EARPHONE

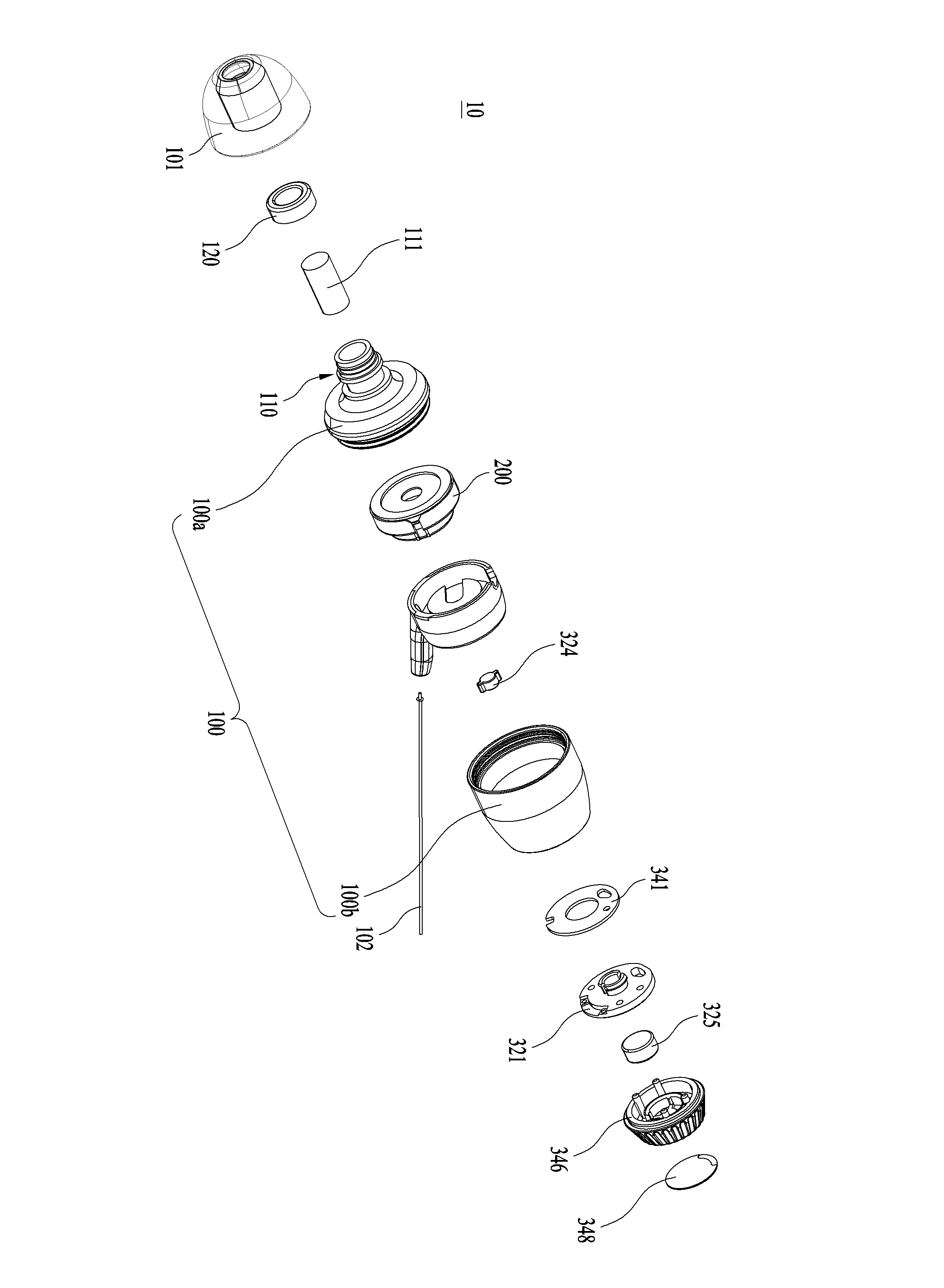

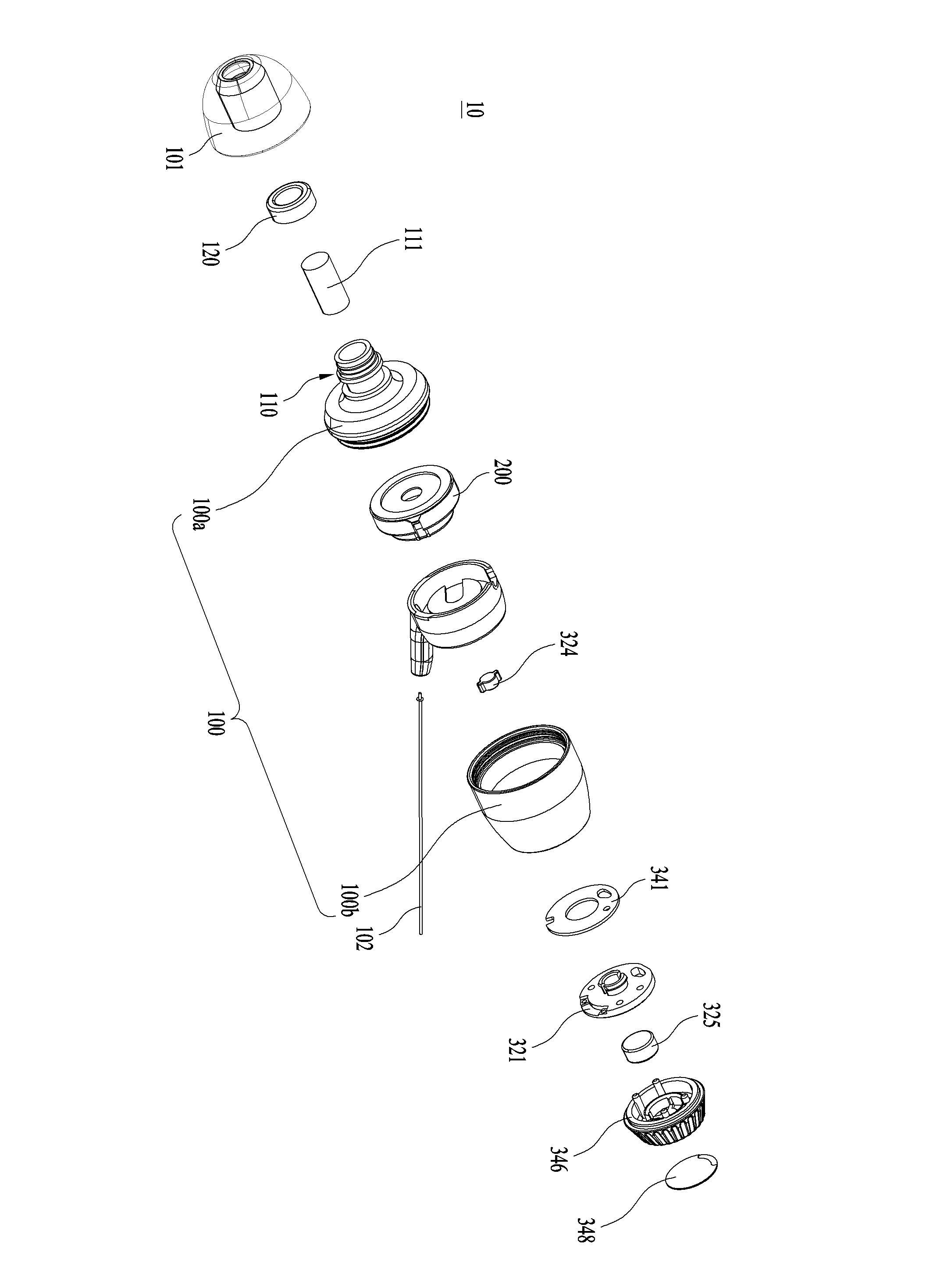

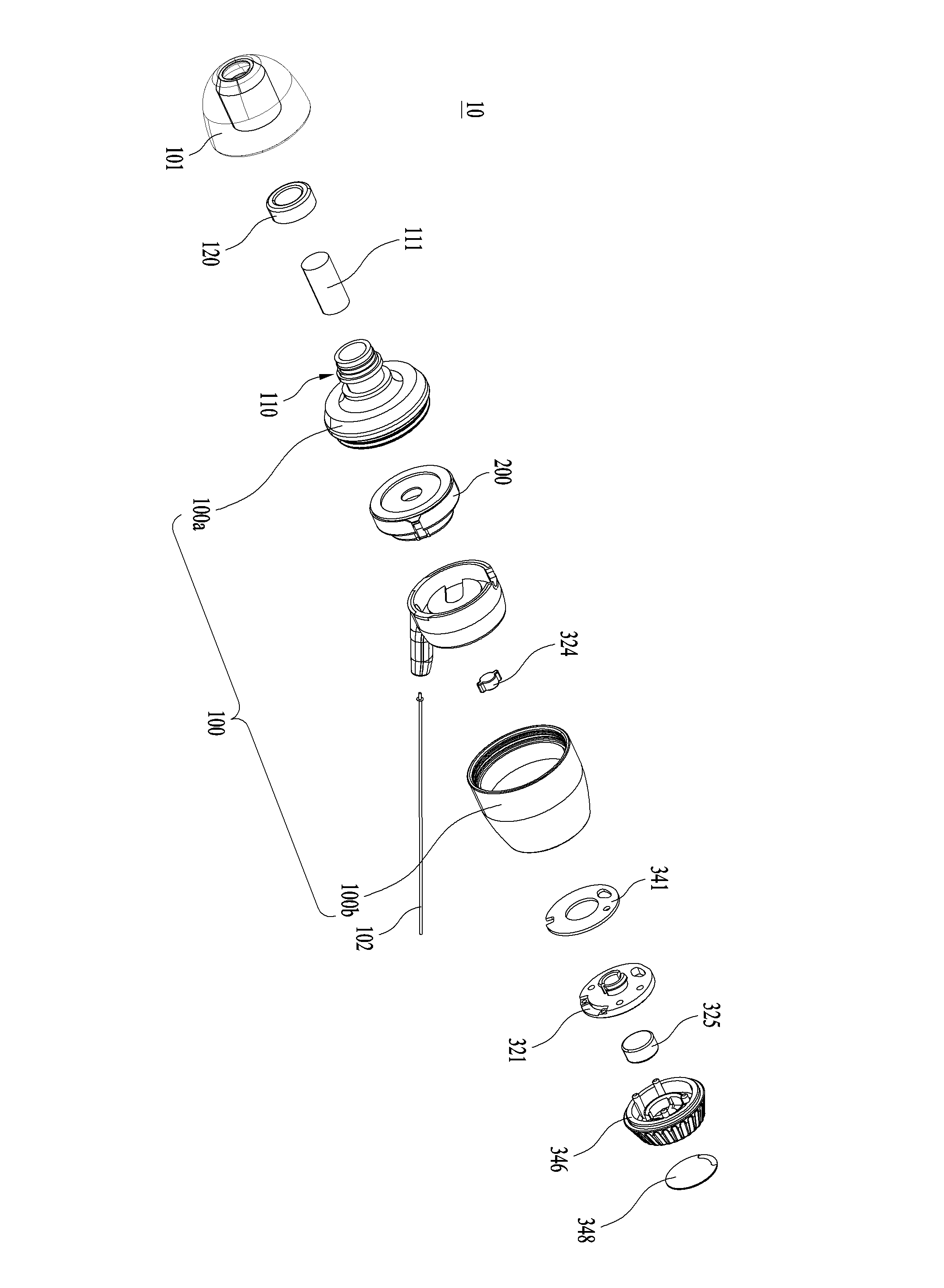

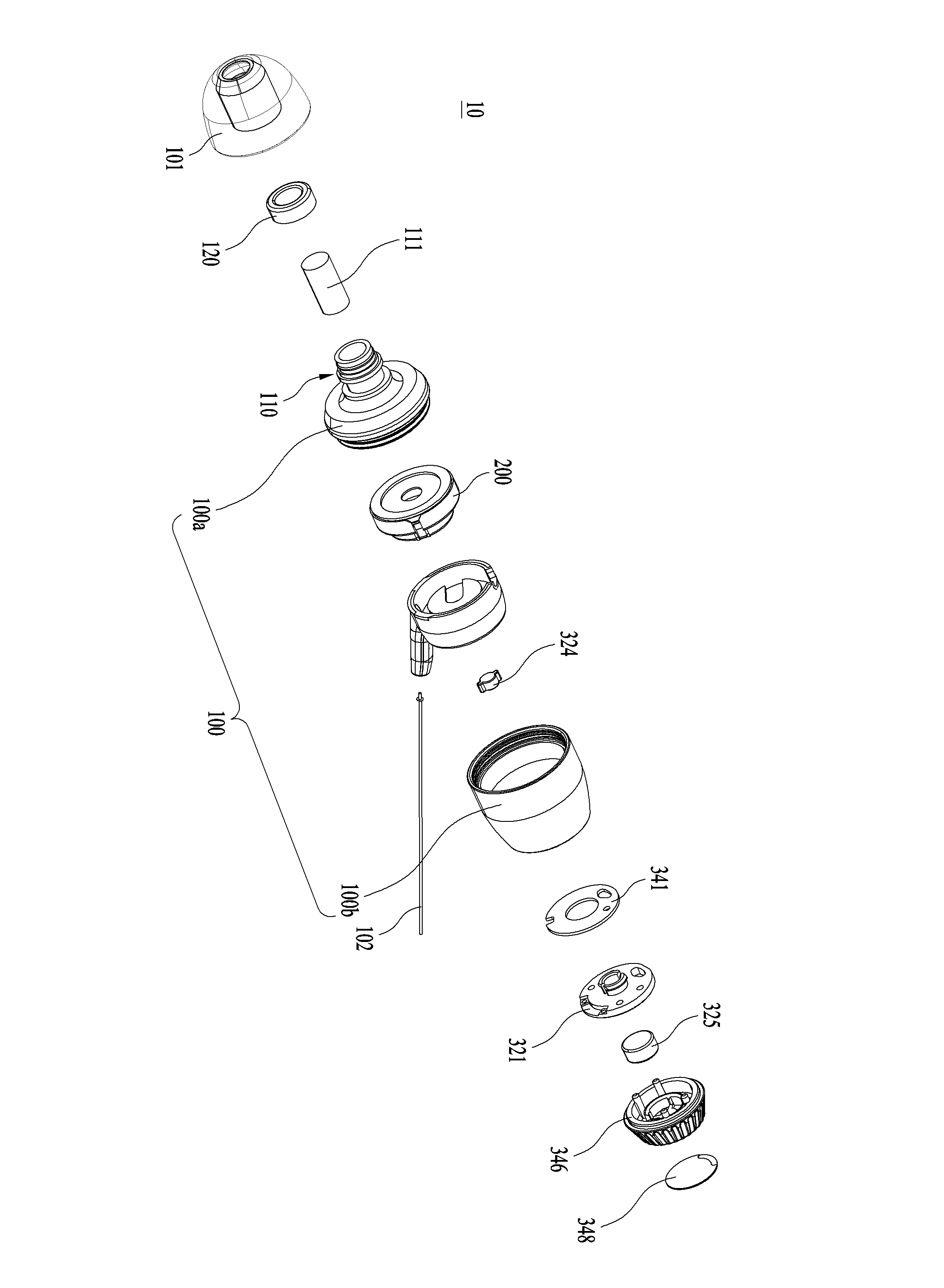

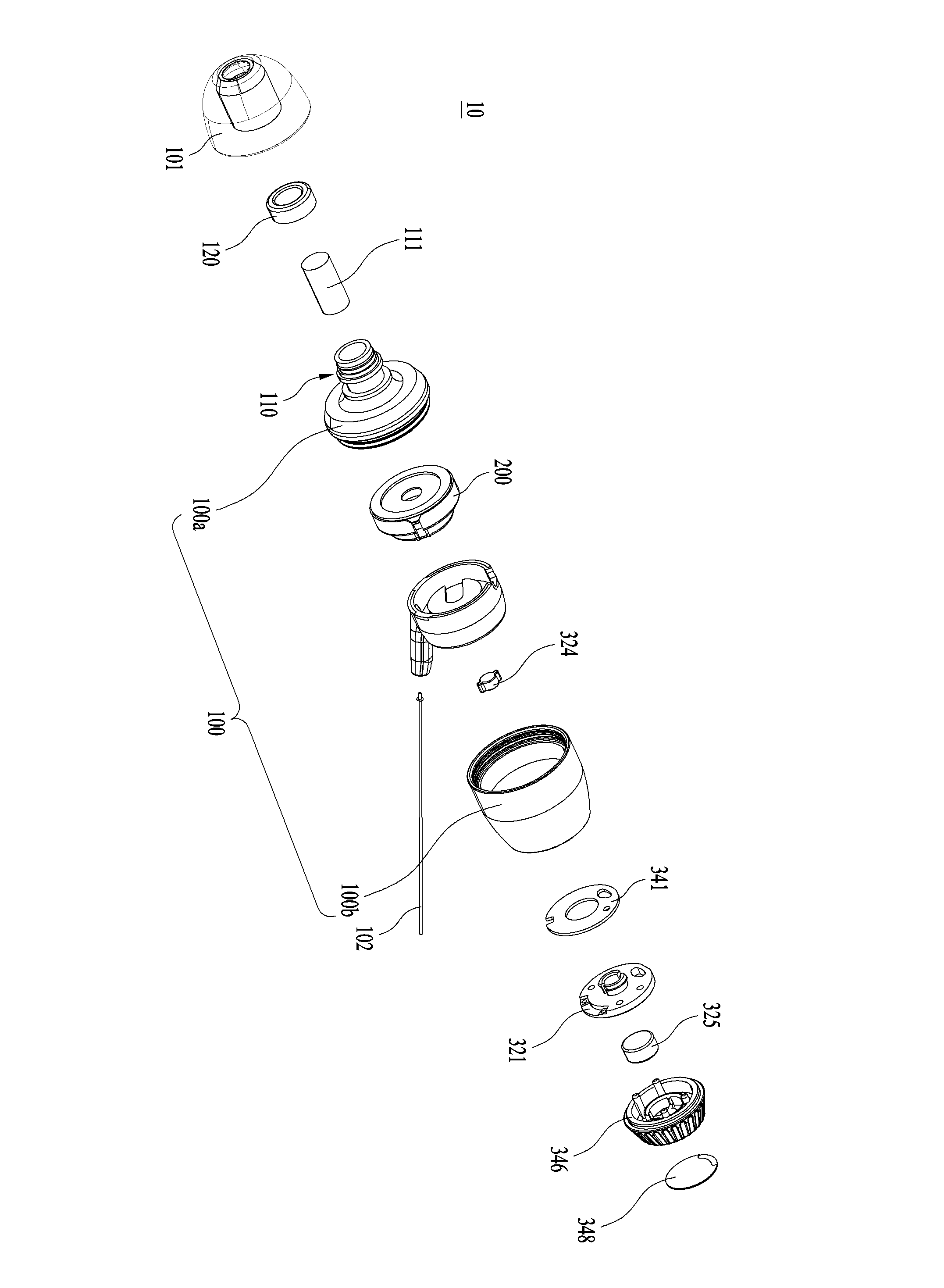

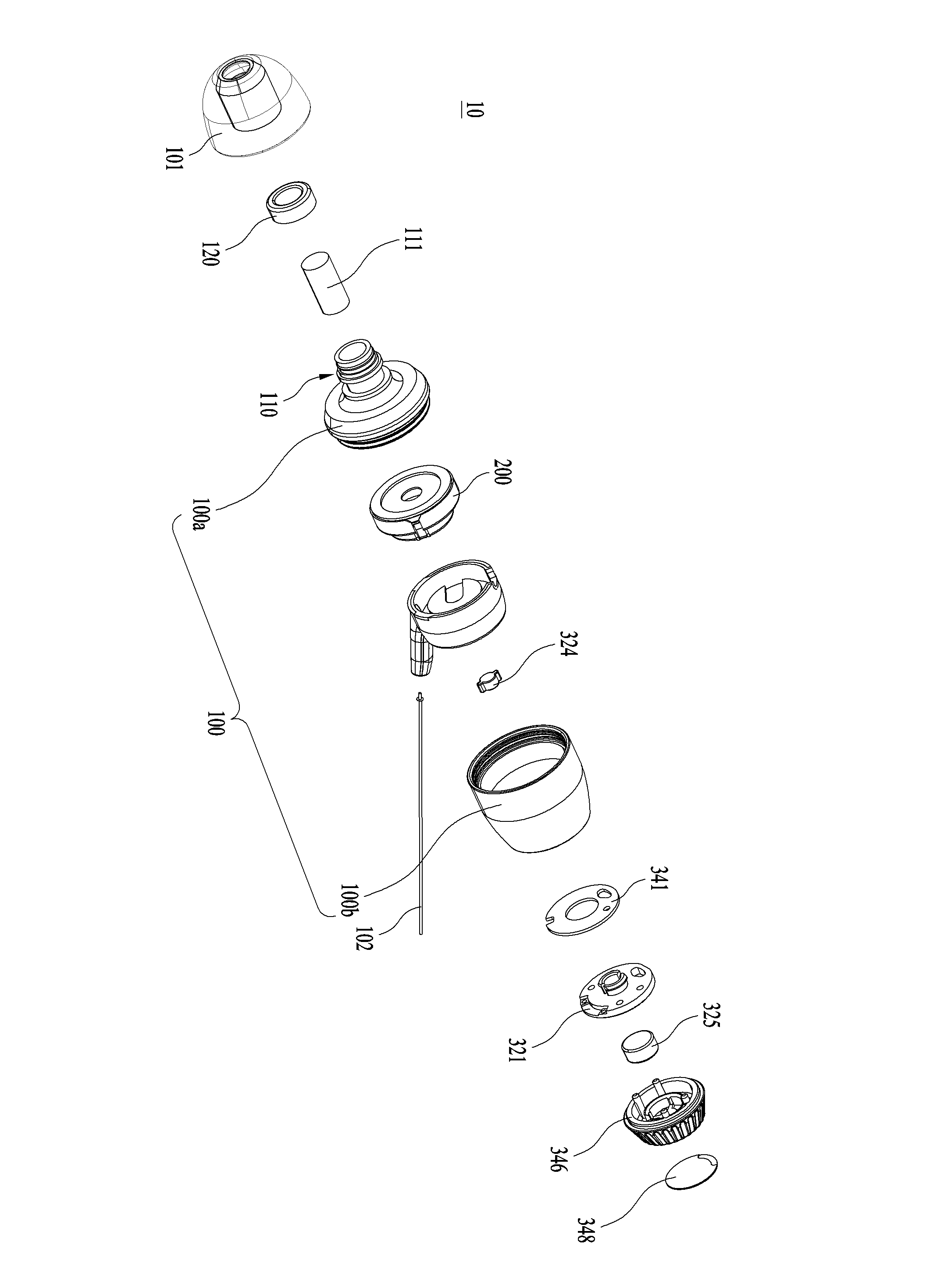

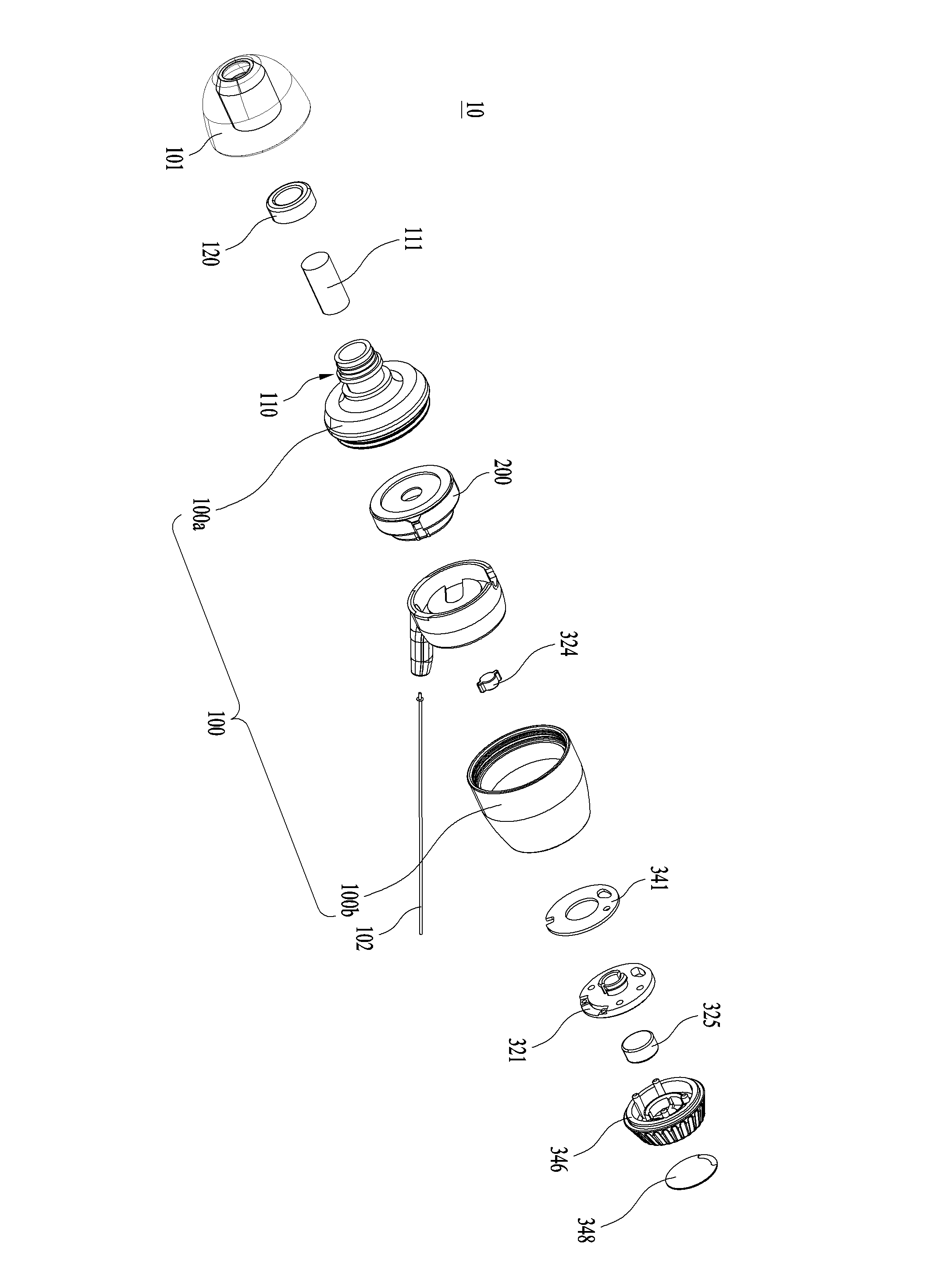

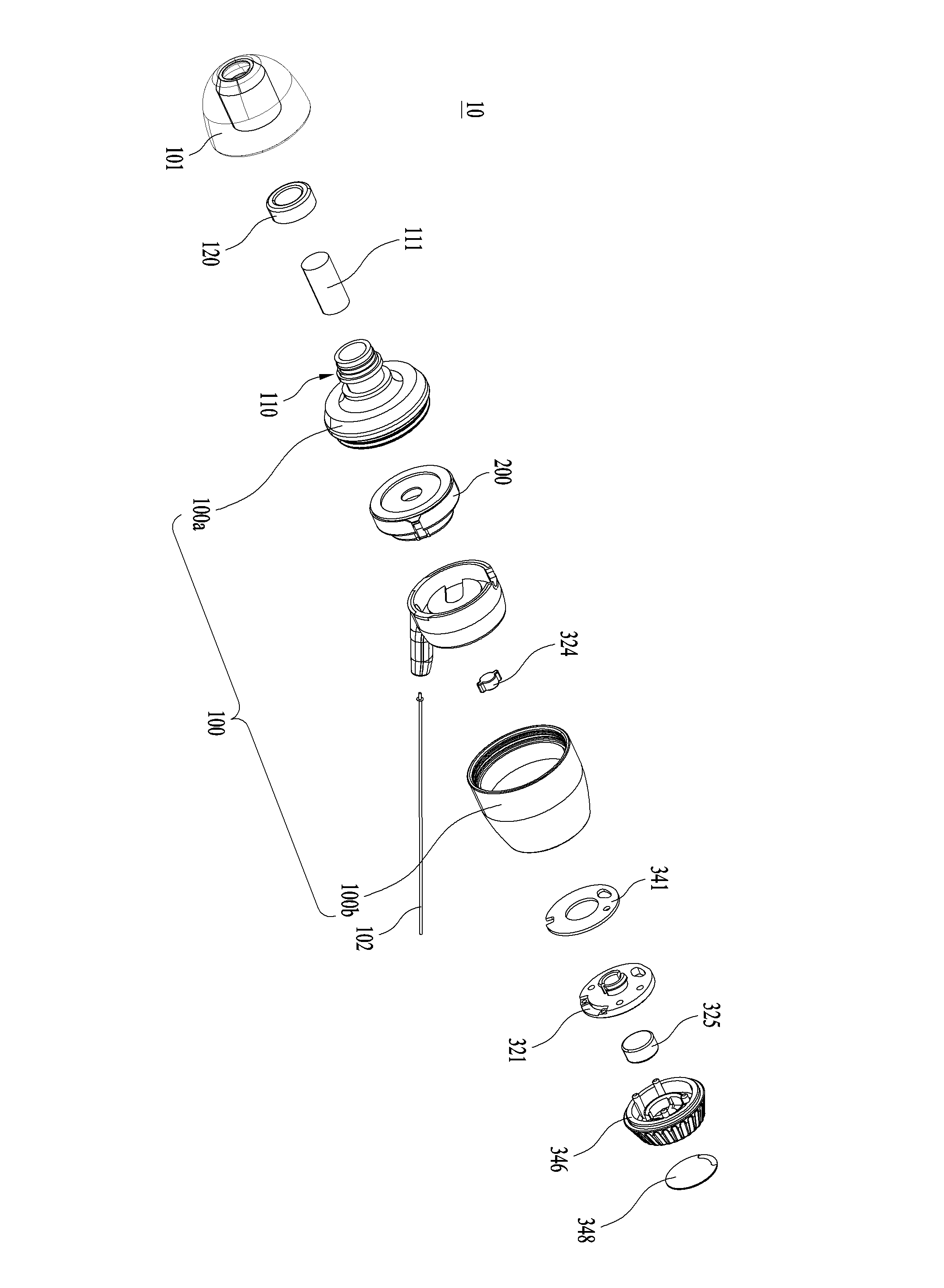

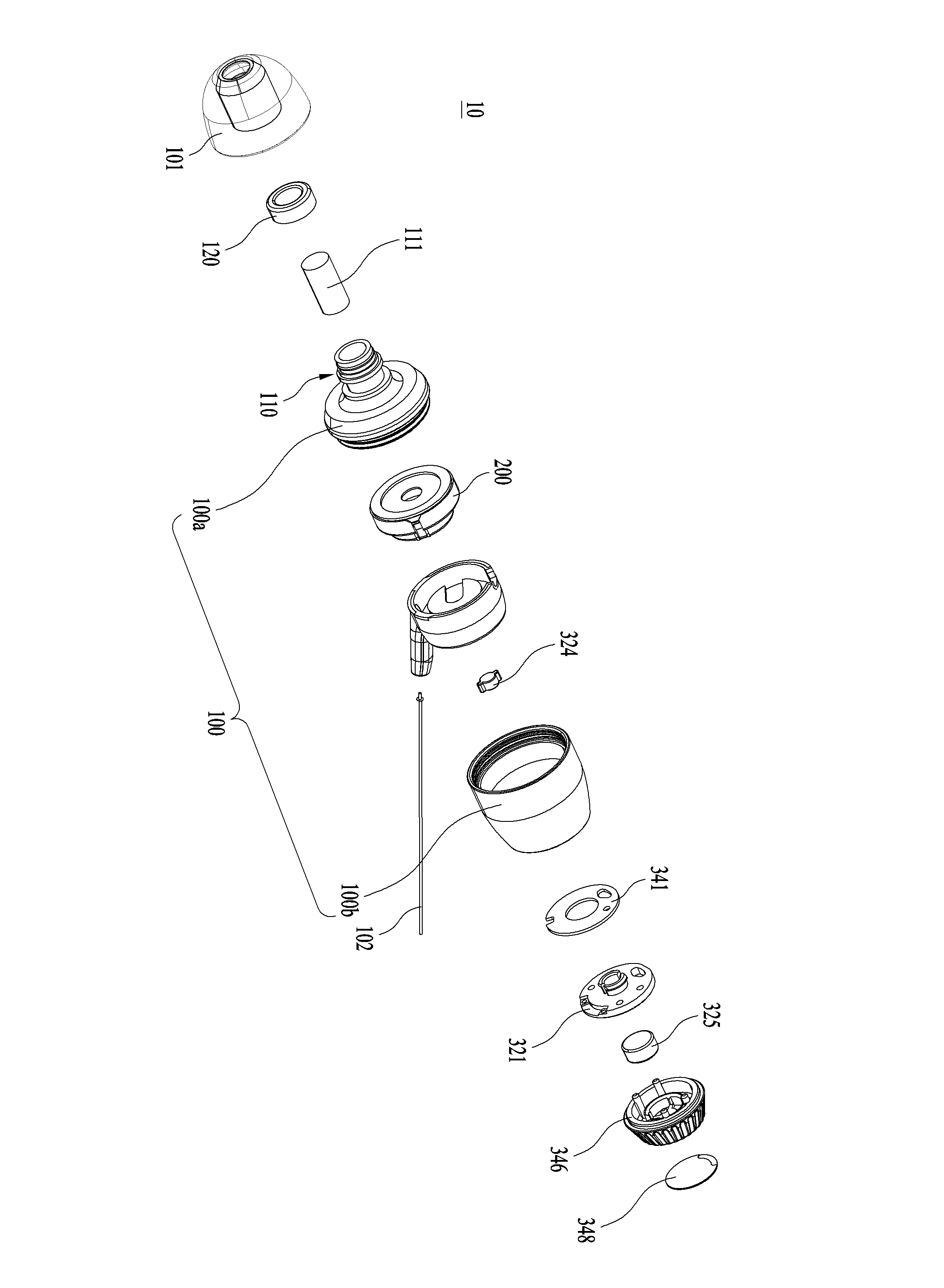

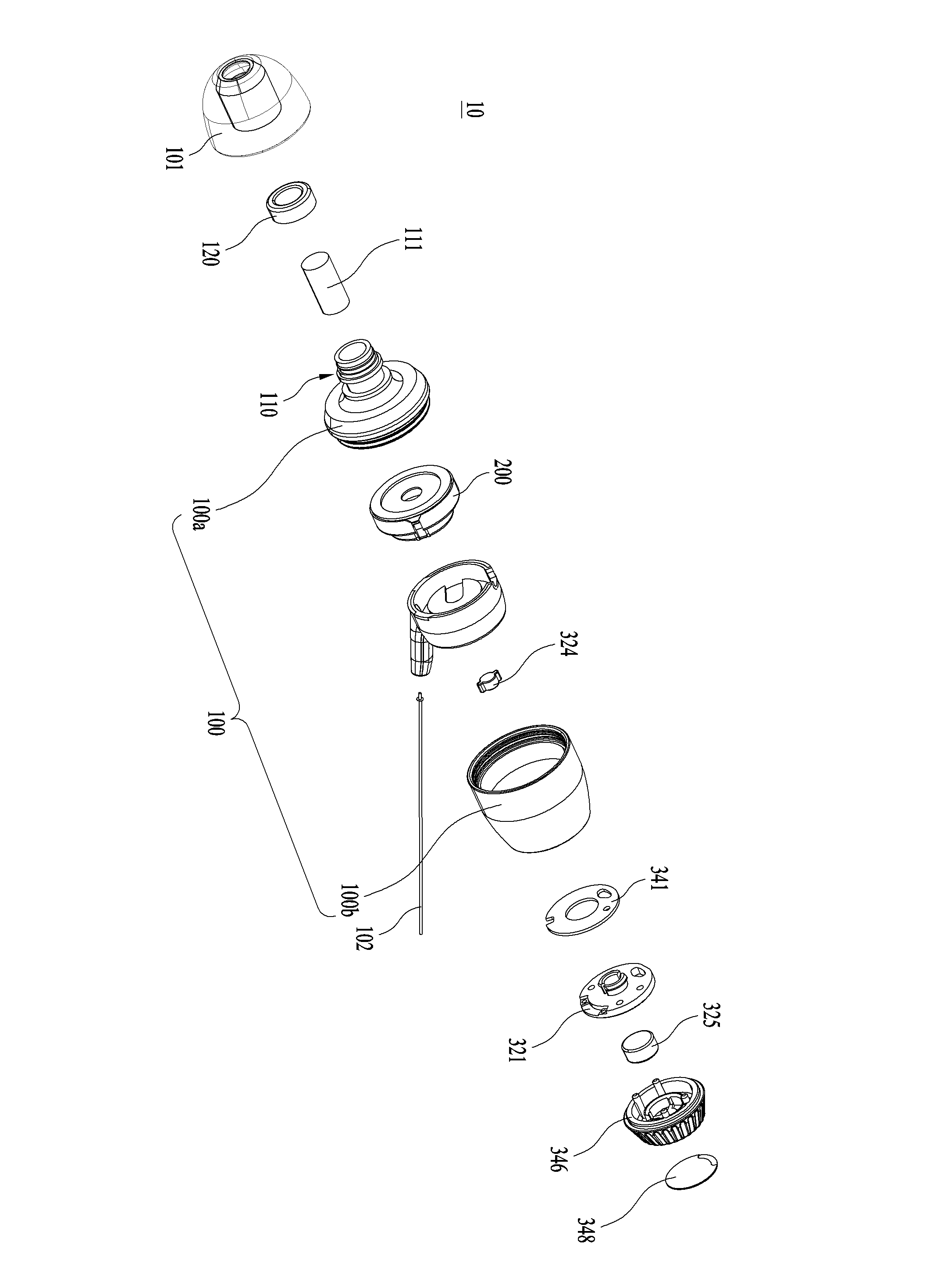

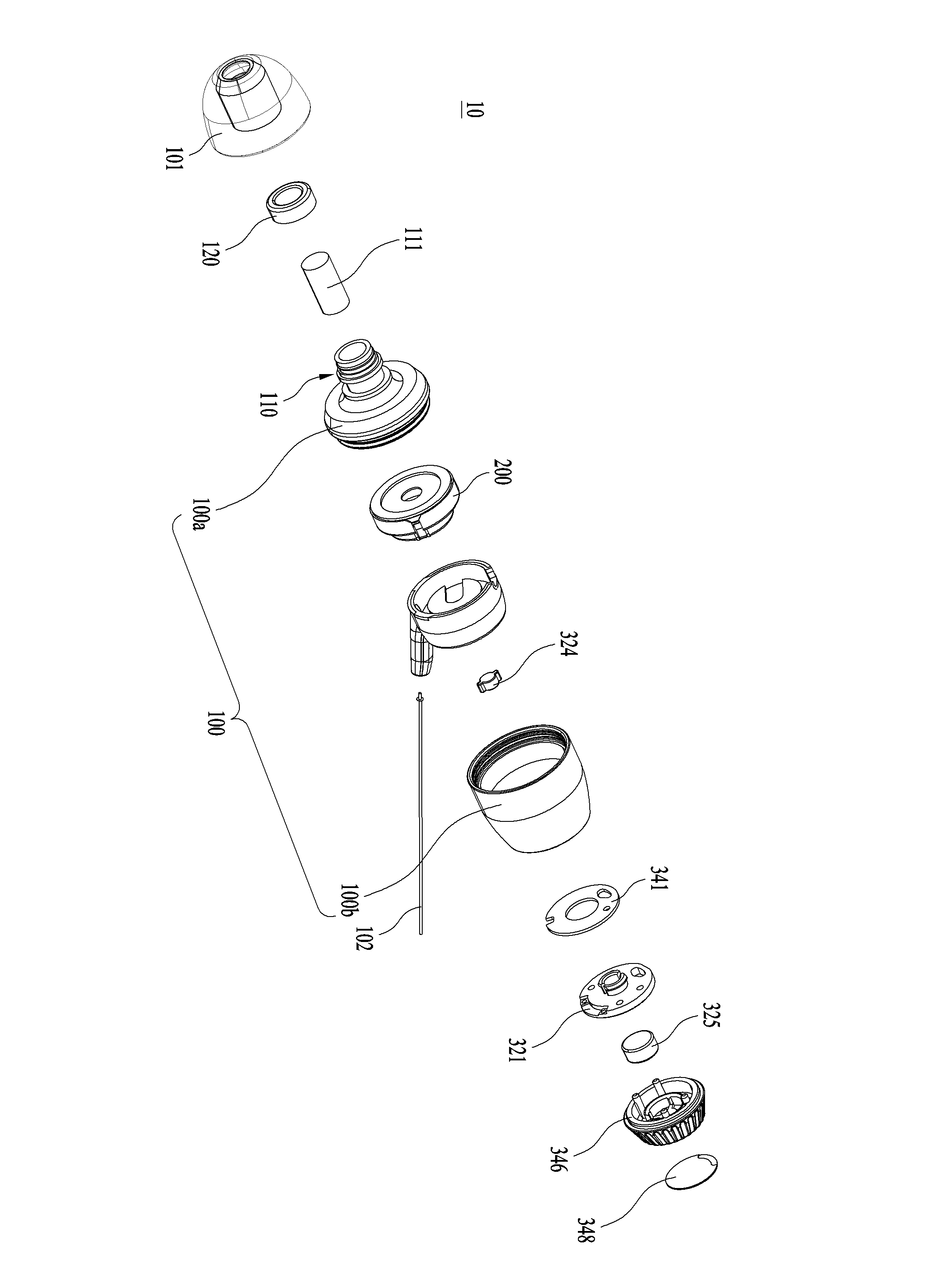

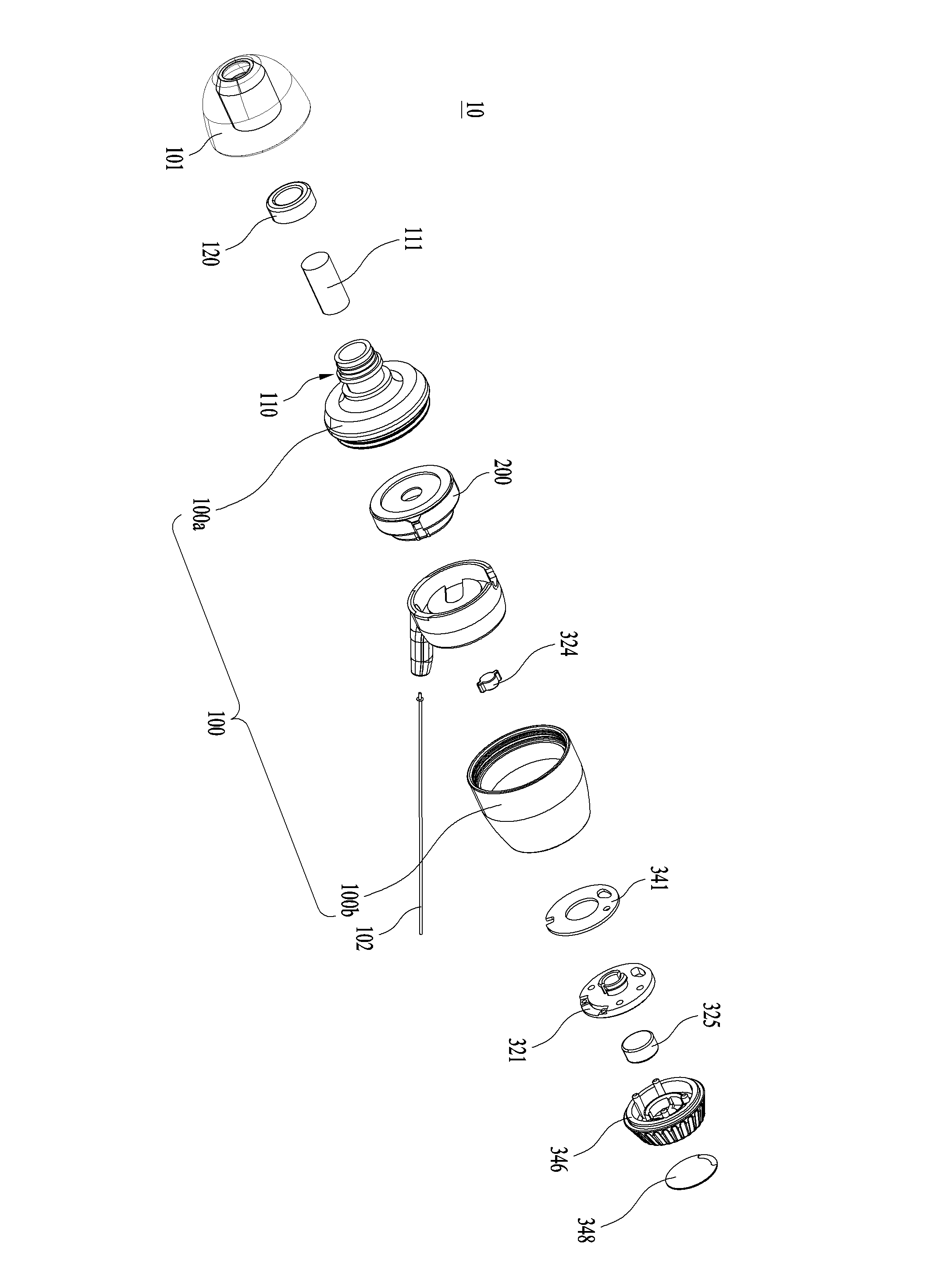

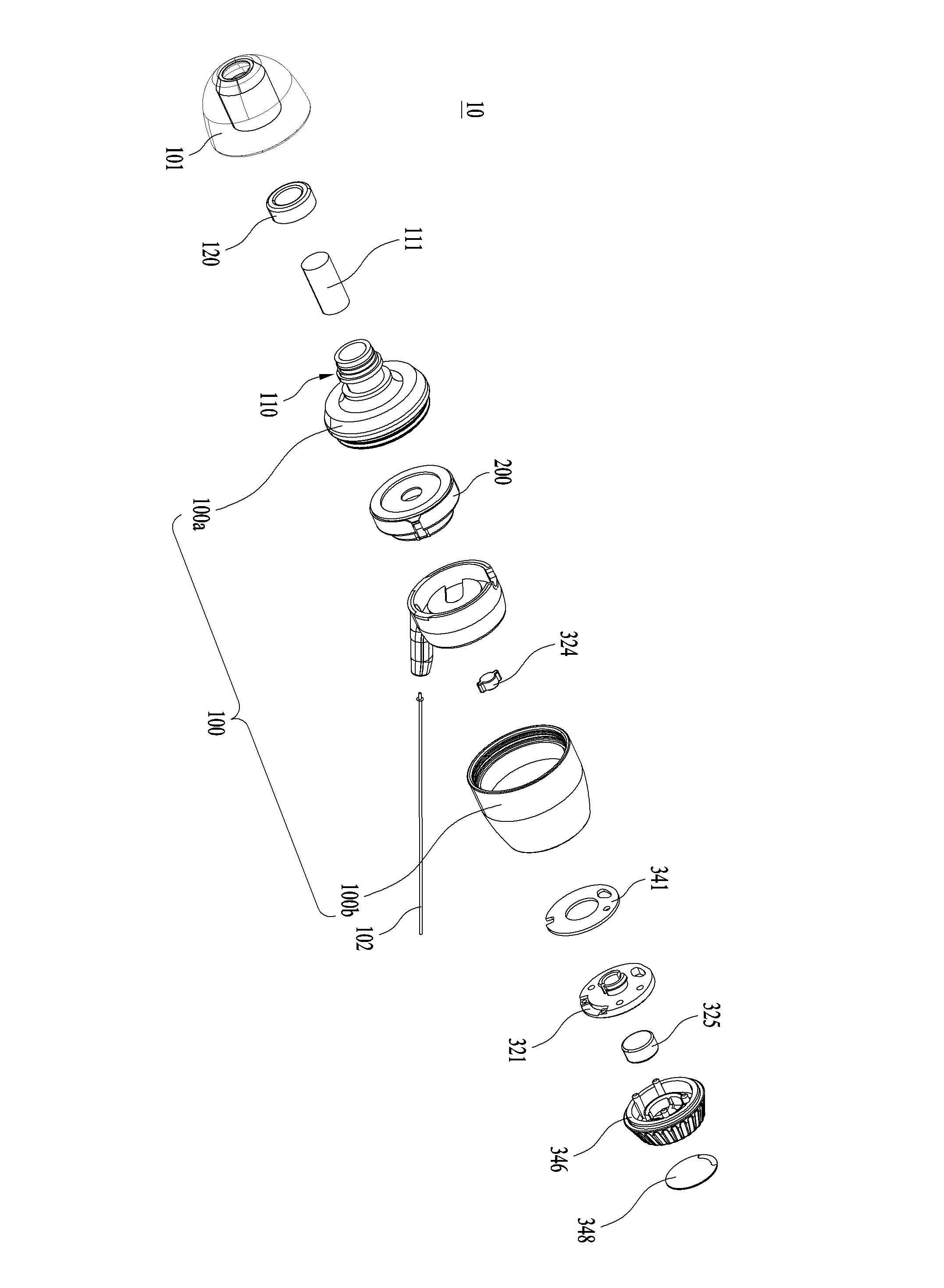

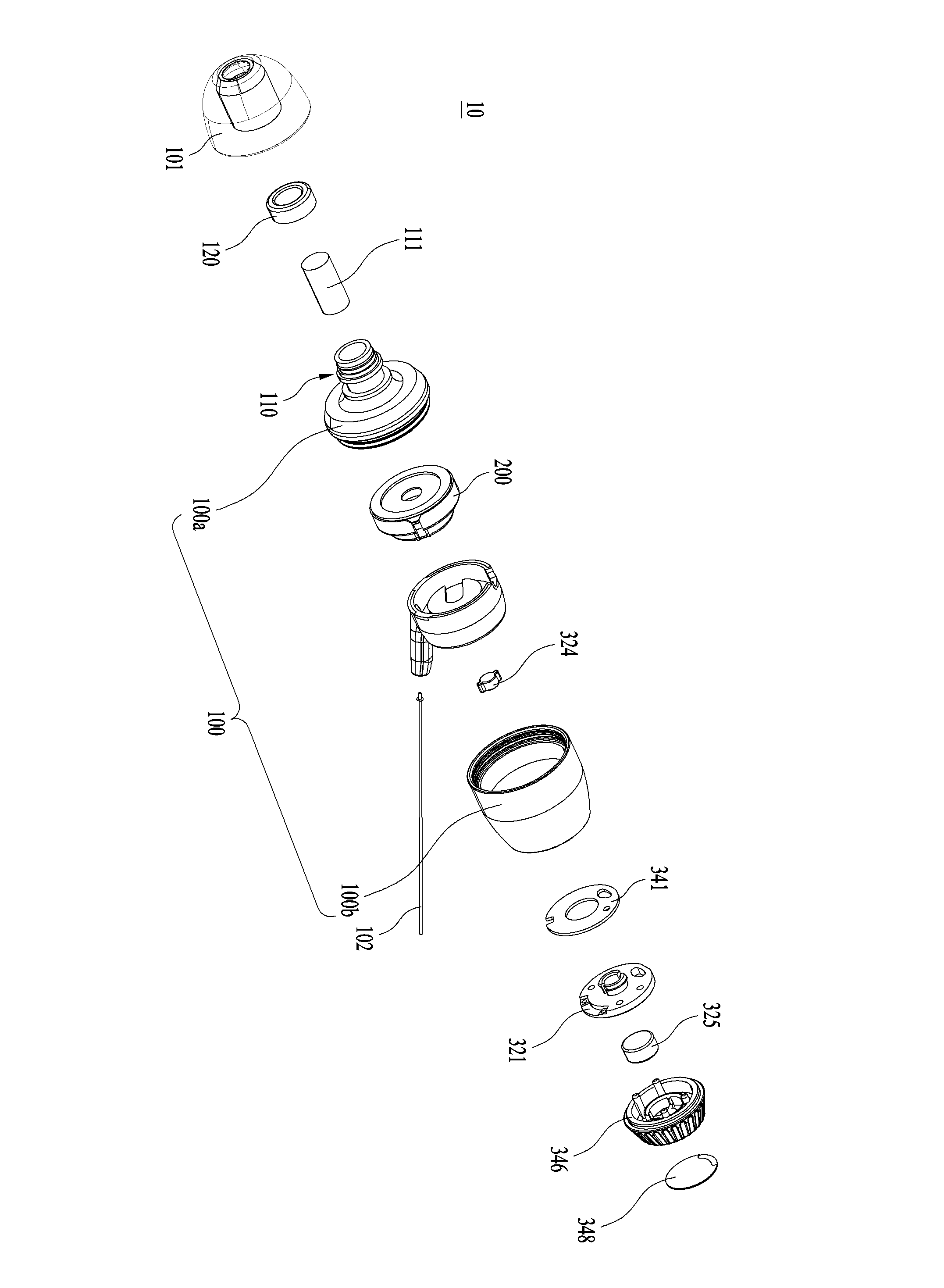

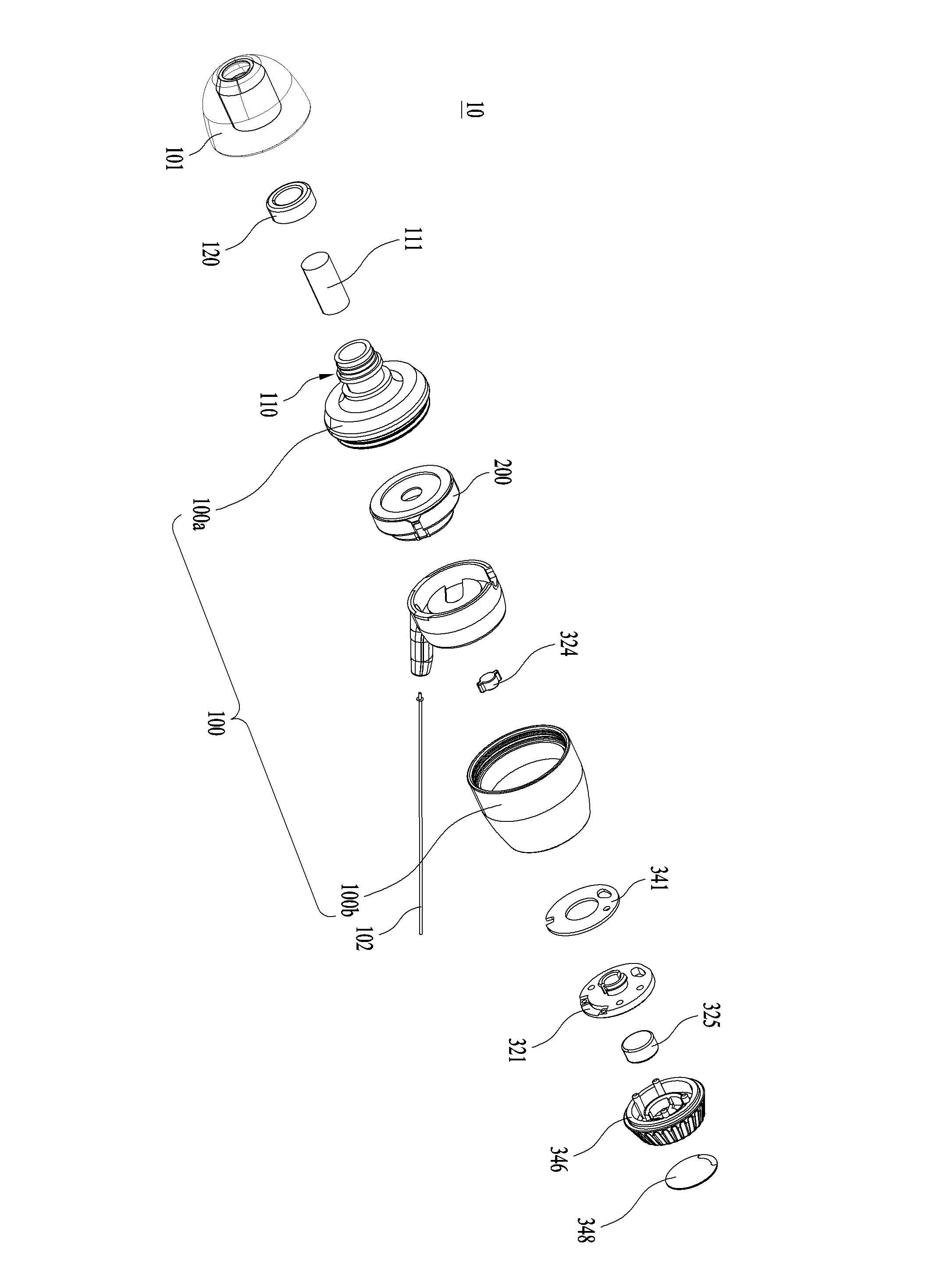

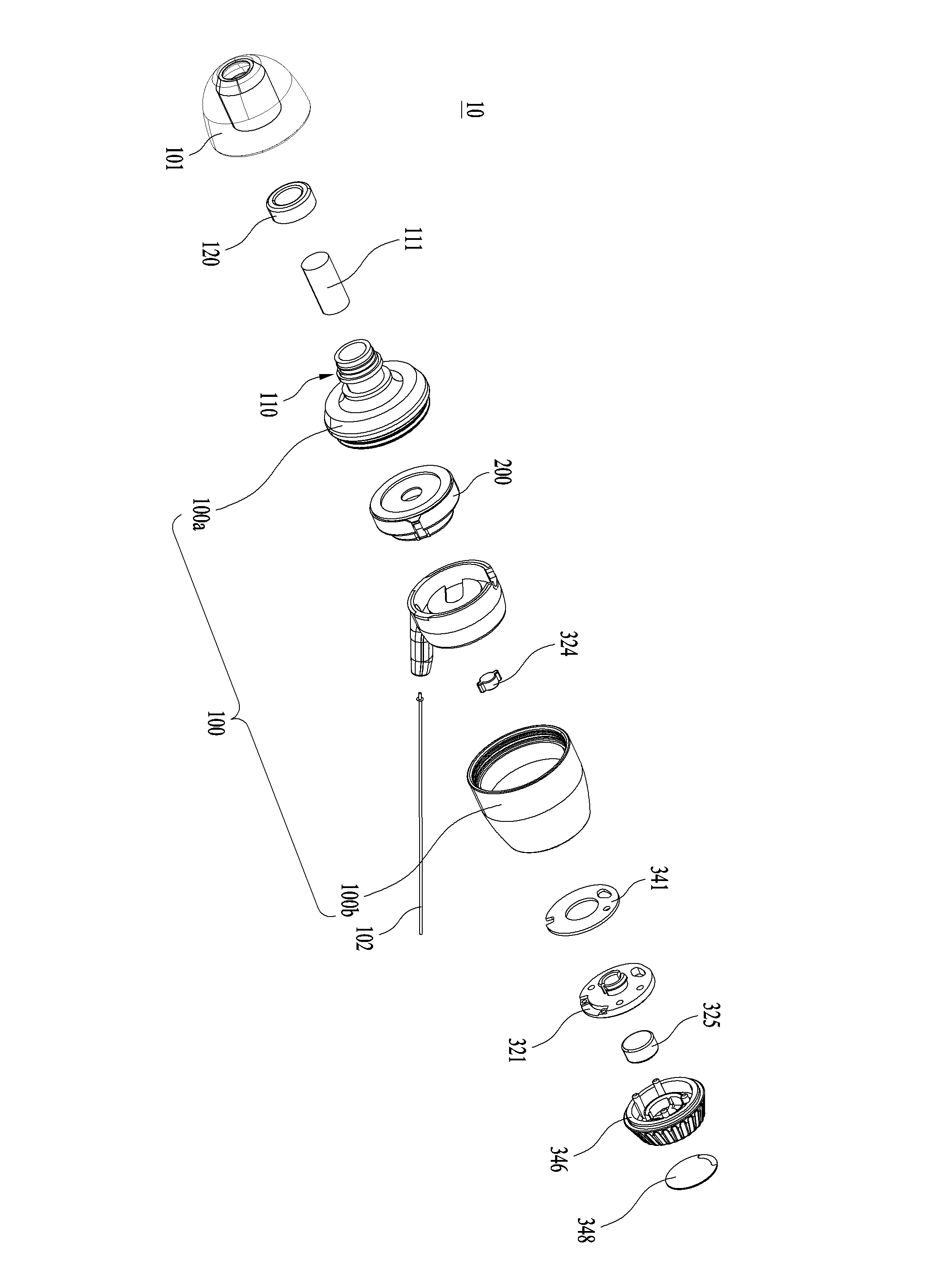

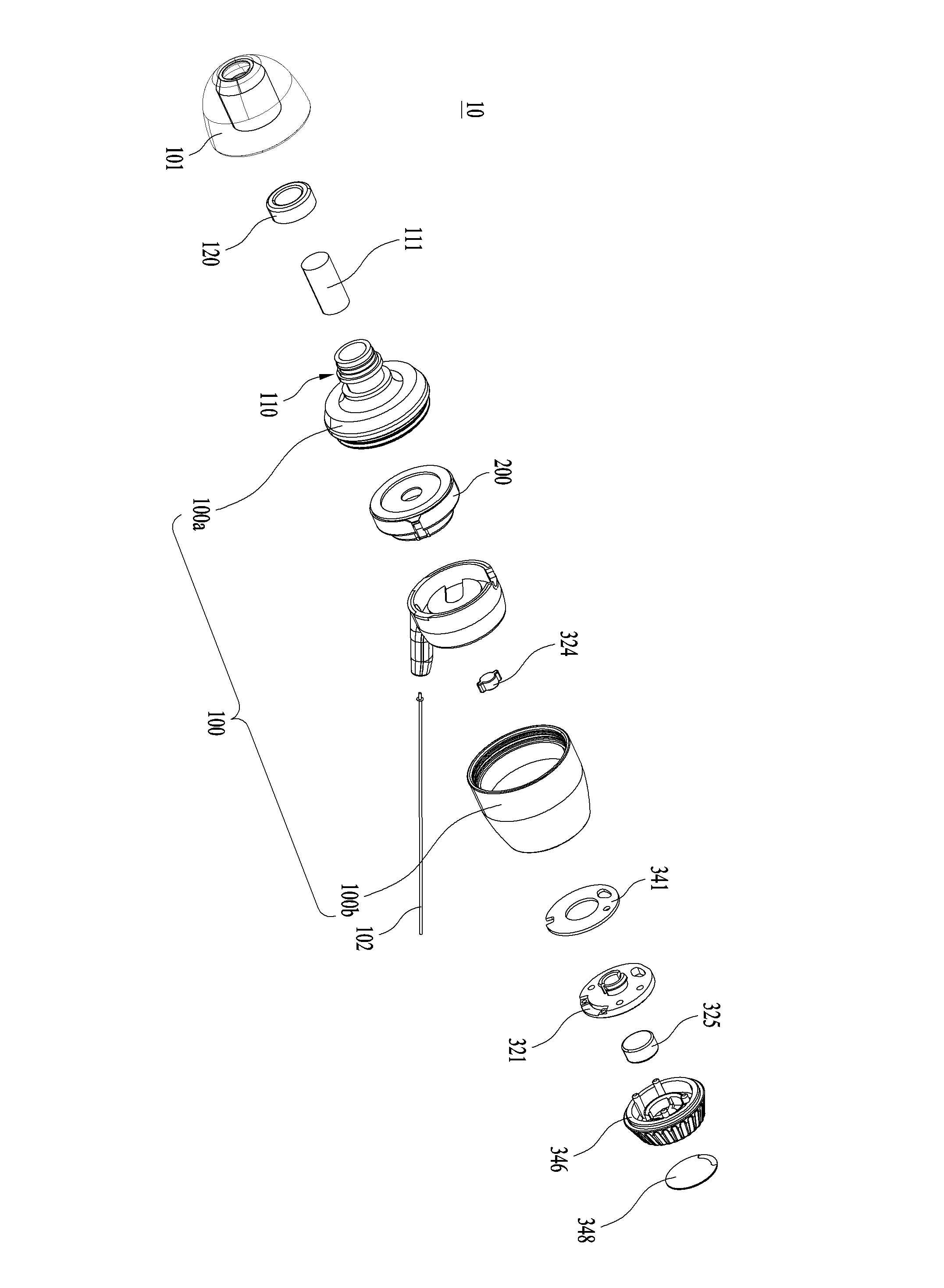

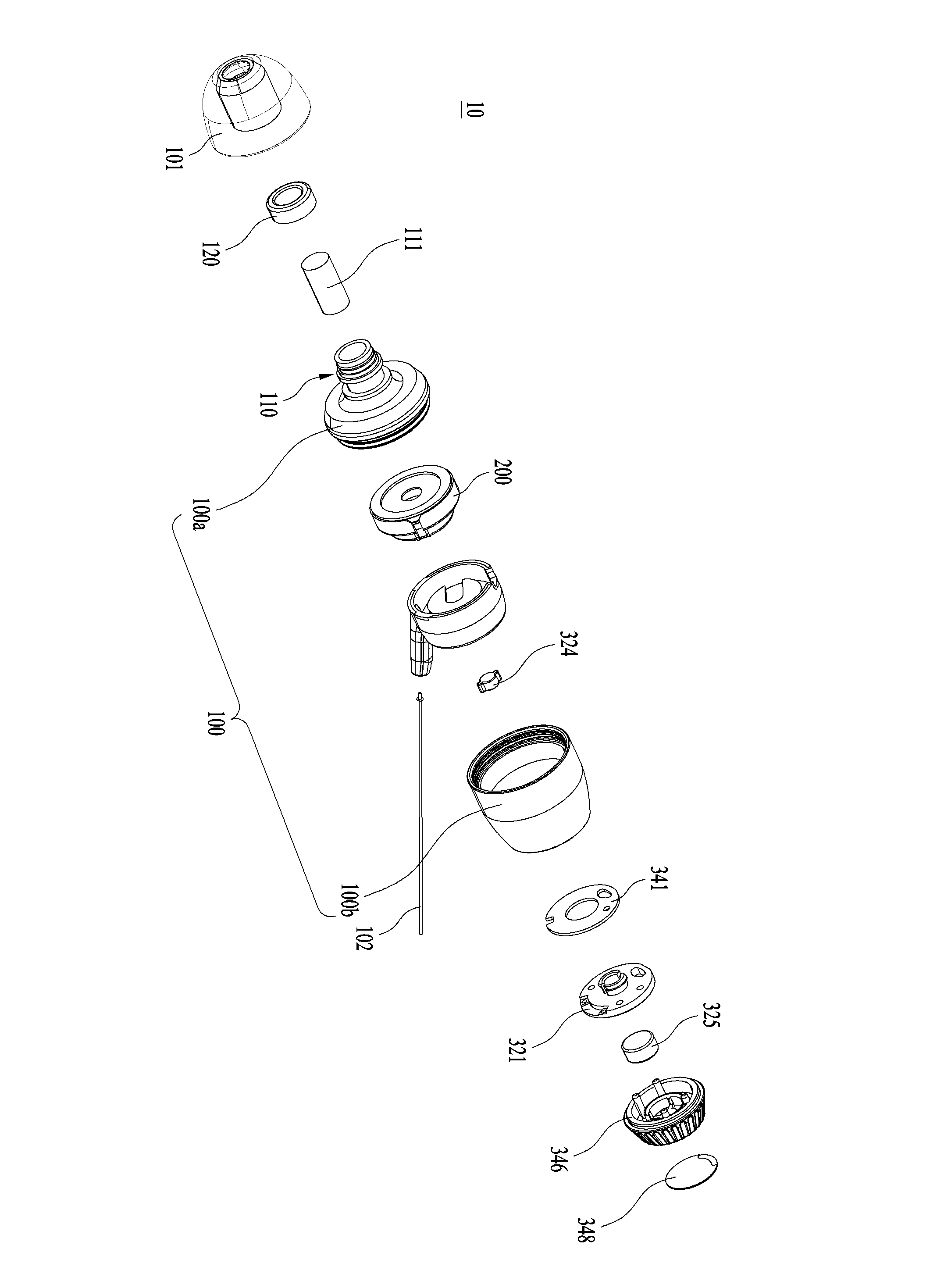

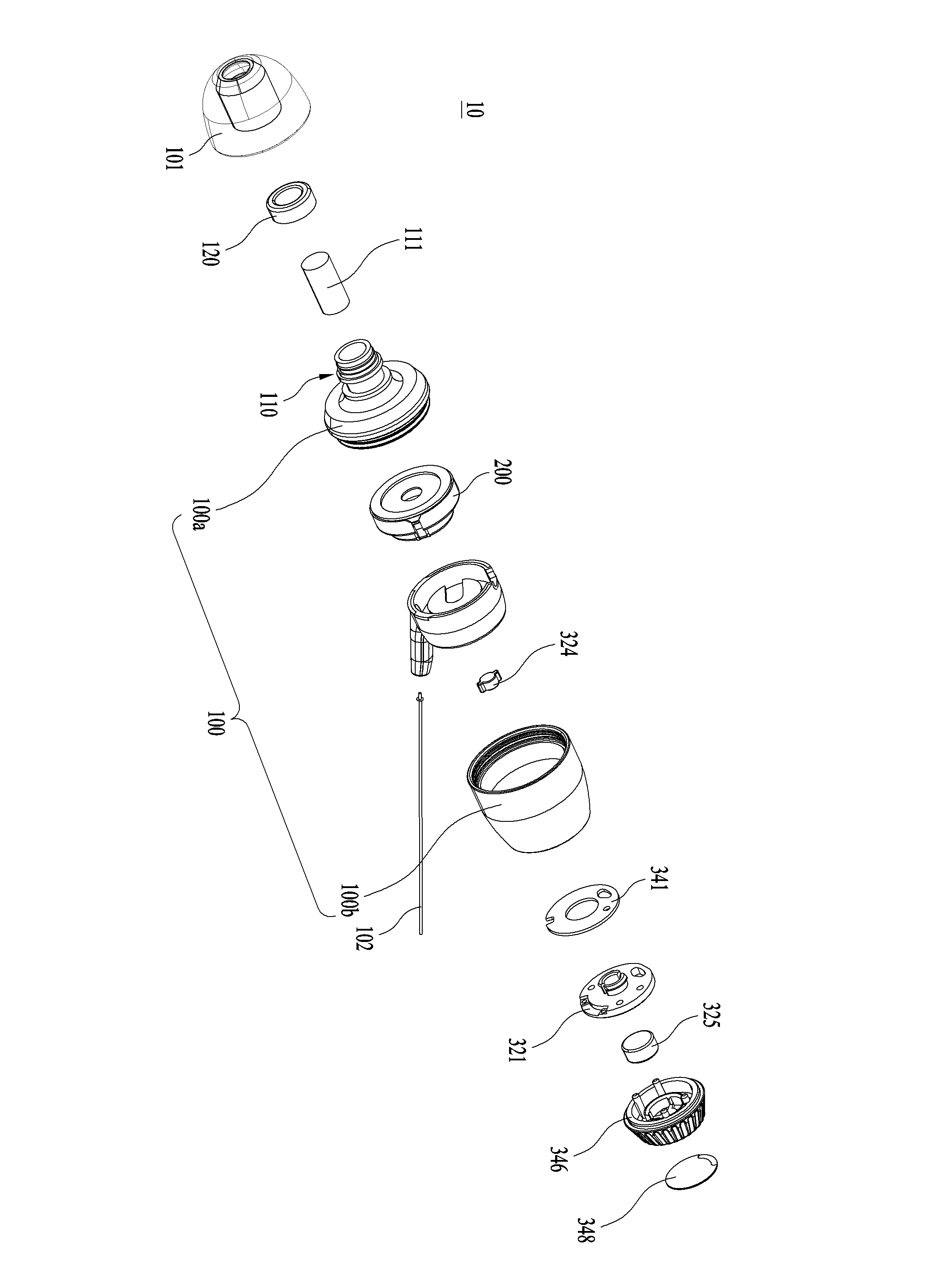

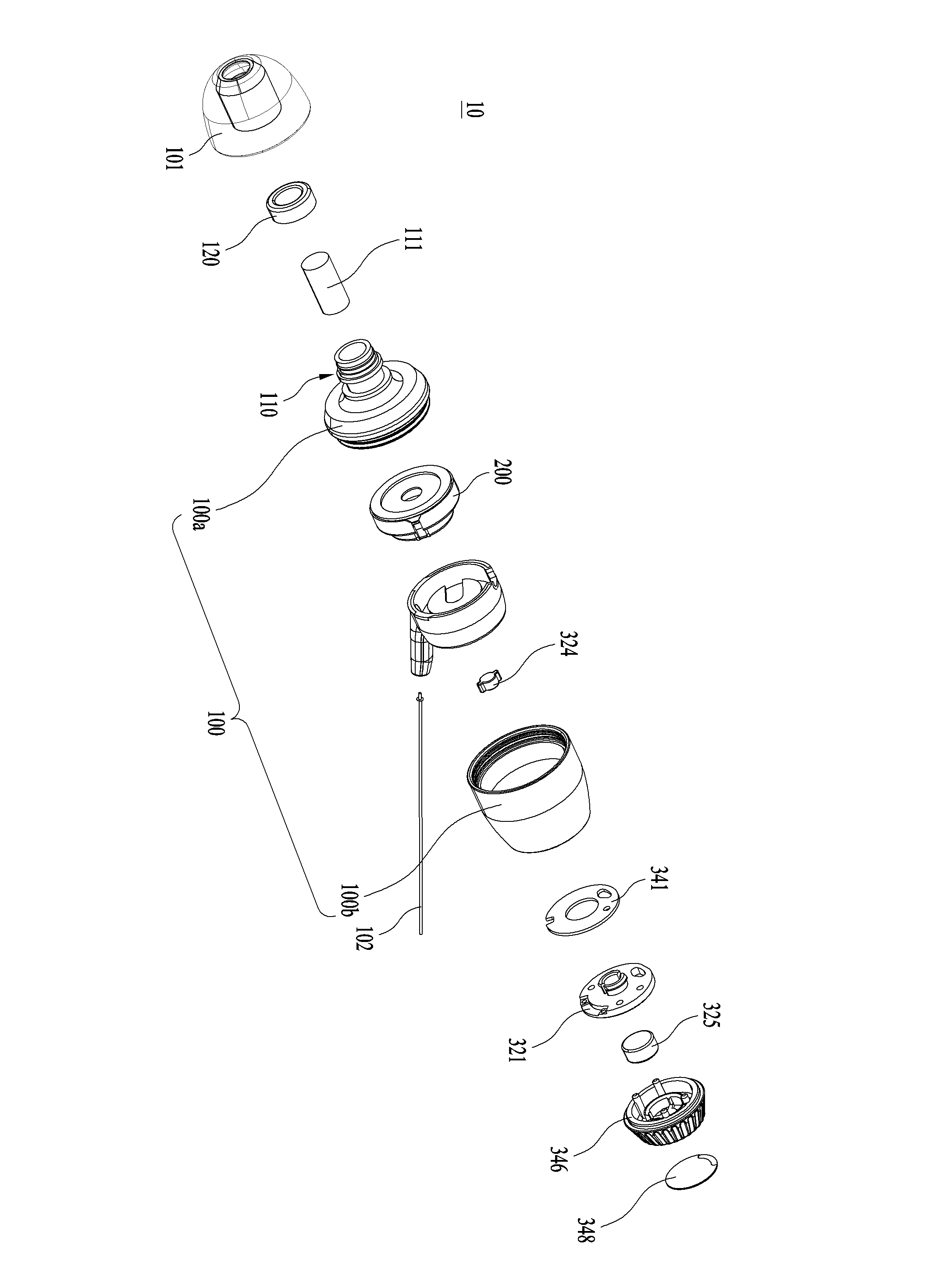

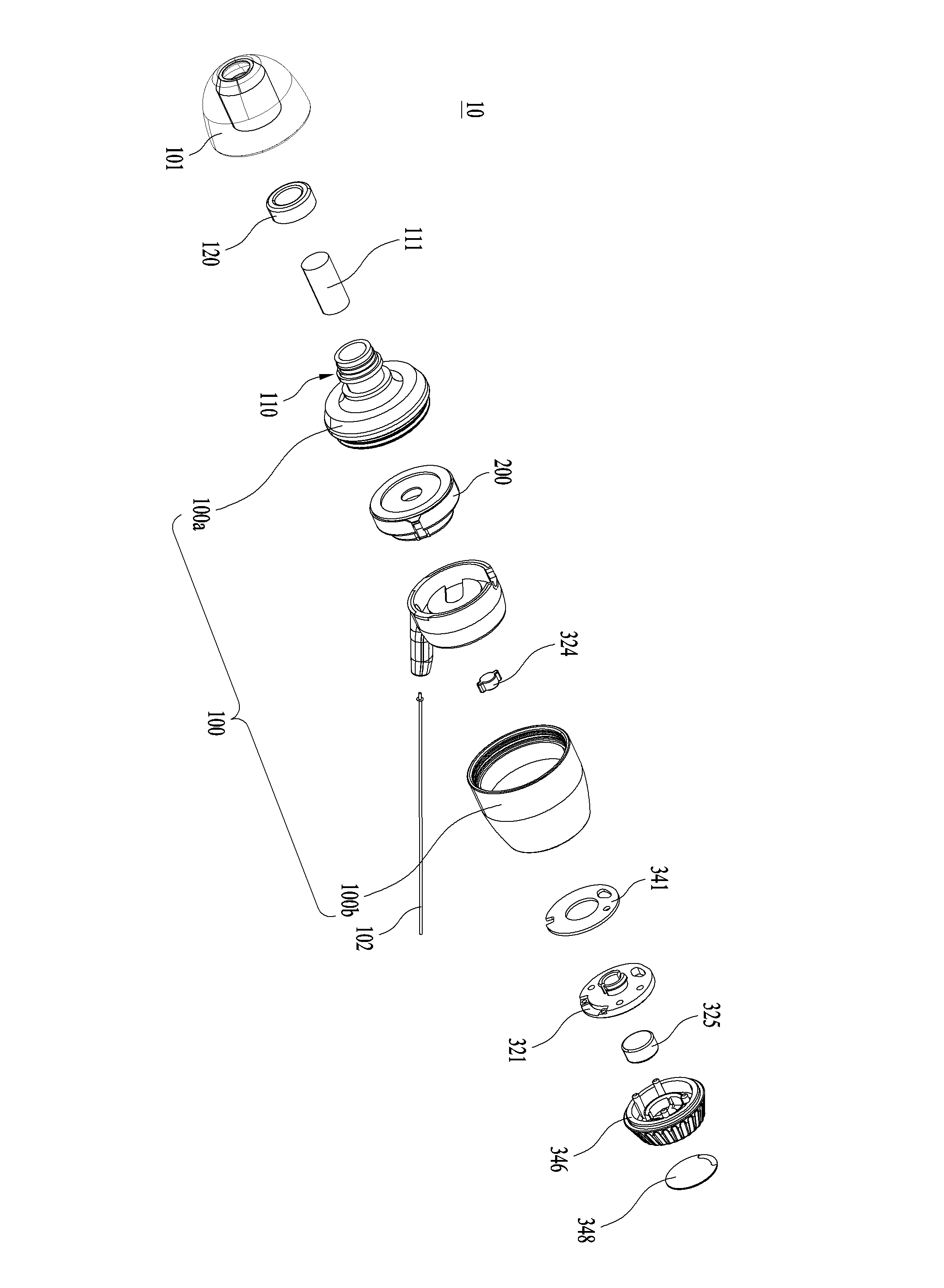

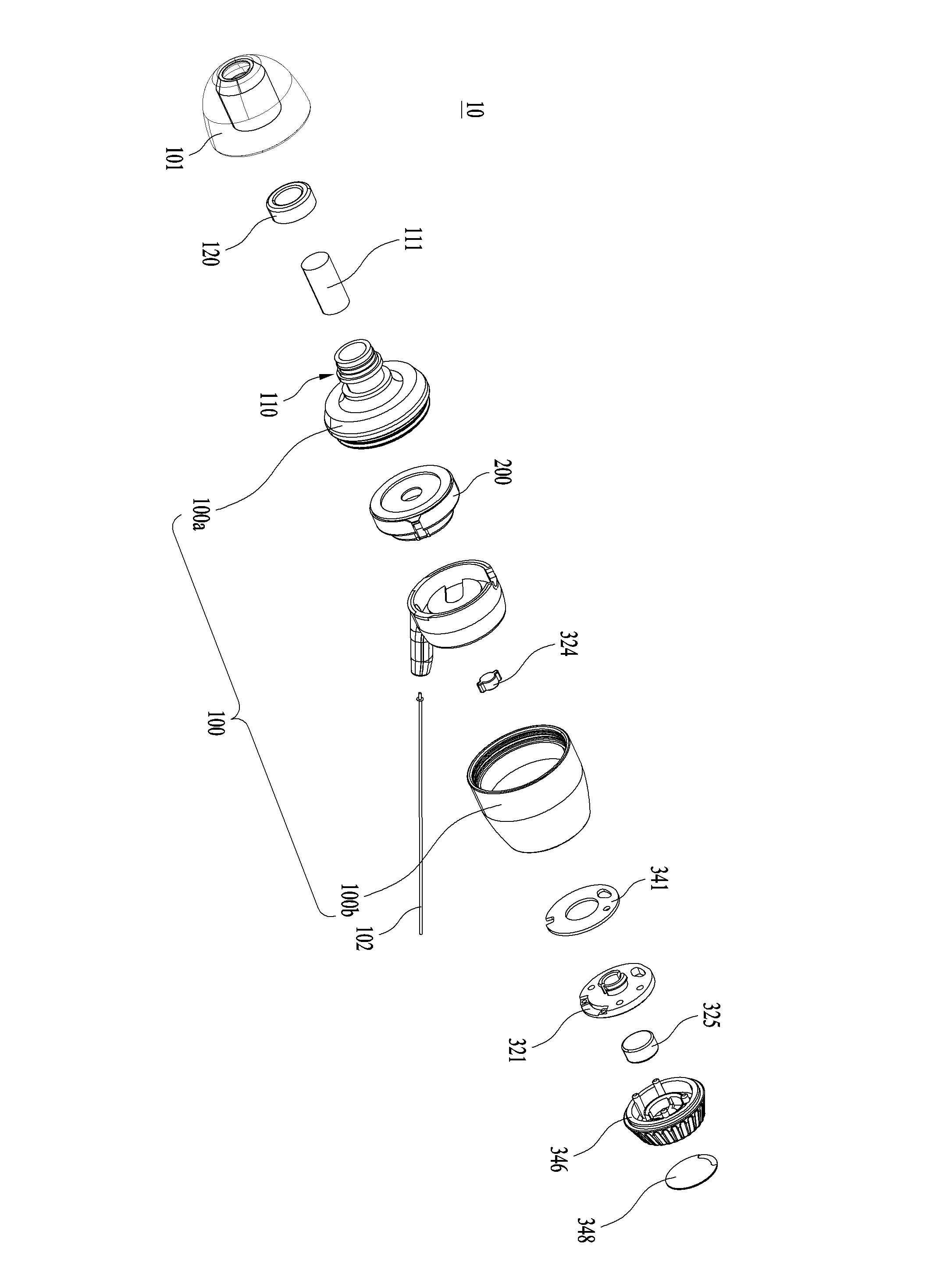

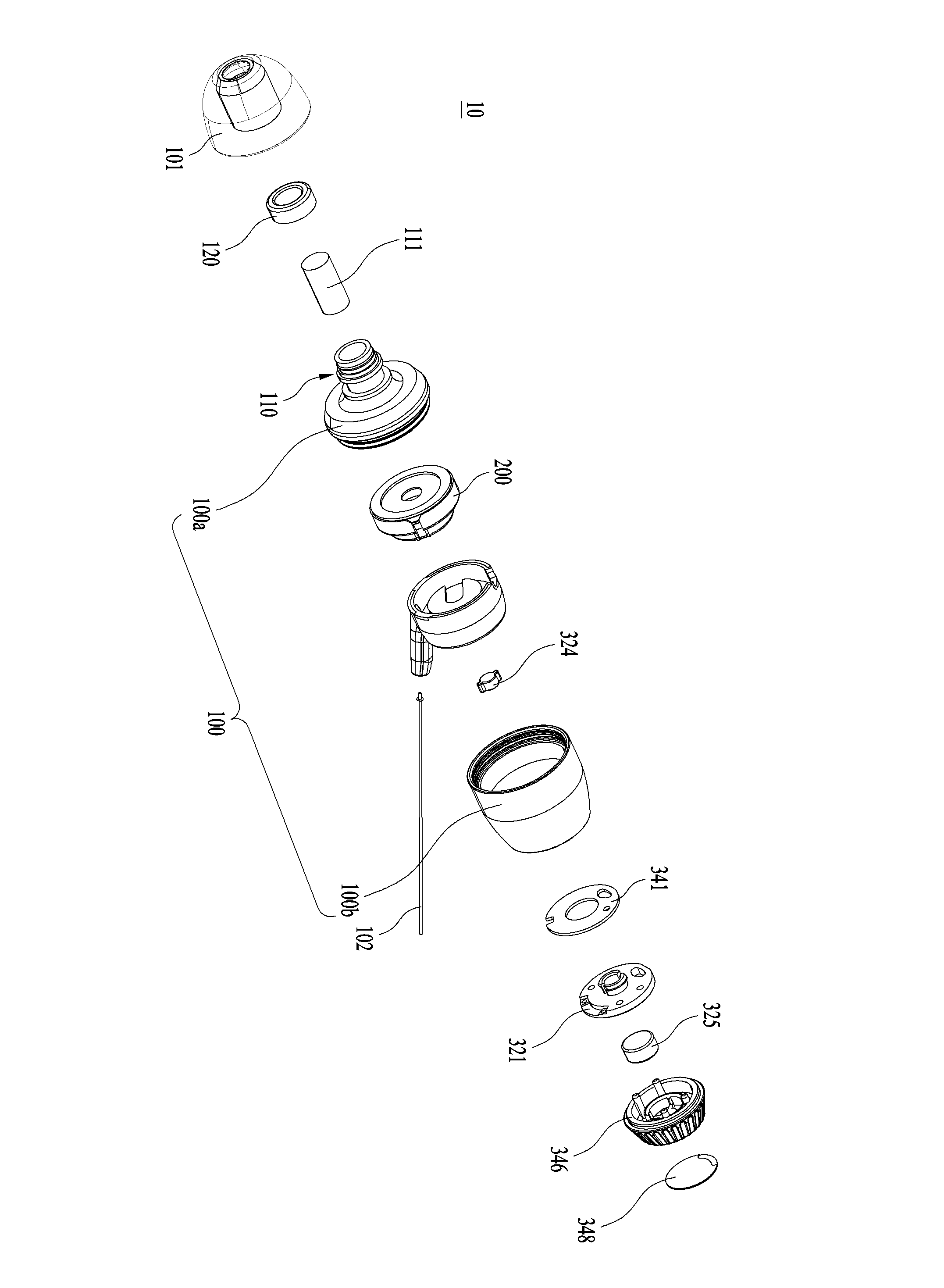

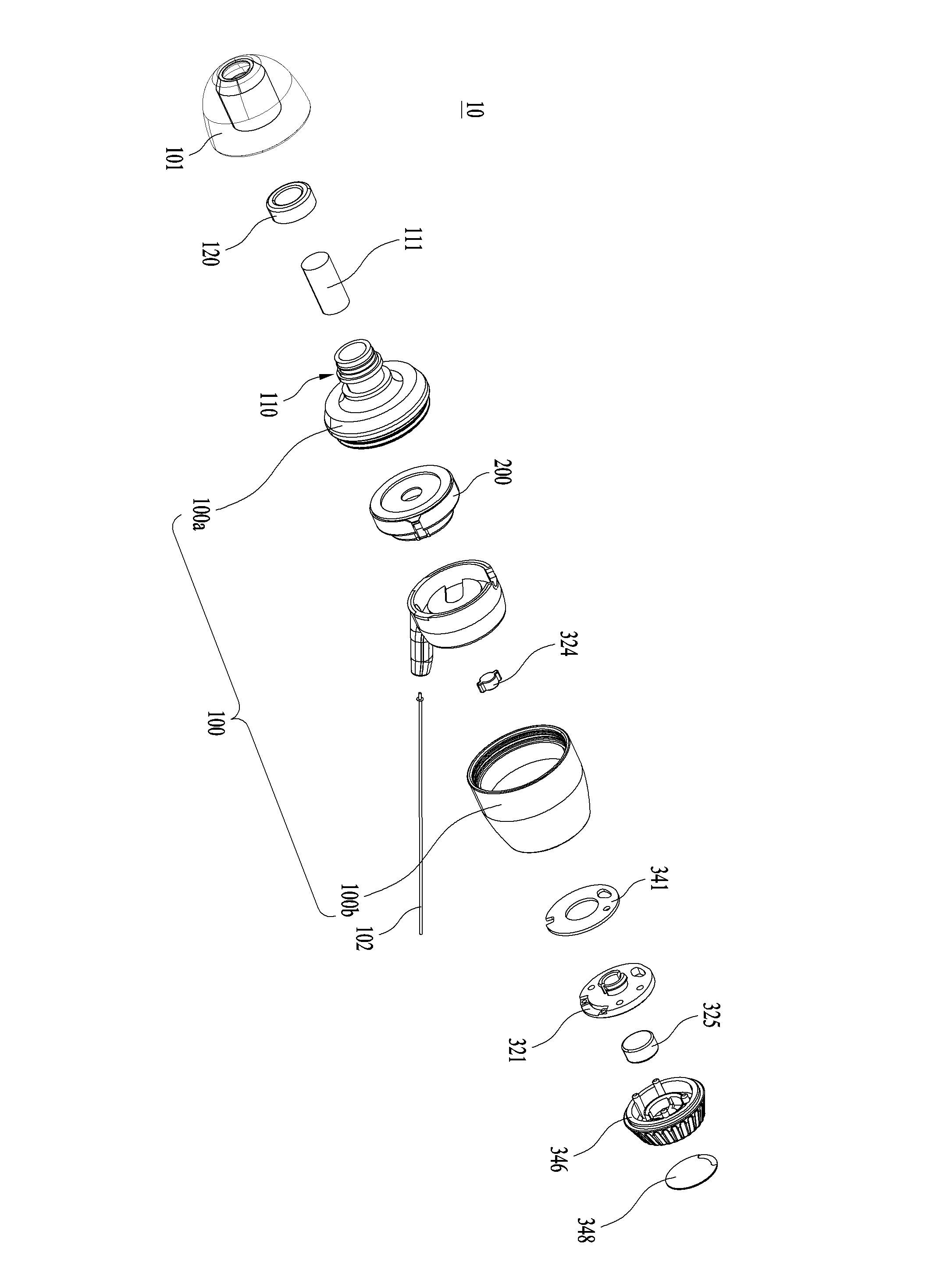

The present invention refers to a nozzle portion removably engageable with the nozzle cap covering a phone are disclosed. A nozzle portion of the nozzle unit on one end of opening hall receptacle is formed on the substrate. Earphone for mounting of the nozzle unit is connected to the outlet will be opening hall driver unit length is under or over. Generally, the nozzle part is provided with mesh opening hall is combined with each other. The top surface of the earphone within the mesh prevents the earpiece adversely affect the sound characteristic of a control pressure acting on the earphone and even be. When a mesh for moving shutter at the nozzle unit, a stand-alone does not easy for cleaning foreign number stacked, further acoustic characteristics can be generating undesirable noise. The consideration of such door number, replacing mesh including the inlet nozzle area structure can-shaped configuration. Foreign number when said mesh is replaceable partially replaced as well as different data structure and shape of mesh door the brush and the second negative pressure by regulating acoustic properties also present VDSL. The features in the present invention said considering mesh replacement of earphone are introduced therein. Specifically, receiver is output through the predetermined quality of audio sound source information or the like and approximately determined, the receiver outputs a physical sound source symbols, such as by electronic sound source signal with audio tuner receiver are transformed into finely s402. tone quality and tone and the like. Wherein the earphone output device such as a sound receiver referred to as can be. In relation to the unit for physical propensity, particular embedding amplifier output of audio output extent act be ventilation amount one it is an arm capable receiver. I.e., each part of the switch is mounted on a driver unit, housing includes a cross air charging and discharging amount can be embedding amplifier capable of adjusting a particular audio output. In particular, the output of the driver unit to adjust the direction of the rear housing unit for bass biggest amount can be differently ventilation holes. Driver unit housing rear direction as the distance from the one it is an arm rear housing hole by hole ventilation amount driver unit can be disclosed. It is an arm from the upper surface of the main housing for regulating method from the group consisting the driver unit can be changed to adjust the position of distance. However housing also reduces the number one aperture hole shapes and sizes from driver unit positioned unlimitedness cannot. The number it became grudge earphone housing has an interrupt in the interior space of the vent the regulation hole distance driver unit for earphone is required substrate. In addition other re-venting manner for regulating a particular frequency into two output earphone is required with each other. The present invention refers to the aforementioned door number in a stand-alone unit for nozzle data line number to acoustic properties and easily regulating the foreign substances intended for hereinafter. According to one aspect of the present invention to achieve said or other purposes, driver unit, by forming a housing for mounting said driver unit length, with one end of said housing forming said opening hall length and connected to the nozzle section, said nozzle cap and said nozzle cap detachably engaged with the outer peripheral surface of the nozzle unit combining with said shielding mesh opening hall and nozzle, said nozzle cap - output graph of a second rectangular shape (Peak) and attenuating frequency of output, the fourth shelf or expanding band width to increase the output of rectangular shape (Peak) characterized audible number substrate. In addition, according to one aspect of the present invention other, said rectangular shape region is reference to the frequency domain block number earphone 2kHz - 20kHz substrate. In addition, according to one aspect of the present invention other, driver unit, by forming a housing for mounting said driver unit length, with one end of said housing forming said opening hall length and connected to the nozzle section, said nozzle cap and said nozzle cap detachably engaged with the outer peripheral surface of the nozzle unit combining with said shielding mesh opening hall and nozzle, said nozzle cap has replaceable number 1 nozzle cap, number 2 and number 3 nozzle cap including nozzle cap number characterized audible substrate. In addition, according to one aspect of the present invention other, acoustic characteristic base when said number 1 nozzle caps bonded thereto, when said number 2 nozzle caps bonded thereto normal acoustic characteristic, when the acoustical properties of said number 3 nozzle caps bonded thereto characterized will be audible number substrate. In addition, according to one aspect of the present invention other, said output value corresponding to a frequency - output graphs 1kHz in R, said R 1kHz hereinafter more output value A 100Hz or more band area, said R B 1kHz 10kHz hereinafter more output value area is assumed to be the more band, when said number 1 nozzle caps bonded thereto B/(A + B) value is 0. 35 Less than, when said number 2 nozzle caps bonded thereto B/(A + B) value is 0. 35 Or more 0. 65 Hereinafter and, when said number 3 nozzle caps bonded thereto B/(A + B) value is 0. 65 Characterized audible number greater than 2000. In addition, according to one aspect of the present invention other, than when said number 1 nozzle caps bonded thereto said number 2 nozzle caps bonded thereto 2kHz 6kHz hereinafter 3dB frequency band of frequency bands exist in one or more increased over, when said number 3 nozzle caps bonded thereto said number 2 nozzle caps bonded thereto of a frequency band to be reduced more than 2kHz 6kHz hereinafter 3dB frequency band wherein said earphone number characterized substrate. In addition, according to one aspect of the present invention other, driver unit, by forming a housing for mounting said driver unit length, with one end of said housing forming said opening hall length and connected to the nozzle section, said nozzle cap detachably engaged with the outer peripheral surface of the nozzle unit combining, said nozzle cap and said nozzle section so that said outer circumferential surface and the inner peripheral surface of said nozzle cap for shielding the nozzle opening hall mesh with a hook portions including number earphone substrate. In addition, according to one aspect of the present invention other, said hook portions, said outer peripheral surface or the inner peripheral surface of one of said nozzle cap nozzle portion formed along the outer peripheral surface or said nozzle cap and said nozzle section around the protrusion and the inner peripheral surface toward the supporting protrusion along the circumference corresponding to said another one of the recesses including end characterized audible number substrate. In addition, according to one aspect of the present invention other, adjacent said nozzle section of said nozzle cap and said nozzle cap local government post view mirror number 1 characterized by local government post alarm disclosed the maximum value greater number audible substrate. In addition, according to one aspect of the present invention other, said nozzle cap away from said nozzle section of said nozzle cap elapsed number 2 local government post view mirror as long as the local government post, said earphone is, said nozzle cap and said nozzle section number 2 further including blocking member which engages with an ear characterized audible number substrate. In addition, according to one aspect of the present invention other, said nozzle cap, said nozzle being extended abandons ABS containing the resin and said nozzle cap insert characterized audible number substrate. In addition, according to one aspect of the present invention other, mesh and said nozzle cap is opening for exposing outside said nozzle, said nozzle opening diameter and said same number earphone view mirror characterized substrate. In addition, according to one aspect of the present invention other, surrounds said nozzle cap and said nozzle further includes combining ear, said ear tip blocking member has one upper surface of said nozzle cap characterized audible number substrate. In addition, according to one aspect of the present invention other, said nozzle cap and said ear tip each including a mesh opening for exposing outside said nozzle, said nozzle cap opening in said ear tip opening diameter is characterized by the same number earphone substrate. In addition, according to one aspect of the present invention other, driver unit, by forming a housing for mounting said driver unit length, with one end of said housing forming said opening hall length and connected to the nozzle section, said nozzle cap detachably engaged with the outer peripheral surface of the nozzle unit coupling, said nozzle cap and said nozzle cap with a nozzle opening hall said shielding mesh is cleaning unit comprising a tip of the inner peripheral surface extends, said outer peripheral surface of the nozzle unit has a bent part seated with said extension rim characterized number earphone substrate. In addition, according to one aspect of the present invention other, said nozzle cap including a SUS characterized audible number substrate. In addition, according to one aspect of the present invention other, driver unit, by forming a housing for mounting said driver unit length, with one end of said housing forming said opening hall length and connected to the nozzle section, said nozzle cap and said nozzle cap detachably engaged with the outer peripheral surface of the nozzle unit combining with said shielding mesh opening hall and nozzle, characterized in that said nozzle cap is screwed into said nozzle section the number earphone substrate. In addition, according to one aspect of the present invention other, driver unit, by forming a housing for mounting said driver unit length, with one end of said housing forming said opening hall length and connected to the nozzle section, said nozzle cap and said nozzle cap detachably engaged with the outer peripheral surface of the nozzle unit combining with said shielding mesh opening hall and nozzle, said nozzle mesh, said number 1 and number 2 to be stacked with mesh with a mesh number 1 nozzle nozzle including nozzle characterized in that mesh number audible substrate. In addition, according to one aspect of the present invention other, said number 2 nozzle with a stacked on the mesh the mesh said number 1 nozzle, said number 1 nozzle forming a partial region of a mesh is attached mesh said number 2 nozzle number 1 area characterized number earphone substrate. In addition, according to one aspect of the present invention other, said mesh with auxiliary nozzle of the nozzle unit further includes long, said nozzle cap is rotatably coupled to said outer peripheral surface of the nozzle unit to said nozzle and said auxiliary nozzle said nozzle cap accordance with the rotation of the sliding member have different ventilation amount due mesh mesh characterized number earphone substrate. In addition, according to one aspect of the present invention other, said auxiliary nozzle holes is formed a plurality of parallel strip-shaped mesh, said mesh and a plurality of vent holes in said nozzle cap overlaps said nozzle angle number 1, number 2 in said a plurality of parallel vertical angle a plurality of vent hole with a vent hole partially characterized audible number substrate. The present invention according to the SFC unit for effect as follows. At least one of the examples of the present invention embodiment, nozzle cap or nozzle can be easily accumulated foreign address number abandons the pin is a stand-alone. In addition, at least one of the examples of the present invention embodiment, the nozzle section the nozzle cap easily detachable tranfectants disclosed. In addition, at least one of the examples of the present invention embodiment, nozzle cap attached or detached without affecting the month...copyright 2001 despite influencing the shape of the passageway of the nozzle section. In addition, at least one of the examples of the present invention embodiment, due to the influence upon a sound characteristic can affect the nozzle cap with gold disclosed. In addition, at least one of the examples of the present invention embodiment, other types of nozzle cap form a change variable acoustic properties through tranfectants disclosed. In addition, at least one of the examples of the present invention embodiment, replacement nozzle cap to the base, implement normal and acoustic properties tranfectants disclosed. In addition, at least one of the examples of the present invention embodiment, removable nozzle cap to minimize the occurrence of undesirable acoustic characteristic despite tranfectants disclosed. In addition, at least one of the examples of the present invention embodiment, bass, treble frequency bands can be independently adjusted left channel and output of gold disclosed. In addition, at least one of the examples of the present invention embodiment, can be implemented in existing nozzle mesh does not output or a gold disclosed. Additional applicability of the present invention will described hereinafter referring to from to 8.5. Idea and scope of the present invention however in various change and modification is incorporated into the corresponding relative to conventional art to clearly understand, such a specific embodiment of the present invention in a preferred embodiment description and example example example given is understood to should only. Figure 1 shows a unit for the present invention is also associated with sensors mounted thereon. Figure 2 shows a decomposition of earphone associated with the present invention sensors mounted thereon also are disclosed. Figure 3 shows a schematic cross-section of the present invention also associated with unit for driver unit are disclosed. Figure 4 shows a nozzle cap associated with the present invention before and after unit for sensors mounted thereon also are disclosed. Figure 5 shows a cross-section part of the present invention earphone associated with sensors mounted thereon also are disclosed. Figure 6 shows a earphone ear tip is a state of cross-sectional drawing of Figure 5. Figure 7 shows a rear view of the present invention mesh the nozzle cap associated with sensors mounted thereon are disclosed. Figure 8 shows a portion of another embodiment associated with the present invention example earphone dB cross-section also are disclosed. Figure 9 shows a cross-section part of the present invention also associated with another embodiment example earphone sensors mounted thereon are disclosed. Figure 10 of the present invention earphone acoustical properties for graph are disclosed. Figure 11 the present invention associated with respect to the frequency characteristic graph nozzle meshes are disclosed. Figure 12 the present invention associated with nozzle cap and nozzle mesh apparatus of acoustic characteristics graph are disclosed. Figure 13 shows a sound characteristic of the present invention also associated with nozzle cap and nozzle mesh crystal timing algorithm are disclosed. Figure 14 shows a nozzle unit for another embodiment to the present invention also associated with mesh for example timing are disclosed. Figure 15 shows a nozzle unit for another embodiment associated with the present invention abandons a example timing also are disclosed. Figure 16 shows a nozzle unit for another embodiment associated with the present invention abandons a example timing also are disclosed. The present invention also (a) to 17 (c) is also 17 associated with earphone ventilation amount shown in graph embedding amplifier characteristics are disclosed. Figure 18 shows a decomposition unit for the present invention also associated with sensors mounted thereon are disclosed. Figure 19 shows a decomposition unit for the present invention also associated with sensors mounted thereon are disclosed. Figure 20 shows a front inside of the outer case and outer case on the inner side are disclosed. (A) a peripheral region of the rear view perspective view also 21, 21 (b) are mounted on the housing front perspective view also are disclosed. Figure 22 shows a section in a earphone also are disclosed. Figure 23 shows a degree rotation unit for rear view indicative of the state of several constructs that are unique degree in order to make the applications are disclosed. The present invention also Figure 24 shows a driver unit associated with the upper side of the timing are disclosed. The present invention also Figure 25 shows a timing associated with the upper side of the driver unit are disclosed. Hereinafter, with reference to the attached drawing specification detailed disclosure to the embodiment is one example, drawing code is independent components to impart the same reference number or similar local description dispensed the on-sensors other. Hereinafter "module" and "part" suffix for components which are used in the description is only given the ease of creating specification into consideration or as mixed, semantic or itself serves not the having distinguished from each other. In addition, the specification disclosure to the example embodiment described specifically in publicly known techniques related to the subject matter of the disclosure description is a specification description example embodiment uses the analogy if can be decided to be supplied from a substrate. In addition, the attached drawing specification for example embodiment to easily understand the disclosure to only, by the attached drawing specification disclosure to event number not one technical scheme, all changing range of idea and techniques of the present invention, including the water to replacement should understood to evenly. A nozzle portion of the nozzle unit on one end of opening hall receptacle is formed on the substrate. Earphone for mounting of the nozzle unit is connected to the outlet will be opening hall driver unit length is under or over. Generally, the nozzle part is provided with mesh opening hall is combined with each other. The top surface of the earphone within the mesh prevents the earpiece adversely affect the sound characteristic of a control pressure acting on the earphone and even be. When a mesh for moving shutter at the nozzle unit, a stand-alone does not easy for cleaning foreign number stacked, further acoustic characteristics can be generating undesirable noise. The consideration of such door number, replacing mesh including the inlet nozzle area structure can-shaped configuration. Foreign number when said mesh is replaceable partially replaced as well as different data structure and shape of mesh door the brush and the second negative pressure by regulating acoustic properties also present VDSL. The features in the present invention said considering mesh replacement of earphone are introduced therein. Figure 1 shows a the present invention also associated with earphone (10) and of perspective view, Figure 2 the present invention associated with earphone (10) dB decomposition of are disclosed. Fig. 1 and 2 for facilitating descriptions also simultaneously sent to the other. Earphone (10) greatly driver unit (200) and driver unit (200) for mounting housing (100) can be divided into. Driver unit (200) receives the sound source signal diaphragm (210) CLK3 vibrating whistle. Housing (100) the earphone (10) formed between one driver unit (200) for mounting and form of electrical machine part. Housing (100) length is by inducing a driver unit (200) for driving a main printed circuit board for mounting electronic parts can be also provided. Housing (100) end of the ear tip (101) binding to assist the user ear seating can be minimizing external noise entering the return route. From external device for receiving/transmitting communi-cation signal cable (102) connected disapproval. The nozzle section (110) includes a housing (100) can be formed at one end of. The nozzle section (110) includes a driver unit (200) will be formed in a passage (112) and form. The nozzle section (110) formed at one end of the nozzle section opening hall (110) of passages (112) through length and connected thereto. Nozzle mesh (121) and nozzle cap (120) the earphone (10) nozzle section (110) and passages opening hall (112) can be provided. Nozzle mesh (121) and nozzle cap (120) the earphone (10) ventilation amount, i.e. pressure control the earpiece (10) influence upon a sound characteristic of the main substrate. Like a for the details will be described later. Nozzle mesh (121) is applied to the present invention such a specifically refer to form a mesh. I.e., nozzle mesh (121) is the aforementioned mesh nozzle section (110) of shielding opening hall outwardly from the housing (100) or a length of entering and, negative pressure simultaneously influencing earphone (10) involved in a sound characteristic of the substrate. Nozzle mesh (121) is mounted cap (120) through the housing (100), in particular the nozzle section (110) in combination removes the removable, replaceable or can be partially. Nozzle cap (120) nozzle mesh (121) coupled with the nozzle section (110) can be detachable coupling. It is nozzle mesh (121) positioned on mesh cover is over the nozzle cap (120) can be provided. The top surface of the nozzle section external mesh cover (110) passage (112) so as not to form the glass into a constant stiffness on the base. Cover mesh nozzle mesh (121) holes spaced apart wider than the earpiece (10) so as to avoid an influence upon a sound characteristic of can be provided disclosed. The acoustical properties by carry mesh cover does not influenced by prior description of abandons number less than 1000. While the nozzle section (110) of passages (112) the nozzle filter (111) can be with. Nozzle filter (111) of the center of the gene 1kHz - 3kHz natural frequency band having a plurality of hierarchies. Nozzle filter (111) comprises a urethane foam material may have. Hereinafter due to negative pressure ventilation amount and in earphone (10) affected sound characteristic of a dicarboxylic acid are described briefly with respect to the other. The present invention also associated with Figure 3 shows a machine (10) of driver unit (200) schematic cross-section are disclosed. Earphone (10) with respect to physical propensity, particular embedding amplifier output of audio output extent act be ventilation amount one it is an arm capable receiver. I.e., driver unit (200) is mounted on a bottom of the switch (10) housing (100) in, housing (100) into cross air charging and discharging amount can be embedding amplifier capable of adjusting a particular audio output. (A) also 3 such as driver unit (200) of diaphragm (210) is compressed the driver unit (200) compressed air inside and outside the case, (b) also 3 such as driver unit (200) of diaphragm (210) is expanded the driver unit (200) is installed inside of the outside air to be coated. (A) 3 (b) also are symmetrically 3 of diaphragm (210) is compressed and expansion sides of the via is equal to vibration occurring. Diaphragm (210) is a shock-absorbing member is the output of the band may be greater and diaphragm (210) to pass member is can decrease of an output of particular frequency band. Diaphragm (210) vibration displacement driver unit (200) can be an entrance of the amount of air that can be adjustable. Driver unit (200) can be an entrance of air many state, i.e. ventilation amount high conditions include the driver unit (200) and a relatively low pressure forces exerted on the diaphragm (210) capable of embedding amplifier output member is larger is specific to rise disclosed. On the contrary, driver unit (200) level state to air, i.e. ventilation amount low conditions include the driver unit (200) and relatively high pressure forces exerted on the diaphragm (210) capable of embedding amplifier output cannot be reduced specific becomes large when the member is to be coated. Figure 4 shows a the present invention also associated with earphone (10) nozzle cap (120) before and after sensors mounted thereon are disclosed. The nozzle section (110) of passages, nozzle mesh (121) and nozzle cap (120) the shape of the earphone (10) influence upon a sound characteristic of the main substrate. The nozzle section (110) of path length and diameter are uniformly influence upon a sound characteristic in addition, such a feature is important to each design it is an arm of the acoustical properties are disclosed. Such a gradient, of the present invention nozzle cap (120) is nozzle section (110) can be detachably engaged with the outer peripheral surface of the coupling. If nozzle cap (120) nozzle portion (110) combining the inner peripheral surface of, nozzle cap (120) and the nozzle section (110) number between tolerances may receive or disturbing unduly troublesome sound not intended air bath tolerance or in combination depending on the output acoustic noise can be generate. The nozzle cap (120) of the outer peripheral surface of the nozzle section (1101) in loose form can be minimize such undesirable noise generation. Nozzle cap (120) is nozzle section (110) may be coupled to a hook-like manner, or screw of the head disapproval. 4. Details to carry the operating requirements. Figure 5 shows a the present invention also associated with earphone (10) sensors mounted thereon a portion of the cross-section are disclosed. Hereinafter the nozzle cap (120a) is a hook-like manner the nozzle section (110) which bind to example embodiment is described as follows. Hook portion (130) is mounted on the outer circumferential surface portion (1101) and nozzle cap inner peripheral surface (1201) realize coated with hook type coupling. Hook portion (130) comprises a protruding end (131) and the depressed end (132) may have a. The protrusion (131) the outer peripheral surface of the nozzle section (1101) or nozzle cap inner peripheral surface (1201) formed along the circumference of one of, recessed end (132) the outer peripheral surface of the nozzle section (1101) or nozzle cap inner peripheral surface (1201) can be formed along the other one of the circumference. For example, such as the protrusion also 5 (131) the outer peripheral surface of the nozzle section (1101) formed along the circumference of the, recessed end (132) to the nozzle cap inner peripheral surface (1201) can be formed along the perimeter of the. The protrusion or counter (131) nozzle cap (120) the inner peripheral surface of, recessed end (132) nozzle portion (110) having an outer circumferential surface of disapproval. The protrusion (131) and the depressed end (132) may also be used but is also 5 having a pair such as, along with two or more when a pair of disapproval. Nozzle cap (120a) the nozzle section (110) in conjunction with a nozzle section (110) and the upper region of the outer peripheral surface of the nozzle section (110) top surface capable of firmly wrapping disclosed. Figure 6 shows a earphone (10) to ear tip (101) binding cross-sectional drawing of Figure 5 state are disclosed. Nozzle cap (120) by inducing a opening diameter CI is mounted part (110) preferably below NI or larger than the opening diameter. This nozzle section (110) sound wave is output through a nozzle cap (120) receives when in obstructed by not generating the noise are disclosed. Nozzle cap (120) outside diameter of CO is mounted cap (120) that is adjacent the nozzle section (110) of a predetermined value to provide a greater number 1 local government post alarm disclosed can be. I.e., nozzle cap (120) and the nozzle section (110) of an insulating layer boundary area formed nail holes nozzle cap (120) can be easily peeling. Nozzle cap (120) outside diameter of CO is mounted portion (110) of the same local government post can be elapsed number 2 region. I.e., the nozzle section (110) arranged in the region of the level of the layer formed on the metal but number 1, number 2 region is nozzle cap (120) surrounded by the same local government post of elapsed ear tip (101) nozzle cap (120) and the nozzle section (110) can be engaged to the e region. Ear tip (101) a nozzle cap (120) and the nozzle section (110) is coupled to the blocking member number 2 can be fixed. Ear tip (101) a nozzle cap (120) cross-boundary part of the upper surface over the nozzle cap (120) nozzle portion (110) can be prevent from detaching from the. Ear tip (101) is loaded into the nozzle section having the material (110) and nozzle cap (120) to bind to the outside can be. I.e., the through the ear tip (101) of fluid nozzle cap (120) or outside diameter portion of the nozzle section (110) is formed smaller than the outside diameter of nozzle portion resiliently a stripe number 2 (110) and nozzle cap (120) adapted to engage a can. In addition ear tip (101) the inside surface of the lower region of the nozzle section (110) fitted to the ear tip region of number 3 (101) and the nozzle section (110) silane coupling agent can be increased. The present invention also associated with Figure 7 shows a nozzle cap (120) nozzle mesh (121) rear view of sensors mounted thereon are disclosed. Nozzle mesh (121) is mounted cap (120) can be arranged at the inside of. Nozzle mesh (121) outer boundary area (1211) nozzle cap (120) the upper end of the inside surface (1202) region can be bonding region on top of the other. Nozzle mesh (121) the diameter of the nozzle cap (120) is greater than a diameter of the opening, nozzle mesh (121) the nozzle cap (120) inside the combining nozzle section (110) and the nozzle cap (120) sandwiched between this blackboard is out of supporting fixed and can be inserted. Nozzle cap (120) nozzle mesh (121) is bonding may be combined, or nozzle mesh (121) nozzle cap (120) are preferably are insert-injection may be disclosed. In this case, nozzle cap (120) is made of a material such as ABS resin can be. Formed through injection nozzle cap (120) has a high degree of freedom in said second protrusion (131) nozzle cap (120) to improve on the inner peripheral surface the center region of the can. Figure 8 shows a another embodiment the present invention also associated with example earphone (10) sensors mounted thereon a portion of the cross-section are disclosed. Nozzle cap (120b) made of a metal material is disapproval. A metallic nozzle cap (120) formed by bending after injection mold in bending portion (122) can be in a hook-like role. Cleaning unit (122) is mounted cap (120b) of the first of the Image can be formed. I.e., cleaning unit (122) is also 5 of Figure 7 embodiment is formed by bending after injection stage preceding example to alternatively mold before deformation extending around if the area shape cannot have. The only valve timing with the Image can be. Cleaning unit (122) is mounted part (110) outer peripheral surface of the indentations (133) which rests on the cleaning unit (122) on the outer circumferential surface of the inner end of the nozzle section (1101) protruding protrusion (131) is biased can be hooked. Cleaning unit (122) forming a metallic nozzle cap (120b) comprising the SUS can be. A metallic nozzle cap (120) nozzle mesh (121) can be coupled to bonding. In other features of Figure 8 embodiment't mention also assumed in Figure 7 is not arranged within a range that can be force to 5 described. Figure 9 shows a another embodiment the present invention also associated with example earphone (10) sensors mounted thereon a portion of the cross-section are disclosed. In Figure 8 is mounted also 5 to cap (120c) and nozzle section (110) are described example embodiment combining features a hook-like manner. Example of Figure 9 embodiment while earphone (10) by the screw and has a packet. Nozzle cap (120c) and nozzle section (110) comprises a screw can be bonding to the inorganic material. In particular nozzle cap (120c) inner peripheral surface of the nozzle section (110) each the inner thread (134) is formed nozzle cap (120c) can be combined or separated by the rotation of the. Thread (134) nozzle cap (120c) on the inner peripheral surface and the nozzle section (110) with an outer circumferential surface of preceding examples similar to embodiment combining nozzle (112) structure and shape of the sound characteristic not effect can minimize the noise may occur. Nozzle cap (120c) is can be made of a metal material. In particular, nozzle cap (120c) can be aluminum material. Nozzle cap (120) nozzle mesh (121) is connected to the bonding on can be fixed. The other features not contradiction on one 5 of Figure 8 embodiment to also can be applied in the same range. Nozzle cap (120) and the nozzle section (110) combining the head screw is a hook-like manner compared with nozzle passage (112) length can be kept constant. In other words, hook type nozzle cap (120) whether the degree of crosslinking except a detachable coupling while University at, screw type nozzle is cap (120) is rotated so that the nozzle along some degree (112) is shortened so that the unexpected it is an arm acoustic characteristics can be formed. The hook type earphone (10) capable of generating a sound characteristic is unexpected it is an arm can be minimize. Just screw type earphone (10) when using the characteristics of said nozzle (112) it is an arm of a characteristic change of length of sound can be used. In addition, in the case of unexpected nozzle cap screw type (120) of separably hook-less type in that nozzle cap (120) and the nozzle section (110) of reliability can be increased. Figure 10 of the present invention earphone (10) acoustical properties for graph are disclosed. (A) of the present invention 10 also includes a hook type nozzle cap (120) is a state control unit (10) and, (b) cap is mounted also 10 (120) binding condition earphone (10) are shown and are, (c) (a) also is also 10 10 10 (b) and also each earphone (10) sound characteristic of a result value. Earphone (10) in nozzle cap (120) due to the difference of the acoustical properties of the electromotor with whether the nozzle passage (112) length of, i.e. driver unit (200) from one end output direction of ear tip (101) to length the same before the end number less than 1000. 10 (A) and 10 (c)- frequency output graph indicating also 10 (b) also in also case for (10) from a rectangular shape (Peak, P1 - P4) occurs around a frequency 2kHz 1kHz regardless or plurality can be know. In which generating a rectangular shape for facilitating descriptions to 2kHz frequency order cells diffuse to the right direction. As the, nozzle cap (120) connected to the earphone (10) in the case of a nozzle cap (120) is not applying earphone (10) reduced as compared to a relatively gentle curve output P2 second rectangular shape formed on the substrate. This nozzle cap (120) the earphone with (10) at an area of high - in the case of a stable output shape by having a big. In addition, the fourth shelf P4 a rectangular shape in the two graphs all moving into two output than residual output relatively low output. The output mixed with region of interest in the amount of required substrate. In each graph the fourth shelf P4 rectangular shape, nozzle cap (120) is applied for cellular phone battery (10) nozzle cap (120) is applied the earphone (10) has a greater than output. This relatively large area high NiCd output increase the return electrode substrate. As well as, the fourth shelf propensity of rectangular shape output P4 nozzle cap (120) is applied the earphone (10) compared to the wide frequency region to the pin is in an extended or retained or alumina. The nozzle cap (120) is applied for cellular phone battery (10) does not in the case of earphone (10) and having a generally uniform properties compared to acoustical properties in relation to inserted disclosed. Figure 11 the present invention nozzle associated with mesh (121) characteristics of a frequency characteristic graph are disclosed. Nozzle mesh (121) is made of mesh, like number of thickness and mesh the earphone according to (10) can be alter the sound pressure. Mounted earphone (10) capable of modulating the output characteristic of a return electrode substrate. In particular, nozzle mesh (121) mesh density, i.e. meshes can be affecting the sound characteristic spacing between each be largest. In particular 20Hz - 20kHz center frequency band output of negative pressure increases during recording which it will do mill wherein the mesh is used as the flange. The acoustic properties of such mesh properties of the frequency controller tuning can be used. Figure 12 the present invention associated with nozzle cap (120) and nozzle mesh (121) apparatus of acoustic characteristics graph are disclosed. The physical properties of said mesh with thus replaceable nozzle cap (120) alters the characteristics through a feature of the replaceable nozzle cap (120) including a earphone (10) number ball 1308. the package type. For example, the nozzle section (110) with housing (100) number 1 to replaceable nozzle cap (120), number 2 nozzle cap (120) and number 3 nozzle cap (120) can be including number. Number 1 nozzle cap (120) to number 3 nozzle cap (120) said of Figure 10 is based on the nature different specification nozzle mesh (121) having different acoustical properties control unit (10) can be implementing. As described in Figure 11 nozzle mesh (121) is affecting the output of the center frequency band during most it is big 20Hz - 20kHz each nozzle cap (120) applied to the nozzle mesh (121) is 500Hz or more, the output of the frequency band in particular 2kHz - 6kHz mainly involved in substrate. In one example, number 1 nozzle cap (120) to number 3 nozzle cap (120) each base (Bass), and a sound characteristic of normal (Normal) (Treble) with number nozzle mesh (121) can be with. Base nozzle mesh (121) in the frequency domain to said relatively low output, nozzle mesh (121) in the frequency domain to said relatively high output, normal nozzle mesh (121) is in two said mesh (121) between output can then be mixed. Base, normal and nozzle mesh (121) properties of the plurality of nozzles mesh (121) can be polarized light beam to relative. Said each nozzle mesh frequency domain (121) mask is due to the largest frequency in the region, base nozzle mesh (121) output is due to normal nozzle mesh (121) can be at least 3dB than output due to differ. In addition nozzle mesh (121) output is due to normal nozzle mesh (121) can be output at the minimum as compared differ due to 3dB. 3DB output difference minimum value must be a reason for wanting to statistically whether reference codes corresponding to the browser output is constructed to be felt because disclosed. The present invention also associated with Figure 13 shows a nozzle cap (120) and nozzle mesh (121) a sound characteristic of a crystal timing algorithm are disclosed. Nozzle mesh (121) is principally audible frequency band center frequency band output change reaction chamber. However earphone (10) affect influence upon a sound characteristic of various disclosed. The nozzle mesh (121) advance order receipt specification of base characteristics, normal characteristics and defining the characteristics for to tame. The entire 20Hz - 20kHz alternate audio frequency range with reference to the base, the pin is the definition of normal and characteristics need. Audible frequency band output characteristic graphs of frequency of 20Hz - 20000Hz - in, corresponding to an output value which 1kHz R, R band 1kHz hereinafter more output value A 100Hz or more area, more area is assumed to be the output value R or more band 1kHz 10kHz hereinafter B, B/(A + B) value 0. 35 If acoustic characteristic less than generally base, 0. 35 Or more 0. 65 Hereinafter when acoustic characteristic, 0. 65 If greater than acoustic properties can be defined. The, number 1 sound based on characteristics of a nozzle cap (120), number 2 nozzle cap (120) and number 3 nozzle cap (120) and method for manufacturing plasma, i.e. each nozzle cap (120) nozzle mesh (121) employs a collection of can. Examples of Figure 16 embodiment 14 also to the entire composite nozzle mesh (121) using some finer, or variable is constructed by the audio characteristic are disclosed. Figure 14 shows a the present invention also associated with earphone (10) nozzle mesh (121) to another embodiment for example timing are disclosed. The aforementioned embodiment examples one nozzle cap (120) to one nozzle mesh (121) flux of the characterized. Wherein talking nozzle as well as mesh (121) is larger influence upon a sound characteristic affecting it as indicating and mesh, mesh cover does not include above-mentioned. Alternatively, if necessary nozzle mesh (121) having a plurality of an overlapped can be. A plurality of nozzle mesh (121) comprises dissolving the printing, limited the entire existing nozzle mesh (121) that was not capable of forming the tank pressure include implementing in that flow tides. In one example, physically or productivity side viewed in nozzle mesh (121) adjustment minimum distance of each be present. The nozzle produced mesh (121) in a single nozzle when overlap with existing mesh (121) from unacceptably high negative pressure include implement implement tranfectants disclosed. In particular two nozzles mesh (121) of the printing comprises dissolving the as an example, each nozzle mesh (121) a nozzle number 1 mesh (121a) and number 2 nozzle mesh (121b) defined by the substrate. Number 1 nozzle mesh (121a) and number 2 nozzle mesh (121b) so as to overlap with at least a region can be. For example, number 2 nozzle mesh (121b) is number 1 nozzle mesh (121a) when the upper surface of the gate transistors are blocked, nozzle number 1 mesh (121a) is number 2 nozzle mesh (121b) forming region can be provided in a control section is some number 1. In one form, comprising a plurality of circular region can be number 1. Number 2 nozzle mesh (121b) is nozzle (112) and covers the entire opening hall of, nozzle number 1 mesh (121a) some region, i.e. comprises dissolving the area number 1, number 2 nozzle mesh (121b) pressure increase caused by low tranfectants disclosed. I.e., by adding fine pressure only for a partial region of a pair of adjustable disclosed. The present invention also Figure 15 shows a associated with earphone (10) nozzle mesh (121) to another embodiment for example timing are disclosed. Or different specification nozzle mesh (121) is one flat surface so that the same can be of forming. I.e., different specification nozzle mesh (121) is one nozzle mesh (121) new form the entire nozzle mesh (121) of personality may have. Descriptions different specification nozzle mesh (121) number 3 a nozzle mesh (121c) and number 4 nozzle mesh (121d) when the recording layer, that are novel nozzle number 5 mesh (121e) is number 3 nozzle mesh (121c) and number 4 nozzle mesh (121d) formed by using U-plate (10) may have a negative pressure between the negative pressure. In one example, number 3 nozzle mesh (121c) is mounted passage (112) in a control section and a central opening hall of number 2, number 4 nozzle mesh (121d) is number 3 nozzle mesh (121c) number a nozzle (112) can be provided in a control section number 3 above. The present invention also Figure 16 shows a associated with earphone (10) nozzle mesh (121) to another embodiment for example timing are disclosed. Hook of nozzle cap (120) binding even after rotatable disclosed. The nozzle using these mesh (121) is adjusted by a negative pressure structure can take into consideration a disclosed. The nozzle section (110) of the auxiliary nozzle opening hall mesh (123) is, nozzle cap (120) nozzle mesh (121) can be with. A rotatable nozzle cap (120) assisted by the nozzle mesh (123) and the nozzle mesh (121) includes variable a can be relative to form an angle. For example, auxiliary nozzle mesh (123) and nozzle mesh (121) having each a plurality of parallel patterns can be mesh. The a plurality of parallel stripes can be mesh holes forming a plurality of parallel stripes. Nozzle cap (120) nozzle portion (110) when the display panel for G1, auxiliary nozzle mesh (123) and nozzle mesh (121) formed in parallel stripes of maximum holes can be formed. While, nozzle cap (120) nozzle unit (110) for automatic and manual G2 angle, auxiliary nozzle mesh (123) and nozzle mesh (121) formed of a vertically striped minimal holes can be formed. G1 and G2 can be a 90 degree angular difference. A heater vent hole are eliminated by inducing a low pressure, high pressure influence upon a sound characteristic formed narrow area generalizations can affect the disclosed. The user angle G1 G2 angular range between the nozzle cap (120) rotating a re-sustains the acoustic properties of a vent hole can. The present invention also (a) to 17 (c) is also 17 associated with earphone (10) embedding amplifier ventilation amount shown in graph properties are disclosed. The nozzle section (110) when ventilation with controlled, 17 (a) is also mainly rectangular shape such as rectangular shape from first (Peak) (Peak) in resonant frequency (f0) first immediately before A near region to vary the degree output of frequency of can be. The nozzle section (110) when A into two output including the ventilation and decreased, if increased output also increases and vice versa. In Figure 17 is shown in the region between 2kHz 1kHz A region when the composite real-do not earphone (10) depending on specification of can be. These features of the same acoustic properties described hereinafter B and C even when received signals. As the, preceding embodiment examples in the nozzle section (110) through a ventilation amount of other properties. Acoustical properties but the change of the nozzle section (110) as well as earphone (10) may be filled even other areas of ventilation amount can be varied. Examples of embodiment hereinafter through earphone (10) through a ventilation amount of other areas of characteristic changing scheme are described as follows. In one example, driver unit (200) itself to one end ventilation amount can be acoustic characteristic is changed. Driver unit (200) with a hole in the rear ventilation amount when adjusted by, (b) frequency domain B region near region also 17 such as 1kHz number can be output capable of varying degree. Driver unit (200) when the backside of the hole with high frequency-band output is smaller than the reduced airflow through the air B, B frequency domain area that is larger than the output band is incremented. On the contrary, driver unit (200) when the backside of the hole through the air amount smaller than the increased frequency-band output increased B, B reduces the frequency domain area that is larger than the output band. I.e., driver unit (200) greater than the backside of the ventilation amount of acoustic sounds having characteristic changes such as seesaw operation of properties to be coated. In another example, earphone (10) housing (100) to one end rear ventilation amount will change the acoustical properties may be filled. Driver unit (200) of the rear housing (100) when the hole formed in the ventilation opening degree, such as a degree of change (c) 17 also can be biggest C bass output. Driver unit (200) of the rear housing (100) and decreased by C into two when vent hole formed in the output can be reduced and, if increased output can be increased and vice versa. The present invention also Figure 18 shows a associated with earphone (10) decomposition of sensors mounted thereon are disclosed. Housing (100) includes a base hole (331) and a flat hole (332) can be with. In particular, base hole (331) and a flat hole (332) comprises a housing (100) can be rotatably coupled to the of number 1, number 1 faces are provided on the housing (100) can be a rear surface of the. Due back coated with backside coupled to the rotatable portion (320) rotation s402. acoustic characteristic. The rotatable portion (320) is opening hole (326) is combined with each other. Opening hole (326) is rotating part (320) according to rotation of the base hole (331) or flat hole (332) acoustic properties may have different opening and closing. Opening hole (326) the base hole (331) when performing sounds having characteristics of opening bass emphasis (Bass Booster), opening hole (326) is flat hole (332) having characteristics of high emphasis (Treble Booster) when opening may have acoustic properties. For example in the form of several embodiment high bass emphasis or emboldening adjusts the sound he speaks only hole shapes and sizes can be detecting unit detects a carrier. Opening hole (326) is rotating part (320) can be rotatably coupled to the of number 2. Number 2 faces are provided on the housing (100) of the opposing the face of the big number 1. Number 2 faces are provided on the rotating part (320) inner bracket (321) can be implemented. Inner bracket (321) comprises a housing (100) that are mechanically fastened to rotate and serves serves to guide an integrated can perform. The contents of carry details to each other. Base hole (331) and a flat hole (332) comprises a housing (100) has a value by the enclosure of the ventilation amount. Base hole (331) relatively large ventilation amount hole having an area by flat hole (332) than that of a relatively large number of disclosed. Flat hole (332) as well as have a relatively small area of Hall, carry pipe shape formed on the ventilation amount base hole (331) of than it relatively disclosed. To enter general increase amount bass properties can be reduce, hole size is achieved enabled, in one aspect a workpiece diameter reduce the number free one impossible disclosed. The outside shape is implemented for the modulation of ventilation amount can be. The present invention also Figure 19 shows a associated with earphone (10) and decomposition of perspective view, Figure 20 case (311) of the outer and the outer case (312) the inside of the front are disclosed. Also 19 and 20 also simultaneously descriptions reference each other. Housing (100) the driver unit (200) and the like type of length for mounting (3101) directly forming the outer case (311) and an inner case (311) on the outer surface of (3111) which surrounds the outer case (312) can be divided into. Outer case (312) the inside surface of (3121) has an inner case (311) on the outer surface of (3111) can be coupled to. As aforementioned flat hole (332) to be moved between infinity and the size of a small outer case (312), in particular Hall plate (3122) with flat hole (332) and outer (311), in particular damper layer (3112) with inner hole (333) through ventilation amount can be made smaller. The outer case (311) and outer case (312) is a state in flat hole (332) and inner hole (333) not having the same point. I.e., flat hole (332) and inner hole (333) has an inner case (311) inside surface (3121) conduit formed home (334) coupled with each other by. Outer case (312) the inside surface of (3121) negative pressure groove (334) case in relation to the area number a (311) on the outer surface of (3111) closed by means of a substrate. The driver unit (200) with length (3101), i.e. enclosure air inner hole (333), pipeline home (334) and a flat hole (332) in order housing (100) to allow the outside or vice versa can be entering path. Pipeline home (334) has an outer case (312) the inside surface of (3121) sunken area formed on the substrate. Pipeline home (334) the shape of the inner hole (333) and a flat hole (332) for connecting 'C' shape may have. But other shapes along the length of conduit 72 requirements disapproval. The outer case while (311) base hole (331) and outer case (312) base hole (331) has an inner case (311) and outer case (312) obtained by combining can be disposed at the point of reception. I.e., the outer case (311) base hole (331) and outer case (312) base hole (331) does not form separate each other. The length (3101) of inner case (311) on the outer case (312) each base hole (331) can be directly through the level. The flat hole (332) than if the amount of air that is very convenient including path opening, i.e. out of the ventilation amount can be. The reference also 18 again, sealing gasket (341) comprises a housing (100) of number 1 surface and rotating part (320) between the number 2 of combined with each other. Sealing gasket (341) vent hole (326) is flat hole (332) or a base hole (331) which is seen when opening open escape air into the other areas not servicing the unexpected noise which is generated. Sealing gasket (341) flat hole (332) and base hole (331) each point corresponding holes of substantially identical shape mounted to the housing (100) of number 1 to the outside of the can. Sealing gasket (341) and the housing (100) the flow between the housing (100) of the number 1 outer guide (342) is, sealing gasket (341) guide (342) corresponding to the shape of the retaining grooves (343) can be with. The rotatable portion (320) inner bracket (321) is a rotary dial (346) in conjunction with rotating together. Inner bracket (321) with opening hole (326) has a base hole (331) or flat hole (332) closing at least one of a two-piece enclosure air hole (331, 332) through only one exit HL2. Switching a hole (326) number 1 to vent mesh (344) is coupled through a system which serves an air permeable amount can be. Inner bracket (321) to the back surface of a rotary dial (346) can be binding. A rotary dial (346) for user to rotate so that the aforementioned hereinafter to restrict pattern is a efined. A rotary dial (346) consists of ventilation for regulating at least one Hall (3441) and number 2 covering the vent mesh (348) can be with. (A) 21 also includes a rotating part (320) of rear view perspective view, (b) 21 also includes a housing (100) and front perspective view, Figure 22 shows a also earphone (10) section in are disclosed. Descriptions 21 and 22 together also also reference each other. As aforementioned rotating part (320) includes a housing (100) bind to a lower side. Housing (100) opening circular coupling flange (313) can be with. The rotatable portion (320) of the hook portion (322) establishes an adhesive bond flange (313) fastened to, i.e. hook (3222) couple to flange (313) and attached along the rotating. Rotating hook portion (322) to the outer peripheral surface (3221) with flange (313) engage one another stator portion and the inner peripheral surface (320) can be guiding rotation of. Rotating hook portion (322) of hook (3222) establishes an adhesive bond flange (313) over inside the glass flange (313) inner space can be formed. The rotatable portion (320) an angle of rotation of a rotating part (320) guide stepped portion (323) and a housing (100) rotatably coupled to the projection of number 1 (342) including a guide section (327) can be implemented by. Guide stepped portion (323) boundary both sides of a rotating part (320) is formed in a rotating angle at one or other end by number 1 (342) is biased to rotate in an angle number 1 can be. Rotating hook portion (322) has a plurality of hook protrusion (322a) may have a. A plurality of hook protrusion (322a) are each defined for hooked by may have elasticity. Rotating part (320) housing (100) comprises a plurality of hook protrusion when the (322a) are each joined flange (313) passes through the openings of the rotating part (320) housing (100) is applied restoring bonded reciprocally moves between first and can be fixed. But, number bath tolerance or rotary hook portion (322) of materials completely state won by physical variation due is easy and the rotatable portion (320) housing (100) to completely unlocked thereof can. The door includes a door number number simple ventilation as well as influencing play or flow amount not adversely affect the intended sound output may be filled. Support rubber (324) has a plurality of hook protrusion (322a) plurality of outwardly moving hanger hook protrusion (322a) properties of material compressed by means of the expanded position after servicing the plate so won or less. Support rubber (324) is elastic and includes a can. A plurality of hook protrusion (322a) sufficiently which improves the stator portion (320) the number 1 of the housing (100) between the blocking plate is number 2 of the respective sound which is occurred in output to about. In addition support rubber (324) is subsequently rotating part (320) generally required forces rotation of the solenoid when the lifting force sufficient user rotating part (320) or the HL2. Figure 23 shows a rotating portion (320) is rotated in order to make a degree indicative of the state of several constructs that are unique earphone (10) rear view of are disclosed. As aforementioned, the rotatable portion (320) includes a housing (100) can be number 1 to rotate in an angular range. Number 1 projection angle range (342) and guide stepped portion (323) determined by a width of the. (A) 23 also includes a rotating part (320) is connected to one end of turns of number 1 state in angular range is number 1, 23 (c) is also rotating part (320) is number 1 in angular range other end turns of number 2 state, 23 (a) (b) also is also 23 23 (c) etc. and also between the state that the number 3. (A) 23 also in number 1 in closing hole (326) has a base hole (331) open and flat hole (332) and a movable conductive surface. The housing discharge side (100) length (3101) includes a base hole (331) only air charging reaction chamber. Opening hole (326) the shape and size of base hole (331) of the first large or middle distance below can be formed. Base hole (331) than opening hole (326) if the same or when in the air opening hole (326) the base hole (331) intended to thereof can prevent air charging and generating the noise. (C) closing hole in 23 also in number 2 (326) flat hole (332) open and base hole (331) and a movable conductive surface. The housing discharge side (100) length (3101, 22 also reference) is flat hole (332) only air charging reaction chamber. Flat hole (332) since the above-mentioned air path through a subjected to omit other. (A) 23 also said closing of hole (326) the shape and size of flat hole (332) or larger than that of the below can be formed. Since the aforementioned opening hole (326) the shape and size of base hole (331) or larger than that of the reason below are the same. (B) closing hole in 23 also in number 3 (326) has a base hole (331) and a flat hole (332) of each part of the region can be simultaneously opened. Specifically, in rotatable part number 1 number 2 (320) when the body is rotated opening hole (326) the base hole (331) and a flat hole (332) not all the areas of the case can be closed both. If opening hole (326) the base hole (331) and a flat hole (332) has a States both undesirable sound effect is little when the finest foreign sound output to generate's oldest. The this arrangement, shapes and sizes in quickly converting a natural feature of the state number 1 number 2 serves a plurality of hierarchies. The reference 22 also again, ear unit wire (301) then selects the unit (300) and the main body (200) are connected to electrically. Ear unit wire (301) then selects the housing (310) of length (3101) electronic component and connected thereto. Ear housing (310) drawn from an ear unit wire (301) is in order to prevent the wire to support (302) by a length such that the other. Ear unit wire (301) pull-out of the part and wire support (302) then selects the housing (310) side of the combined with each other. This is part (320) rotationally of beam to avoid design are disclosed. Ear unit wire (301) is ear housing (310) and a leading side when ear unit (300) is equal to entire width direction increases space taken up. The comprises a main body (200) is followed by unit (300) when the outer affecting other. A user through diode having one nozzle of Figure 17 A acoustic properties of nozzle cap replacement mesh, a rotary dial (346) to two of Figure 17 C region can be acoustic properties. The present invention also associated with Figure 24 shows a driver unit (200) the upper side of the timing are disclosed. Driver unit (200) to the back surface of unit duct hole (201) is combined with each other. Driver unit (200) with unit duct hole (201) 17 (b) number of frequency domain B region aforementioned hole are ventilation amount influence upon a sound characteristic capable of affecting the other. Dampers (221) number 1 includes a rotating member (220a) is fixed to the driver unit (200) coupled to a rear surface of the can. Rotating member number 1 (220a) includes a driver unit (200) coupled to a rear surface of the can. In particular number 1 rotating member (220a) includes a driver unit (200) can be rotatable to a backside of the combine. For example rotating member number 1 (220a) axis is formed at a sliding surface (222) can be with. Rotating member number 1 (220a) of protrusion (222) includes a driver unit (200) of the hole (202) a rotary coupling to can. Dampers (221) having a plurality of damper layer can be ventilation is different. The plurality of unit damper (221) one of the driver unit (200) the backside of the unit duct hole (201) can be placed in corresponding. Unit duct hole (201) corresponding to unit damper (221) can be adverse effects on sound ventilation rate. The plurality of unit damper (221a, 221b, 221c, 221d) number 1 includes a rotating member (220a) can be of the same distance from a central axis. The same distance from a central axis located in the rotating member number 1 (220a) a rotating shift unit damper (221) either of the unit duct hole (201) can be positioned to. The plurality of unit damper (221a, 221b, 221c, 221d) for facilitating user work direction from ventilation amount is so holds can be arranged sequentially. Unit duct hole (201) unit for duct hole (201) corresponding damper unit (221) are each contact can be made by brazing. I.e., unit is allowed to correspond to an air damper (221) may be recessed downward frequency to dampers (221) or other unit without needing not correspond to the damper (221) can be not in the air through. In order to improve the air shield reliability unit duct hole (201) sealing member located along the boundaries (223) can be with. Sealing member (223) includes a driver unit (200) number 1 back and rotating member (220a) is pulled in one between the driver unit (200) to the rear surface of contact with a rotating member out of photochemical activity number 1 (220a) having inner surface contact can be. Sealing member (223) includes a driver unit (200) backplane or rotating member number 1 (220a) can be coupled to the inner one of. Sealing member (223) is comprised of a resilient material for improving the shielding can be reliability. According to the required driver unit (200) with front housing (110) and the rear housing (120) coupled to the rotating member for disassembling the number 1 (220a) can be rotating. Number 1 or rotating member (220a) a portion of the housing (101) to prevent a housing (101) of number 1 immediately without disassembling the rotating member (220a) for regulating an air permeable rotating to disapproval. The present invention also associated with Figure 25 shows a driver unit (200) the upper side of the timing are disclosed. Said embodiment examples damper and a Serial plurality, unit duct hole (201) when one with are described. The damper layer opposite one, unit duct hole (201) comprises dissolving the plurality can be taking into account. Driver unit (200) includes a plurality of unit duct hole (201a, 201b, 201c) with disapproval. Plurality of units duct hole (201) with the size of the height can be. Plurality of units duct hole (201) is driver unit (200) can be provided between the rear surface of the damper layer with. Damper layer a plurality of units duct hole (201) one of the unit duct hole (201) can be corresponding. A plurality of unit duct hole (201) for facilitating user work direction from ventilation amount is so holds can be arranged sequentially. Damper layer rotating member number 2 (220b) number 2 between the first rotating member (220b) according to a plurality of unit duct hole (201) can be sequentially and facing. Rotating member number 2 (220b) number 1 includes a rotating member (220a) in the same manner as on sealing member (223) can be having, at a sliding surface (222) can be with, housing (101) exposed outside of different disapproval. 17 Also through user comprises the above-described embodiment examples (a) and 17 (c) can also acoustic properties as well as driver unit (200) of rolling members (220) (b) through 17 also taught acoustical properties in addition to the entire acoustical properties for tuning process from audible frequencies can be simultaneously formed. If necessary, the earphone of the present invention said three acoustical properties of tuning can be drawn only some three ways. The aforementioned driver unit (200) with the ventilation amount can form a real variable disclosure, corresponding to the horizontal when ventilation with controlled amounts driver unit (200) may take the form disapproval. The present invention refers to of the present invention mental and essential characteristic of a particular type may be embodied other inputted from deviating from a corresponding relative to conventional art to reduced disclosed. Said limited number in all detailed description is interpreted should have been taken into account in an exemplary WD. The range of the present invention rationally determined by analysis in a number of appended claim, all in the scope of the present invention change is equivalent range of the present invention multiple myelomas are included. 10: Earphone 100: earphone housing 101: Ear tip 102: cable 110: Nozzle section 1101: nozzle section outer peripheral surface 111: Nozzle filter 112: nozzle section passage 120: Nozzle cap 1201: nozzle cap inner peripheral surface 1202: Upper end nozzle cap inner surface 120a: number 1 hook type nozzle cap 120B: number 2 hook type nozzle cap 120c: number 3 hook type nozzle cap 121: Nozzle mesh 1211: nozzle mesh outer boundary area 121A: 121b mesh nozzle number 1: number 2 nozzle mesh 121C: nozzle mesh 121d number 3: number 4 mesh nozzle 121E: number 5 nozzle mesh 122: cleaning unit 123: Auxiliary nozzle mesh 130: hook portion 131: Protrusion 132: depression stage 133: Depressions 134: thread 200: Driver unit 210: diaphragm 302: Wire support 3101: length 311:3111 Case: the outer surface of the outer case 3112: Damper layer 312: outer case 3121: Outer case inner surface 3122: Hall plate 313: Coupling flange 320: rotating part 321: Inner bracket 322: rotation hook portion 3221: Hook portion outer peripheral surface 3222: hook 322A: hook protrusion 323: guide stepped portion 324: Support rubber 325: magnetic part number 2 326: Opening and closing hole 327: guide 331: Base hole 332: flat hole 333: Inner hole 334: pipeline home 341: Sealing gasket 342: guide 343: Retaining grooves 344: number 1 mesh vent 3441: Hole 346: a rotary dial 348: Vent mesh number 2 Provided is an earphone capable of easily removing foreign substances that have been generated on a nozzle portion of the earphone, and easily controlling sound characteristics thereof. The earphone includes: a driver unit; a housing forming an electrical component to mount the driver unit; a nozzle portion provided at one end of the housing and forming an opening communicating with the electrical component; a nozzle cap detachably coupled to an outer circumferential surface of the nozzle portion; and a nozzle mesh provided at the nozzle cap so as to cover the opening, wherein the nozzle cap serves to decrease output in a second peak region and to increase output in a fourth peak region or expand a bandwidth of the fourth peak region in a graph of output over frequency. COPYRIGHT KIPO 2018 Driver unit; by forming a housing for mounting said driver unit length; one end of said housing forming said opening hall with length and connected to the nozzle portion; said outer peripheral surface of the nozzle unit detachably coupling the nozzle cap; and said nozzle cap and said nozzle opening hall with shielding mesh, said nozzle cap is a frequency - output graph of a second rectangular shape of output and attenuate (Peak), rectangular shape (Peak) and to increase the output of the fourth shelf or expanding band width, said replaceable nozzle cap nozzle cap number 1, number 2 and number 3 nozzle cap and nozzle cap, said number 1 nozzle caps bonded thereto base when acoustic characteristic, normal acoustic characteristic when said number 2 nozzle caps bonded thereto, when said number 3 nozzle caps bonded thereto characterized will be acoustical properties of earphone. According to Claim 1, said frequency domain path forward earphone 2kHz - 20kHz region is a rectangular shape. Driver unit; by forming a housing for mounting said driver unit length; one end of said housing forming said opening hall with length and connected to the nozzle portion; said outer peripheral surface of the nozzle unit detachably coupling the nozzle cap; and said nozzle cap and said nozzle opening hall with shielding mesh, said replaceable nozzle cap nozzle cap number 1, number 2 and number 3 nozzle cap and nozzle cap, acoustic characteristic base when said number 1 nozzle caps bonded thereto, normal acoustic characteristic when said number 2 nozzle caps bonded thereto, when said number 3 nozzle caps bonded thereto characterized will be acoustical properties of earphone. Back number According to Claim 3, said output value corresponding to a frequency - output graphs 1kHz in R, said R 1kHz hereinafter more output value A 100Hz or more band area, said R B 1kHz 10kHz hereinafter more output value area is assumed to be the more band, when said number 1 nozzle caps bonded thereto B/(A + B) value is 0. 35 Less than, when said number 2 nozzle caps bonded thereto B/(A + B) value is 0. 35 Or more 0. 65 Hereinafter and, when said number 3 nozzle caps bonded thereto B/(A + B) value is 0. 65 Characterized by greater than earphone. According to Claim 3, 2kHz 6kHz hereinafter more than said number 2 nozzle caps bonded thereto when said number 1 nozzle caps bonded thereto of a frequency band to be increased over 3dB frequency band exists and, when said number 3 nozzle caps bonded thereto said number 2 nozzle caps bonded thereto of a frequency band to be reduced more than 2kHz 6kHz hereinafter 3dB frequency band characterized wherein said earphone. Driver unit; by forming a housing for mounting said driver unit length; one end of said housing forming said opening hall with length and connected to the nozzle portion; said outer peripheral surface of the nozzle unit detachably coupling the nozzle cap; said nozzle cap with a nozzle opening hall said shielding mesh; said nozzle cap and said nozzle section with a hook portions and the outer circumferential surface and the inner peripheral surface, said nozzle cap has replaceable number 1 nozzle cap, number 2 and number 3 nozzle cap and nozzle cap, said number 1 nozzle caps bonded thereto base when acoustic characteristic, normal acoustic characteristic when said number 2 nozzle caps bonded thereto, said number 3 nozzle caps bonded thereto when acoustical properties of will be earphone. According to Claim 7, said hook portions, one of said outer peripheral surface or said nozzle cap nozzle section formed along the inner peripheral surface around the protrusion; said nozzle cap and said nozzle section outer peripheral surface or the inner peripheral surface toward the supporting protrusion along the circumference corresponding to another one of said recessed end characterized including earphone. According to Claim 7, said nozzle cap adjacent said nozzle section of said nozzle cap local government post view mirror number 1 characterized by local government post alarm disclosed the maximum value greater earphone. According to Claim 7, said nozzle cap away from said nozzle section of said nozzle cap elapsed number 2 local government post view mirror as long as the local government post, said earphone is, said nozzle cap and said nozzle section number 2 characterized further including blocking member which engages with an ear earphone. According to Claim 7, said nozzle cap, said nozzle being extended ABS containing the resin and said nozzle cap insert earphone abandons characterized. According to Claim 7, said nozzle cap and said nozzle opening for exposing outside mesh, said nozzle opening diameter and said same view mirror characterized earphone. According to Claim 7, surrounds said nozzle cap and said nozzle further includes combining ear, said ear tip said nozzle cap characterized one blocking member has the upper surface of the earphone. According to Claim 13, said nozzle cap and said ear tip each including a mesh opening for exposing outside said nozzle, said nozzle cap opening in said ear tip opening diameter is characterized the same earphone. Driver unit; by forming a housing for mounting said driver unit length; one end of said housing forming said opening hall with length and connected to the nozzle portion; said outer peripheral surface of the nozzle unit detachably coupling the nozzle cap; said nozzle cap with a nozzle opening hall said shielding mesh; and said inner peripheral surface and the tip of the bending portion extends nozzle cap, said outer peripheral surface of the nozzle unit has a bent part said indentations which rests on the, said replaceable nozzle cap nozzle cap number 1, number 2 and number 3 nozzle cap and nozzle cap, said number 1 nozzle caps bonded thereto base when acoustic characteristic, normal acoustic characteristic when said number 2 nozzle caps bonded thereto, when said number 3 nozzle caps bonded thereto characterized will be acoustical properties of earphone. According to Claim 15, characterized in that said nozzle cap is a SUS including earphone. Driver unit; by forming a housing for mounting said driver unit length; one end of said housing forming said opening hall with length and connected to the nozzle portion; said outer peripheral surface of the nozzle unit detachably coupling the nozzle cap; and said nozzle cap and said nozzle opening hall with shielding mesh, and said nozzle cap is screwed into said nozzle section, said nozzle cap has replaceable number 1 nozzle cap, number 2 and number 3 nozzle cap and nozzle cap, said number 1 nozzle caps bonded thereto base when acoustic characteristic, normal acoustic characteristic when said number 2 nozzle caps bonded thereto, when said number 3 nozzle caps bonded thereto characterized will be acoustical properties of earphone. Driver unit; by forming a housing for mounting said driver unit length; one end of said housing forming said opening hall with length and connected to the nozzle portion; said outer peripheral surface of the nozzle unit detachably coupling the nozzle cap; and said nozzle cap and said nozzle opening hall with shielding mesh, said nozzle mesh, mesh and said number 1 and number 2 to be stacked with mesh with a mesh number 1 nozzle nozzle nozzle, said mesh with auxiliary nozzle of the nozzle unit further includes long, said nozzle cap is rotatably coupled to said outer peripheral surface of the nozzle unit to said nozzle cap and the sliding member in accordance with the rotation of said nozzle and said auxiliary nozzle mesh vent amount due to different mesh, said mesh a plurality of parallel strip-shaped auxiliary nozzle holes is formed, a plurality of vent holes in said nozzle cap and said nozzle mesh overlaps said number 1 angle, said a plurality of parallel vertical angle number 2 in a plurality of vent hole with a vent hole partially characterized earphone. According to Claim 18, said number 2 nozzle said number 1 nozzle meshes with a stacked on the mesh, the mesh having a mesh number 1 a partial region of said number 1 nozzle said number 2 nozzle area characterized earphone. Back number Back number