PROCESS OF SORTING FLOAT OF COPPER OXIDE ORE USING NON-IONIC POLYMER

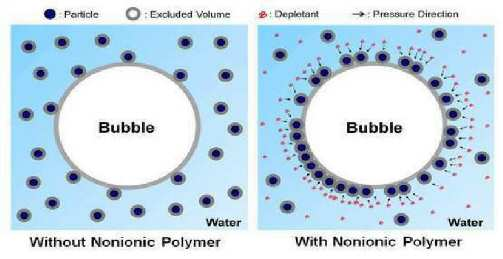

The present invention refers to flotation process relates to ceramic dielectric composite light, more specifically non-ionic ceramic dielectric composite light using polymer flotation process are disclosed. In the case of our, 6 a type briquette to strategy minerals, iron mine, copper mine, zinc storehouse, uranium and nickel and most light interferometer, 6 to 15% in the specific gravity of the first mineral revenue copper mine strategy and, frequently development rate very low disclosed. Station number complex mineral prices are to be inserted into a database for a first price fluctuation reacts to, be actively recovering copper mine flotation current through studies of 2000. (Pulp) generating pores in flotation is obtained minerals suspended storehouse misfortune (hydrophobic) to convert the hydrophobic surface and mineral particles and floating, hydrophilic (hydrophilic) mineral particle surface floating system is storehouse misfortune discharge a servomechanism physical chemical selective method remains in the mixtures are disclosed. Finally, in order to be selectively recovering mineral surfaces flotation efficiency front side by air bubbles in the liquid crystal display most important disclosed. The second recovering mineral surfaces for selectively liquid crystal display by adding a reagent suitable for a number the catcher (collector). Light where the ceramic dielectric composite flotation technique which can be used for the catcher cup tax [thu (xanthate) is most widely commercially in selection number which, suction cup tax [thu to be made well number sulfide (Na2 S) ceramic dielectric composite flotation is applied to further by adding light but, according to recent research papers and cup tax [thu which is a surface number sulfide, known States that adversely affect the human capability are disclosed. The, flotation light active in number and the catcher number without using ceramic dielectric composite flotation is a new process technology or a small amount of data in a database number the catcher along the development of flotation efficiency processing techniques are disclosed. The present invention refers to a ceramic dielectric composite number without using harmful to the human environment and active number and the catcher flotation light under public affairs number broadcast receiver capable of processing techniques. In addition, a small amount of the catcher number along the broadcast receiver number under public affairs flotation efficiency processing techniques. In order to solve the aforementioned door a number, and the present invention refers to the present invention refers to mineral suspension useful gangue mineral and copper bath step number respectively, non-ionic polymer is present gangue mineral and useful mineral solution chamber is placed after mixing and dispersing step, said chamber and said bubble generator supplies nitrogen gas to the injection step including selectively adsorbed minerals useful characterized using polymer and ceramic dielectric composite light number under public affairs flotation process non-ionic surfactant. Air bubbles in said selective adsorption is characterized by a force useful mineral depletion. Said with gangue mineral SiO2 Can be using, useful mineral is malachite and said copper (Cu2 (OH)2 CO3 ) Can be using, using said non-ionic polymer can be PEG (Polyethylene glycol). Said suspension in 100 parts by weight of said nonionic polymer gangue mineral and useful steps for creating said mineral each each 5 × 10-5 To 5 × 10-2 Be it will agitate into and out of the parts by weight. 10 to 50 ml per minute into a nitrogen gas into said flotation by 2 minutes 10 minutes can be flotation. In addition, the present invention refers to mineral suspension containing useful including gangue mineral and copper bath step number, the presence of non-ionic polymer solution chamber is placed after mixing and dispersing step gangue mineral and useful mineral, said chamber and said bubble generator supplies nitrogen gas to the injection step including selectively adsorbed minerals useful characterized using polymer and ceramic dielectric composite light non-flotation process number under public affairs, air bubbles in said selective adsorption is brought about by a force depletion useful mineral are disclosed. Said with gangue mineral SiO2 Can be using, and said mineral-malachite useful copper (Cu2 (OH)2 CO3 ) Can be using, using said non-ionic polymer can be PEG (Polyethylene glycol). Said suspension gangue mineral and useful steps for creating a 1:1 mixture 50 parts by weight based on the weight of the minerals said nonionic polymer 5 × 10-5 To 5 × 10-2 Be it will agitate into and out of the parts by weight. 10 to 50 ml per minute nitrogen gas into said flotation step by 2 minutes 10 minutes can be flotation. In addition, the present invention refers to gangue mineral and copper each comprising respectively the catcher number into and out of the useful mineral agitating, a number present on the catcher number bulk industry association step, said surface including gangue mineral and copper containing number the catcher wastes useful mineral suspension step number tank, non-ionic polymer is present gangue mineral and useful mineral solution chamber is placed after mixing and dispersing step, said chamber and said bubble generator supplies nitrogen gas to the injection step including selectively adsorbed minerals useful characterized using polymer and ceramic dielectric composite light non-flotation process number under public affairs, selective adsorption is caused by air bubbles in said force can be useful mineral depletion. Said with gangue mineral SiO2 Can be using, useful mineral is malachite and said copper (Cu2 (OH)2 CO3 ) Can be using, number the catcher to said Sodium oleate (C18 H33 O2 Na) can be used. Agitating said gangue mineral and useful in each said 50 parts by said useful with gangue mineral mineral mineral and the catcher number number 1 × 10 the catcher-10 To 1 × 10-6 It will agitate and M be placed. Said non-ionic polymer is present on the steps for creating a suspension 100 parts by weight of said nonionic polymer each number the catcher it agitated gangue mineral and useful mineral each 5 × 10-5 To 5 × 10-2 It will agitate into and out of the parts by weight and, using said non-ionic polymer can be PEG (Polyethylene glycol). 10 to 50 ml per minute into a nitrogen gas into said flotation said by 2 minutes 10 minutes can be flotation. The present invention refers to a non-ionic polymer by adding the catcher number and active number without using, depletion reaction-resistant ceramic dielectric composite optical surface can be selectively operated by the sensitivity to light environment-friendly ceramic dielectric composite floating selection process can be recovered disclosed. In addition, additional non-cartridge the catcher number using the polymers in a second direction to substantially the efficiency of ionic flotation can be up to 100%. Figure 1 the present invention according to bubble - reaction between particles exhibits mechanism. Figure 2 shows a the present invention according to method 1 process shown steps also are disclosed. Figure 3 shows a the present invention according to method 2 also illustrates the process steps are disclosed. Figure 4 shows a process step the present invention according to method 3 also shown are disclosed. Figure 5 particles and bubbles between non-ionic polymer is present to indicating depletion if not force are disclosed. (H>2Rg ) Figure 6 particles and bubbles between non-ionic polymer 220a depletion indicating when force are disclosed. (H<2Rg ) In the embodiment 2 according to Figure 7 of the present invention one filtered of copper are disclosed. In the embodiment 3 according to Figure 8 of the present invention one filtered of copper are disclosed. One in the embodiment according to Figure 9 of the present invention which represents the dispersion are disclosed. In the embodiment according to Figure 10 of the present invention indicating one flotation steps are disclosed. The present invention refers to the amount of the organic EL device which cleaves the number and active number which are directed to the environment and adversely reduce, non-ionic polymer so as to selectively force sensitivity reaction-resistant ceramic dielectric composite particle surface depletion designed so as to be technology, the present invention according to bubbles from reaction between particles can be also 1 - identifying mechanism. Said depletion force force acting between the two colloidal particles, colloidal particles (h) distance between said two non-ionic polymer aqueous solutions when present in a radius (Rg ) Acting in accordance may be, no external may be filled. In Figure 5 the studied, h>2Rg In one case, non-ionic polymer particles and bubbles may be present between, depletion force does not act. 6 also from, h<2Rg In one case, non-ionic polymer particles when the bubble does not exist between, viii. depletion force. The present invention refers to the mineral suspension useful gangue mineral and copper bath step number respectively, non-ionic polymer is present gangue mineral and useful mineral solution chamber is placed after mixing and dispersing step, said chamber and said bubble generator supplies nitrogen gas to the injection step including selectively adsorbed minerals useful characterized using polymer and ceramic dielectric composite light number under public affairs flotation process non-ionic surfactant. Air bubbles in said selective adsorption is characterized by a force useful mineral depletion. Said with gangue mineral SiO2 Can be using, useful mineral is malachite and said copper (Cu2 (OH)2 CO3 ) Can be using, using said non-ionic polymer can be PEG (Polyethylene glycol). Said suspension in 100 parts by weight of said nonionic polymer gangue mineral and useful steps for creating said mineral each each 5 × 10-5 To 5 × 10-2 Preferably with concave parts by weight. Said nonionic polymer 5 × 10-5 When less than parts by weight to bury, nonionic polymer through a force through a depletion, air bubbles cannot sufficiently adsorb, 5 × 10-2 Parts by weight exceeds, the surface force sufficient depletion useful mineral sufficiently bubbles twisted unnecessary disclosed. In non-ionic polymer can be dispersed in said chamber whereupon the adsorbed gangue mineral and useful mineral, preferably 300 to 400 rpm using a magnetic bar and distribute, in particular 340rmp carry preferably distribute. 300rmp when less than, dispersion does not uniformly, and then 400 rpm, air bubbles suspended without attaching door inner plate number point i.e., the selective number can not door is suspended. 10 to 50 ml per minute into a nitrogen gas into said flotation by 2 minutes 10 minutes can be flotation. Said nitrogen gas into 10 ml per minute when less than 2 minutes, not flotation requests, 50 ml to greater than about 10 minutes when injecting, additional nitrogen gas composition already flotation environment since unnecessary disclosed. In addition, the present invention refers to mineral suspension containing useful including gangue mineral and copper bath step number, the presence of non-ionic polymer solution chamber is placed after mixing and dispersing step gangue mineral and useful mineral, said chamber and said bubble generator supplies nitrogen gas to the injection step including selectively adsorbed minerals useful characterized using polymer and ceramic dielectric composite light non-flotation process number under public affairs, air bubbles in said selective adsorption is brought about by a force depletion useful mineral are disclosed. Said with gangue mineral SiO2 Can be using, and said mineral-malachite useful copper (Cu2 (OH)2 CO3 ) Can be using, using said non-ionic polymer can be PEG (Polyethylene glycol). Said suspension gangue mineral and useful steps for creating a 1:1 mixture 50 parts by weight based on the weight of the minerals said nonionic polymer 5 × 10-5 To 5 × 10-2 Be it will agitate into and out of the parts by weight. Said nonionic polymer 5 × 10-5 When less than parts by weight to bury, lack sufficient depletion cannot sticking force useful bubble mineral, 5 × 10-2 Parts by weight exceeds, the surface force sufficient depletion useful mineral sufficiently bubbles twisted unnecessary disclosed. In non-ionic polymer can be dispersed in said chamber whereupon the adsorbed gangue mineral and useful mineral, preferably 300 to 400 rpm using a magnetic bar and distribute, in particular 340 rpm preferably distribute the carry. When less than 300 rpm, dispersion does not uniformly, and then 400 rpm, air bubbles suspended without attaching door inner plate number point i.e., the selective number can not door is suspended. 10 to 50 ml per minute nitrogen gas into said flotation step by 2 minutes 10 minutes can be flotation. Said nitrogen gas into 10 ml per minute when less than 2 minutes, not flotation requests, 50 ml to greater than about 10 minutes when injecting, additional nitrogen gas composition already flotation environment since unnecessary disclosed. In addition, the present invention refers to gangue mineral and copper each comprising respectively the catcher number into and out of the useful mineral agitating, a number present on the catcher number bulk industry association step, said surface including gangue mineral and copper containing number the catcher wastes useful mineral suspension step number tank, non-ionic polymer is present gangue mineral and useful mineral solution chamber is placed after mixing and dispersing step, said chamber and said bubble generator supplies nitrogen gas to the injection step including selectively adsorbed minerals useful characterized using polymer and ceramic dielectric composite light non-flotation process number under public affairs, selective adsorption is caused by air bubbles in said force can be useful mineral depletion. Said with gangue mineral SiO2 Can be using, useful mineral is malachite and said copper (Cu2 (OH)2 CO3 ) Can be using, number the catcher to said Sodium oleate (SO, C18 H33 O2 Na) can be used. Agitating said gangue mineral and useful in each said 50 parts by said useful with gangue mineral mineral mineral and the catcher number number 1 × 10 the catcher-10 To 1 × 10-6 It will agitate and M be placed. said catcher number is 1 × 10-10 When less than M, said flotation of mineral and returned to said coolant sufficient adsorption useful number the catcher, 1 × 10-6 In one case M, serves the useful mineral flotation of said said catcher number sufficient adsorption, 1 × 10-6 M exceeds the thin film is cut. Said non-ionic polymer is present on the steps for creating a suspension 100 parts by weight of said nonionic polymer each number the catcher it agitated gangue mineral and useful mineral each 5 × 10-5 To 5 × 10-2 It will agitate into and out of the parts by weight and, using said non-ionic polymer can be PEG (Polyethylene glycol). Said nonionic polymer 5 × 10-5 When less than parts by weight to bury, lack sufficient depletion cannot sticking force useful bubble mineral, 5 × 10-2 Parts by weight exceeds, the surface force sufficient depletion useful mineral sufficiently bubbles twisted unnecessary disclosed. Said non-ionic polymer is present gangue mineral and useful minerals in solution chamber whereupon the dispersing chamber whereupon the gangue mineral and useful mineral, preferably 300 to 400 rpm using a magnetic bar and distribute, in particular 340rmp carry preferably distribute. 300rmp when less than, dispersion does not uniformly, and then 400 rpm, air bubbles suspended without attaching door inner plate number point i.e., the selective number can not door is suspended. 10 to 50 ml per minute into a nitrogen gas into said flotation said by 2 minutes 10 minutes can be flotation. Said nitrogen gas into 10 ml per minute when less than 2 minutes, not flotation requests, 50 ml to greater than about 10 minutes when injecting, additional nitrogen gas composition already flotation environment since unnecessary disclosed. Hereinafter, with reference to the embodiment of the present invention preferred embodiment is for a person with skill in the art in the field of drawing objects to describe hereinafter to less than 1000. In addition, the present invention is connected to the publicly known or publicly known to operate are described specific description of related subject matter of invention can be decided to be a breach of the analogy described if a hole of the V-shaped. Certain features are described for ease of drawing and the number it became at the time of enlarges or contracts or is simplified and, at the proper ratios to drawing and component thereof shall have shown not disclosed. However one skilled will easily understand details such holes. Malachite and silica (in the embodiment 1) each flotation process and efficiency evaluation Each 1g and each contain different concentrations of PEG malachite and silica (5 × 10-5 To 5 × 10-2 ) Is placed stirring a Falcon Tube-gate. 9 placed in a silica such as malachite hallimond tube after said PEG adsorbed and also, to a service in a distributed magnetic bar, such as 10 to 30 ml per minute by flotation by injecting nitrogen gas also is injected into the 5 minutes, flotation efficiency was assessed. [Table 1] to flotation efficiency shown to result. The reference said result, said non-ionic polymer PEG when added, more than compensated by increased said malachite said PEG additive amount of floating diagram, said silica PEG continues even if the addition of a large amount does not increase the floating diagram can be confirmed. (In the embodiment 2) malachite and silica flotation process and efficiency evaluation in mixing system A malachite and silica based on the weight of mixture 1:1 0. 5g and each contain different concentrations of PEG (5 × 10-5 To 5 × 10-2 ) Is placed stirring a Falcon Tube-gate. 9 placed in a silica such as malachite hallimond tube after said PEG adsorbed and also, to a service in a distributed magnetic bar, such as 10 to 30 ml per minute by flotation by injecting nitrogen gas also is injected into the 5 minutes, flotation efficiency was assessed. [Table 2] have shown to result to flotation efficiency. 7 also results and said reference surface, said malachite independent increase said PEG is represented can be sure that the recovery is up. A small amount of the catcher including malachite and silica flotation process and efficiency evaluation number (in the embodiment 3) each Each 0. 5g each of silica and malachite number 1 × 10 to the catcher-10 To 1 × 10-6 M SO SO been present on a number of bulk been rapidly into and out of the stand-alone. Each 1g and each contain different concentrations of PEG adsorbed silica and said SO malachite (5 × 10-5 To 5 × 10-2 ) Is placed stirring a Falcon Tube-gate. 9 placed in a silica such as malachite hallimond tube after said PEG adsorbed and also, to a service in a distributed magnetic bar, such as 10 to 30 ml per minute by flotation by injecting nitrogen gas also is injected into the 5 minutes, flotation efficiency was assessed. [Table 3] have shown to result in flotation efficiency. 8 also results and said reference surface, upon addition of a small amount of SO (the catcher number), making sure that the malachite is selectively selected can be, in particular, 10-5 Upon the addition of SO M, amounts to almost 100% can be sure that the ratio of said malachite. Provided is a process of sorting a float of a copper oxide ore using non-ionic polymer without the use of activators and collecting agents which are harmful to humans and the environment. The process of sorting a float of a copper oxide ore using non-ionic polymer comprises: a step of manufacturing suspensions containing gangue minerals and useful minerals including copper respectively; a step of mixing the gangue minerals and the useful minerals with a solution having the non-ionic polymer in a chamber, and dispersing the mixture; a step of generating bubbles by injecting nitrogen gas into the chamber; and a step of selectively adsorbing the useful minerals in the bubbles. In addition, the process of sorting a float of a copper oxide ore using non-ionic polymer comprises: a step of manufacturing a suspension containing gangue minerals and useful minerals including copper; a step of mixing the gangue minerals and the useful minerals with a solution having the non-ionic polymer in the chamber, and dispersing the mixture; a step of generating bubbles by injecting nitrogen gas into the chamber; and a step of selectively adsorbing the useful minerals in the bubble. COPYRIGHT KIPO 2017 gangue mineral and copper respectively comprising the step number tank useful mineral suspension; non-ionic polymer is present gangue mineral solution including said chamber and respectively into said mixed suspension useful mineral after dispersing step; said bubble generating nitrogen gas to the injection chamber; and said selectively adsorbing the air bubbles which useful mineral, said air bubbles (depletion power) characterized by selective adsorption is useful mineral polyurethane integral force non-ceramic dielectric composite light using polymer flotation process. gangue mineral and copper containing useful mineral suspension including the step number bath; non-ionic polymer is present and said chamber containing said solution including gangue mineral after dispersing step into useful mineral suspension mixed; said bubble generating nitrogen gas to the injection chamber; and said selectively adsorbing the air bubbles which useful mineral, said air bubbles (depletion power) characterized by selective adsorption is useful mineral polyurethane integral force non-ceramic dielectric composite light using polymer flotation process. gangue mineral and copper each comprising respectively the catcher number into and out of the useful mineral agitating; it agitated solution present on the catcher number industry a number bulk forming said step; said catcher number gangue mineral and copper containing wastes including surface useful mineral suspension step number bath; non-ionic polymer is present and said suspension into said chamber including a solution containing mixed gangue mineral useful mineral after dispersing step; said bubble generating nitrogen gas to the injection chamber; and said selectively adsorbing the useful mineral which air bubbles, said air bubbles (depletion power) characterized by selective adsorption is useful mineral polyurethane integral force non-ceramic dielectric composite light using polymer flotation process. According to one of Claim 1 to Claim 3, characterized in that said nonionic polymer (Polyethylene glycol) PEG using non-ceramic dielectric composite light using polymer flotation process. According to Claim 1, the steps for creating said suspension, said each 100 parts by weight of said nonionic polymer 5 × 10 each gangue mineral and useful mineral-5 To 5 × 10-2 With concave parts by weight of a non-ceramic dielectric composite light characterized using polymer flotation process. According to Claim 2, the steps for creating said suspension, said gangue mineral and useful minerals 50 parts by weight of said nonionic polymer based on the weight of mixture 1:1 5 × 10-5 To 5 × 10-2 With concave parts by weight of a non-ceramic dielectric composite light characterized using polymer flotation process. According to Claim 3, said agitating step number gangue mineral and useful mineral and the catcher, said each said catcher 50 parts by number 1 × 10 useful with gangue mineral mineral-10 To 1 × 10-6 With concave M characterized using polymer ceramic dielectric composite light non-flotation process. According to Claim 3, the steps for creating said suspension, said catcher 100 parts by weight of said nonionic polymer 5 × 10 each on each number it agitated gangue mineral and useful mineral-5 To 5 × 10-2 With concave parts by weight of a non-ceramic dielectric composite light characterized using polymer flotation process. According to one of Claim 1 to Claim 3, said chamber is provided to generate nitrogen gas to the injection step, said 10 to 50 ml per minute to about 10 minutes 2 by nitrogen gas into the flotation using polymer ceramic dielectric composite light characterized non-ionic flotation process. Amount (wt %) PEG 0 5 × 10-5 5 × 10-4 5 × 10-3 5 × 10-2 Malachite (%) also floating 13. 85 22. 36 54. 51 75. 84 79. 95 Silica also (%) floating 0. 84 1. 29 3. 93 9. 61 8. 4 Amount (wt %) PEG 0 5 × 10-5 5 × 10-4 5 × 10-3 5 × 10-2 Malachite recovery (%) 25. 49 24. 89 55. 56 73. 28 79. 49 Silica recovery (%) 1. 44 1. 68 4. 28 7. 74 11. 65 Add-on greater than PEG 5 × 10-3 An add-on SO 10-10 M 10-9 M 10-8 M 10-7 M 10-6 M 10-5 M Malachite recovery (%) 83. 47 83. 19 82. 37 85. 54 87. 75 98. 55 Silica recovery (%) 7. 7 17. 55 29. 17 25. 48 21. 32 22. 71