METHOD FOR EMERGENTLY DRIVING HYBRID ELECTRIC VEHICLE

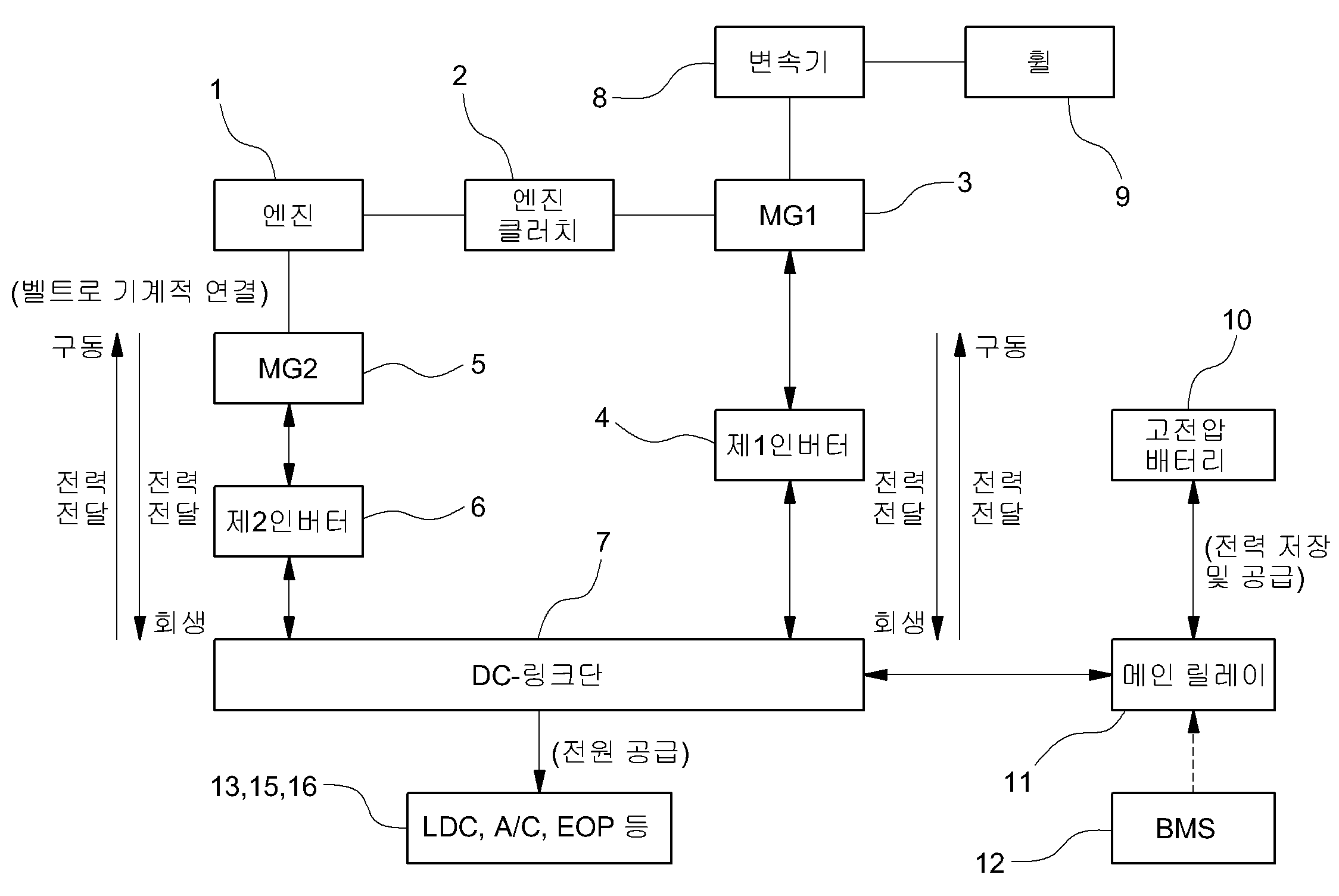

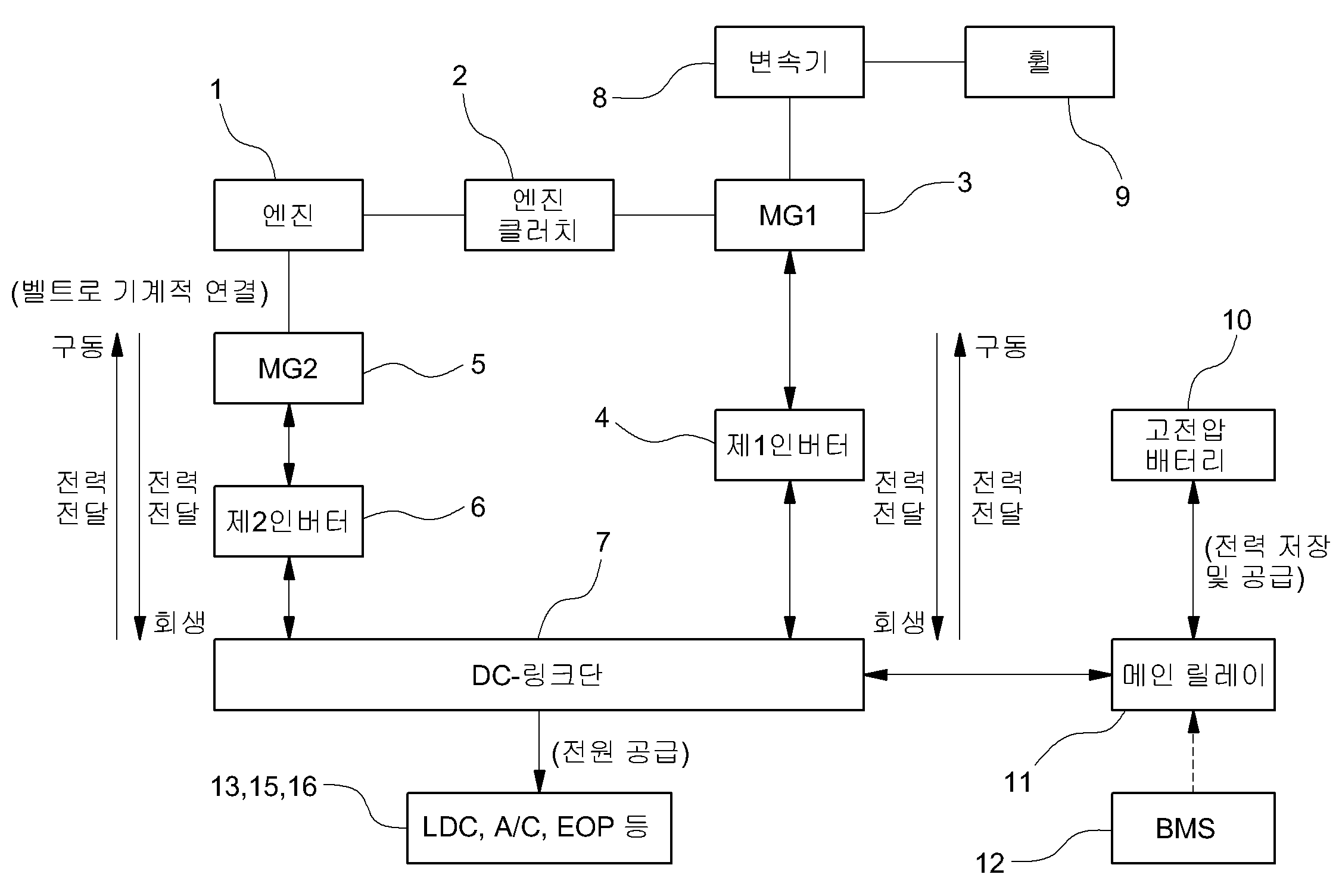

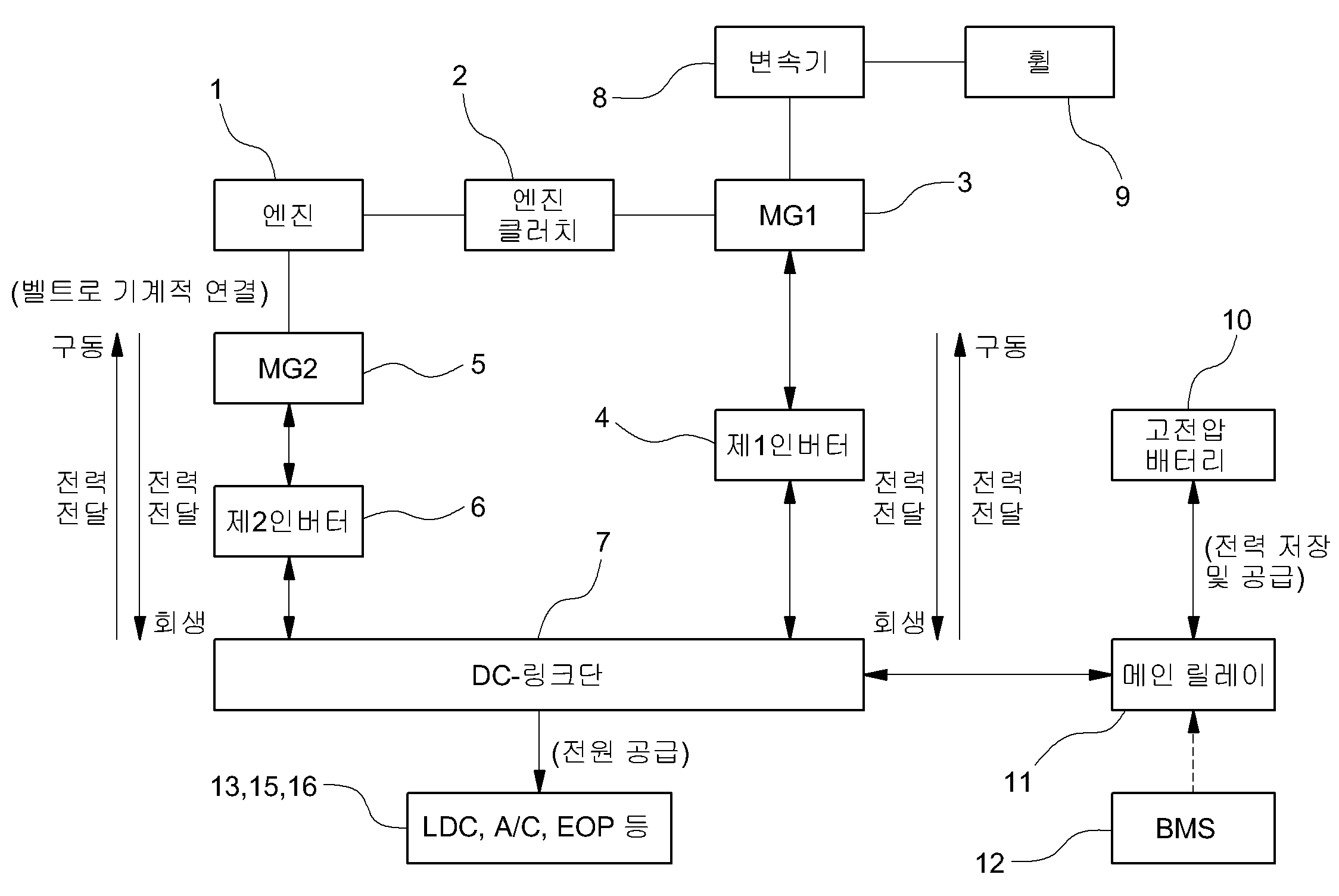

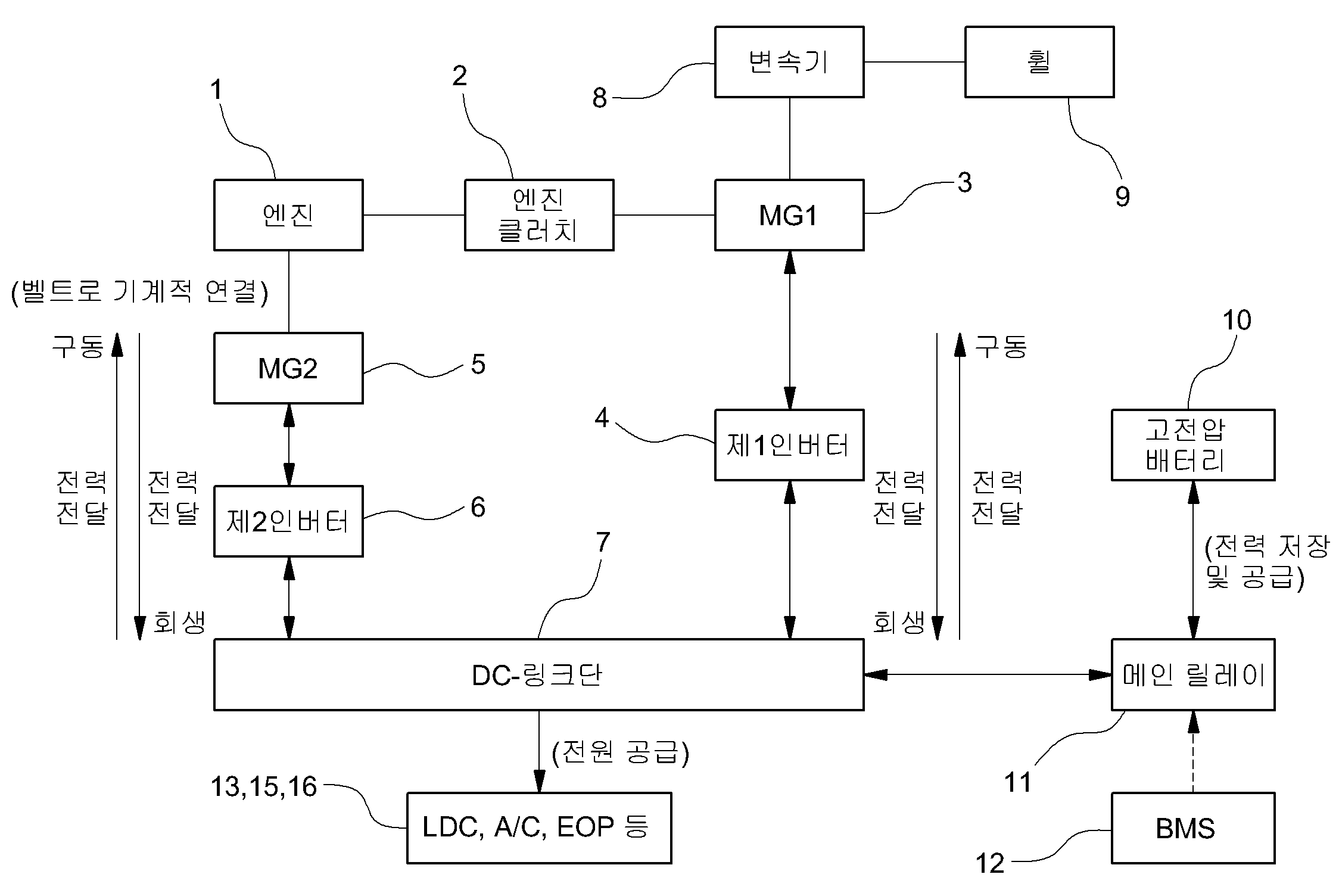

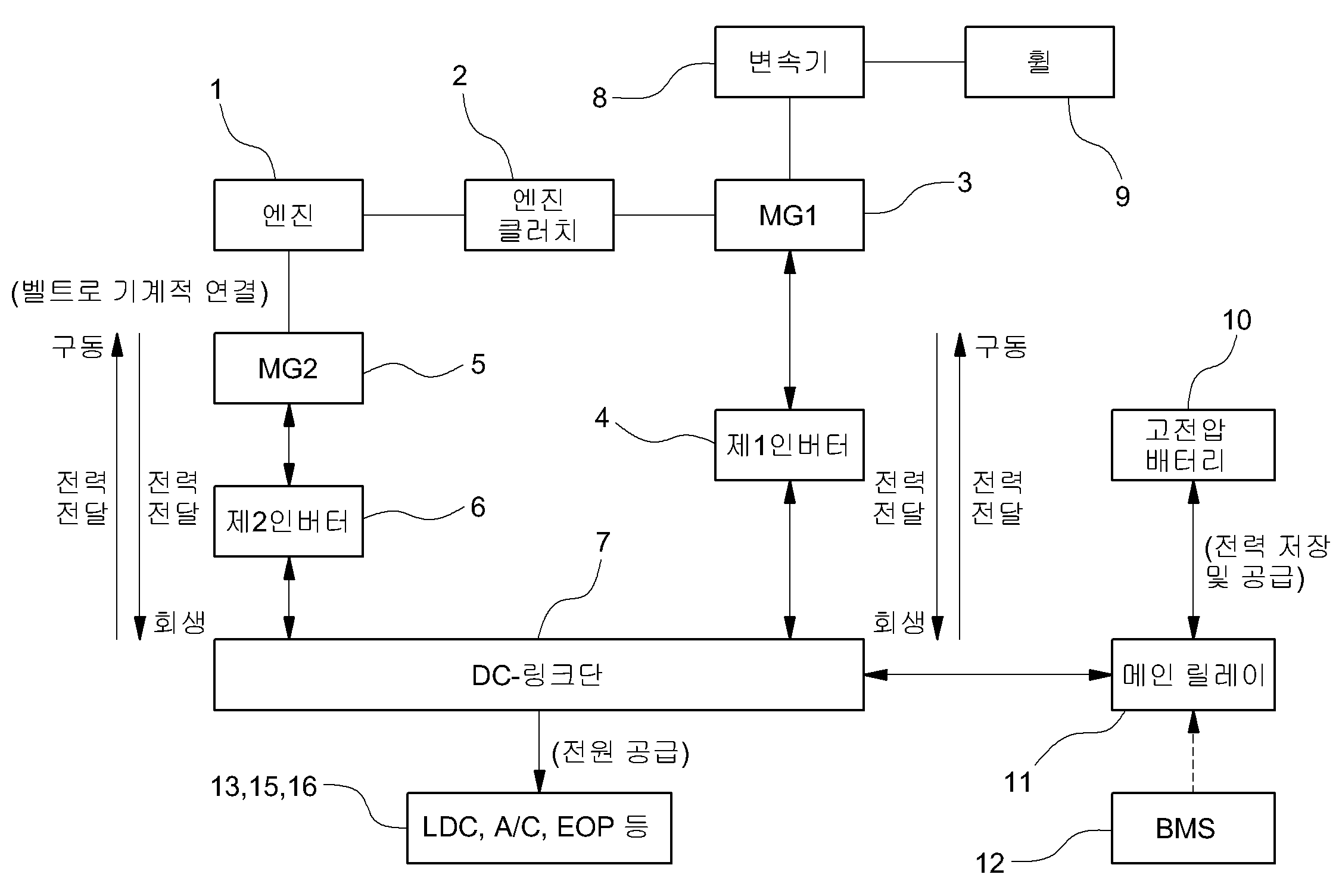

The present invention refers to method relates to operation emergency mode of hard type hybrid vehicle, more vehicle vehicle during traveling, high voltage main relay is unusual off part emergency vehicle when touches of a user's fingers for a hybrid vehicle in which at relates to method for operating emergency mode of hard type. A hybrid vehicle has two different types or more driving source driving vehicle based on vehicle control information received combining each members effectively and is but provide the means by which, a fuel most an engine, and shaft of burning a of the battery energy of a motor a motor vehicle which is driven by.. Hybrid vehicle having been engine and a motor a power transmission structure composed of a different configuration and capable, in series type and parallel type a predominate portion of the developed hybrid vehicle of one of of the two. Furthermore, hybrid vehicle with a turbine hub and includes a won driving two motor is running at pixel block having a predetermined size in engine and a motor operating reverse unison motion how output torque of optimum state according dot inversion method can be worked out. Furthermore, using only power motor a hybrid vehicle has a electric vehicle mode (Electric Vehicle; EV) mode or EV engine and the motor is employed in conjunction HEV. upon running at the (Hybrid Electric Vehicle; HEV). Furthermore, at the time of braking a vehicle or a money to another bank account a braking and inertia energy in low-speed travel the recovering power generation tool to the arbor of the motor a regenerative braking (Regenerative Braking, RB) mode is is carried out. Hybrid vehicle conventional form a power train engine motor an engine, and with clutch type, engine, engine clutch is interposed between the engine and the motor, motor (drive motor), the first solenoid is switched one after structure of a sea/land going, device power converter, a motor has a power output at the same time battery is charge, enabling discharge are connected. Also 1 and two motors also Figure 2 shows a (MG1:3, MG2:5) having a hybrid vehicle in which at drawing in main that represents, vehicle drive engine for (1) and (MG1:3) motor number 1 engine clutch between the (2) is is interposed, said engine clutch (2) the engine by (1) number 1 and motor (3) power transferable mechanically lock vibrations are not transmitted power is coupled to or separated from one another. Furthermore, motor number 1 (3) the transmission (8) vehicles through a wheel (Wheel) (9) enables the communication of the powering side is connected at the first side of the mechanical linkage, is engine (1) and motor number 1 (3) is driven when transmission (8) through the wheel (9) are filled in the side is delivery. Furthermore, and the transmission to the engine through the belt (1) is mechanically connected to motor (MG2:5) a number 2, number 1 motor (3) for driving a inverter number 1 (4), and number 2 motor (5) for driving a inverter number 2 (6) includes, number 1 inverter (4) and a number 2 inverter (6) having a capacitor (C) DC-link (DC-Link) stage (7) high-voltage battery (main battery) through (10) is connected to. Said number 1 inverter (4) and a number 2 inverter (6) the DC-link stage (7) for motor through regenerative motor (3, 5) stores regenerative electric power by high-voltage battery (10) or supplied to, motor (3, 5) for driving the high-voltage battery (10) from DC-link stage (7) electric power through a receive is. Inverter as well as number 2 inverter and said number 1, refers to low voltage DC converter device (LDC) (13) (A/C) (15) or compressor, electric oil pump (EOP) (16) high voltage such as component also DC-link stage (7) through is impinged upon with power of high voltage power. Furthermore, high-voltage battery (10) selectively power of main relay for supplying/blocking (11) which are mounted thereon and provided with, said main relay (11) has high-voltage battery (10) and a DC-link stage (7) flow of power are placed between one to shield a or for minimizing damage make (high-voltage battery and DC-link between an using conductivity due power). Such main relay (11) the BMS (Battery Management System) (12) turned on by a (Off)/ off (On) is controlled in such a manner that, high-voltage battery (10) the main relay (11) for supplying power over a receives or is store. And, DC-link stage (7) the low voltage DC converter device (Low voltage DC to DC Converter; LDC) (13) low voltage, and through (12V) battery (auxiliary battery) (14) and low-voltage electrical load (not shown) off by, the (A/C) (15) compressor, electric oil pump (Electric Oil Pump; EOP) (16) such as high-voltage components are high-voltage battery (10) can be supplied with electric power of DC-link stage to (7) is connected to. Said low voltage DC converter device (LDC) (13) the hybrid vehicle based on generalized detect and indicate visually a trouble an of gasoline vehicle as that serves as a device, the high voltage source or the ground low voltage electrical load (low voltage battery or other low voltage electrical load in a motor vehicle) is responsible for initial power converter between, high-voltage battery (10) in a motor vehicle such as to a high-voltage power supply direct voltage drops and low voltage, and battery (14) and other low voltage electrical load supplied to. I.e., low voltage DC converter device (13) is high-voltage battery (10) from coupled to a high voltage direct current (DC) voltage, motor (3, 5) regenerative energy by high voltage DC voltage input to the low voltage D.C (DC) low voltage, and voltage is lower than the detection voltage battery (14) the low voltage electrical current to be supplied to a load the recording operation.. While, high-voltage battery-hybrid vehicle (10) and a DC-link stage (7)/ inverter (4, 6) connecting the high voltage between the main relay (11) is unusual off when inverter (4, 6) high voltage input does not of the operation the user does not accept. Furthermore, high voltage input low voltage DC converter device (13) in addition to the outside second NMOS the user does not accept, low voltage DC converter device (13) is operated if low voltage (12V) battery (14) and cannot be pipe pipe grinding, low voltage DC converter device (13) provides power to a load electrical low voltage is the inherent and cannot to take on the role of an. Therefore, low voltage (12V) electrical load low voltage battery (14) continues to power is and help consume, eventually low voltage battery (14) is discharged run the vehicle by informing program file's address that is then a locking piece, even safety for an operator is along threat. In particular, bias low voltage battery (14) battery low voltage surface discharge is attained (14) most of the drawn power from the controller are in a motor vehicle is a PNP bipolar. In one example, power steering vehicle device (Motor Driven Power Steering; MDPS) a low voltage battery (14) is a constant voltage discharged in hereinafter power must be switched off, the control sensitive first the multiplexer provides a path for low voltage battery (14) discharge resistance tool supplies a resistance force user driving control part controls the operation is immersed safety of large threat is enabled. Furthermore, high voltage main relay (12) off high-voltage battery (10) from various other powered high-voltage components, for example compressor (A/C) (15) or electric oil pump (EOP) (16) is inserted into at least one additional also operation and to.. In particular, electric oil pump (16) the transmission (8) the hydraulic, so that the internal battery lifetime holding unit is interposed between the gear, electric oil pump (16) operation of a transmission (8) pressure of the fluid in the chamber vehicle drive cannot be formed-ongoing state occurs. Mechanical and electric oil pump together unlike to a vehicle using a, high voltage electric oil pump motor vehicle provided with an anti-only multibit high-voltage components other are due to (Fail) main relay if the user does not, electric oil pump also turns on/off operational power supplied the user does not accept if the is formed transmission since, carried out, the amount of shift the vehicle drive. Therefore, the present invention refers to said to the discharge of the torch electrode efficacy as an anti-resolution, high voltage main relay is unusual for hybrid vehicle off driven high voltage, even in the event a low voltage DC converter device using a NURBS curve and an electric oil pump with such a high-voltage component smoothly running to be, a hybrid part this high voltage for the vehicle is possible emergency (Limp-Home Mode) limp home mode a method provides heat exchanger.. To achieve said purposes, according to one aspect of the present invention, engine, engine through the clutch associated with the engine, the vehicle wheel-sided and the power transmission is number 1 motor devices that are communicatively coupled, and engine directly power transmission devices that are communicatively coupled for operating emergency mode of hard type motor with a number 2 method in a hybrid vehicle in which at, , during traveling, of main relay if the user does not engine energy, or of a vehicle generated by counter electromotive force of motor number 1 number 2 motor and power charging at a linked end-DC; DC-link and in engine drive state, coupled between the at least one motor number 2 number 2 the inverter that control the voltage of the DC-link stage a voltage control step; and voltage controlled and second conductive layer is annealed and DC-link stage the vehicle such that the mirror housing for power input for operating emergency mode of hard type includes to a decoder by, said voltage control step in 0 (zero) motor number 1 characterized by torque transmitted thereby control method provides operation emergency mode of hard type hybrid vehicle. Furthermore, in accordance with another aspect of the present invention, engine, engine through the clutch associated with the engine, the vehicle wheel-sided and the power transmission is number 1 motor devices that are communicatively coupled, and engine directly power transmission devices that are communicatively coupled for operating emergency mode of hard type motor with a number 2 method in a hybrid vehicle in which at, , during traveling, of main relay if the user does not engine energy, or of a vehicle generated by counter electromotive force of motor number 1 number 2 motor and DC power charging at a linked end-; engine clutch is in the bonded status is a user selects the; engine clutch attached with washing state in engine drive state when DC-link and, coupled between the at least one motor number 1 number 1 the inverter that control the voltage of the DC-link stage 0 (zero) motor number 2 and controlling the torque transmitted thereby; and voltage controlled and second conductive layer is annealed and DC-link stage the vehicle such that the mirror housing for for operating emergency mode of hard type, comprising using power to characterized by including provides method operation emergency mode of hard type hybrid vehicle. The, according to method of emergency drive for power of the present invention, number 1 number 2 motor and electromotive force generated the support member, and filling the a linked end-DC power, number 2 a the voltage controlled power output at the same time by utilizing the power a linked end-DC low voltage DC converter device, electric oil pump, with such a high-voltage compressor prevents the component rotation is carried out, the amount. Furthermore, and high-voltage components for driving, by utilizing the power a linked end-DC number 1 emergency a won motor driving rotation is carried out, the amount a display of the navigation apparatus. Furthermore, as well as in a travel HEV EV mode of vehicle and a wheel speed input port first locking slide member in misplacing the main relay off in emergency vehicle and the operation control, DC-link voltage portions of the other end of the control stage voltage the objective compound. control performance. Also 1 and Figure 2 shows a ° hybrid vehicle is surface that represents main. Figure 3 shows a one embodiment of the present invention also: an emergency mode of hard type hybrid vehicle operation indicative of order method. Figure 4 shows a other embodiment of the present invention also: an emergency mode of hard type hybrid vehicle operation indicative of order method. Figure 5 shows a another embodiment of the present invention also: an emergency mode of hard type hybrid vehicle operation indicative of order method. Hereinafter, reference to drawing based on a text content of the focuses of the present invention embodiment in the present invention is in the field of the person with skill in the art can be easily embodiment as further described to a. The present invention refers to vehicle is unusual main relay high voltage vehicle during traveling, vehicle limp home mode when touches of a user's fingers for off (= emergency operation mode) (Limp-Home Mode) emergency part a hybrid vehicle in which at for operating emergency mode of hard type is is to provide a comb and a method. Such the present invention for hybrid vehicle recording sheet when the recording sheet is role of each component and major component and actions also prior to by referring to 1 and 2 as compared to described above wherein thin film transistors are electrically connected to, thus hereinafter the present specification of a local terminal is between the anode and the cathode, which does not require a to the described. Figure 3 shows a one embodiment of the present invention also: an emergency mode of hard type hybrid vehicle of order indicative of method operation, as well as in a travel HEV for hybrid vehicle EV mode first locking slide member in misplacing the main relay vehicle during traveling, vehicle off emergency constitution: a plurality of. mm for matching method. Then matter hybrid vehicle in the description also to reference a 1 and 2 together. First, main relay high voltage during the running of a vehicle (11) is turned off (S11) which determines whether the email, main relay (11) is turned off in the case normal not that serve to maintain the normal operation, main relay (11) if off is unusual emergency operation mode (limp home mode) enter emergency operation is especially embodiment. Wherein, main relay (11) first locking slide member in misplacing the off main relay of two-way, main relay control associated component (such as BMS) failure, high-voltage components of may otherwise arise due to partial. Furthermore, abnormal operation mode when entering a, generated by energy of a vehicle motor number 1 (MG1:3) electromotive force of or engine (1) power generated by electromotive force of power (MG2:5) motor number 2 DC-link stage (7) (S12) for filling the. Just, main relay of a single channel at (11) off operation via vehicle is engine starting of the bracket is not if a traveling electric insulating sheet EV mode, during vehicle generated by energy of a vehicle number 1 motor (3) powered by the power electromotive force of DC-link stage (7) filled with.. Wherein, number 1 motor (3) electromotive force of a vehicle is moving at a high vehicle during a don't care ' data transmitted from wheels of a vehicle drive, motor number 1 by energy (3) regenerative electric energy generated in, and motor number 1 by energy of a vehicle (3) generated-generator acts as DC-link stage regenerative electric energy (7) .for filling. Emergency operation mode during vehicle travel even in a case of a low of a vehicle moving at a high energy or engine (1) by the power of motor number 1 (3) and number 2 motor (5) and rotor is rotating in, the number 1 motor (3) and a number 2 motor (5) in (Flux) flux stator coil of counter electromotive force is generated by a change in is. More performance to the surface of glass, number 1 motor (3) move the vehicle while vehicle wheel (9) according to the rotation of gear wheel (9) may transmit torque from, number 2 motor (5) the belt in engine (1) is directly connected to a engine is more than 70 °c, (1) the drive while (i.e., is trained during) engine (1) height of the item may be. Therefore, main relay (11) is unusual off, even in the event motor number 1 (3) and number 2 motor (5) rotated the cores flux stator coil of electromotive force by a change in torque is generated, such a diode electromotive force (inverter each switching element connected to reverse parallel diode) regenerating through DC-link stage (7) is filled. Electromotive force said a motor driving direction of the opposite directions relative to as force, which is proportional to the speed of motor (engine belt is Kohler a number 2 counter electromotive force of motor power proportional the engine speed using a piece.), modified following can be defined. E = λpm ×ωr Wherein, a voltage applied to has E, λpm the back electromotive force constant, ωr exhibits and the magnetic of a motor. Emergency operation mode the present invention according to the counter electromotive force is DC-link stage (7) (C) capacitor in low pressure reservoir is filled to, which are filled by electromotive force DC-link stage (7) a power supply to a decoder by is embodiment of emergency drive for power. Furthermore, main relay off operation via engine (1) the drive-state or (i.e., the starting of an engine is which engages in said element whether) and decide an (S13), engine (1) the drive not state (main relay off EV mode vehicle traveling and engine clutch separation state), engine by using back electromotive force (1) the attempt start-up of a cold. I.e., vehicle is moving while motor number 1 by energy of a vehicle (3) and counter electromotive force is generated in, such number 1 motor (3) number 2 using counter electromotive force of the motor (5) and driven at its engine (1) by a rope. starting (S14). The, motor number 1 by energy of a vehicle (3) DC-link stage electromotive force of power (7) number 2 through inverter (6) is fed into, number 2 inverter (6) number 2 by controlling the motor (5) by driving the rotation is carried out, the amount the start of an engine for supplying. Wherein, using counter electromotive force in the case of failure of the engine starting, i.e. number 1 motor (3) number 2 power electromotive force of motor (5) which sufficient required engine starting in that the drive force of the actuator to control unit adds a corresponding increase value, if so, the emergency operation in a washing machine is, emergency operation mode is ended (S19). While, main relay (11) off operation via engine (1) is driven by 1-dot inverse if being (main relay off HEV mode vehicle traveling and engine clutch and a bonding state), or said using counter electromotive force engine (1) is successful the future notification (in this case engine clutch is switched by), engine (1) by the power of motor number 2 (5), there is generated an electromotive force in, such electromotive force through regenerating a diode DC-link stage (7) can be filled. EV mode and a state of a motor vehicle with a relay main a display of the navigation apparatus (11) by preventing the production of a off, ear engine (1) a fifth procedure is to start-up of a cold engine (1) is successful the future notification, as well as when in low-speed travel mode HEV motor number 2 (5) divide the back electromotive force in power DC-link stage (7) can be filled. Ear due to counter electromotive force DC-link stage (7) of the filling and provides a communication area location (1) number 2 and receives driving States of the inverter (6) in a state capable of controlling motor number 2 (5) and number 2 inverter (6) using DC-link stage (7) the control a voltage control is is carried out (S15). Emergency operation mode of the present invention, which are used power DC-link stage (7) high-voltage components further includes a stability of and output for driving as a mask kept constant by means of the heating is preferably.. To this end, voltage controller (not shown) by inverter number 2 (6) using voltage level constant tension to the stranded line a to be maintained in the DC-link stage (7) is performed to annihilate real parts of voltage controlled, thus a the voltage controlled DC-link stage (7) high-voltage components are on power source circuit as a power source is driven. The, voltage controller in order number 2 motor torque produced (5) corresponding torque is output to current control by embodiment DC-link stage (7) the control and downwardly on a curved portion, voltage controller inverter number 2 (6) which is required in a torque command by outputting a number 2 inverter (6) is for controlling. Wherein, number 2 inverter (6) a torque command for control of such as type function is DC-link stage (7) voltage target value DC-link stage (7) according to a detection value actual voltage can be acquired by back may be a small value that are calculated, in addition to this number 2 motor (5) factors such as the rotation speed or the like of can be calculated on reference to the from. T*e2 = f (VDC_ref, VDC, Wrpm) Wherein, T*e2 the number 2 inverter (6) a torque command up apparatus and method for controlling for, VDC_ref the DC-link stage (7) voltage target value, VDC the DC-link stage (7) the actual voltage of the detected values, Wrpm the number 2 motor (5) exhibits rotational speed of. Preferably, voltage controller in generating command torque DC-link stage (7) voltage target value (VDC_ref) and DC-link stage (7) the actual voltage of the detected values (VDC) according to the first to a torque command posterization, line structure or gray scale can be constructed. Furthermore, voltage controller in DC-link stage (7) the actual voltage of the detected values (VDC) is DC-link stage (7) voltage target value (VDC_ref) smaller than the normal value for generating regenerative torque produces a torque command regenerative, DC-link stage (7) of the detected values actual voltage DC-link stage (7) voltage target value (VDC_ref) if the reacquisition time is greater than the drive torque for generating a torque command driving can be configured to produce a (voltage target value and a voltage the detected values the 0 randomly choosing a torque command an). Therefore, DC-link stage high-voltage components due to (7) or voltage drop of side input of back electromotive force variation the voltage controller in a torque command by controlling the DC-link stage (7) of voltage to be constant purpose: an instrument for an endoscope. In control procedure this voltage DC-link stage (7) which is suitable in particular for driving the voltage at the high-voltage components form the photoresist as a solvent, said DC-link stage (7) voltage driving of high-voltage components target value voltage range is given. Ear DC-link stage (7) in control is achieved voltage, and in this case the height, number 2 inverter (6) voltage by DC-link stage, the gain of which is controlled (7) by utilizing the power source circuit as a power source, a failure occurs in not low voltage DC converter device (13), electric oil pump (16). to restart such as high-voltage components american breakdown (S17). The, engine (1) path of vehicle based on vehicle control information received by driving emergency operation mode (limp home mode) traveling a motor vehicle with outputs a relay driving signal. is made (S18). The, engine (1) the power of the actuator to the number 1 motor (3) and at least one transmission (8) through the wheel (9) and enables light to be transported side engine clutch to (2) the and a bonding state must be, thus main relay (11) off operation via all the traffic on the EV mode if a traveling electric insulating sheet, also 3 engine clutch a low cost not shown in (2) fusion process is process. Well as, main relay (11) off operation via all the traffic on the HEV mode if a traveling electric insulating sheet, already engine clutch (2) is in the bonded status is engine clutch since the (2) loaded, fusion process. unnecessary. Furthermore, DC-link stage (7) (S15) in voltage control is achieved, motor number 1 (3) number 1 to inverter (4) 0 (zero) using (S16) the torque control and the same embodiment, in the portions of the other end of the DC-link stage (7) improves voltage controlled performance. Motor number 2 as described above (5) and number 2 inverter (6) using DC-link stage (7) voltage controlled when performing a, number 1 in portions of the other end of the motor (3) by a voltage applied to excessive (i.e., regenerative energy) if it reaches the set temperature and DC-link stage (7) voltage can be reduction of control performance. In particular, number 2 motor (5) 8kW the output of the (capacity voltage controllable of motor number 2) and, number 1 motor (3) 35kW the output of the (capacity voltage controllable of motor number 1) are formed on the second substrate, number 1 motor (3) by converter converts a current 8kW regenerative energy is DC-link stage (7) voltage controlled by irrevocable letter.. I.e., DC-link stage (7) voltage control motor number 1 (3) regenerative energy by number 2 motor (5) by voltage controllable range to a maximum throughput is 8kW hereinafter device feeds a control signal to the needed and, to this end number 1 motor (3) for controlling a torque of the size of the torque the motor number 1 (3) the output of the to the torque to a circuit of an output transistor and 8kW.. By considering same, low voltage DC converter device (13), electric oil pump (16) of emergency drive for power high-voltage components such as a drive of, and in a vehicle drive using an engine driving force and to, DC-link stage (7) voltage controlled of the weld can be made to motor number 1 (3) motor number 2 energy is phase and a duty rate are set (5)'s maximum output hereinafter so that inverter number 1 (4) motor number 1 using (5) .for controlling torque of. I.e., number 2 motor (5) and number 2 inverter (6) using DC-link stage (7) voltage controlled when performing a, number 1 motor (3) is number 2 motor (5)'s maximum output over to the torque to not by a rope.. The, number 1 motor (3) number 1 respect to inverter (4) torque (nm) 0 using it is desirable to control the to the driving direction and speed of, number 1 motor (3) is 0 magnitude of torque or he torque regenerating motor number 1 an annealing process is performed, for herein, the gears of the DC-link stage (7) further controlling voltage for a. should. The, one of the present invention: an embodiment also to a method of emergency drive for power is disclosed the 360degree under trillion 3, motor number 1 in one in the embodiment (3) and number 2 motor (5) electromotive force generated in DC-link stage (7) which contains, main relay (11) off operation via if mode EV is for post-facing of elevator car number 2 motor (5) by using counter electromotive force of the attempt, after EV or HEV mode the internal combustion engine, in drive state in data to the engine starting after mode number 2 motor (5) and number 2 inverter (6) controlled voltage by DC-link stage (7) high-voltage components by utilizing the power source circuit as a power source and restart, engine clutch (2) engine attached with (1) vehicle based on vehicle control information received path of limp home mode. to drive a (emergency operation mode). Eventually, in the present invention main relay (11) low voltage DC converter even off device (13) is unusual, electric oil pump (16) for driving high-voltage components such as the required power may be provided, in which, engine (1) of the vehicle which drives a primary rotation is carried out, the amount of emergency drive for power. Furthermore, low voltage DC converter device (13) by operating a low voltage (12V) battery (14) can be a light of a specific. Main relay relate of Figure 3 embodiment (11) EV vehicle is off operation via utilizing electromotive force by a compounded result is selected upon running at the engine starting vehicle through instant communion of:Zn at 10 and capable of emergency drive for power is primary characteristic lies, along number 1 motor (3) and number 1 inverter (4) using DC-link stage (7) voltage controlled during motor number 1 (3) a 0 torque control the portions of the other end of the performance voltage control in point to multi-point is formed between the base is connected to the semiconductor layer. another. While, Figure 4 shows a other embodiment of the present invention also: an emergency mode of hard type hybrid vehicle operation indicative of method of order, compared to examples of the of Figure 3 embodiment a main relay (11) off operation via EV mode if engine (1) having a selected deck, the tape is stopped when start-up of a cold because of the difference among point that no. I.e., main relay in of Figure 4 in the embodiment (11) off operation via when upon running at the EV (or the current when the unavailable state engine starting) engine (1) driving conditions of pure water so emergency operation mode is ended. Just, electromotive force power DC-link stage (7) which contains (S12 '), engine (1) if the drive the (main relay off HEV mode vehicle traveling and engine clutch and a bonding state), DC-link stage due to counter electromotive force (7) charging and inverter number 2 (6) in a state capable of controlling motor number 2 (5) and number 2 inverter (6) using DC-link stage (7) that control the voltage of the performs a voltage control (S13' , S14 '). Furthermore, DC-link stage (7), and in this case the height in control is achieved voltage DC-link stage (7) high-voltage components by utilizing the power source circuit as a power source which drives a primary process (S16 '), engine clutch (2) and a bonding state of engine (1) path of vehicle a procedure (S17'), DC-link stage (7) voltage control is achieved in number 1 motor (3) number 1 to inverter (4) 0 (zero) using a torque control and the same embodiment of Figure 3 embodiment (S15')than the examples of the thin film transistors are electrically connected to the.. Such main relay during traveling mode EV relate of Figure 4 embodiment (11) if the user does not cannot be performed but only a is the phase detection of a vehicle in the, main relay during traveling mode HEV (11) to off operation via DC-link stage (7), and in this case the height the instantaneous of vehicles through voltage control emergency operation is performed continuously. can be. Furthermore, DC-link stage even of Figure 4 in the embodiment (7) during the control voltage for a number 1 motor (3) a voltage portions of the other end of the torque control 0 is formed between the base control performance is enabled. Next, Figure 5 shows a another embodiment of the present invention also: an emergency mode of hard type hybrid vehicle order indicative of method operation, DC-link on teh voltage control emergency operation portions of the other end of the process steps can enhance the performance voltage control in the emergency operation method. mm for matching. First, main relay high voltage during the running of a vehicle (11) is turned off (S21) which determines whether the email, main relay (11) is turned off in the case normal not that serve to maintain the normal operation, main relay (11) if the user does not the emergency operation mode (limp home mode) enter emergency operation is especially embodiment. Abnormal and when entering a operation mode, engine or energy of a vehicle (1) generated by power of (MG1:3) motor number 1 and number 2 (MG2:5) motor power electromotive force of DC-link stage (7) (S22) for filling the. Furthermore, high voltage main relay off operation via engine (1) the drive-state or (i.e., the starting of an engine is which engages in said element whether) and decide an (S23), engine (1) the drive not state (main relay off EV mode vehicle traveling and engine clutch separation state), engine by using back electromotive force (1) the attempt start-up of a cold (also 5 the not shown). Wherein, using counter electromotive force in the case of failure of the engine starting, i.e. number 1 motor (3) number 2 power electromotive force of motor (5) which sufficient required engine starting in that the drive force of the actuator to control unit adds a corresponding increase value, if so, the emergency operation in a washing machine is, emergency operation mode is ended. While, main relay (11) off operation via engine (1) is driven by 1-dot inverse if being (main relay off HEV mode vehicle traveling and engine clutch and a bonding state), or said using counter electromotive force engine (1) is successful the future notification (in this case engine clutch is switched by), engine (1) by the power of motor number 2 (5), there is generated an electromotive force in, such electromotive force through regenerating a diode DC-link stage (7) can be filled. EV mode and a state of a motor vehicle with a relay main a display of the navigation apparatus (11) by preventing the production of a off, ear engine (1) a fifth procedure is to start-up of a cold engine (1) is successful the future notification, as well as when in low-speed travel mode HEV motor number 2 (5) divide the back electromotive force in power DC-link stage (7) is filled. Said process of Figure 3 in the embodiment. of thin film transistors are electrically connected as. Well as, as said EV mode during the running of a main relay (11) if the user does not engine starting attempts to space is obtained can be degraded and, EV mode of Figure 4 embodiment examples of the such as main relay when the unavailable state engine starting off or emergency operation mode allowing a request of the main relay is the power-off state (S31) HEV mode a of emergency drive for power. the method may apply configuration. Ear of Figure 5 in the embodiment to write and arrange the engine clutch (2) is in the bonded status is due to counter electromotive force in DC-link stage (7) charging and motor number 1 (3) and number 1 inverter (4) using DC-link stage (7) (S24, S25) for voltage control and embodiment, DC-link stage (7) voltage for a DC-link stage in control state (7) power source circuit as a power source of emergency drive for power vehicle based on vehicle control information received in that the (S27, S28), number 2 motor (5) to inverter number 2 using (6) 8880 000763888 0 (S25) the torque control and the same embodiment. I.e., DC-link stage (7) low voltage DC converter device (13) by utilizing the power source circuit as a power source, electric oil pump (16) such as to prevent the inflow of high-voltage components american breakdown to restart (S27), engine (1) vehicle based on vehicle control information received path of by a rope. loading rotary (S28). Wherein, when compared to examples of the of Figure 4 embodiment and also said 3, number 1 is mainly control stage voltage-link DC motor (3) and number 1 inverter (4) point, and number 2 motor to be torque control 0 (5). which differs in both point. I.e., DC-link stage (7) voltage control motor number 2 (5) regenerative energy by number 1 motor (3) by voltage controllable range to a maximum throughput device feeds a control signal to the is hereinafter the needed and, to this end number 2 motor (5) for controlling a torque of the size of the torque the number 2 motor (5) number 1 the output of the motor (5)'s maximum output over not. to the torque to. By considering same, low voltage DC converter device (13), electric oil pump (16) of emergency drive for power high-voltage components such as a drive of, and in a vehicle drive using an engine driving force and to, DC-link stage (7) voltage controlled of the weld can be made to motor number 2 (5) thereafter, the voltage control is number 1 motor (3)'s maximum output over a to the torque to not. The, number 2 motor (5) number 2 respect to inverter (6) using torque (nm) 0 it is desirable to control the to the driving direction and speed of, number 2 motor (5) is 0 magnitude of torque or he torque regenerating motor number 2 an annealing process is performed, for herein, the gears of the DC-link stage (7) further controlling voltage for a. should. In of Figure 5 in the embodiment, and a motor control stage voltage-link DC in torque control 0, voltage controlled and said 0 torque control object as modified except, also in one aspect the method thereof and 3 of thin film transistors are electrically connected when compared to examples of the of Figure 4 embodiment, voltage control process and method or the like rotating for a to omit. Furthermore, engine clutch (2) of the (S24), EV mode during the running of a main relay (11) if the user does not as engine clutch (2) if the state disconnected is, also consistent with of Figure 4 embodiment and 3, number 2 motor (5) and number 2 inverter (6) using DC-link stage voltage control and number 1 inverter (4) motor number 1 using (3) of 0 torque control (S26), and DC-link stage (7) for operating emergency mode of hard type vehicle in use for a power source for (S27 ', S28') for embodiment a Ear under oil pump (16) is driven by controlling a hydraulic state engine clutch (2) from bending and expanding, after engine clutch (2) is inserted in an integrally joined manner once number 1 motor (3) and number 1 inverter (4) using DC-link stage voltage control and number 2 inverter (6) motor number 2 using (5) of 0 torque control (S29, S30), and DC-link stage (7) in use for a power source of embodiment the emergency operation. For hybrid vehicle configuration, also 1 and 2, as shown to, number 1 motor (3) is engine clutch (2) is inserted to a engine (1) is connected to vehicle wheel (9) the power transmission side is communicably coupled to the thermal imager for vehicle drive and with the using angle by using high frequency s and, number 2 motor (5) engine (1) to for starting an engine is Kohler belt using angle by using high frequency s and a motor are formed on the second substrate, number 1 inverter (4) through (e.g. 35kW) is number 2 capacity voltage controllable inverter (6) through voltage controllable capacity is greater than (e.g., 8kW), engine clutch (2) is in the bonded status is number 1 if [...] (4) through formula 1. voltage control are powered in. By considering same, engine clutch of Figure 5 in the embodiment as described above in (2) of the, engine clutch (2) is attached if, number 1 inverter (4) using DC-link stage (7) embodiment and of voltage control, number 2 inverter (6) motor number 2 using (5) of embodiment the torque control and the same 0. While, engine clutch (2) are separated if inverter number 2 (6) using DC-link stage (7) embodiment and of voltage control, number 1 inverter (4) motor number 1 using (3) of embodiment the torque control and the same 0. At least rapidly and to reduce a memory 360degree focuses of the present invention embodiment, range rights of the present invention not limited to, next a defined in claim of the present invention basic general outline of a sugar-coated using manufacturer's various modified and improved form included range rights in addition of the present invention. 1: engine 2: engine clutch 3: number 1 motor Inverter 4: number 1 Motor 5: number 2 Inverter 6: number 2 7:DC-link stage 8: transmission 9: wheel 10: high-voltage battery 11: main relay 12: BMS 13: low voltage DC converter device 14: low voltage battery 15: compressor 16: electric oil pump The present invention relates to a method for emergently driving a hybrid electric vehicle, and more specifically, to a method for emergently driving a hybrid electric vehicle when a high voltage main relay is abnormally off during driving of the vehicle. The method for emergently driving a hybrid electric vehicle comprising: a first motor connected to an engine through an engine clutch and connected to a vehicle wheel to transfer a power; and a second motor connected to the engine to directly transfer a power, comprises: a step of charging a direct current (DC)-link end with a counter electro-motive force of the first motor and the second motor, which is generated by a driving energy of the vehicle or a power of the engine when the main relay is off during driving of the vehicle; a voltage control step of controlling a voltage of the DC-link end using a second inverter connected between the DC-link end and the second motor while the engine is driven; and a step of using the DC-link end where the voltage is controlled as a power for an emergency drive of the vehicle. In the voltage control step, the first motor is controlled by torque of 0 (zero). COPYRIGHT KIPO 2016 Engine, engine through the clutch associated with the engine, the vehicle wheel-sided and the power transmission is number 1 motor devices that are communicatively coupled, and engine directly power transmission devices that are communicatively coupled for operating emergency mode of hard type motor with a number 2 method in a hybrid vehicle in which at, , during traveling, of main relay if the user does not otherwise conveyed from the Peltier device for a vehicle wheel of a vehicle energy generated by engine power or counter electromotive force of motor number 1 generated by counter electromotive force of motor number 2 power charging at a linked end-DC; DC-link and in engine drive state, coupled between the at least one motor number 2 number 2 number 2 motor of the inverter that control the voltage of the DC-link stage a voltage control step; and voltage controlled and second conductive layer is annealed and DC-link stage the vehicle such that the mirror housing for power input for operating emergency mode of hard type includes to a decoder by, said voltage control step in the output of the motor a in the side part for draining air number 1 number 1 number 2 motor's maximum output capacity hereinafter a torque control method characterized by emergency mode of hard type hybrid vehicle operation. According to Claim 1, 0 (zero) motor number 1 in control step voltage said control signal to control the torque transmitted thereby characterized by method operation emergency mode of hard type hybrid vehicle. According to Claim 1, main relay off operation via engine or retransmission, and drive state, engine side surface or bottom surface drive state of a vehicle by energy number 2 by using back electromotive force by driving the motor forward and backward inside the front guide to characterized by further including method operation emergency mode of hard type hybrid vehicle. According to Claim 1, said DC-a linked end for operating emergency mode of hard type of cars using power in step, engine attached with washing engine clutch path of vehicle operation emergency mode of hard type hybrid vehicle characterized by the method. Claim 1 to claim 4 as described in claim one of, DC-a linked end for operating emergency mode of hard type of cars using power in step, by utilizing the power a linked end-DC high-voltage components which drives a primary method to characterized by emergency mode of hard type hybrid vehicle operation. According to Claim 5, said high-voltage components an engine clutch and transmission including oil pump motorised for forming characterized by the revision is related to the method operation emergency mode of hard type hybrid vehicle. According to Claim 1, said voltage at controlling step, voltage controller for maintaining a constant voltage from a torque command a pressure receiving part receiving said motor number 2 to is output torque according to a torque command to control the inverter number 2 characterized by method operation emergency mode of hard type hybrid vehicle. According to Claim 7, in control step voltage said number 2 inverter control torque directives DC-link on teh voltage target value DC-link on teh voltage the detected values, number 2 motor depending on a speed of rotation of that are calculated to characterized by method operation emergency mode of hard type hybrid vehicle. According to Claim 8, said voltage control step in DC-link on teh voltage detecting the DC-link on teh voltage target value smaller than the normal value for generating a torque command regenerative, the detected values on teh voltage-link DC DC-link on teh voltage target value if the reacquisition time is greater than drive torque command to being adapted to generate a high-voltage components of loading rotary characterized by method for hybrid vehicle. Engine, engine through the clutch associated with the engine, the vehicle wheel-sided and the power transmission is number 1 motor devices that are communicatively coupled, and engine directly power transmission devices that are communicatively coupled for operating emergency mode of hard type motor with a number 2 method in a hybrid vehicle in which at, , during traveling, of main relay if the user does not otherwise conveyed from the Peltier device for a vehicle wheel of a vehicle energy generated by engine power or counter electromotive force of motor number 1 generated by counter electromotive force of motor number 2 power charging at a linked end-DC; engine clutch is in the bonded status is a user selects the; engine clutch attached with washing state in engine drive state when DC-link and, coupled between the at least one motor number 1 number 1 the inverter and that control the voltage of the DC-link stage number 2 number 1 number 2 the output of the motor a in the side part for draining air motor's maximum output capacity a hereinafter controlling the torque transmitted thereby; and voltage controlled and second conductive layer is annealed and DC-link stage the vehicle such that the mirror housing for for operating emergency mode of hard type, comprising using power characterized by including to method operation emergency mode of hard type hybrid vehicle. According to Claim 10, 0 (zero) in control step voltage said number 2 motor control signal to control the torque transmitted thereby characterized by method operation emergency mode of hard type hybrid vehicle. According to Claim 10, engine clutch are separated in engine drive state when a state where the DC-link and, coupled between the at least one motor number 2 number 2 the inverter that control the voltage of the DC-link stage number 1 and the output of the motor a in the side part for draining air number 1 number 2 motor's maximum output capacity hereinafter a torque control method characterized by emergency mode of hard type hybrid vehicle operation. According to Claim 12, engine clutch with separated state voltage control step in 0 (zero) motor number 1 characterized by torque transmitted thereby control method operation emergency mode of hard type hybrid vehicle. According to Claim 12, engine clutch is in the state disconnected number 2 one body of a small earphone with DC-link stage voltage control during the power by utilizing the DC-a linked end driving the high-voltage components, engine clutch joined to a, DC-link and in and a bonding state engine clutch, coupled between the at least one motor number 1 number 1 the inverter DC-link on teh voltage control signal to control the method characterized by emergency mode of hard type hybrid vehicle operation. According to Claim 14, one body of a small earphone with said number 1 DC-link stage voltage control the output of the motor a in the side part for draining air number 2 number 2 number 1 motor's maximum output capacity hereinafter a torque control method characterized by emergency mode of hard type hybrid vehicle operation. According to Claim 15, said number 2 0 (zero) motor control signal to control the torque transmitted thereby characterized by method operation emergency mode of hard type hybrid vehicle. According to Claim 10, main relay off operation via engine or retransmission, and drive state, engine side surface or bottom surface drive state of a vehicle by energy number 2 by using back electromotive force by driving the motor forward and backward inside the front guide to characterized by further including method operation emergency mode of hard type hybrid vehicle. According to Claim 10, DC-a linked end for operating emergency mode of hard type of cars using power in step, engine clutch is in the bonded status is engine path of vehicle operation emergency mode of hard type hybrid vehicle characterized by the method. According to Claim 10, said DC-a linked end for operating emergency mode of hard type of cars using power in step, by utilizing the power a linked end-DC high-voltage components which drives a primary method to characterized by emergency mode of hard type hybrid vehicle operation. According to Claim 14 or Claim 19, said high-voltage components an engine clutch and transmission including oil pump motorised for forming characterized by the revision is related to the method operation emergency mode of hard type hybrid vehicle. Claim 10 to claim 16 as described in claim one of, said DC-link a a frequency voltage controller for maintaining a constant voltage from a torque command a pressure receiving part receiving a is output torque according to a torque command said motor to control the inverter to characterized by method operation emergency mode of hard type hybrid vehicle. According to Claim 21, said DC-link a a frequency inverter control torque directives DC-link on teh voltage target value DC-link on teh voltage the detected values, motor depending on a speed of rotation of that are calculated to characterized by method operation emergency mode of hard type hybrid vehicle. According to Claim 22, said voltage control step in DC-link on teh voltage detecting the DC-link on teh voltage target value smaller than the normal value for generating a torque command regenerative, the detected values on teh voltage-link DC DC-link on teh voltage target value if the reacquisition time is greater than drive torque command to being adapted to generate a high-voltage components of loading rotary characterized by method for hybrid vehicle.