THREE-DIMENSIONAL PRINTER

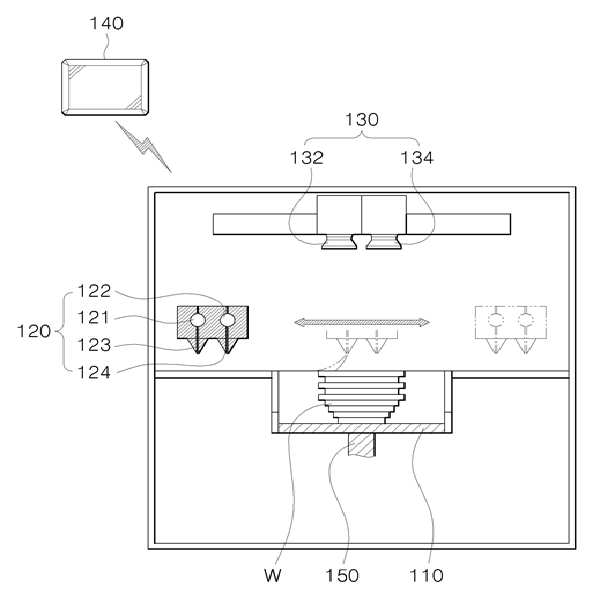

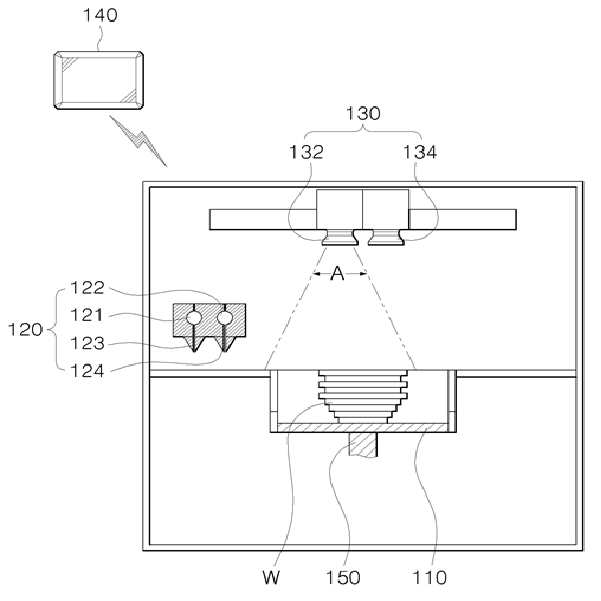

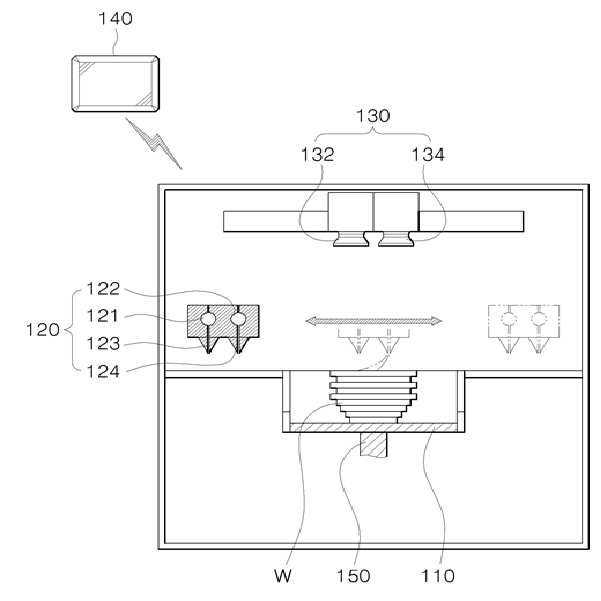

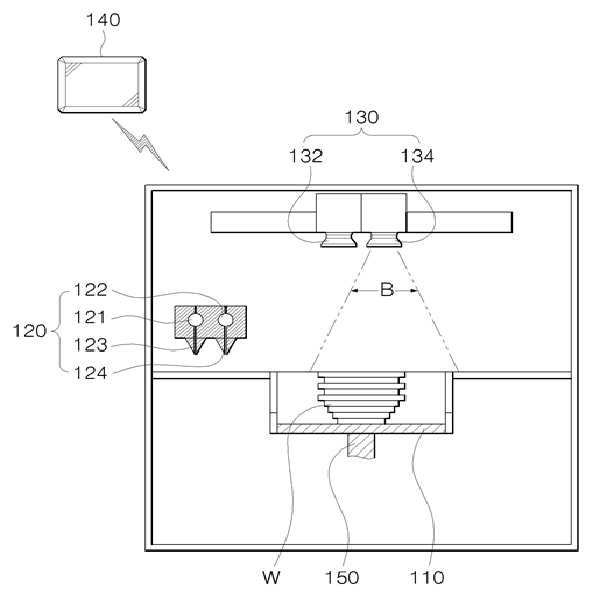

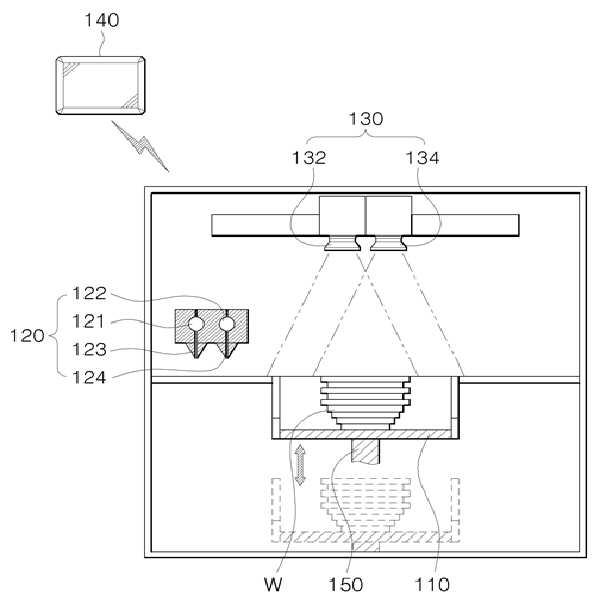

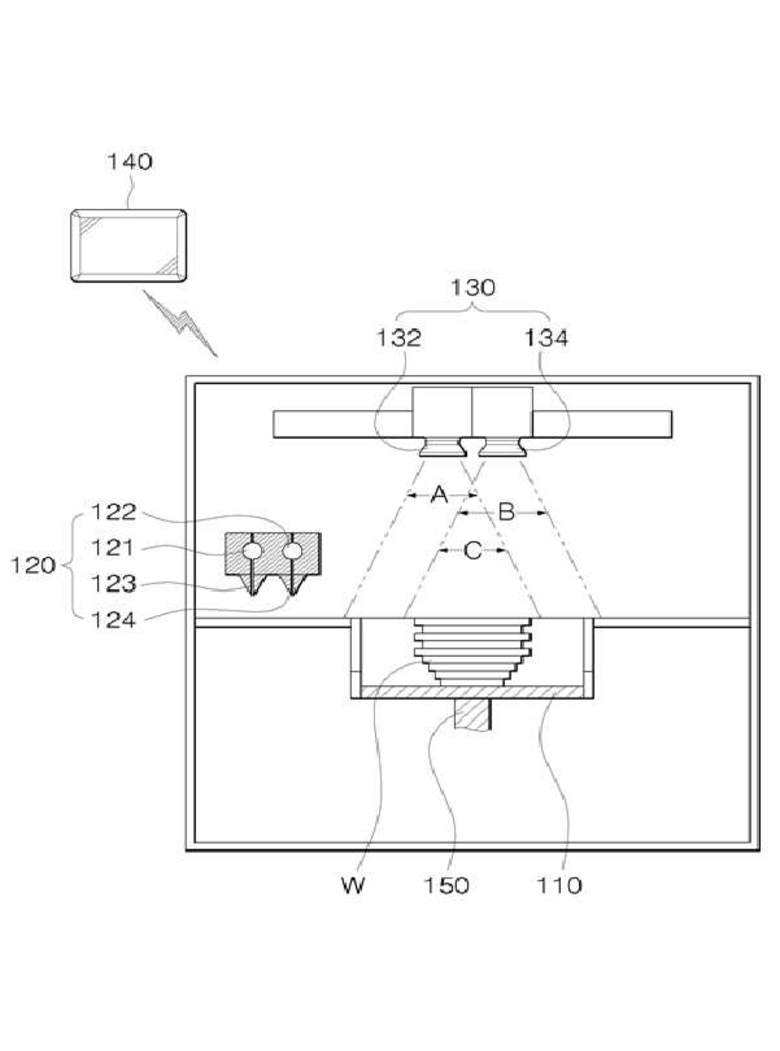

The present invention refers to relates to a three-dimensional printer, more particularly Figure the nozzle output bed using different materials supplied material while supplying the laser beam to the output nozzle while three-dimensional printer left and the sintering material are disclosed. A compensation registration described in the background art patent number 1705696 reference, generally the printer print object by character, such as the graphics printing and design device, a control device or the like is ground printer printing business, etc. support are home. The printer has a paper or sheet material object of the existing method and moving in a predetermined direction in the 2 dimensional printing both fine ink root but, when the three dimensional shape can be recent 3 form an appearing in the printer, the printing technique to form three-dimensional shape formed by three-dimensional printer device can be implemented in a substrate. In the presence of a designer and designer CAD (CAD) or cam (CAM) number cookies using generates a 3 dimensional modeling data, 3 dimensional shape data generated using a so-called 3 dimensional printing method keeps a small article is the seam number number appearing, such 3D printer industry, life, etc. medical thermal utilized in various fields. The basic principle generally 3D printer object layer providing a thin 2D 3D so that it are disclosed. I.e., 3D printer method is photocurable resin cured part scanning laser beam scan utilizing the principles on SLA (Stereo Lithography Apparatus), SLA functional polymer or metal powder instead of using laser beam scanning with a photocurable resin in functional polymer or metal powder is consolidated using principle of SLS (Selective Laser Sintering) forming, thermoplastic resin using IM (Inkjet modeling), lime powder using 3DP (3Dimension Printing) etc.. Back number The present invention refers to a polymeric material and metal material can be a use different processed, using different materials one nozzle can be applied onto the bed, while laser beam having a wavelength different of the upper face of sintering can be obtained by arranging a plastic output efficiency and an electromagnetic actuator pin is three-dimensional printer number can be used. In order to achieve said purposes such as, vertical grooves while the output supply sintering material laminated plastic bed; said polymeric material and metal material is equipped at one side of said bed while receiving the supplied bed received while applying said polymeric material and metal material bed out to an upper nozzle; applying said polymeric material and metal material on th bed sinter aligning a laser irradiation; and said nozzle, and said control section including a three-dimensional printer operation of laser irradiation plower number number number substrate. In the present invention according to a three-dimensional printer, a laser irradiating unit said polymeric material applied onto said nozzle supplied in said bed of irradiating the laser diode and the laser sintering, sintering metal material applied onto said bed for aligning the laser optical fiber can be. The present invention according to a three-dimensional printer said bed is installed under the bed further comprises said river organization can be downwardly car, said car river organization drive is said number by number 1308. the water level. Said number of the upper face of said metal material are sintered in said polymeric material is a fisherman of the substrate is a polymeric material laminated to said metal chloroethane river organization car number underneath bed capable of the height. Said polymeric material said nozzle receiving groove receiving the number 1, number 2 receiving groove receiving said metal material, said polymer material at the top of the bed effluent received storage groove said number 1 number 1 slit, said number 2 number 2 at the top of the metal material received storage groove comprising said bed effluent can be slit. the bed at the top of the nozzle said nozzle further comprises a transfer member can be left, right and left movement of the movable member by said number to said water level number can be disclosed. The present invention according to a three-dimensional printer using a polymeric material and metal material different processed applied onto the nozzle into the nozzle one bed is material and improve space can be, different materials while other wavelength laser beam with a sintering material into plastic stacking another method of using a three-dimensional printer devices one weft can be efficiency and can be an electromagnetic actuator. Figure 1 shows a three-dimensional printer configuration according to the example of the present invention embodiment shown determine also are disclosed. Figure 2 shows a bed material on top of the nozzle also 1 also shown in applying the state that it is exposed to a surface are disclosed. Also shown in Figure 3 shows a state in which the polymeric material using a laser irradiation also 1 shown in the sintering are disclosed. Figure 4 shows a nozzle 1 also using metal material also shown in applying the state that the upper bed surface are disclosed. Figure 5 shows a critical dimension is also shown in laser sintering material 1 also state that it is exposed to a surface are disclosed. Also shown in Figure 6 shows a state in which the down bed is also 1 be moved up or down by the shown are disclosed. Hereinafter, the present invention according to a preferred embodiment with reference to the attached drawing example detailed the on-sensors other. The prior, the specification range and claim defining the terms or word sense and subsequent analysis or a pre-conventional don't be not, its own invention best method described in the invention for most appropriately define a general outline of a term that feeling by principle, to meet the technical idea of the present invention must be interpreted S. semantics and general outline. Referring to the drawing, a three-dimensional printer according to example of the present invention embodiment (100) includes a bed (110) on, the nozzle (120) and, a laser irradiation (130) on, number control unit (140) and, car river organization (150) can be further comprises. Said bed (110) which carry down the river organization (150) movable vertically by a, said bed (110) selects the output (W) is provided on the left while the sintering material to be coated. Said bed (110) of a polymeric material and metal material is supplied as the laser irradiation (130) illuminated laser wavelength (W) to output on the left while billboard on a sintering, said bed (110) polymeric material and metal material that is supplied to the nozzle (120) are received. Said nozzle (120) polymer material and metal material different materials while receiving said bed (110) moves to the top of said bed while (110) while applying at the top of the effluent could be bonded each other. Said nozzle (120) is number 1 containing groove (121), number 2 containing groove (122), slit number 1 (123), and slit number 2 (124) and, (not shown) can be further includes a horizontal blade member. Said number 1 containing groove (121) is said bed (110) applied on top of a polymeric material are positioned, said polymer material is preferably a polymer powder (Polymer Powder) preferably is used but, is limited to a desired sequence has the PA (Nylon) and PEI sequence can be used a-Ultem (Ultem). Said nozzle (120) is said number 1 containing groove (121) number 1 connector (not shown) connected to while, said number 1 connector (not shown) out through the grooves in said number 1 (121) the polymer material is supplied and be received in the, said number 1 containing groove (121) a polymeric material that is received ink - jet (ink-a jet) by using the bed (110) preferably applied on top of. Said number 2 containing groove (122) is said bed (110) are positioned on top of the applied metal material, said metal material comprises metal - jet (metal-a jet) by using the bed (110) preferably applied on top of, said nozzle (120) is said number 2 containing groove (122) which is connected to a number 2 connector (not shown) while, said number 2 connector (not shown) out through the grooves in said number 2 (122) is fed into and be received in the metal material, said metal material is preferably a metal powder (Metal Powder) is used preferably. Said number 1 containing groove (121) is slit number 1 (123) connected with, said number 1 slit (123) said number 1 the grooves (121) polymer material received in said bed (110) and exits at the top of, said number 2 containing groove (122) is slit said number 2 (124) is connected to, said number 2 slit (124) said number 2 the grooves (122) metal material received in said bed (110) while outlet at the top of the light through the substrate. Said nozzle (120) is said ink - jet type and metal - jet type using a has the across, using electric field EHD (Electro Hydro Dynamic) scheme and syringe pressure is not as can be using discharging tank number (Dispensing) administration, according to desired specifications said ink - jet type, metal - jet type, in EHD (Electro Hydro Dynamic), administration of a plate-like nozzle (Dispensing) number in one said tank (120) preferably applied to use. Said nozzle (120) (not shown) left movable member by said bed (110) and be replaced with bearings at the top of the, horizontal blade member (not shown) which carry number is said control section (140) number by the surface of the patterning device disclosed. Said nozzle (120) by said bed (110) towards the laser irradiation on applying a polymeric material and metal material (130) and illuminated by laser sintering, said laser irradiating unit (130) includes a laser diode (132) on optical fiber laser (134) having a predetermined wavelength. Said laser diode (132) is said nozzle (120) through said bed (110) and a polymeric material applied on sintering, said laser diode (132) is a large area laser irradiation is high with the lower three wavelengths, said laser diode (132) illuminated laser has a wavelength in 10600 provided 10700 nm preferably. Said optical fiber laser (134) is said nozzle (120) through said bed (110) applied on metal material and sintering, said optical fiber laser (134) is adjusted over a wide range has a foothold. Said optical fiber laser (134) illuminated laser has a wavelength in 1060 provided 1070 nm preferably. Said laser diode (132) on said optical fiber laser (134) as well as a conventional description thereof dispensed the on-sensors other. Said bed (110) away is with said laser diode (132) is number 1 region (A) and aligning said optical fiber laser (134) is number 2 region (B) aligning said number 1 region (A) and (B) the sound generating bodies the number 3 region and said number 2 region is formed (C), said polymeric material and said metal material that is number 3 region (C) preferably in stacked are sintered. Said bed (110) for rising car river organization (150) has said bed (110) supplied to said metal material is a polymeric material and said upper laser irradiation (130) on a sintering the sintered surfaces said bed (110) are attached underneath a, said car river organization (150) number the drives of the control section (140) number by the surface of the patterning device disclosed. Said number control unit (140) is down said river organization (150) for driving said number plower rather than only the nozzle (120), said laser irradiation (130) preferably number plower behavior. Said number control unit (140) is said nozzle (120), said laser irradiating unit (130), and said car river organization (200) by the operation of a polymeric material and metal material different processed sequentially number one nozzle (120) using bed (110) outputs (W) can be applied onto the plastic shell can be improve space, different materials laminated plastic material while other laser beam with a wavelength (W) sintering one weft into another method of using a three-dimensional printer devices can be efficiency and can be an electromagnetic actuator. The present invention refers to drawing example embodiment shown in and described with reference to an exemplary to avoid a is but, if various deformation and equally to the person with skill in the art art therefrom will understand enabling other embodiment examples. The technical idea of the present invention defined by appended claim of true technology protection range generated by the will. 100: Three-dimensional printer 110: Bed 120: Nozzle 121: Grooves number 1 122: Grooves number 2 123: Number 1 slit 124: Slit number 2 130: Laser irradiation 132: Laser diode 134: Optical fiber laser 140: Number control unit The present invention provides a three-dimensional printer including: a bed which is vertically movable, and outputs supplied material as a sculpture by sintering and stacking the material; a printing nozzle which is provided at one side of the bed, receives a polymer material and a metal material supplied onto the bed, and flows out and applies the received polymer and metal materials to a top portion of the bed; a laser irradiation unit which irradiates lasers onto the polymer and metal materials to sinter the polymer and metal materials flown out and applied onto the bed; and a control unit which controls operations of the printing nozzle and the laser irradiation unit. Therefore, the three-dimensional printer can improve utilization of material and space by applying the polymer material and the metal material that are different materials onto the bed by using one printing nozzle, thereby enabling the polymer and metal materials applied onto the bed to be outputted as the sculpture. Further, the three-dimensional printer can improve efficiency and practicality by irradiating the lasers with different wavelengths onto the different materials, and sintering and stacking the materials such that the sintered and stacked materials can be outputted as the sculpture, thereby enabling different types of three-dimensional printing methods to be used in a machine. COPYRIGHT KIPO 2018 Vertical grooves while the output supply sintering material laminated plastic bed; said polymeric material and metal material supplied bed while receiving the received while applying said polymeric material and metal material bed out to an upper nozzle; applying said polymeric material and metal material on th bed sinter aligning a laser irradiation; and said nozzle, and said operation of a laser irradiation control section and number plower number, said a laser irradiating unit, supplied in a polymeric material applied onto said bed sintering said nozzle number 1 wavelength range for aligning laser diode and, sintering metal material applied onto said bed for said number 1 and number 2 optical fiber laser beam with a wavelength range different from the laser wavelength range, the nozzle, a polymeric material for receiving said receiving groove number 1, number 2 receiving groove receiving said metal material, said polymer material at the top of the bed effluent received storage groove said number 1 number 1 slit, said number 2 number 2 at the top of the slit and said metal material received storage groove said bed effluent, water level is the number by said number, said number 1 containing groove, said number 2 containing groove, said number 1 slit and said number 2 can transfer member on said bed at the top of the left slit including a three-dimensional printer. Back number According to Claim 1, said bed is installed under the terminal portion additionally includes river organization bed down, said control section said number by the number of vertex printer cosmetologic river organization drive is down. According to Claim 3, of the upper face of said substrate to said polymeric material is said number a fisherman are sintered in a metal material is a polymeric material laminated to said lower bed height chloroethane river organization car number metal characterized by moving three-dimensional printer. Back number Back number