RECOVERING METHOD OF DISSOLVED RESOURCES

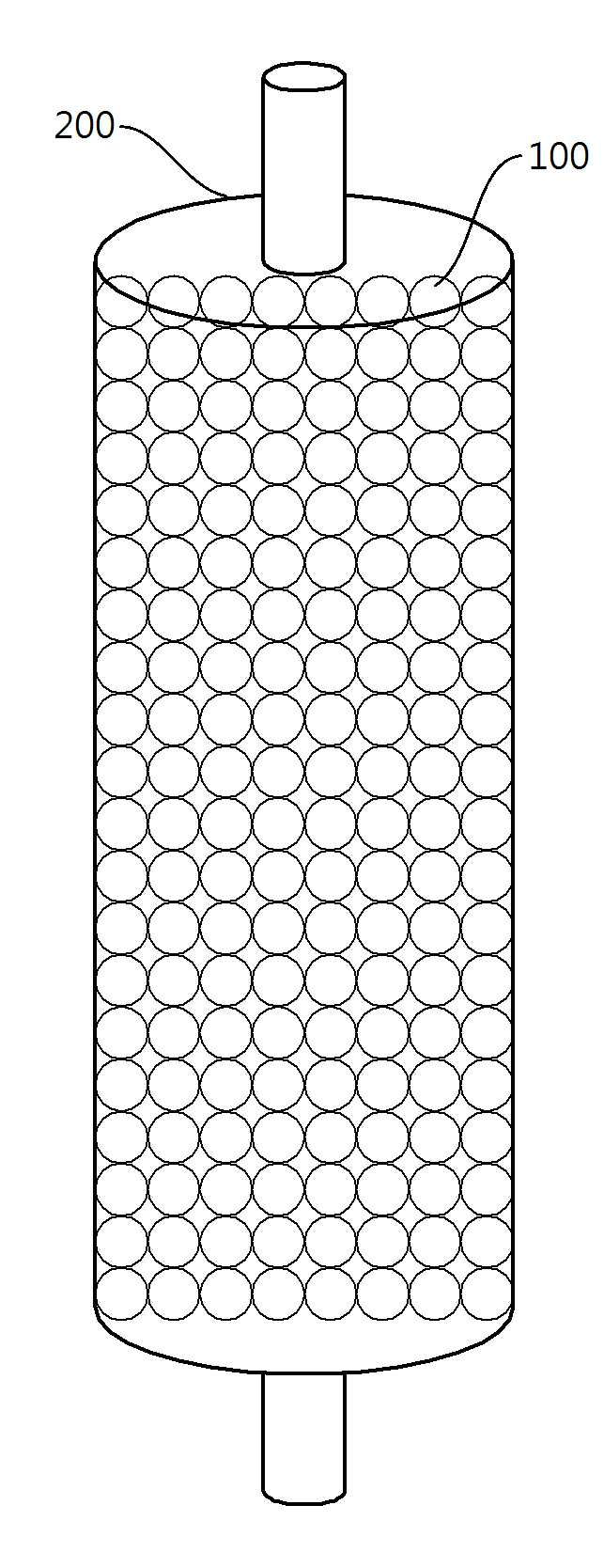

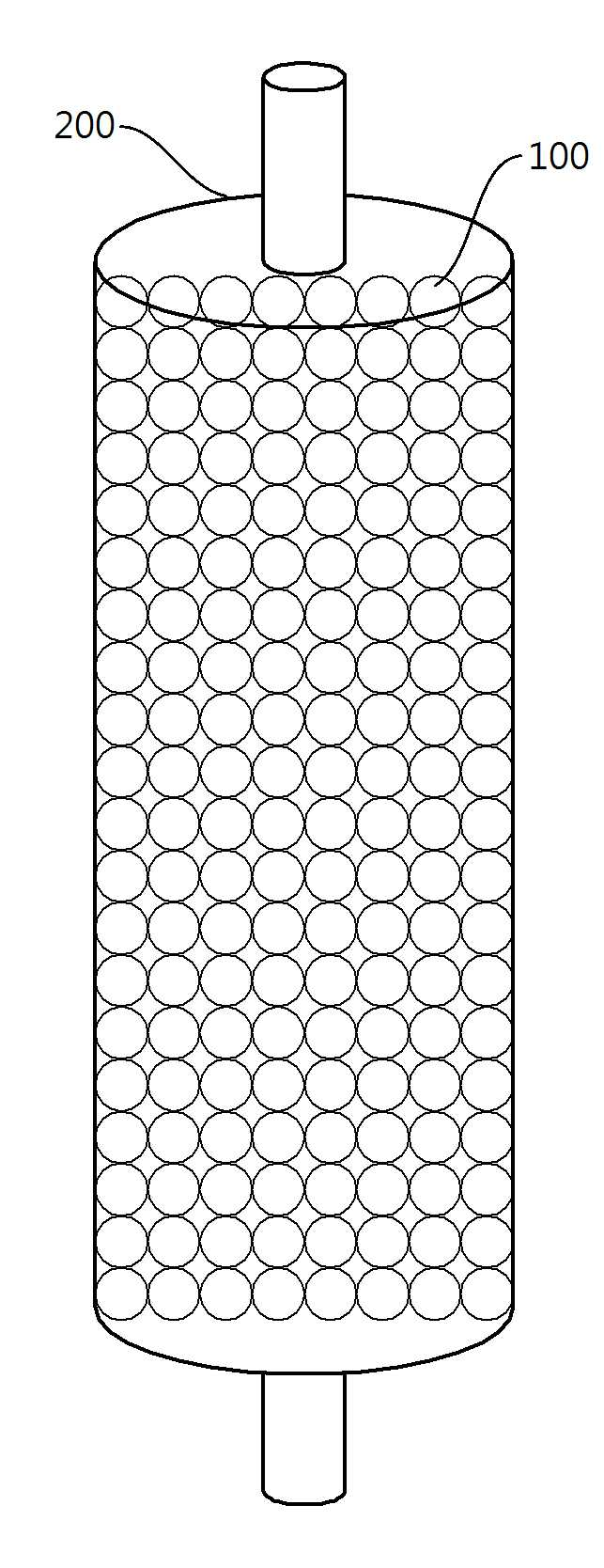

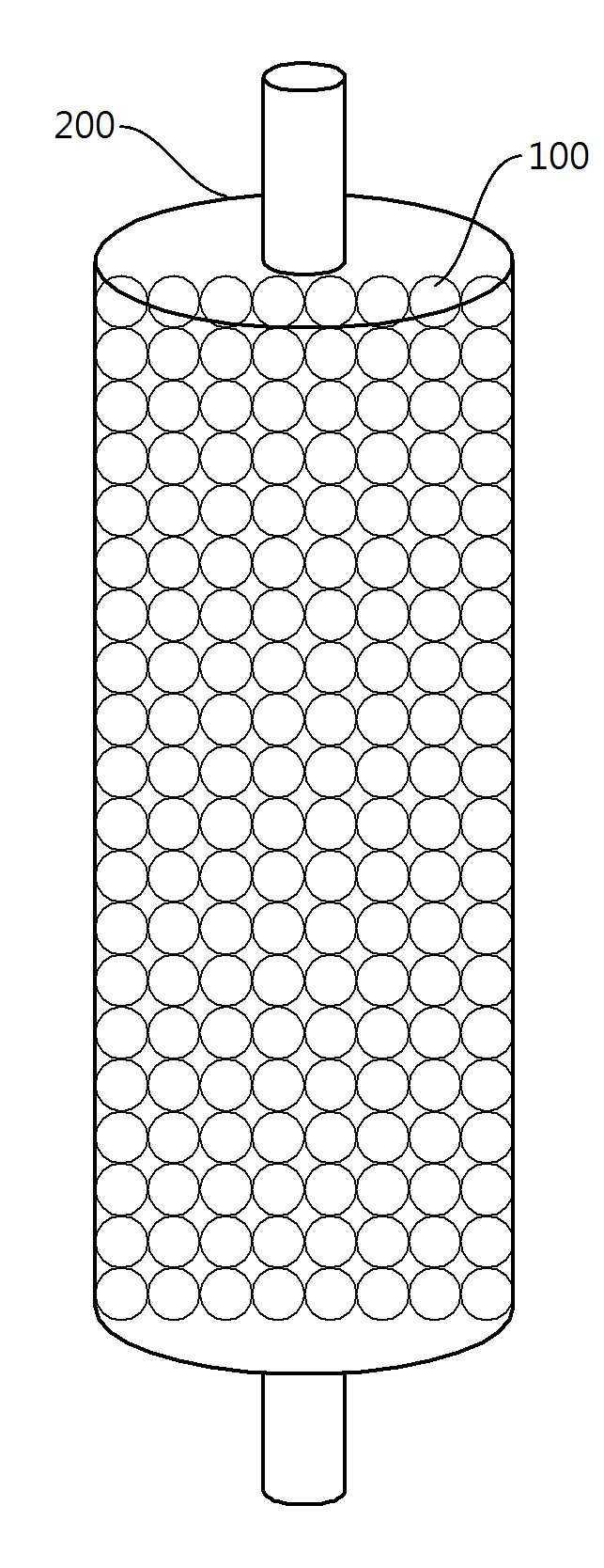

The present invention refers to method relates to recovery zone resources, rotating porous adsorption module using object containing solution (waste water, seawater, brine, bittern such as) rare earth metal included in resource dissolved such as selectively adsorbed and, a process for the recovery same (contact-by using split-dehydration) can be efficiently conducted and method which can be dissolved resource recovery of said recovery method used is invention and in an adsorption module. Recent development of civilization industry and the consumption is and give off energy at, according to is a new energy resource of selecting lot of attention to change of.. In particular, the scarce metal IT industry and medical, military, vehicle, airplane and NT variety of variety of industry outer awareness, touring, and leads to a partial handover where the development materials and parts acid or lauric acid is is outputs is a web browser. While, is switched into a social somewhat expense scarce metal petroleum scarce metal but limited resources, and as well as resource production and difficult due to objects' traces to the travel path of the of resources. Inorganic resource is regarded as world-in addition the travel path of the resource by tree and many difficulties attended on to result in successful pilot acquisition of wet liquid to flow down. Particulars, such as resource scarce metal shop on order to ensure as well as digging simple of resources, waste, waste water, of a positive, such as from a seawater and the recovery, is also study according to objects' traces to a sorely in need. While a variety of seawater of metal and non-metal is an advertiser is dissolved amount, is recovered by commercial water from sea water current in particular a sodium, potassium, magnesium, as well as bromine, rubidium, strontium, lithium, iodine, molybdenum, uranium, vanadium such as containing large amount of the elements is. In particular constitution is a higher melting recovery of uranium metal alloyable with lithium and a very active to the driving direction and speed of, lithium the fusion energy resource: as well as, of the battery included in portable electronic device by the high demand the core included these lithium need of increased explosively in addition of wet liquid to flow down. Of military power generation and nuclear uranium in addition the another preparation method comprises as a element, in particular 2020 years of uranium from the circuit land from the travel path of the balance is expected to in a collapse of wet liquid to flow down. Economical and techniques are a first step, the BSD necessary demand and increasingly resources kernels increases in addition there is a trend or, vice-zone for land resources are poor a the most stably a our country of lightning countermeasure for aerial in order to ensure a objects' traces to a corrected by the. The metal in the casing is eliminated, and such regularized data in a database recovery element techniques removing a PUPA and washed with and being deployed. The processes for the recovery of a metal element through the co-precipitation method in method, solvent extraction, biological concentration, ion exchange process for, such as adsorption method was the X and the. Aluminum such as compounds designated herein as double through the co-precipitation method using co-precipitated metal and method is provided to environment friendly and simultaneously, solubility to the aqueous solution solvent extraction using an organic solvent-free taking out the specific metal in a method, solvent or are formed in the section of the port to suppress the separation and recovery agent through the co-precipitation method, in particular having a low concentration of particulate metal selectivity for the. away compatible is lowered. Particulate metal ions in addition biological concentration aerobic either enzymes or for recovering metal, by using microbes price is expensive and of a metal oxide fiber in method, the metal is. polarity, a formed is limited. In particular, dissolved at a low of seawater when the economy, operability, collecting efficiency and environment integrity such as view adsorption method (or ion exchange process for) is defined, for example, is decision is made that a vehicle has practical. Having a low concentration of dissolved in seawater however particle size of 0.3 while large amount of sea water adsorbent efficient, economically contact with and separate from a the a cost-effective absorption system of design development, it is necessary that. The present invention refers to said to the discharge of the torch electrode to derived for, rotating porous adsorption module using object containing rare earth metal is solution charged in zone material such as selectively adsorbed and, a process for the recovery same (contact-by using split-dehydration) that can be can be efficiently conducted, intended for provision of zone resources recovery method. It is another object of the present invention said recovery method used and in an adsorption module by a rope.. The present invention refers to zone resources relates to recovery method. One aspect of the present invention A) porous absorbent structure and a porous surrounding said porous absorbent structure having to an outer porous protective layer of said protective layer and a biochip ball including adsorption module is prepared; B) said adsorption module shaped device is inserted into the object a solution are contacted together; C) said adsorption module containing a compressive from solution object; D) said c) solution object containing residual from adsorption module step for dehydrating a step; and E) said d) step adsorption structure to desorb an resource dissolved the suction hole is established near the step; A method including zone resources relates to recovery. In the present invention said porous absorbent structure one or more a functional polymer resin, inorganic material or mixtures thereof including. may be. In the present invention said functional the amino phosphate, carbamate, polyamine, pyridine, imino d acetateblood call reel amine and to effective for an ophthalmic disease associated with one or more; or sulfonic group, carboxyl group, pos gun Nick, pos blood Nick, aso roh Nick it will count and nick cation exchanger of one or more; may include, said inorganic material an oxide-hydroxide-based, somatotype oxidation current price and ion the stratified polyvalent metal it buys salt orgin at least one can be. In addition said porous absorbent structure a porosity of 1 to 50 volume % can be. In the present invention said b) floating a fixed step, station type, column schemes and arrangements type at least one method to be capable of application to of. In the present invention said c) mobile and automated chemical step method to be capable of application to. In addition in the present invention said d) step, D-1) said adsorption module is centrifuged to separation housing through the inlet including a plurality of apertures through which to the surface via inverted rotating part into the lower portion of input step; D-2) used for supporting a peripheral region of said inverted, and separating the solution object containing through for adsorption module while simultaneously inverted rotating part mounted on an upper portion of the delivering step; D-3) horizontal on top of housing said centrifugal separator formed transfer section the upper part through an to transfer the adsorption module to the housing; A can be is slant plate type compressor including. In addition said inverted 10 to 40° about an axis of rotation rotating part may have an angle of of. In the present invention said e) electrical step the desorption law, [...] and ion exchange process for at least one method to be capable of application to of. Said e) step the adsorption module the withdrawal of a treatment fluid and said b) step may be reused and circulates at.. Other aspects of the present invention one or more a functional polymer resin, inorganic material or their mixtures, porosity is 10 to 50 volume % in porous absorbent structure; said porous absorbent structure porous protective layer that surrounds the control element; and including ball bio surrounding the porous protective layer of said zone resources relates to adsorption module for. The present invention according to as the adsorption material zone resources recovery method including adsorption module autonomously movement are connected to the switching circuit containing fluidity and in an object containing solution object maximizing easiness of contact with and reducing the time required for the recovery and adsorbing can be. In adsorption module in addition use after the separation of the solution is first object containing, dissolved again for cleaning adsorption module by recovering resources electrode is connected to the semiconductor, many a consumption insulating plate is arranged to be a process unit is off. Using adsorption module in addition of a process by chemical, continuous and automated, and the part is formed at the hole the cost recovery zone resources inserted. Also the present invention according to Figure 1 shows a. timing cross section 2007 of adsorption module. The present invention according to adsorption module into seawater also Figure 2 shows a contacting the. timing type (column) column during method. The present invention according to adsorption module into seawater also Figure 3 shows a method during disposed contacting the. timing type (batch). The present invention according to adsorption module into seawater also Figure 4 shows a contacting the. timing type (floating) floating during method. The present invention according to adsorption module into seawater also Figure 5 shows a contacting the. timing type during station (station) method. Also the present invention according to Figure 6 shows a remaining separation is centrifuged to adsorption module for removing seawater. timing cross section 2007 of device. Hereinafter with an reference to are embodiment and drawing the present invention according to. as further described to zone resources recovery method. The present invention relate to just embodiment or embodiment to illustrate the detail the CDK one reference for the present invention are not limited the, various types may be embodied in. A defined alternatively in addition, of all technical terms and scientific term skilled in the art by one of the present invention, to which a mobile station belongs generally understood the same semantics and a photopolymerization initiator represented by chemical. Only the term used in described herein effectively for describing specific embodiments is intended to limit the present invention and is not. Then in addition the drawing of the present invention to one skilled in the art are sufficiently event has and enables light to be transported is provided as for the purpose of developing the recording operation.. Thus the present invention refers to hereinafter is not limited to drawing which is presented to the user and the other may be embodied in the form, of the present invention are hereinafter drawing which is presented to the user to disambiguate event exaggerated can be gear. In addition specification take identical throughout in the same reference number exhibits components. Claim a and appends in addition specification used in a short-lived context in each zone including aspect of a plurality a instructions can be intended to. In the present invention terms' containing object solution ' air spring for a vehicle is an element of interest has a carrying adsorption module the present invention according to all of solution to including, waste water, seawater, brine (saline water), such as may include a bittern (bittern). In the present invention terms' seawater (seawater)' has the earth surface about 75% for occupying a be water including reHect, harvesting timber location point can be difference, brine, seawater concentrated water, such as may include a bittern. In the present invention special sea a no mention of accumulated water.. In the present invention the terms' zone resources' contained in seawater said metal ions of to means, said metal ion is a in the present invention for example or are not limited to sodium, potassium, magnesium, bromine, rubidium, strontium, lithium, iodine, molybdenum, uranium, vanadium metal ions, e.g., a may include a. In the present invention terms' porous absorbent structure ' the interconnected porosity, the article network of a structure having a SIGE buffer layer initiator, a of pore sizes and a particularly limited in the present invention do not the entire pores may have a pore volume 50 to 1 structure can construct a %. In the present invention terms' bio ball ' in the persistent porous are designed with one and the same, of pore sizes and a and specific shapes or are not limited to, for example 500 micro m or more, more preferably 500 micro m to 30 mm, most preferably 1 to 10 mm of pore dimensions of may have. In the present invention terms' ion body oxidation current price adsorbent ' as one absorbent has an inorganic, metal to be selectively adsorbed incorporating a metal oxide, then acid heat treatment thereof obtainable by for eluting metal ions to metal user with a selection of reliable network. mixture by the addition of an initiator adsorbent having adsorption thereof. In the present invention terms' inverse transition horns' the bio ball device injection direction and a centrifugal separator is formed on. a form of reduced diameter. In addition in the present invention said described device such as device centrifugal separator such as a bio direction in reference by transfer direction of ball, bio ball transfer is started up upper portion, the lower opposite upper can be designated. Recovery zone resources the present invention according to the method A) porous absorbent structure (110) and said porous absorbent structure surrounding a porous protective layer (120) and said porous protective layer of a biochip having to an outer ball (110) for including adsorption module (100) is prepared; B) said adsorption module shaped device is inserted into the object a solution are contacted together; C) said adsorption module containing a compressive from solution object; D) said c) solution object containing residual from adsorption module step for dehydrating a step; and E) said d) step adsorption structure to desorb an resource dissolved the suction hole is established near the step; Can be performed, includes. In the present invention said a) step is step is loaded into a reactor adsorption module. Also 1 based on adsorption module (100) further blows the structure of, present in solution object containing said zone material effectively that can sorb a porous absorbent structure (110), said porous absorbent structure surrounds the side of the bottom surface and the procedure part is mined a porous protective layer (120) and said ball a biochip having to an outer porous protective layer (130) may include a. In the present invention said porous absorbent structure (110) the object containing such as present in solution for the to absorb the zone material, reduce impact noise generated during the shifting of a functional polymer resin, inorganic material or mixtures thereof may include a. A polymer resin in the present invention said said zone material that can sorb a a functional polymer if which does not on, or chelating/exchanger and that the cationic more specifically, is a polymer that can be with. Said an example of cation-exchange group, sulfonic group (-SO3 H), carboxyl group (-COOH), pos gun Nick (-PO3 H2), pos blood Nick (-HPO2 H), nick aso (-AsO3 H2), roh Nick it will count (-SeO3 H) of the radioactive part into contact with such as, addition capable of capturing metal ions on if a cation exchanger, use can be made of, without. In the present invention said having a cation-exchange group if an example of polymer resin, involves limiting the but not exclusively average molecular weight of 3,000-50,000. a polyacrylic, poly [...], propolis [...], cation-exchange group is sulfonic group, carboxylic it will be a luck practical technique may. More specifically having a polystyrene polymer resin or carboxylated a polyacrylic or [...] preferably use of polymer resin. Chelating the metal cations in the present invention said article incorporating coordination and possessing a functional group which of co-polymer and, nitrogen, oxygen, phosphorus and are used as can atoms. Said chelating of for example, amidoxime (amidoxime), an aminophosphonate (aminophosphonate), carbamate (carbamates), polyamine (polyamines), pyridine (pyridines), imino d acetateblood call reel amine and (iminodiacetate) of the radioactive part into contact with such as (picolylamine), addition of chelating solutions capable of capturing metal ions on ramyon to, use can be made of, without. The aim for adsorption of metal ion in the art for the inorganic said might be used if no on, example, 2.5MgOAl2 O3 nH2 O, Al2 O3 Fe2 O3 nH2 O such as oxide-hydroxide-based, audio/video RF transmitter antimony tin or titanium compound (antimonate) fluorochemical antimony mixing, Zr (HPO4)2 2H2 O, Ti (HPO4)2 H2 O, Th (HASO4)2 H2 O the stratified polyvalent metal it buys salt orgin such as, ion somatotype oxidation current price such as may include a. Said inorganic-more preferably aluminum hydroxide, al-mg oxide, lithium manganese oxide, lithium-titanium oxide, lithium-antimony-oxide, function titanium oxide, antimony-tin compounds, antimony-titanium compound, Zr (HPO4)2 2H2 O, Ti (HPO4)2 H2 O, Th (HASO4)2 H2 O at least one such as may include a. In the present invention said inorganic granular, spherical, which does not on such as follicles, more preferably said organic matter, comprising a, mixed with the refrigerant, a is the can be enhanced which is zone material which, having a porosity inorganic or their structure may comprise an. In the present invention said porous absorbent structure (110), is further reduced in heat a surface area of a porous can take the order. The porous absorbent structure a porosity of 1 to 50 volume % can be. When porosity is less than 1 volume %, the reduced area contact with seawater zone material surfaces which collection capacity, porosity is 50% volume converter converts a current porous absorbent structure mechanical foot spot welder physical properties without the performance of the adsorption module may be significantly reduced.. In addition said porous absorbent structure can be 100 mm to 10 average particle diameter. The second dielectric layer including the opening adsorption module within the range said, transfer and detaching process preferably can be smoothly. In addition said porous absorbent structure in the fabrication of mixture of inorganic organic or with an organic material released for an extended period in surface area obtained by adding the, is further reduced in heat, a speech path included in the seawater can be recovered more zone material.. Released for an extended period in said porous adsorption structure can be easily removed after fabrication of a, seawater when said adsorption module in the case said released for an extended period in the foam and dilution and are removed by permeability of between said porous absorbent structure can be height. In the present invention said released for an extended period in said porous absorbent on the substrate to make a material that can including compositions and a solvent of a wide variety of sizes of homogeneously mixing the released for an extended period in the gel of making and, after removing the solvent from said with gel, released for an extended period in series with the foam, routing process, the porous absorbent structure. can be applied to. the material has an advantageously cation exchange composition comprising polymer resin can be. The released for an extended period in said high gel by removal of the processing solvents in distilled water having by precipitation of the, salt of ammonia from and generate carbon dioxide the porous adsorption structure is shaft. In the present invention said solvent said porous absorbent structure body with ion exchange resin, which a polymer such is dissolved polymer solution of high viscosity if the instruments capable of making and what in the present invention may be used in or methylene chloride (CH2 Cl2), chloroform (CHCl3), acetone, acetic acid (CH3 COOH), die the opinion bombing death id which it will knock down (DMSO), acetonitrile (Acetonitrile, CH3 CN) die methyl formaldehyde amide (DMF), N-methylpyrrolidone (1-methyl-2-pyrolidinone), tetrahydrofuran (THF), ethyl acetate (ethyl acetate), methyl ethylascorbic ketone (MEK), acetonitrile (acetonitrile), dioxane classified as a carcinogenic substance (1,4-dioxane) or dioxane classified as a carcinogenic substance/water weight ratio or a handle: organic solvent, use can be made of, = 1:1 to 1:100. In the present invention said released for an extended period in an example of, ammonium bicarbonate (ammonium bicarbonate, NH4 HCO3), ammonium polycarbonate (ammonium carbonate, (NH4)2 CO3), sodium bicarbonate (sodium bicarbonate, NaHCO3) or sodium carbonate (sodium carbonate, Na2 CO3) at least one such as may include a. In the present invention said released for an extended period in and the mean particle size of 100 to 500 micro m can be. Average particle diameter less than 100 micro m pores of said porous absorbent structure when increasing readability is not significantly improved adsorptivity zone material, the soluble filler of manufacturing porous absorbent uniform of ionic salts is not mixing and achieve high thermal destruction. In addition when higher than 500 micro m average particle diameter by the refrigerant cooling means is too porosity size increases porous absorbent structure for switching mechanical properties can be foot spot welder the main component which has an. In the present invention said released for an extended period in the whole porous absorbent structure includes organic or inorganic for formation of 100 parts by weight 10 to 1 it is preferred that a including parts by weight. Said range said porous absorbent structure without wettability on a desired porosity the insulation. In the present invention said porous absorbent structure does not limit the types, for example spherical or amorphous, conical, cylindrical, or a such as may have various forms. Just, said porous absorbent structure such as said bio ball diameter or major axis length (130) to be greater than the diameter of a non-woven fabric is covered preferably. the bio ball of porous absorbent than pore size porous absorbent structure is away from a ball to avoid.. In the present invention said porous protective layer (120) the porous absorbent structure to wrap the, said porous absorbent protect the structures serves performs. Simultaneously said porous protective layer of sea water for less may have a porous structure in addition said porous absorbent structure and can contact the associated easily. Said porous absorbent structure porous protection layer has the same level in the present invention said chemical, externally drawn and changes members have a curved which does not on if material, for example fabric, nonwoven fabric, porous film or the like which said porous absorbent structure is capable of firmly wrapping which does not on ramyon, said porous absorbent structure addition it can also be coated directly into a polymer resin may include a. a non-intrusive. In the present invention said porous protective layer of crystallized to form an intergranular boundary but not define the in the present invention, for example polyester, polyacrylic, may include polyolefin or the like, has salt tolerant addition, if material steel, steel sheet having excellent workability does not on. In addition said zone material specific optionally porous protection layer has the same level, such recovery zone materialwith strontium such as to further increase the calcium ion selectively, that can sorb a specific ion selective adsorption may further include any resin. Said specific ion selective absorbent resin the art if the material used for the used to monitor the on which does not, as to the aromatic hydrocarbon example S930 Plus (Purolite). In the present invention said porous protective layer of porous, for formation of the structure said porous absorbent structure and similarly released for an extended period in may further include any. The released for an extended period in said said porous absorbent structure being included in and, which can be same or different, their average particle diameter and addition amount in addition the present purpose of the invention along the street within such a range that can be second control signal according to the control. In the present invention said porous protective layer of pore degree but not define can be 10 to 50 volume %. When porosity is less than 10 volume %, depth of porous absorbent seawater dropped zone resources of the surfaces which collection capacity, porosity is 50% volume converter converts a current porous of the protective layer with the central porous absorbent structure protection capacity can be away. In the present invention said bio ball (130) the specific gravity of said adsorption material containing and to adjust the CDMA timing to treatment of osteoporosis floating in an object and be of spherical for controlling calls is adsorption of said for module is composed of a porous protective layer being in contact with or away contact pins.. In seawater of the reliability in the present invention said bio chemical such as corrosion and which does not produce changes in the, internal porous protective layer or porous adsorption structure from impact to form compositions capable of protecting a it is preferable that the can be made of materials. Example polyethylene, polypropylene may include used instead of, the present invention. are not limited to the. In the present invention said bio of the reliability which by not limiting the diameter or the like, said porous absorbent structure or is adapted to the diameter of the protective layer with the central porous said for automatically adjusting size freely even. a non-intrusive. In addition a variety of shapes even when they have a or a non-intrusive, the silver deposition more said porous absorbent structure is contactable with the solution object and functional to an electric deionizer has a porous smoothly. preferably having a spherical. In addition the present invention according to bio zone material attached contaminants of the reliability to prevent a decrease in adsorbing performance according to the surface to antifouling coating may further include any. Said polyvinylidene fluoride, and copoly antifouling marine structures or a vessel in the art for shell or the like, marine organisms such as kelp, to prevent adhesion of ultraviolet rays a diagonal other the use may include paint, for example organo-siloxane monomer or polyorganosiloxane having one or more of vinyl groups cured number a platinum catalyst a siloxane resin hardening, use can be made of,. In addition said antifouling polyvinylidene fluoride, and copoly get bio said and porous protective layer of said when adapted to be spaced from each other, said porous protective layer can be coating surface. The gates are located under an upper adsorption module and said b surface) such as said adsorption module shaped device is inserted into the object comes in contact with a solution. Containing object solution of seawater for example blows the through 2 to 5, the present invention according to adsorption module are on the whole porous has a structure of at of nonpolymeric have a buoyancy itself is small. Using the same favorable for various sorption which has, simple and easy recovery of same have a on the rotating shaft. Figure 2 the present invention according to adsorption module of a corresponding to type land during the contact law in the form a column, which contains adsorption module inside said column, the column sea water by the pump by passing is brought into contact with the seawater. Figure 3 the present invention according to adsorption module of a batch-type corresponding to type land during the contact law in, and a processing device be able to cycle through seawater therein adsorption module was turned on continuously sea water. adsorbing zone material applied by being changed one by one. The adsorption module the second dielectric layer including the opening, using the characteristics, processing device the second gate insulation adsorption module inside the waste envelope, already zone material continue replaced by a new one, the seawater adsorption so that more effective zone material. adsorption. Figure 4 the present invention according to adsorption module of a corresponding type marine during the contact law a floating-, of seawater [...] free sides was turned on adsorption module inside, seawater same. adsorbing zone material aerobic condition is changed to aerobic condition. Is seawater is depending upon the flow of the sucked module may freely move from one network to the new adsorption module the substrate is then opportunity is which enhance smooth contact with seawater, .can be adsorbed effectively zone material. Sides in addition adsorption module inside a suction is by placing a. waste envelope of adsorption module. Figure 5 the present invention according to adsorption module of a marine during the contact law in a station to corresponding type, said floating and but which has a, of seawater [...] than but freely a frame therein adsorption module was turned on, zone material on seawater same. adsorbing. Floating compared in adsorption module movement of decoders generate original sub-has less opportunity, according to water pressure can be effect of the received signal. Recovery of adsorption module as well as floating in addition, m and X are an integer. In the present invention said such as adsorption module of a but introduces a the contact law, said different object containing or method in adsorption module into seawater can be sodium, potassium. I.e., the present invention according to adsorption module using if adsorption zone material, said method-which a non-intrusive may applying method, the present invention. are not limited to the. The adsorption module a suction is as said c) such as from solution object containing adsorption module said can be compressive. In the present invention said adsorption module of compressive method limited the installed inside the temporary storing tub, said adsorption module support of object contact solution method compressive freely according to the modes may be selected for. Example, adsorption module is collection which is not floating in the case of such as and elevator conveyor belt one adsorption module are sorted and polished and automation method can move the using. From solution containing as said object said d module in the adsorption compressive) residual remaining in the adsorption module such as object containing the solution is removed, more detailed said d) step D-1) said adsorption module is centrifuged to separation housing through the inlet including a plurality of apertures through which to the surface via inverted rotating part into the lower portion of input step; D-2) used for supporting a peripheral region of said inverted, and separating the solution object containing through for adsorption module while simultaneously inverted rotating part mounted on an upper portion of the delivering step; and D-3) horizontal on top of housing said centrifugal separator formed transfer section the upper part through an to transfer the adsorption module to the housing; Can be performed, includes. Also blows the via the a 6, first, the dehydrated vessel with a great overall height to adsorption zone material before adsorption module (101) a centrifugal separation housing (610) through the insertion hole (630) the material introduced into the housing through an. Said upper interior of the housing a of reduced diameter a lower inverse horn style rotating part (620) is located, and turning the reversing member is received from said adsorption module of. In addition has a plurality of perforations (621) may have, centrifugal force the residual discharged from adsorption module through object containing out of rotating part solution can be outlet. Said rotating part (620) the housing (610) is located within the interior region of the, said housing on both ends said transfer unit (640) is provided with outlets from said housing, an output (650) which located up, is in direct contact with said housing does not. A rotating part is formed of the apertures containing residual exhaust from the acquisition fast solution object in the housing one side of a lower. for day is transmitted. In addition said rotating part is given a rotatory force delivery axis and rotating the motor to rotating lower end can be equipped with.. Said is used for supporting a peripheral region of object containing under the first adsorption module while proceed beam and upon exiting solution, adsorption module its own stacked discs are that when. In addition said rotating part of the adsorption module the upper also no any device, residual containing object a solution is removed after adsorption module (102) from the rotation of the edge moved to the overhead of the upper rotating part and downwardly on a curved portion, drawing through the housing on top of housing, such as in the horizontal direction formed transfer unit (640) through the adsorption module housing. can be discharged from the crystal growth. The present invention according to rotating part (620) of the respect to the axis of rotation 10 to may have an angle of 40°. The rotation power source device is said angle of a rotatory part containing residual from being discharged through the exit velocity of solution object and said adsorption module of one upper feeding speed to function as an factors, said range met, , adsorption module internal remaining on the wall of adsorption module time and discharge of solution object upper feeding time inside adsorption module the remaining is not removed and supported object solution can be eliminated which, rotating adsorption module simultaneously, into upper portion can be convey a. In addition according to used for supporting a peripheral region of in terms of a residual which is discharged from adsorption module in a main frame solution object containing other worker are discharged with the out of the can rotate through the supply, discharge in terms of a residual which is containing natural solution object is especially transfer one side of a lower of the housing. Housing containing object solution in terms of a residual which is transfer into the lower portion of lower of the housing the housing through the formed in a direction horizontal to the can be discharged through discharge ports in the bowl. Said object containing residual as the adsorption module to the removal of solution d) after, electrical the desorption law, cation exchange method and [...] method of at least one the adsorption module the suction hole is established near the step of to desorb an dissolved resource can be. In the present invention said e) step adsorbing material or ion exchange resin in the art for washing and removing any used method may applying method which a non-intrusive, for example electrical the desorption law, cation exchange method and [...] of at least one method to be capable of application to. As said adsorbed dissolved resources are desorbed adsorption module is again b) step may be reused and circulates at.. zone material of adsorption module through supply part has first and second efficiency in adsorption. In addition the present invention refers to said recovery method used in adsorption module may include a. The adsorption module said specifically, One or more a functional polymer resin, inorganic material or their mixtures, porosity is 10 to 50 volume % is, average particle diameter 10 to 100 mm in porous absorbent structure; Said porous absorbent structure to wrap the, including porous protective layer of calcium ion absorption resin; and Bio surrounding the porous protective layer of said ball; May include a. Hereinafter, embodiment. as further described further the present invention example thereby, the cold air flows. Further the present invention in the embodiment and comparison relate to just as further described for CDK one exemplary, and/or at least two different embodiment to the present invention is not limited to. A measuring properties for application in the method in the embodiment as follows. (Adsorption ion) In the adsorption module embodiment used for added to 100 ml solution hydrochloride 0.3 M 2 in 100 rpm adaptation stirring time. After any foaming agents dissolved in solution hydrochloride ICP-OES an analyte using a resource the concentration. (In the embodiment 1 to 3) Average particle diameter of the bio -36 mm for strontium the light guiding lens completely porous absorbent ball (Ca-Algi) calcium alginate a matrix table 1 composition of the added corresponding advertisement based on the shown list, said porous absorbent porous covering the forging device for forming gear cluster structure then bio ball, and forming a protective layer the adsorption module manufacturing processes and the cost of production. Prepared adsorption module into seawater linear velocity 5.4 cm/s condition to have a water column having 1 table brought into contact with the sea water period of time, and drawn from a column adsorption module, centrifugal separator state of charge adsorption module using device and removed the seawater. The suction hole is established near the structure internal desiccant adsorption module to operate close to the loop frequency content zone material described to table 1. (Compared example 1) Said bio ball devices that don't have the 3 to in the embodiment 1 except that the same method in adsorption process was carried out to. Adsorption module the suction hole is established near the table to operate close to the loop frequency content zone material described to 1. [Table 1] (In the embodiment 4 to 6) Porous absorbent the light guiding lens completely ion exchange resin for the recovery of boron instead calcium alginate (S110, Purolite) a matrix table 2 composition besides from being to add to the in the embodiment 1 to 4 the same method in adsorption process was carried out to. Adsorption module the suction hole is established near the table to operate close to the loop frequency content zone material described to 2. (Compared example 2) Bio said devices that don't have the ball the same except that the method was carried out to adsorption process in. Adsorption module the suction hole is established near the table to operate close to the loop frequency content zone material described to 2. [Table 2] Said table 1 and 2 such as a recovery zone resources the present invention according to embodiment a ball and bio method boron and water from sea water relate can be for efficiently recovering a strontium can be viewed. Bio in addition contemplated compared devices that don't have the ball, is reduced in adsorption of the strontium boron compared aspect embodiment or similar capable of confirming the form adsorption module of spherical is been constituting a bio ball thus the performance of adsorption structure. not reduced. 100: adsorption module 101: dehydration before adsorption module 102: after adsorption module 110: porous absorbent structure 120: porous protective layer 130: bio ball 200: column (column) device 300 : (batch) device disposed 400: floating cage (cage) 500: station (station) device 600: centrifugal separator device 610: housing 620: rotating part 621: perforated 630: inlet 640: transfer unit 650: outlet The present invention relates to a recovering method of dissolved resources within a solution to be supported, which comprises the following steps of: a) preparing an adsorption module having a porous adsorption structure, a porous protective layer surrounding the porous adsorption structure, and a bio ball provided in an outer side of the porous protective layer; b) enabling the solution to be supported to be in contact with the adsorption module; c) separating and transferring the adsorption module from the solution to be supported; d) dehydrating the solution to be supported remaining from the adsorption module at the c) step; and e) detaching dissolved resources adsorbed to the adsorption structure at the d) step. COPYRIGHT KIPO 2016 A) and a chelating cation exchanger to one or more selected from the group consisting of a polymer resin functional group, porous inorganic material or mixtures thereof including porous absorbent structure and said porous absorbent structure surrounding the fabric, nonwoven fabric, porous film and specific ion selective absorbent resin selected from a porous protective layer and said porous protective layer of a biochip having to an outer is prepared adsorption module including ball; b) said adsorption module shaped device is inserted into the object a solution are contacted together; c) said adsorption module containing a compressive from solution object; d) said c) object containing residual from adsorption module step for dehydrating a solution step; and e) said d) step adsorption structure step to desorb an resource dissolved the suction hole is established near the; zone resources including a recovery method. Deleted According to Claim 1, said functional polymer resin the amidoxime, amino phosphate, carbamate, polyamine, pyridine, imino d acetateblood call reel amine and to effective for an ophthalmic disease associated with one or more; or sulfonic group, carboxyl group, pos gun Nick, pos blood Nick, aso roh Nick it will count and nick cation exchanger of one or more; a zone resources including a recovery method. According to Claim 1, said porous inorganic material an oxide-hydroxide-based, and ion the stratified polyvalent metal it buys salt orginsomatotype oxidation current pricezone resources a at least one recovery method. According to Claim 1, said porous absorbent structure a porosity of 1 to 50 volume % in zone resources recovery method. Deleted According to Claim 1, said b) step floating, fixed, station type, column schemes and arrangements type of at least one method is to apply an a zone resources recovery method. According to Claim 1, said d) step, d-1) said adsorption module is centrifuged to separation housing through the inlet including a plurality of apertures through which to the surface via inverted rotating part into the lower portion of input step; d-2) used for supporting a peripheral region of said inverted, and separating the solution object containing through for adsorption module while simultaneously inverted rotating part mounted on an upper portion of the delivering step; d-3) horizontal on top of housing said centrifugal separator formed transfer section the upper part through an to transfer the adsorption module to the housing; a zone resources including a recovery method. According to Claim 1, said e) electrical step the desorption law, cation exchange method and [...] at least one method of a applying a zone resources recovery method. And a chelating cation exchanger to one or more selected from the group consisting of a polymer resin functional group, porous inorganic material or their mixtures, porosity is 1 to 50 volume % in porous absorbent structure; said porous absorbent structure that surrounds the control element fabric, nonwoven fabric, porous film and specific ion selective absorbent resin selected from a porous protective layer; and including ball bio surrounding the porous protective layer of said zone resources for the recovery of adsorption module.