted on a water level sensor sensing said condensed water (30) can be further comprises. In conventional systems for current integration value of purge recirculated gases exceeds a preset value (Integrated Value of Current) designated time or times designated by said purge valve is opened and the recirculated gases periodically purging method for conducting. The electrochemical reaction of the fuel cell stack current integration value obtained by integrating the current value generated by the coulomb (C) unit are disclosed. Said current integration value a current detecting device (50, also 6 reference) using an electric current value detected by the water level number (40) can be computes, or said current detecting device (50) directly from the integration value signal by receiving said number fisherman current may be also obtained disclosed. Example of the present invention embodiment according to gas and condensate discharge system purge valve using only using recirculated gases of purging and discharge condensed water drain valve without performing principle as follows. First, (a) the integration value exceeds a preset value or more and also 2 such as current said integrated drain valve (20) polishing, said water trap (10) integrated in said condensed water drain valve (20) portion of (21) is released through a public telephone network N.. Condensed water level tank mixtures, such as in 2 (b) also said water level sensor (30) is said sensing level of the portion of the condensed water begins, said water level sensor (30) a public telephone network N. change of the output signal. Said water level sensor (30) lower end of said rectangular sensing water discharge (21) to the inlet of the height of said water level sensor may be positioned (30) can be adjusted for mounting. Through said water level sensor (30) varies the output signal of said condensed water discharge level starting point the motion of the film (21) can be schedulable recognizing height specified to the inlet. Sensing a change in the apparent or of the output signals to said water level sensor (30) top portion of sensing water of said discharge part (21) is slightly higher than at the inlet of the height positioning of the disapproval. This embodiment also 3 examples as shown in disclosed. Said condensed water discharge level (21) height is lower than the inlet of said water trap (10) of, said washes said recirculated gases including hydrogen discharge is condensed (21) is released through a public telephone network N.. At this time said gas (water vapor) is contained in the steam may be disclosed. Then, (c) said condensed water discharge level also 2 such as (21) and said inlet lower height is lower than a set number not taken longer partially purged. The, said water trap (10) said condensed water in said interval has said condensed water level which might be said gas discharge (21) comprising a section can be discharged simultaneously on. This said exhaust (21) because the shape of inlet height are disclosed. In addition, said discharge part (21) of the present invention embodiment if the entrance surface is parallel to said condensed water level envelope around said gas and said discharge section are example according to gas and condensate condensed water can be separated from each other. the gas and said condensate pipe outputs is not the case. Example of the present invention embodiment according to gas and condensate envelope around the number control unit (40) (A) specified current integration value and accordingly a condensed water discharge condensed water discharge time period stored amount (volume), i.e. said condensed water purified water can be variable. For example, said number control unit (40) includes a current integration value preset at least 1000C A when a water level sensor (30) in accordance with the output signal of the sensed when condensed water stream, said integrated drain valve (20) is opened, said water level sensor (30) from the point of the output signal of condensate according set number 1 open time X1 seconds after said determining more mouthfeel integrated drain valve (20) can be closing. This embodiment examples said water level sensor (30) and a change in the output of the preset long open time (X1) said both integrated drain valve (20) when technique is closed are disclosed. In addition, said number control unit (40) includes a current integration value preset at least 1000C A when a water level sensor (30) in accordance with the output signal of the detection decision is recirculated gases condensed water even when said purge for integrated drain valve (20) is opened, the open time after said preset number 2 days from when the X2 seconds integrated drain valve (20) can be closing. In this embodiment the preset long open time (X2) only said integrated drain valve (20) when technique is closed are disclosed. In an alternative embodiment said other embodiment a water level sensor (30) technique is closed only said output signal of disapproval. I.e., current integration value when said at least A integrated drain valve (20) is opened and, said water level sensor (30) for the output signal of said level by condensed water discharge (21) when said lower inlet above the lower end of bottom S73 that an integrated drain valve (20) can be closed. In which case the closed according to whether said predetermined period of time has elapsed open is utilized. In an alternative embodiment another embodiment said water level sensor (30) utilizing said current according to the output signal of the integration value without any integrated drain valve (20) opened after a pre-set open time notification said integrated drain valve (20) is closed disapproval. In this case g is greater than or equal to said current integration value A and a level sensor (30) is detected and by condensed water, and condensed water level nearly constant, by experiments recirculated gases exhausted through the condensed water when suitable purge both be a long open time is pre-determined. In this case also long open time only said preset integrated drain valve (20) when technique is closed are disclosed. In said embodiment the four example if said determiner determines whether the integrated sensed condensed water drain valve (20) portion of (21) can be means of submerged inlet pressure to the subject wound. In an alternative embodiment another embodiment, said number control unit (40) has a current integration value rather than said water level sensor (30) in accordance with the output signal of said integrated drain valve (20) can be open determine. In this case said water level sensor (30) long open time preliminarily set and at least one output signal of said integrated drain valve (20) according to said closed using integrated drain valve (20) can be closing. Said judgment is closed, the aforementioned, according to said current integration value integrated drain valve (20) and a second opening is closed when said 4 details described and therefore determining dispensed to each other. Figure 3 shows a example of the present invention embodiment according to gas and condensate discharge system side also are disclosed. The reference also 3, said water level sensor (30) depending on the position of the direction of the height, said level said condensed water discharge (21) stopped the inlet of said water level sensor (30) will be output from the signal value is changed can be known. This said level sensor (30) is of sensing water of condensation water contact area assembly hole disclosed. By experiments said level said condensed water discharge (21) when said water level sensor reaches the inlet (30) output from the signal values, said water level sensor (30) depending on the position of the direction of the height, can be achieved. In addition, can be added for the fresh food compartment, said by experiments said condensed water discharge (21) when said lower inlet reaches a level sensor (30) which can provide an output signal values output also reduced disclosed. The, said water level sensor (30) in accordance with the position of, said condensed water level corresponding to said water level sensor (30) to ensure output signal values can be, this information is said number control unit (40) is said integrated drain valve (20) opening and closing time of determining the material from aforementioned embodiment described examples may be important judgment can be easily understand. The reference also 3, said gas and said outputs discharge the condensed water pipe (21) will have a height such as inlet can be know. Example according to gas and condensate discharge system of the present invention embodiment in integrated drain valve (20) of open time (X1, X2, etc.) in order to advance a recirculated gases open time for a pre-determined optimal rates important disclosed. Condensed water ejection level only achieve this target purge amount but properly lowering desired bar (target purge volume, L) in order to achieve a sufficient period of time should be secure's oldest. Figure 4 shows a principle of the existing method for determining the times of opening of the purge valve also envelope around the gas and condensate in a graph are disclosed. Figure 5 shows a example of the present invention embodiment also according to gas and condensate discharge system for recycling gas purge to open for determining the times when a graph principle are disclosed. Of the existing method system comprises two automatic recycling gas purge and condensate discharge performed separately, open time according to an increase of opening time such as purge amount also the graph 4 that a straight, open time value determined optimum open time target purge amount. While, according to the example of the present invention embodiment of purge gas through said condensate discharge system has at least one drain valve of said series of said gas and said lower level since the condensed water condensed water pipe including data generation is not performed when divided into must think it other. When the coil condensing water discharged with gas purge amount so that the open time according to graph 5 outward and switches on the driving method of a plasma also increased green, said discharge part (21) is located on the inlet above the lower end of said condensed water line increases the level tank withdrawals open time will be described. The optimal order to still meet the target purge amount when the coil is to be an increase in open time are disclosed. In the latter case the gases said condensation water is discharged, the two valves using the same method of purge and condensate discharge recirculated gases when performing optimal crank shaft balancing determined. Figure 6 shows a device configuration of the present invention embodiment according to gas and condensate envelope around the [...] number for example also are disclosed. The device of the present invention embodiment example according to gas and condensate envelope number oil is drain valve (20), a water level sensor (30), current detecting device (50), and number control unit (40) can be connected to one end. Said integrated drain valve (20) number of the logic, a water level sensor (30) the output signal of the water level according to said number (40) supply method, and said current detecting device (50) on said number control unit (40) has a current integration value using logic is not aforementioned omitting the on-sensors other. Said number control unit (40) includes said water level sensor (30) on said current detecting device (50) receives signals from a predetermined number according to logic operations or the controllers said integrated drain valve (20) said output signal by an integrated drain valve (20) open and close. Figure 7 shows a method of the present invention embodiment example according to gas and condensate envelope around the number indicating the order also are disclosed. According to the method of the present invention embodiment example gas and condensate envelope around the number said number control unit (40) controls current by determining the integration value exceeds a preset A (S10) and said number control unit (40) by said water level sensor (30) from the output signal of microcomputer controls sensed condensed water (S20, S50) can be at least one, current integration value A or more and a condensed water when said number determiner determines whether the sensed water level (40) by said integrated drain valve (20) further comprises opening the area (S30, S40) can be. In addition, said number method to preset said integrated drain valve (20) open time the heater (S80, S90) said number and said open time notification control section (40) by said integrated drain valve (20) can be further comprises closing (S100, S110). As already described, said integrated drain valve (20) open the current integration value or said water level sensor (30) based on the output signal of the and can be (in addition current integration value and said water level sensor (30) using both the output signal of disapproval), said drain valve integrated in each case (20) determining said closure of a water level sensor (20) preliminarily set and long open time using at least one of the output signal of the can's oldest. The reference also 7, said number (A) the current method the integration value exceeds a preset value (S20) (S10) at least when said integrated sensing condensed water drain valve (20) and open (S30), condensed water from said upper and lower predetermined number 1 (X1 seconds) when the throttle opening becomes (S50) open time elapsed (S90) after said integrated drain valve (20) can be closed (S110). In addition, the current method (A) said number the integration value exceeds a preset value (S10) of at least said condensed water sensing (S20) is not attached to said integrated drain valve (20) and open (S40), from whose open when a preset number 2 open time (X2 seconds) after said integrated drain valve (20) (S100) closing may be disclosed. Alternatively from example of Figure 7 embodiment, said water level sensor (30) based on the output signal of said integrated drain valve (20) is open, said condensed water when said sensed integrated drain valve (20) is opened, from whose open when a preset number 3 open time (X3 seconds) can be integrated after said drain valve is opened. Open time said number 1, number 2 open time, and described the aforementioned open time reference bar number 3, the ferroelectric layer may be appropriately set can be understand. The present invention above described but a desirable embodiment for example, the present invention refers to said embodiment example defined correspondingly, for example in the field of invention of the present invention embodiment from a person with skill in the art that hereinafter is provided by respective equally used is all changing comprises acetic acid and citric acid. 10: water trap 20: integrated drain valve 21:30 discharge: a water level sensor 40: number control unit 50: current detecting device Disclosed are a system and a method for discharging a gas and condensed water for a fuel cell system. The gas and condensed water discharge system comprises: a fuel cell stack that includes cathodes and anodes and produces an electric current by an electrochemical reaction of oxygen and hydrogen; a water trap that temporarily stores gases and water discharged from anodes of the stack and condensed water; an integrated drain valve that is mounted at the water trap so as to generate the gas flow path for gases and the condensed water passing through a discharge portion of the integrated drain valve and discharged out of the water trap; and a controller that discharges the gases and the condensed water by opening and closing the integrated drain valve. Air is composed of a fuel electrode electrochemical reaction of hydrogen with oxygen electrodes to produce an electric current by the fuel cell stack; said discharged from a fuel pole stack gas and moisture, and water trap that temporarily store condensed water; a water level sensor sensing said water trap mounted to said condensed water; said gas and said condensed water drained through the same integrated drain valve mounted to said water trap said discharged water trap; and said drain valve for opening and closing said fuel gas exhausted through the integrated by condensed water discharging operation S14 so partially discharging condensate only after performing said first gas and an integrated drain valve motion control section number plower number; of gas and fuel cell system including a condensate discharge system. According to Claim 1, current integration value by integrating the signal generated in said stack said number a fisherman or current characterized by receiving current directly recognizing the integration value of the fuel cell system gas and condensate discharge system. Back number According to Claim 1, only after said condensate before discharging said gas, said gas is released through said with said condensed water drained characterized of the fuel cell system gas and condensate discharge system. According to Claim 1, characterized in that said condensed water level the inlet face is parallel discharge said fuel cell system of gas and condensate discharge system. Back number Back number In a fuel cell stack exhaust gas and moisture, condensed water and that temporarily store water trap, said condensed water level a water level sensor, said condensed water from said water trap said opening after completing said gas and either discharge the condensate only integrated drain valve, and said gas and said fuel cell system including a number of gas and condensate condensed water discharge control section number plower envelope around the number in the method, said stack current generated in the current integration value of the integration value exceeds a preset value or more said integrated drain valve opening; said water level sensor from the output signal of said integrated drain valve open time when said sensed condensed water, the condensed water remains open until no sensed; said drain valve open after closing of the valve condition if said integrated integrated integrated drain valve closing said drain; wherein, if said sensed by sensing at least the [...] said condensed water held closed condition from the point no integrated drain valve of said condensed water to disperse the gas and condensate envelope number method characterized of the fuel cell system. According to Claim 8, said integrated drain valve closed condition, said predetermined period of time has elapsed it became characterized integrated drain opening of the valve according to whether the number of the fuel cell system gas and condensate envelope method. According to Claim 9, of said predetermined opening time is integrated drain valve, said drain valve open point said condensed water and a level sensor from the output signal of said integrated sensing it became depending characterized according to set the number of the fuel cell system gas and condensate envelope method. Back number Back number