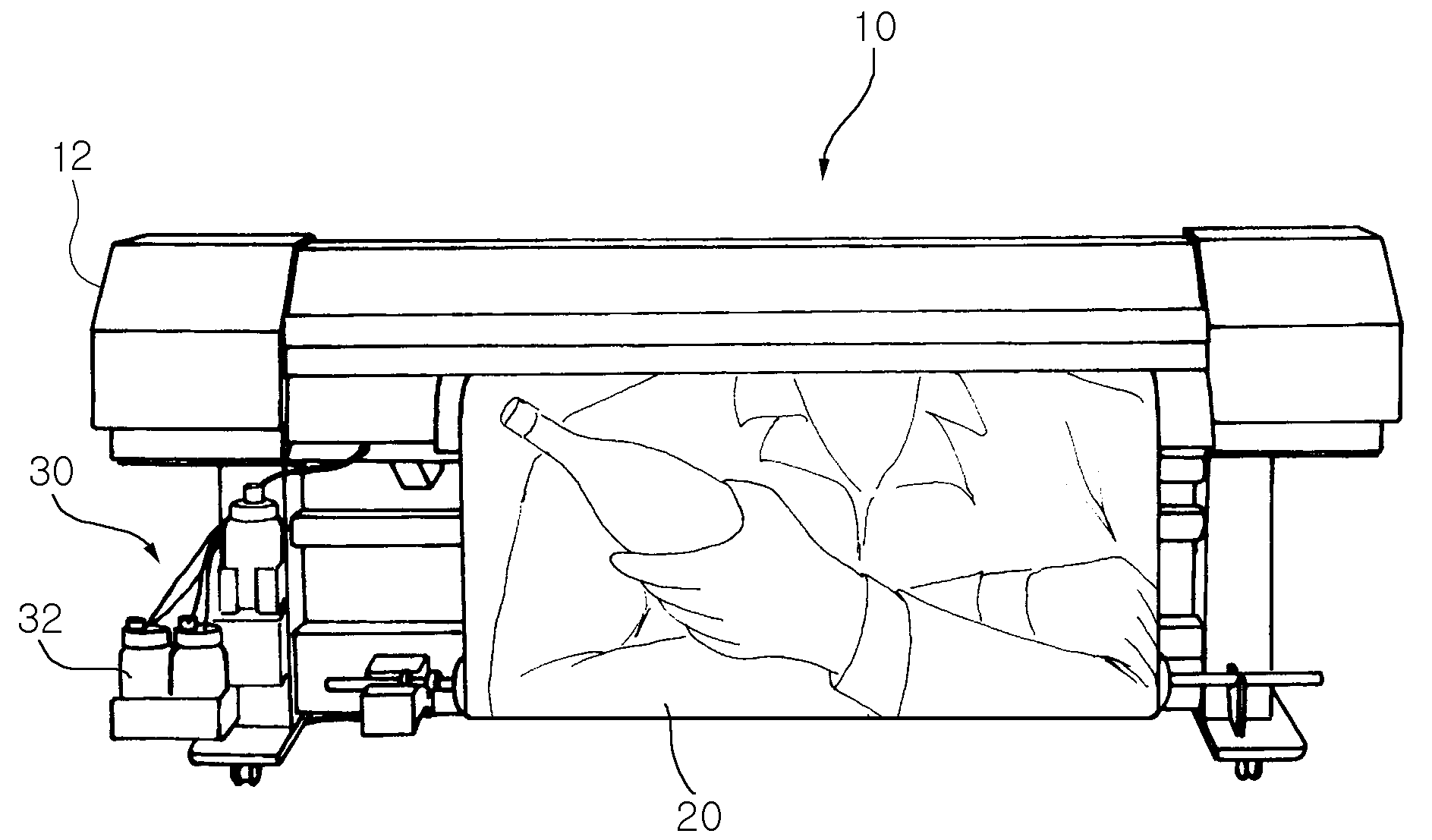

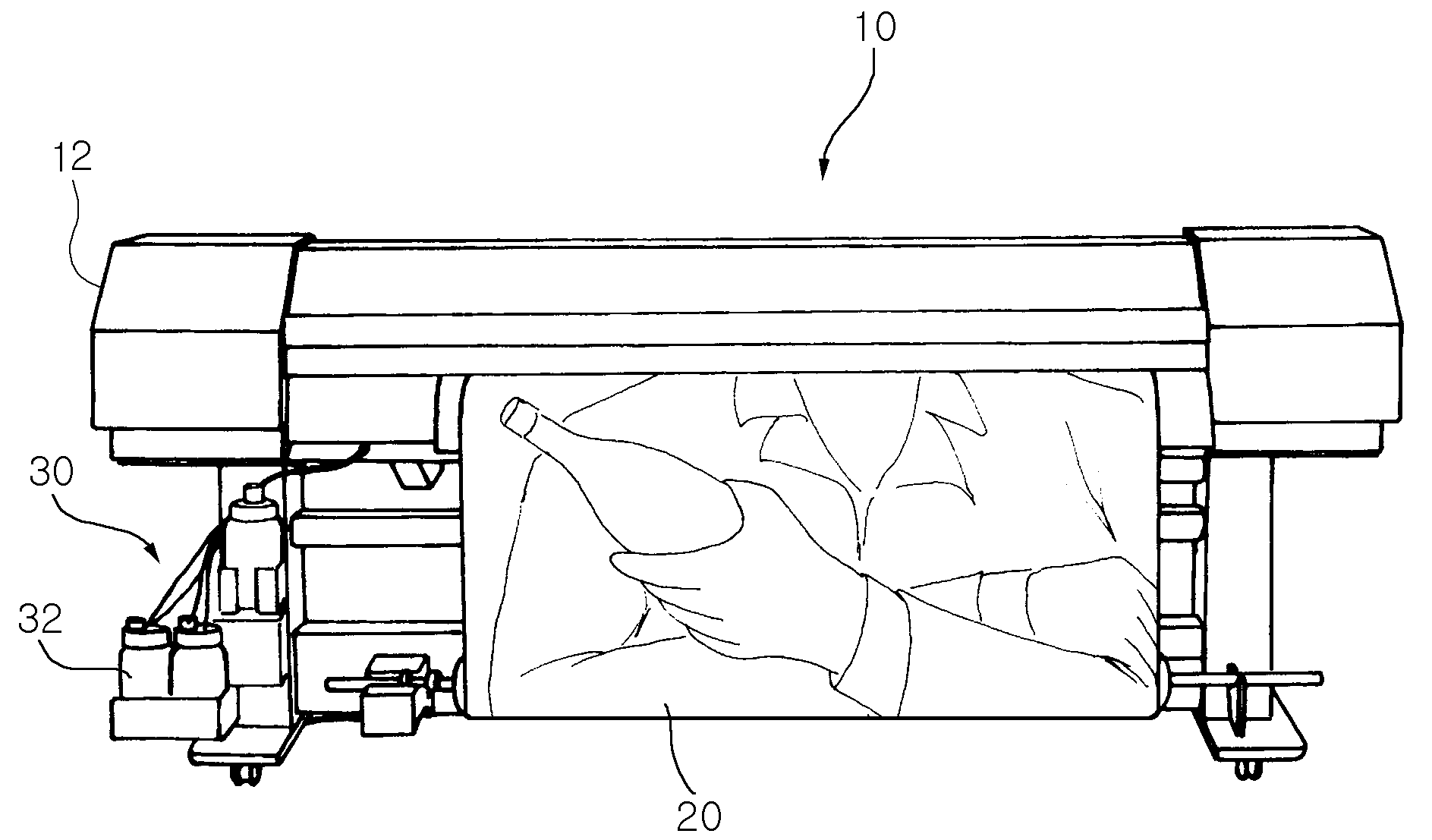

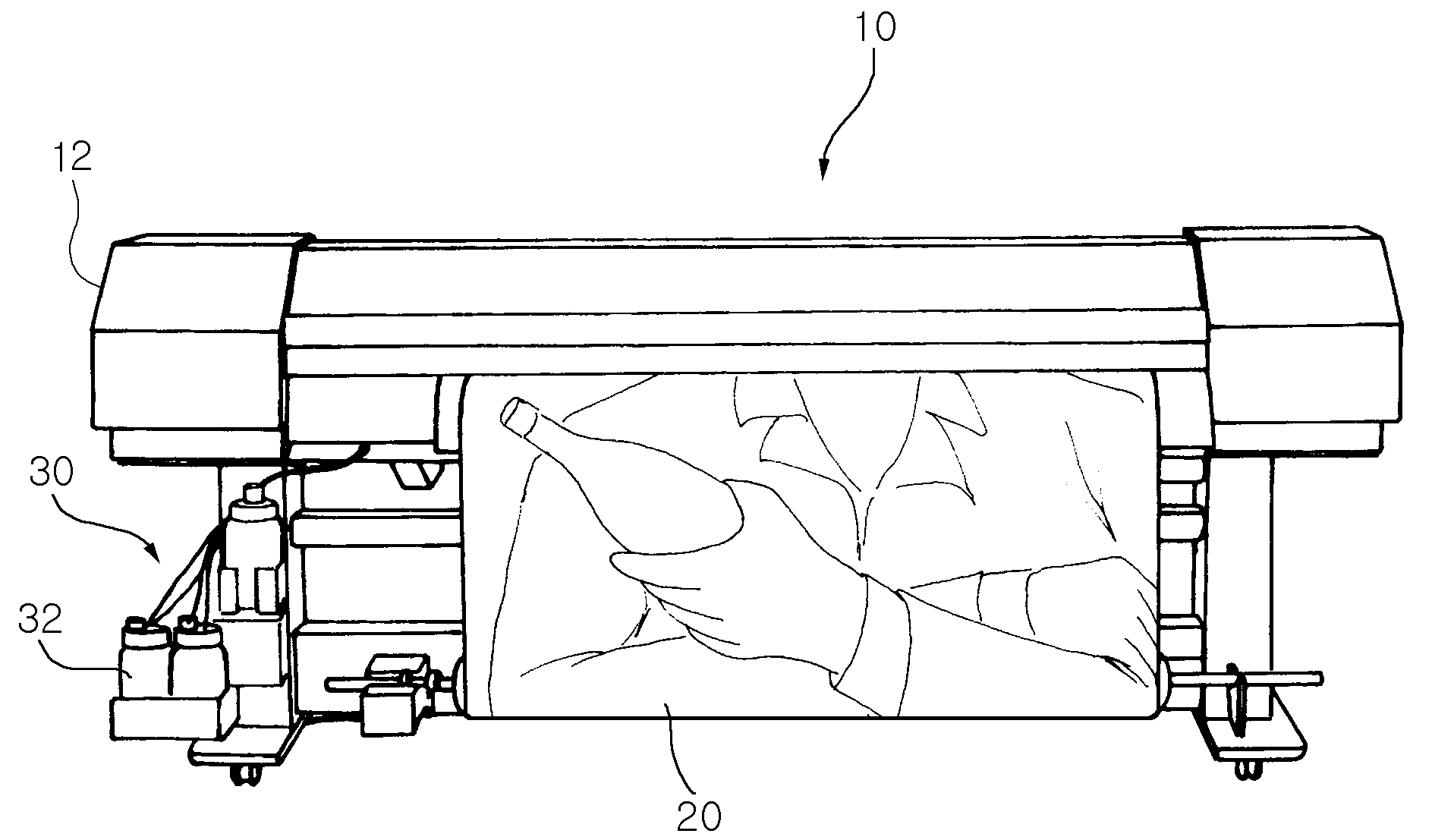

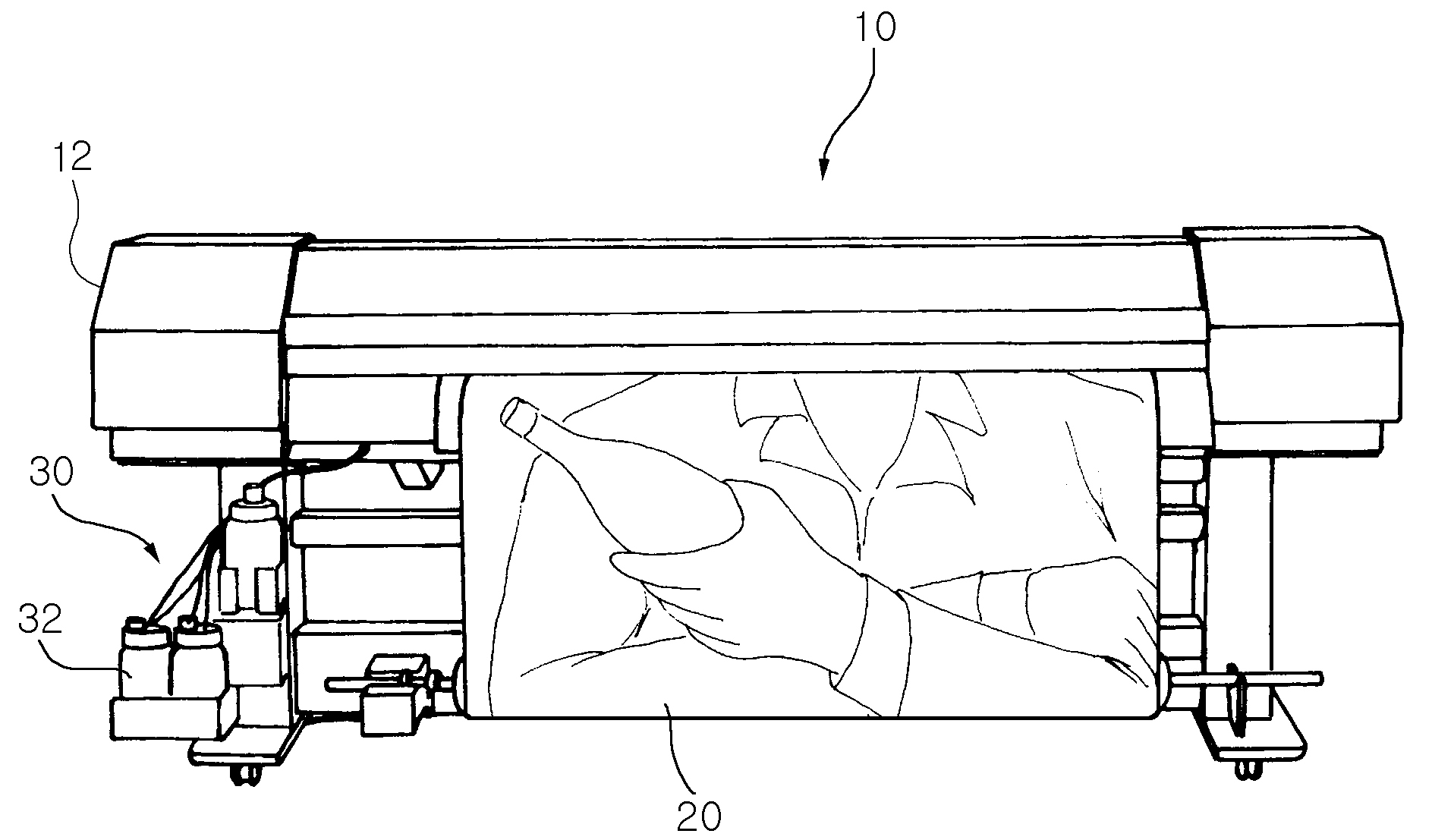

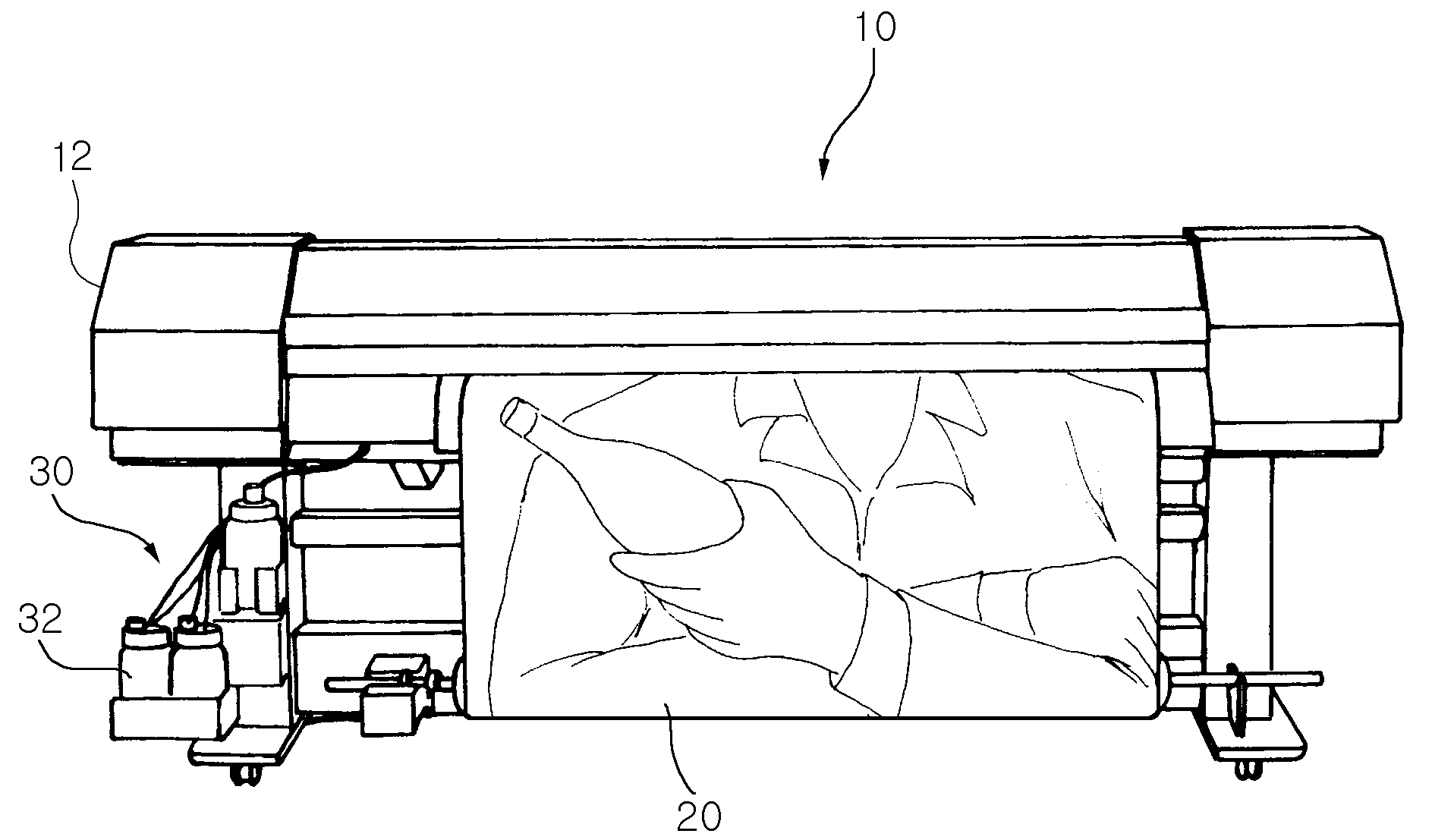

TEXTILE PRINTER

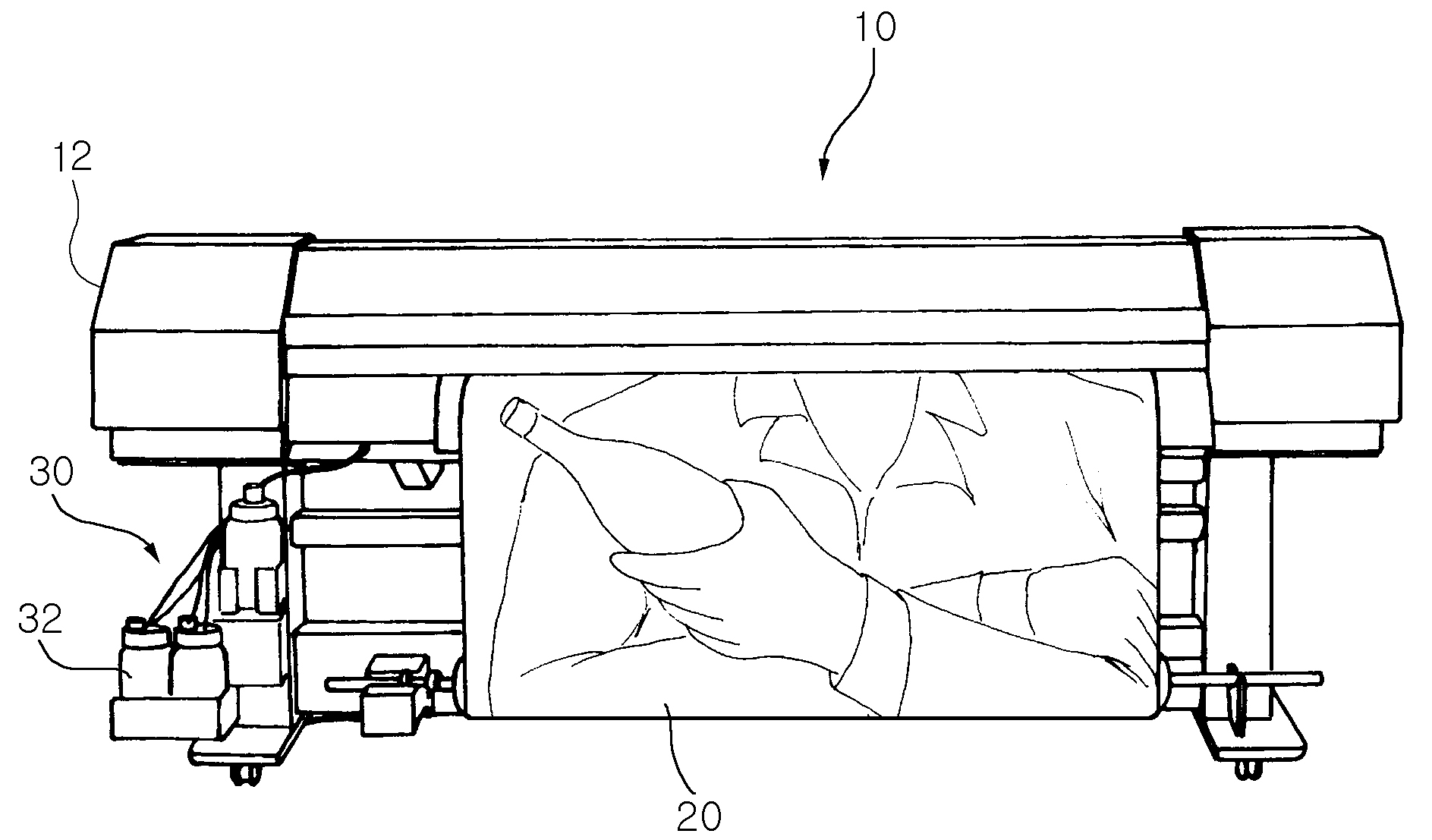

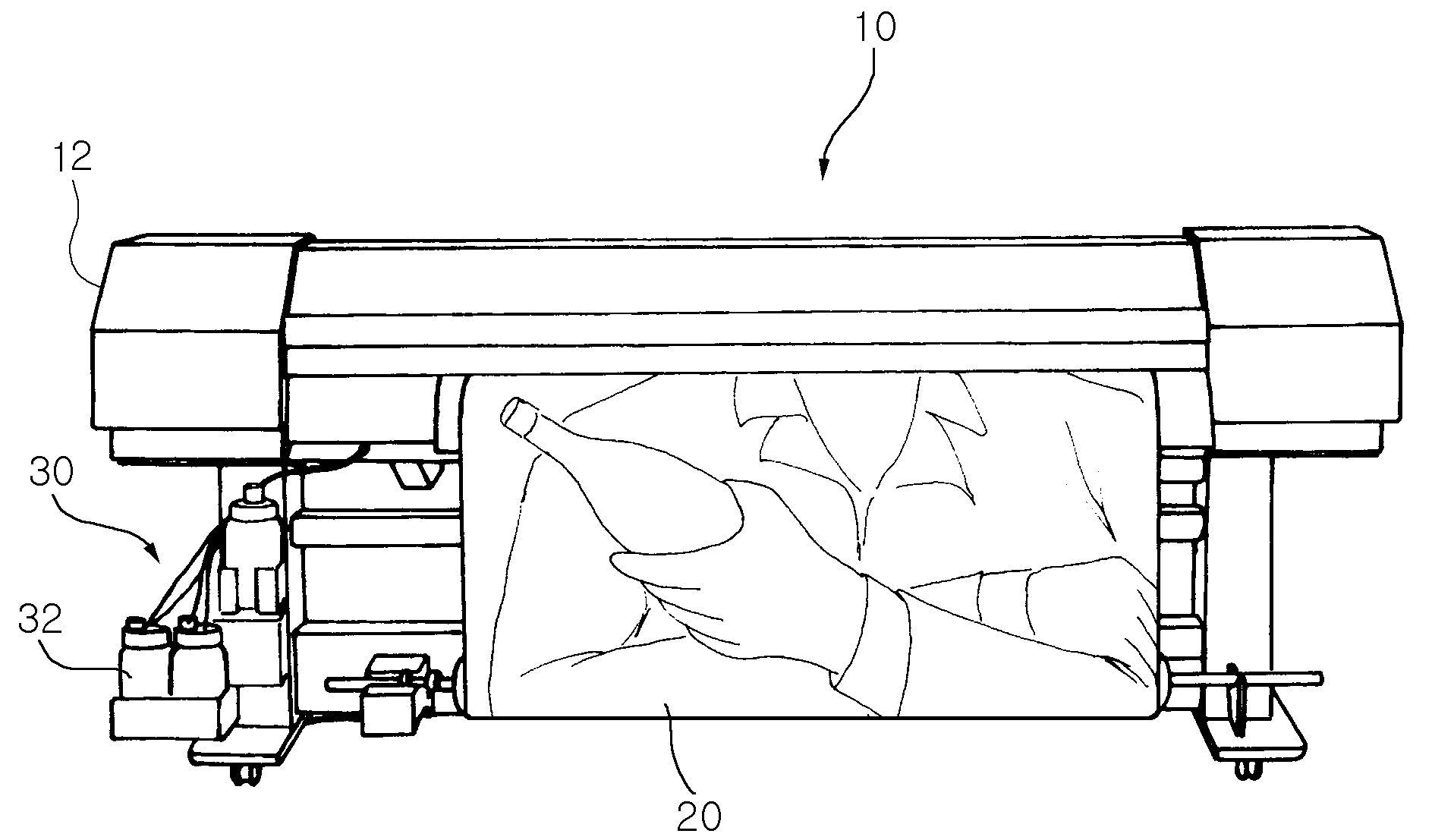

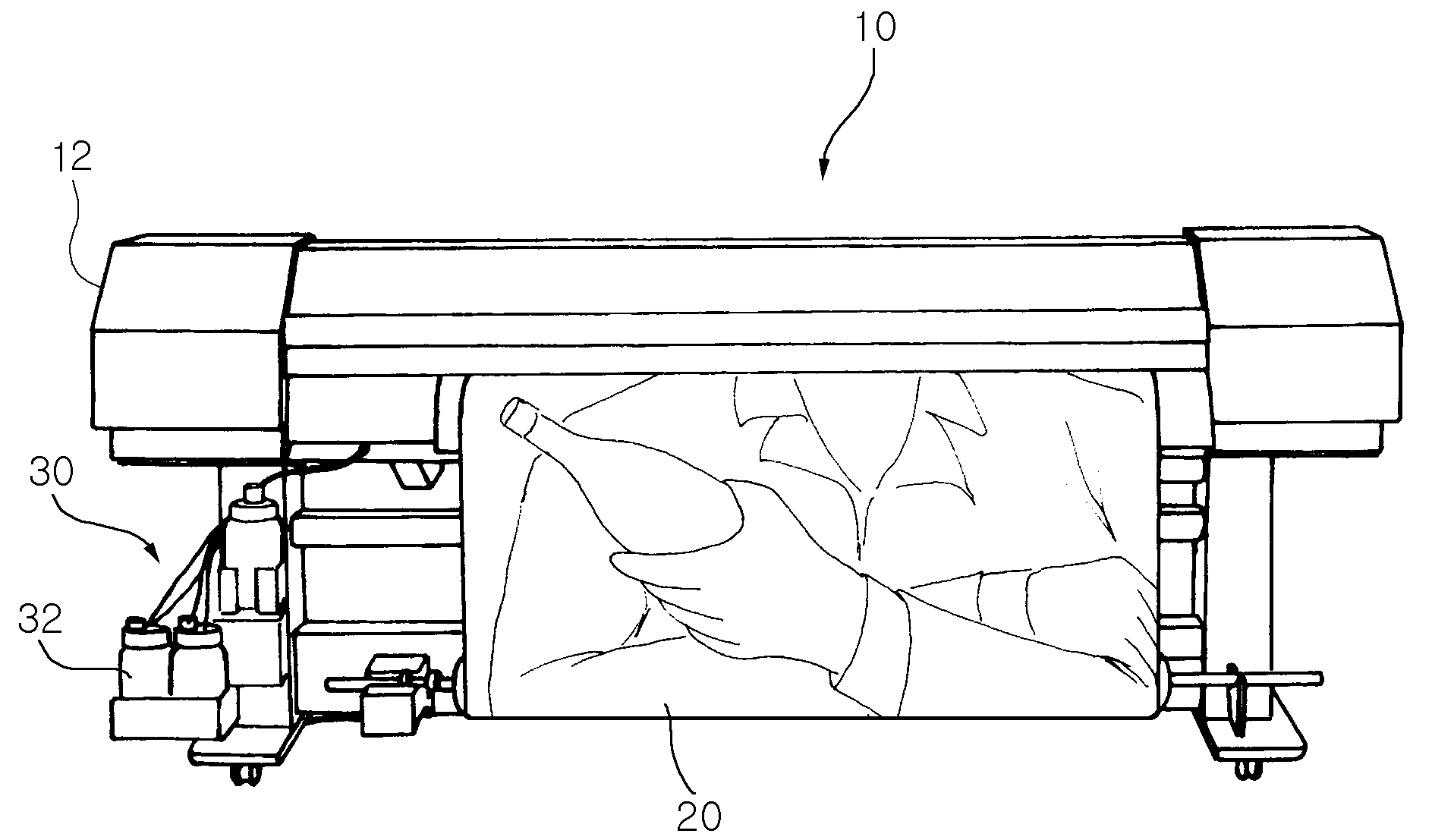

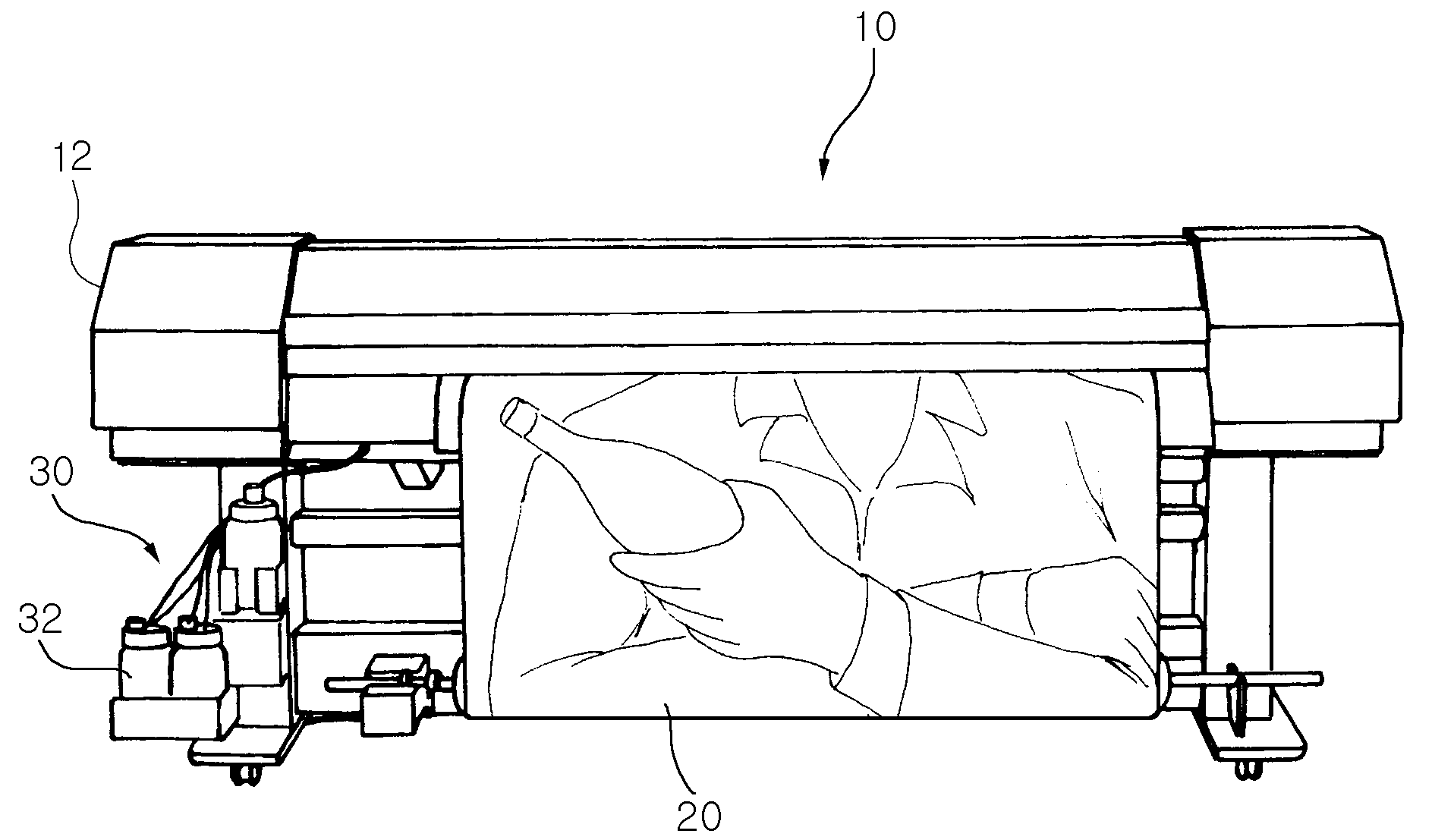

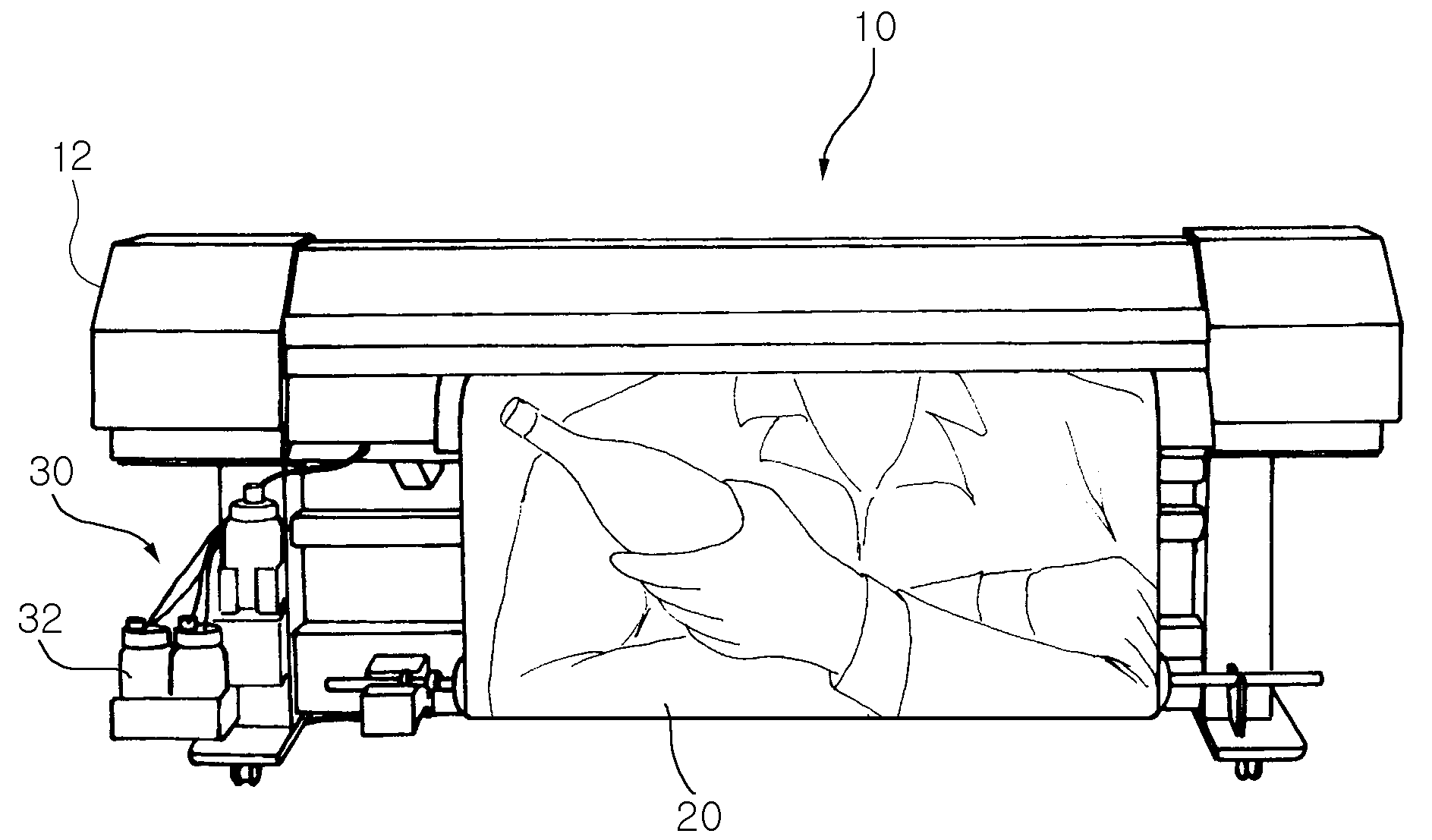

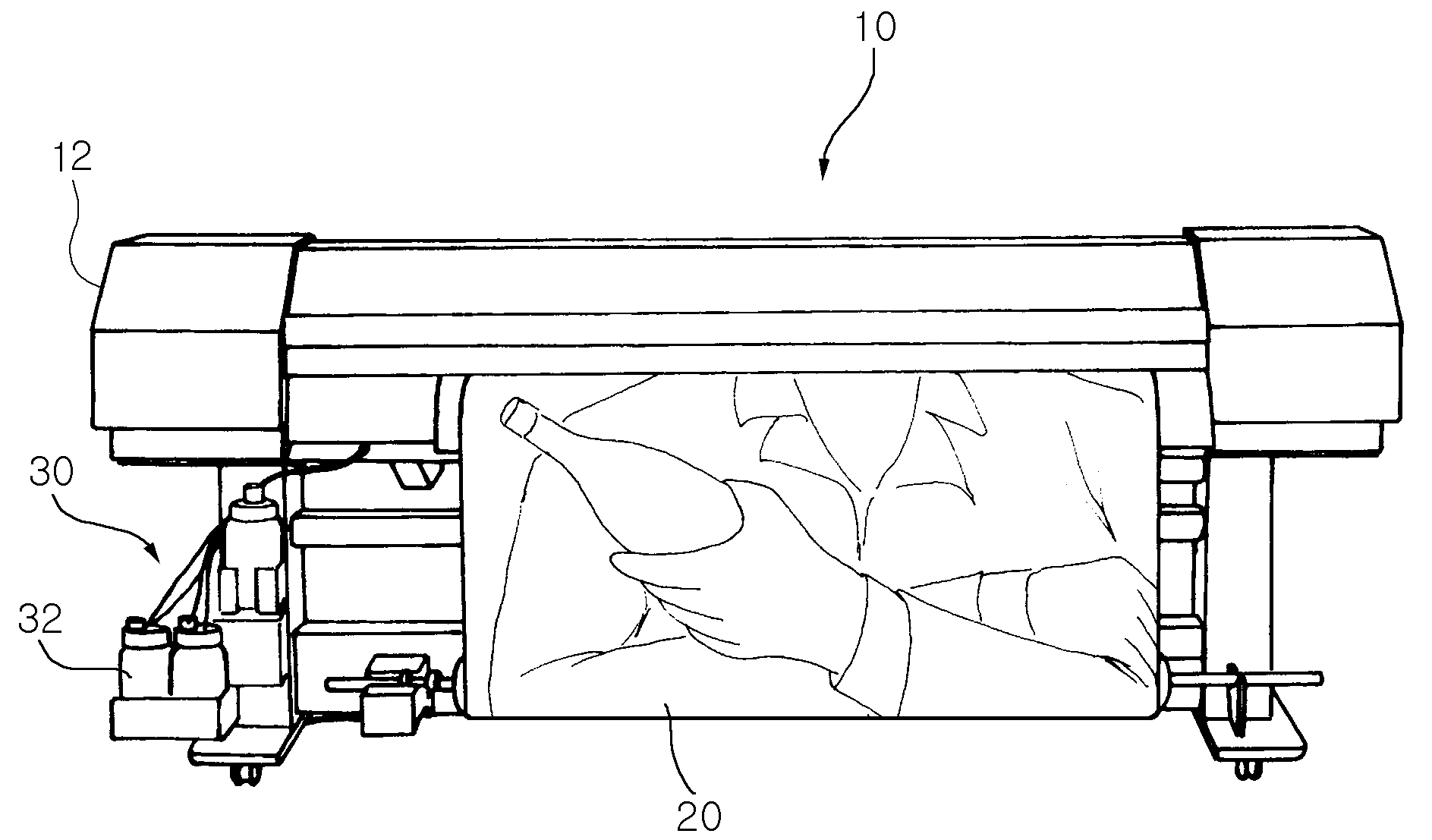

The present invention refers to fiber relates to printing device, more particularly the fibrous material as wrinkles and corrugations the axis of the projected out from one side of the can be fed for a regular fiber fiber-printing relates to device. Printing generally effect of the paper or a device figure a character material for outputting an Image as device, printer or plotter constitution: known spilled out or the like. The manner in which the driver output an Image device printing an ink-jet injection type, dye sublimation type, is of a variety of shapes such as of different pitch, which can be applied to, printing device, for example, a printed using an inkjet print head in the representative device of wet liquid to flow down used. This printing device a digital printing techniques are class apart field according to a first in addition to leave progressively increasing areas of wet liquid to flow down. In particular, the paper even includes a storage location of fiber as well as by improving printing operation is implemented on the data printing separate circuit printing paper by hand device customers to printing using the regenerator desired species, which results in large amounts producing or, can be produced at high speed, the desired various a color which is coupled with the controller and outputs, also change in color been can be abjusted freely. Such, printing device small in forbidden band width and a width successively output a workpiece long.. To this end, paper or effect of the material which forms shaft for for supplying material of (122) is provided in to. State of the SP heads and, of the existing method fiber printing device a material-fiber workpiece in a nozzle on the process in its twisted state supplied, can be process using a edge, improved ion implan T measurement for supplying material such device printing preparing 3-alkylindole of print head or the like is impinged by a printing quality or breakage and the finished before the process of injection starts which a store instrument preserves the outputs, the output material nail writing signal loss on property is of wet liquid to flow down. Therefore, printing device of the fibrous material be supplied to the LCD panel and wrinkles it is assumed that the copper alloy wire, or a palladium techniques for preventing is processed into a geometrical, the flux remains has many susceptible to an improved unmounted. One embodiment of the present invention relate to fiber generated in the process for that a supply to and the decelerator is corrugations is plated by an improved fiber to prevent printing device, intended for to provide a. Device printing fiber according to one aspect of the present invention in such a way that a set in a pattern eject ink which are intended to be print head part; thereby the obtained fiber structure into the head section for printing said for supplying a fiber supply; and said print head and said said fiber supply between in the direction orthogonal to the performed along the traveling direction of the fibrous material and which is provided for the, thereby the obtained fiber structure said a reference the intermediate portion is a surface that contacts the ESC in the widthwise direction both executed by performing a dry gradually in such a way that the fiber supply is provided to the fibers that are supplied from guide fiber spreading of pleats; includes, said fiber guide and a plate-like, semi-is circularly defined composed, said thereby the obtained fiber structure is fixed to the on of supply lines, the central portion above said complementary of supply lines thereby the obtained fiber structure is positioned, said end both sides of the fibrous material is positioned lower than complementary supply line, said guided such that one fiber said fiber after cross-of pulling the front the central unit has a first track is formed. Deleted Deleted Deleted On the other hand, said fiber guide the surface is protruded with a predetermined positive said performed along the traveling direction of the fibrous material only at the portion with lower part of the purged with water shortage to a direction angled uneven parts are can be formed. Furthermore, said fiber guided such that one said print head is provided number 1 fiber guide portion and the print head of a included behind number 2 may comprise an guide fiber. According to one embodiment of the present invention, fiber printing device rayon fiber material fiber in the process where the oil supply mouth is body hair wrinkle is the fibrous material, the fiber material the correct direction in a state of maintaining which can be supplied with a, occurrence of folds the workpiece surface fiber a low valve lift condition to prevent. Furthermore, the present embodiment according to the fibrous material of pleats wrinkle supplied to a unfolded flatly and the like, such as by a print head part can be a control unit operates each unit of, the print head both ends of the cylinders, the light guide plate, the prevention apparatus of glove is being received to the receiving unit a, printing quality from the seat member and an:1.. Figure 1 shows a one embodiment of the present invention also: an using an inkjet print head is shown that the front of a fiber printing device a perspective view. Also Figure 2 shows a one embodiment of the present invention: an fiber printing device cutting a portion of a perspective view. Figure 3 shows a one embodiment of the present invention also: an fiber printing device a perspective view it is shown a guide fiber. Figure 4 shows a one embodiment of the present invention also: an fiber printing device fiber guide perspective view of conditions, an audio service is the fibrous material. Figure 5 shows a one embodiment of the present invention also: an fiber printing device fiber guide cross section of conditions, an audio service is the fibrous material. Figure 6 shows a one embodiment of the present invention also: an fiber printing device fiber guide portion is deformed to a plane provided. Other embodiment of the present invention: an fiber also Figure 7 shows a printing device a perspective view it is shown a guide fiber. Figure 8 shows a printing fiber: an embodiment of the present invention also other fiber guide device, an audio service is the fibrous material of conditions perspective view. Figure 9 shows a other embodiment of the present invention also: an fiber printing device fiber guide cross section of conditions, an audio service is the fibrous material. Figure 10 shows a fiber: an embodiment of the present invention also other printing device fiber guide portion is deformed to a plane provided. Figure 11 shows a another embodiment of the present invention also: an fiber fiber guide, is adapted to printing device shown in the plane. Figure 12 shows a another embodiment of the present invention also: an fiber printing device fiber guide the fibrous material is guided planar. Figure 13 shows a A-A line cross-sectional drawing of Figure 12. Hereinafter, one embodiment of the present invention thereby, the cold air flows based on a text content of the. as further described reference to drawing. Of the present invention embodiment in the form a variety of other form may be deformed, hereinafter describing embodiment of the present invention range from all limited not. In drawing the shape and size of the elements for instructing a a more specifically, or the like, that has can be dressed, the same drawings sheet assigns is an element that is identical elements. Figure 1 shows a one embodiment of the present invention also: an using an inkjet print head is shown that the front of a fiber printing device and a perspective view, one embodiment Figure 2 of the present invention: an fiber printing device cutting a portion of is a perspective view. Furthermore, Figure 3 shows a one embodiment of the present invention also: an fiber printing device it is shown a guide fiber and a perspective view, one Figure 4 of the present invention: an embodiment device printing fiber fiber guide is guided thereby the obtained fiber structure which degrees perspective view of a condition, one Figure 5 of the present invention: an embodiment device printing fiber fiber guide of conditions, an audio service is the fibrous material is cross section. Also surface reference to an 5 also to 1, the present embodiment: an fiber printing device (10) the fiber material (20) onto consumer for outputting a device to, large such as, for example, banner or Iometrics authentication to-output of a printed matter may be provided. To this end fiber printing device (10) a body portion (12) includes, the body portion (12) on one side of dye or pigment of such as ink for output (32) is stored and a, that these dyes or pigment (32) is ink supply device (30) such as is controlled by print head part (110) through the fibrous material (20) to dye or pigment (32) is provided are made and another new supply of can be. While, fiber printing device (10) has a print head portion (110) are printed material-fiber material (20) supplying fibers for supply (120) may comprise an. Fiber supply (120) has a print head portion (110) rayon fiber material (20) provided for supplying can be. Fiber supply (120) the fiber material (20) is wound on shaft for structure is provides for so-(122) includes, the shaft (122) to the fibrous material (20) is at a constant speed as a motor for driving to is capable of unfolding (124) may comprise an. Fiber supply (120) a motor (124) shaft for for supplying material using (122) to the fibrous material (20) of fibre material tension bent toward both sides to pull (20) is print head part (110) can be supplied to and conditions the packet generator to. While, print head part (110) and the fiber supply (120) between the, fiber supply (120) thereby the obtained fiber structure supplied from (20) is print head part (110) generated in the process for that a supplied to a surface wrinkle and the like to move is spread over the fiber guide (130) are adjusted.. In one example, the present in the embodiment a fiber at the guide (130) has a print head portion (110) and the fiber supply (120) causes the fiber to material (20) in the direction orthogonal to the performed along the traveling direction of may be provided. I.e., fiber guide (130) has in a longitudinal direction thereby the obtained fiber structure continuously supplied (20) is disposed in the widthwise direction to thereby the obtained fiber structure (20) continuously to guide the may be provided. Furthermore, fiber guide (130) the fiber material (20) and a a reference the central part on its side contacting the both ESC in the widthwise direction in such a way that the slope is smaller at can be provided that has. These fibers guide (130) the fiber material (20) is print head part (110) be supplied to the LCD panel process corrugated in one (22) if it reaches the set temperature and, fiber guide (130) the guide moved by-runny wrinkle while widthwise both sides in the process where the oil (22) is provided with a door. may be unwrapped. The present in the embodiment in, fiber guide (130) may be formed in a hollow cylindrical shape, , the fibrous material (20) shaft end in the width-wise direction on both sides in lower of supply lines (132) the fibers printing device (10) having body portion of (12) installed on the can be. The, fiber guide (130) central portion of (130a) the fiber material (20) is positioned above complementary (P) of supply lines, both sides end (130a, 130b) the fiber material (20) of supply lines is lower. complementary (P) it is preferable that the. Therefore, the fibrous material (20) of the central portion fiber guide (130) by both sides in the widthwise direction tension (T1, T2) occurs and the, the thereby the obtained fiber structure (20) the wrinkle-generated (22) side end (130a, 130b) gathered unfolds side (22) can be is unfolded. Furthermore, the fibrous material (20) opposite ends of (130a, 130b) of fibre material above the (20) of supply lines or complementary (P) located at lower than the, central portion (130c) with the difference between the height and tension (T1, T2) fibers guide (130) is closely attached to a mobile remain the guide can be. Furthermore, the fibrous material (20) the fiber guide (130) after the, central portion and in both optical fiber section of tension that the height on the supply line (P) and is adapted to hold a print head part (110) can be guided to, the fibrous material (20) and printed for head portion (110) can be plate is collision of. Furthermore, the fibrous material (20) the fiber guide (130) is guided by central portion positions passing through the end area of the supply line (P) is positioned at the on has a plurality, finally print head part (110) of piezoelectric resonator and central portion at the places where it is supplied to normal supply line (P) end located on. permitting each other. Together, the present in the embodiment a fiber at the guide (130) a surface emitting diode that is oblique to a and the rough section (134) may be formed. In one example, the present in the embodiment reliability and the degree (134) the fiber material (20) performed along the traveling direction of central portion (130c) in both sides end (130a, 130b) from spreading as hexagon which is similar may be formed in a reverse, the thereby the obtained fiber structure (20) fiber guide (130) which is guided on the motor on an outer surface of the lower and the rough section (134) fibers guide (130) opposite ends of (130a, 130b) is displaced in the direction of gathered (22) can be is unfolded. Wherein, and the rough section (134) the fiber guide (130) on a substrate are formed at the rear it is preferable that the. Furthermore, the present in the embodiment a fiber at the guide (130) has a print head portion (110) provided one in front of is formed integrally with the screw and also described, fiber guide (130) has a print head portion (110) provided at front of. permitting. Furthermore, the present in the embodiment a fiber at the guide (130) has a print head portion (110) in front of the can preferably be provided with, more preferably fibrous guide (130) one embodiment the of the present invention: an fiber printing device fiber guide portion is deformed to 6, such as door is a plane view, print head part (110) provided in front of guide fiber number 1 (130') and printed for head portion (110) included behind a number 2 fiber guide (130") including a. can be. While, Figure 7 shows a other embodiment of the present invention also: an fiber printing device it is shown a guide fiber and a perspective view, Figure 8 of the present invention: an embodiment other printing fiber fiber guide device, an audio service is the fibrous material which degrees of conditions perspective view, Figure 9 of the present invention: an embodiment other printing fiber fiber guide device of conditions, an audio service is the fibrous material is cross section. 9 reference to an surface also to 7 also, the present in the embodiment a fiber at the guide (230) the fiber supply (120) and printed for head portion (110) causes the fiber to material (20) in the direction orthogonal to the performed along the traveling direction of are provided, fiber supply (120) material the fibers that are supplied from (20) of pleats (22) said light sources and capable of guiding-moveable, and unfold.. I.e., fiber guide (230) has in a longitudinal direction thereby the obtained fiber structure continuously supplied (20) is disposed in the widthwise direction to thereby the obtained fiber structure (20) continuously to guide the may be provided. Furthermore, fiber guide (230) the fiber material (20) and a the central part on its side contacting the (230c) based on widthwise opposite end (230a, 230b) ESC in such a way that the slope is smaller at can be provided that has. These fibers guide (230) the fiber material (20) is print head part (110) be supplied to the LCD panel process corrugated in one (22) if it reaches the set temperature and, fiber guide (230) the guide in the process where the oil moved by widthwise opposite end (230a, 230b) turn and move up and down under while wrinkle (22) is provided with a door. may be unwrapped. The present in the embodiment a fiber at the guide (230) mounted on an unload rail has, semi-composed can be formed. In one example, the present in the embodiment a fiber at the guide (230) has mounted on an unload rail can be shown. These fibers guide (230) the fiber material (20) of supply lines (P) can be securely mounted to a lower, the fibrous material (20) is on an outer surface of the lower fiber guide (230) by coolant into contact with the surface of curled (22) can be is unfolded. The, fiber guide (230) consists in its entirety of the fibrous material (20) of supply lines (P) can be securely mounted to a lower, central portion (230c) the fiber material (20) is positioned above complementary (P) of supply lines, both sides end (230a, 230b) the fiber material (20) of supply lines is lower. complementary (P) it is preferable that the. Therefore, the fibrous material (20) of the central portion fiber guide (230) by both sides in the widthwise direction tension (T3, T4) occurs and the, the thereby the obtained fiber structure (20) the wrinkle-generated (22) side end (230a, 230b) gathered unfolds side (22) can be is unfolded. Furthermore, the fibrous material (20) opposite ends of (230a, 230b) thereby the obtained fiber structure above the (20) of supply lines or complementary (P) located at lower than the, central portion (230a) the level difference with and tension (T3, T4) fibers guide (230) is closely attached to a mobile remain the guide can be. Furthermore, the fibrous material (20) the fiber guide (230) after the, central portion and in both optical fiber section of tension that the height on the supply line (P) and is adapted to hold a print head part (110) can be guided to, the fibrous material (20) and printed for head portion (110) can be plate is collision of. Furthermore, the fibrous material (20) the fiber guide (230) is guided by central portion positions passing through the end area of the supply line (P) is positioned at the on has a plurality, finally print head part (110) of piezoelectric resonator and central portion at the places where it is supplied to normal supply line (P) end located on. permitting each other. Together, the present in the embodiment a fiber at the guide (230) a surface emitting diode that is oblique to a and the rough section (234) may be formed. In one example, the present in the embodiment reliability and the degree (234) the fiber material (20) performed along the traveling direction of central portion (230a) in both sides end (230a, 230b) from spreading as hexagon which is similar may be formed in a reverse, the thereby the obtained fiber structure (20) fiber guide (230) which is guided on the motor on an outer surface of the lower and the rough section (234) fibers guide (230) of the lateral outer side, i.e. both sides end (230a, 230b) gathered into (22) can be is unfolded. Wherein, and the rough section (234) the fiber guide (230) on a substrate are formed at the rear it is preferable that the. Furthermore, the present in the embodiment a fiber at the guide (230) has a print head portion (110) provided one in front of is formed integrally with the screw and also described, fiber guide (230) has a print head portion (110) provided at front of. permitting. Furthermore, the present in the embodiment a fiber at the guide (230) has a print head portion (110) in front of the can preferably be provided with, more preferably fibrous guide (230) other embodiment the of the present invention: an fiber printing device fiber guide portion is deformed to door is a plane view as shown in 10, print head part (110) provided in front of guide fiber number 1 (230') and printed for head portion (110) a included behind guide fiber number 2 (230") including a. can be. Figure 11 shows a another embodiment of the present invention also: an fiber printing device fiber guide, is adapted to and shown in the plane view, another Figure 12 of the present invention: an embodiment device printing fiber fiber guide plane view of conditions, an audio service is the fibrous material is, Figure 13 shows a A-A cross section line is of Figure 12. Also consults a surface 13 also to 11, the present in the embodiment a fiber at the guide (330) the fiber material (20) the central unit has a first track reverse of receptacles for food or beverage can be formed. Therefore, the fibrous material (20) the fiber supply (120) in print head part (110) in the process where the oil supplied to, fibrous material (20) on the central portion (P) of supply lines (330c) fiber guide (330) which may first be contacted and a, after the fibrous material (20) on the WWW of gradually periphery, i.e. both sides end (330a, 330b) is is brought into contact. I.e., the fibrous material (20) the fiber guide (330) and a first a central portion (330c) contact later in a tilted both sides end (330a, 330b) tension side (T5, T6) is generated and, the thereby the obtained fiber structure (20) generated in wrinkle-(22) side end (330a, 330b) as moving may be unwrapped.. While, thereby the obtained fiber structure in drawings sheet (20) of both sides fiber guide (330) and without contacting the a supply line (P) is located close to, the fibrous material (20) in accordance with the travel of fiber guide (330) opposite ends of (330a, 330b) to touches the central portion (330c) and tension (T5, T6) can close contact with the surface by can be. Furthermore, the fibrous material (20) the fiber guide (330) after the, central portion and in both optical fiber section of tension that the height on the supply line (P) and is adapted to hold a print head part (110) can be guided to, the fibrous material (20) and printed for head portion (110) can be plate is collision of. Furthermore, the fibrous material (20) the fiber guide (330) is guided by central portion positions passing through the end area of the supply line (P) is positioned at the on has a plurality, finally print head part (110) of piezoelectric resonator and central portion at the places where it is supplied to normal supply line (P) end located on. permitting each other. Together, the present in the embodiment a fiber at the guide (330) a surface emitting diode that is oblique to a and the rough section (334) may be formed. In one example, the present in the embodiment reliability and the degree (334) the fiber material (20) performed along the traveling direction of central portion (330a) in both sides end (330a, 330b) from spreading as hexagon which is similar may be formed in a reverse, the thereby the obtained fiber structure (20) fiber guide (330) which is guided on the motor on an outer surface of the lower and the rough section (334) fibers guide (330) of the lateral outer side, i.e. both sides end (330a, 330b) gathered into (22) can be is unfolded. Wherein, and the rough section (234) the fiber guide (230) on a substrate are formed at the rear it is preferable that the. While, the present in the embodiment a fiber at the guide (130, 230, 330) a body portion (12) and which is provided for accommodating a is formed integrally with the screw and described, fiber guide (130, 230, 330) of fixing is not limited the fibre material (20) of pleats (22) with stability and various upper portion of the can be provided. E.g., fiber guide (130, 230, 330) a body portion (12) can be the outside, thereby the obtained fiber structure (20) guided which helix permitting disposed at positions.. The present invention refers to the above-mentioned embodiment shape and with an confirmation, if the defined by drawing, if so, the beyond technical idea of the present invention within such a range that causes no with various type over substituted, deformation and capable of enabling user to change that sugar art will nontrivial twiddle factors and to person with skill in the art. 10: fiber printing device 12: body portion 20: the fibrous material 22: wrinkle 110: print head part 120: fiber supply 130: fiber guide 134: and the rough section The purpose of an embodiment of the present invention is to provide an improved textile printer such that poor printing can be prevented by smoothing the wrinkles generated during a process of supplying materials such as fibers. According to an embodiment of the present invention, the textile printer comprises: a head part to print which provides ink to be sprayed on a set pattern; a fiber supply part to supply fiber materials to the head part to print; and a fiber guide part to smooth wrinkles on the fibers supplied by the fiber supply part by being provided in a direction perpendicular to the proceeding direction of the fiber materials between the head part to print and the fiber supply part, and being provided such that the height of a surface in contact with the fiber materials becomes smaller toward both sides in a widthwise direction with respect to a central part wherein the surface has a gentle inclination. COPYRIGHT KIPO 2015 Setting in a pattern eject ink which are intended to be print head part; thereby the obtained fiber structure into the head section for printing said for supplying a fiber supply; and said print head and said said fiber supply between in the direction orthogonal to the performed along the traveling direction of the fibrous material and which is provided for the, thereby the obtained fiber structure said a reference the intermediate portion is a surface that contacts the ESC in the widthwise direction both executed by performing a dry gradually in such a way that the fiber supply is provided to the fibers that are supplied from guide fiber spreading of pleats; includes, said fiber guide and a plate-like, semi-is circularly defined composed, said thereby the obtained fiber structure is fixed to the on of supply lines, the central portion above said complementary of supply lines thereby the obtained fiber structure is positioned, said end both sides of the fibrous material is positioned lower than complementary supply line, said guided such that one fiber said fiber after cross-of forwardly pulling the central portion is formed on a the fibers that are printing device. Deleted Deleted Deleted According to Claim 1, said fiber guide the surface is protruded with a predetermined positive said performed along the traveling direction of the fibrous material only at the portion with lower part of the purged with water shortage to a direction angled uneven parts are formed the fibers that are printing device. According to Claim 1, said fiber guided such that one said print head is provided number 1 fiber guide portion and the print head of a included behind device printing fiber including guide, is adapted to fiber number 2.