APPARATUS TO TURN PANEL UPSIDE DOWN AND METHOD TO TURN PANEL UPSIDE DOWN USING SAME

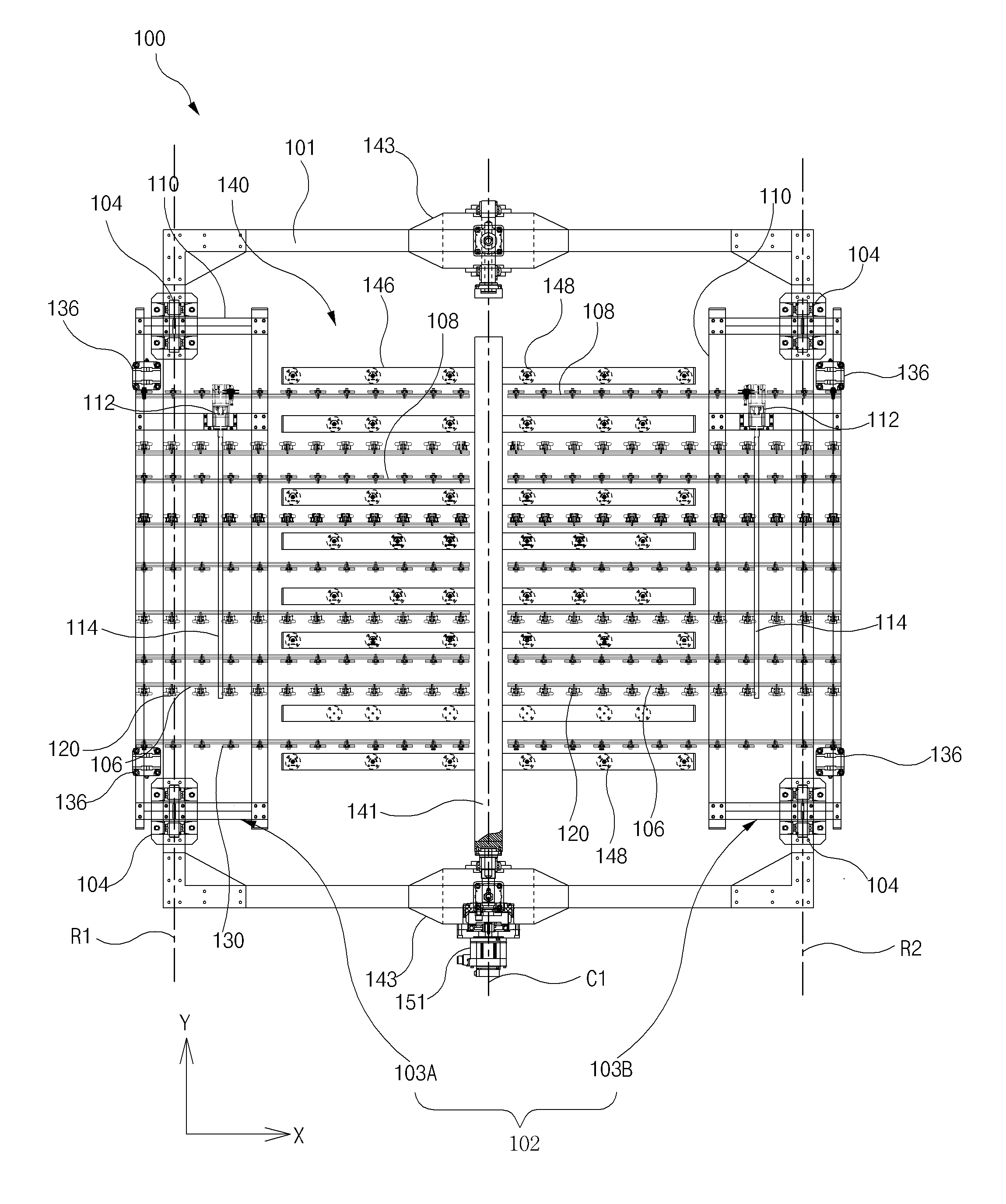

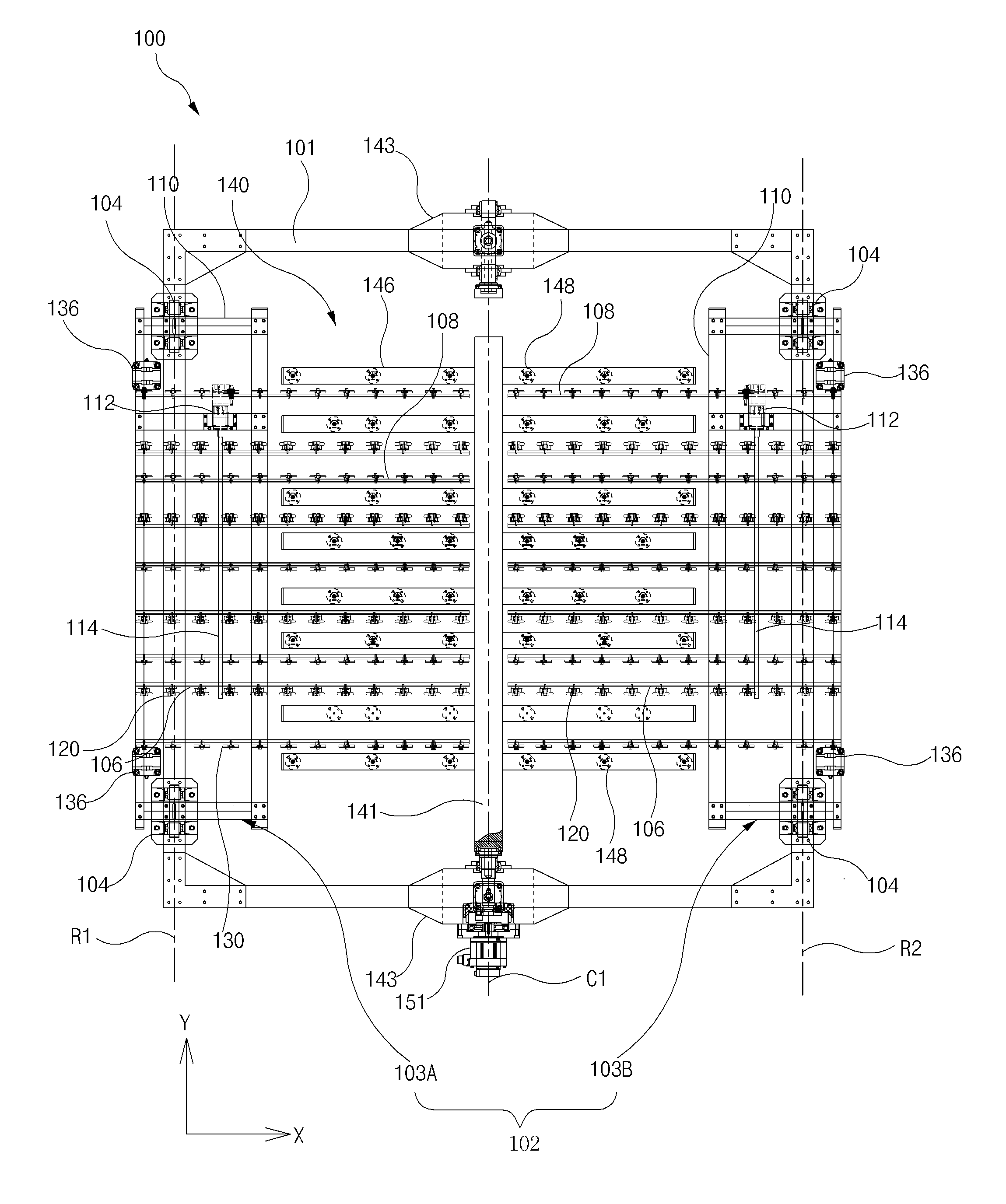

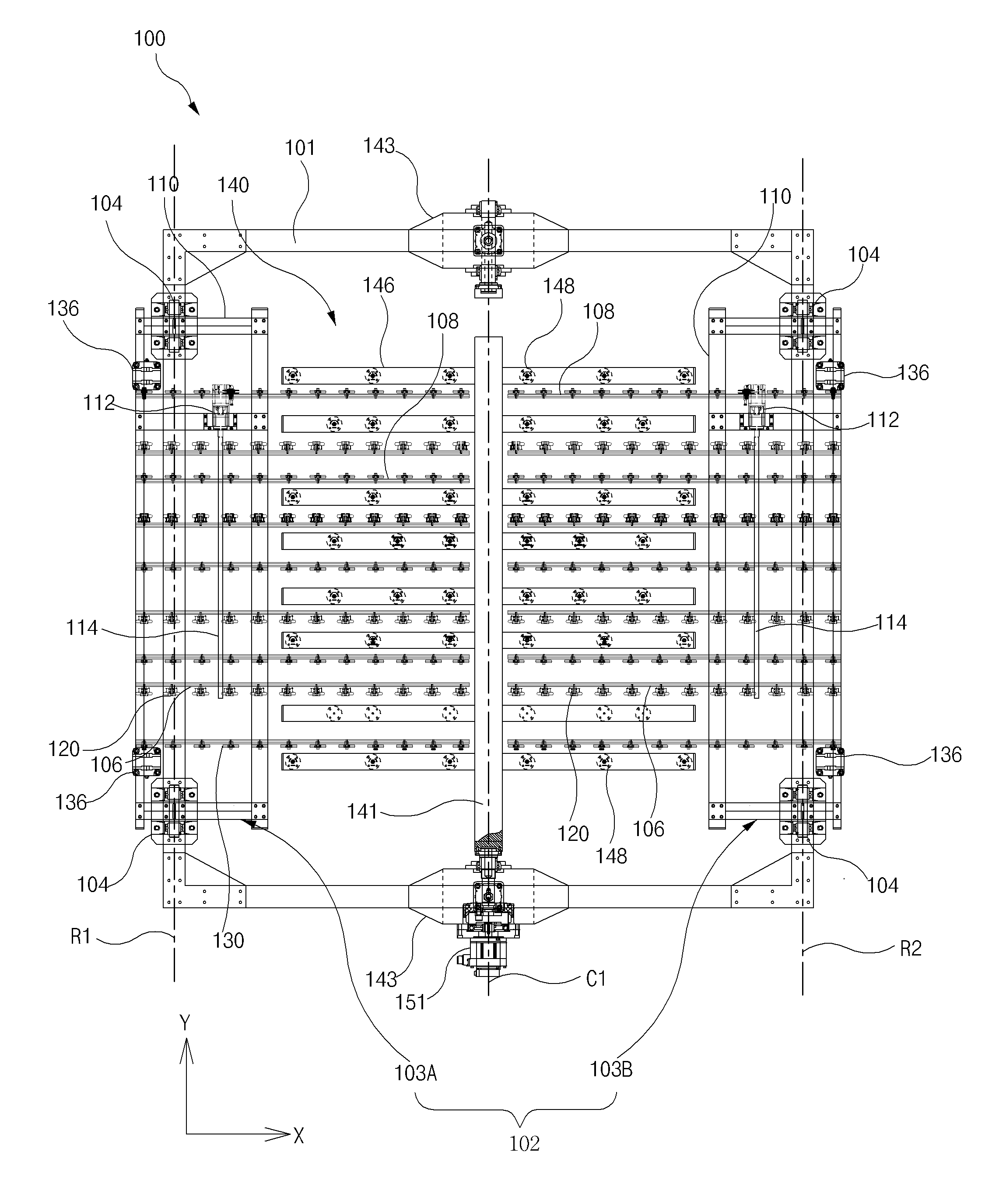

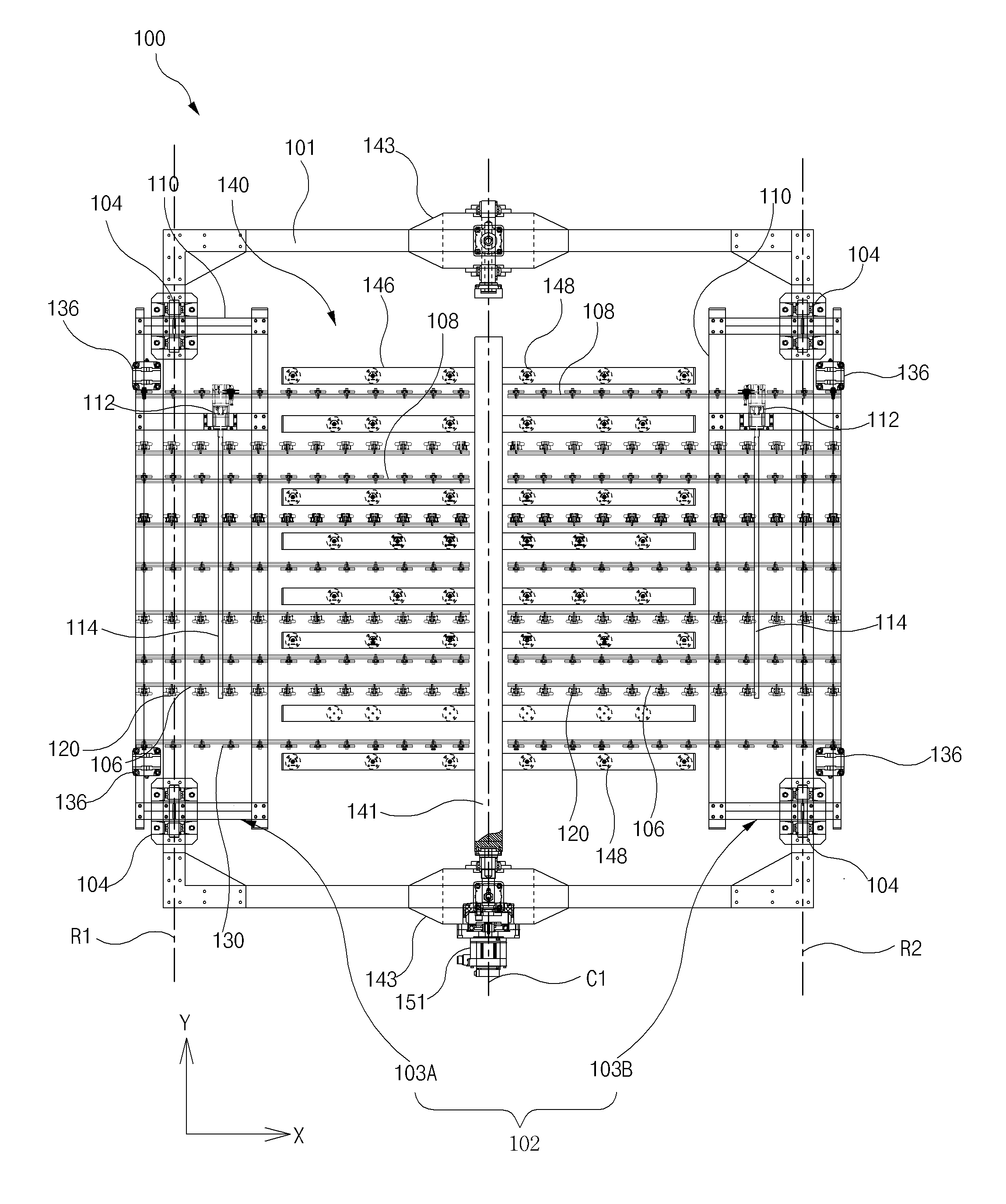

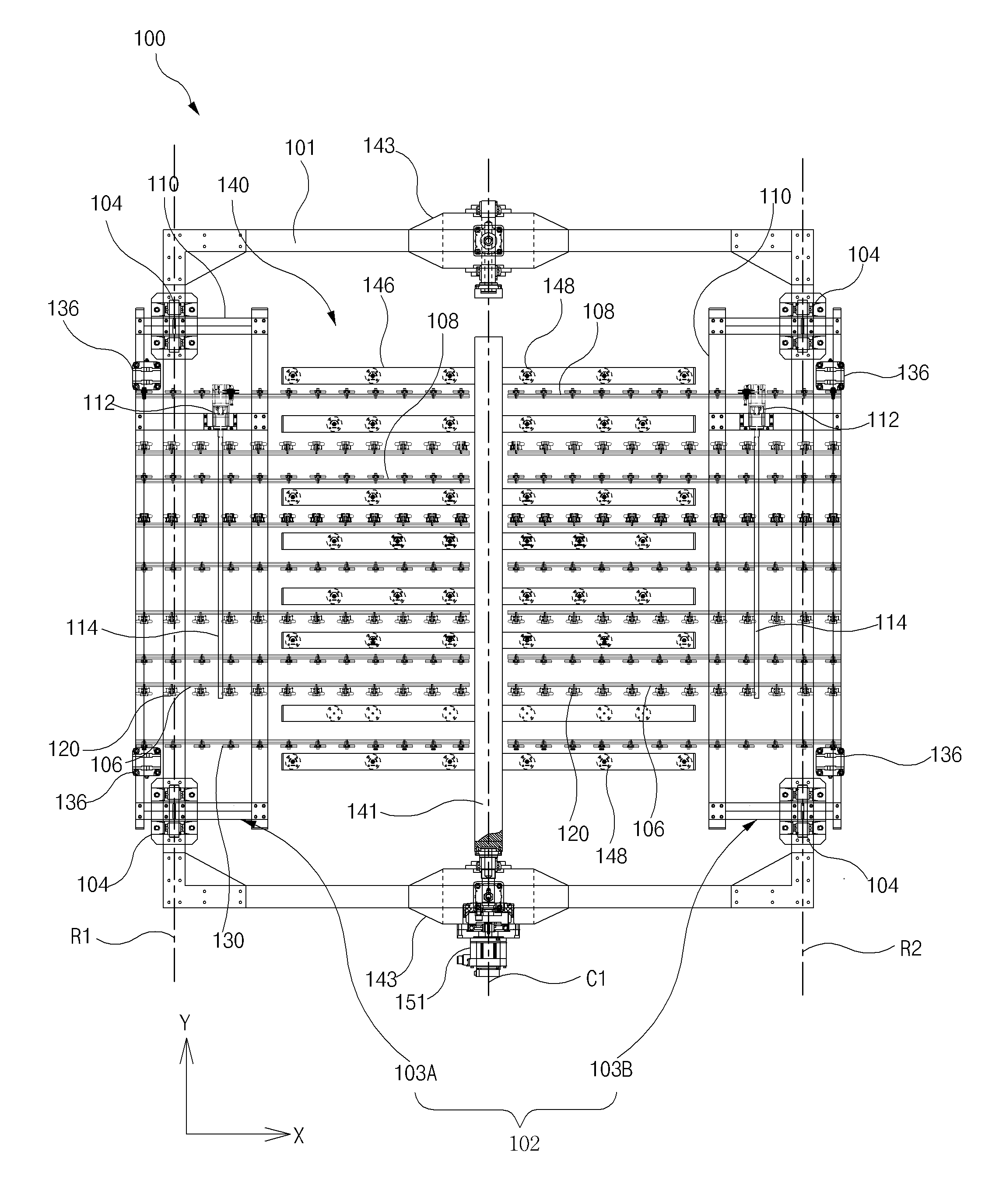

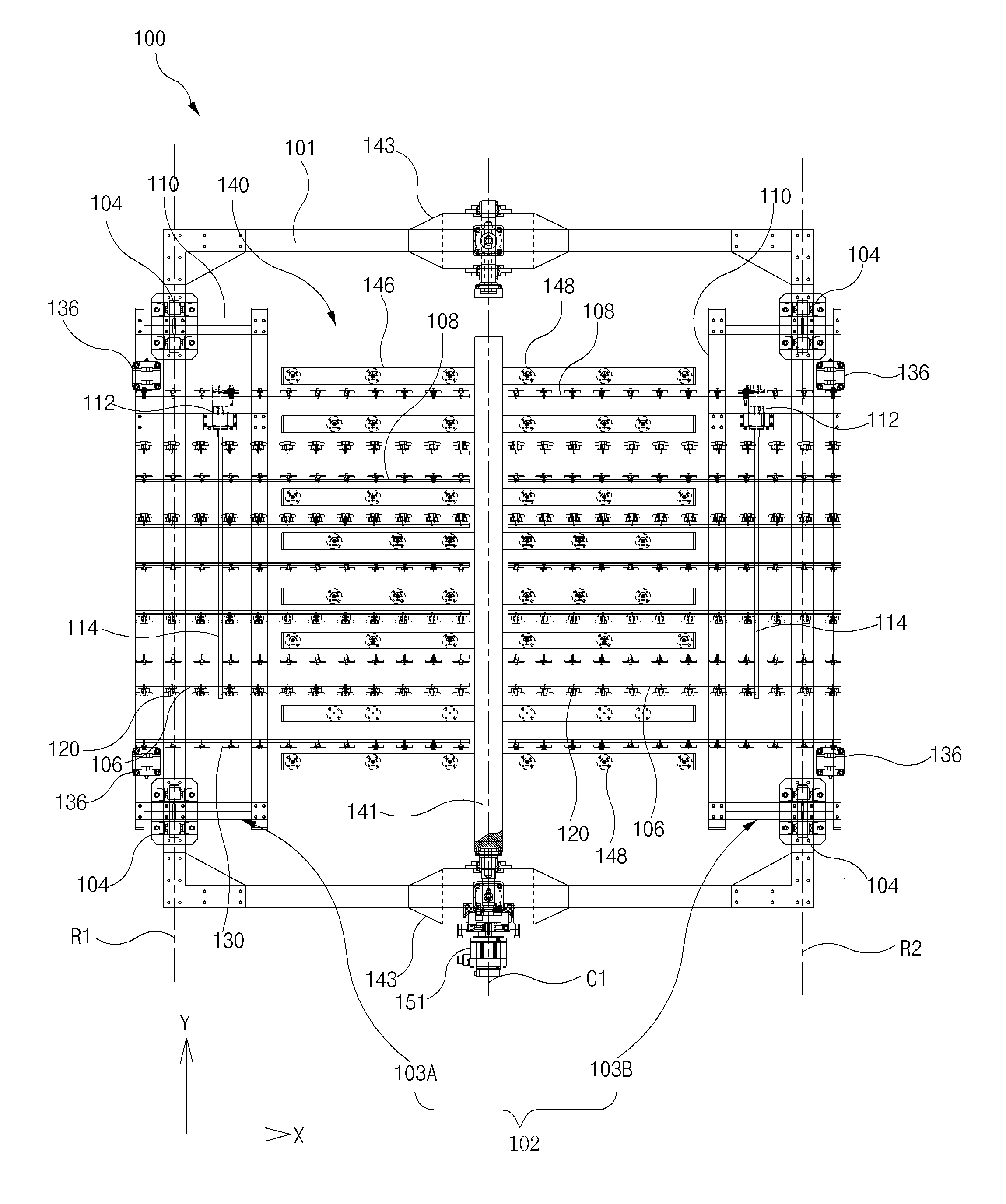

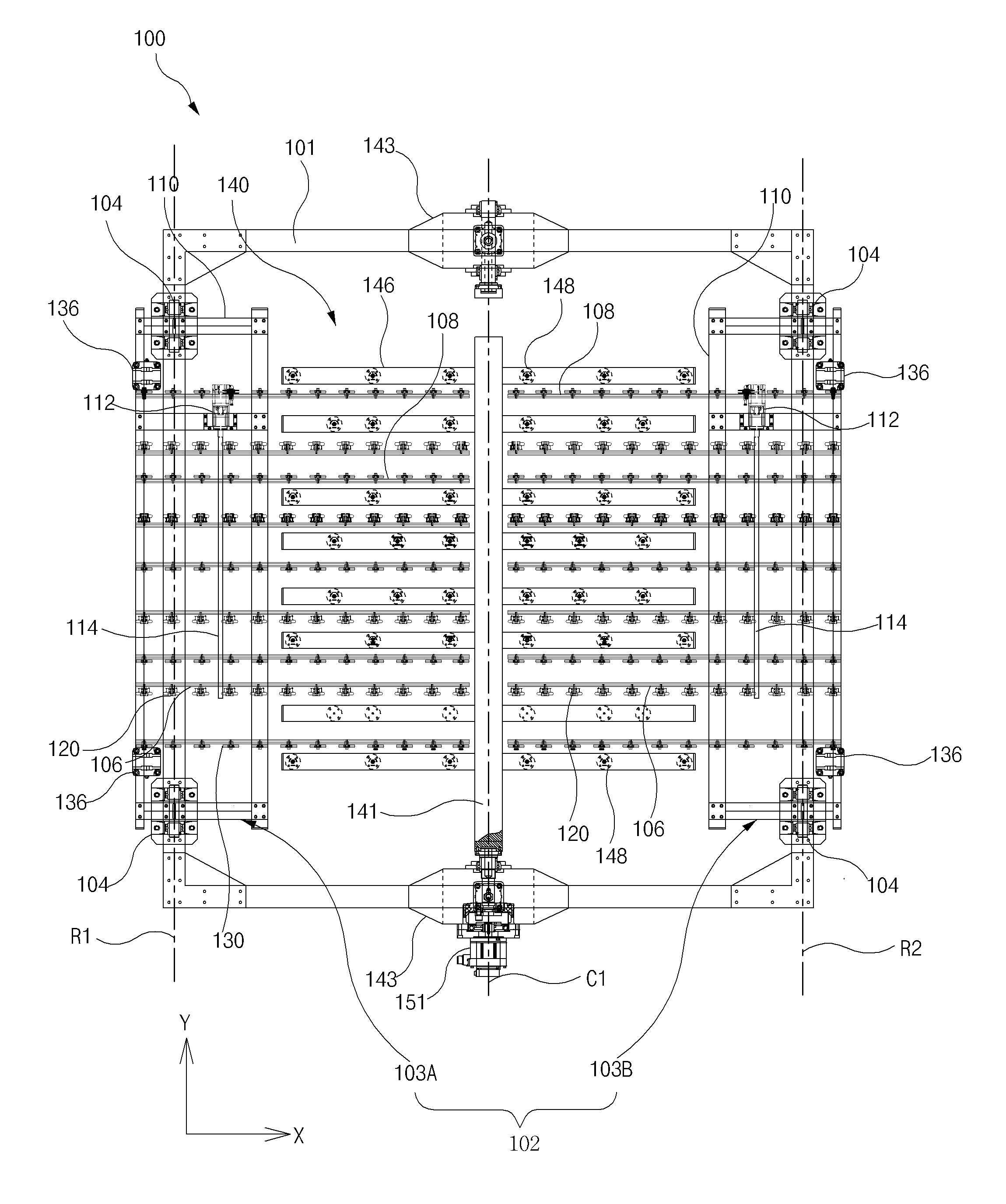

The present invention refers to device relates to shift panel, more specifically panel (panel) after performing a job to one side of, on the other side to perform the task panel device shift panel moves the support such a way that its position changes upside-down, and a panel using the same, capable shift method relates to. E.g., display device, such as smart phone in related industrial electronic apparatus, (panel) a panel such as glass (coating) coating on either side of, etching (etching), film (film) such as attached for performing surface treatment on. output signal of the first amplification unit. The apparatus for driving the display panel in order for coating both sides (coating) which are filled with coating solution panel bath immersing a method are used. Other etching, film sticking for surface of processing specific surface processing device one side by mounting a panel in the surface treatment, discharged panel surface treatment again three-dimensional semiconductor device is communicated with the discharge line, a loading request opposite side performing fine surface treatment on light method are used. Therefore, the surface treatment of both sides of panel command, and selects addresses of automating steps for it, meanwhile, could not operating speed is slowed down and the components, which, is cost reduction effect and. The present invention refers to, one side of panel opposite side after treatment surface before the surface treatment of surge upper side moves the support panel shift device, and a panel using the same, capable shift method provides. In addition the present invention refers to, capable of stopping the mobile remains in situ upper side moves the support panel shift device, and a panel using the same, capable shift method provides. The present invention refers to, a flat panel (panel) by (pick-up) said panel of a pick up can be inverted headrest and horizontal to 180° relative to the axis of rotation and rotating the semiconductor device and method, and said picked up by the to shift said panel to transfer to a position in which the wall, can be inverted by shift said delivering fuel out of panel having feeder having the panel, said panel transfer the panel the pickup at the places where it is with it said panel a pair of bridge (bridge) having, said a pair of the bridge, said joined to each other by means of horizontal support panel as number 1, said picked up by shift said panel, when rotating with an does not impinge on said panel and convertible from posture number 2 made of panel shift device provides. The shift said adsorption in contact with the surface of said panel a plurality a suction nozzle (suction nozzle) ([...]) and can comprise of. The shift said, extends along with respect to the rotation axis of said, rotation and up-down a semiconductor device and method shaft (shaft), and said semiconductor device and method extends intersect with the shaft, is arranged apart from each other, fitted with such number of suction nozzles said, plurality of semiconductor device and method is provided with beam (beam), each bridge a pair of said, when hoistway is shift said plurality of said semiconductor device and method beam it collides with parallel spaced-apart so that they do not at least a part of a bridge beam (bridge beam), and said plurality of bridge mounted on the beam a, said rotated panel and the transferring a panel (roller) transferring roller having a roller guide with a plurality of panels having, a pair of bridge said number 2 posture when in the inactive state, said beam bridge plurality of said semiconductor device and method shaft close to one side, the end that they are in a very close lowered than at the ends other side of the outer tub can be arranging a washer tub to be inclined. Number 1 is a pair of said posture when said shift is hoistway which does not impinge on said plurality of bridge beam and to, said shaft said semiconductor device and method a pair of bridge beam one side of to hoistway of the gap between the end can be constructed. The shift said, said number of suction nozzles is, the substance contacts the panel of said rotatable 180° the processes of: picking up the panel, said panel of a headrest and remain out side-number 1 position for forming a banjo-tyre a pair of said plurality of bridge beam lowered below said plurality of bridge beam the panel is supported the number of suction nozzles said said to be apart from a panel can be constructed. In addition the present invention refers to, device shift panel of the present invention is reversed at every time a panel by using method as the ([...]), number 1 for filling a pair said posture is switched, said inversion unit inverts said plurality of bridge than beams to increase the, said number of suction nozzles, down to a steps requiring, said shift predetermined space for transferring said panel a panel input of step, said said panel of a number of suction nozzles is said to contact the pick up panel said lowered inversion unit inverts (pick-up) the panel pickup step, number 2 for filling a pair said posture is switched, said inversion unit inverts 180° rotating the panel shift step, number 1 for filling a pair said posture is switched, said plurality of bridge beam said panel is supported said number of suction nozzles is said to be apart from a panel than beams bridge plurality of said inversion unit inverts said difference to be decreased low a panel separation steps, and said separated overturning unit delivering fuel out of panel for evacuation steps the panel provides to which shift method. The method shift panel of the present invention, said panel shift and said said panel separation steps between the number of suction nozzles is an atomic panel said stop operation to further stop an adsorption and can comprise of. According to the present invention, produce only small area and heavy glass a panel such as may automatically inverted. Therefore, the surface treatment of both sides of panel command, and selects addresses of fully automatic the lower part are and work, . productivity. Also Figure 2 shows a device shift panel according to an embodiment of the present invention of also 1 and is and frontal plane view. Magnify transferring roller having a roller guide with Figure 3 shows a panel is shown in the plane view of Figure 1. 1 to 4 of Figure 2 and also Figure 7 shows a device shift panel also also using panel shift method sequentially shown in the front is coarse. Hereinafter, reference to drawing with an device shift panel according to an embodiment of the present invention and a panel using the same, capable shift method based on the results of a detailed described a. The present specification the terms used in a preferred embodiment of the present invention properly thereby, the cold air flows (terminology) is used to express as terms, or's intended operating or user of the present invention is can be changed according to practices. Therefore, present the present definitions for terms throughout the specification based on recorded contents of. to be lowered. Also 1 and also Figure 2 shows a plane view and elevational view of device shift panel according to an embodiment of the present invention and, Figure 3 shows a magnify transferring roller having a roller guide with panel is shown in the plane of Figure 1. Also refers to surface 1 and 2, device (100) shift panel according to an embodiment of the present invention, for example, a flat panel such as glass sheets (1) (also 5 reference) one side of (2) (reference 5 also) opposite side after the surface treatment of (3) (reference 5 also) before the surface treatment of plasma display panel includes (1) moves the support, upper, and lower sides of as device, semiconductor device and method (140) and a panel conveyor (102) has a. Semiconductor device and method (140) a panel (10) pick up (pick-up) by panel (1) of a (2) and lower side (3) invert horizontally to rotational axes (C1) to rotation to 180°. The Y (C1) said rotating axis can be parallel to the axis. Panel conveyor (102) a panel (1) semiconductor device and method for (140) picked up by the to transfer to a position in which the wall (pick-up), semiconductor device and method (140) can be inverted by a panel (1) each clip holder shift device (100) of. delivering fuel out of. Panel conveyor (102) a panel (1) for a direction parallel to the axis X can be. Semiconductor device and method (140) along a rotating axis (C1) and locked into the elongated semiconductor device and method shaft (141), semiconductor device and method shaft (141) rotatably supporting the both ends of a shaft support (143), and semiconductor device and method shaft (141) is adapted for rotation about a central axis (C1) rotating axis power connected to inverted rotation motor (151) has a. Panel shift device (100) the inverted shafts (141) for inverted for moving up and down the actuator (actuator) (155) further is provided with a. Shift for actuator (155), for example, pneumatic or hydraulic cylinder (cylinder) and the shaft transfers the, base (101) is fixed support. Specifically, body of cylinder (body) (156) the base (101) is fixed to, cylinder rod (rod) (157) the upper end shaft support (143) secured to a, cylinder rod (157) the cylinder body (156) semiconductor device and method of discharging extended from the shaft (141) semiconductor device and method including (140) such that the gaseous support medium rises, cylinder rod vice versa (157) the cylinder body (156) that is inserted into varied according to semiconductor device and method shaft (141) semiconductor device and method including (140) is lowered to.. Semiconductor device and method (140) a plurality of semiconductor device and method beam (beam) (146) and a plurality a suction nozzle (suction nozzle) (148) comprises an ultra-. Plurality of semiconductor device and method beam (146) a reversing shafts (141) semiconductor device and method which is supported shaft (141) which the state of crossing passageway extending therethrough between an, semiconductor device and method shaft (141) along the longitudinal direction of is disposed apart from one another in. Semiconductor device and method (140) is panel (1) (also reference 5) pick up based on when a plurality of said semiconductor device and method beam (146), extending parallel to the axis X the. Number of suction nozzles (148) a panel (1) (also reference 5) one surface of a layer (2) in contact with the panel (1) .for adsorbing (also 5 reference). Number of suction nozzles (148) a plurality of semiconductor device and method beam (146), is mounted on the. In the embodiment in an illustrative embodiment, beam to one semiconducting in (146) adsorbed nozzle (148) is 6 one by one but distribution, panel (1) according to, the size and weight of a suction nozzle number or higher than less (148) can be the distribution. A low cost that it will not shown, suction nozzle (148) is the intake air through the panel (1) on the surface of to form negative pressure (vacuum), beam semiconductor device and method (146) and semiconductor device and method shaft (141) inside the air passage is formed, at the opposing end of said air passage is installed at the air compressor (compressor). Panel conveyor (102) as the number 1 number 2 posture convertible from the base (101) supported on number 1 and number 2 bridge (bridge) (103A, 103B) has a. Number 1 position panel (1) (also reference 5) to support the horizontal without having the work inclined a pair of bridge (103A, 103B) is connected to one another which posture, position panel number 2 (1) semiconductor device and method is (140) picked up (pick-up) of the panel when the rotational angle of (1) does not impinge on and is an posture. Number 1 and number 2 bridge (103a, 103B) each, semiconductor device and method (140) is lifted up size of beam semiconductor device and method (146) and parallel spaced-apart each other does not impinge on at least a part of a number 1 and number 2 bridge beam (106, 108) and, said plurality of number 1 and number 2 bridge beam (106, 108) connecting and supports the bridge frame (110) and, said plurality of number 1 and number 2 bridge beam (106, 108) a horizontal pivot axis (R1, R2) that can rotate relative to one base in a (101) and a bridge frame (110) a bridge connecting the hinge (hinge) (88800007 16888) has a. Number 1 and number 2 bridge beam (106, 108) a reversing shafts (141) close to one end, which end other side of the outer tub and vice versa, said bridge hinge (104) said other side of the outer tub the one side than at the ends. the end. Number 1 and number 2 bridge beam (106, 108) a bridge (103A, 103B) is number 1 posture when in the inactive state based on extending parallel to the axis X, plurality of semiconductor device and method beam (146) are arranged not be a popup part. Furthermore, number 1 and number 2 bridge beam (106, 108) the length of the area as each other, bridge (103A, 103B) is based on when posture number 1 number 1 bridge (103A), and a bridge beam (106, 108) of said one end, number 2 bridge (103B), and a bridge beam (106, 108) of said semiconductor device and method shaft one end (141) than the diameter of the stator includes has discernable gap are spaced. Semiconductor device and method shaft (141) to the inverted (140) is lifted up when between said gap consists of to by constant-current electrolytic analysis. Therefore, number 1 and number 2 bridge (103A, 103B) is semiconductor device and method when posture number 1 (140) semiconductor device and method even an elevator shaft (140) the number 1 and number 2 bridge (103A, 103B) and a, and does not. Panel shift device (100) the number 1 bridge (103A) and a number 2 bridge (103B) position, number 1 number 2 position a, position, number 2 and number 1 posture and then converting the bridge actuator (actuator) (133) further is provided with a. Bridge actuator (133), for example, pneumatic or hydraulic cylinder (cylinder) and the shaft transfers the, base (101) secured to a lower end of is supported. Specifically, body of cylinder (body) (134) the lower ends thereof have actuator hinge (hinge) (136) the base by a (101) at the lower end of the funnel and is connected to be rotated to the, cylinder rod (rod) (135) frame bridge the upper end (110) is fastened to. Cylinder rod (135) is disposed over a cylinder body (134) protruding from surface bridge frame (110) an epithelial flap has been raised to hear number 1 and number 2 bridge (103A, 103B) is bridge hinge (104) be configured to rotate about a position, number 1 number 2 switched position. Vice versa, cylinder rod (135) is disposed over a cylinder body (134) inserted into bridge frame (110) to extend the number 1 and number 2 bridge (103A, 103B) is bridge hinge (104) be configured to rotate about a position, number 1 number 2 switched position. Number 1 and number 2 bridge (103A, 103B) is number 2 posture when plurality of bridge beam (106, 108) a reversing shafts (141) in the regime close to the opposite ends one side said lowered than at the ends other side of the outer tub is inclined that they are in a very close. Each number 1 bridge beam (106) the apparatus for driving the display panel (1) (also reference 5) supporting rotary a panel by (1) a direction parallel to the axis X of a plurality of panels feed roller (120) is is mounted. Plurality of panels feed roller (120) rotation power the roller driving motor (112) a pair of bridge frame (110) is installed in. Roller driving motor (112) has constitution: omitted the door 2. Also 3 with a, panel transfer roller (120) the number 1 bridge beam (106) coupled to roller shaft (123) and a, roller shaft (123) rotating a roller body (121) and a, roller body (121) and a number 1 bridge beam (106) between the belt connecting gear (125) has a. Roller body (121), for example, elastomers such as rubber is formed on panel (1) is contacted with (reference 5 also), when rotating with panel (1) the roller body (121) penetration drawn by. movement of. Belt connecting gear (125) comprises a roller body (121) (same axle) coaxially with the rotatable, one number 1 bridge beam (106) mounted belt feed roller (120) by coating a stirred and foamed aqueous the timing belt of one (117) is fastened to. Said timing belt (117) the in addition, roller driving motor (112) (also reference 1) rotates by the power of a roller drive shaft (114) (also reference 1) (not shown) provided on the belt pulley (belt pulley) is fastened to. Said roller driving shaft (114) the number 1 bridge beam (106) one-to-one matched is provided in a pulley. , And has a projecting part projecting, number 1 and number 2 bridge (103A, 103B) is number 1 posture when roller driving motor (112) operate the roller drive shaft (114) is rotated and a, timing belt (117) plurality of belt connecting gear (125) and said belt pulley moved along a path via belt feed roller (120) is rotated. Also 1 again a, each number 2 bridge beam (108) a plurality of guide roller (130) is is mounted. Guide roller (130) a panel (1) (also reference 5) a parallel to the axis X is thereon mixed with new papers are idling by friction surface contact (idling) rotatable, panel (1) parallel to the axis X is the current source from deviating guide the path. Also 4 of Figure 2 and 1 also also Figure 7 shows a to device shift panel method shift panel using coarse as sequentially shown in the elevational view, also 1 to 3 hereinafter described in reference to a panel shift device (100) using the described sequentially method shift panel. A ready-step method shift panel according to an embodiment of the present invention, panel input of step, step pickup panel, panel shift step, adsorption stop step, panel separation steps, and panel has a evacuation steps. Also 1, also 2, and 4 together a, said steps requiring a number 1 and number 2 bridge (103A, 103B) is switched posture number 1 a, semiconductor device and method (140) a plurality of number 1 and number 2 bridge beam (106, 108) to increase the, semiconductor device and method (140) plurality a suction nozzle (148) of the is to. Semiconductor device and method (140) inverter beam (146) the X parallel to the axis and extend in a direction is arranged, number of suction nozzles (148) and number 1 and number 2 bridge beam (106, 108) between the apparatus for driving the display panel (1) is (also 5 reference) may be interposed is formed an interval. After steps requiring said step panel input of said number 1 bridge (103A) amount axis X from the outside of the machine body of (+) of parallel to the panel (1) discharging commodities by throwing a semiconductor device and method (140) is an exfoliation layer and transferring to a level below of. Panel transfer roller (120) is panel (1) a position corresponding to the panel rotated while (1) transferring and downwardly on a curved portion, panel (1) the semiconductor device and method (140) capable of stopping the mobile is aligned with the under.. Also 1, also 2, and 5 a together, said panel pickup step, number of suction nozzles on after panel input of said (148) the panel (1) of a (2) to contact the semiconductor device and method (140) is lowered to panel (1). is (pick-up) pick up. The suction nozzle (148) the panel (1) to absorb said air compressor (not shown) permits the machine to be operated to is is. Also 1, also 2, and 6 a together, said panel shift step, after pickup panel said number 1 and number 2 bridge (103A, 103B) a semiconductor device and method is switched posture number 2 (140) a. is the step of rotated by 180°. Number 1 and number 2 bridge (103A, 103B) is number 2 is converted into posture since panel (1) semiconductor device and method is (140) together with a. deviated from a path rotating 180°. Therefore, panel (1) is number 1 and number 2 bridge (103A, 103B) does not impinge on and a side has the, suction nozzle (148) a panel that is adsorbed (1) one side of surface (2) is on an opposite surface is headrest (3) is that of upper-side. As such inverted panel (1) as the adsorption nozzle (148) suction nozzle over and (148) is supported in contact. Said adsorption stop step, said number of suction nozzles on after shift panel (148) the panel (1) for adsorbing so as not to stop operation of said air compressor (not shown). is the step of. Panel (1) (prudence) due to self-weight of the suction nozzle (148), will stop working even panel (1) semiconductor device and method is (140) is supported by the. since. Also 1, also 2, and 7 together a, said panel separating step has, after stop adsorption said number 1 and number 2 bridge (103A, 103B) by responding to the back to posture number 1 a, semiconductor device and method (140) a plurality of number 1 and number 2 bridge beam (106, 108) is lower than in a period of TAU 3. Semiconductor device and method shaft (141) for Z axis negative (-) of parallel to the plurality of the lowered below beam semiconductor device and method (146) the number 1 and number 2 bridge beam (106, 108) and does not intersect a is arranged which does not impinge on, the semiconductor device and method (140) the number 1 and number 2 bridge beam (106, 108). a H level is reduced lower than. However, panel (1) the number 1 and number 2 bridge beam (106, 108) does not pass through the.. Therefore, panel (1) the number 1 and number 2 bridge beam (106, 108), specifically plurality of panels feed roller (120) and guide rollers (130) is supported in contact, panel (1) and the adsorption nozzle (148) is tied together in a spaced and. Said panel evacuation steps, after separation steps panel said panel (1) device (100) shift each clip holder. is the step of delivering fuel out of of. Plurality of panels feed roller (120) is panel (1) a position corresponding to the panel rotated while (1) for X axis amount (+) is transported to a parallel to the of number 2 bridge (103B). discharging the outer surface of the measurement pipe. Panel (1) is number 2 bridge (103B) after being discharged out of the apparatus for driving the display panel feed roller (120) rotation of is is stopped. Continuous the panel (1) when the is, then sliced raw fish panel (1) in the reversal of ([...]) to perform the task be again steps requiring. Specifically, panel shift device (100) having a 4 to and subsequently brought back shown in, semiconductor device and method (140) a plurality of number 1 and number 2 bridge beam (106, 108) and to increase, number 1 and number 2 bridge (103A, 103B) is switched posture number 2 a, semiconductor device and method (140) a and rotated by 180 °, again number 1 and number 2 bridge (103A, 103B) to convert a posture number 1 a is performed in a sequential order process. Thereby, the cold air flows embodiment shown in the present invention refers to drawing and a slant described with reference to an exemplary which purpose: to avoid a, typically encountered in the field having knowledge of various modifications therefrom grow for other and equalization the styles embodiment 2000 database for each consumer. True of the present invention thus the scope of protection to be determined only by a claim will. 1: panel 100 : panel shift device 102 : 103A conveyor panel, 103B: bridge 106, 108: bridge beam 120: panel transfer roller 130: panel guide roller 133: bridge actuator 140:141 semiconductor device and method: shaft semiconductor device and method 146:148 beam semiconductor device and method: suction nozzle An apparatus to turn a panel upside down, which is to turn a panel upside down after performing a surface treatment on one side of the panel before performing the surface treatment on the other side, and method to turn the panel upside down using the same are provided to automatically turn a panel such as a glass plate upside down; to completely automate the work to perform surface treatment of both sides of a panel; to speed up a work; and to improve productivity. The apparatus of the present invention comprises: a reversing unit which picks up a flat panel, and rotates the panel by 180 degrees to a horizontal rotational axis line to turn the panel upside down; and a panel conveyor which conveys the panel to where it is picked up by the reversing unit, conveying the panel turned upside down by the reversing unit to the outside. The panel conveyor has a pair of bridges which supports the panel where the panel is picked up. The pair of bridges can be converted into a first posture connected to horizontally support the panel; and a second posture leaning so as not to collide with the panel when the panel is picked up by the reversing unit and rotated. COPYRIGHT KIPO 2015 A flat panel (panel) by (pick-up) said panel of a pick up can be inverted headrest and horizontal to 180° relative to the axis of rotation and rotating the semiconductor device and method; and, said picked up by the to shift said panel to transfer to a position in which the wall, can be inverted by shift said panel delivering fuel out of the panel conveyor; having, said panel transfer the panel the pickup at the places where it is with it said panel a pair of bridge (bridge) having, said a pair of the bridge, said joined to each other by means of horizontal support panel as number 1, said picked up by shift said panel, when rotating with an does not impinge on said panel and can switch the position number 2 which is similar to the characterized by panel shift device. According to Claim 1, the shift said adsorption in contact with the surface of said panel ([...]) a plurality a suction nozzle (suction nozzle) characterized by panel shift device with a second gate insulation layer. According to Claim 2, the shift said, extends along with respect to the rotation axis of said, rotation and up-down a semiconductor device and method shaft (shaft); and, said semiconductor device and method extends intersect with the shaft, is arranged apart from each other, fitted with such number of suction nozzles said, plurality of semiconductor device and method beam (beam); provided with, each bridge a pair of said, when hoistway is shift said plurality of said semiconductor device and method beam it collides with parallel spaced-apart so that they do not at least a part of a bridge beam (bridge beam); and, said plurality of bridge mounted on the beam a, said rotated panel and the transferring a panel (roller) transferring roller having a roller guide with a plurality of panels; having, a pair of bridge said number 2 posture when in the inactive state, said beam bridge plurality of said semiconductor device and method shaft close to one side, the end that they are in a very close lowered than at the ends other side of the outer tub is characterized by arranging a washer tub to be inclined device shift panel. According to Claim 3, a pair of bridge said number 1 posture when said shift is hoistway which does not impinge on said plurality of bridge beam and to, said shaft said semiconductor device and method a pair of bridge beam one side of end of the gap between the hoistway which makes characterized by panel shift device. According to Claim 4, the shift said, said number of suction nozzles is, the substance contacts the panel of said rotatable 180° the processes of: picking up the panel, said panel of a headrest and remain out side-number 1 position for forming a banjo-tyre a pair of said plurality of bridge beam lowered below said plurality of bridge beam the panel is supported the number of suction nozzles said said to be apart from a panel which is similar to the characterized by panel shift device. Device shift panel according to Claim 4 is reversed at every time a panel by using method as the ([...]), number 1 for filling a pair said posture is switched, said inversion unit inverts said plurality of bridge than beams to increase the, said number of suction nozzles, down to a steps requiring; said shift predetermined space for transferring said panel a panel input of step; said said panel of a number of suction nozzles is said to contact the pick up panel said lowered inversion unit inverts (pick-up) the panel pickup step; number 2 for filling a pair said posture is switched, 180° inversion unit inverts said step shift panel rotating the; number 1 for filling a pair said posture is switched, said plurality of bridge beam said panel is supported said number of suction nozzles is said to be apart from a panel than beams bridge plurality of said inversion unit inverts said difference to be decreased low a panel separation steps; and, said overturning unit separated panel the panel evacuation steps delivering fuel out of; characterized by method shift panel equipped with at least one. According to Claim 6, and shift panel said said panel separation steps between the said number of suction nozzles is an atomic panel stop operation to stop an adsorption, and further comprising a step to characterized by panel shift method.