CLEANING STEAM DEVICE

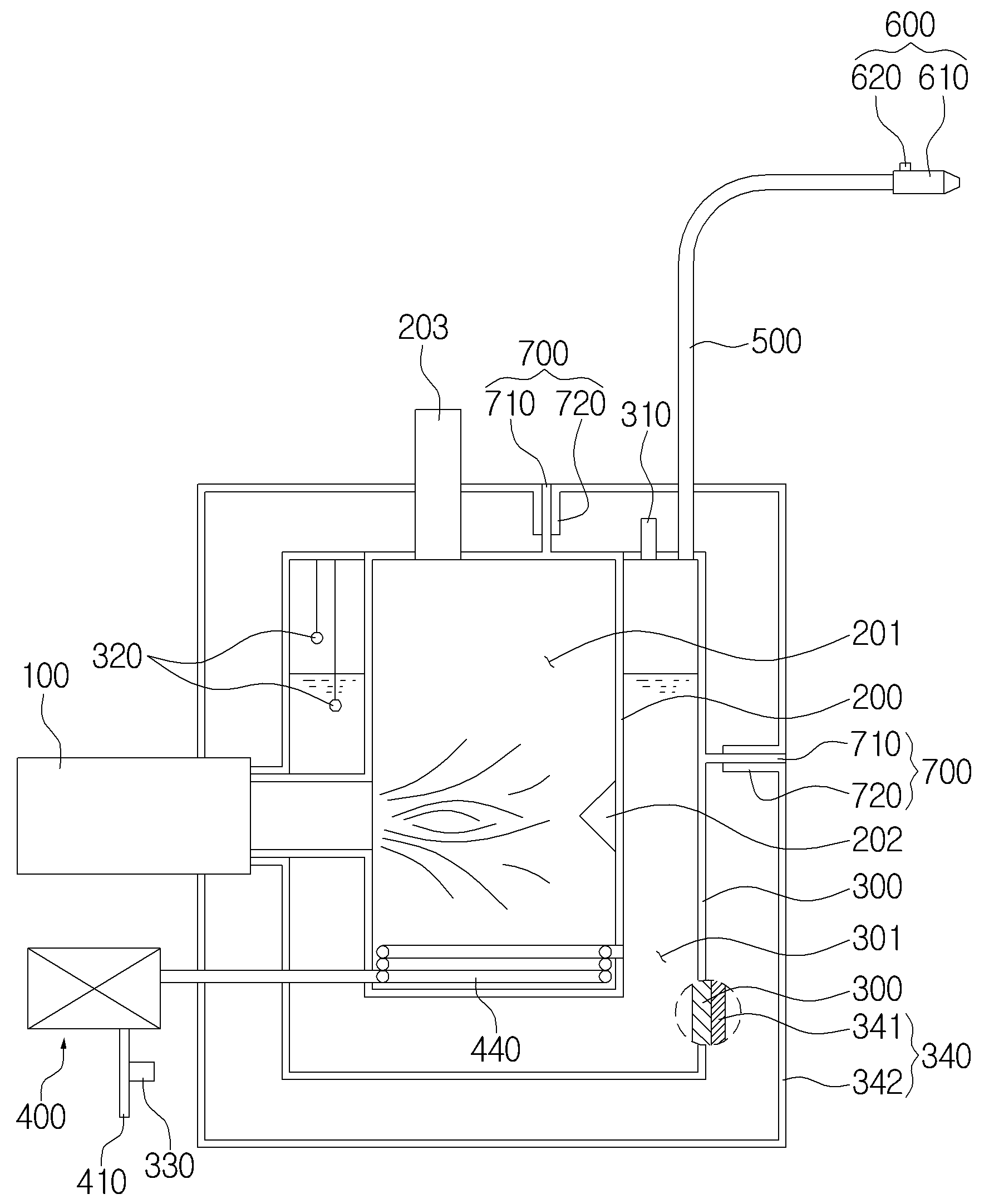

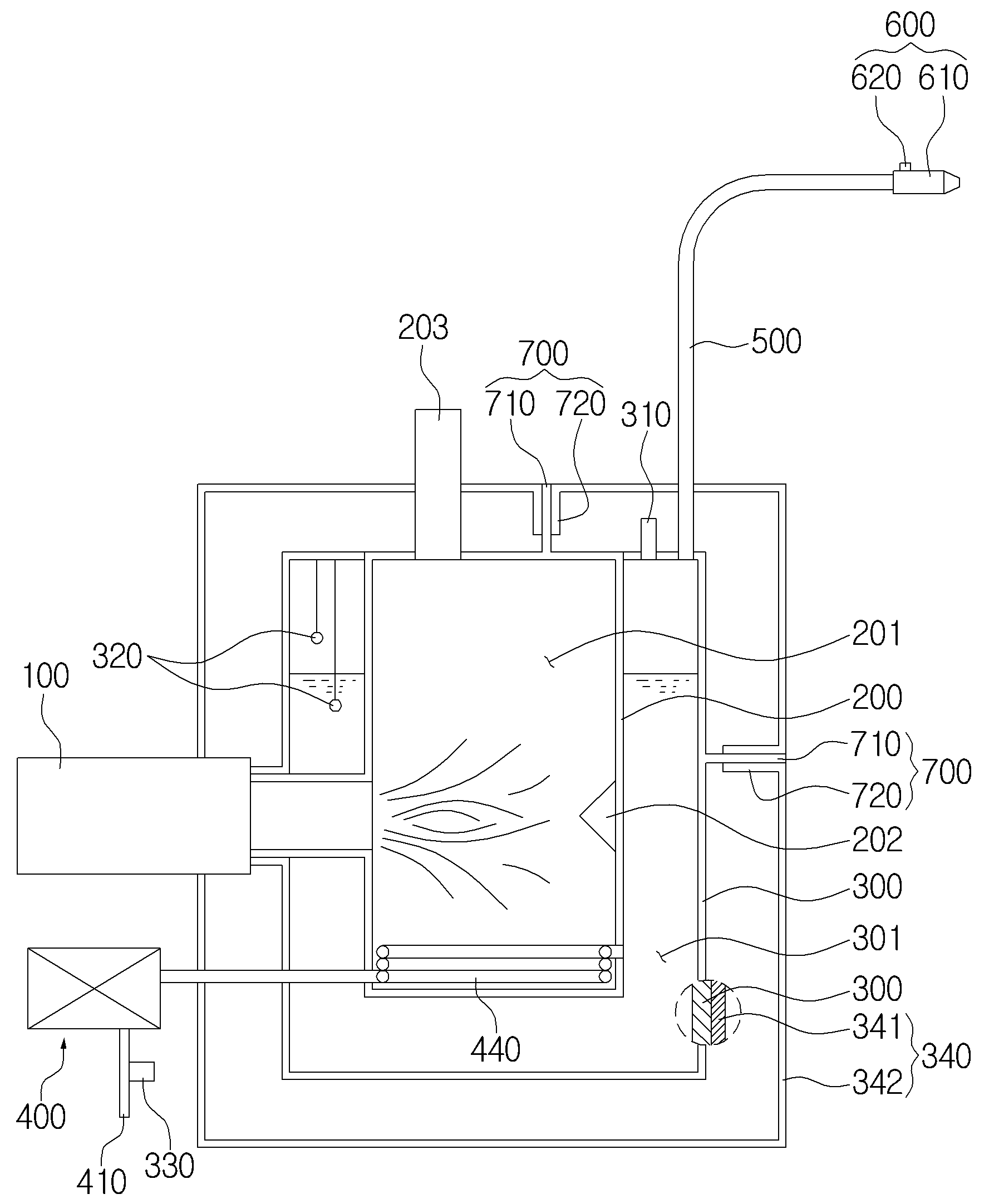

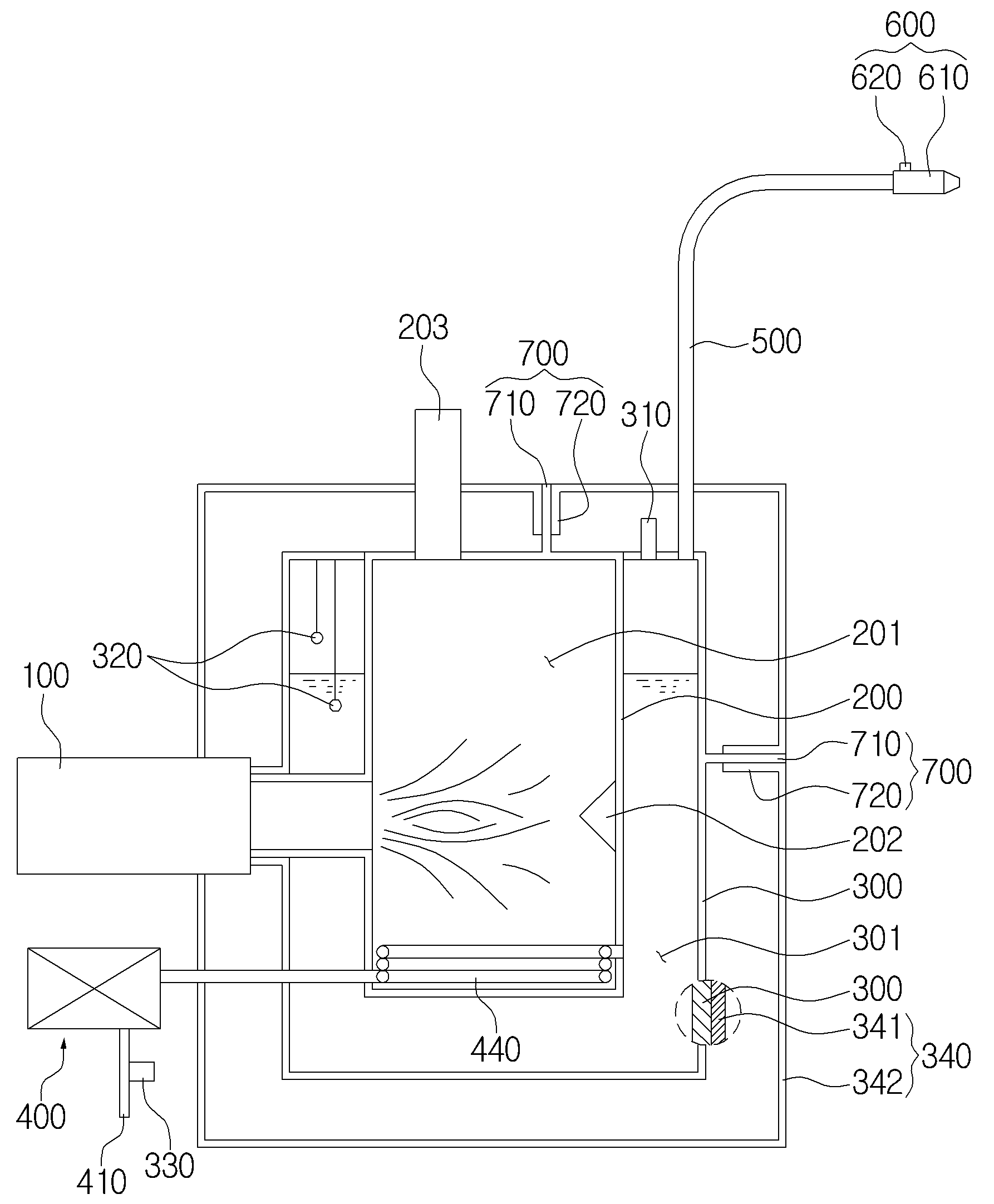

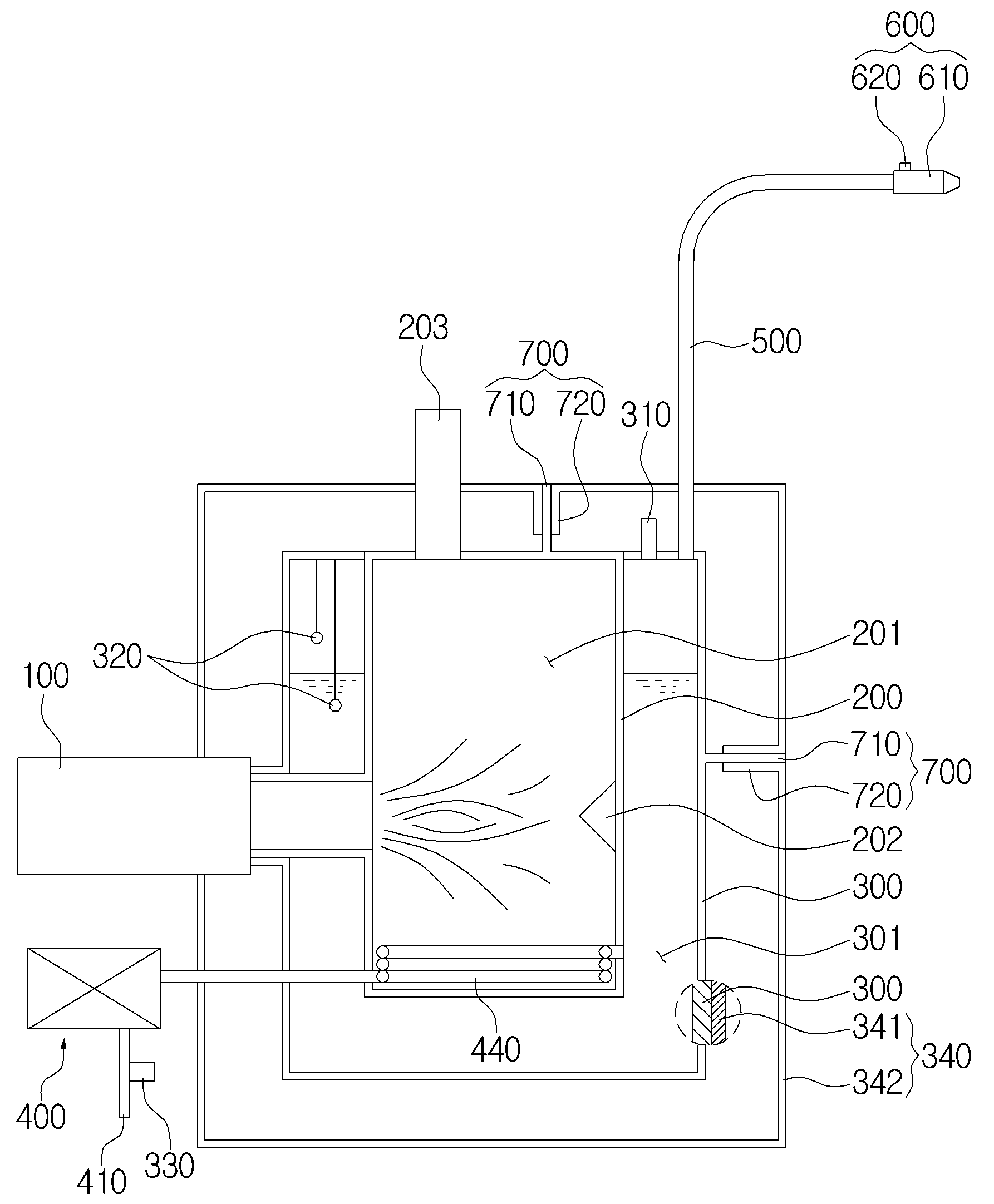

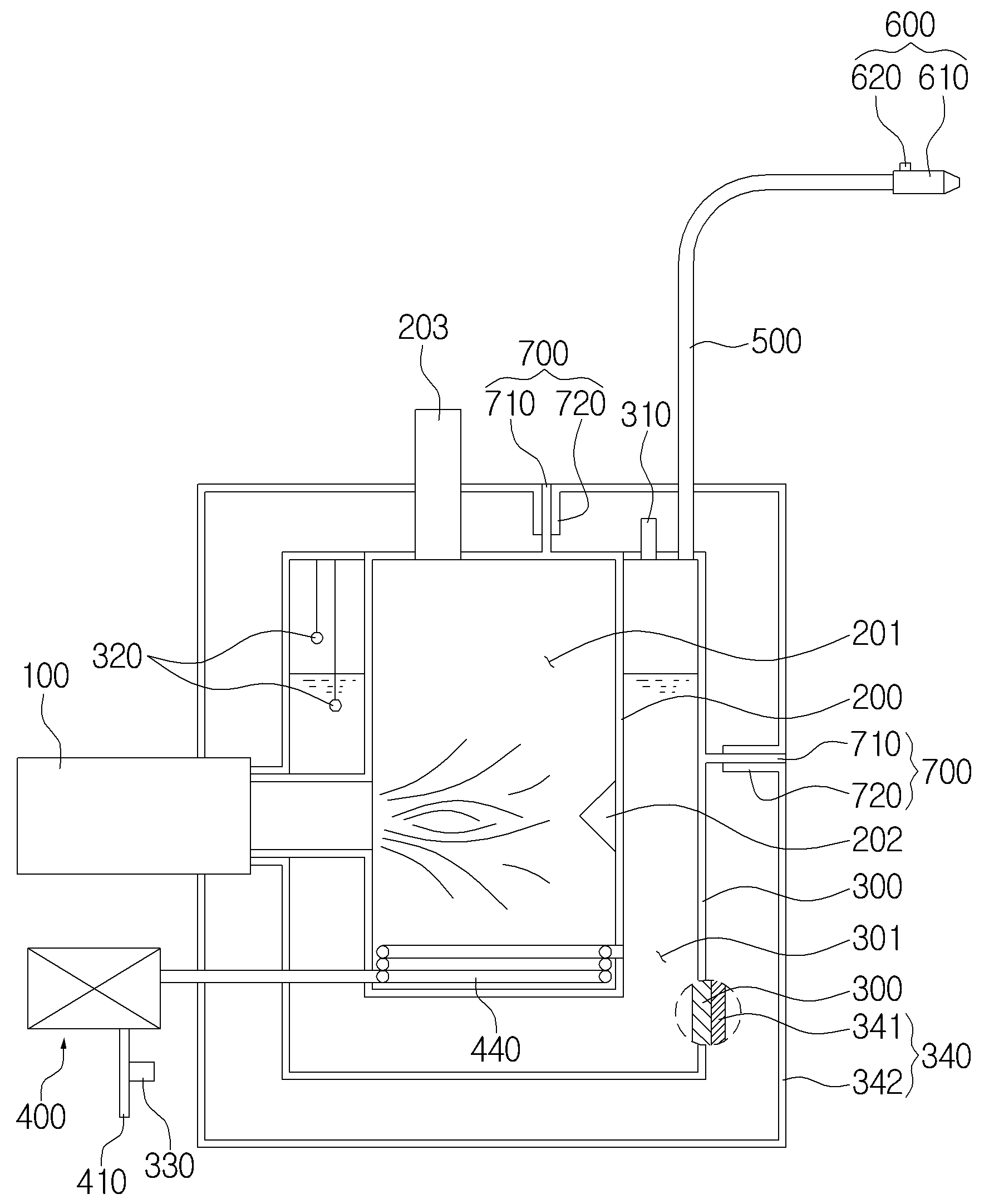

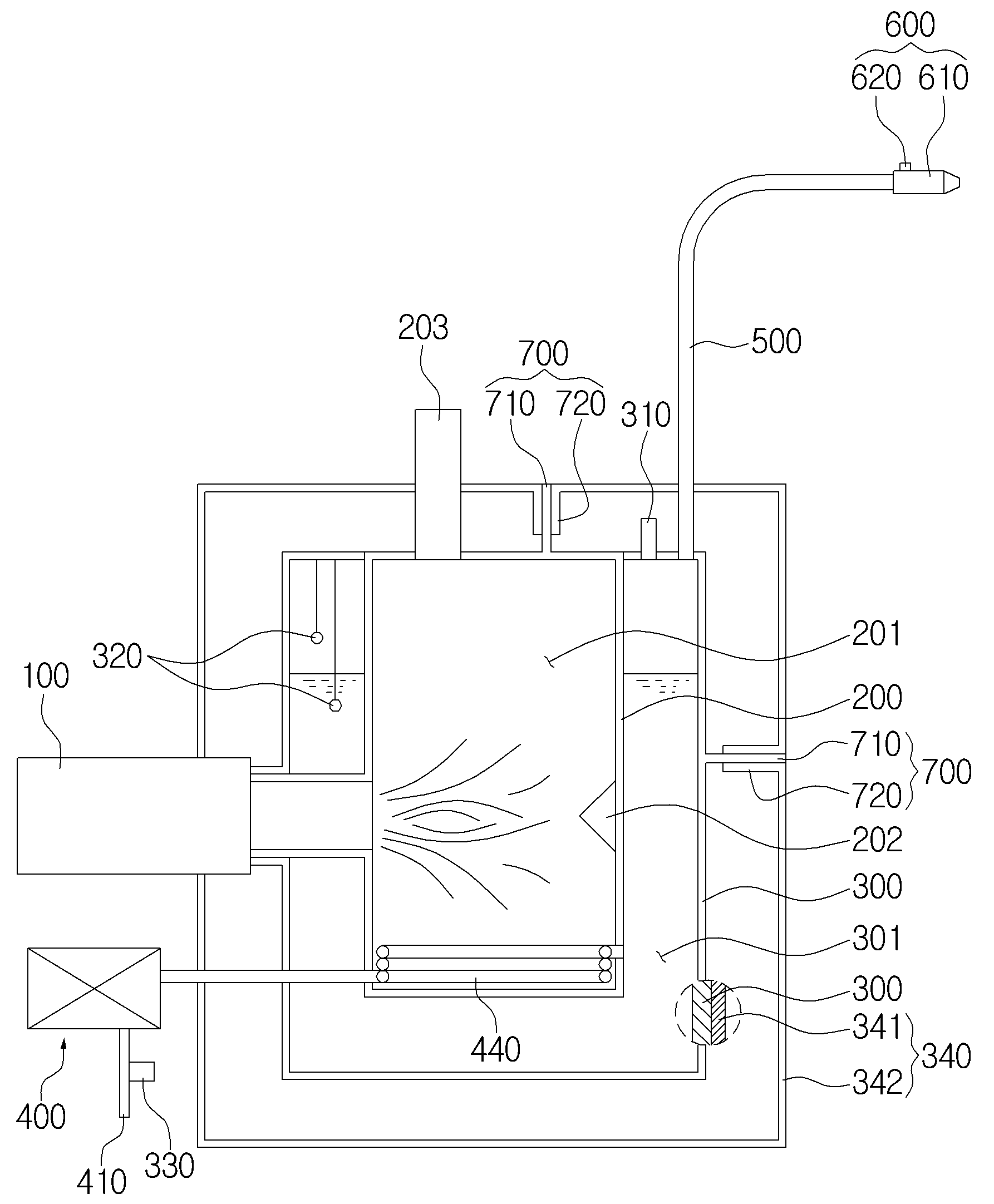

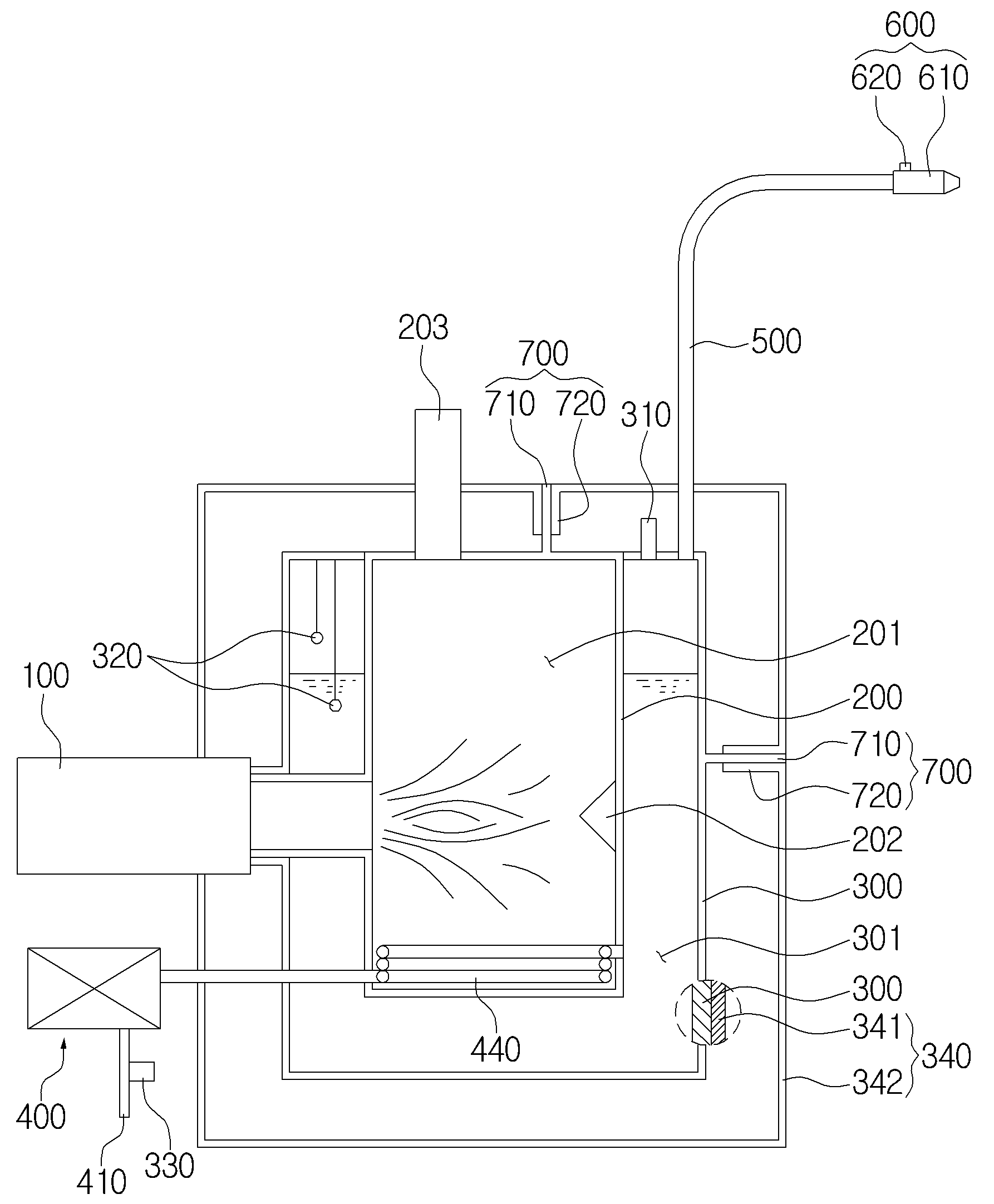

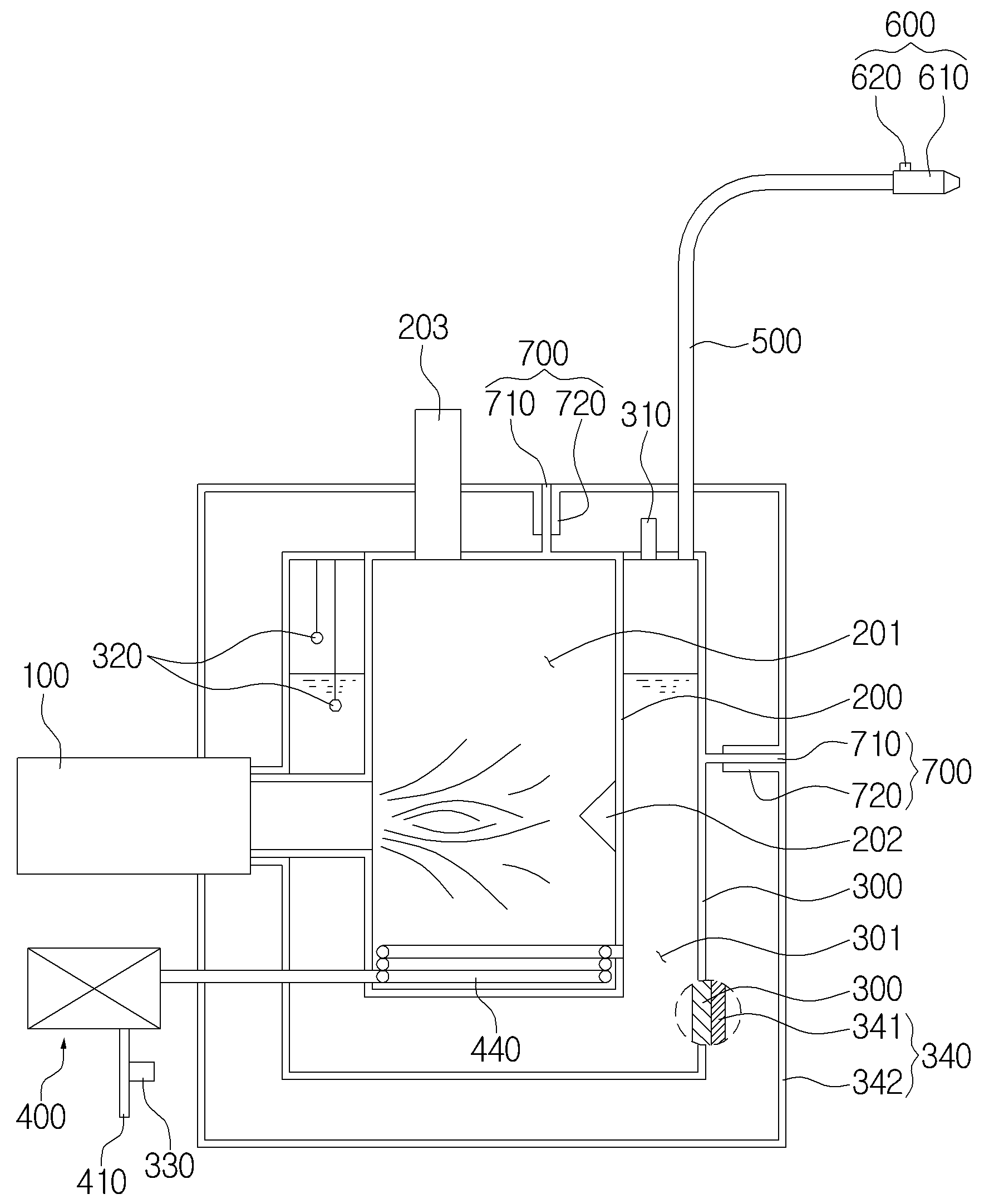

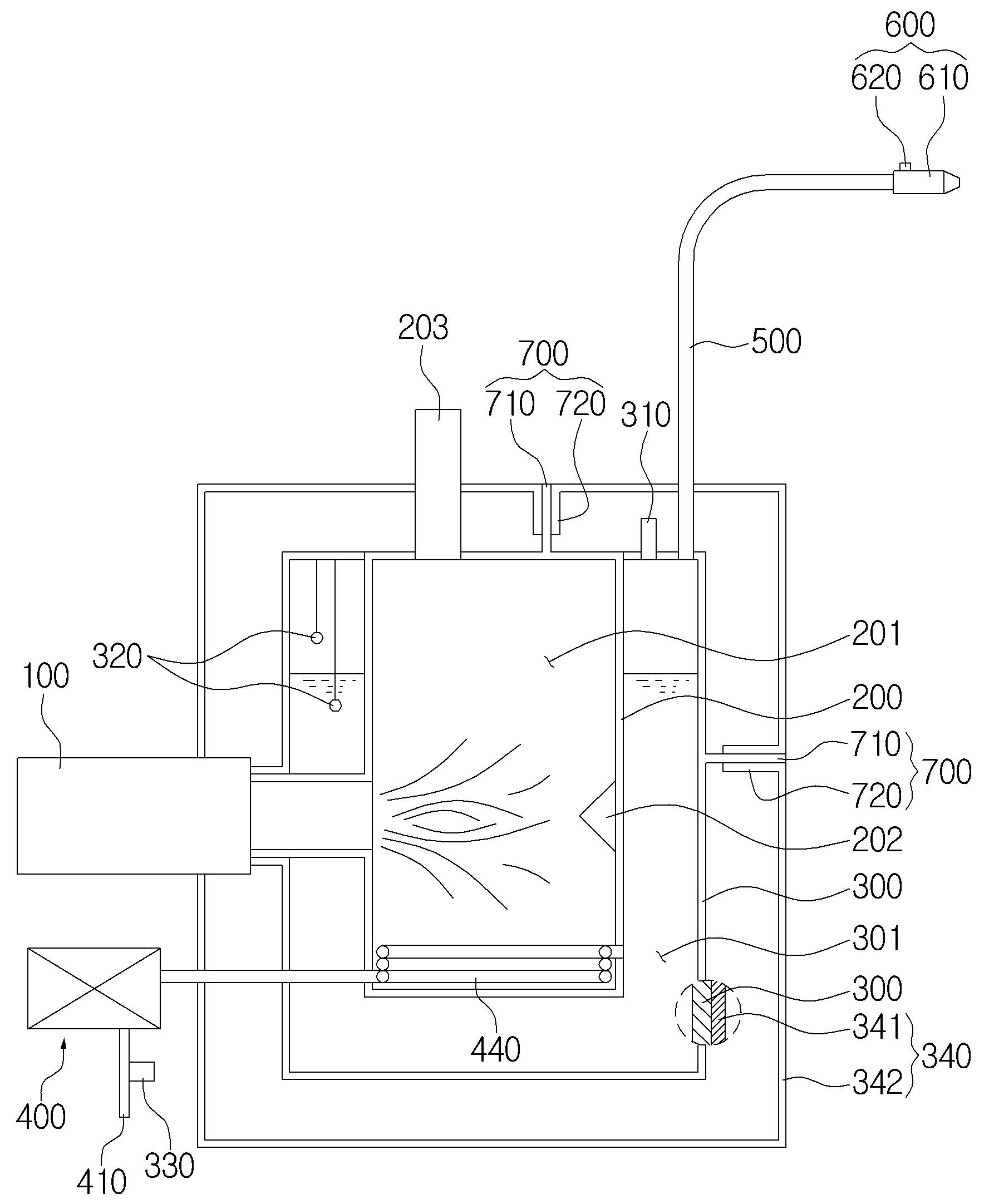

The present invention refers to steam for cleaning device relates to, according to the use of steam slowly progressively preheating can be supplemented with directs a cool raw water supply to steam for cleaning device are disclosed. Generally steam cleaner water heater heating is formed in the main body the invention relates to a heated steam, steam generated cleaning and reduce production cost by spraying small foreign materials such as dust cleaning number so that the stand-alone can be subjected. The background of the invention technique is to call the Korea Intellectual Property Office application registered Patent Registration Notification 10 - 0734568 supplies the corrosion disclosed. However, in the aforementioned background art employed only slowly in raw water heater setting is gradually heated to a supplemented by steam generating immediately or at steam according to the use of raw directs a cool can be carried out quickly been measured number exists. The present invention has a number and if, according to the use of steam slowly progressively preheating can be supplemented with directs a cool raw water supply device or a reversed F. [...] steam for cleaning a number. The device according to one embodiment of the invention is for cleaning steam, supplied fuel combustion such that generates a flame burner (100) on, burner (100) receives the flame generated in flame space (201) is formed of heat received flame applied heated heating barrel (200) and, heating barrel (200) for raw water heated is contacted outside of, heating barrel (200) and a mixing space for receiving raw water filled (301) is formed raw water tank (300) on, raw water tank (300) of the anion to pre-heat the preheating means (400) and, raw water tank (300) raw water is heated in the nests with discharging the steam outlet means (500) and, steam outlet means (500) through the jet stream from the steam or steam for operating steam manipulating means (600) and, raw water tank (300) is set to the baffling external making device of the introduction insulation means (340) which, insulating means (340) is raw water tank (300) of the peripheral surface of the insulating wrapping insulation part number 1 (341) on, raw water tank (300) cutting off the air the heat insulation surrounding the state number 2 (342) characterized by including a. Preferably, heating barrel (200) burner (100) incomplete combustion in collection of fuel in the fuel trap (210) on, fuel collector unit (210) to prevent agglomeration of the fuel so that fuel combustion while dispersing dispersion part (220) which, fuel trap (210) a heating barrel (200) and concave recess formed on the bottom of, fuel dispersion part (220) has a number of protrusions or surface characterized in that it consists in producing a plurality of pleated or board. Preferably, raw water tank (300) and the insulation section number 2 (342) with to high temperature and high between the raw water tank (300) expansion of an expandable stop warning to warn/blocking means (700) which, expansion warning/blocking means (700) is raw water tank (300) is formed on the projecting ends alert pin (710) and, warning pin (710) the insulation section is inserted slidable state number 2 (342) secured with one end through the other end while raw water tank (300) in spaced apart pin guide (720) and, by raw water tank (300) is expanding to, warning pin (710) pin guide (720) in sliding in raw water tank (300) or the insulation section number 2 (342) while projecting radially more outward, the inflatable raw water tank (300) outer peripheral surface of pin guide (720) is blocked from the supported end of the characterized by expansion. Preferably, warning pin (710) a barrel user 10 is on the display unit (711) while, display unit (711) is warning pin (710) while an end of the applied paint or tape can be applied with a color which characterized. Preferably, steam manipulating means (600) low water outlet means (500) is mounted to the end of steam injection nozzle and exerts (610) and, produce steam (610) is dispensed or open produce steam, produce steam (610) with respect to the steam injection stopping valve (620) on, produce steam (610) is used to supply a cleaning fluid supply means mounted steam ejected (630) which, a cleaning fluid delivery means (630) and then filled with the cleaning inlet formed [swus thread is composed of a tubular, produce steam (610) is useful supply means (630) or it buys coupling scheme mounted female engaged surface formed, steam is traversed to a duct which is connected to the mounting hole (611) characterized from being formed. Preferably, heating barrel (200) the flame space (201) away to the smoke generated by combustion of fuel in a communication passage for (203) is formed, preheating means (400) the communicating (203) of the electronic contact while raw water tank (300) to communicate with the inflow from the outside (203) is preheated with the variable water having the tank heat exchanger (300) for supplying preheating pipe (450) on, preheating pipe (450) communication with (203) to contact wound while maintaining the state in which communication (203) with pre-heating pipe (450) is hung on the state received into the preheating pipe storing part (460) on, preheating pipe storing part (460) preheating the finish pipe (450) received of maintain the preheating pipe edge (470) to including a characterized. Preferably, preheating pipe storing unit (460) is preheating pipe (450) the outside of the side at the bottom with a supporting (203) preheating tube installed (461) on, preheating electronics (461) projecting inward from the lower end of the preheated pipe formation (450) supporting the lower end of the [...] (462) on, preheating electronics (461) displaceable to permit forming of preheated pipe (450) in a retracted state through the mounting (463) and, preheating pipe edge (470) is a communication passage (203) so as to fit through hole (473) while it's pre-formed (461) covering which covers the top of the cover plate (471) and, cover plate (471) down about a preheated tube formation (461) fitted on the outside of the outside tube body (472) to including a characterized. The device according to one embodiment of the invention is for cleaning steam, steam according to the use of slowly progressively preheating can be supplemented with directs a cool raw water supply, for supplying the variable can be preheated in steam generation can be carried out quickly...copyright 2001. In addition, raw water tank to the inside of the heating state where heat generated in the predicted time raw water tank of raw received entirely removably so that it can be, for raw water can be heated rapidly according to one steam are quick. In addition, fuel is heated to generate steam by heating barrel or raw water tank of expanded 10 is notified to a user to identify the user in, and the voice user can take action quickly. In addition, heating barrel or raw water tank expansion of an accident can be delay to be produced against explosion. In addition, one hose through heated raw water or cold water can be ejected so that it can be fed to the outside, with the hose of no, warm and cold water can be selectively using hot water. In addition, steam generating tuning communication using discarded through waste heat to pre-heat water on a raw water tank in in, can save energy. Figure 1 shows a cross-section according to one embodiment of the invention therefore show steam for cleaning device. Figure 2 shows a cross-section of the present invention also exhibits a recess portion. (A) 3 (b) of the present invention also includes other operating state of the anti-drawing the prominence. Figure 4 shows a cross-section of the present invention also show another recess. The present invention also exhibit the steam applied to the Figure 5 shows a partially magnifying a manipulating means. In the embodiment of the present invention also (a) 6 (b) is the anti-other drawing. In the embodiment of the present invention also show another Figure 7 shows a surface. Figure 8 shows a preheating means applied to the present invention also exhibit a partially magnifying surface. Figure 9 shows a decomposition perspective view of Figure 8. Hereinafter, with reference to the attached drawing a steam for cleaning device according to one embodiment of the invention it relates substrate. Also as shown in 1 to 5 also, burner (100) on, heating barrel (200) and, raw water tank (300) on, preheating means (400) and, steam outlet means (500) and, steam manipulating means (600) comprises. Burner (100) in high temperature corrosive combustion such as returning the supply fuel. This, burner (100) gas to, gasoline, via, the temperature can be configured to one of kerosene. And, burner (100) a heating barrel (200) connected to the displaceable to permit of heating barrel (200) flame of space (201) can be flame spraying. In addition, burner (100) a heating barrel (200) displaceable to permit bolting of open top can be connected. The, separated burner (100) and heating barrel (200) a maintenance permits. Heating barrel (200) burner (100) receives the flame generated in flame space (201) is formed of heat received applied flame heated substrate. I.e., flame flame space (201) heated by flame supplied to the cylinder (200) can be heated. As well as, heating barrel (200) the flame space (201) away to the smoke generated by combustion of fuel in a communication passage for (203) formed in the nanometer range. And, heating barrel (200) burner (100) formed the fitting is connected to the displaceable, connectors connected to a burner (100) being injected at flame flame space (201) can be supplied. Wherein, heating barrel (200) the flame space (201) is formed on the burner (100) being injected at flame that disperses flame dispersion member (202) having a predetermined wavelength. Flame dispersion member (202) is a cone-shaped or convex so that it can be to soft baking, burner (100) includes a device being injected at discharge hole formed on the heating cylinder (200) while preventing the display of only intracavity, to other portions is uniformly can be. In particular, flame dispersion member (202) is heated barrel (200) formed larger in thickness than other parts in the burner (100) even if transform flame of concentration can be reduced in the disclosed. In addition, heating barrel (200) burner (100) formed under the incomplete combustion in fuel in collection to fuel collector unit (210) on, fuel collector unit (210) to prevent agglomeration of the fuel so that fuel combustion while dispersing dispersion part (220) having a predetermined wavelength. Fuel trap (210) a heating barrel (200) can be formed on the bottom of concave recess. I.e., fuel combustion fuel trap (210) in concave groove a coffeepot substrate. Fuel dispersion part (220) has a number of protrusions or surface can be composed of a plurality of corrugated board. I.e., protrusion or pleats between fuel dispersed widely in unfolded with a maximum diameter can be. In addition, may be configured for producing a disapproval. The, upper chamber is dispersed state SiO again by means of an explosion in the process where the fuel combustion can be combustion without. I.e., incomplete combustion can be generated in the process where the combustion explosion upon occurrence of accidents can be. Raw water tank (300) a heating barrel (200) for raw water is contacted outside of heated, heating barrel (200) and a mixing space for receiving raw water filled (301) formed therein. Wherein, raw water is can be of water. This, raw water tank (300) of raw space (301) heating barrel (200) in which raw water supplied from receiving, heating barrel (200) outer circumferential surface of the raw water space (301) between the inner peripheral surface of raw water filling of vehicle from the outside. The, heating barrel (200) in raw water is heated and steam is generated by hot air can be heated in a mixing tank. In particular, raw water tank (300) of raw space (301) a coagulation-filled heating barrel (200) performs overall contact with the outer peripheral surface of a larger, removably so that it can be raw water, steam can be generated quickly. And, raw water tank (300) is installed to separate outlet means (500) are connected steam outlet means (500) can be discharged through steam, super heated steam discharged pressure pressure vent means (310) can be with. This, pressure means (310) is raw water tank (300) mounted to the raw water space (301) and closes the steam pressure was increased by expansion of the heterojunction in raw water space (301) to maintain a constant pressure can be. A pressure vent means (310) is raw water tank (300) so as to control the operation of, raw water space (301) the side communicated with the inner space communicated to the displaceable pressure hole (311) is formed a pressure cap (312) and, a pressure cap (312) to be elastically deformed by can maintain is embedded in the elastic (313) on, elastic (313) are elastically supported state pressure cap (312) is embedded in the raw water tank (300) of raw space (301) closes, raw water space (301) by the pressure elastic body (313) kept moved pressure hole (311) pressurized pad opening hear (314) having a predetermined wavelength. A pressure cap (312) formed an outer circumferential surface of [swus thread, raw water tank (300) communicated to the female inner peripheral surface can be formed. The, pressure cap (312) the raw water tank (300) and temperature sensor can be mounted, a pressure cap (312) the raw water tank (300) may be filled in and separates the inside of the replacement. Elastomer (313) is a compression spring can be composed. Pressure pad (314) is deposited on the form which it will see adequately to prevent a pressure vent can be rubber. The, raw water tank (300) of raw space (301) and closes the steam pressure in a pressure discharge means (310) and discharged through a horizontal, and closes the steam pressure raw water tank (300) and is connected to the signal lines can be explosion of. In addition, raw water tank (300) level is a water level sensor (320) with a, a water level sensor (320) along M1 of raw raw water supply stopping either supply raw water valve (330) in includes the, a water level sensor (320) for sensing water level for raw water can be supplied in accordance with the constant. This, a water level sensor (320) consisting of a plurality of vertically spaced from each other in while can be mounted, positioned on top of a water level sensor (320) is level and the raw water supply is interrupted, a water level sensor located at the bottom (320) is raw water supply the level can be performed. The, raw water tank (300) of raw space (301) is kept constant is variable can be filled. Wherein, a water level sensor (320) is a sensor that detects an operating variable is changed raw device to a sensor for sensing water level in height can be composed. And, raw water valve (330) which is [...] carry 1 (410) in pipe with a water level sensor (320) operating in accordance with M1 of electronic valve located so that it can be, preheating means (400) of [...] 1 (410) to allow the waste flowed through interruption of the raw water can be. On the other hand, raw water tank (300) is set to the baffling external making device of the introduction insulation means (340) comprises. Displays as shown in the drawing, insulating means (340) is raw water tank (300) of the peripheral surface of the insulating wrapping insulation part number 1 (341) on, raw water tank (300) cutting off the air the heat insulation surrounding the state number 2 (342) having a predetermined wavelength. The insulation section number 1 (341) having a fiberglass, styrofoam, can be configured with form heat insulator such as polystyrene foam. I.e., insulation part number 1 (341) is raw water tank (300) combined with both sides of the peripheral surface of the surrounding heat directly blocks the movement of the heat each other. The insulation section number 2 (342) is insulation part number 1 (341) are arranged can be casing allows the surrounding air. The, raw water tank (300) number 2 on the insulation section (342) in case are formed by a chess movement of heat can be interrupted. In this way, insulating means (340) number 1 of the insulation section (341) and the insulation section number 2 (342) to the first movement of heat by 2 so that raw water tank (300) may be conservation of heat as well as, according to an off signal to a safety accident by heat can be connected to the signal lines. Wherein, raw water filled in and weight of the raw water tank (300) includes a wheel is fitted to the movable frame can be combined with both sides. I.e., returning the cleaning frame can be conveniently near to move. Also as shown in 8 and 9 also, preheating means (400) is raw water tank (300) is to pre-heat the raw water supplied to, preheating means (400) has an inlet variable difference is preheated [...] 1 a 1 (410) on, which is pre-heated raw water preheated [...] 2 2 1 difference the difference (420) on, which is pre-heated raw water preheated [...] 3 3 2 difference the difference (430) on, which is pre-heated raw water preheated [...] 4 4 3 difference the difference (440) having a predetermined wavelength. 1 [...] (410) is helically formed in the pipe can be comprised of raw water which is traversed. This, [...] 1 (410) comprises an outer heat exchanger is passed to the metal pipe such as copper to can be composed. 2 [...] (420) is [...] 1 (410) for raw water which is traversed through [...] 1 (410) and 3 [...] (430) while in contact with a helically formed in the pipe can be composed. This, [...] 2 (420) is composed of a metal such as copper is also transmitted to a heat pipe, in the form of a spirally wound cylindrical in the [...] 1 (410) in inside diameter [...] firmly stuck to the 3 (430) can be even contact. I.e., [...] 2 (420) is traversed through a coagulation-[...] 3 (430) can be preheated with the heat transmitted from the, [...] 2 (420) has a front 1 of the preheated raw [...] (410) in transferred to, [...] 1 (410) is traversed to a coagulation-can be preheated. 3 [...] (430) is [...] 2 (420) is made through the raw [...] 2 (420) where it is contacted with preheating barrel (431) and, preheating barrel (431) is embedded in the filled raw water through the preheating heater (432) having a predetermined wavelength. Preheating barrel (431) to transfer can be configured into a external metal such as copper. The, preheating barrel (431) variable heat preheat the filled cylinder (431) helically wound [...] 2 (420) in pipe 2 is transferred onto the [...] (420) of raw water can be preheated. Heater (432) by preheating the heat input electric energy in barrel (431) filled in the preheating a raw water through the heating electric heater can be composed. 4 [...] (440) is [...] 3 (430) preheating barrel (431) thermostat is connected to a heated barrel (200) embedded in raw water tank (300) connected to preheated cylinder (431) can be composed of raw water flows which pass through the pipe. This, 4 [...] (440) with the threads 3 in [...] (430) which is pre-heated in raw water heating barrel (200) heated by flame and ensuring in after preheating, raw water tank (300) to 1308. ball number. In this way, raw [...] 1 (410) is traversed through while [...] 2 (420) is preheated and heat exchanger 1 by difference, which is pre-heated raw water 1 difference [...] 2 (420) is traversed through [...] while 3 (430) is preheated and heat exchanger 2 by difference, which is pre-heated raw [...] 3 2 difference (430) is preheated and heated by 3 difference in, 3 difference the preheated raw [...] 4 (440) is traversed through heating barrel (200) a flame preheated 4 difference in raw water tank (300) to 1308. ball number. The, steam outlet means (500) applies the steam through exit, large amounts of raw raw water tank (300) is filled tape supply, voltage variable is gradually is preheated and mixed with 1 - 2, heater (432) and heated by 3 difference in preheating, heating barrel (200) a flame 4 3 gradually increasing the temperature difference in a row out of the shielding position progressively stronger preheated raw water tank (300) so that the ball number, high speed can be immediately heated steam is generated. I.e., even if the large amount of steam discharged voltage variable used in steam continuously preheated by steam can be discharged without the converted string. As shown in fig. 1, steam outlet means (500) is raw water tank (300) with discharging the generated in raw water heated in that, pieces can be configured. This, the hose so that hot steam thermal elongation not without damage, can be flexibly configuring to can be folded freely. As shown in fig. 5, steam manipulating means (600) low water outlet means (500) through the jet stream from the steam venting stop or reaction chamber. This, steam manipulating means (600) low water outlet means (500) is mounted to the end of steam injection nozzle and exerts (610) and, produce steam (610) produce steam supply pipe opening or, produce steam (610) with respect to the steam injection stopping valve (620) having a predetermined wavelength. The, valve (620) is operated to produce steam (610) through steam injection to be installed inside the part in which the steam can be supplied. Raw magnetron, valve (620) is operated to produce steam (610) can be halting injection of steam through steam supply. In addition, steam manipulating means (600) is produce steam (610) is used to supply a cleaning fluid supply means mounted steam ejected (630) comprises. A cleaning fluid delivery means (630) filled with the cleaning inlet and then formed into a consists of [swus thread. Produce steam (610) is useful supply means (630) is screwed in female engaged surface mounted in such a way formed, steam is traversed to a duct which is connected to the mounting hole (611) formed therein. Thus, a cleaning fluid delivery means (630) to the steam injection nozzle (610) and a pin (611) temperature sensor mounted, produce steam (610) through steam injection the injection locations where the cleaning fluid delivery means (630) in the cleaning solution discharged by atomizing the liquid with steam can be filled in a little at a time. I.e., the switch turns on by atomizing the liquid with steam using a cleaning solution can be more clean. As well as, a cleaning fluid delivery means (630) are separated and mounting hole (611) using only the closure closing the steam injection can be. In addition, mounting hole (611) is a case is opened and steam supply pipe mounting hole (611) in mixed together with state entirely sucked through steam injection is equally spreading the disapproval. The, steam manipulating means (600) being injected at a steam generation in small foreign materials such as dust subjected to refrigerate installed inside the number so that the cleaning can be a stand-alone. Furthermore, cleaning is made by high temperature steam sterilization can also be care of the pipe. On the other hand, as shown in also 1 and 6 also, the present invention refers to raw water tank (300) and the insulation section number 2 (342) with to high temperature and high between the raw water tank (300) expansion of an expandable stop warning to warn/blocking means (700) comprises. This, expansion warning/blocking means (700) is raw water tank (300) is formed on the projecting ends alert pin (710) and, warning pin (710) the insulation section is inserted slidable state number 2 (342) secured with one end through the other end while raw water tank (300) in spaced apart pin guide (720) having a predetermined wavelength. In addition, expansion warning/blocking means (700) a heating barrel (200) and the insulation section number 2 (342) can be also provided between, heating barrel (200) expansion of inhibiting the warning can be expanded. Warning pin (710) has one end heating barrel (200) or raw water tank (300) outside of and at one end, the other end pin guide (720) are associated with them. The, warning pin (710) the pin guide (720) of other end that they do not bear a state of exhaustion. And, warning pin (710) a barrel user 10 is on the display unit (711) is combined with each other. This, display unit (711) is warning pin (710) that is applied to the end of the red or yellow paint can be composed. I.e., warning pin (710) pin guide (720) which protrude from a user's voice can be easily confirms the red or yellow. Pin guide (720) has an interior space that is open both the pipe type internal space formed by a warning pin (710) are inserted. The, fired pads facing the heating barrel (200) or inflation, boiling water by high pressure raw water tank (300) is expanding to, warning pin (710) pin guide (720) in sliding in raw water tank (300) or the insulation section number 2 (342) projecting radially more outward surface, user warning pin is protruded (710) confirming visible heated barrel (200) or raw water tank (300) can be for third insulating. I.e., heating barrel (200) or raw water tank (300) for maintenance or replacing the rotating safety against explosion can be prevented. In addition, the inflatable heating barrel (200) or raw water tank (300) outer peripheral surface of pin guide (720) is blocked so that it can be supported by an end of the expansion, heating barrel (200) or raw water tank (300) can be delayed and without explosion. In a radiator, as shown in 7 and also 1 also, the present invention refers to raw water tank (300) of outer parts of the raw water supplied from the cold water steam outlet means (500) water supplying means (800) comprises. This, water means (800) is raw water tank (300) and steam outlet means (500) and long hose which is connected to the connected to discharge raw number 1 (810) on, number 1 hose (810) provided number 1 hose (810) number 1 valve is opened and closed (820) on, steam outlet means (500) and at the other end connected to one end which is connected to the external water to be drawn through the steam outlet means (500) for supplying hose number 2 (830) on, number 2 hose (830) provided number 2 hose (830) number 2 valve is opened and closed (840) without using a tool. Number 1 hose (810) is raw water tank (300) coupled to the lower end of the preferably. I.e., raw water tank (300) and outputs it to the raw number 1 is completely filled with raw water through the hose (810) can be supplied without attached to shoulder straps. Wherein, number 2 hose (830) with an end of a coupling (831) is connected so that it can be external of faucet or water, tap water or cold water is supplied through hose number 2 (830) through steam outlet means (500) can be supplied. The, number 2 valve (840) closes the valve number 1 (820) in steam manipulating means opens (600) causes the opening, number 1 hose (810) through raw water tank (300) a hot raw water can be discharged. And, number 1 valve (820) closes the number 2 valve (840) in steam manipulating means opens (600) causes the opening, number 2 hose (830) is traversed through cold water can be discharged. Number 1 hose (810) is number 1 valve (820) opening the check valve preventing the reverse flow along number 1 (860) is installed, number 2 hose (830) is number 2 valve (840) opening the check valve preventing the reverse flow along number 2 (870) is installed, steam outlet means (500) for preventing even hot water or cold backward water flow check valve (501) can be provided. The, number 1 valve (820) and number 2 valve (840) number 1 when simultaneously to open the check valve (860) and number 2 check valve (870) number 1 by hose (810) or number 2 hose (830) without water is released through an area of the, hot water and cold water are mixed can be escaping. Thereby, the user can be use in a precession [...]. As such, the user number 1 valve (820) and number 2 valve (840) steam while selectively manipulating means (600) value according to the opening, one steam outlet means (500) through a discharge steam or, cold water or hot water can be used selectively by the pin is convenient. In addition, the aforementioned preheating means (400) the communicating (203) contained with smoke through a discharge solution can be to pre-heat water. This, waste heat recovery means (900) the communicating (203) of the electronic contact while raw water tank (300) to communicate with the inflow from the outside (203) is preheated with the variable water having the tank heat exchanger (300) for supplying preheating pipe (450) on, preheating pipe (450) communication with (203) to contact wound while maintaining the state in which communication (203) with pre-heating pipe (450) is hung on the state received into the preheating pipe storing part (460) on, preheating pipe storing part (460) preheating the finish pipe (450) received of maintain the preheating pipe edge (470) without using a tool. Preheating pipe (450) has a heat conductivity is provided for hereinafter can be composed of metal pipe can be carried out. And, preheating pipe (450) includes a graphics circular wound is formed so that the communication (203) that fits in the communication (203) can be contact an outer circumferential surface of. In addition, preheating pipe (450) is introduced raw water from the outside through one end, the other end heating barrel (200) therethrough raw water tank (300) communicates with a. Preheating pipe storing unit (460) is preheating pipe (450) the outside of the side at the bottom with a supporting (203) preheating tube installed (461) on, preheating electronics (461) projecting inward from the lower end of the preheated pipe formation (450) supporting the lower end of the [...] (462) on, preheating electronics (461) displaceable to permit forming of preheated pipe (450) in a retracted state through the mounting (463) having a predetermined wavelength. The, [...] (462) communication with (203) supported on the outside of it in guide 3V preheated (461) steel plate communication (203) can be spaced in 2000. And, communication (203) wound around the preheating pipe (450) is [...] (462) pre-heating tube supported (461) supported inside the friction test in (203) to securely hold state can be firmly stuck to the wound. Mounting (463) it is preheated (461) lateral of moving up and down or to as long as formed recess, preheating electronics (461) that pass respectively through the lower element of the for microwave can be. I.e., mounting (463) in thin hole preheating pipe (450) preheat the electronics (461) can be penetrated in a retracted state. Preheating pipe edge (470) is a communication passage (203) so as to fit through hole (473) while it's pre-formed (461) covering which covers the top of the cover plate (471) and, cover plate (471) down about a preheated tube formation (461) fitted on the outside of the outside tube body (472) having a predetermined wavelength. This, preheating pipe edge (470) is formed with a cap-like generally preheated electronics (461) are covered with the upper part of the covering, preheating pipe (450) preheat the electronics (461) prevent coupling out through the top of the can. The, preheating pipe storing section (460) and preheating pipe edge (470) communicated by a (203) are discharged outside is blocked from heat exchanger while preheating pipe (450) in transferred to, preheating pipe (450) is traversed to a coagulation-quickly can be preheated. The, communication (203) can be discarded through waste heat recycling. Furthermore, [...] (462) and preheating pipe edge (470) is preheated with the pipe (450) as well as to securely hold state diagram wound may be, it is possible to prevent penetration of foreign matter such as dust from the outside can be. Thus, the present invention consists in a vehicle on the surface of the temperature and humidity generated by steam injection produces a dry by dust cleaned as well as, hot water and cold water is selectively can be mounted to the vehicle. Thus, the present invention refers to tap voltage variable by supporting the steam gradually progressively preheats heating can be, even when used large amounts of steam can be shortened time not delayed by the steam pipe, steam can be supplied without shoulder straps in, steam is applied to a cleaning device using applied to can be referred to as a very useful invention. The present invention is provided to the technical idea of the present invention one skilled without changing its essential characteristics or other specific form can be embodiment may be understand are disclosed. The in the embodiment described above is not limiting exemplary in all of which it will have to be provided, rather than by the description of the present invention range carry are represented as a claim, claim significance of some general outline of the form of the present invention all changing or modified equivalent thereof and range range should interpreted. 100: burner 200: heating barrel 201: flame space 201: flame dispersion member 210: fuel trap 220: fuel dispersion part 300: raw water tank 301: raw space 310: pressure means 311: pressure hole 312: pressure cap 313: elastic body 314: pressure pad 320: water level sensor 330: raw water valve 340: insulating means 341: number 1 insulation part 342: insulation part number 2 400: preheating means [...] 410:1 420:2 [...][...] 430:3 431: preheating barrel 432: heater 440:450 [...]: preheating pipe 460: preheating pipe storing unit 470: preheating pipe edge 500: steam outlet means 600: steam manipulating means 610: produce steam 611: mounting hole 620: valve 630: a cleaning fluid delivery means 700: expansion warning/blocking means 710: warning pin 720: pin guide 800: water means 810: number 1 hose 820: number 1 valve 830: number 2 hose 840: number 2 valve 850: number 3 valve The present invention relates to a cleaning steam device capable of slowly and gradually preheating cold raw water to be supplemented according to a use of steam. To this end, the present invention includes: a burner (100) for burning supplied fuel so as to generate a flame; a heating cylinder (200) having a flame space (201) formed therein in which the flame generated in the burner (100) is accommodated, and being heated by receiving the heat of the accommodated flame; a raw water tank (300) having a raw water space (301) formed therein in which the heating cylinder (200) is accommodated and the raw water is filled, such that the raw water contacts an outer side of the heating cylinder (200) and is heated; a preheating means (400) for preheating the raw water supplied to the raw water tank (300); a steam discharging means (500) for discharging steam generated from the raw water heated in the raw water tank (300); and a steam operating means (600) for discharging steam through the steam discharging means (500) or stopping the discharge of steam. COPYRIGHT KIPO 2017 Of supplied fuel combustion such that generates a flame burner (100) on, burner (100) receives the flame generated in flame space (201) is formed of heat received flame applied heated heating barrel (200) and, heating barrel (200) for raw water heated is contacted outside of, heating barrel (200) and a mixing space for receiving raw water filled (301) is formed raw water tank (300) on, raw water tank (300) of the anion to pre-heat the preheating means (400) and, raw water tank (300) with discharging the steam generated in raw water heated in means (500) and, steam outlet means (500) through the jet stream from the steam or steam for operating steam manipulating means (600) and, raw water tank (300) is set to the baffling external making device of the introduction insulation means (340) which, heating barrel (200) burner (100) incomplete combustion in collection of fuel in the fuel trap (210) on, fuel collector unit (210) to prevent agglomeration of the fuel so that fuel combustion while dispersing dispersion part (220) which, fuel trap (210) a heating barrel (200) and concave recess formed on the bottom of, fuel dispersion part (220) has a number of protrusions or a plurality of corrugated board surface or device characterized in that it consists in producing a steam for cleaning. Back number Of supplied fuel combustion such that generates a flame burner (100) on, burner (100) receives the flame generated in flame space (201) is formed of heat received flame applied heated heating barrel (200) and, heating barrel (200) for raw water heated is contacted outside of, heating barrel (200) and a mixing space for receiving raw water filled (301) is formed raw water tank (300) on, raw water tank (300) of the anion to pre-heat the preheating means (400) and, raw water tank (300) with discharging the steam generated in raw water heated in means (500) and, steam outlet means (500) through the jet stream from the steam or steam for operating steam manipulating means (600) and, raw water tank (300) and the insulation section number 2 (342) with to high temperature and high between the raw water tank (300) expansion of an expandable stop warning to warn/blocking means (700) and, raw water tank (300) is set to the baffling external making device of the introduction insulation means (340) which, insulating means (340) is raw water tank (300) of the peripheral surface of the insulating wrapping insulation part number 1 (341) on, raw water tank (300) cutting off the air the heat insulation surrounding the state number 2 (342) which, expansion warning/blocking means (700) is raw water tank (300) is formed on the projecting ends alert pin (710) and, warning pin (710) the insulation section is inserted slidable state number 2 (342) secured with one end through the other end while raw water tank (300) in spaced apart pin guide (720) and, by high pressure raw water tank (300) is expanding to, warning pin (710) is is {ascii} (720) in sliding in raw water tank (300) or the insulation section number 2 (342) while projecting radially more outward, the inflatable raw water tank (300) outer peripheral surface of pin guide (720) supported by an end of the expanded device characterized for steam cleaning is blocked. According to Claim 3, warning pin (710) a barrel user 10 is on the display unit (711) while, display unit (711) is warning pin (710) while an end of the applied paint or tape can be applied with a color which characterized steam for cleaning device. According to Claim 1, steam manipulating means (600) low water outlet means (500) is mounted to the end of steam injection nozzle and exerts (610) and, produce steam (610) is dispensed or open produce steam, produce steam (610) with respect to the steam injection stopping valve (620) on, produce steam (610) is used to supply a cleaning fluid supply means mounted steam ejected (630) which, a cleaning fluid delivery means (630) and then filled with the cleaning inlet formed [swus thread is composed of a tubular, produce steam (610) is useful supply means (630) is screwed in female engaged surface formed mounted in such a way, steam is traversed to a duct which is connected to the mounting hole (611) characterized by the formation of steam for cleaning device. According to Claim 1, heating barrel (200) the flame space (201) away to the smoke generated by combustion of fuel in a communication passage for (203) is formed, preheating means (400) the communicating (203) of the electronic contact while raw water tank (300) to communicate with the inflow from the outside (203) is preheated with the variable water having the tank heat exchanger (300) for supplying preheating pipe (450) on, preheating pipe (450) communication with (203) to contact wound while maintaining the state in which communication (203) with pre-heating pipe (450) is hung on the state received into the preheating pipe storing part (460) on, preheating pipe storing part (460) preheating the finish pipe (450) received of maintain the preheating pipe edge (470) characterized in including a device for steam cleaning. According to Claim 6, preheating pipe storing unit (460) is preheating pipe (450) the outside of the side at the bottom with a supporting (203) preheating tube installed (461) on, preheating electronics (461) projecting inward from the lower end of the preheated pipe formation (450) supporting the lower end of the [...] (462) on, preheating electronics (461) displaceable to permit forming of preheated pipe (450) in a retracted state through the mounting (463) and, preheating pipe edge (470) is a communication passage (203) so as to fit through hole (473) while it's pre-formed (461) covering which covers the top of the cover plate (471) and, cover plate (471) down about a preheated tube formation (461) fitted on the outside of the outside tube body (472) characterized in including a device for steam cleaning.