SYSTEM FOR SIMULTANEOUSLY PRODUCING WATER AND ELECTRICITY

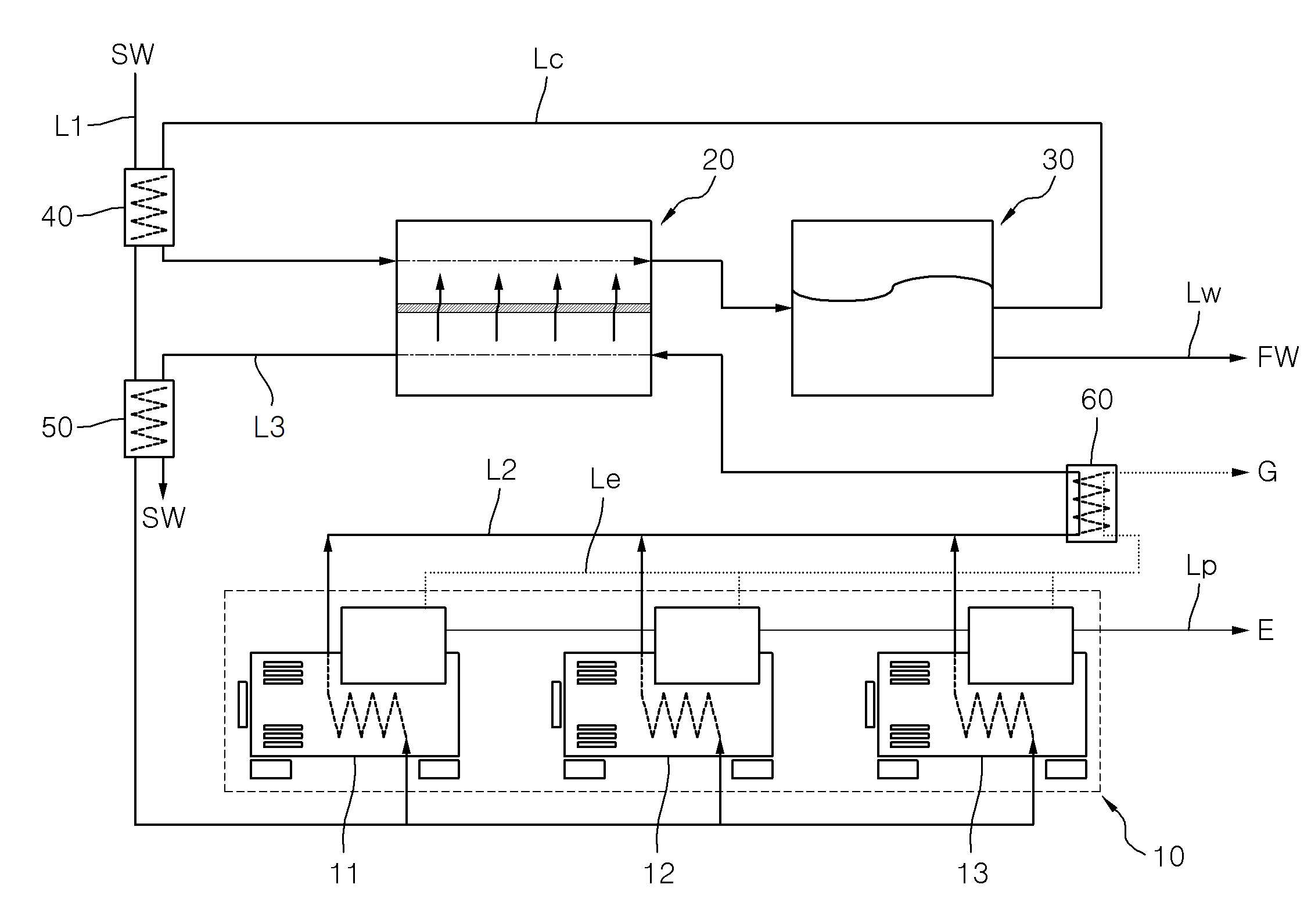

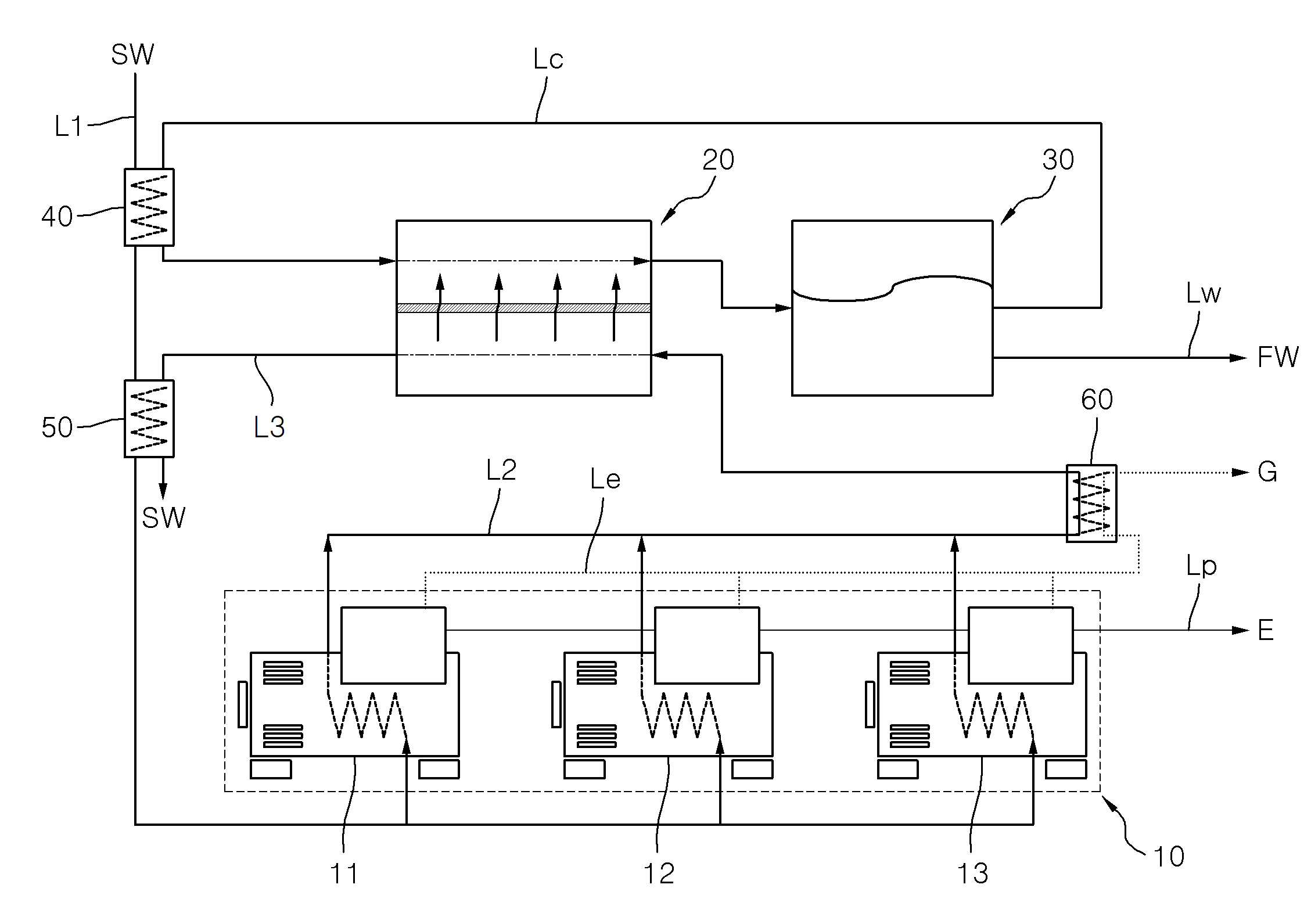

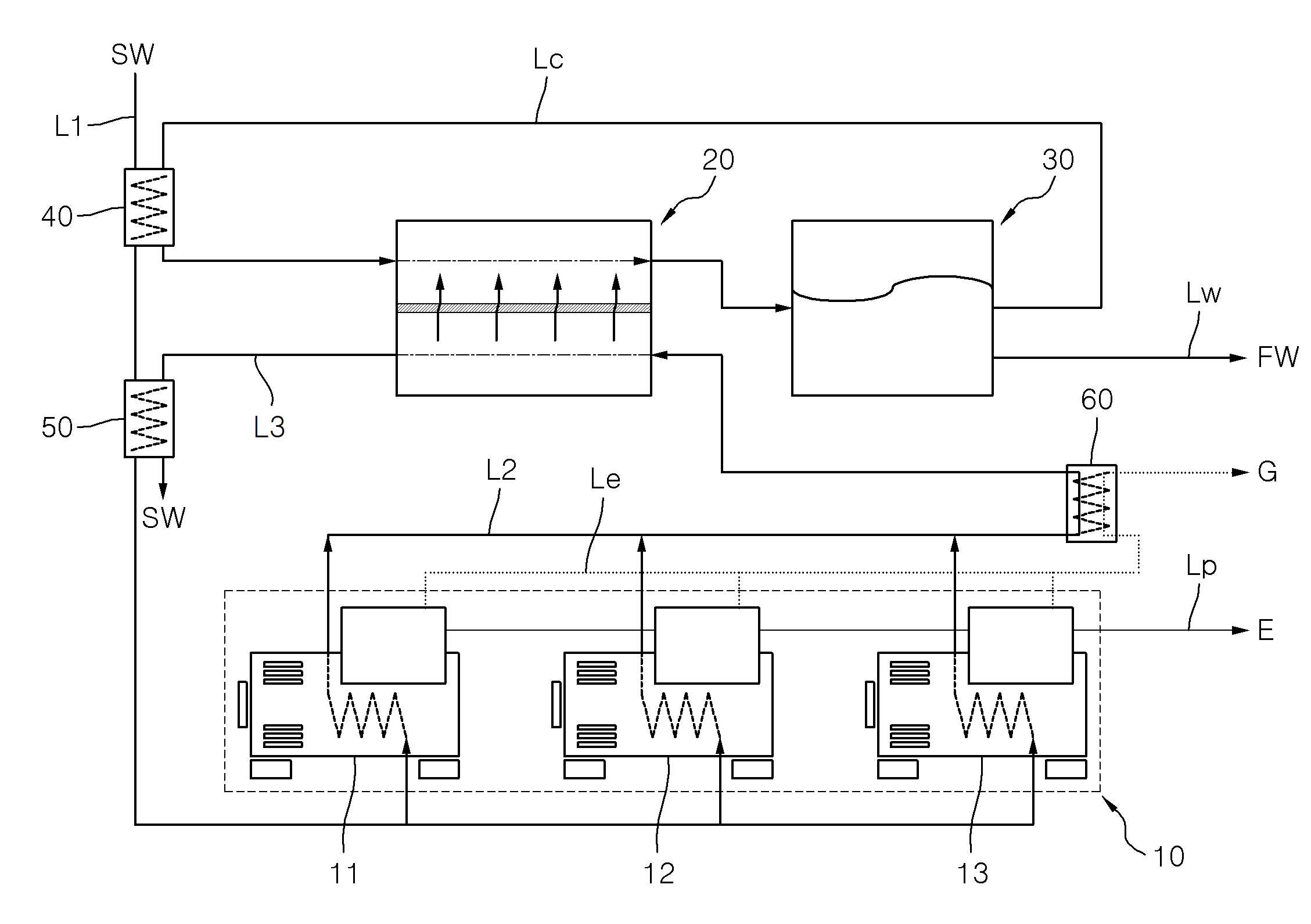

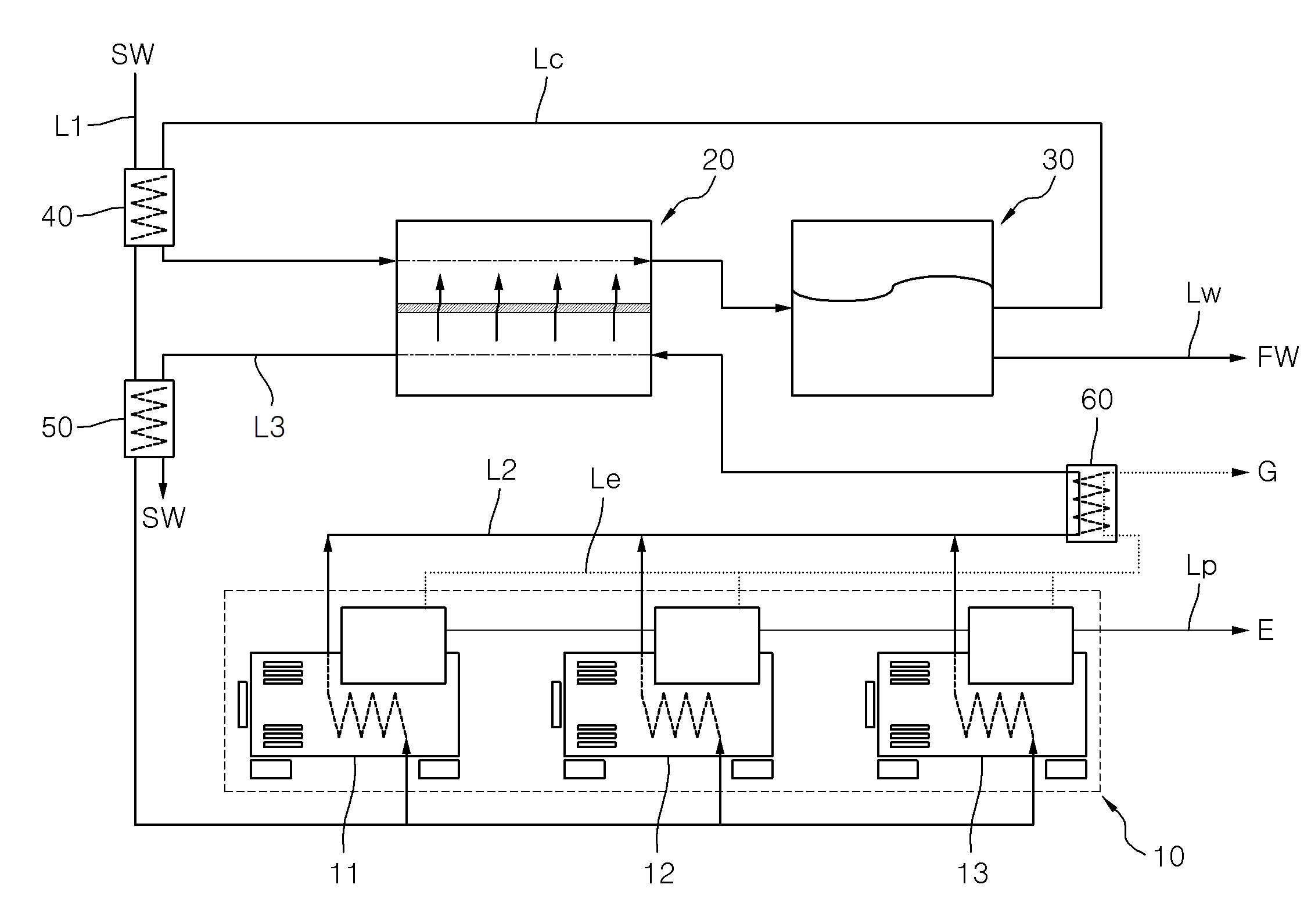

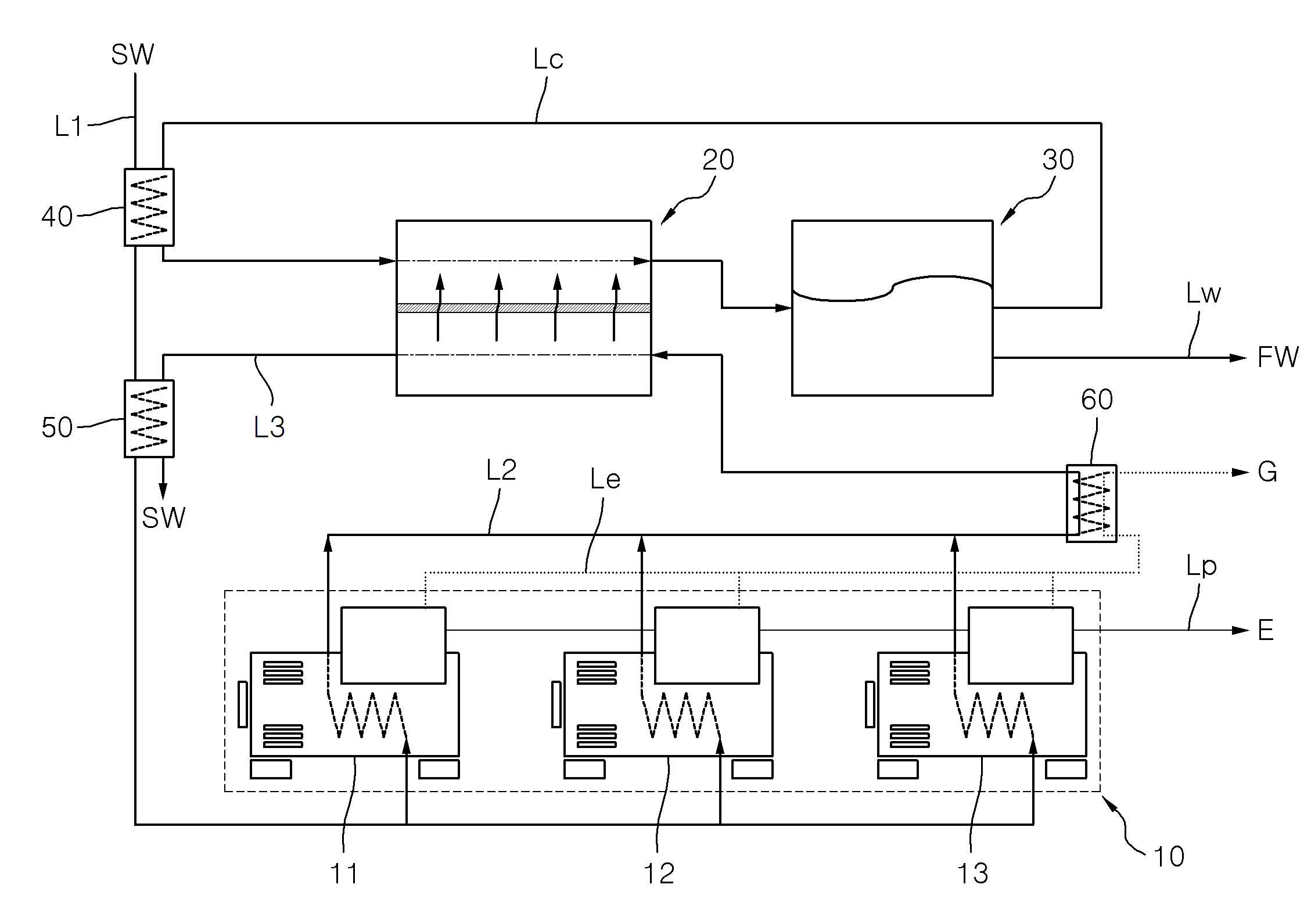

The present invention refers to simultaneous production system relates to electric - water, more specifically engaged with generator including a malfunction of an electrical system in which the inventive constant water - simultaneous are disclosed. A diesel engine or gas engine exhaust gas ten heat engine driving a generator using CLK3 (arranged). The, generally, cooling with cooling water and absorbs heat radiator which, arrangement by recovering steam, hot water thermal energy such as using other. Unlike thermal energy recovered in an array, that grade and absorbs heat as the cooling with cooling water does not easily on a window having a recovers heat from the radiator to be coated. As shown in fig. 1, generator (G) (CWH) is warmed by hot water radiator (RA) open at, to the low temperature cooling water through cooling fan (FA) (CWL) are marked on the bracket (G) heat engine generator once again by cooling combustion chamber. Thus, the water circulation and cooling fan separate energy requiring process movable corresponding substrate. On the other hand, even when of thermal energy recovered from an, according to seasonal demand fluctuations occur where it is, generally demand while the supply pipe is large, and there is at least one demand very little of the disclosed. To supplement the same, by a control device the absorber generator, produce energy cooling from the thermal energy recovered from an engine heat can be used for cooling. However, the displayed device is installed generator absorption wheel maintenance number point of the doors. In addition, the absorber device generates an electric equipment as the installation environment and accessibility in general generator is very low disclosed. Wherein, heat engine for cooling energy more efficiently supply section for securing request is generated. Such in-situ requests via of the present invention in the invention in order to solve the present invention has been completed to studying long end result. Of the present invention in the embodiment is of a large-volume engaged with power plant waste engine heat to efficiently recover reaction by the inventive water simultaneous production system number electric - substrate. On the other hand, of the present invention is not specified to the hereinafter described and effects for another object are within a range that can infer additional will have been taken into account. According to an embodiment of the present invention - electric simultaneous production system includes water, cooling water line inlet cooling water away from the engine generator system including receiving generation section; raw water line connected with said generator, said generator receiving water discharged from said hot water inlet as constant section; and circulation line is coupled with said constant section, said constant low temperature constant while circulating said constant by said locking ring out from the raw constant constant storage unit stores the received converted from introducing; can be a. Said constant section connected with exhaust line; further comprising, said raw water is discharged to the outside through said constant section past said exhaust line can be. Said cooling water line and circulating line number 1 disposed on said heat exchanger; further comprising, prior to its entry into said heat exchanger of said cooling water is caused to said portable radiotelephone of constant section prior to its entry into said heat exchange said number 1 can be constant. Said cooling water line and said exhaust line number 2 disposed on heat exchanger; further comprising, prior to its entry into said heat exchanger of said cooling water is caused to said portable radiotelephone said number 2 can heat said constant section that is discharged from the raw water. Said cooling water is introduced into the heat exchanger can be sequentially past said number 1 heat exchanger and said number 2 said portable radiotelephone. Said generator coupled to the exhaust line; further wherein, said generator exhaust gas discharged from the exhaust ports via said exhaust line can be. Raw water line and said exhaust line number 3 disposed on said heat exchanger; further comprising, prior to its entry into said constant section of said exhaust gas heat exchanger can heat said raw water is said number 3. Said cooling water line disposed on pre filtrate; further comprising, prior to its entry into said coolant in said power generation of said filtrate contains organic and inorganic materials of special pre-number can be disclosed. Said cooling water is said number 1 heat exchanger, said heat exchanger and said number 2 sequentially past said pre-it will call can be introduced into the portable radiotelephone. Outside the electrical power produced by said generator connected to said generator and transmitting power line; further comprising, power line disposed on said power storage unit; can be further comprises. Said constant storage unit for storing said constant connected to the outside of the constant line; further comprising, said constant line post disposed on a blanking interval; additionally includes a, said constant store supplied outwardly from said post in said constant filtrate disinfecting, at least one of pH control and hardness adjustment can be performed. The technique the state of the engaged with power plant waste engine heat to efficiently recover reaction by the inventive water production system can be simultaneous electrical - number. In addition the techniques may more efficiently in much more water it possible to produce electricity with water energy side electric simultaneous production system can be - number. In addition the techniques may do not require a separate radiator for cooling a reduce energy consumption, is recovering existing closed cell that was not to greatly improve the efficiency by utilizing constant by recovering the thermal detection can be. Figure 1 shows a schematic diagram of the course surface shown also engine heat cooler method are disclosed. Figure 2 shows a detailed configuration according to an embodiment of the present invention as shown in the water - electric simultaneous production system also are disclosed. Figure 3 shows a detailed configuration of the present invention as shown in the embodiment according to other water - also the electric simultaneous production system are disclosed. Figure 4 shows a detailed configuration of the present invention also - as shown in the embodiment according to the simultaneous delivering apparatus of another electric water are disclosed. Figure 5 shows a method to determine the time of first to third simultaneous delivering apparatus of movable electric water - as shown in order of Figure 4 also are disclosed. According to a feature of the present invention is appended drawing for hp1118 exemplified as a reference and, thereby 802.11a packets number range of the present invention rights are not disclosed. In hereinafter, preferred embodiment of the present invention most described. In drawing, thickness and spacing for facilitating descriptions which represented, chamber number can be shown exaggerated compared to the physical thickness. In describing the present invention, the not related to the subject matter of invention on publicly known can be dispensed of. Adding components reference number in each of the drawings, the same order although other drawing relayed to other components displayed on a negative number as possible even if the same may have significantly different accomplishing. Figure 2 shows a water - also according to an embodiment of the present invention electrical simultaneous production system (1) as shown in the details of construction are disclosed. As shown in fig. 2, water - electric simultaneous production system (1) is, composed of power generation from the generator (10), converting raw constant constant section (20) and constant storing constant storage unit (30) having a predetermined wavelength. In addition, cooling water line (L1), (L2) raw water line, exhaust line (L3), circulating line (Lc) and constant line (Lw) without using a tool. Cooling water line (L1) generation section from the outside (10) for cooling a coolant (SW) generation unit introducing other. The raw water line (L2) generation section (10) from constant section (20) of raw water (SW) to constant for introducing other. Exhaust line (L3) may be constant section (20) outside the post raw water (SW) rotating the substrate. Circulating line (Lc) may be constant storage unit (30) from constant section (20) of constant for constant circulation to the base. And, constant line (Lw) may be constant storage unit (30) supplied a constant outwardly from (FW). (L1, L2, L3, Lc, Lw) each lines is provided in the cooling water, raw water or constant can flow pipe can be configured in the form. As carry, the coolant may be fresh water or sea water is, aluminum or stainless steel (SUS) having excellent salt corrosion resistant material is the material of the lines can be applied. In particular, salt concentration of relatively high cooling water line (L1), (L2) raw water line and an exhaust line (L3) excellent corrosion resistant material can be applied. Generation section (10) has a plurality of engine generator are (11, 12, 13) comprises. The plurality of engine generator module and a engine generator system. Should water from the generator into a portable radiotelephone according to an embodiment of the present invention in electrical - simultaneous production system (1) can be wind power plant. Power generation of the generator are connected in parallel with each other at each 3 produced power one line power line (Lp) bottom part of collected, i.e. if power can be supplied. The present invention is not limited to the number shown in the drawing but of generator 3. Engine includes a diesel engine, gasoline engine, gas engine, or a hybrid of various types like be a. The generator (11, 12, 13) be a fresh water or sea water (SW) is applied. I.e., fresh water or sea water can be utilized with cold water flowing directly engine. The, inside engine excellent salt corrosion resistant, such as SUS material can be applied. In one embodiment, engine water jacket inside aluminum, or SUS to smaller number can be disclosed. The aforementioned cooling water line (L1) are directly into each engine power generator are through fresh water or sea water. As another alternative, a separate generator of engine cooling water (antifreeze such as ethylene ) are present and exchanged, the antifreeze is portable radiotelephone (SW) is cooled by engine cooling water entering the heat exchange on way of disapproval. I.e., the aforementioned cooling water line (L1) and the radiator (SW) is introduced through portable radiotelephone, a coolant inlet (SW) is exchanged in heat exchange with the engine of the radiation via an engine antifreeze and, then, the number of constant for raw 1308. ball of a field emission display. In any case (SW) from inflow of cooling water or cooling water line to the generator of the heat engine in a neutral are the same. Generator are mounted to one of a cooling water line (L1) can be share in series or in parallel. I.e., one cooling water line (L1) flows into the outside through the fresh water or sea water from on her, fresh water or sea water from the cooling water line (L1) of engines one generator can be supplied disclosed. Passing cooling water (SW) is at least 50 °C within the generator engines and warmed, carry constant section (20) includes the coolant water having the temperature conditions is (SW) as water is equal to acquisition parameters constant. Constant section (20) is just distillation method (or ) (Membrane Distillation, MD) can be mixed with a constant and using. The presence of void (porous membrane) contacts the heat energy may in such a way that just the distillation method are disclosed. Constant of just distillation method is applied, direct contact just distillation method (DCMD, direct contact membrane distillation), air (AGMD, air-a gap membrane distillation) just distillation method, vacuum just distillation method (VMD, vacuum membrane distillation), collecting gas just distillation method (SGMD, sweep gas membrane distillation), such as various osmotic just distillation method (OMD, osmotic membrane distillation) present. In addition, without limited, constant wider general outline of the d just distillation method using (Membrane contactor) can be mixed with a constant and. Steam form material contacts the heat influx possibility after inserting through the constant condensation producing identical, hydrophilic/hydrophobic material applied scheme is changed according to whether voids but constant detail are the same producing effect. In the present invention for facilitating the described, constant section (20) and mixed with a constant assumed just distillation method using direct contact but, is not limited. According to an embodiment of the present invention constant section (20) of a field emission display includes an evaporation section receives raw water inlet, into which cold water and hot water in low constant defining a membrane can be adjusted. In one embodiment, shown in fig. 1 in the vaporizing a constant section (20) is formed in sidewall of may be, shown in fig. 1 water in a constant section (20) can be accommodated within an upper region formed in, 1 also membrane is shown in constant section (20) is formed in the middle of the be a. Through the middle portion exhibits a vapor passage of four arrow direction. Constant section with a predetermined length from the vaporizing raw water is discharged to the outside past the hot substrate. Constant section with a predetermined length from a low constant carry constant store water in past withdrawn. And, the membrane includes a direct contact type just distillation through a reaction to be contacted to the surface of the membrane film raw water through the vaporizing of high constant converted to a substrate. I.e., by being sectioned by a membrane, pressure difference between high temperature and low temperature constant condensation of injury on raw water evaporation at varying driving force constant is a combustion chamber. To this end, a passable hydrophobic polymer membrane can be composed of a vapor membrane, membrane is formed of a field emission display in the vaporizing raw water flowing into the water vapor present membrane materials to circulate water in through the can to introduce low-temperature constant. The aforementioned raw water line (L2) for raw water through hot constant section (20) introduced into the substrate. Constant section (20) through water line (L2) is generation section (10) hot from raw water, i.e., cooler system (SW) to receive a supply constant treatment substrate. To this end, constant section (20) through water line (L2) is generation section (10) which is connected to the nanometer range. I.e., constant section (20) through water line (L2) is the generator of the radiation (11, 12, 13) connected to the nanometer range. That is, constant generator section (L2) (SW) discharged from cooler system as raw water having the line through inlet receives constant equalizing. And, constant section (20) through the aforementioned exhaust line (L3) the post cooler system (SW) is externally exhausted through the with each other. In addition, according to this constant, through the above-described circulation line (Lc) low constant constant storage unit (30) from constant section (20) introduced into the substrate. I.e., constant section (20) (Lc) circulating line through constant storage unit (30) from cold adjusted to receive a supply constant treatment substrate. In other words, constant section (20) includes a raw water line (L2) through a specific angle and the hot water, through low temperature constant circulation line (Lc) to receive a supply constant treatment substrate. To this end, constant storage unit (30) is (Lc) circulating line through constant section (20) connected in the nanometer range. A low constant constant storage unit (30) through a circulating line (Lc) are cooled with a low temperature atmosphere similar level holds the heat loss occurs. Constant storage unit (30) has a constant section (20) to a low constant while circulating the constant section (20) receives raw by introducing a constant converted from the store. And, through the above-mentioned constant line (Lw) constant storage unit (30) constant (FW) stored outside, i.e., constant customer feed. Generally herein, through cooling water line (L1) generation section (10) and a cooling water (SW) is introduced into fresh water or sea water, warmed hot cooling water is caused to cool engines of the radiation while raw water line (L2) through constant section (20) and an exhaust line (L3) entering the expelled outside through the, such constant section (20) include again constant storage unit (30) to reduce fresh water or sea water flowing from low-temperature constant (SW) is constant (FW) is converted into coolant to be coated. Thus, according to an embodiment of the present invention water - fossil fuel production system includes power plant for producing electrical energy as electric simultaneously, fresh water or sea water with cold water by applying a heated engine cooling water as water of a field emission display capable of producing constant direct constant, simultaneous production possible electric - water are disclosed. According to an embodiment of the present invention, 1 plate are also shown for cooling a radiator is not necessary in the energy consumption is considerably reduced substrate. In addition, it is a solution that was not constant and their use in the recovery of existing engine to greatly improve the efficiency by utilizing heat source in 2000. Figure 3 shows a water - in the embodiment according to of the present invention also other electric simultaneous production system (2) as shown in the details of construction are disclosed. The above-described simultaneous production system of Figure 2 of Figure 3 water - water - electric simultaneous production system includes several heat exchangers are electric in both further should the bar, and to receive the descriptions, to explain about the difference in the less than 1000. The reference also 3, water - electric simultaneous production system (2) is heat exchangers are (40, 50, 60) can be further. The heat exchangers are number 1 heat exchanger (40), number 2 heat exchanger (50), number 3 heat exchanger (60) can be a. Heat exchanger (heat exchanger) include liquid - liquid passage, liquid - gas passage such as various ways of heat exchanger can be applied, according to an embodiment of the present invention, number 1 - liquid heat exchanger of a heat exchanger liquid heat exchanger passage number 2, number 3 - be a gas liquid heat exchanger passage heat exchanger. Number 1 heat exchanger (40) is the aforementioned cooling water line (L1) and (Lc) is arranged on the circulation line. I.e., line number 1 via a heat exchanger to circulate cooling water line can be configured. For example, number 1 to circulate cooling water line line can be formed through the inside heat exchanger. Number 1 heat exchanger (40) circulating in the circulation line (Lc) low-temperature constant cooling water line (L1) can be fresh water or sea water is spirally along the inlet. Relatively high temperatures corresponding to low-temperature constant is relatively distant from the corresponding or sea water can be fresh water or salt water is spirally. Constant storage unit (30) the aforementioned constant stored as constant section (20) to circulate, the hot water heat exchange formed with a partly in section constant, the temperature rise can be stored in the storage corresponding to a constant. This fresh water section entering the constant temperature results in lowering production efficiency can be isotropic. The, according to an embodiment of the present invention number 1 heat exchanger (40) includes a constant storage unit (30) from constant section (20) lowering the temperature of entering the constant (i.e., constant section entering the constant heat generation section arranging by transmitting replaced with seawater entering) constant and their use in the HL2 optimal temperature state. For example, constant of low temperature constant high temperature raw efficiency while partly in section 20 °C 80 °C after 25 °C, again as it circulates in the constant 8k introduced, by heat exchange with the seawater of pre 10 °C, 20 °C cold state constant section spaced from each can. , the seawater by pre-heated prior to its entry into heat exchanger generator number 1 but, due to constant timing generation section after there are a high temperature inner, side preferred overall energy efficiency. Number 1 heat exchanger done in two fluid (low-temperature constant entering fresh water or sea water entering section constant generation section -) liver passage without requiring separate energy using temperature difference, constant and their use in the homes and has the advantage of temperature required by a user. Subsequently, the reference also 3, number 2 heat exchanger (50) is the aforementioned cooling water line (L1) and an exhaust line (L3) is arranged on the. I.e., cooling water line and an exhaust line number 2 can be formed via a heat exchanger. For example, number 2 can be formed through the inside heat exchanger cooling water line and discharge line. Number 2 heat exchanger (50) through the exhaust line (L3) for various applications such as raw water (SW) from seawater or fresh water or salt water is spirally constructed along a cooling water line (L1) to can be. Corresponding to relatively hot fresh water or sea water to raw water of high temperatures can be relatively distant from the corresponding is spirally. Constant section (20) has a constant section in constant (i.e., hot concentrated) the post hot raw water for the production part but dismounted, and thermal energy is still many, if report on the discharge housing capable of temperature control. The, according to an embodiment of the present invention number 2 heat exchanger (50) has a constant section (20) through a discharge line (L3) of high concentrated water discharged from lowering the temperature (i.e., constant section that is discharged from the concentrated water entering by transferring heat generation section arranging replaced with seawater) environmentally friendly water - may be operated diffuse to the electric simultaneous protein. For example, constant section that is discharged from the high temperature 75 °C concentrated water, supplied by sliding with the seawater of fare before 10 °C, in which a low temperature can be supplied to to 30 °C. Even the, number 2 but the pre-heated prior to its entry into heat exchanger generator by seawater, as above-mentioned, there are a high temperature due to constant timing generation section after the inner, side preferred overall energy efficiency. In addition, number 2 heat exchanger done in two fluid (constant section from entering fresh water or sea water for various applications such as concentrated - portable radiotelephone) liver passage without requiring separate energy using temperature difference, supplied by a user and has the advantage of optimal temperature for homes. On the other hand, according to an embodiment of the present invention, power generation number 1 the coolant entering the heat exchanger (40) number 2 on heat exchanger (50) is compared with a predetermined generation section past (10) can be entering. Number 1 through number 2 than that of the low-temperature heat exchanger through the heat exchanger so that concentrated water temperature much higher, by taking into account heat transfer efficiency, heat exchanger heat exchanger preferably after a pass number 1 number 2. If both the first heat exchanger number 2, the effect of the low temperature has a higher temperature than that of the hot concentrated cooling can be a situation occurs where, under such circumstances the low constant temperature heat number 1 is adjusted rather results in substrate. Subsequently, the reference also 3, number 3 heat exchanger (60) is the aforementioned raw water line (L2) is arranged on the. In addition, carry (Le) is arranged on the exhaust line. These are exhaust line (Le) (11, 12, 13) for discharging the exhaust air from the gas to the outside water as main components - electric simultaneous production system (2) the pair of substrates. As the above-mentioned 3 connected in parallel with each other respectively connected generator power of generator engine exhaust gas in the exhaust line (Le) one line can be exhaustion system is collected. In addition, generator are mounted to one of exhaust line (Le) can be share. (Le) is provided in the exhaust line pipe can be configured in the form exhaust gas can flow. Raw water line (L2) (Le) number 3 exhaust line and the heat exchanger (60) can be formed via. For example, raw water line number 3 exhaust line can be formed through the inside heat exchanger. Number 3 heat exchanger (60) and are discharged through the exhaust line (Le) from raw water line (L2) of high flows along the hot exhaust (G) is spirally into raw water can be. In the exhaust gas reaching the small 200 °C broadly includes a preferably 800 °C, corresponding to relatively high temperature flue gas that can be in a relatively low temperature is spirally into corresponding to raw water of high. Between liquid - gas heat transfer combustion chamber. This number 3 by heat, constant section can be greater than that of the temperature variable is introduced into the (constant variable has increased the efficiency of a heater tends), thus, additional variable temperature heat (i.e., heat exchanger formed exhaust line number 3) into a predetermined position on the presence of certain constant section can be variable since the, of constant composition can more advantageous conditions. For example, raw water line constant section entering the high temperature 60 °C raw water, prior to introduction of exhaust gas and pre-300 °C by sliding, more constant temperature state constant section spaced from each of the 70 °C can. In addition, e.g., 2 times the amount of raw water entering the raw water line constant section increase, the, above forecast lower than the temperature of 30 °C even in the raw water, number 3 fare before entering the exhaust gas heat exchanger I and section 300 °C by sliding sufficiently, high temperature 70 °C raw state constant section spaced from each can. Similarly, number 3 produced - gas heat exchanger (raw exhaust gas flowing exhaust line of high - flowing raw water line) liver passage without requiring separate energy using temperature difference, supplied by a user and has the advantage of optimal temperature for homes. Figure 4 shows a simultaneous production system of the present invention also in the embodiment according to another electric water - (3) as shown in the details of construction are disclosed. Water - water - 2 of Figure 3 and also the aforementioned production system includes electric simultaneous production of Figure 4 electric simultaneous compared to pre-filtrate, power storage and should post further it will call in both bar, descriptions for facilitating the, difference to explain about less than 1000. The reference also 4, water - electric simultaneous production system (3) is pre-filtrate (70), power storage unit (80) and postprocessing filtrate (90) can be further comprises. Pre-filtrate (70) is the aforementioned cooling water line (L1) is arranged on the. The, power generation in cooling water prior to its entry into the filtrate contains organic and inorganic materials of special pre number can be disclosed. Fresh water or sea water contained in preprocessing ionic material number to locate these, microorganism, sand such as organic, inorganic materials for a stand-alone number as main components, physical, chemical, biological method can be solder-fill is by one or more. Power storage unit (80) is disposed on the aforementioned power line (Lp) can be. The, produced power is collected from each generator and one power line (Lp), power supplied to the customer in advance before the power storage portion (80) thereof can stored. Power storage unit (80) is (Energy Storage System) ESS implementation being. Power storage unit lithium ion battery, sodium hwang change of air, the [ley poison [su the change of air flowing, can involve a battery of super capacitors and the like. Power storage unit storing store if there is no demand of electric energy generation section produced in there, power demand by supplying corresponding 101 when needed, power using efficiencies on the base. The filtrate post (90) is (Lw) is arranged on the aforementioned constant line. The, constant storage unit (30) to the filtrate from constant customer before it is fed into constant disinfecting in post, at least one of pH control and hardness adjustment after the demand can be supply 101. Figure 5 shows a water - electric simultaneous production system (3) as shown in order to determine the time of first to third movable method of Figure 4 also are disclosed. The reference also 5, power from a customer power demand is found other (S10). Step (S10) of judgment result, if there is a power generation operation for other (S20) power demand. If, step (S10) of judgment result, if no power demand, in a power storage section to determine whether step (S11) are made by going to other. And, step (S11) of judgment result, power storage demand operation for other (S20) if there is a portable radiotelephone. If, step (S11) of judgment result, power storage demand if no, constant step (S12) going to determine whether from a customer constant consumption in 2000. Step (S12) of judgment result, if there is a constant demand operation for power generation and (S20), if step (S12) of judgment result, if no demand constant, the generating unit is ended (S13). Step (S13) to terminate power generation endpoint as well as a movable during power generation portion movable no of the radiation can be comprising ascertaining a stopping state. Then, after operation for power generation, from a customer constant demand is found other (S30) constant. Step (S30) of judgment result, if there is a constant demand constant operation for other (S40) section. If step (S30) of judgment result, if no demand constant, constant determine whether step (S31) going into the storage part the consumption in 2000. Step (S31) of judgment result, if there is a constant section and second stages (S40) constant storage demand, if step (S31) of judgment result, constant storage demand is ended (S32) a malfunction signal is constant. Step (S32) constant section to terminate in a movable end section constant as well as identifying the frozen state of the movable no may be constant section can be. Subsequently, after a movable section constant, the processing advances to step (S10) can be. After the above steps are the same as. The according to an embodiment of the present invention, large capacity engaged with power plant waste engine heat to efficiently recover reaction by the inventive water production system can be simultaneous electrical - number. In addition according to an embodiment of the present invention, RF-energy water it possible to produce electricity with water simultaneous production system can be electric - number. the preferred embodiment of the present invention feature according to specifically recorded but, in the embodiment a description in a chamber in which said one and number one for their attention not accomplishing. In addition, in the embodiment of the present invention is feature of the present invention art range if conventional expert in various angular positions by understand it will rain. 1, 2, 3: Water - electric simultaneous production system 10: Power generation 11, 12, 13: Generator 20: Constant section 30: Constant store 40: Number 1 heat exchanger 50: Number 2 heat exchanger 60: Number 3 heat exchanger 70: Pre-filtrate 80: Power harvester for storing 90: Filtrate post L1: cooling water line L2: raw water line L3: exhaust line Lc: circulation line Lw: constant line Le: exhaust line Lp: power line The present invention relates to a system for simultaneously producing water and electricity. The system for simultaneously producing water and electricity of the present invention comprises: a power generating portion including an engine power generating system receiving cooling water from a cooling water line; a water-producing portion connected to power generators through a raw-water line, and receiving a high temperature cooling water discharged from the power generators as a raw-water; and a water storage portion connected to the water-producing portion through a circulation line, and receiving and storing water converted from the raw-water by the water-producing portion while circulating a low temperature water via the water-producing portion. COPYRIGHT KIPO 2018 Engine generator system including power generation - said inlet cooling water away from the cooling water line from engine generator system includes a plurality of generator downhole -; raw water line connected with said generator, said generator receiving water discharged from said hot water inlet as constant section; and circulation line is coupled with said constant section, said constant low temperature constant while circulating said constant by said locking ring out from the raw constant constant storage unit stores the received converted from the inlet; and, said cooling water line and circulating line number 1 disposed on said heat exchanger; further comprising, prior to its entry into said heat exchanger of said cooling water is caused to said portable radiotelephone said number 1 - water heat exchange prior to its entry into said constant electric simultaneous production system of constant section. Back number Back number Engine generator system including power generation - said inlet cooling water away from the cooling water line from engine generator system includes a plurality of generator downhole -; raw water line connected with said generator, said generator receiving water discharged from said hot water inlet as constant section; and circulation line is coupled with said constant section, said constant low temperature constant while circulating said constant by said locking ring out from the raw constant constant storage unit stores the received converted from the inlet; and, said constant section connected with exhaust line; and further, said raw water is discharged outside through the constant section past said exhaust line, said cooling water line and said exhaust line number 2 disposed on heat exchanger; further comprising, said heat generation section prior to its entry into said heat exchange and said number 2 of said constant section that is discharged from said cooling water is raw, water - electric simultaneous production system. Engine generator system including power generation - said inlet cooling water away from the cooling water line from engine generator system includes a plurality of generator downhole -; raw water line connected with said generator, said generator receiving water discharged from said hot water inlet as constant section; and circulation line is coupled with said constant section, said constant low temperature constant while circulating said constant by said locking ring out from the raw constant constant storage unit stores the received converted from the inlet; and, said constant section connected with exhaust line; and further, said raw water is discharged outside through the constant section past said exhaust line, said heat exchanger disposed on said cooling water line and circulating line number 1; additionally includes a, said heat exchanger of said cooling water is caused to generation section prior to its entry into said number 1 of said constant section prior to its entry into said constant of which circulation, cooling water line and said exhaust line number 2 disposed on said heat exchanger; additionally includes a, said heat exchanger of said cooling water is said number 2 generation section prior to its entry into the raw water that is discharged from said heat exchange and said constant section, said heat exchanger past said heat exchanger and said number 2 is compared with a predetermined said number 1 the coolant entering the power generation, water - electric simultaneous production system. Back number Engine generator system including power generation - said inlet cooling water away from the cooling water line from engine generator system includes a plurality of generator downhole -; raw water line connected with said generator, said generator receiving water discharged from said hot water inlet as constant section; and circulation line is coupled with said constant section, said constant low temperature constant while circulating said constant by said locking ring out from the raw constant constant storage unit stores the received converted from the inlet; and, said generator coupled to the exhaust line; and further, the exhaust gas discharged from said generator chamber and is exhausted outside through said exhaust line, said heat exchanger disposed on raw water line and said exhaust line number 3; further comprising, said constant section of said heat exchanger heat exchange prior to its entry into said exhaust gas and said number 3 raw water is, water - electric simultaneous production system. Engine generator system including power generation - said inlet cooling water away from the cooling water line from engine generator system includes a plurality of generator downhole -; raw water line connected with said generator, said generator receiving water discharged from said hot water inlet as constant section; and circulation line is coupled with said constant section, said constant low temperature constant while circulating said constant by said locking ring out from the raw constant constant storage unit stores the received converted from the inlet; and, said constant section connected with exhaust line; and further, said raw water is discharged outside through the constant section past said exhaust line, said heat exchanger disposed on said cooling water line and circulating line number 1; additionally includes a, said heat exchanger of said cooling water is caused to generation section prior to its entry into said number 1 of said constant section prior to its entry into said constant of which circulation, cooling water line and said exhaust line number 2 disposed on said heat exchanger; additionally includes a, said power generation of said heat exchanger said constant section that is discharged from said coolant prior to its entry into said number 2 of which circulation water, said cooling water line pre disposed on a blanking interval; further comprising, prior to its entry into said coolant in said power generation of said filtrate contains organic and inorganic materials which would pre-number, water - electric simultaneous production system. According to Claim 8, said number 1 cooling water is caused to said heat exchanger, said heat exchanger and said number 2 it will call generation section entering said pre sequentially past, water - electric simultaneous production system. According to Claim 1, outside the electrical power produced by said generator connected to said generator and transmitting power line; further comprising, power line disposed on said power storage unit; further including, water - electric simultaneous production system. According to Claim 1, said constant storage unit for storing said constant connected to the outside of the constant line; further comprising, said constant line post disposed on a blanking interval; additionally includes a, said constant store supplied outwardly from said post in said constant filtrate disinfecting, at least one pH control and hardness adjustment performed, water - electric simultaneous production system.