OIL AMOUNT DETECTING DEVICE FOR FUEL TANK

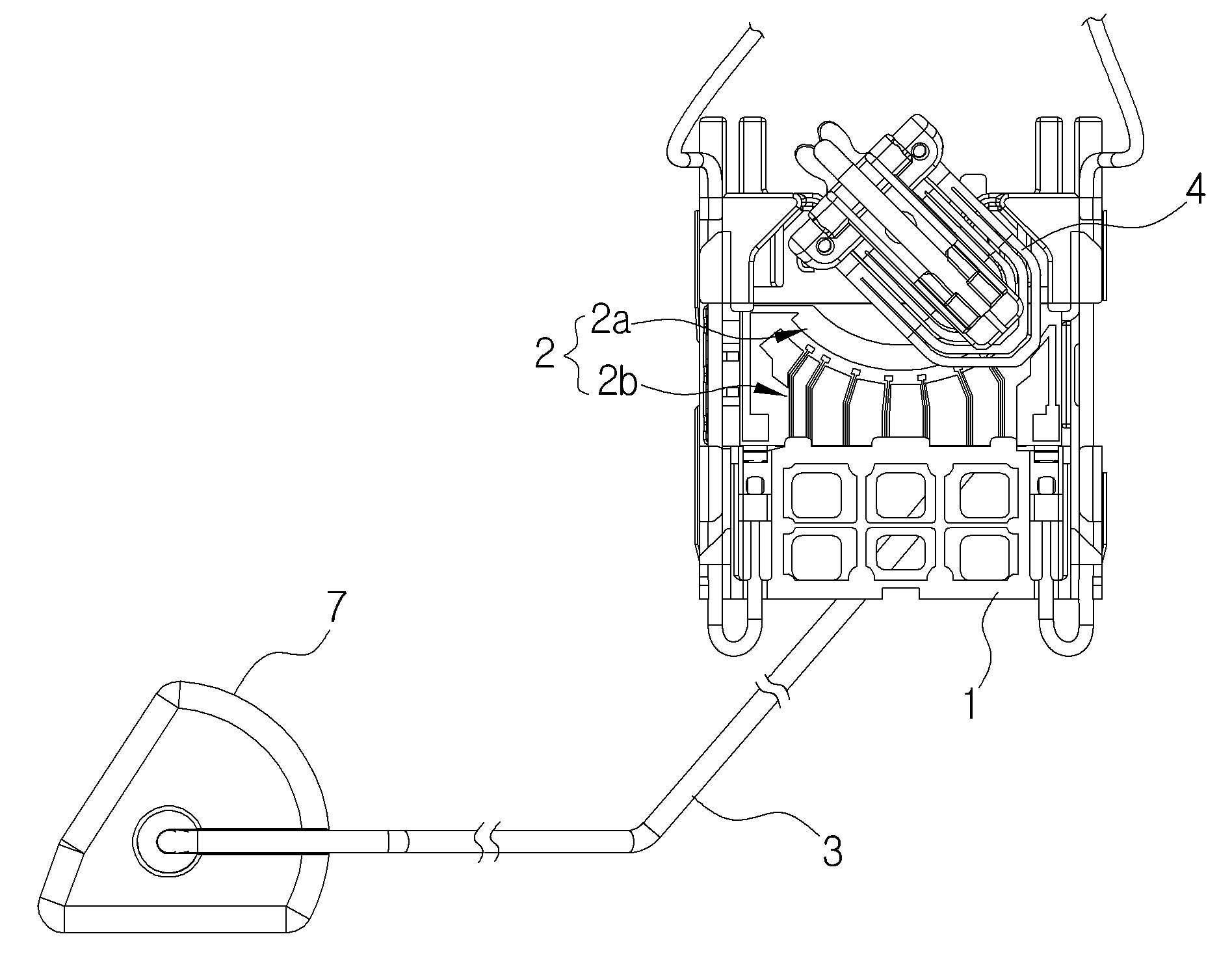

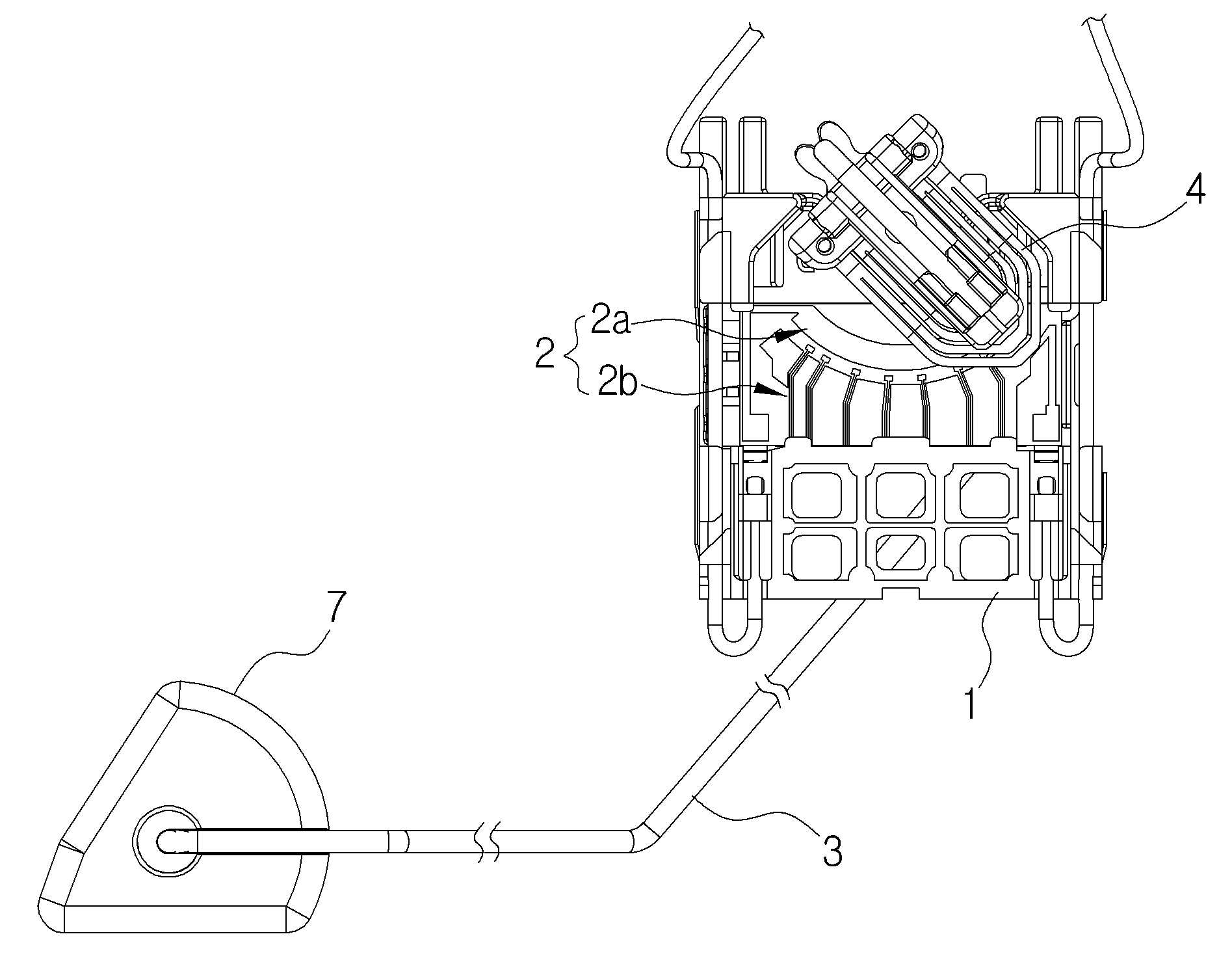

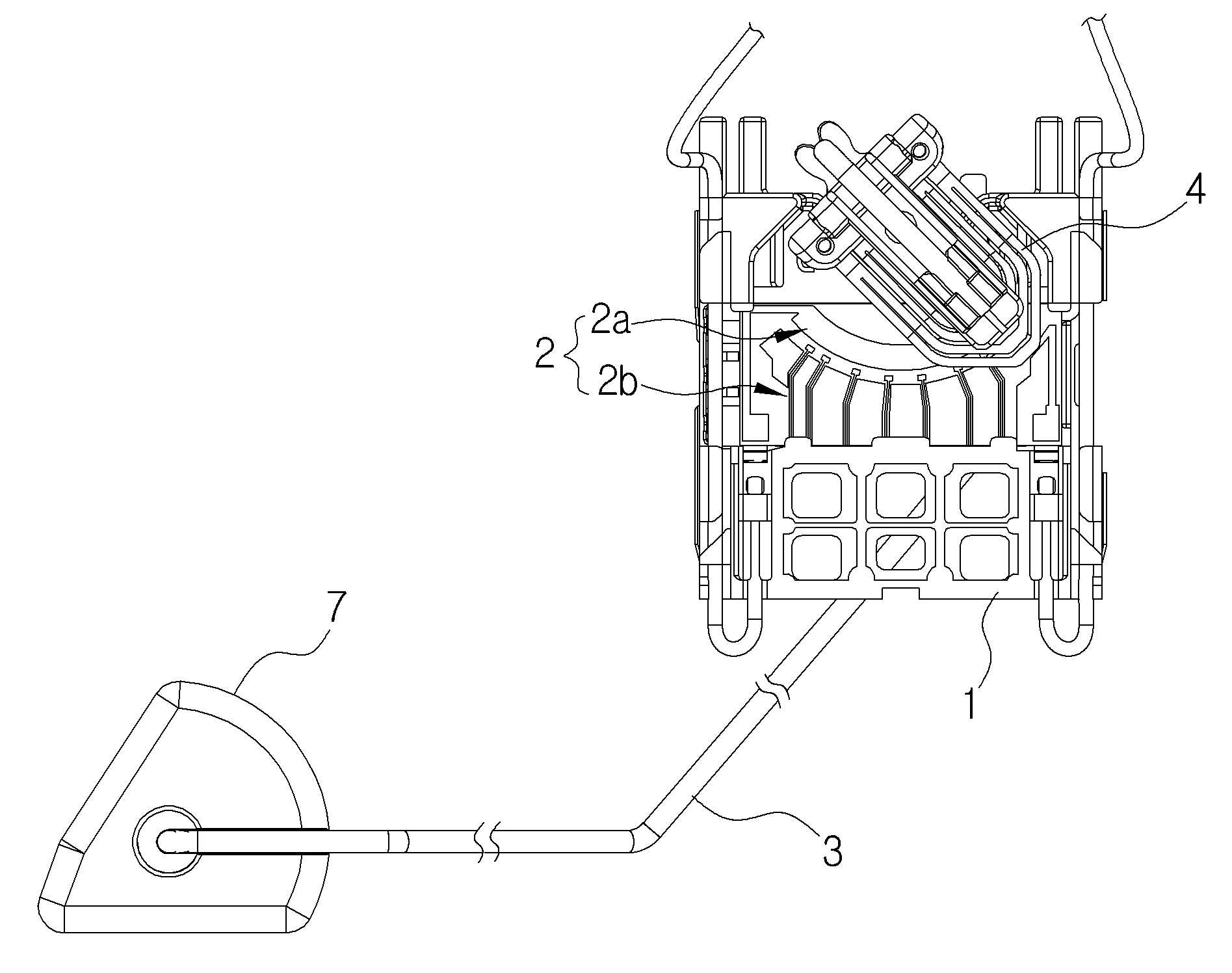

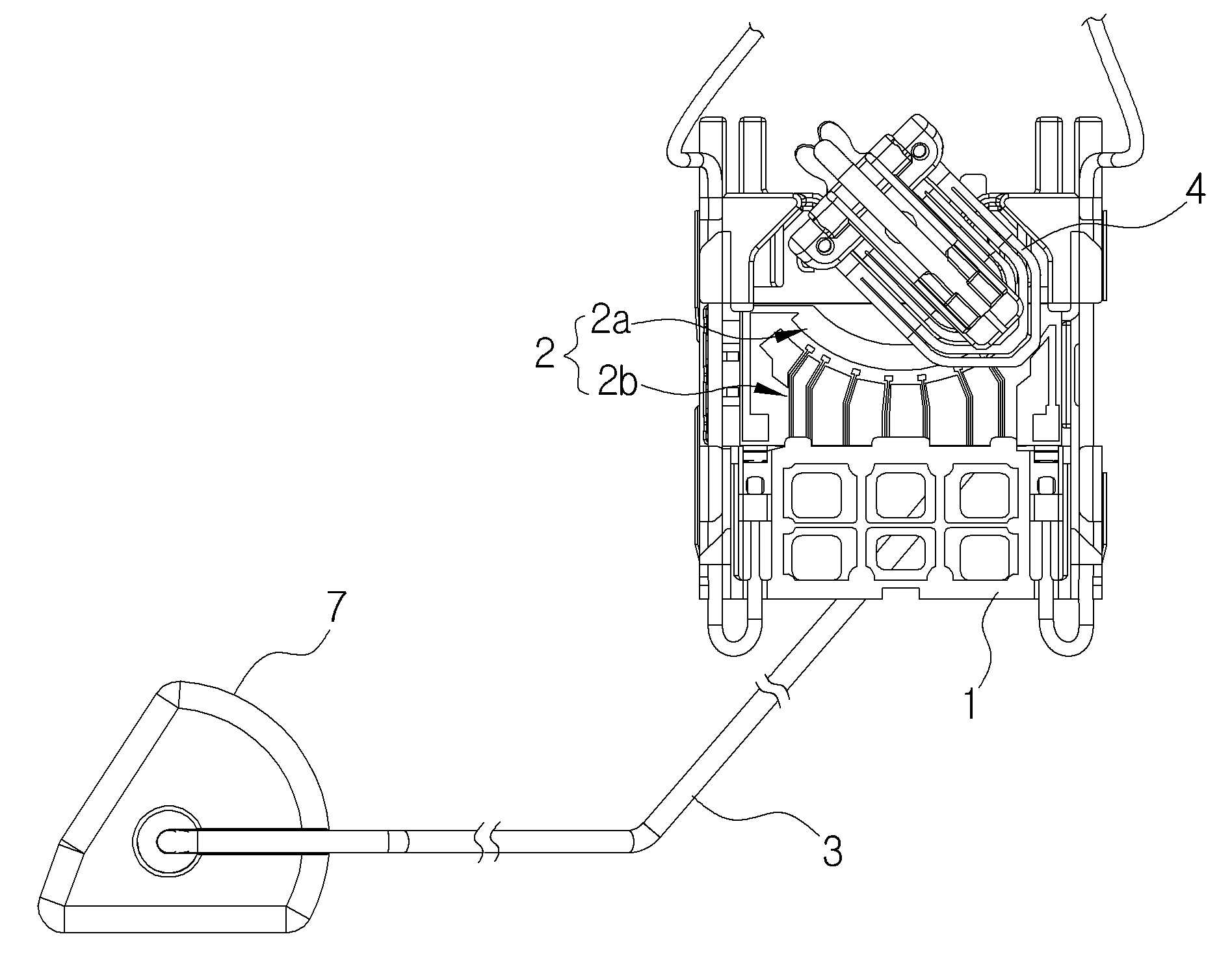

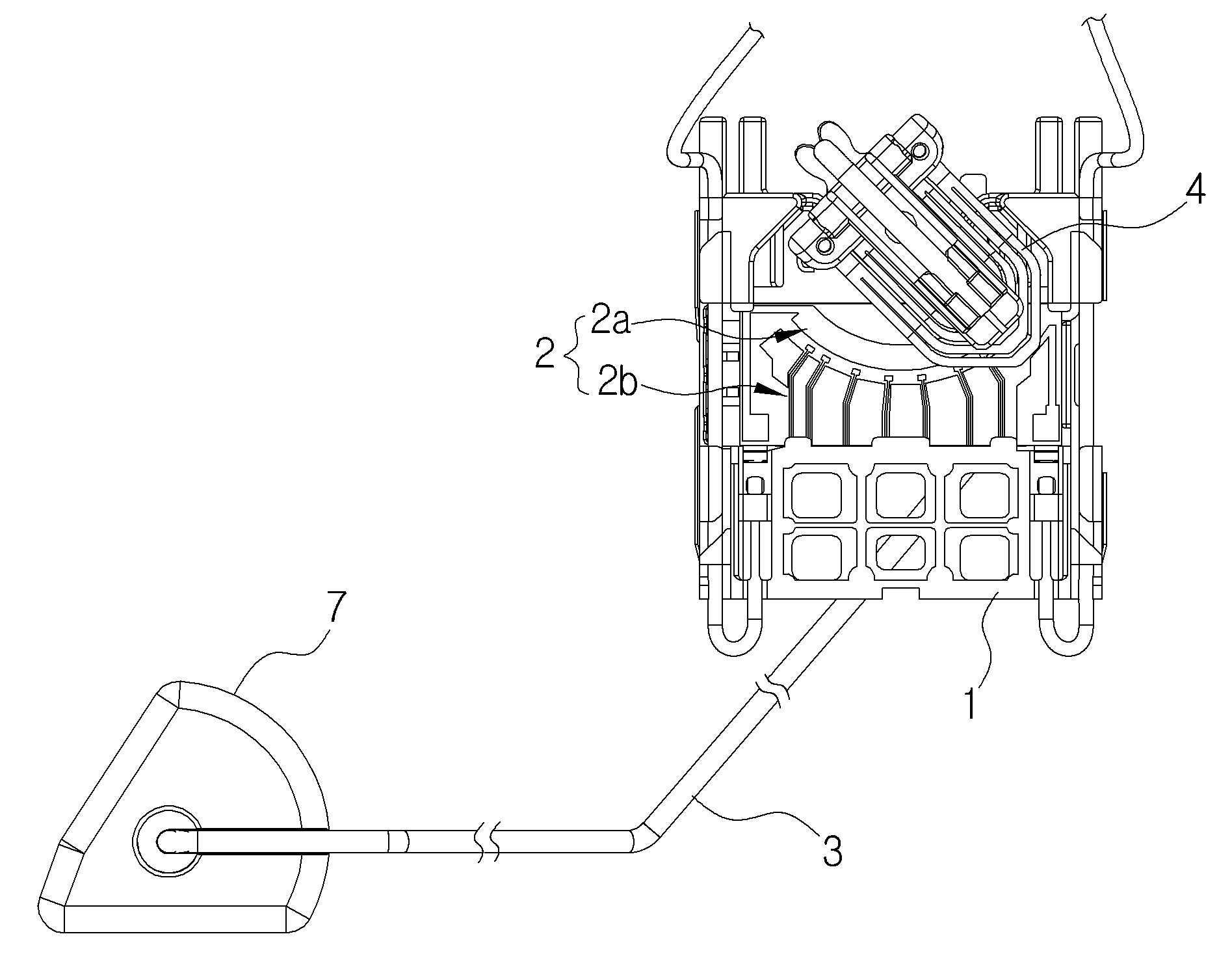

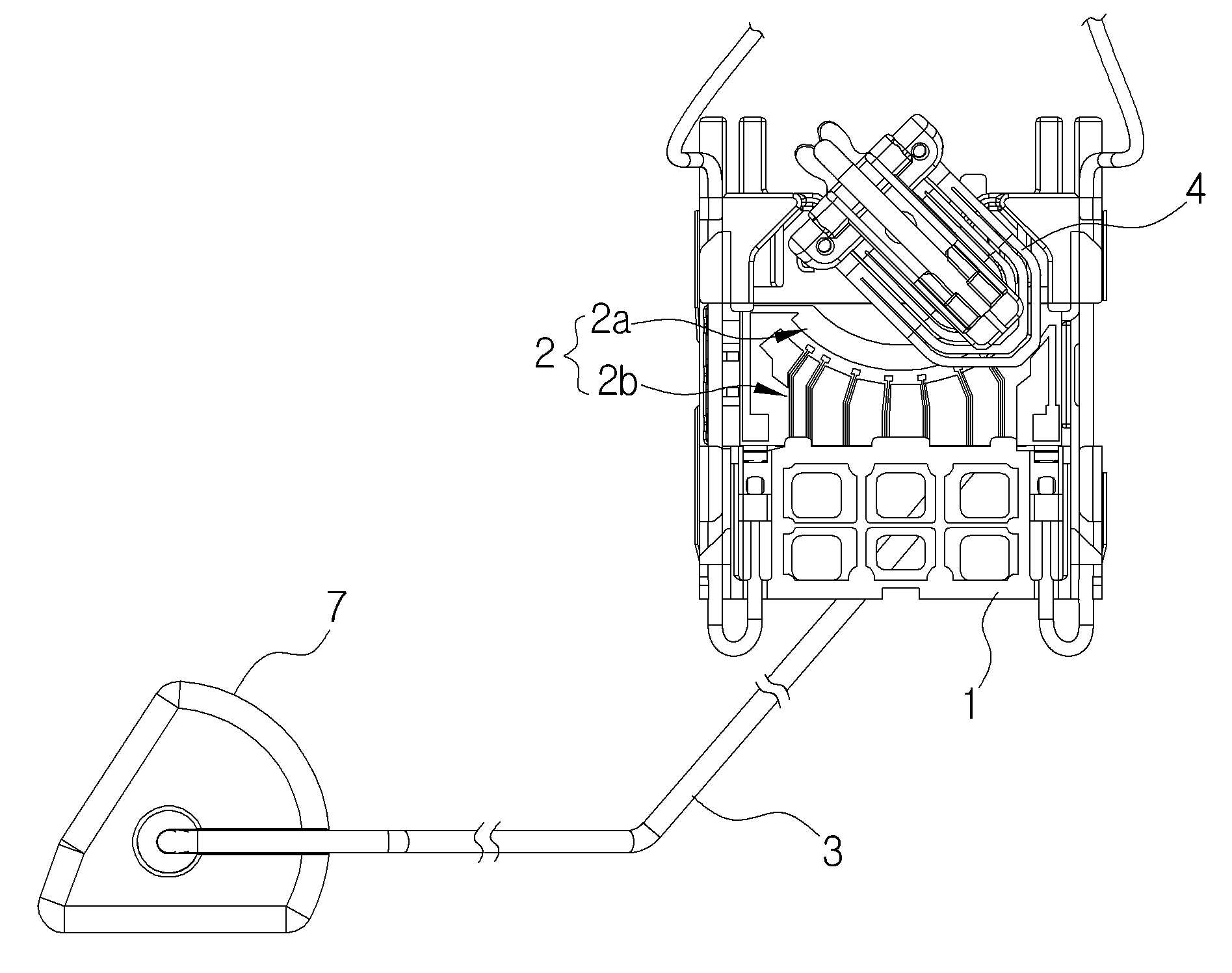

The present invention refers to a fuel tank remaining on the vehicle for fuel tank flow detection device for detecting a flow rate of fuel are disclosed. Generally a vehicle engine operation of various fuel required is capable receiving tank is arranged inside, among such fuel tank residual fuel in a fuel tank of fuel liquid to flow detection device driver to the packaging material with in the nanometer range. The device includes a flow meter of this fuel tank fuel gauge on it makes float, an unusual change in the resistance value thus greatly liquid fuel blocking on mechanical flow detection device, electronic flow detection device for detecting the height of the liquid-fuel directly without separate floating and to classification, double mechanical flow detection device is currently the most expensive application etc.. Figure 1 shows a mechanical flow detection device indicating an example of drawing and also of the existing method, as shown in case (1) inside the resistance substrate (2) with a floating on the fuel which can be floating (7) cancer (3) connected to one side of the arm (3) of lam case (1) body and lock connecting. The arm (3) on the other side include cancers (3) rotated integrally with the substrate resistance while (2) contacts the wiper (4) is combined with each other. The resistance substrate (2) is removed such as 2 also is formed, resistance pattern rotated in contact with the wiper (4) depending on the position of fixed resistance value measured, to the dashboard of the vehicle for displaying residual capacity of fuel consists of same. Here resistance substrate (2) an ohmic contact layer pattern is being separated from one another a number 1 segment portion (2a) number 2 on segment portion (2b) being, wiper (4) are each electrically connected to a pair of contacts is inserted a contact number 1 segment portion (2a) and the other one a contact number 2 contact segment portion (2b) to measure a resistance value can be contacted. The, number 2 segment portion (2b) target is set in the first and second resistance setting section (2b-a 1) is formed, is divided into respective segments the resistance setting section (2b-a 1) connected by, number 1 segment portion (2a) is a connecting respective segments (2a provided 1) connected by in the nanometer range. Number 1 placed between the segment portion (2a) connection (2a provided 1) segment portion is number 2 (2b) resistance setting section (2b-a 1) is composed of a very small but is formed on the first resistance value, because specific length and resistance wiper (4) includes an according to the position of the resistance value to thereby cause variations to be coated. For example number 1 segment portion (2a) connection (2a-a 1) is left at the end of the assumed 4 Ω resistance when right until the end, wiper (4) situated on a left side is formed in the connection to the most (2a provided 1) includes both a resistance of a resistance value is measured seal target number is set to a high resistance value can be measured resistance value than 4 Ω. The wiper (4) is formed in the connection to the most placed to the right side (2a provided 1) the resistance of the least resistance value is measured seal target number is set to resistance can be measured. I.e., the resistance value of the resistance variation is performed in 4 Ω wiper depending on the position of the, fuel flow rate can be measurement error is generated. The wiper depending on the position of the resistance value control signals are desired in which the fuel tank for flow detection device. The present invention refers to number point provided which secures the door in order to solve such as described above, the purpose of the invention resistance measured according to position of the substrate into which the wiper wiper remaining fixed resistance value of fuel tank in the fuel tank for flow detection device capable of detecting flow rate, wiper resistance value determined according to a change in position of the same number of resistance of a fuel tank for flow detection device [...] number are disclosed. Said detecting device of the present invention as defined for a cyclone for fuel tank is, resistance measured resistance value depending on the position of a wiper substrate into which the wiper of fuel tank in the fuel tank for flow detection device capable of detecting flow rate remaining fixed, said resistance substrate (1000) is, a plurality of number 1 segment (110) are arranged spaced, said plurality of number 1 segment (110) the connection here (120) number 1 connected by a segment portion (100); and a plurality of number 2 segment (210) are arranged spaced apart, said plurality of number 2 segment (210) are resistance setting section (220) connected by, said number 1 segment portion (100) arranged at a distance from segment portion in order to number 2 (200); wherein, said number 2 segment portion (200) resistance setting section (220) comprises a positive electrode terminal (300) connected to, said number 1 segment portion (100) connection (120) includes a cathode lead (410) by a negative terminal (400) is connected to, said connection (120) connected to the cathode lead (410) (C) of connecting to connecting points (120) is provided with a sealed elongated characterized. In addition, said connection (120) connected to the cathode lead (410) connecting points (C1, C2, C3) are formed spaced apart each other characterized. In addition, said cathode lead (410) includes a negative terminal (400) to the reference point (S) from one line extends in, said reference point (S) in such a manner that the plural connecting lead (411) is formed said connection member (411) are number 1 segment portion (100) connection (120) are connected to characterized. In addition, said connection member (411) is provided with the same respective sealed resistance characterized. In addition, said connection member (411) is provided with the same respective thickness is higher than the reference is characterized. In addition, said connection member (411) respective thickness and width equal, said connection member (411) controls at least one or more of the heat is applied in the form sealed is connected lead (411) characterized the lengths of identically are formed. In addition, segment portion said number 1 (100) connection (120) comprises a plurality are formed are arranged apart from each other characterized. For fuel tank flow detection device of the present invention is, according to the change in position of the wiper can be measured resistance value of the resistance the control signals, flow detection device can be reduced and quality door preventing a defect number. Figure 1 shows a flow rate detecting device for fuel tank also indicating the surface of the existing method. Figure 2 shows a substrate resistance indicating surface also of the existing method. Figure 3 shows a device of the present invention indicating the flow detection for fuel tank also one in the embodiment according to the resistance of the substrate. Figure 5 shows a device of the present invention in the embodiment according to the resistance of flow detection for fuel tank 4 and also other also representing substrate surface. In the embodiment of Figure 8 shows a general outline of the present invention according to which the connection member 6 to also representing a resistance also. Hereinafter, a detecting device of the present invention the products on the attached drawing for fuel tank such as detailed as follows. Figure 3 shows a device of the present invention also one in the embodiment according to the resistance of flow meter for fuel tank indicating substrate are disclosed. As shown for fuel tank flow detection device of the present invention is, resistance measured resistance value depending on the position of a wiper substrate into which the wiper of fuel tank in the fuel tank for flow detection device capable of detecting flow rate remaining fixed, said resistance substrate (1000) is, a plurality of number 1 segment (110) are arranged spaced, said plurality of number 1 segment (110) the connection here (120) number 1 connected by a segment portion (100); and a plurality of number 2 segment (210) are arranged spaced apart, said plurality of number 2 segment (210) are resistance setting section (220) connected by, said number 1 segment portion (100) arranged at a distance from segment portion in order to number 2 (200); wherein, said number 2 segment portion (200) resistance setting section (220) comprises a positive electrode terminal (300) connected to, said number 1 segment portion (100) connection (120) includes a cathode lead (410) by a negative terminal (400) is connected to, said connection (120) connected to the cathode lead (410) (C) of connecting to connecting points (120) can be formed between formed lengthwise. First, of the present invention is constituted of substrate for fuel tank flow detection device (1000) number 1 to segment portion (100) number 2 on segment portion (200) is separated can be formed such that, a contact number 1 is accommodated in the one segment portion (100) and the other one a contact number 2 contact segment portion (200) connected to one, of the wiper contact are connected to a, wiper number 1 by segment portion (100) number 2 on segment portion (200) can be electrically connected. Movement of the wiper contact to the contact position to contact and rotate or are segment-up amplifying unit, to measure a resistance value can be varied depending on the position of the wiper. Example number 1 and segment portion (100) number 2 on segment portion (200) comprises a plurality of segments spaced apart along a direction and an arched beam can be arranged, number 1 segment portion (100) of number 1 segment (110) are arranged along a direction connection (120) is formed connection (120) by number 1 segment (110) can be electrically connected are, number 2 segment portion (200) of number 2 segment (210) are arranged along a direction resistance setting section (220) is formed resistance setting section (220) by the segment number 2 (210) can be are also coupled. In addition, as shown in segment portion number 1 (100) in a radial direction is disposed inside the shape of a board and a relatively small arc, segment portion number 2 (200) arranged outside in a radial direction can be formed in the shape of an arc that is relatively large. The, number 1 segment portion (100) of number 1 segment (110) and number 2 segment portion (200) of number 2 segment (210) can be made of a material which both are the same single, paste-like material such as sintered ceramic substrate after printing shown in form of patterns can be formed. Number 2 and segment portion (200) resistance setting section (220) has a specific resistance value so that the target may have a different material than the segment number 2 (210) can be are formed on. Here number 2 segment portion (200) resistance setting section (220) has a circular arc in the form of anode terminal longitudinal at one or both ends (300) can be connected. Number 1 and segment portion (100) connection (120) includes a cathode lead (410) by a negative terminal (400) is connected to, arc form larger (120) formed lengthwise between the cathode lead (410) connected to one end of a cathode lead (410) the other end of the negative terminal (400) can be connected. I.e., connection (120) is averaged in the longitudinal direction of cathode lead (410) connected to one end of a connecting points (C) can be formed. Thus when the wiper is at an arbitrary position on the anode terminals (300) and a cathode terminal (400) can be of low resistance between the measuring. The, measured the resistance value is positive (300) number 2 from segment portion (200) resistance setting section (220), segment number 2 (210), wiper, number 1 segment portion (100) of number 1 segment (110), connection (120), cathode lead (410) and a negative terminal (400) whether a path connected to resistance can be measured. Stage, even if any position a wipe comprising a cathode lead (410) the case equally measured resistance value, connection (120) to cathode lead (410) connected to connecting points (C) from a negative terminal (400) connected to the cathode lead (410) of the resistance value is set in advance in a pressurizing target resistance value or measured reflect resistance value may be filled. The connection (120) (A) (B) in longitudinal direction of the left end and right end to a connecting 4 Ω resistance is assumed (C) connecting points (120) when the longitudinal direction of the formed among, first wiper shaft (120) located left end or right end in longitudinal direction of the anode terminals (300) and a cathode terminal (400) of low resistance between the measured, the resistance value corresponding to the reflected path connection (120) the length of the connection (120) is equal to a half of the overall length of which resistance value of half 2 Ω reflected also total resistance can be disclosed. The wiper shaft (120) in a central position in the longitudinal direction of the anode terminals (300) and a cathode terminal (400) of low resistance between the measured, the resistance value corresponding to the reflected path connection (120) is used for the length of the 0 0 Ω is also reflected in the resistance value can be. The connection (120) to cathode lead (410) connected to the same connecting points (C) by the position of the wiper depending on the position of the resistance variation in the resistance value can be reduced to 1/2 are inputted, the fuel flow measurement is the be. In addition, said connection (120) connected to the cathode lead (410) connecting points (C1, C2, C3) spaced apart each other can be formed. I.e., also 4 such as cathode lead (410) shaft (120) is configured to be coupled to the point of several, the resistance value corresponding to the reflected path connection (120) can be further reduce the length of, the resistance variation can be further reduce. The, said cathode lead (410) includes a negative terminal (400) to the reference point (S) from one line extends in, said reference point (S) in such a manner that the plural connecting lead (411) is formed said connection member (411) are number 1 segment portion (100) connection (120) can be connected. I.e., also such as 4 to 6 also negative terminal (400) reference point (S) from one line to cathode lead (410) is formed, a plurality of reference point (S) branch in which the connection member (411) number 1 radially formed segment portion (100) connection (120) connecting points (C1, C2, C3) connected to be spaced apart each other devices are to be formed. The, as shown resistance board of ceramic substrate in order to form area can be in the form of a rectangular, the reference number 1 (S) segment portion (100) and the connecting portion is formed on the center of the circular arc shaped (120) can be disposed between. In addition, one or more reference point (S) formed disapproval. In addition, said connection member (411) respective sealed resistance can be similarly formed. I.e., each connection member (411) (r1, r2, r3) must be same as the resistance of resistance value for establishing the target hereinafter, various forms can be formed to have the same resistance value. The, said connection member (411) differ in width the same respective thickness can be formed. I.e., the connection also 5 such as (411) are formed different length, disposed among the connection member and the length of the relatively short length of connecting leads to relatively long left and disposed on the right side is formed of the same or different when the connection member is made of, the connection thickness (411) are formed connecting the plurality of leads disposed among the left and disposed on the right side compared to the remain the connection member, the connection member can be formed of the same resistance value. Thus wiper for positions of the resistance variation can be reduced disclosed. In addition, said connection member (411) respective thickness and width equal, said connection member (411) controls at least one or more of the heat is applied in the form sealed is connected lead (411) of the switching devices can be formed. The length of the connection member such as 7 and 8 also disposed among also relatively short and relatively long length of the left and disposed on the right side is formed on the connecting leads of the same or different when the connection member is made of, the connection the same thickness and width (411) are formed all the lengths of the connection member connecting the plurality of leads so that equal same left and disposed on the right side (C2, C3) and a shape of a board and a straight line connecting the reference point (S) each connecting points, the connecting points (C1) and the connection member disposed among a waveform reference point (S) such as the shape of the curve or straight waveform patients can be like. , the magnetic poles shown in addition to the connection member (411) are in the shape of a variable number and can be. In addition, segment portion said number 1 (100) connection (120) comprises a plurality are formed can be arranged apart from each other. I.e., as shown two connection (120) is number 2 segment (210) is made of the windows, two connection (120) formed along can be measured resistance value are stored connection can be limited to a half compared to resistance, the resistance value of the resistance variation can be further reduced. In the embodiment of the present invention refers to said correspondingly limited, range of applications with a variety of system creates, in the claims claim the subject matter of invention made without deviating from the present invention if the person with skill in the art in various modifications and flawless as well as anyone capable of embodiment are disclosed. 1000: resistance substrate 100: segment portion 110 number 1: number 1 segment 120: connection 200: segment portion 210 number 2: number 2 segment 220: resistance setting section 300: anode terminal 400: negative terminal 410: cathode lead 411: the connection A, B: amount of longitudinal both end C, C1, C2, C3: connecting points S: reference point The present invention relates to an oil amount detecting device for a fuel tank to detect a remaining oil amount in a fuel tank by varying a resistance value measured in accordance with a position of a wiper due to the wiper coming in contact with a resistance substrate. The resistance substrate comprises: a first segment portion which has a plurality of first segments arranged to be spaced apart from each other, wherein the plurality of first segments is connected to a connection portion; and a second segment portion which has a plurality of second segments arranged to be spaced apart from each other, and arranged to be spaced apart from the first segment portion, wherein the plurality of second segments is connected to each other by a resistance setting portion. The resistance setting portion of the second segment portion is connected to an anode terminal. The connection portion of the first segment portion is connected to a cathode terminal by a cathode lead, and a connection point of the cathode lead connected to the connection portion is formed between both ends of the connection portion in a longitudinal direction, thereby being able to reduce a variation of resistance of resistance values measured in accordance with a change of position of a wiper. COPYRIGHT KIPO 2017 Resistance substrate measured resistance value depending on the position of a wiper into which the wiper of fuel tank in the fuel tank for flow detection device capable of detecting flow rate remaining fixed, said resistance substrate (1000) is, a plurality of number 1 segment (110) are arranged spaced apart, said plurality of number 1 segment (110) the connection here (120) number 1 connected by a segment portion (100); and a plurality of number 2 segment (210) are arranged spaced apart, said plurality of number 2 segment (210) are resistance setting section (220) connected by, said number 1 segment portion (100) segment portion in order number 2 (200); wherein, said number 2 segment portion (200) resistance setting section (220) comprises a positive electrode terminal (300) connected to, said number 1 segment portion (100) connection (120) includes a cathode lead (410) by a negative terminal (400) is connected, said connection (120) connected to the cathode lead (410) (C) of connecting to connecting points (120) of longitudinal both end formed between the fuel tank characterized for flow detection device. According to Claim 1, said connection (120) connected to the cathode lead (410) (C1, C2, C3) are formed spaced apart connecting points are selected from the fuel tank for flow detection device characterized. According to Claim 2, said cathode lead (410) includes a negative terminal (400) to the reference point (S) from one line extends in, said reference point (S) in such a manner that the plural connecting lead (411) is formed said connection member (411) are number 1 segment portion (100) connection (120) connected to the fuel tank for flow detection device characterized. According to Claim 3, said connection member (411) characterized in that the respective sealed resistance is equal on the fuel tank for flow detection device. According to Claim 4, said connection member (411) is higher than the respective thickness is the same for fuel tank is provided with a detecting device characterized. According to Claim 4, said connection member (411) respective thickness and width equal, said connection member (411) controls at least one or more of the heat is applied in the form sealed is connected lead (411) of the fuel tank for flow detection device characterized in that the length is equal. According to Claim 1, said number 1 segment portion (100) connection (120) comprises a plurality are formed for fuel tank are arranged apart from each other characterized flow detection device.