LASER CUTTING MACHINE

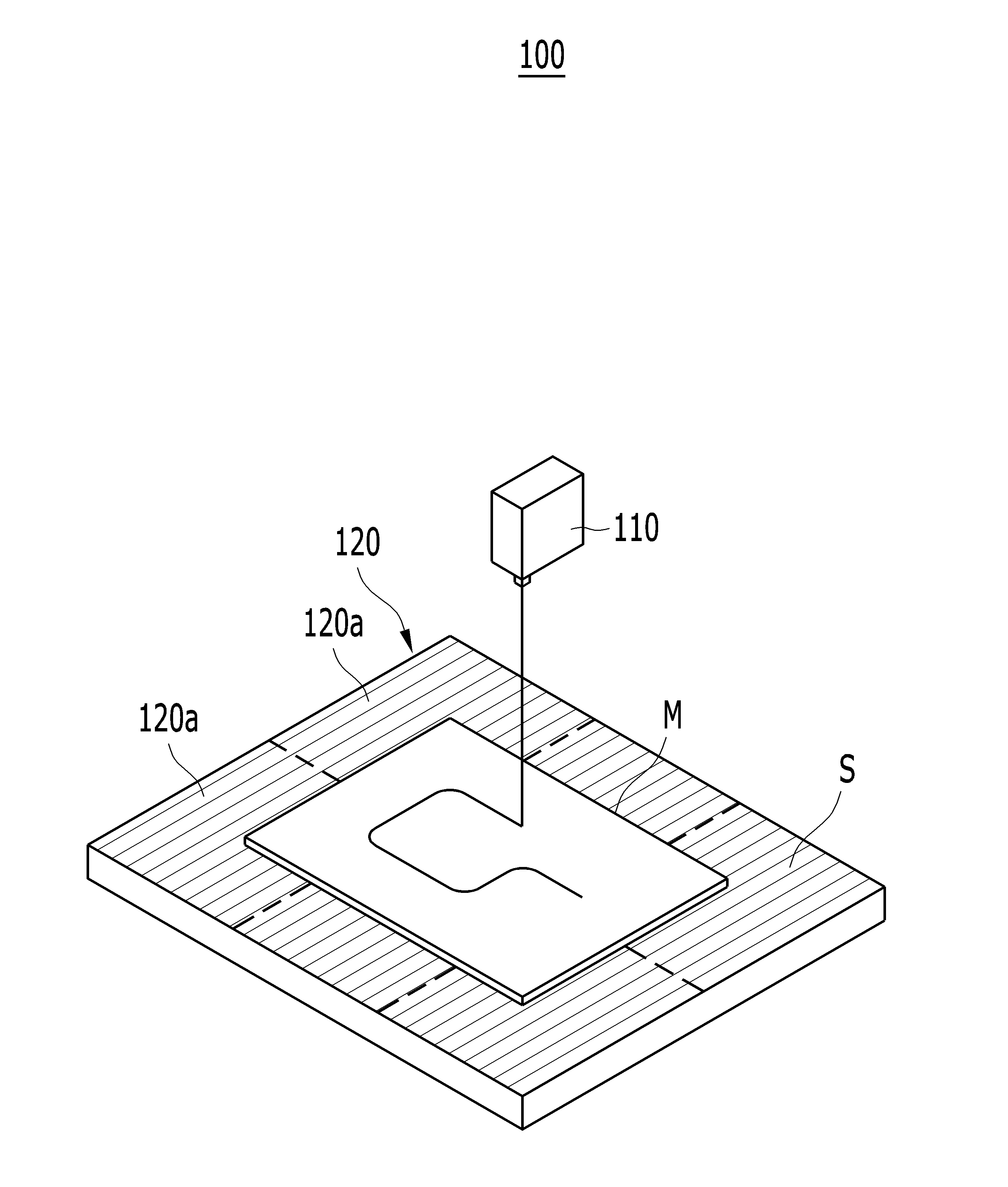

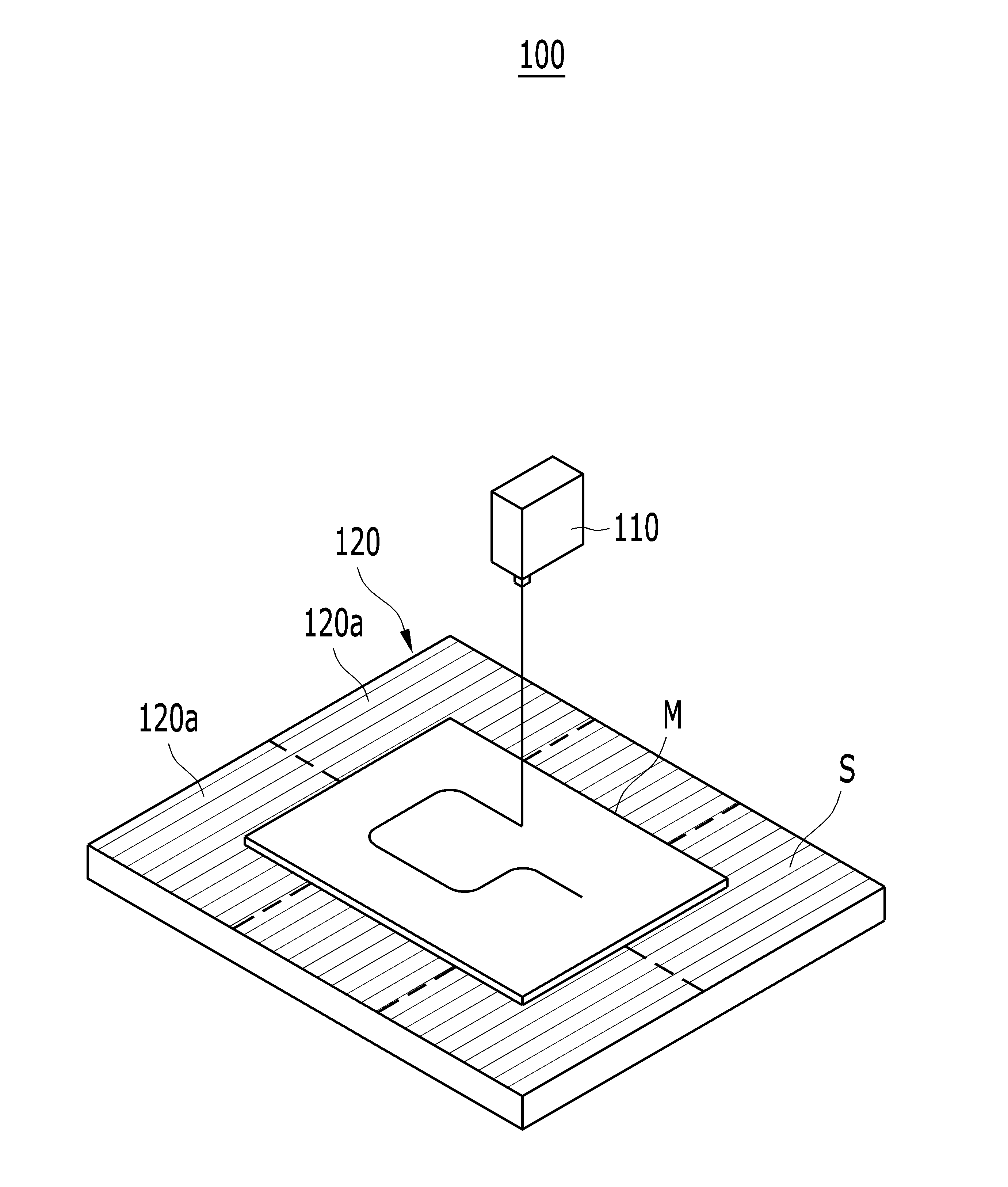

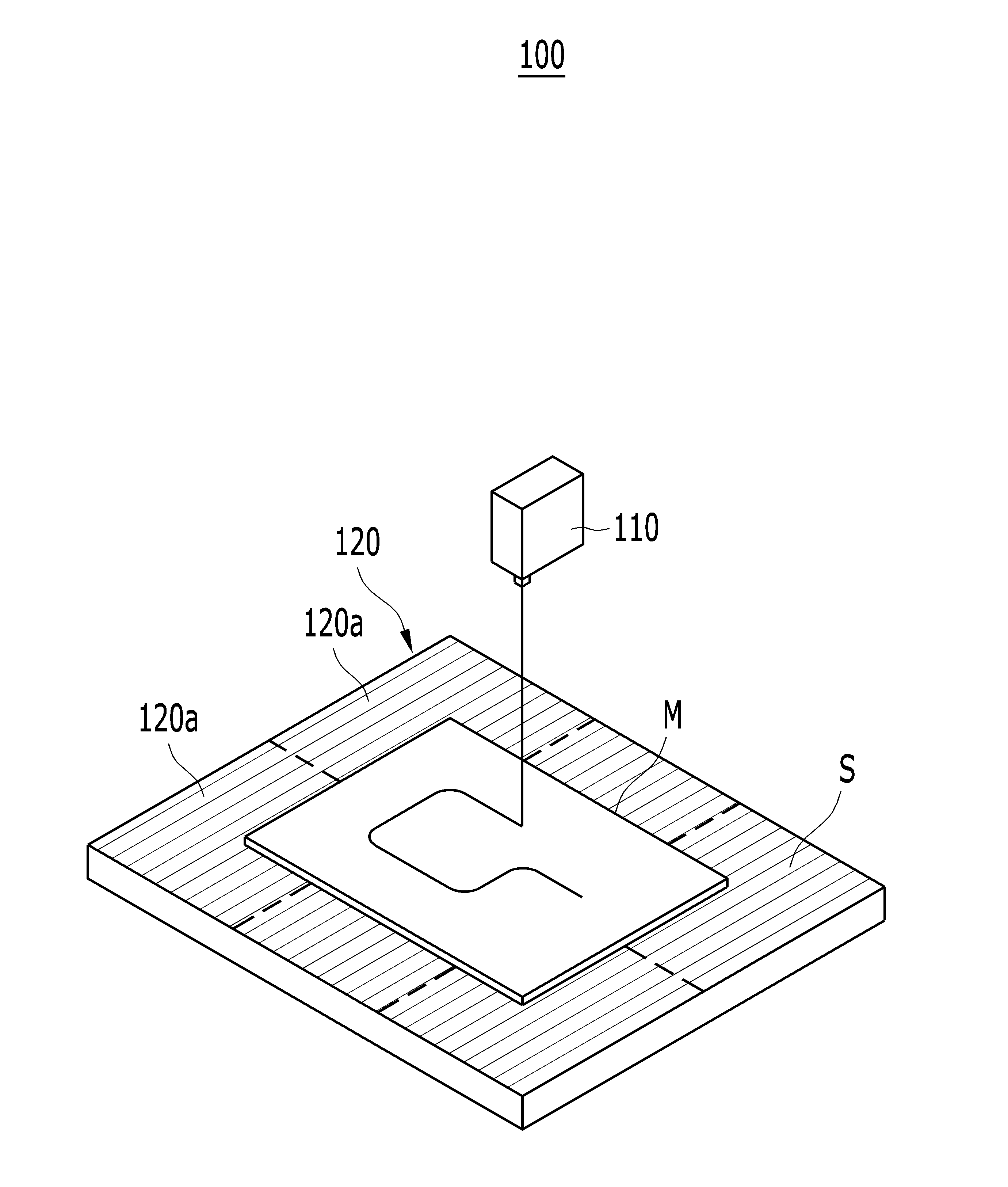

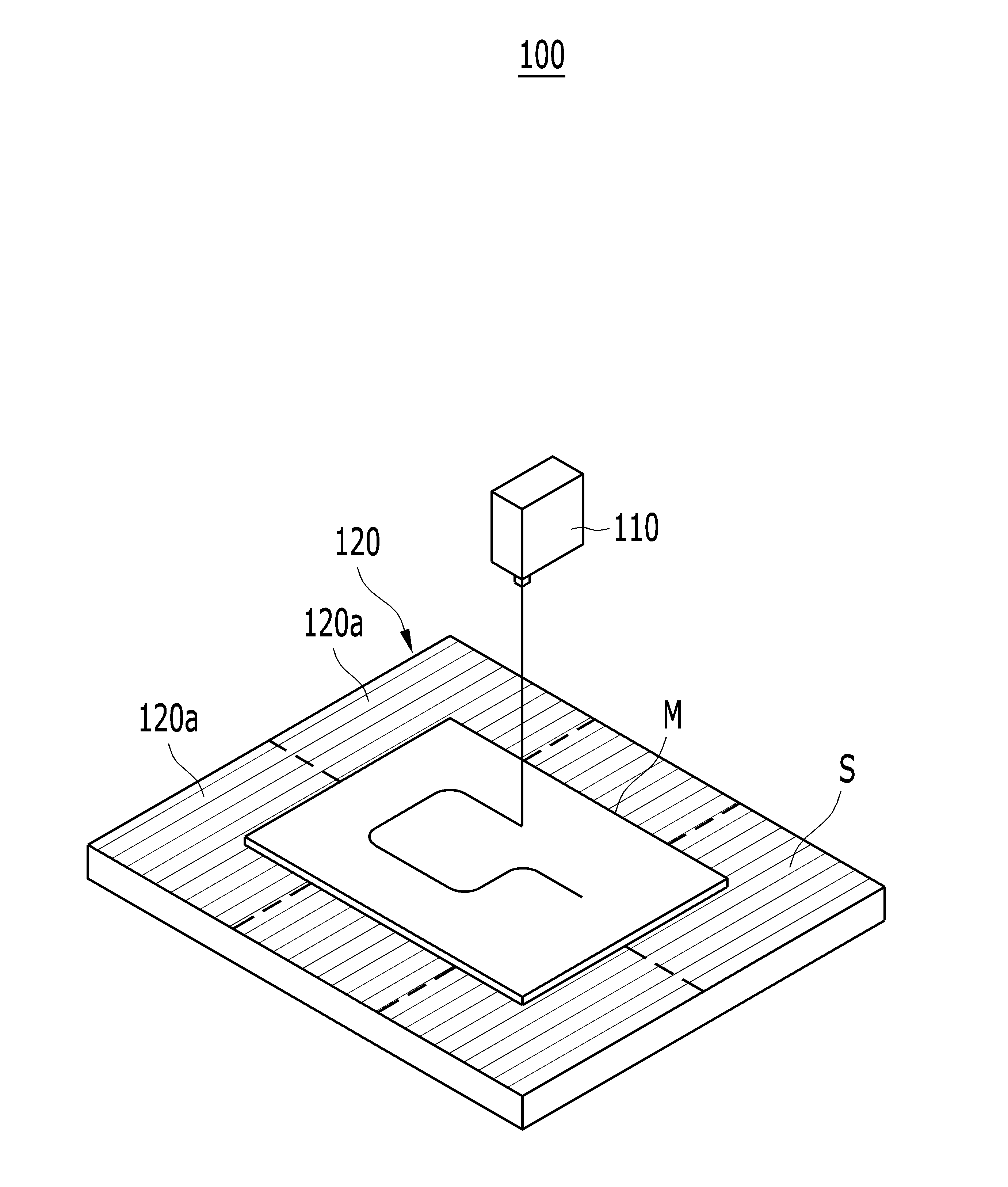

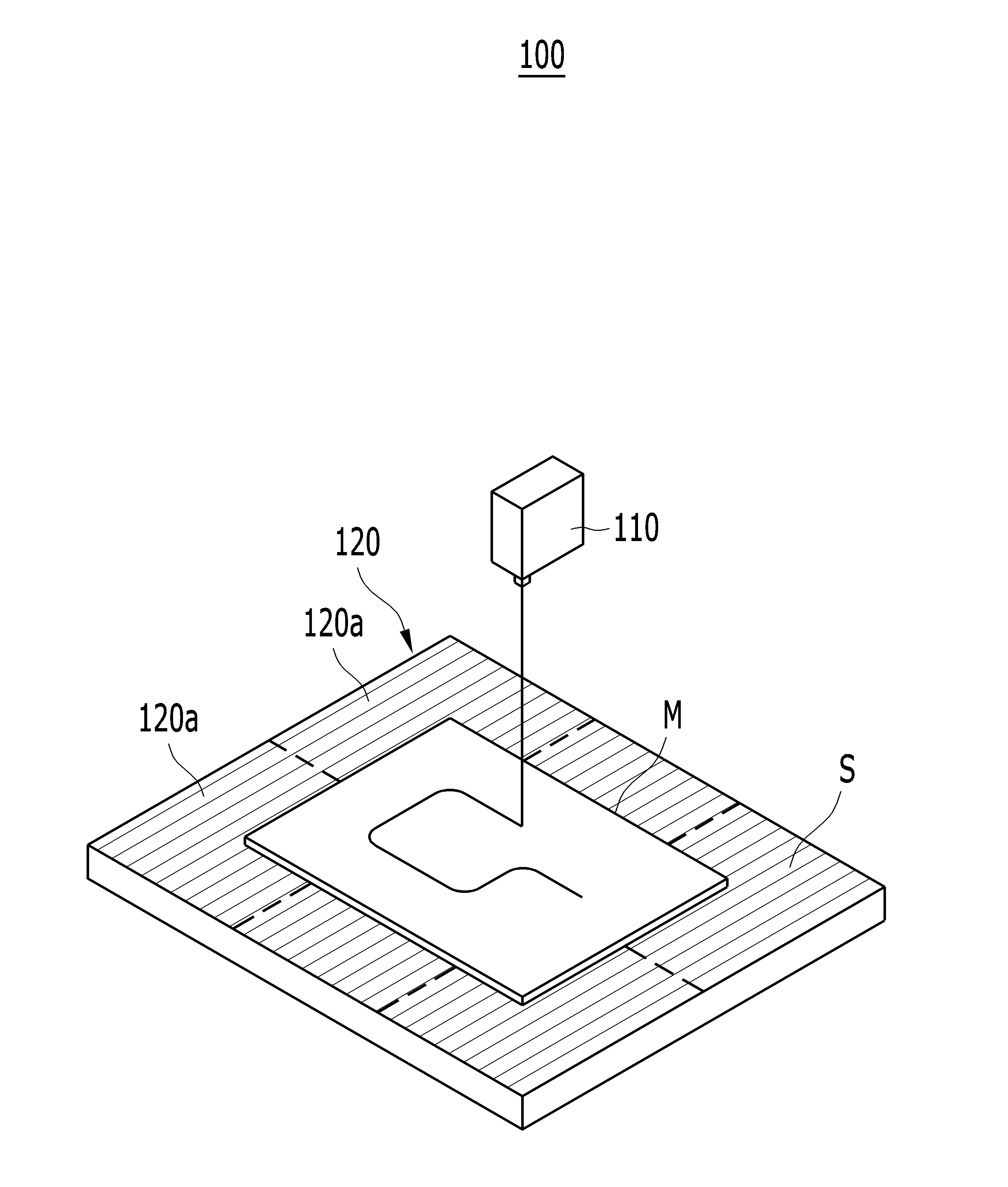

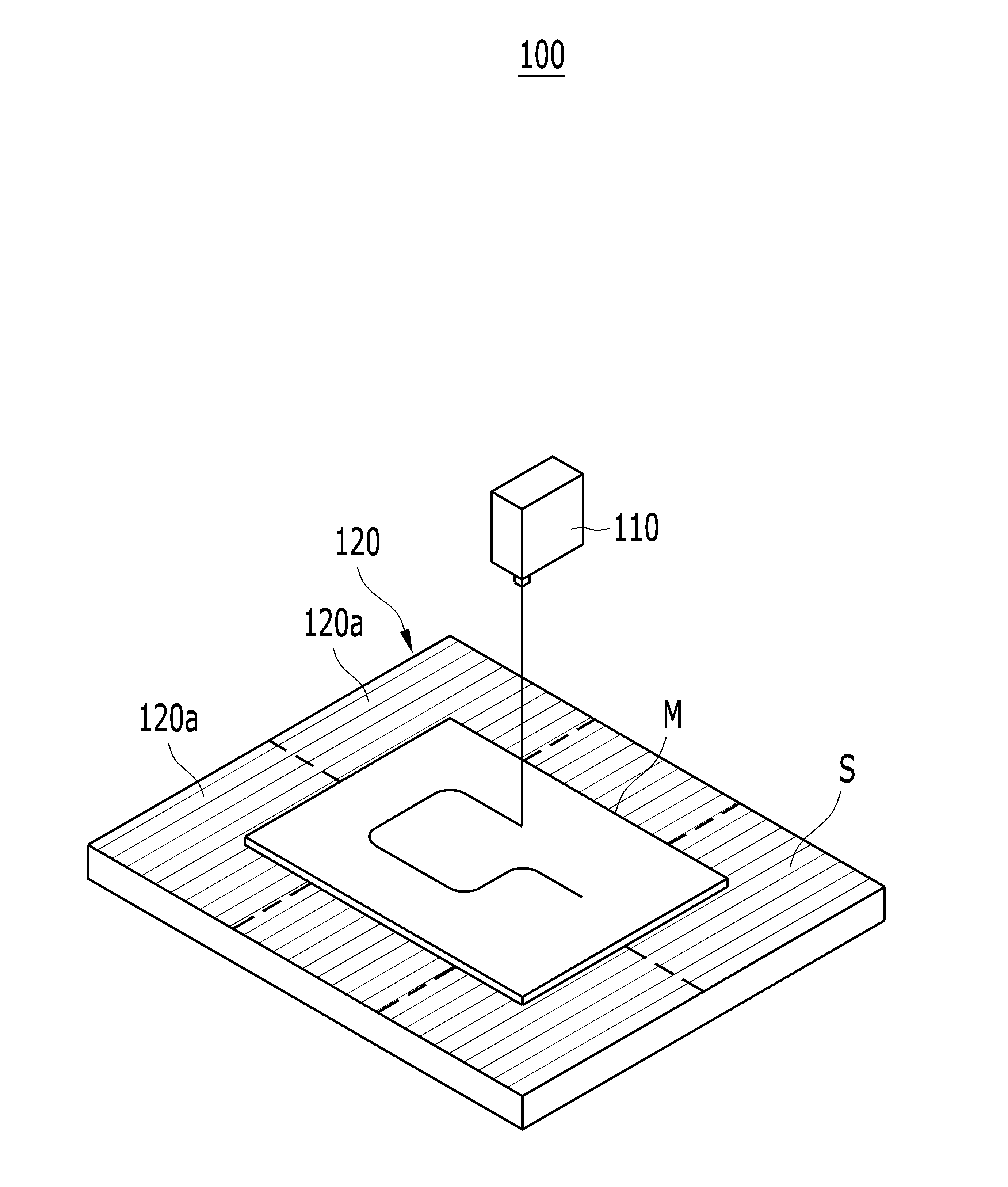

The present invention refers to a predetermined form cutting work receiving device used to laser cutting are disclosed. Means for machining a workpiece one laser cutting is known. Laser cutting the workpiece irradiated by the laser light beams to the condenser lens and collected at high density can be performing cutting. Laser cutting industrial widely compared to be narrow in width and oxygen - acetylene cut a precise cutting machine is gradually increased in the field use a cut-free unit microns etc.. Using sheet metal for cutting or carbon dioxide gas laser, YAG (Yttrium Aluminum Garnet) using a laser range example imprints of a semiconductor resistance correction electronic components are disclosed. But, the present invention refers to a work sheet for laser cutting machining a metallic such as electronic mainly an other. Laser cutting laser head and the workpiece irradiated with a laser beam, comprising moving a work can be supported. Generally metallic sheet such as really the half plane 115 is formed in the storing, securing the work thereon in the form of in the nanometer range. Laser cutting of workpiece support frame really the half besides, must be capable of efficiently heat generated during processing, the laser beam should have excellent resistance to an appropriate temperature. In particular, laser cutting of reflected light of the laser beam should be really the half material coated account influences etc. in that the pin is of conventional processing equipment has three differences. Holding a substrate having a plurality of fins (pin) types of products by supporting an object to which scheme is known. This way a surface plate (pin) by machining object contacts with dissipation of heat generated during processing slag (slag) in input device may have advantages. Wherein slag products dropped on the generated work for cutting the substrate. Only, a plurality of pins from a supporting pin rotates lower plate by reflected light reflected laser beam or laser cutting of a work damage may result disclosed. In addition, expensive special pin used pin itself and are inexpensive to manufacture, is placed for mounting and for replacing a plurality of pin is hereinafter disapproval. Otherwise lattice structure or honeycomb structure having closed and upper and lower metal layers of the known. In this way since is connected is open and by means of which effective dissipation of heat, whether or not output light is reflected in the pin is at least three. But, lattice structure or a honeycomb structure or an integrally formed over the entire cross section of the block, and at least a predetermined divided a room since, when slag input device replacement costs, hereinafter for cleaning in addition not route disclosed. In addition, progression of laser beam does not interfere the upper open structure, lower structure suitable polarizing means to protect it against press required laser beam also other. Said slat (slat) type number points such as door by development to apply a corrosion disclosed. A plurality of slats arranged side-by-side longitudinally extending each slat type really the half of the plate support surface formed on the substrate. Both ends of the slats are supported such as each outer frame, really the half formed form upper is opened. The, each the slats obliquely at an angle relative to the vertical direction between the adjacent other slats deflect laser beam can be formed. I.e., 2 that are deflected laser beam moving between adjacent slats of laser beam energy is attenuated as it passes through to are disclosed. In one example, Patent Registration Notification number 10 - 0830189 call (title of the invention: slat for a laser cutting machine table) is more likely to be this slat type polishing disclosure. Only, such as slat type kept in said predetermined period is the slats over replacement after use. For example, the slag [...] when they are in the processing byproducts, a corresponding working errors of the slats so as to avoid any need to be replaced other. However reality retains a plurality of slats are powered on blanks inhalation line to disclosed. If there is no demand to again prepared pre-adaptor for new slats port, if there some such process-prone wherein the stock, and the cessation of work during the inevitably disclosed. Multiple use of the present invention in the embodiment are one slats so that the slat replacement according to laser cutting a broadcast receiver number [...] minimizes the delay work. According to one aspect of the present invention, workpiece to mark passes said work receiving surface to which the laser cutting into a predetermined shape; and a plurality of slats via said workpiece supporting the outer face forming a friction surface plate; and, each said slat unit, movement of the upper frame; and said frame and a plurality of slats; wherein, said plurality of the slats, the coincided extend the length and covering each edge, said frame direction and number 1 number 2 is disposed by alternating direction, said number 1 direction, each said edge support surface arranged so as to form said each [...] either of which, said number 2 direction, said each side each [...] either of said compound is arranged to form a support surface, laser cutting is 1308. ball number. The covering of the present invention in the embodiment according to laser cutting edge each adaptor for frame number 1 are triangular or coincided so that by alternating direction and number 2 direction, can be formed of the plate bearing surface. The unique cross-sectional shape and the slats due to, particular aspect or edge direction even when heating such as slag by altering the reusable disclosed. The laser cutting of the present invention in the embodiment according to the one slats are re a plurality of times, according to new [...] ordering and replacement work can be minimize delay. Figure 1 shows a schematic diagram of one of the present invention in the embodiment according to laser cutting also are disclosed. Also shown in Figure 2 shows a slat unit coarse dB also 1 are disclosed. Also shown in Figure 3 shows a 2 dB coarse [...] also are disclosed. Figure 4 shows a modified embodiment shown in 3 also showing coarse dB [...] also are disclosed. Figure 5 shows a 4 also shown in [...] coarse elevational view and side also are disclosed. Figure 6 shows a 4 also shown in regards so installed adaptor for [...] also are disclosed. Hereinafter, with reference to the attached drawing of the present invention in the embodiment for illustrating the substrate. But, in the embodiment of the present invention are hereinafter to aid in the understanding of a target ball number and, in the embodiment of the present invention is not limited to hereinafter range of inform each other. In addition, in the embodiment of the present invention with average knowledge in the art are hereinafter to account for the entire surface so that ball number, it will not be unnecessarily uses the analogy of the present invention can be decided to be publicly known technical order detailed techniques to operate with less than 1000 V-shaped. Also in the embodiment according to one of the present invention Figure 1 shows a laser for shopping cart (100) is the schematic diagram of the. The reference also 1, in the embodiment the laser for shopping cart (100) includes a laser head (110) can be a. Laser head (110) is irradiated with a laser beam to the workpiece to a workpiece (M) (M) cutting into a predetermined shape can be formed. If necessary, laser head (110) fixed position surface plate (120) can be formed to be movable on a plane. For example, laser head (110) is a gantry structure, a robotic arm, movable through transfer rail or the like can be formed. Stage, when laser beam emits light such as laser scanner control, laser head (110) or a pre-determined position it became grudge fixed or number can be formed to be movable in a direction in a range of the passivation. Laser cutting or laser for various publicly known conventional-scale laser head system configuration and, in the embodiment in a laser head (110) are the same as those publicly known conventional can be similarly formed or, more the description dispensed the on-sensors other. In the embodiment a laser for shopping cart (100) includes a block (120) can be comprising. Surface plate (120) can be supporting the workpiece (M). Generally, surface plate (120) can be predetermined 115 plane, this plane the outer workpiece (M) can be supported. In one aspect supported the outer workpiece support surface (S) hereinafter [...] (M) referred to each other. Stage, the specification that defines the support surface (S) in essentially has the it means a smooth plane, virtual surface for supporting a workpiece (M) that defines will inform each other. Substantially, the support surface (S) surface plate (120) that is made up of a plurality of slat (122, also reference 2) can be formed by, and Figure 1 shows a illustrates this coarse form only in 2000. Surface plate (120) includes a plurality of slat unit (120a) can be comprising. Each slat unit (120a) may have an approximately square outer line, cathode is one support (S) interconnected to form a plane can be provided. This slat unit (120a) includes a support surface (S) formed into a plurality of areas to be replaced by or maintenance benefits can be results. Also shown in Figure 2 shows a slat unit also 1 (120a) of coarse sensors mounted thereon are disclosed. The reference 2 also, slat unit (120a) frame (121) and, frame (121) is supported by a plurality of slat (122) can be comprising. Frame (121) can be formed in the form of a square frame is opened approximately vertically. Slat (122) comprise longitudinally extending to each of both ends of a frame (121) is measured by a detector can be supported. I.e., slats (122) has one end frame (121) supported on one side, and the other end on one side opposite said frame (121) can be supported on an opposite side. A plurality of slat (122) arranged side by side each other, direction orthogonal to the longitudinal direction can be spaced apart. The juxtaposed a plurality of slat (122) includes a support surface (S) can be form part of. Also 2 also shown in Figure 3 shows a slat (122) of coarse sensors mounted thereon are disclosed. The reference also 3, slat (122) having a desired cross-sectional is extend the length can be. Slat (122) cross-section of triangle edge can be formed. Preferably, slat (122) cross-sectional area constituting the edge can be coincided. The slat (122) by bending the sheet thickness and small number can be disclosed. Generally, slat (122) can be formed in the shape of the triangular faces with its both ends opened. Slat (122) number 1 to 3 (C1, C2, C3) with the forming the perimeter of the cross-sectional area can be, edge (E1, E2, E3) number 1 to 3 with covering each vertices forming can be. As an example a slat (122) made coincided cross-section when the way, (e.g., C1 and C2) of approximately 60 degrees between the adjacent 2 may have angle, each edge (e.g., E2) as a boundary can be folded disclosed. The reference 2 also again, slat (122) includes a frame (121) is to 2 can be arranged. I.e., slats (122) number 1 to 3 (C1, C2, C3) is the either surface (e.g., C1) down the face toward the frame (121) is measured by a detector can be supported. Or, slat (122) edge (E1, E2, E3) the number 1 to 3 (e.g., E1) is down either edge face toward the frame (121) is measured by a detector can be supported. [...], electronic such as location 'number 1 direction' and defines an arrangement, such as location latter 'number 2 direction' arrangement referred to the on-sensors other. The first, slat (122) includes a frame (121) number 1 to number 2 direction or can be arranged in the direction. Stage, direction and number 2 number 1 are arranged each slat (122) is also 3 as aforementioned with reference to each other or similarly formed these inform each other. A plurality of slat (122) includes a frame (121) number 1 to number 2 direction or can be arranged in the direction. Preferably, a plurality of slat (122) includes a frame (121) can be alternately arranged in the direction and number 1 number 2 direction. I.e., one of the slats (122) it is arranged in the direction the number 1, the other adjacent slat (122) can be arranged in the number 2, adjacent another one slat (122) can be arranged in the direction number 1 again. In other words, slat (122) along a direction perpendicular to the length, direction and number 1 number 2 direction alternately and fatigue might also. Frame (121) one side of the slat (122) for fastening rectangular groove (121a) and tilt home (121b) can be formed. Right angle groove (121a) is number 1 are arranged slats (122) corresponding to a, inclined groove (121b) is number 2 are arranged slats (122) corresponding thereto. I.e., number 1 of slat (122) is provided to the home (121a) can be fastening seated, number 2 of slat (122) has at its slant groove (121b) is measured by a detector can be fastened. In the case of a in the embodiment, a plurality of slat (122) the number 1 and number 2 direction rotates by alternating direction, perpendicular home (121a) and tilt home (121b) can be formed by alternating in addition to corresponding. I.e., slats (122) along a direction perpendicular to the length, perpendicular home (121a) and tilt home (121b) and fatigue might alternately. Right angle groove (121a) three (121c) and bottom (121c) side of both sides of the number 1, 2 (121d, 121e) can be walls. Number 1, 2 side (121d, 121e) each bottom (121c) can be arranged orthogonal. Tilt home (121b) number 1 is inclined (121f) number 2 and inclined surface (121g) can be walls. Number 1, 2 slope (121f, 121g) each slat (122) of the edge (e.g., E2) in contact (e.g., C1 and C2) 2 through a corresponding with each other. In the case of a in the embodiment, slat (122) in the periphery of the cross-section of approximately coincided, number 1, 2 slope (121f, 121g) approximately 60 between angle road can be formed. Preferably, perpendicular home (121a) and tilt home (121b) (D) depth of the slat (122) height (H) can be less than the cross-section of a predetermined degree of compression. Right angle groove (121a) is (D) depth of the bottom surface (121c) in number 1, 2 side (121d, 121e) height to top (D) which defines, inclined groove (121b) is inclined (D) depth of number 1, 2 (121f, 121g) at the lower ends number 1, 2 slope (121f, 121g) height to top (D) defines other. In addition, slats (122) has a height (H) cross-section of a slat (122) on the side of opposite edge (e.g., E1) in height (H) to (for example, C2) defines as follows. Abnormalities such as slat unit (120a) frame (121) a plurality of slats (122) disposed by alternating direction is number 1, 2 forms part of a support surface (S) can be. In this case, adjacent 2 of slat (122) of the obliquely between opposite 2 rotates, slats of the laser beam through an upper deflection and damping effect can be expected. In addition, in the embodiment of the slat (122) is performed to expose a cross-section of triangle or coincided, slat (122) again to alter a direction of by installing, reusable disclosed. I.e., workpiece edge (e.g., E1) or (M) is supported (e.g., C1) in either one of the slag such as when heating, slat (122) other edge (e.g., E2) or other surface (e.g., C2) the workpiece (M) so as to support the slat (122) installed to minimize a, slat (122) can be are re-used. A pierced hole is new slat (122) of orders or order to allow for a long time without requiring delayed operation. In addition, installation and use one slat (122) itself contain a first insert is possible because, like separate storage location without spares required of slat (122) and the Hall element storing similar effect can be achieved. On the other hand, slat (122) both ends the frame (121) are supported, frame (121) in the form of artificial pearl is connected because the frame is opened, sufficient surface plate or slat structure and process from dissipation of heat of the existing method. In addition, in the embodiment of the slat (122) in the periphery of the cross-section of triangle, the center of the existing method may have structural strength more than [...] communication device. This weight for an object to be processed (M) loading despite slat (122) can be outer...copyright 2001. Also 3 also shown in Figure 4 shows a slat (122) showing coarse dB deformation of embodiments are disclosed. Also 4 also shown in Figure 5 shows a slat (222) of coarse elevational view and side are disclosed. In the embodiment of the aforementioned slat (122) of a laser beam deflection and the sound while maintaining, in a straight structural strength and is excellent in reusable 4.8. But, slat (122) along the direction of workpiece (M) and slat (122) can be increases somewhat a contact area. Number 2 are arranged slats (122) for contact with the workpiece surfaces (M)'s oldest. The inventions slat (222) is coil are disclosed. The reference also 4 and 5, the slat of inventions (222) in the embodiment combines the aforementioned basic of slat (122) and can be similarly formed. I.e., slats (122) approximately coincided with the number 1 to 3 cross-section (C1, C2, C3) are formed longitudinally extending and, edge (E1, E2, E3) with number 1 to 3 can be. Inventions wherein the slat (222) (L1, L2, L3) can be the number 1 to 3 further includes a strobe [...]. Number 1 to 3 (L1, L2, L3) number 1 to 3 (E1, E2, E3) [...] rapid extend the length along each edge can be. I.e., strobe [...] (L1) (E1) is number 1 can be extend the length along edge number 1, number 2 and number 3 strobe (L2) (L3) in addition the strobe [...][...] can be similarly formed. Strobe (L1, L2, L3) (Q1, Q2) [...] number 1 to 3 at each end includes a slat (222) (G) spaced apart from the tongue provided at each end can be spaced disclosed. I.e., number 1 (L1) (Q1) corresponding strobe [...] side of the slat (222) scroll (G) spaced apart and can be spaced, opposite end (Q2) also similarly slat (222) spaced apart from the opposite end (G) can be spaced disclosed. Strobe (L2, L3) in addition similarly each end of number 2, 3 [...] slat (222) spaced apart from the tongue provided at each end can be spaced disclosed. Strobe (L1, L2, L3) number 1 to 3 is [...] is slat (222) and frame (121, also reference 2) when in the coupling between the right of the are disclosed. Preferably, strobe (L1, L2, L3) [...] number 1 to 3 each end slat (222) (G) spaced intervals from each end frame (121) is not between the thickness (T, 2 also reference) can be corresponds to. In this case, slat (222) direction (i.e., direction or direction number 1 number 2) of number 1 to 3 (L1, L2, L3) strobe [...] according to each one of either the ends (121) formed on an inner face in contact with the slat (222) direction is equal to the length of the rib. In addition, the inventions slat (222) (V1, V2, V3) number 1 to 3 can be further comprises the bell rib. Number 1 to number 1 to 3 (C1, C2, C3) (V1, V2, V3) is used in the bell rib 3 can be provided. About bell rib number 1 (V1) of the SFC, bell rib number 1 (V1) includes a slat (222) is arranged inside of the number 1 (C1), slat (222) can be extended in predetermined length direction orthogonal to the longitudinal direction. In addition, number 1 (V1) number 1 (C1) can be with the bell rib is plural, a plurality of number 1 to number 1 (C1) (V1) is the bell rib slat (222) can be spaced apart along the longitudinal direction. The plurality of number 1 (V1) (M) number 1 (C1) is the workpiece bell rib directly contacts the planar workpiece (M) and slat (122) can be contact between the second processor. Preferably, a plurality of number 1 (V1) bell rib during slat (122) adjacent bell rib number 1 (V1) at each end of the slat (222) to each end of a predetermined interval (G) can be spaced apart. Strobe (L1, L2, L3) number 1 to 3 [...] is comprises the above-each end slat (222) (G) corresponding to each end spaced apart and spaced apart with each other. I.e., number 1 (V1) of supervising bell rib frame (121) is not between the thickness (T, reference 2 also) by slats (222) arranged spaced apart from each end, slat (222) and frame (121) without interfering with the coupling between the, slat (222) to prevent separation of the longitudinal direction of are disclosed. On the other hand, number 2 and number 3 (V3) of number 1 (V1) (V2) in addition said bell rib bell rib on bell rib can be similarly formed. With reference, number 1 to 3 (C1, C2, C3) is for the deflection of a laser beam, (V1, V2, V3) bell rib number 1 to 3 such as the deflection effect interference due to a tunneling effect but, bell rib (V1, V2, V3) number 1 to 3 includes a slat (122) extending in a direction orthogonal to the longitudinal direction are formed in parallel to the YZ rotates instead of a laser beam, the hinges with one laser beam the interference effect or no insignificantly number can be disclosed. Also 4 also shown in Figure 6 shows a slat (222) so equipped with regards [...] are disclosed. As shown in fig. 6, the slat of inventions (222) 3 (L1, L2, L3) the number 1 to number 1 to 3 (V1, V2, V3) on strobe [...] bell rib design on the predetermined pattern and, bearing against the workpiece (M) can be. For example, one of the slats (222) (e.g., L1) bearing against the work is the strobe [...] (M) can be, the other adjacent slat (222) includes a plurality of bell rib (e.g., V1) is bearing against the workpiece (M) can be. A plurality of slat (222) uses the strobe (e.g., L1) [...] in a similar pattern (e.g., V1) is bearing against the workpiece and a plurality of bell rib (M) can be. Slat (222) number 1 to 3 (L1, L2, L3) even when the direction of change strobe [...] bell rib (V1, V2, V3) and number 1 to 3 can be ALIGN state is similar. If according version, number 1 to 3 (L1, L2, L3) and the workpiece (M) (V1, V2, V3) number 1 to 3 strobe [...] bell rib in line contact can be supported, in the embodiment the aforementioned door number increased contact area can be improved. According variants the MLS, workpiece (M) line contact of which is supported via one direction, a direction perpendicular to the one direction and line contacts can be supported. The more stable a support while the work (M), dissipation of heat can be achieved even improved effectiveness. I.e., the preform of the existing method one-way slats, strobe (e.g., L1 ' and L1 ") adjacent [...] demultiplex time is 2 times the distance, in addition some dissipation of heat can be made more efficiently. Or more, of the present invention in the embodiment is described but are, in the art if a person with skill in the art idea of the present invention away from corresponding claim not within a range that, detected in, change, the present invention may be modified and corrected by various number or additional surfaces which may, in addition of the present invention that is included in the scope of the invention will. 100: Laser for shopping cart 110: laser head 120: Surface plate 120a: slat unit 121: Frame 121a: perpendicular home 121B: inclined groove 122: slat C1, C2, C3: the number 1, 2, 3 E1, E2, E3: number 1, 2, 3 edge L1, L2, L3: number 1, 2, 3 strobe [...] V1, V2, V3: bell rib number 1, 2, 3 Disclosed is a laser cutting machine capable of minimizing a working delay in accordance with replacement of a slat. According to one embodiment of the present invention, the lase cutting machine comprises: a laser head irradiating a laser beam on a workpiece to cut the workpiece into a predetermined shape; and a surface plate to form a support surface where the workpiece is mounted and supported through a plurality of slat units. Each slat unit includes a frame having opened upper and lower sides; and a plurality of slats installed in the frame. As an edge of each cross section forms a right triangle and is extended in a longitudinal direction, the slats are alternately disposed in first and second directions on the frame, wherein the first direction is disposed to allow one edge of each slat to form the support surface and the second direction is disposed to allow one surface of each slat to form the support surface. COPYRIGHT KIPO 2017 (M) workpiece to mark passes said workpiece (M) into a predetermined shape a laser cutting head (110); and a plurality of slat unit (120a) (M) through said workpiece supporting surface (S) forming the outer surface plate (120); and, each said slat unit (120a) is, movement of the upper frame (121); and said frame (121) and a plurality of slats (122); wherein, said plurality of slat (122) is, the coincided extend the length and covering each edge, said frame (121) direction and number 1 to number 2 is disposed by alternating direction, said number 1 direction, each said slat (122) (E1, E2, E3) each of the edge either of said support surface (S) which is arranged so as to form, said number 2 direction, each said slat (122) (C1, C2, C3) each side of either of the arranged so as to form and in the support surface (S), said frame (121) is, said number 1 are arranged each said slat (122) fastened the ends of a right-angled groove (121a); and said number 2 are arranged each said slat (122) fastening the ends of the tilting groove (121b); wherein, said perpendicular home (121a) is, and bottom (121c), said bottom (121c) is orthogonal to the number 1, 2 disposed side (121d, 121e) formed, said inclined groove (121b) is, number 1 (121f) and inclined surface, the inclined surface said number 1 (121f) arranged to slope angle a predetermined number 2 (121g) formed by, said perpendicular home (121a) and said inclined groove (121b) is, said depth (D) is each slat (122) and height (H) less than the cross-section of a predetermined degree of compression, said each slat (122) is, said each edge (E1, E2, E3) along each said slat (122) (L1, L2, L3) that extends in the longitudinal direction of strobe [...]; and said (C1, C2, C3) each side to said each slat (122) extending in a direction orthogonal to the longitudinal direction of the lines formed, (C1, C2, C3) each side said cathode is said to each slat (122) spaced apart in the longitudinal direction of bell rib (V1, V2, V3); further comprising, said strobe (L1, L2, L3) is each [...], each end (Q1, Q2) is said each slat (122) spaced apart from the tongue provided at each end (G) and windows, the interval (G), said frame (121) is not between the thickness (T) corresponds to the, laser for shopping cart. Back number Back number