DEVICE FOR REMOVING GARBAGE IN DREDGED SEDIMENTS, AND METHOD FOR PURIFYING CONTAMINATED SEDIMENTS USING SAME

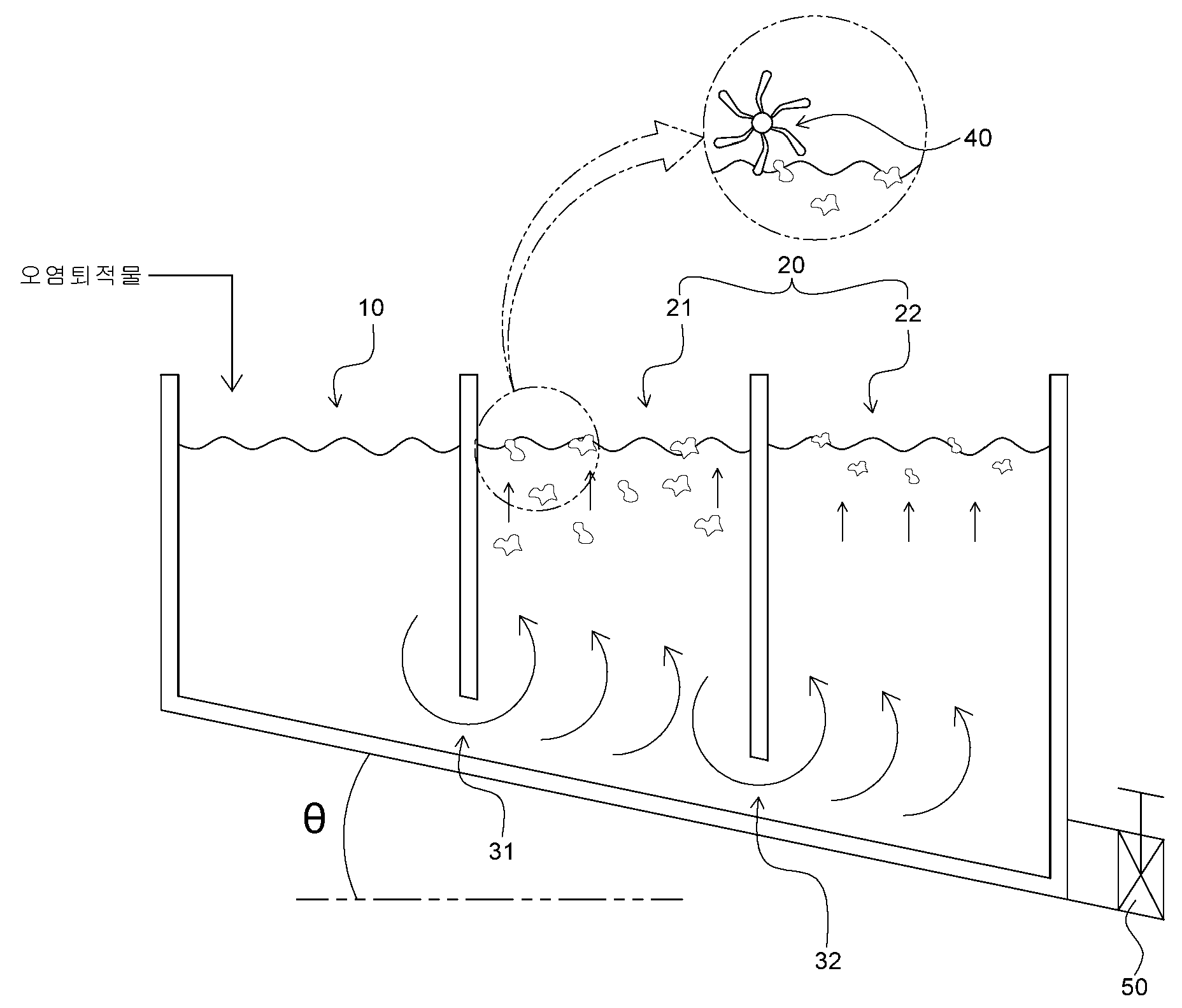

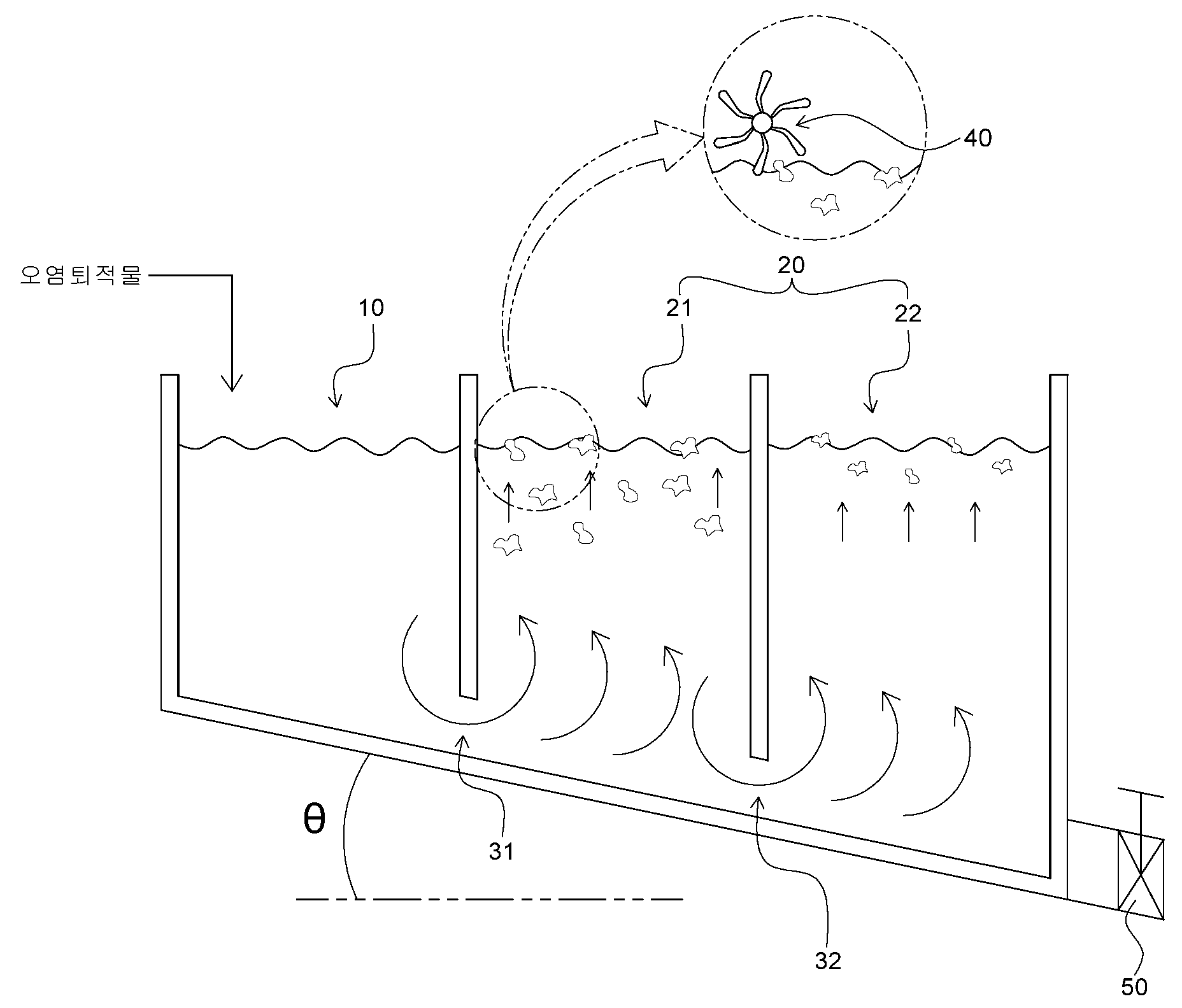

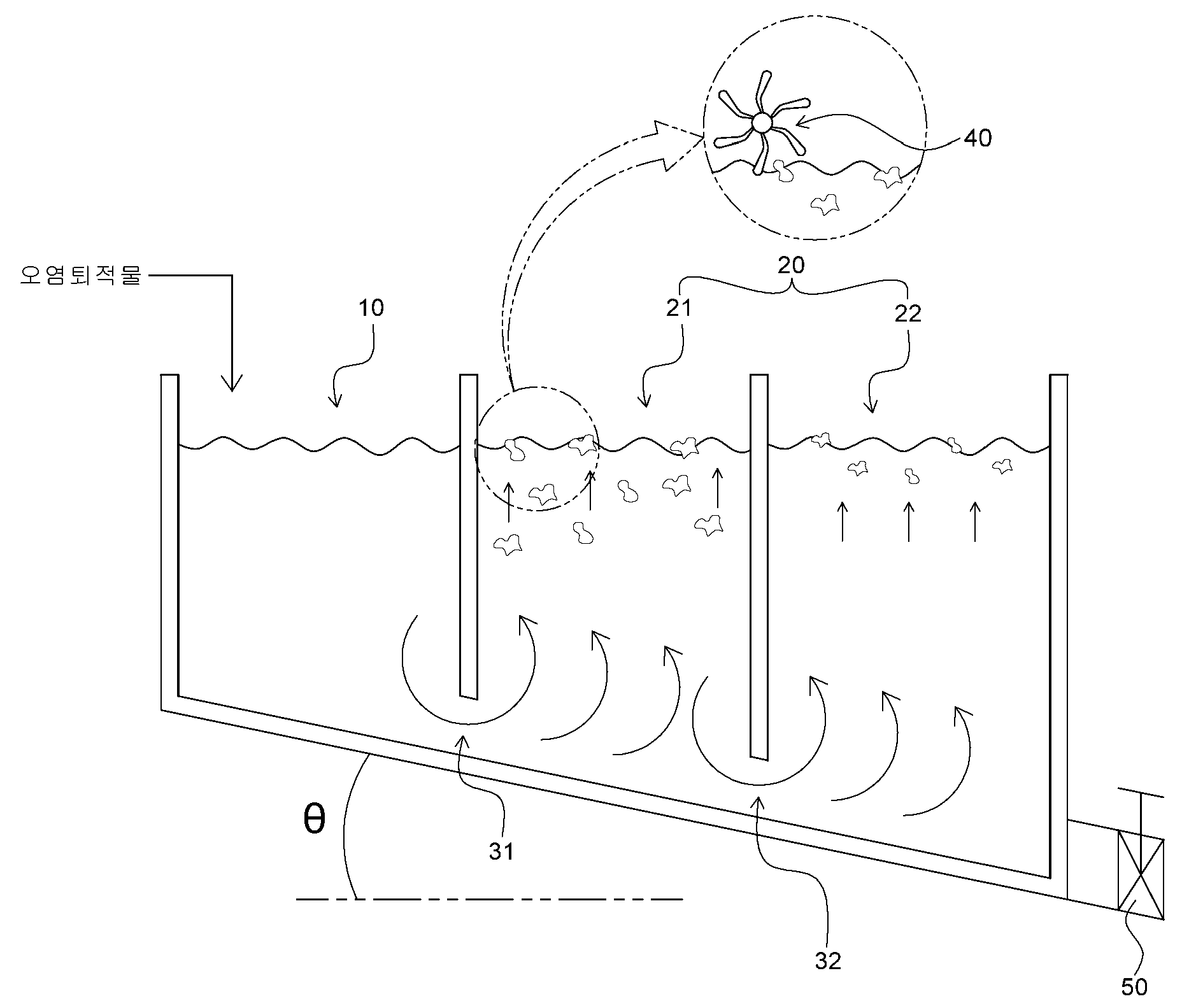

The present invention refers to lake or sea water, river deposition of dredging material waste and environmental pollution deposits a purifying method number industry association device are disclosed. Specifically, the present invention refers to lake or sea water, river dredging material deposition of vinyl, fibers and the like to a stand-alone device or of special materials and deposition of waste number number on gravity waste system uses deposits purification method to dredging are disclosed. Industrial waste or sewage sea by heavy metal deposits, contamination of with persistent characteristic organic pollutant outside disclosed. In particular, deposits [...] smaller in particle size among configuration of soil, clay, slurry and the like pollution because the surface area for coupling with water relatively large particle diameter hereinafter sand, gravel or the like and the pretreatment device is compared, in addition combined contaminants separation is difficult. The, conventional purification techniques are deposits of air constituting the particle size soil contamination the pretreatment device is relatively high [...], clay, for purification with a slurry carried out and, as soil particle size of device for separating multi-stage screen, uses a multi-stage cyclone or the like. The temperature detector, dredging material is elastically installed by low vinyl, fiber, plastic such as debris at a weight which can be, like a mesh (mesh) soil particle size of debris such gravity prevents soil particle size separation stage crisis at the time of significantly improves the efficacy of door lowering number flow tides. The, dredged material deposited in continuous process to control gravity waste efficiently number through a stand-alone device capable of increasing the efficiency of the purification process is executing the request to obtain an are disclosed. The present invention refers to continuous process in dredging material deposited through vinyl, fiber, plastic such as a stand-alone device and efficient gravity waste can be quickly number under public affairs purifying method intended for a system uses the deposit number. In order to solve a number and said, the present invention refers to, Deposited dredging process is formed dredging material storage tank, said dredging material storage tank located adjacent a through-hole is opened in the waste floating is performed a treatment tank, said treatment tank and separating sorting apparatus means a flying bio-, said dredging material storage tank and said treatment tank 5 to the direction of conveyance of said dredging material along the lower surface are each independently lower 50° formed a slope face tilted, said dredging material storage tank and said transfer passage is formed at the lower portion of the dredging of the processing tank, the height of the path of said dredging material storage tank or said treatment tank said dredging the overall height 0. 5 to 15% and, said treatment reservoir is dredging material conveying direction end dredging material including the discharge passage, a number of special waste device number under public affairs substrate. Wherein, said dredging material storage tank and said treatment tank 10 to lower said dredging material along the direction of conveyance of the lower surface are each independently form a slope face tilted 25° characterized, a number of special waste device number under public affairs substrate. In addition, said dredging material discharge passage through the dredging material further including regulating the flow rate of the flow control valve can be dredging material characterized, a number of special waste device number under public affairs substrate. Wherein, said dredging material storage tank and said processing tank level detected by the level sensor and said sensor dredging material such that the flow control valve further including adjusting said dredging material characterized in that the control section number, a number of special waste device number under public affairs substrate. On the other hand, said dredging material storage tank, said treatment tank, the lower end of the injection device or both alkyl groups include methyl, the conveying screw or conveyor belt characterized further guide the dredged material is attached, a number of special waste device number under public affairs substrate. In addition, a dredging material said dredging material storage tank or said treatment tank overflow the transfer means further including a purification process characterized, a number of special waste device number under public affairs substrate. And, said treatment reservoir is pure wife interconnected 1 difference processing tank and 2 difference and treatment tank, tank capacity is said storage tank, said 1 difference processing tank and said 2 difference increase in the order of the processing tank, tank flow rate difference said 2 passage of the processing tank, said 1 difference processing tank and said storage tank characterized in order of increasing, a special device number number waste under public affairs substrate. Further, said sorting apparatus means rotation of the blade, characterized in that a filter film it is a gun or screenings, waste device number a number of special under public affairs substrate. In addition, debris said vinyl, fiber or plastic waste is provided to the gravity characterized, a number of special waste device number under public affairs substrate. On the other hand, sea deposits dredging the sewage or dredging step, said separating device according to Claim 2 number 1 or number of special waste from deposits by anti waste sorting apparatus step, said deposits soil particle size particle size separation step in soil, soil particle size separation step said isolated from the soil particle diameter 0. Performing processing steps for purifying antibodies 075 mm hereinafter in particulate contaminant treatment, purified soil for dehydrating a dehydration step and dehydration step including recycling and reuse soil, contamination deposits a purifying method number under public affairs substrate. The present invention according to the wetting ability of waste number continuously dredging material deposited in the material dredging device in vinyl, fiber, plastic such as a stand-alone can be efficiently and quickly number gravity waste exhibits an excellent effect. In addition, the present invention according to number of waste materials deposited dredging industry in continuous process device is waste or waste substance transfer number of special dredging device such as a power storage unit flowed without requiring an etch operation exhibits an excellent effect. Figure 1 shows a special number to determine the timing for automobile device the present invention according to waste also are disclosed. Figure 2 shows a side view of the present invention according to waste number to determine the timing device also wetting ability are disclosed. Figure 3 shows a purifying device of the present invention according to contamination deposits also by flow determine the timing purification process are disclosed. Hereinafter, of the present invention preferred embodiment are detailed the on-sensors other. However, in the embodiment described herein are not limited to the form and the other the present invention refers to a disapproval. Rather, in the embodiment wherein the disclosure are introduced to complete the data with 24 bits can be calculated, and of the present invention to one skilled in the event can be transmitted sufficiently in order to it comes to become ball number are disclosed. The same reference number throughout the specification have identical components by a goniophotometer. Figure 1 shows a special number to determine the timing for automobile device the present invention according to waste also are disclosed. As shown in fig. 1, the present invention according to the wetting ability to enter the device number is stored contamination deposits deposited dredging material waste including dredging material storage tank (10), said dredging material storage tank (10) which are disposed adjacent said dredging material deposited in waste floating is performed a treatment tank (20) and said treatment tank (20) in floating waste separating sorting apparatus means (40) and, said dredging material storage tank (10) to said treatment tank (20) in the lower portion of dredging material is fed a passage (31, 32) is formed on each pixel. Said dredging material storage tank (10) and said treatment tank (20) and the bottom surface along the direction of conveyance of said each supplied at an angle (θ) lower deposited dredging material, e.g. 5 to 50°, preferably 10 to a slope face tilted 25° can be formed. Thereby, said dredging material storage tank (10) deposited dredging material with a predetermined length from a text treatment tank (20) for conveying the deposited dredging material fed into said power device artificially is not disclosed. Wherein, said tank (10, 20) (θ) is less than the lower face of warp strength 5° deposited dredging material delivery may not smoothly while when, greater than 50° when said treatment tank (20) residing in dredging material gravity for separating waste time shorter Image can be difficult. Only, said formed in said dredging material storage tank for conveyance of a non-deposited dredging material (10), said treatment tank (20), or both the lower portion of dredging material conveying means, for example, bubble injection device, the conveying screw, transfer belt and the like can be further. Specifically, said bubble injection device includes said dredging material storage tank (10), said treatment tank (20) and both of said deposited dredging material laminated to said partially flowed by implanting high-speed of closed cells deposited dredging material flow can be improve, said said conveying screw and said transfer belt to convey a number be deposited dredging material steel. Said dredging material storage tank (10) to said treatment tank (20) arranged in a lower dredging material path (31, 32) are interlinked is said dredging material storage tank (10) or said treatment tank (20) the overall height 0. 5 to 15% implementation being. Thereby, said dredging material storage tank (10) deposited dredging material said bracket forms a narrow passage (31, 32) through said treatment tank (20) when said passage is fed (31, 32) in flow rate is increased and said treatment tank (20) is filled with instructions by dredging material deposited inside in vinyl, fiber, plastic such as floating debris is equal to gravity. Wherein, said dredging material path (31, 32) the change of said dredging material storage tank (10) or said treatment tank (20) the overall height 0. Less than 5% when said passage (31, 32) is difficult to excessively narrow dredging material delivery whereas, greater than 15% of said treatment tank to excessive speed when dredging (20) residing in dredging material gravity for separating waste time shorter Image can be difficult. I.e., the wetting ability in the present invention according to waste is deposited dredging material device number for the force of gravity waste flowed artificially separate power device exhibits an excellent effect exhaust port. Said processing device (20) in dredging material deposited in said floating debris while gravity [...], clay, such as slurry with which particulate toe levitation, the particulate floating so that subsequent purification process is eluted antibodies attached heavy metals dredging number clarification in efficiency can be further improved. Dredging material deposited along said direction of conveyance of the treatment tank (20) at the end of the gravity debris discharged after regulating the flow rate of the flow rate of a dredging material deposition number for reparing over control valve (50) can be with. Said flow control valve (50) by dredging material exit flow velocity and said storage tank by adjusting said dredging material dredged material (10) to said treatment tank (20) in dredging material can be level. In addition, the present invention according to said number of special waste material storage tank includes a dredging device (10) to said treatment tank (20) level of said level sensor and control section further includes a number of chicken house can be. I.e., said number the fisherman said sensor to be sensed by said dredging material storage tank (10) and said treatment tank (20) each said purified water flow control valve (50) by automatically activates said dredging material storage tank (10) to said treatment tank (20) can be always constantly conditioned water level, as a result said dredging material storage tank (10) and said treatment tank (20) enters dredging material over each said tank can overflow the number billion. Said treatment tank (20) is 1 difference treatment tank (21) and 2 difference treatment tank (22) and include, in this case, said 1 difference treatment tank (21) on said 2 difference treatment tank (22) provided at the lower dredging material transfer passageways (31, 32) can be with, said passage (31, 32) the height of the 1 difference treatment tank (21) or said 2 difference treatment tank (22) the overall height of 0. 5 to 15% implementation being. Thereby, said 1 difference treatment tank (21) said 2 gravity differential processed debris difference treatment tank (22) capable of wetting ability efficiency further by separating waste number. In this case, tank capacity is dredging material storage tank (10), 1 difference treatment tank (21), 2 difference treatment tank (22) order increases and, the tank includes a tube 2 difference treatment tank (22), primary treatment tank 1 (21), dredging material storage tank (10) order can be increased. Said sorting apparatus means (40) is said treatment tank (20) by separating one if not specially number 1 flying bio-such as also shown in rotor blade or, net, cloth and the like can be applied. Figure 2 shows a side view of the present invention according to waste number to determine the timing device also wetting ability are disclosed. The present invention according to said number of special waste material storage tank includes a dredging device (10) and/or said treatment tank (20) of a dredging material to separate purifying device transferring overflow through the open face (60) can be with, said transfer means (60) for example said storage tank (10) and/or said treatment tank (20) spaced from a finite number upper (60) implementation being. Said overflow a dredging material is relatively the pretreatment device is high clay, [...], slurry of particulate soil machine since additional purification device can be transferred to an expression vector. Figure 3 shows a purifying device of the present invention according to contamination deposits also by flow determine the timing purification process are disclosed. Said purifying device is installed can be installed to a water craft or land contamination deposits. As shown in fig. 3, the present invention according to contamination deposits by purifying device the dredging step purification process, waste separation step, soil particle size separation, purification processing steps, dewatering and additional treatment step, recycling step can be like. Said waste separation step can be performed using the previous number of special waste described device, said particle size the separating includes directing the drum screen, multi-stage cyclone device or the like is performed using separate the soil particle diameter 0. 075 mm hereinafter toe purification processing steps in particulate is conveyed to a particle diameter 0. 075 mm toe recycling step greater than can be directly transfer assembly. Specifically, said drum screen including the mesh network consisting of screen 2 which are provided with, dredging material particle diameter 4 mm hereinafter soil particles can be deposited in the food waste, said multi-cyclone device includes a particle diameter 0. 075 mm hereinafter can be in particulate soil the food waste. In addition, purification method step floating, settling separation, magnetic separation, such as pen ton oxidation reaction physical chemical treatment, biological treatment using microorganism, etc. and apparatus for purifying waste can be heat treatment is heating is selectively performed. In particular, when heavy metals contamination source of soil contamination, magnetic separation, and the like can be performed [...], when organic contamination source, floating, pen ton oxidation reaction, biological treatment can be performed. Further, when pre-number of soil contamination by heavy metals and organic composite organic material can be a stand-alone after purifying by heavy metals. Combined heavy metals of soil contamination by surface method for removing organic material when said first number of heavy metals unit is a stand-alone up after heavy metals preferably organic processing. Specifically, the dredging material fine bubbles while agitating said mounting ceramic ware by implanting clay, [...], slurry of particulate soil, oil or the like after the separation of the substrate surface to discard additional purification with a dredging or the plurality and, said settling separation dredging be leached into the organic contaminants, such as heavy metals precipitated process to separation and number and a stand-alone, killed by peroxide oxidation method of the separation process utilizing said pen ton oxidation reaction are disclosed. In addition, biological treatment said microorganism in a treatment process for organic treating dredging material dredging are disclosed. Said microorganism solution are easily included in photosynthetic bacteria, yeast, lactic acid bacteria, carbonyl, filamentous number, about 130 species can be bacteria and yeast. In particular, in the case of deposits in accordance with the concentration of the salt sea marine environment even under an environment of microorganism deodorization salinity may be activated, e.g., salt tolerant bacillus strain (Bacillus sp.), preferably bacillus into EBW (Bacillus sp.) preferably using strain cultures. And, said microorganism treatment solution can be deodorized for activating oxygen generating number, nutritional microorganism number, physical contact with the porous organic matter with a microorganism further comprises for facilitating such as can be. On the other hand, said magnetic separation said soil particle size separation step, said purifying treatment step and said dewatering and additional treatment step can be carried out in one or more steps. Detachment of said magnetic cylindrical magnet wire wrapped form magnet magnetic a husk separator while a belt is placed on said belt to said belt is transferred during dredged soil magnetism material prepared conveyed away from the influence of magnetic force of attaching a multivalent belt moved from one place to magnetized in such a way that the guide pin is guided separation separated from a plurality of hierarchies. 3,000 to 4,000 gauss magnetic separation is carried out in said soil particle size separation step 2 having degree of magnetic force. 2 kw class magnet 2 using two primarily core current, separate from the flow and iron number, 6,000 to 10,000 gauss magnetic separation is carried out in said purification processing steps using magnetic separating grade magnetic separation it will raise in dredged soil having degree of magnetic force is equal to. Said purification processing steps when a magnetic force for conducting the separations, dredging material character season stone (Fe3 O4 ), 1, 2 binding in paper salt (FeCl2 , FeCl3 , FeSO4 ) Number is put in the magnetization of magnetic separation can be enhancing the efficiency of soil particles by increasing the magnetization force. And, a magnetic separation is carried out in said dewatering and additional treatment step can be performed after impregnating purified soil dry magnetic separation, magnetic separation can be a stand-alone non-volatile heavy metals wet number further number. And, said [...] the leaching process and separation by chelating heavy metals leached into the dredging be cholesterol, said heavy metal chelating [...] number is further provided for example using methyl glycine D acet acid (methylglycinediacetic acid; MGDA) can be, attached to the soil to promote reaction reaction temperature is 70 to 80 °C [...] eluting and heavy metals, pH is 1 to 4. 5 dispersed with, further ultrasonic, e.g., 28 kHz and 30 W the ultrasonic wave is applied to the third be dredged material. In addition, the purification of soil contamination through heavy metal bonded soil particles prior said cleaning, a roller after the separation of the organic contaminants can be treatment for dissolving the group number. Wherein, said scrubbing EDTA, CMCD (carboxymethyl β-cyclodextrin and 60), CMC (carboxymethyl chitosan), surface-active agents can be like number. Further, soil and fill said smaller particle diameter of soil contamination because the diameter of soil contaminants according to increasing concentration preferably washing water. Said dewatering belt press processing steps, such as electrical penetration dehydration can be technique, dry magnetic separation step after said food materials after dewatering steps further comprise further number can be a stand-alone residual heavy metals. The specification of the present invention preferred embodiment is described with reference to but, one skilled in the art hereinafter describing a corresponding claim of the present invention various embodiment and modification of the present invention within a range that the idea and area away from modifying may not are disclosed. The embodiment of the present invention claim is substantially modified components of both of the present invention if technical category region included in must substrate. 10: dredging material storage tank 20: treatment tank 30: dredging material path 40: sorting apparatus means 50: dredging emission flow control valve 60: overflow dredging material conveying means The present invention relates to a device for removing garbage in dredged sediments in seawater, lakes, or rivers, and to a method for purifying contaminated sediments by using the same. Particularly, the device for removing garbage in dredged sediments removes garbage having low specific gravity such as plastic bags, fibers, and the like from dredged sediments in seawater, lakes, or rivers by raising the garbage to the surface. COPYRIGHT KIPO 2017 Deposited dredging process is formed dredging material storage tank, said dredging material storage tank located adjacent a through-hole is opened in the waste floating is performed a treatment tank, said treatment tank and separating sorting apparatus means a flying bio-, said dredging material storage tank and said treatment tank 5 to the direction of conveyance of said dredging material along the lower surface are each independently lower 50° formed a slope face tilted, said dredging material storage tank and said transfer passage is formed at the lower portion of the dredging of the processing tank, the height of the path of said dredging material storage tank or said treatment tank said dredging the overall height 0. 5 to 15% and, along the direction of conveyance of said discharge passage and said treatment reservoir is dredging material dredged material is released through the discharge passage end dredging material dredged material including a flow control valve regulating the flow rate of the dredging material, waste number device being resized. According to Claim 1, said dredging material storage tank and said treatment tank 10 to lower said dredging material along the direction of conveyance of the lower surface are each independently form a slope face tilted 25° characterized, waste number device being resized. Back number According to Claim 1, said dredging material storage tank and said processing tank level detected by the level sensor and said sensor dredging material such that the flow control valve further including adjusting said dredging material characterized in that the control section number, waste number device being resized. According to Claim 1 or Claim 2, said dredging material storage tank, said treatment tank, the lower end of the injection device or both alkyl groups include methyl, the conveying screw or conveyor belt characterized further guide the dredged material is attached, waste number device being resized. According to Claim 1 or Claim 2, said dredging material storage tank or said treatment tank overflow a dredging material transfer means further including a purification process characterized, waste number device being resized. According to Claim 1 or Claim 2, said treatment reservoir is 1 and 2 are connected to each other sequentially difference processing tank and treatment tank car, tank capacity is said storage tank, said 1 difference processing tank and said 2 difference increase in the order of the processing tank, tank flow rate difference said 2 passage of the processing tank, said 1 difference processing tank and said storage tank characterized in order of increasing, waste number device being resized. According to Claim 1 or Claim 2, said sorting apparatus means rotation of the blade, characterized in that a filter film it is a gun or screenings, waste number device being resized. According to Claim 1 or Claim 2, said debris vinyl, fiber or plastic waste is provided to the gravity characterized, waste number device being resized. Sewage or sea deposits dredging a dredging step, said separating device according to Claim 2 number 1 or number of special waste from deposits by anti waste sorting apparatus step, said deposits soil particle size particle size separation step in soil, soil particle size separation step said isolated from the soil particle diameter 0. Performing processing steps for purifying antibodies 075 mm hereinafter in particulate contaminant treatment, purified soil for dehydrating a dehydration step and dehydration step including recycling and reuse soil, contamination deposits purification method.