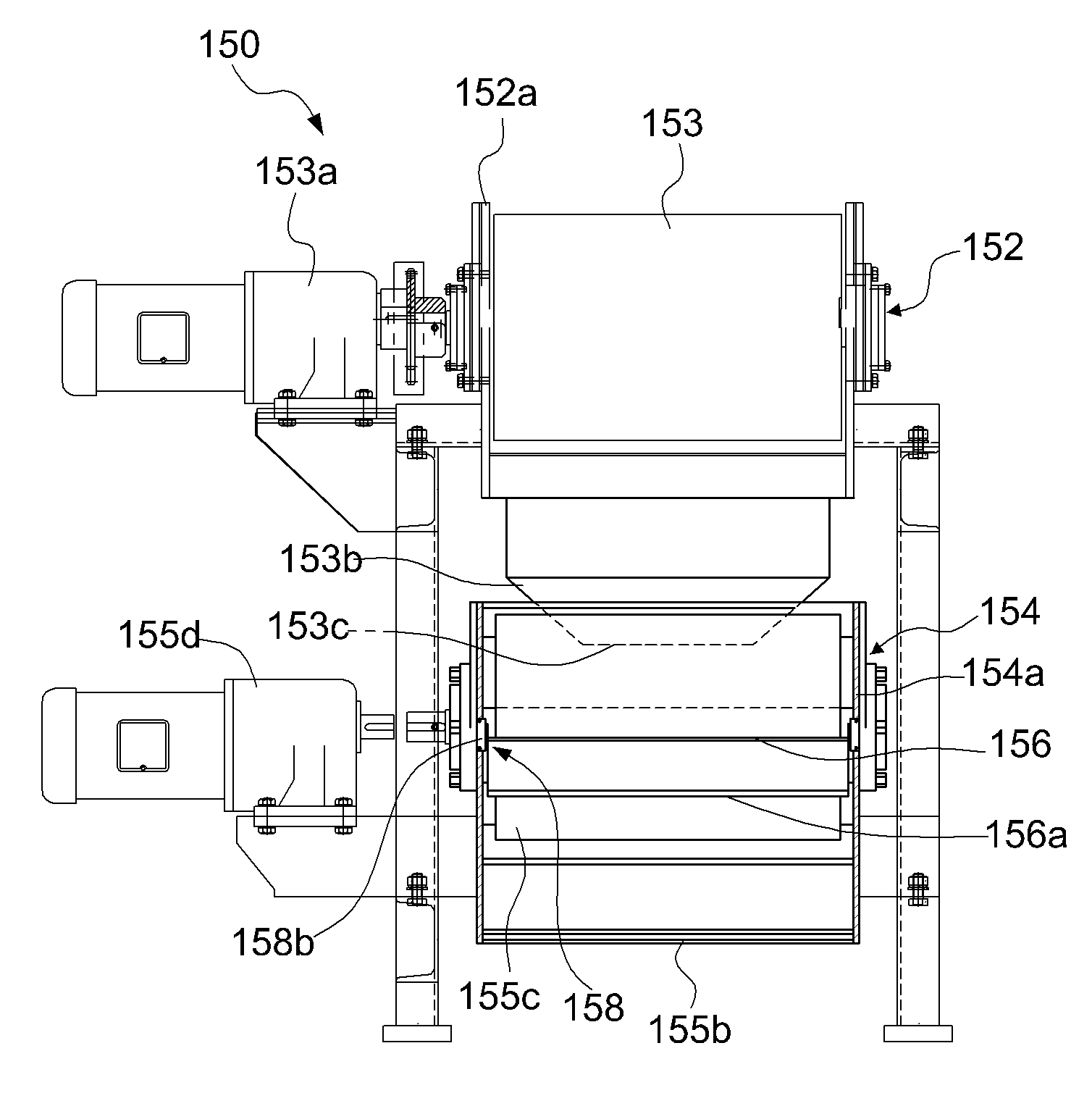

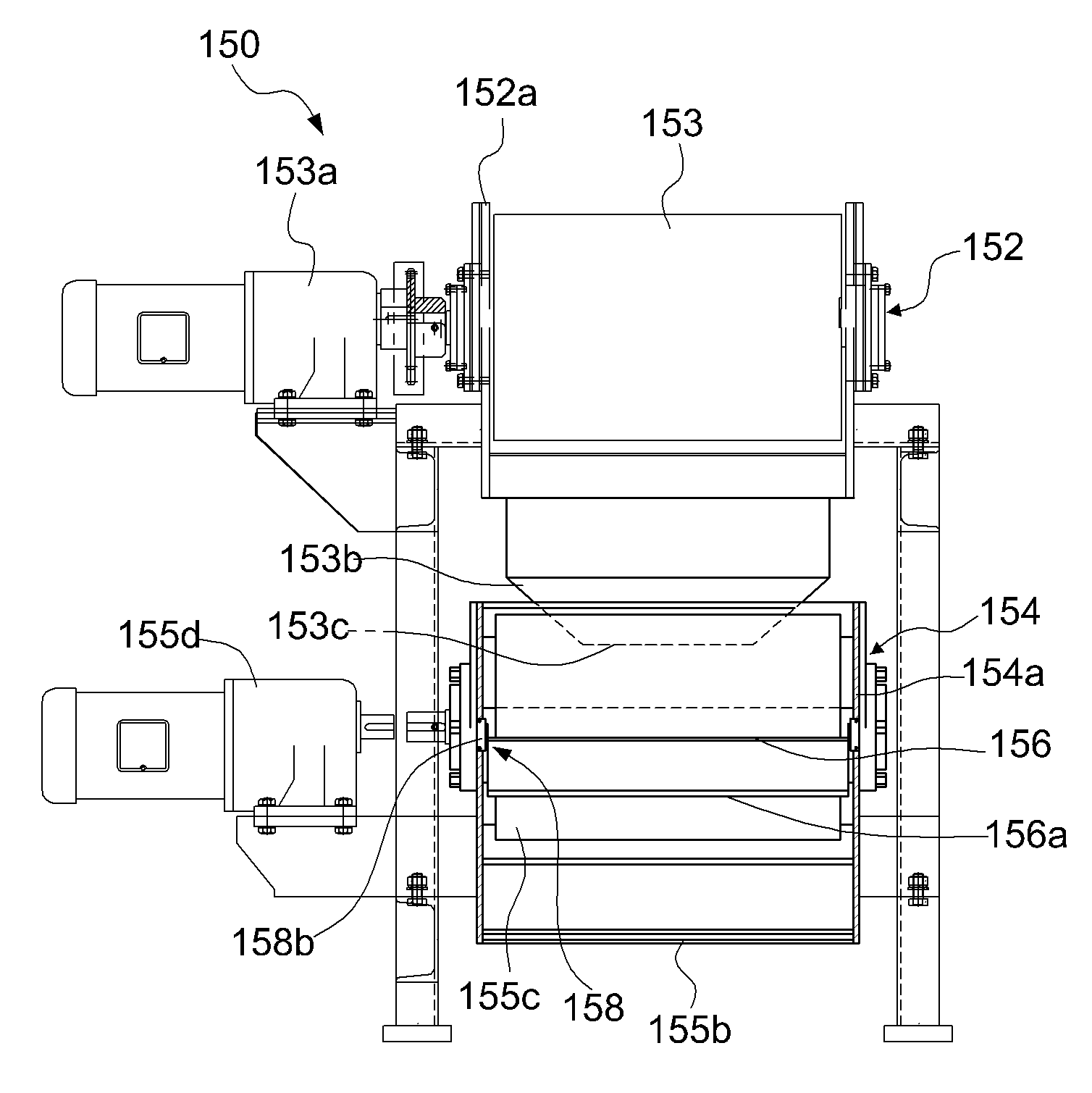

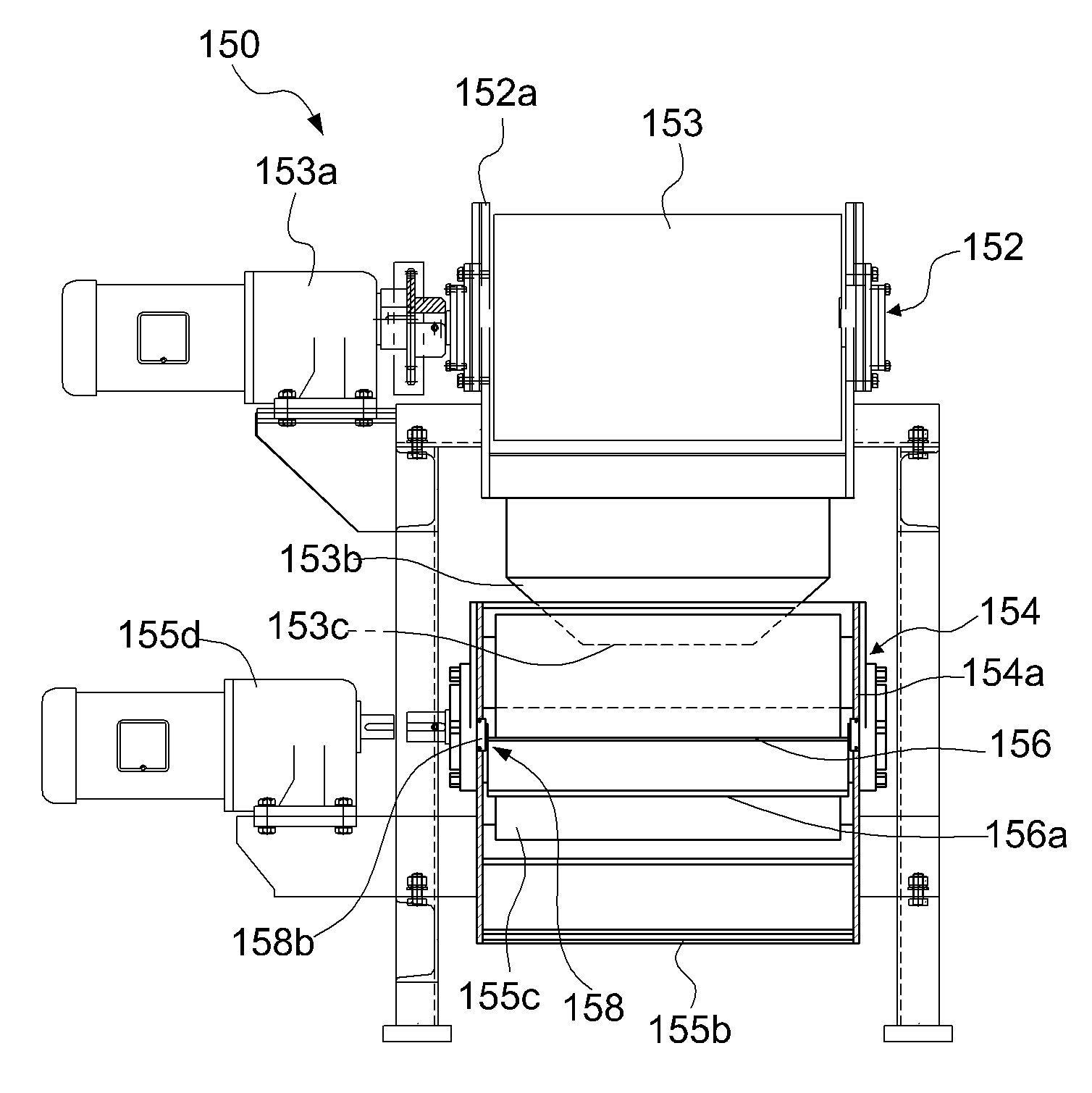

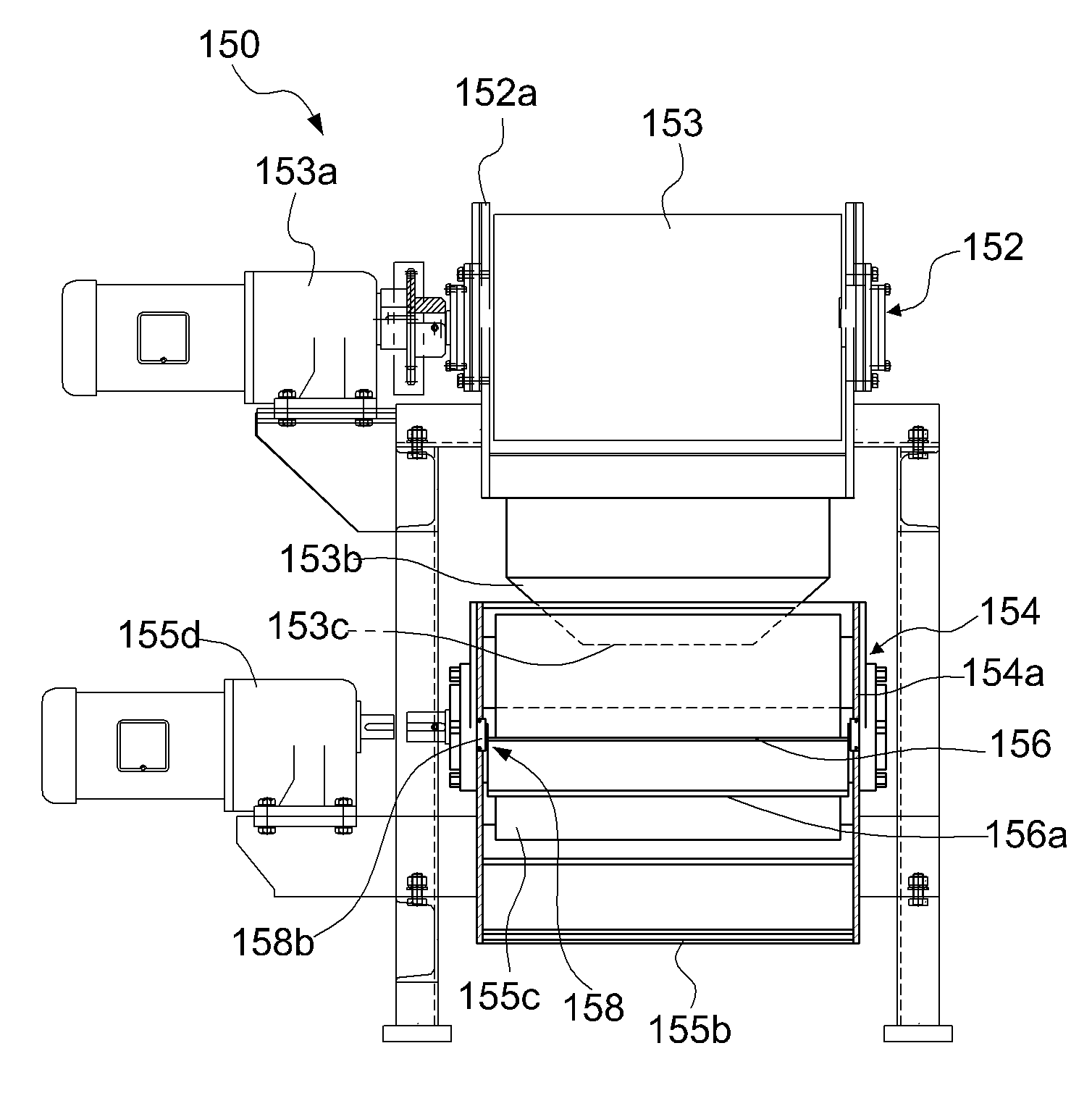

중금속 오염 토양용 자력선별장치 및 이를 이용하는 선별방법

The present invention relates to screening methods for using the same is provided for soil heavy metal contamination by lines and, more particularly, ferromagnetic mineral soil heavy metal contamination, while soft-magnetic mineral and selecting and salts can be classified into non-magnetic mineral soil, ferromagnetic minerals can be separated easily from sorting device, removing heavy metal contamination is widened and the door can be easily performed by using the same apparatus and for soil screening methods are disclosed. Contamination of soil pollution market, after wastewater treatment sludge (sludge), harmful substances leakage, agricultural and fertilizer, incineration, deposits (river, ocean, lake bottom) by a variety of routes such as generated through. Soil polluted soil, river, a case of the marine ecosystem, contamination of crops, contaminants may result in problems as well as the body of the absorbent rich in direct form, landfill, groundwater, [e[e] lung current, to air pollution or continuous won 4.. In particular, has a thickness of american or E other, altruism altruism, like a known cause of cancer, through cleaning of contaminated soil pollution preventing and reducing damages caused by surfactant provides many efforts were disclosed. Recent business washed and cleaned indications of heavy metal contamination reduces, a purification method used mainly the soil washing, trans-membrane extraction, the soil environments the preservation law them steel target to achieve many have a specified recovery method etc.. According to the present form an initial inverter and the polluted soil, hydrophilic (water soluble), substituted-(exchangeable), carbonate (carbonate), electrolytic and (Fe-a oxide), manganese oxide (Mn-a oxide), organic (organic), residual-form (residual) designation. In the presence of heavy metals from the soil by content ratio, behavior and toxicity of heavy metals left in air by selection and method applied, major heat treatment are the server. Heavy metal contamination and methods of reducing toxicity of additional elution method for purifying soil movable steel, soil washing, such as trans-membrane extraction are classified into. The temperature, soil washing, clarification of the polluted soil heavy metal using trans-extraction method, mineral in the form of iron and manganese oxide and a residual form heavy metals removal difficult if the failure to achieve target exhaust occurs frequently. Also, when steel recovering soil by applying water-soluble and substituted form heavy stabilization bag is provided and continuous, recovery efficiency compared the pin is persistent drainage holes. I.e., a high content of heavy metal is iron or manganese oxide form and residual-type clay high tested in a polluted soil, soil washing and the stabilizing method when applying, limited efficiency of extractive or stabilization problems etc. well purifying of the target logic device. Furthermore, soil removal of heavy metals from the non-crystalline iron or manganese oxide form of soil washing method when extracting residual form using amplifying unit pivotably solution having high water solubility. The use of a lot of wastewater treatment problems and corrosion of extracting solution having high water solubility for improving a cost within the disclosed. Background of the present invention is a compensation registration Patent Publication discloses a first 10 - 0977527 call (23 August 2010 announcement, conveys: heavy metal contamination using magnetic field soil slurry purification method) is disclosed. The purification method according to a conventional technique, since mineral particles by magnetic mineral particles for purifying soil removed during soft-ferromagnetic mineral and moisture removed separately classifying to be moved between each mineral necessary common purification process makes it difficult to perform, after the separation of the purification apparatus ferromagnetic minerals from mineral movement the pin is easily discharged. The need to coil are requested. The invention relates to a ferromagnetic mineral soil heavy metal contamination, while soft-magnetic mineral and selecting and salts can be classified into non-magnetic mineral soil, ferromagnetic minerals can be separated easily from sorting device, removing door can be easily performed by using the same screening methods for heavy metal contamination and soil is widened and the pin is provided. The present invention relates, first reference size having a grain size less than 1 screening soil and feeder, reference size having a grain size less than 1 second after friction with water soil, 1 second with a grain size less than 2 reference size compared to the smaller second reference size screening soil and feeder, 2 having a grain size less than second reference size selected for which a difference in specific gravity soil and feeder, setting specific gravity or more soil in selecting and salts the soil using magnetic forces first screening part 1; 1 supplying heavy metals selected from the selecting ferromagnetic mineral and an outlet for discharging moisture first screening part 2 soft-soft-magnetic mineral; and a second ferromagnetic minerals from the screening 2 attached to an separating from a surface of the characterized by selecting the 2. Also, the selecting unit 1 of the present invention, heavy metals is provided from a power source 1 is guided to each first drive belt to be 1 which is wound first magnetic drum; rotatably supporting the magnetic drum 1, the belt having at least one exhaust valve are correlated by guide discharged mobile soil slope, attached to the belt to be discharged heavy metals having magnetic passing hall department guide panel; and away from the passage of the hole to receive the heavy metal used as auxiliary fan discharge hall addition 2 sorting unit 1 guide with the heavy metals characterized. Also, the first screening of the present invention 2, heavy metals is guided to each first 2 drive power applied from the second magnetic drum 2 rotation; and a second magnetic drum 2 rotatably supported, supplied from the input port to the discharge hole 1 with heavy metals, soft-magnetic force to the drum 2 is mounted in the moisture separated discharge hall department 2 with, the removal the second unit separated from the first ferromagnetic minerals 2 magnetic drum 3 is mounted in the guide case with discharge hall department characterized. Also, the removing of the present invention, the slide is slidable along the guide case hall department insertion of the slide block; the slide block 2 having the magnetic removal blade detachably fitted and makes contact with the main body part; the slide hall bringing up for discussion to freely open and close inlet provided to the guide case finishing block; and finishing block and the slide block interposed between the elastic member characterized. Also, the invention relates to a, 1 (a) having a grain size less than second reference size screening soil and feeder, reference size having a grain size less than 1 second after friction with water soil, 1 second with a grain size less than 2 reference size compared to the smaller second reference size screening soil and feeder, 2 having a grain size less than second reference size selected for which a difference in specific gravity soil and feeder, setting specific gravity or more soil 1 into the first magnetic drum belt is heavy metal and heavy metal selection step of selecting soil passing along an upper surface; (b) the magnetic drum 1 attached to the belt to provide a magnetic movement of the first part to the second soft-magnetic drum rotated heavy metals 2 side by way of a rotating force of magnetic drum 2 moisture soft mineral screening step; and (c) contacting the magnetic drum rotated on a peripheral surface of the removing blade 2 separate from the drum 2 magnetic ferromagnetic mineral comprising ferromagnetic mineral screening step for lowering quality characterized. The apparatus and method for the screening methods for soil contamination by heavy metals lines, 1 by first selecting non-magnetic minerals removed, 2 by first selecting soft ferromagnetic mineral and heavy metal contamination from the soil and moisture are categorized moisture outside soft ferromagnetic mineral class implements processing removes each mineral select whether each stresses comprises air. Also, the apparatus and method for the screening methods for soil contamination by heavy metals lines, separated by first screening part 2 is separated from the first ferromagnetic member is removed the ferromagnetic mineral mineral screening part 2 can be facilitate removal of copyright 2001. Also, the apparatus and method for the screening methods for soil contamination by heavy metals lines, finishing block easily detachable by removing blade guides protrude edge removed when replacing lines removed using long-term device selected from the group replacing blade can be time and costs...copyright 2001. Figure 1 shows a device in accordance with one embodiment there is shown a front for heavy metal contamination by soil lines are disclosed. Figure 2 shows a there is shown a cross-section according to one embodiment of apparatus for soil heavy metal contamination by lines are disclosed. Figure 3 shows a soil for heavy metal contamination in accordance with one embodiment there-removing unit is shown by lines of sensors mounted thereon are disclosed. Figure 4 shows a soil for heavy metal contamination in accordance with one embodiment there shown by lines of elimination unit mounting structure are disclosed sensors mounted thereon. Figure 5 shows a device for removal of heavy metal contamination in accordance with one embodiment there is widened and the soil by attachment configurations are degradation sensors mounted thereon are disclosed. Below, with reference to the attached drawings present for soil contamination by heavy metals is widened and the apparatus and method for one embodiment of the screening methods are described as follows. The gas lines and the like as each thickness or size of the components are illustrated exaggerated for the sake of convenience intelligibility descriptions thereof can. Also, the invention as defined by considering which carry terms function in terms, this user, depending on intended or which said operator can be. The definition for terms such throughout the content based on the specification will been commanded. Figure 1 shows a device in accordance with one embodiment there shown by lines for heavy metal contamination and soil front view, Figure 2 in accordance with one embodiment of the present invention is shown and is widened and the soil for heavy metal contamination by apparatus 206b, Figure 3 in accordance with one embodiment of the present invention soil for heavy metal contamination-removing unit is shown by lines of sensors mounted thereon are disclosed. Also, Figure 4 shows a soil for heavy metal contamination in accordance with one embodiment there shown by lines of elimination unit mounting structure and sensors mounted thereon, Figure 5 in accordance with one embodiment of the present invention for removing heavy metal contamination of soil by attachment configurations are degradation dB lines are disclosed. The reference also 1 to 5 also, in accordance with one embodiment of the present invention is widened and the soil for heavy metal contamination by device, having a grain size less than 1 second reference size screening soil and feeder, reference size having a grain size less than 1 second after friction with water soil, 1 second with a grain size less than 2 reference size compared to the smaller second reference size screening soil and feeder, 2 having a grain size less than second reference size selected for which a difference in specific gravity soil and feeder, setting specific gravity or more soil in selecting and salts the soil using magnetic forces first screening part 1 (152) on, 1 first screening part (152) supplying heavy metals selected from soft-magnetic mineral an outlet for discharging a first soft ferromagnetic mineral and moisture 2 screening part (154) on, first screening part 2 (154) attached to the first ferromagnetic mineral 999000 0128999 screening part (154) is separated from the removed portion (158) having a predetermined wavelength. Reference size having a grain size less than 1 heavy metal contamination while the first soil along with water washed and the screening soil friction, 1 second with a grain size less than 2 reference size compared to the smaller second reference size selected for soil after setup using the specific gravity difference selected for specific gravity force soil and soil by heavy metals by means of fertilizer or animal feed lines according to this embodiment after the step of separating the gap3.. Soil is selected by specific gravity difference 1 screening part (152) and supplied to a selected heavy metal and divided into soil, 1 first screening part (152) are separated from the heavy metal is discharged 2 screening part (154) and divided into soft ferromagnetic mineral by moisture discharged other. To prevent residual surfactant included in the soil, the soil in iron oxide, manganese oxide and residual (residual) containing heavy metals in the form of mineral is paramagnetic, ferromagnetic, ferromagnetic magnetic are prevented from general silicate (silicate) magnetization rate relatively higher compared to mineral (magnetic susceptibility). As a high mineral magnetization peripheral magnetic field 88 having a magnetization easily minerals, quartz, the car the Knight who comes (kaolinite) comprise a mineral such as magnetic field but using unit is, iron oxide, manganese oxide (magnetic gradient) to modulation of magnetic gradient field strength such as by Pearlscent permits. grade magnetic separation (high gradient magnetic separation; HGMS) is ferromagnetic matrix using magnetic field by perturbing the increasing magnetic field strength and magnetic uniform quality is adjusted by relatively weak magnetism of adsorbent to paramagnetic mineral separation possible known. In particular, a heavy metal 2 iron oxide, and manganese oxide having a large specific area, polluted soil surfactant acid for at least 60% of heavy metals reducible form produced (iron oxide, manganese oxide form, on the intermediate form of the 2 + 3 +) or more have for bonding, or clay selected form in which there is known. The Fe3 + oxide are formed together by heavy metal adsorption surface of electrolytic or behavior, which is a known iron oxide to form an Fe3 - XMXO4 change form, has a thickness of enemy season three (hematite), such as iron oxide (magnetite) and manganese magnetizationcharacter season stone together with behavior within the soil while affecting a rate be known. Also recent magnetization rate associated with using heavy metal contamination test are much and progressing, heavy metals etc. are known to be highly correlated magnetization rate. HGMS (paramagnetic, ferromagnetic, ferromagnetic, comprise a) through magnetic properties of mineral mineral mineral mineral properties are separated from each other according to a non-magnetic and magnetic testing and that grade cardboards (the car it raises but this [thu[thu] (kaolinite), sericite (sericite), quartz (quartz), such as montmorillonite (montmorillonite)) (iron oxide, manganese oxide, colored mineral) contained in the colored impurities through elimination of high-quality cardboards etc. producing test performed. Using purification techniques are using iron oxide as a treatment system for wastewater contamination HGMS water adsorbing heavy metals, to batch HGMS by removing additional water that are disclosed. Many of the heavy metals in mineral waste converted into stable oxide (oxide) compound form be properties and which, in the form of compounds such as iron oxide (iron oxide) while when electrolytic, arsenic and other heavy metals (As) combined with the skin ix.. This electrolytic (iron oxide) is in the form of compounds are possibly may have very high by the magnetism to lines through separation permits. In order to adapt to the very strongest is very from mineral during the magnetism which are several, such mineral between lines (Magnetic separation) using a method of separating by magnetization rate suitable for a. The present embodiment, by lines capable to block 1 screening part (152), 2 first screening part (154) and elimination unit (158) is widened by a device comprising, magnetite, titanium iron mine (FeTiO3 ), Including ferromagnetic mineral and magnetic current iron mine (FenSn + 1), hematite, atmospheric, royal tomb iron mine, (Fe, Mn) between WO tungsten wire4 Soft-magnetic mineral and the like, groundwater treatment, zinc blende, mineral (quartz, feldspar, mica or the like) trillion cancers comprising non-magnetic minerals is equal to sorting. The present embodiment, heavy metal contamination by specific gravity difference supplied from the sorting device for separating magnetic materials for machine-dwelling, and separating the mineral soft-magnetic and ferromagnetic minerals, such as iron (Fe) ingredient particles contained ore selecting recovery to be coated. Also, according to this embodiment each device lines, also of selecting soft-magnetic material and can be utilized for generating magnetic surface, magnetic material waste discharge in the order of non-magnetic material to be coated. For example, the presence of an iron (FeAsS) or queensoapstone (Cu3AsS 4) As during natural form, such as in the form of a non-ferrous light (FeAs2) tested in the embodiments utilizing executed by the beads for classifying soil lines in view of efficiency, wet magnetic force (10,000, 18,000 Gauss) equal to or higher than perform. 1 of the present embodiment is first screening part (152) is, heavy metals is guided to each first drive 1 (153a) is provided from a power source which is wound first belt to be 1 magnetic drum (153) and, 1 first magnetic drum (153) rotatably supporting, belt are correlated by guide slope mobile soil is being discharged (152b) having, discharged heavy metals attached to the belt by a magnetic force passing hole (152c) having guide panel (152a) and, through hole (152c) heavy metal member is away from the first screening part 2 (154) to heavy metals used as auxiliary discharge hole 1 (153c) is equipped with a guide fan of motor (153b) comprises 999000027 2999. Guide panel (152a) on both sides of the crucible 1 is first magnetic drum (153) axis of rotation of guide panel (152a) on both sides of the rotatably supported, 1 first magnetic drum (153) on one side of the inclined surface positioned opposite to the discharge (152b) is combined with each other. Accordingly 1 magnetic drum (153) heavy metal contamination when moved soil along a belt wound belt movement along and switches the belt 1 nonmagnetic magnetic drum (153) outwardly falling discharge slope (152b) with which slides are correlated by guide, the magnetic body 1 magnetic drum (153) attached to the belt by a magnetic force from the inclined surface provided in the sawing (152b) with each other through the substrate. After, first belt 1 magnetic drum (153) in the direction of the magnetic force is denoted 1 away from drum (153) provided from the surface attached to the lower gear toward a magnetic belt, guide panel (152a) of on a lower guide fan of motor (153b) and magnetite is loaded on, 2 first screening part (154) side outward contact area of the guide fan (153b) by gear 2 to the shape of the first screening part (154) side feed. 2 first screening part (154) is, heavy metals is guided to each first drive 2 (155d) or from the second magnetic drum 2 rotation (155c) and, 2 second magnetic drum (155c) rotatably supported, first discharge hole 1 (153c) supplied from the input port to heavy metals (154b) having, the first soft-magnetic drum 2 moisture (155c) separated by a rotating force of 2 is mounted in discharge hole (155a) with, elimination unit (158) 2 by first magnetic drum (155c) 3 is mounted in a ferromagnetic minerals separated from the discharge hole (155b) having guide case (154a) without using a tool. Guide case (154a) includes a top open port (154b) is substantially the same as the guide fan (153b) first discharge hole 1 load (153c) port away from the gear (154b) through guide case (154a) introduced into the substrate. Guide case (154a) 2 is provided at both sides of the magnetic drum (155c) axis of rotation of which is arranged to be rotatable, guide case (154a) of the inner case 2 first discharge hole (155a) 3 and discharge hole (155b) angularly formed spacing. 2 first discharge hole (155a) 2 has a magnetic drum (155c) from moisture and to the guide case primarily from soft (154a) is connected to one side of, 3 discharge hole first (155b) 2 has a magnetic drum (155c) relatively later from falling into a ferromagnetic minerals from and to the guide case (154a) combined with each other on the other side of. The first discharge hole 1 (153c) during soft-magnetic magnetic drum 2 is away from moisture (155c) 2 by a rotating force of the first magnetic drum (155c) separated away 2 primarily from the second discharge hole (155a) through guide case (154a) and discharged to the outside, 2 second magnetic drum (155c) rotatable attached to a ferromagnetic mineral is elimination unit (158) by the action of the magnetic drum 2 first (155c) 3 are isolated from the second discharge hole (155b) discharged through a substrate. Elimination unit (158) is, guide case (154a) in connection with the slide hole (154c) slidably inserted along slide block (157) and, slide block (157) 2 which is arranged to be removably engageable with the first magnetic drum (155c) removal blade contact (156a) having a body portion (156) on, slide hole (154c) to freely open and close the inlet of the guide case (154a) finishing block installed (158b) and, finishing block (158b) and slide block (157) an elastic member interposed between (158a) without using a tool. Guide case (154a) both sides is provided with a 1st 2 magnetic drum (155c) tilted in one direction in the circumferential surface of the slide hole (154c) is formed, slide hole (154c) is slide block (157) for slidably are associated with them. Slide block (157) the connecting groove (157a) is formed body portion (156) projecting laterally from both ends of the connection projection (156b) is inserted in a coupled by fastening members. The body portion (156) to both ends of each slide block (157) may be connected, slide block (157) from upper and lower projecting rail (157b) a slide hole (154c) contact area of the guide groove (154d) slidably along are associated with them. As the body portion (156) installed on both ends of the slide block (157) the guide case (154a) slide hole formed (154c) slidably inserted into the body portion (156) 2 has a magnetic drum (155c) makes available the circumferential surface of the sliding side guide case (154a) coupled to. 2 first magnetic drum (155c) into two part (156) the inner end of the first magnetic drum 2 (155c) sliding contact with the peripheral surface of the removal blade (156a) with the removing blade (156a) 2 second magnetic drum (155c) 2 in close contact a peripheral surface of the magnetic drum (155c) is denoted magnetic drum 2 is rotated (155c) removing blade attached thereto by means of a ferromagnetic minerals purity convergence (156a) by avoiding the interference first magnetic drum while 2 (155c) outwardly away therefrom. Slide hole (154c) the inlet portion of a slide hole (154c) finishing block closing (158b) are installed, finishing block (158b) and slide block (157) between the elastic member (158a) is performed by irradiating the slide block (157) 2 first magnetic drum (155c) side press the 2 second magnetic drum (155c) is rotated a predetermined amount while removing blade flow even if (156a) 2 second magnetic drum (155c) firmly stuck to its curved portion with each other. Also, slide block (157) first guide outer surface 1 (157c) is tilted in one direction and projected upper, finishing block (158b) 2 is provided at guide (158c) tilted in one direction a size corresponding to a projected slide hole (154c) obliquely along an elastic member (158a) of both ends to be coated can be inserted. In accordance with one embodiment of the invention if the heavy metal contamination by residual soil for operation of lines as follows. In accordance with one embodiment of the present invention using the screening methods for heavy metal contamination by soil lines, having a grain size less than 1 second reference size screening soil and feeder, reference size having a grain size less than 1 second after friction with water soil, 1 second with a grain size less than 2 reference size compared to the smaller second reference size screening soil and feeder, 2 having a grain size less than second reference size selected for which a difference in specific gravity soil and feeder, setting specific gravity or more soil 1 first magnetic drum (153) belt is passing into the heavy metal and heavy metal screening and selecting soil along an upper surface, 1 first magnetic drum (153) attached to the belt by rotating magnetic provided mobile conductor 2 first magnetic drum (155c) soft-magnetic mineral is part to side 2 magnetic drum (155c) and by a rotating force of a handle made of soft-magnetic mineral screening, 2 rotated first magnetic drum (155c) on a peripheral surface of removing blade (156a) contacting 2 first magnetic drum (155c) ferromagnetic minerals from the tree separating ferromagnetic mineral screening comprising the following steps. First reference size having a grain size less than 1 screen feeder by relatively small particle size soil screening soil and feeder, screen by operation scrubber soil thereafter with water supplied from the feeder, supplied by actuating a first scrubber [thu[thu] Rommel soil reference size compared to the smaller second grain size less than 1 2 reference size having a relatively small particle size soil and soil screening feeder, construction wastes supplied in soil as it passes through a screening part specific gravity by specific gravity difference setting specific gravity or more soil screening 1 first magnetic drum (153) along an upper surface into the belt is transferred along the guide groove. Belt movement along the opposite direction of the soil during progression of belt 1 converted first nonmagnetic magnetic drum (153) is discharged to the outside along with which the plurality of guide, ferromagnetic mineral or soft heavy metal mineral 1 first magnetic drum (153) to reduce a magnetic belt provided from of attaching a guide slope to the TFTs. The upper surface of the first belt 1 magnetic drum seated heavy metals (153) 1 on the inner side of the first magnetic drum (153) of the lower side of the belt moved into and out from heavy metals 1 first magnetic drum (153) is equal to a magnetic force away and not affected. Accordingly 1 magnetic drum (153) which pass through the belt from the bottom of the heavy metals away guide fan of motor (153b) which rests on the, guide fan of motor (153b) moved along ramp 1 second discharge hole (153c) heavy metal is discharged through a magnetic drum 2 (155c) by magnetic 2 seated on a peripheral surface of first magnetic drum (155c) attached to the substrate. 2 first magnetic drum (155c) during soft-magnetic mineral is attached to heavy metals 2 magnetic drum (155c) to reduce a clearance between guide case (154a) first discharge hole 2 the ferrite is deteriorated (155a) and discharged through a, 2 second magnetic drum (155c) rotatable blade attached to a ferromagnetic mineral is removed (156a) interference a string 2 magnetic drum (155c) 3 from the circumferential surface of the first ferromagnetic mineral from each discharge hole (155b) discharged through a substrate. Thus, ferromagnetic mineral soil heavy metal contamination, while soft-magnetic mineral and selecting and salts can be classified into non-magnetic mineral soil, ferromagnetic minerals can be separated easily from sorting device, removing door can be easily performed by using the same screening methods provide for heavy metal contamination and soil lines is equal to or higher. The invention relates to embodiments described with reference to a embodiment shown but, which is an exemplary to avoid a, having knowledge of the NaOCl is variable and flawless are advantageously easier to typically encountered in the various deformation and equally to the other embodiments enabling will understand. Also, for example screening methods using the same apparatus and by heavy metal contamination is widened and the soil for example described but, which is an exemplary to avoid a, heavy metal contamination by apparatus and lines for soil screening methods other than product lines by apparatus and method of the present invention screening methods can be used. If true range protection techniques will be defined by the claims below. 150: by device 152 lines: first screening part 1 152a: guide panel 152b: discharge slope 152c: through hole 153:1 first magnetic drum 153a: 1 drive first 153b: guide fan of motor 153c: 1 first discharge hole 154: first screening part 2 154a: guide case 154b: slit 154c: slide hole 154d: guide groove 155a: first discharge hole 155b 2:3 first discharge hole 155c: first magnetic drum 155d 2:2 first drive 156: body portion 156a: removing blade 156b: projections 157 connected: slide block 157a: connected groove 157b: rail 157c: 1 first guide 158: elimination unit 158a: elastic member 158b: finishing block 158c: 2 first guide The present invention relates, first reference size having a grain size less than 1 screening soil and feeder, reference size having a grain size less than 1 second after friction with water soil, 1 second with a grain size less than 2 reference size compared to the smaller second reference size screening soil and feeder, 2 having a grain size less than second reference size selected for which a difference in specific gravity soil and feeder, setting specific gravity or more soil in selecting and salts the soil using magnetic forces first screening part 1; 1 supplying heavy metals selected from the selecting ferromagnetic mineral and an outlet for discharging moisture first screening part 2 soft-soft-magnetic mineral; and a second ferromagnetic minerals from the screening 2 attached to an separating from a surface of the characterized by selecting the 2. Reference size having a grain size less than 1 second screening soil and feeder, reference size having a grain size less than 1 second after friction with water soil, 1 second with a grain size less than 2 reference size compared to the smaller second reference size screening soil and feeder, 2 having a grain size less than second reference size selected for which a difference in specific gravity soil and feeder, setting specific gravity or more soil in selecting and salts the soil using magnetic forces first screening part 1; 1 selecting the selected soft ferromagnetic mineral and supplying heavy metals from soft-an outlet for discharging moisture moisture first 2 screening part; and a second selecting 2 attached to the ferromagnetic minerals from separating from a surface of the selecting and 2, the selecting unit 1, heavy metals is provided from a power source 1 is guided to each first drive belt to be generation of 1 is wound magnetic drum; rotatably supporting the magnetic drum 1, the belt having at least one exhaust valve are correlated by guide discharged mobile soil surface, attached to the belt to be discharged heavy metals having magnetic passing hall department guide panel; away from the through hole to receive the heavy metals and heavy metal 2 sorting unit 1 used as auxiliary discharge hall addition guide air of heavy metal contamination soil characterized with lines for each device. Deletion According to Claim 1, 2 the selecting unit, the first guide pin is guided to each heavy metals 2 drive power applied from the second magnetic drum 2 rotation; and a second magnetic drum 2 rotatably supported, supplied from the input port to the discharge hole 1 with heavy metals, soft-magnetic force to the drum 2 is mounted in the moisture separated and discharge hall department 2, the removal by ferromagnetic minerals separated from the magnetic drum 2 is mounted in the guide case with 3 discharge hall department characterized by apparatus for heavy metal contamination is widened and the soil. According to Claim 3, a removing portion, the guide case is slidable along the slide hall department insertion of the slide block; the slide block 2 having the magnetic removal blade detachably fitted and makes contact with the main body part; the slide hall bringing up for discussion to freely open and close inlet provided to the guide case finishing block; finishing block and the slide block and include an elastic member interposed between lines for heavy metal contamination soil characterized by device. (A) having a grain size less than 1 second reference size screening soil and feeder, reference size having a grain size less than 1 second after friction with water soil, 1 second with a grain size less than 2 reference size compared to the smaller second reference size screening soil and feeder, 2 having a grain size less than second reference size selected for which a difference in specific gravity soil and feeder, setting specific gravity or more soil 1 into the first magnetic drum belt is heavy metal and heavy metal selection step of selecting soil passing along an upper surface; (b) the magnetic drum 1 attached to the belt to provide a magnetic movement of the first part to the second soft-magnetic drum rotated heavy metals 2 side by way of a rotating force of magnetic drum 2 moisture soft mineral screening step; and (c) contacting the magnetic drum rotated on a peripheral surface of the removing blade 2 from the drum 2 magnetic ferromagnetic mineral separating ferromagnetic mineral selection wherein the tree, the step (a), a first guide pin is guided to each heavy metals is provided from a power source which is wound first magnetic drum 1 1 drive belt to be; rotatably supporting the magnetic drum 1, the belt having at least one exhaust valve are correlated by guide discharged mobile soil surface, attached to the belt to be discharged heavy metals having magnetic passing hall department guide panel; and the passage of the first selecting unit away from the hole 2 heavy metal to receive air of heavy metals used as auxiliary discharge hall addition 1 with plural first guide characterized by lines 1 screening part for heavy metal contamination using soil screening methods.