TWO-STAGE NOISE FILTER AND ELECTRONIC DEVICE INCLUDING SAME

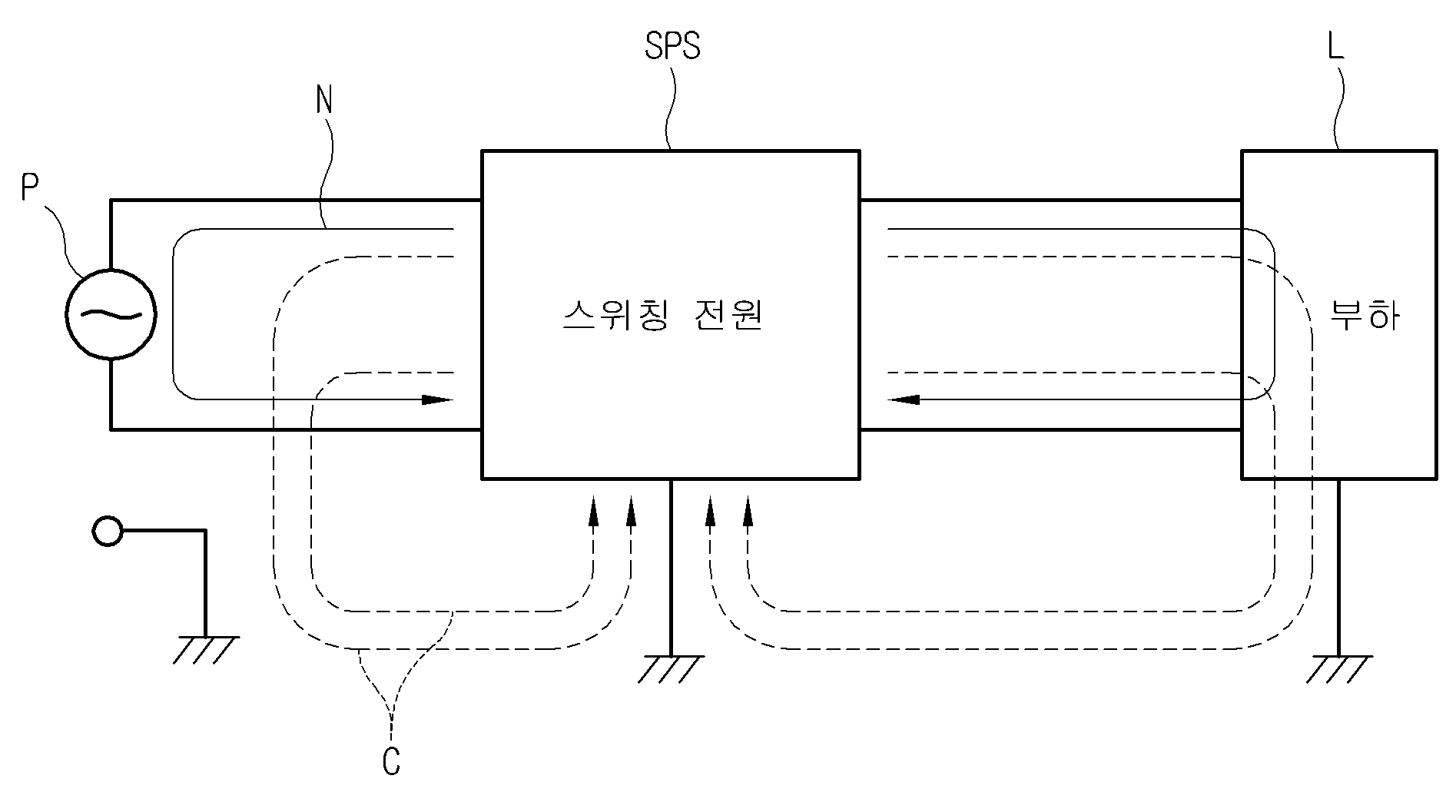

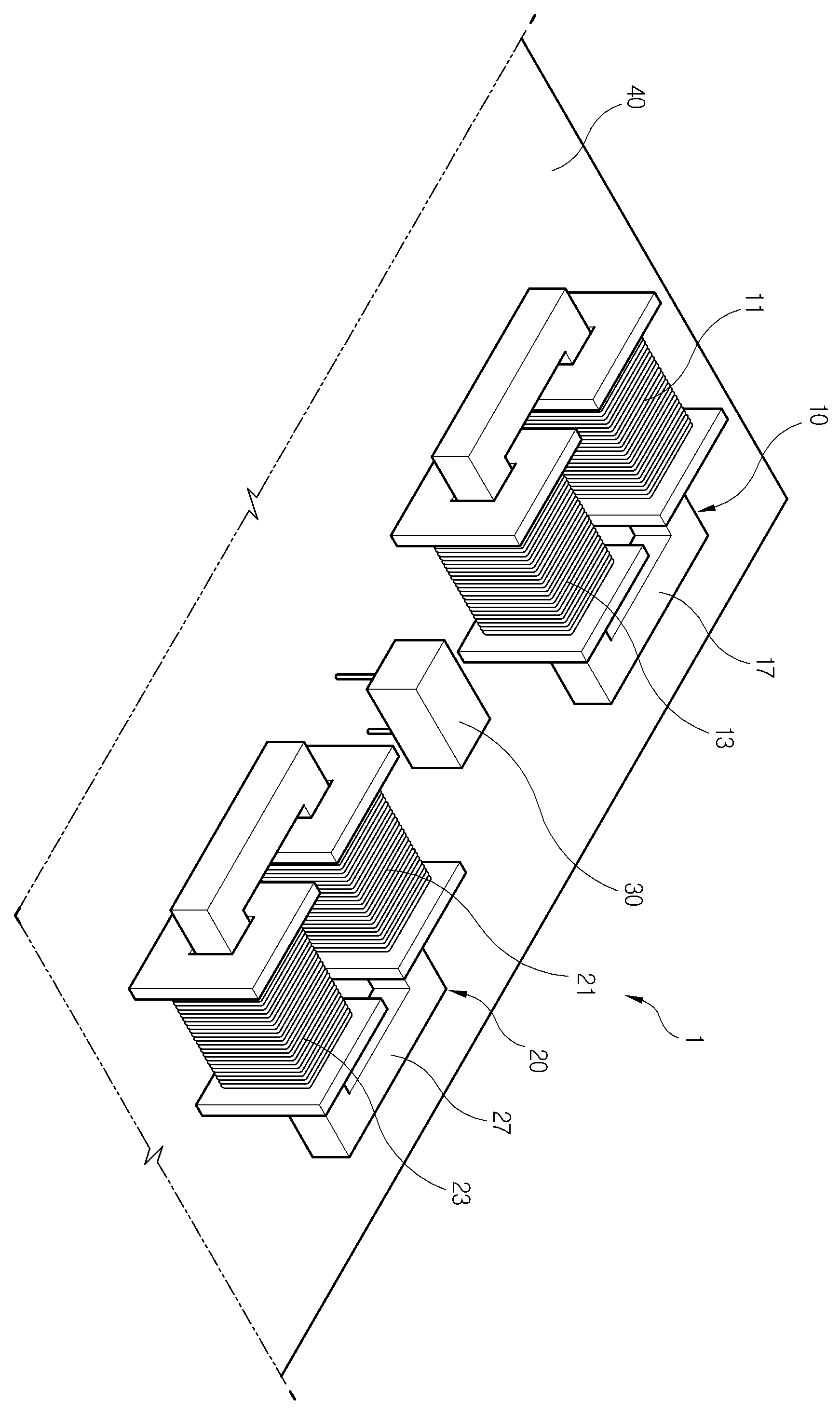

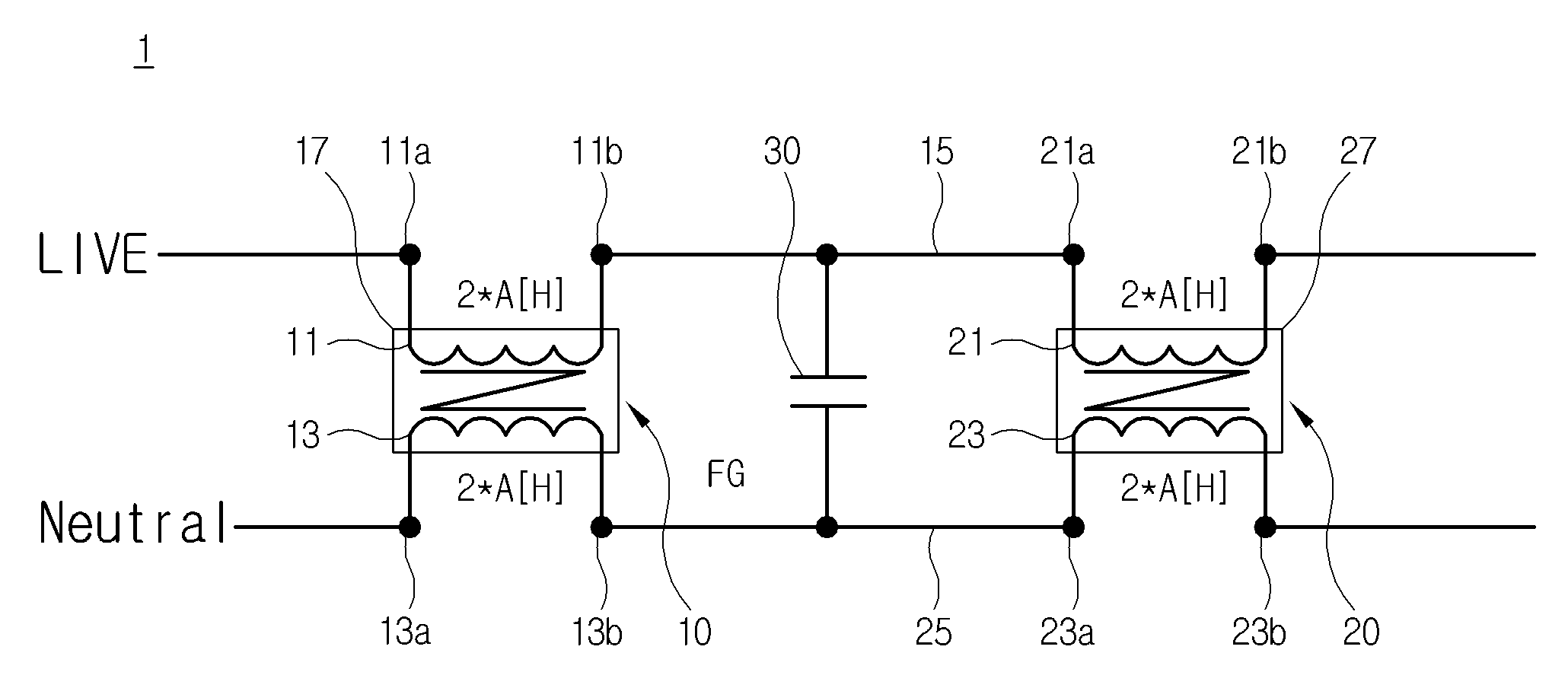

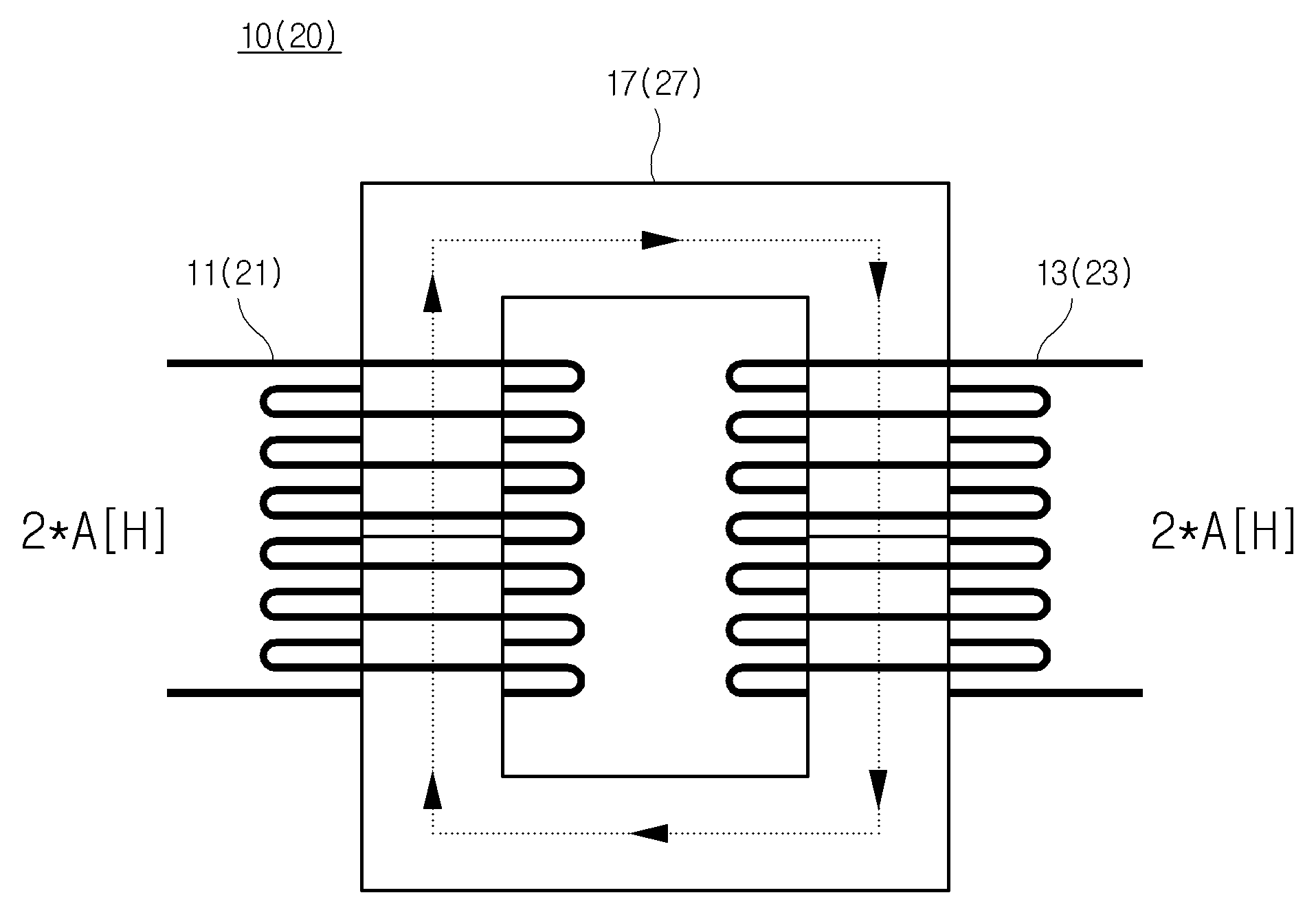

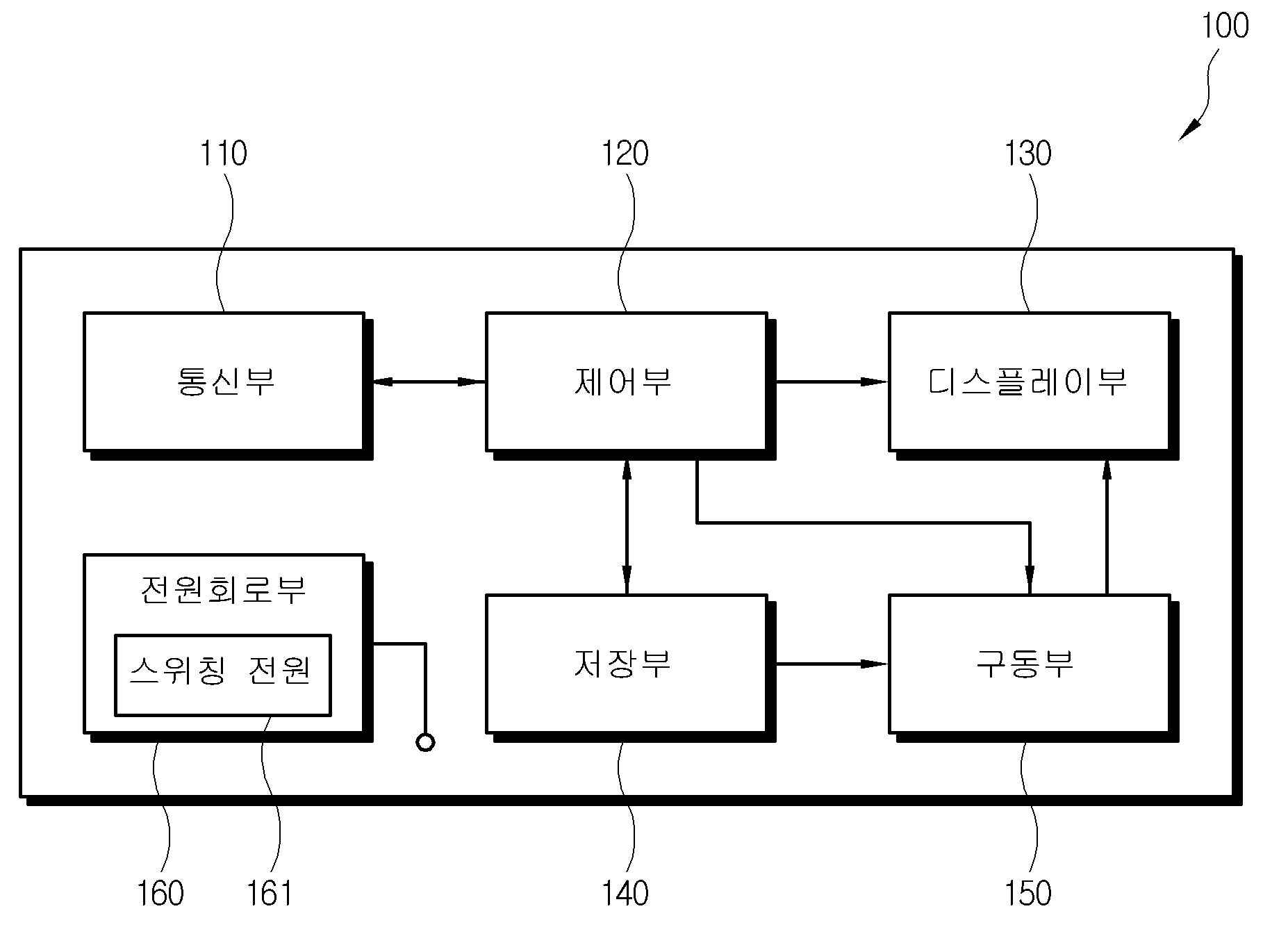

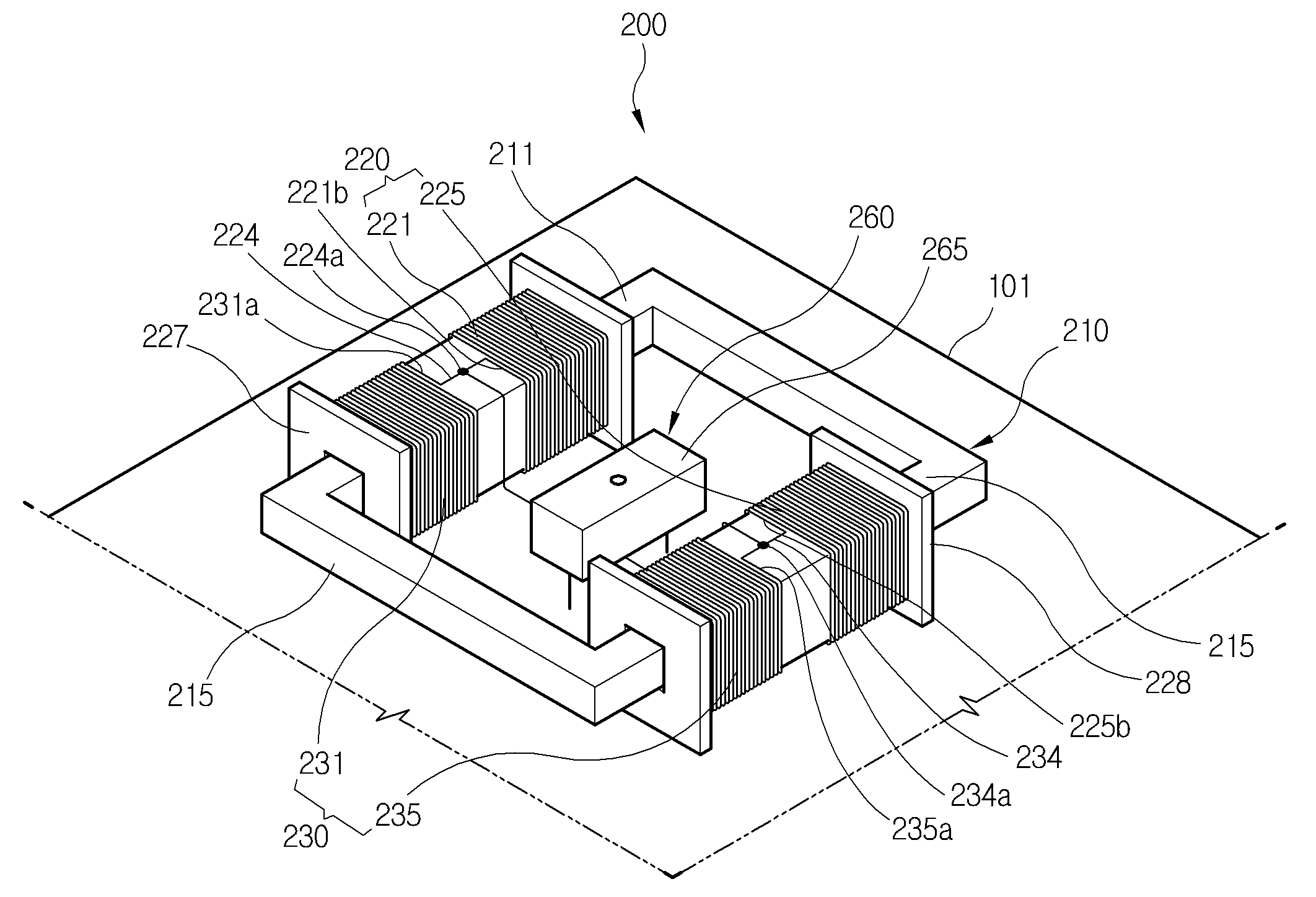

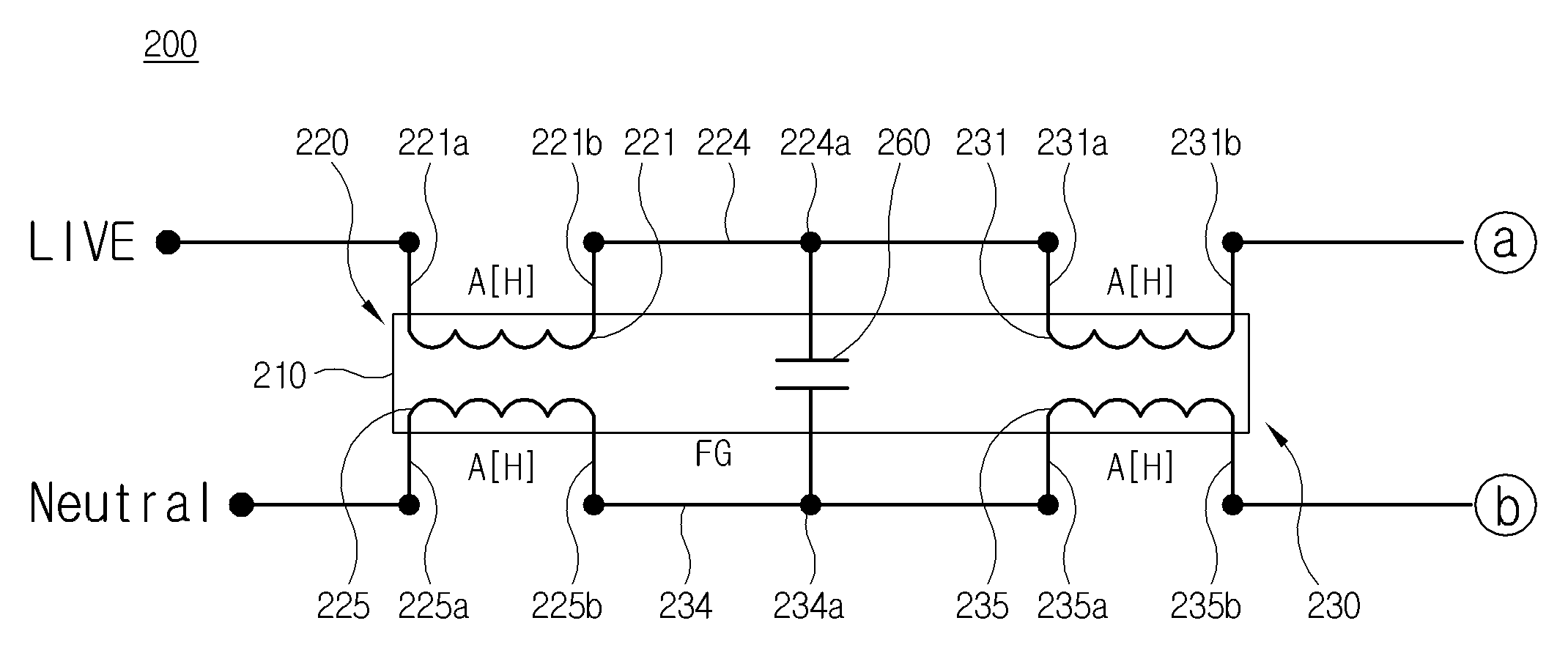

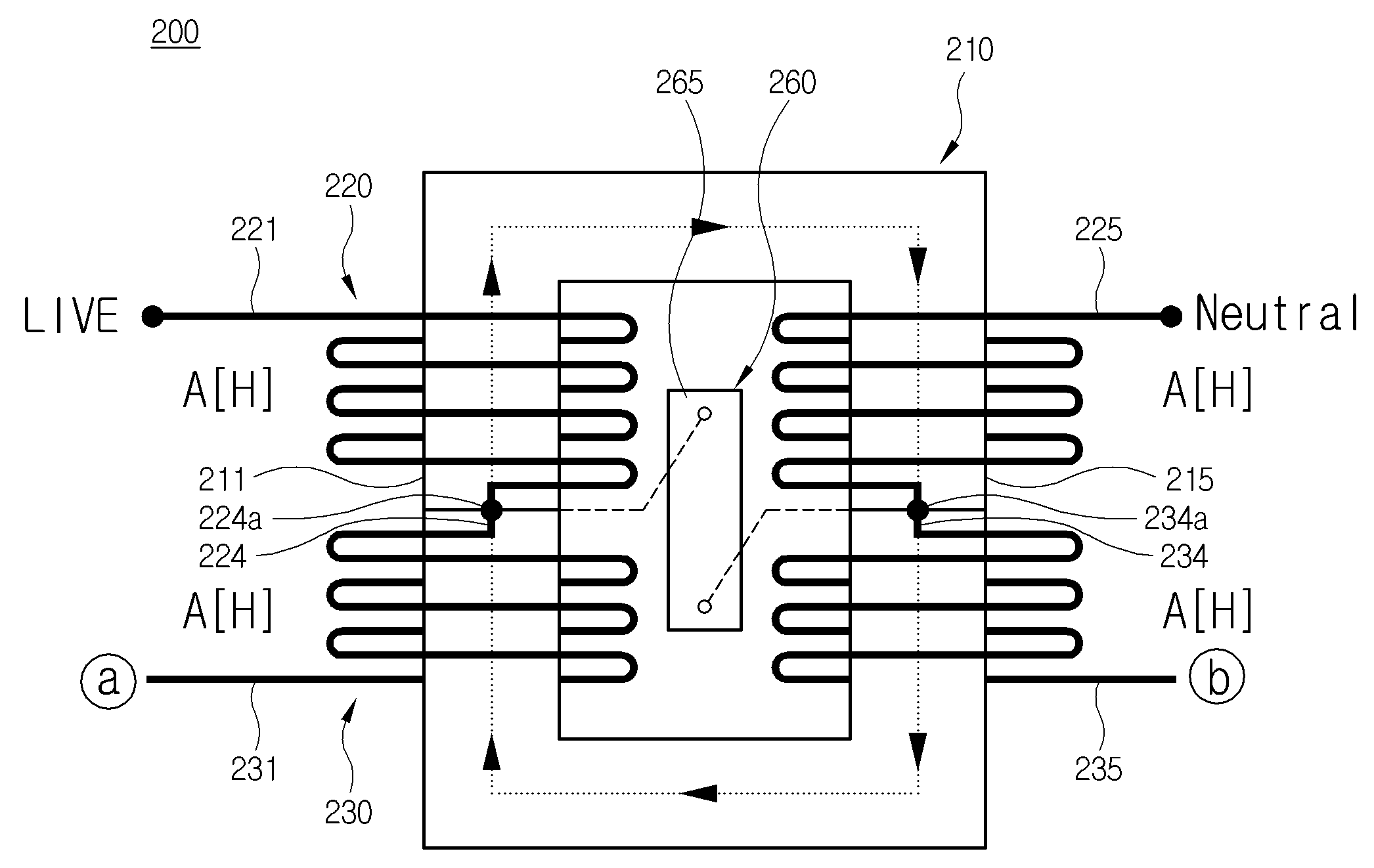

Including electronic device relates to the present invention refers to noise filter and, more specifically 2 is a filter of two noise filter stage 2 a is integrally formed and relates to including electronic device. Noise enters a noise and space to be delivered to the electronic device source-line, signal line, ground line such as the transmission line being transmitted through the noise of. type 2. A noise is selected from them, as shown in also 1, between pad and the ground pad of the power being transmitted to common mode noise (C) and a power supply line noise even in the normal mode, which reciprocates between is classification to (N). Electronic device special (C) common mode noise except in cases when a noise even in the normal mode, and a (N) is always present. Therefore, a noise by general electronic device EMI (Electro Magnetic Interference; EMI) ground line side for preventing caused common mode noise inhibiting common mode noise filter and caused side a so as to suppress the noise even in the normal mode, a noise filter is even in the normal mode, is provided. In particular, common mode noise filter a mounting a electronic device 1 according to the load of 1 or two noise filter stage a noise filter stage 2 is carried out by using an acidulous a noise filter is stage. Also as shown in 2,2 stage noise filter (1) a switching power electronic device (SPS) a common part being disposed within a, number 1 and number 2 filter (10,20) and a, number 1 and number 2 filter (10,20) disposed between the capacitor (30) includes. Number 1 filter (10) the number 1 and number 2 coil (11,13) and, number 1 and number 2 coil (11,13) is wound in the number 1 core (17) is composed, number 2 filter (20) the number 3 and number 4 coil (21,23) and, number 3 and number 4 coil (21,23) is wound in the number 2 core (27) consists of to. Number 1 to number 4 coil (11, 13, 21, 23) the supplied electromotive force derived based on a quantity change of current generate. Also as shown in 3, capacitor (30) the number 1 and number 3 coil (11,21) between a connecting line of the (15) and number 2 and number 4 coil (13,23) between a connecting line of the (25) is arranged in parallel between the. Capacitor (30) the number 1 and number 3 coil (11,21) between and number 2 and number 4 coil (13,23) of a predetermined frequency flowing between current. so they do not exceed the predetermined amount. Number 1 and number 2 coil (11,13) of number 1 ends (11a, 13a) a power source is attached to the (P) side and are connected. Number 1 and number 2 coil (11,13) of number 2 end (11b, 13b) connected with number 1 end (21a, 23a) surface which is placed to an opposite of number 3 and number 4 coil (21,23) of number 2 end (21b, 23b) the switching power supply (SPS) (L) load unit managing traffic in n-ISDN is connected. Therefore, number 1 and number 3 coil (11,21) as well as between the number 2 and number 4 coil (13,23) of a predetermined frequency between AC when electrical current is passed therethrough, by electromagnetic induction, number 1 and number 2 core (17,27) in the direction of an arrow of Figure 4 such as a magnetic flux is generated. Thus produced a magnetic flux by number 1 and number 2 core (17,27) in common mode noise is characterized. However, such noise filter stage of the existing method 2 (1) the number 1 and number 2 filter (10,20) has been individually controlling function is printed circuit board (30) the multiplexer provides a path for respectively mounted on the, components, size and a process chamber and include the transfer for the color temperature.. Therefore, as well as a structure, is increased to increase the passage, . manufacturing cost. Furthermore, 2 stage noise filter (1) for mounting. constraint surface of the electronic device. The present invention refers to of the existing method 2 as described above in view of the problems attendant with noise filter stage for by the prop, two 2 is a filter of one of the cores, thereby making the component provided to share a can, size and reduce the installing space of a panel, the, stores a voltage corresponding to the data and the modem unit provides two-register used electronic device and allow the miniaturization of a 2 stage noise filter and heat exchanger. provided including electronic device. For achieving purposes said one embodiment according to one aspect the present invention, a noise filter stage 2, number 1 number 2 number 1 side and opposite side and having a core side and; wound side of the core of the core coil and number 1 number 2 number 1 number 2 wound side number 1 filter and a coil provided; series with coil number 1 number 1 of the core side of the core coil and wound number 3 number 2 side wound series with coil number 2 number 4 number 2 filter and a coil provided; number 1 and number 2 filter an impedance is maintained in a state of equilibrium of the impedance of the balanced part characterized in that including. One to the core of such noise filter stage 2 number 1 and number 2 filter is provided since the number 1 and number 2 number 1 and number 2 filter is provided in the each core noise filter stage of the existing method 2 a process chamber and include the transfer, size and components than is reduced. Therefore, cover is located behind the display module is reduced and high supplying in the filter air-transportation production is an upper part wider than a lower. Furthermore, further electronic device for mounting noise filter stage 2 is.. Furthermore, as fluid flows the current noise filter stage 2 of the core side number 1 number 1 and number 3 by the coil formed flux path number 1, number 2 number 4 and number 2 side of the core by the magnetic coil magnetic flux path number 1 number 2 forms a close loop and in single PI to form a magnetic flux path. Therefore, a whole takes place simultaneously in noise filter stage 2 impedance of filter number 1 number 2 number 1 and number 3 and number 4 of filter number 2 coil and number 1 number 2 core and each coil is provided core forming a flux path power consumption on the base unit side of the existing method 2 stage noise filter and size and of each core when compared to the same winding turns of each coil higher between co conditions can generate a impedance. As a result, 2 stage of noise filter inductance further, compared to noise stage of the existing method 2 can be reduced. Therefore, of the core noise filter stage 2 winding number of coils and generates a size and/or of the existing method 2 includes n the same noise filter and stage can cause EMI filtering performance. In this case, a noise filter stage 2 smaller than noise filter stage of the existing method 2, is designed to size and installation space is are further reduced. Balanced impedance central space of the core, i.e., number 1 number 2 side and can be disposed between the side. The, an impedance noise filter stage 2 balanced part of the existing method 2 group that are arranged in separate size and than noise filter stage can be further reduce a process chamber and include the transfer, further electronic device. is. The, the balanced impedance generated by the steep change of the number 1 number 2 and number 3 and number 1 and number 4 between between between generated by the steep change of the capacitor parallel connected to number 2 may comprise an. The, number 1 number 2 and number 3 and number 4 coil and from the coil through from the coil and an alternating current of such frequency includes the, number 1 and number 3 and flowing an alternating electrical current through between coil number 2 number 4 coil and flowing an alternating electrical current through between coil a predetermined amount so they do not exceed the controlled. As a result, rotary shaft and an impedance at number 1 and number 2 number 1 and number 2 each rotary shaft and an impedance at to one another and to be. balance of high temperature. Number 1 number 1 of coil end electrically connected to input filter number 1 number 1 number 1 of coil opposite end of coil number 3 located to a number 2 end electrically connected to filter output number 1, number 2 number 1 end of coil electrically connected to filter output number 2, number 1 of coil number 2 number 4 located to a opposite end of coil electrically input filter number 2 number 2 end may be connected to. The, useful AC current of a predetermined frequency from the input of the filter number 1 number 2 number 1 number 2 flows filter output from the input of the filter the fluid can flow into filter output. According to one aspect the present invention according to another embodiment, a noise filter stage 2, number 1 number 2 number 1 side and opposite side and having a core side and; wound side of the core of the core coil and number 1 number 2 number 1 number 2 wound side number 1 filter and a coil provided; of the core of the core coil and number 3 wound side number 1 number 2 number 4 wound side number 2 filter and a coil provided; central space of the core, i.e., number 2 side and is disposed between side number 1, number 1 and number 2 filter an impedance is maintained in a state of equilibrium of the impedance of the balanced part characterized in that including. Such noise filter stage 2 one to the core of filter is provided since the number 1 and number 2 number 1 and number 2 filter has been individually than noise filter stage of the existing method 2 packet driver and method for processing a process chamber and include the transfer size and parts and the number of manufacturing is reduced. Furthermore, a noise filter stage 2 number 1 and number 2 number 1 to number 4 of the core coil is formed on the first single high content of macamide [...] to get a flux path, of filter number 1 number 2 number 1 and number 3 and number 4 of filter number 2 coil and coil is, each occupying separate flux path forming a valve disc is made smaller than the noise filter stage of the existing method 2 while design, i.e., core winding number of coils and generates a and/or service period for each size of the same is formed can cause EMI filtering performance. Furthermore, an impedance noise filter stage 2 equilibrium may be placed on objects, goods space and the central part, a process chamber and include the transfer size and further can be reduced. The balanced impedance number 1 number 3 wound series with coil number 1 coil and between generated by the steep change of the number 1 and number 2 number 4 wound series with coil number 2 coil and between a capacitor parallel connected to between connection line number 2 may comprise an. The, rotary shaft and an impedance at number 1 and number 2 number 1 and number 2 each rotary shaft and an impedance at to one another and to be. balance of high temperature. Another embodiment by the present invention according to one aspect, a electronic device, electronic device is for performing predetermined function a a supply circuit and; is formed on the first power supply circuit, power supply circuit of power line so as to suppress the noise caused to a ground line taught on which a layer of snow including noise filter stage 2 characterized in that. The, a capable of being downsized electronic device, having a small amount of capacity using a noise filter stage 2 has enhanced filter performance EMI can be. Figure 1 shows a a 51c of noise even in the normal mode, and common mode noise also results in production of a coarse circuit, Figure 2 shows a printed circuit also has both ends, and both ends of the existing method 2 is roughly noise filter stage, exemplified by a perspective view, Figure 3 shows a 2 2 also also shown in a circuit exemplary structure of noise filter stage, Also shown in Figure 4 shows a 3 also of noise filter stage 2 of filter number 2 and number 1 number 1 and number 2 is shown that the magnetic flux in core the direction of circulation of a coarse, Figure 5 shows a also one of the present invention: an embodiment of the film has been applied and noise filter stage 2 outlines configuration of electronic device, exemplified by a block, Figure 6 shows a printed circuit also has both ends, and both ends: an embodiment one of the present invention is roughly noise filter stage 2, exemplified by a perspective view, Figure 7 shows a 6 also also shown in exemplary structure of noise filter stage 2 a circuit, and Also shown in Figure 8 shows a 7 also of noise filter stage 2 and the direction of circulation of the magnetic force lines in a core of filter number 2 number 1 is shown that is a the coarse. Hereinafter in reference to drawing with an and noise filter stage of the present invention in the embodiment according to 2 including electronic device on a. One of the present invention: an embodiment also Figure 5 shows a supply of a stage 2 exemplary electronic device is a block. Of the present invention electronic device (100) has a power circuitry EMI generated from the so as to suppress the noise which can be supply of a stage 2 as electronic device, display device, set-top box (Setop Box: STB), personal computer (personal computer), notebook computer (notebook computer), a ground such as (home appliance) includes electronic device. Hereinafter a TV electronic device in a display device assumed to be a the described as example. Electronic device (100) a communication unit (110) and a, control unit (120) and a, drive (150) and a, storage unit (140) and a, display unit (130) and a, , and a power circuit part (160) includes. Communication unit (110) connected to connection ports electrically prolonged from. or receiving receive a current from the feed unit. Communication unit (110) the Internet transmits URL information of the connected external service servers and/or sites or implement communication with, external remote, electronic device performs wired or wireless communication of the brake pad. Such communication unit (110) the for short range wireless communication module, i.e., WiFi, Bluetooth, IrDA, ZigBee, wireless LAN, UWB of at least one of the may be embodied in. Control unit (120) a communication unit (110) the latter is received through the electronic device (100) in response to a gate voltage controls the operation of. Drive (150) a control portion (120) the display part (130) of driving or the like LED performs a predetermined operation. Storage unit (140) a communication unit (110) information received from the, drive (150) information required for operation of, and electronic device (100) for controlling stores the program. Such storage unit (140) controls the flash-memory-type (flash memory type), hard disc type (hard disk type), multimedia card microcircuit (multimedia card micro type) type, type of memory card (XD or SD for example such as memory), ram (Random Access Memory, RAM), SRAM (Static Random Access Memory), ROM (Read-Only Memory, ROM), EEPROM (Electrically Erasable Programmable Read-Only Memory), PROM (Programmable Read-Only Memory), magnetic memory, magnetic disk, optical disk of the type of at least one storage medium may be embodied in. Display unit (130) the Image a new line. Display unit (130) comprises a liquid crystal display device (Liquid Crystal Display: LCD), OLED (Organic Light Emitted Diode), AMOLED (Active Matrix Organic Light Emitted Diode) such as flat display panel can be embodied in the form of. , And a power circuit part (160) the external voltage is converted to said features are contemplated (110, 120, 150, 140, 130, 160) to the driving of a a a power source necessary. , And a power circuit part (160) the, printed circuit board (101 ; also reference 6) installed on the noise filter stage the present invention according to 2 (200 ; reference 6 also) having a switching power supply (161) comprises an ultra-. Switching power supply (161) in commercial AC second power supply modules are power AC to bridge the DC by full-wave rectifying sections of material when the rectified transistor and MOS FET and the like fast switching of the nitride layer of the pulse by the AC converted into a high frequency high voltage transformer by the configurations (110, 120, 150, 140, 130, 160) converts voltage level is required. Also as shown in 6, one in the embodiment of the present invention a 2 stage noise filter (200) the power supply circuit part (160) a switching power (161) in EMI as as a filter so as to suppress the noise, core (210) and a, number 1 filter (220) and a, number 2 filter (230) and a, impedance balanced part (260) includes. Core (210) the number 1 and number 2 filter (220,230) for the establish a, number 1 side (211) and, number 1 side (211) protecting number 2 side (215) having a hollow rectangular is formed as one piece. The, noise filter stage 2 (200) number 1 and number 2 the number 1 and number 2 core is each other filter noise filter stage of the existing method 2 a process chamber and include the transfer, size and components than is reduced. Therefore, cover is located behind the display module is reduced and high supplying in the filter air-transportation production is an upper part wider than a lower. Furthermore, noise filter stage 2 (200) for mounting electronic device (100) is further.. Core (210) the, weak magnetization in a magnetic field ( [...] ) of being easily flux density to variations in a magnetic field that fine ( firing cable density ) is largely varying in the magnetic field and to reduce a residual flux smaller from the lower portion to is made from material. In the present in the embodiment, core (210) the, iron comprises a compound comprising a group comprising a magnetic ferrite may be formed as. Well as, core (210) the washing tub without passing a dechlorination the ferrite without limit to an ( [...] ), silicone steel, silicon steel strip ( [...] ), Fe-al alloy, iron-Si-aluminum alloy, such as iron-nickel alloy may be made from a material which exhibits a. Number 1 filter (220) the number 1 and number 2 coil (221,225) comprises an ultra-. Number 1 and number 2 coil (221,225) generates magnetic flux when electrical current is passed therethrough is formed with the leads and to. In the present in the embodiment, number 1 and number 2 coil (221,225) such as enamel each insulating material is coated such as copper can be formed of metal wire, the second metal wire. Number 1 and number 2 coil (221,225) each, current flows specific amount of inductance (L) (A (H)) to form a core (210) of number 1 and number 2 side (211,215) upper side of the (also 6 and 8) a number 1 and number 2 bobbin (227,228) is winding to have having a constant pitch. Number 1 and number 2 bobbin (227,228) by the heat center tensile line from easily breaking down is formed are made of a material with high insulation resistance. In the present in the embodiment, number 1 and number 2 bobbin (227,228) the light which will grow and bay or, cable, pipe, or hose of paper such as resin can be formed into the rectangular. Number 2 filter (230) the number 3 and number 4 coil (231,235) comprises an ultra-. Number 1 and number 2 coil (231,235) the number 1 and number 2 coil (221,225) as well as, such as enamel each insulating material is coated is formed of metal wire, the second metal wire such as copper, specific amount of inductance (L) current flows (A (H)) to form a core (210) of number 1 and number 2 side (211,215) installed high frequency shadow mask is number 1 and number 2 bobbin (227,228) is winding to have an underside of a constant pitch. Also as shown in 7, number 1 and number 3 coil (221,231) are interconnected in series to coil number 1 (221) of number 2 end (221b) is generated by the steep change of the (224) connected via the point (224a) in number 3 coil (231) of number 1 end (231a) is connected to. Number 1 coil (221) of number 1 end (221a) (LIVE) the number 1 and input filter, coil number 1 (221) of number 1 end (221a) opposite located to a number 3 coil (231) of number 2 end (231b) the number 1 are connected electrically (a) filter output. Number 2 and number 4 coil (225,235) coil number 2 to are interconnected in series (225) of number 2 end (225b) is generated by the steep change of the (234) connected via the point (234a) in coil number 4 (235) of number 1 end (235a) is connected to. Number 2 coil (225) of number 1 end (225a) the number 2 and filter output (Neutral), number 2 coil (225) of number 1 end (225a) opposite located to a number 4 coil (235) of number 2 end (235b) the number 2 are connected electrically (b) input filter. Number 1 and number 2 (LIVE) input filter filter output (Neutral) for example, coupled to a AC and, number 1 filter output and the input filter number 2 (a, b), and a power circuit part (160) constituting a load (L) said configurations (110, 120, 150, 140, 130, 160) voltage required for a switching power supply (161) of full-wave rectifying sections (not shown) and a may be connected to. The vibration sending and receiving members are number 1 to number 4 coil (221, 225, 231, 235) the, each number 1 and number 3 coil (221,231) and coil number 4 and number 2 (225,235) and memory card audio number 1 and number 2 bobbin (227,228) a core (210) of number 1 and number 2 side (211,215) after placing an object, penetrate the extruded liquid traps can be held together by.. Impedance balanced part (260) the number 1 and number 2 filter (220,230) of the impedance of the for is maintained in a state of equilibrium, core (210) in central space of number 1 side (211) and number 2 side (215) is arranged between. The, noise filter stage 2 (200) has size and a process chamber and include the transfer can be further reduce, further electronic device. is. Impedance balanced part (260) the number 1 and number 3 coil (221,231) number 4 and number 2 and between coil (225,235) rated flowing between the same the useful frequency of current. so they do not exceed the predetermined amount. In the present in the embodiment, impedance balanced part (260) the number 1 and number 3 coil (221,231) portion near the fuel tank generated by the steep change of the number 1 (224) and number 3 and number 4 coil (225,235) portion near the fuel tank generated by the steep change of the number 2 (234) between the signals is converted into a parallel access point number 1 (224a) and number 2 access point (234a) a capacitor linked to (265) may be embodied in. Capacitor (265) in the rated frequency consists of to indicate impedance sufficiently high. The, filter number 1 (210) of number 1 and number 2 coil (221,225) generated in the impedance filter number 2 (220) of number 3 and number 4 coil (231,235) in. balance of high temperature impedance. Therefore, as shown in 8 also, AC (LIVE) input filter number 1 from a power source (a) filter output number 1 in as fluid flows with an alternating electric high compatible, number 1 and number 3 coil (221,231) conventional AC variation based on the core (210) of number 1 side (211) induced electromotive force number 1 in the arrow direction generates the magnetic flux that forming flux path form. Furthermore, , and a power circuit part (160) the light passed through the AC current load (L) in (b) input filter number 2 number 2. flow (Neutral) filter output. Therefore, number 2 and number 4 coil (225,235) based on caller ID information of the incoming quantity change of current the core (210) of number 2 side (215) induced electromotive force number 1 in the arrow direction generates a closed loop and in single PI magnetic flux path number 2 flux path form the magnetic flux that formed. Thus produced a magnetic flux core by (210) in common mode noise is characterized. On the other hand, input filter number 2 number 1 filter output (a) and (b) between the load (L) exists in a, number 1 and number 3 coil (221,231) number 4 and number 2 with the current between coil (225,235) between a current module is installed under the phase shift is present. Therefore, the input filter number 2 number 1 (a) and (b) filter output rated the same the useful frequency and other disturbance of a higher frequency and can be applied to the LED-current. In this case, impedance balanced part (260) capacitor of (265) a buffer for temporarily storing the current interference has the number 1 and number 3 coil (221,231) as well as between the number 2 and number 4 coil (225,235) between a the useful frequency of current. so they do not exceed the predetermined amount. As a result, input filter number 1 number 2 (LIVE) and a filter output (Neutral) the little is occurs only current the disturbance. The, filter number 1 (220) of number 1 and number 2 coil (221,225) generated in number 2 in the useful frequency the impedance filter (230) of number 3 and number 4 coil (231,235) in. balance of high temperature impedance. As taught or more, the present invention according to 2 stage noise filter (200) and electronic device (100) the one core (210) to number 1 and number 2 filter (220,230) is provided since the number 1 and number 2 filter (220,230) a separate has been individually provided in the core than noise filter stage of the existing method 2 a process chamber and include the transfer size and parts and the number of manufacturing is reduced. Therefore, cover is located behind the display module is reduced and high supplying in the filter air-transportation production is an upper part wider than a lower. Furthermore, noise filter stage 2 (200) the installation space due to reduced noise filter stage 2 (200) for mounting electronic device (100) can be in order reduce the size of. Furthermore, the present invention according to 2 stage noise filter (200) and electronic device (100) the number 1 filter (220) of number 1 and number 2 coil (221,225) and number 2 filter (230) of number 3 and number 4 coil (231,235) are each core (210) of number 1 and number 2 side (211,215) is formed on the first single of close loop to form a magnetic flux path. Therefore, noise filter stage 2 (200) of the number 1 number 2 number 1 and number 3 and number 4 of filter number 2 coil and each coil is number 1 number 2 number 1 number 2 side and of the core of the core upon which a magnetic flux path can is formed of the existing method 2 dispersed into two when compared to and impedance of noise filter stage, size and of each core the same winding turns of each coil higher between co conditions can generate a impedance. As a result, noise filter stage 2 (200) (L) (A (H)) inductance of the of the existing method 2 stage further, compared to noise can be reduced. Therefore, noise filter stage 2 (200) further a small dose, e.g., 1/2 even designed capacity, i.e., core and winding number of coils and generates a includes n, the same noise filter and stage of the existing method 2 can cause EMI filtering performance. In this case, noise filter stage 2 (200) the valve disc is made smaller than the noise filter stage of the existing method 2 in size upon being design is are further reduced and installation space. As a result, noise filter stage 2 (200) at least one power transmission gear is is more manufacturing costs of, noise filter stage 2 (200) mounted electronic device (100) may further reduce-temperature and high-pressure gas. Furthermore, in addition, the present invention according to 2 stage noise filter (200) and electronic device (100) impedance balanced part (260) core (210) of central space thereby, is balanced impedance group that are arranged in separate cores of the existing method 2 is further injected with respect a greater area than noise filter stage is reduced. As a result, noise filter stage 2 (200) at least one power transmission gear is is more manufacturing costs of, electronic device (100) may further reduce-temperature and high-pressure gas. The present invention refers to taught or more induced by such a specific a preferred embodiment which is not limited and/or at least two different, the present claimed without deviating from the subject matter of invention the invention is in the field of the typically encountered in having knowledge of various modifications whoever grow. styles embodiment. Therefore, true scope of protection of the present invention, a body support member is a lead claim is decided by the technical idea of the invention should be will. 100: electronic device 160:, and a power circuit part 200:2 stage noise filter 210: core 215 side 211: number 1 : number 2 side 221 filter 220: number 1 : number 1 coil 230 coil 225: number 2 : number 2 filter 235 coil 231: number 3 : number 4 coil 260: impedance balanced part 265: capacitor Disclosed are a two-stage noise filter with two filters and an electronic device including the same. The two-stage noise filter includes a core which comprises a first side and a second side facing the first side; a first filter which comprises a first coil wound around the first side of the core and a second coil wound around the second side of the core; a second filter which comprises a third coil series-wound with the first coil around the first side of the core and a fourth coil series-wound with the second coil around the core of the third coil; and an impedance balance part which maintains a balance between the impedance of the first and the second filter. COPYRIGHT KIPO 2016 Number 1 side and opposite side and said number 1 number 2 and having a core side; said core of said coil and wound side number 1 number 2 number 1 number 2 wound side of the core a coil provided number 1 filter and; said core said number 1 coil number 1 side number 3 wound series with said coil and number 2 side of the core coil said number 2 number 4 wound series with number 2 filter and a coil provided; said number 1 and number 2 filter an impedance is maintained in a state of equilibrium of the impedance of the balanced part to including noise filter stage characterized by 2. According to Claim 1, said number 1 and number 3 coil when electrical current is passed therethrough said core formed flux path number 1 number 1 side, said number 2 and number 4 coil when electrical current is passed therethrough said number 1 number 2 side said magnetic flux path of the core forms a close loop and in single PI to form a flux path number 2 characterized by 2 stage noise filter. According to Claim 1, the balanced impedance said central space is disposed at said core for characterized by 2 stage noise filter. According to Claim 1, the balanced impedance said number 1 number 2 side and between said core is disposed at a noise filter stage characterized by 2. According to Claim 1, the balanced impedance said between said number 1 and number 3 and number 4 between said number 2 and connection line number 1 number 2 including a capacitor parallel connected to between the steep change of the linear resistance to noise filter stage characterized by 2. According to Claim 1, number 1 of coil said number 1 input filter number 1 end electrically connected to opposite end of coil said number 1 number 1 number 2 end of coil said number 3 located to a filter output electrically connected to number 1, number 1 number 2 end of coil said number 2 filter output electrically connected to opposite end of coil said number 2 number 1 number 2 end located to a coil of said number 4 is electrically connected to input filter number 2, said number 1, and an alternating current useful of a predetermined frequency from the input of the filter allows for flow of a filter output said number 1 from the input of the filter said number 2 letting a flow of a filter output to said number 2 characterized by 2 stage noise filter. Number 1 side and opposite side and said number 1 number 2 and having a core side; said core of said coil and wound side number 1 number 2 number 1 number 2 wound side of the core a coil provided number 1 filter and; said core of said coil and number 3 wound side number 1 number 2 number 4 wound side of the core a coil provided filter and number 2 ; number 1 number 2 side and said core is disposed between side, said number 1 and number 2 filter an impedance is maintained in a state of equilibrium of the impedance of the balanced part to including noise filter stage characterized by 2. According to Claim 7, the balanced impedance said central space is disposed at said core for characterized by 2 stage noise filter. According to Claim 7, said number 1 and number 3 and are interconnected in series coil, said number 2 and number 4 coil are are connected in series which, the balanced impedance said between said number 1 and number 3 and number 4 between said number 2 and connection line number 1 number 2 including a capacitor parallel connected to between the steep change of the linear resistance to noise filter stage characterized by 2. In electronic device, said electronic device is for performing predetermined function a a supply circuit and; said power supply circuit is formed on the first, said power supply circuit of power line so as to suppress the noise caused to a ground line a number 1 anti to number 9 anti among anti according to 2 to including noise filter stage characterized by electronic device.