STRUCTURE TO REPAIR LOST PART OF CONCRETE STRUCTURE AND METHOD TO REPAIR LOST PART USING SAME

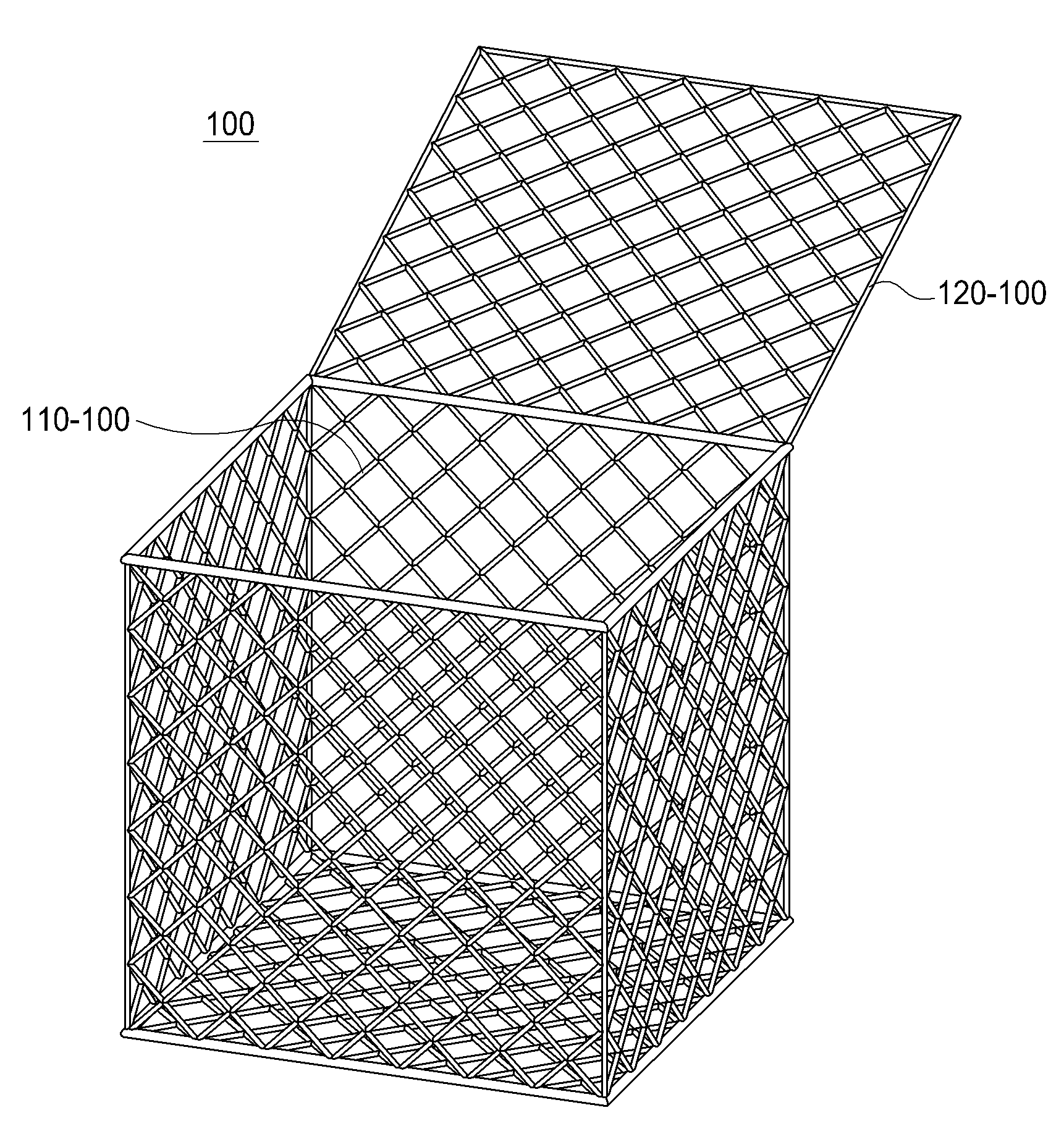

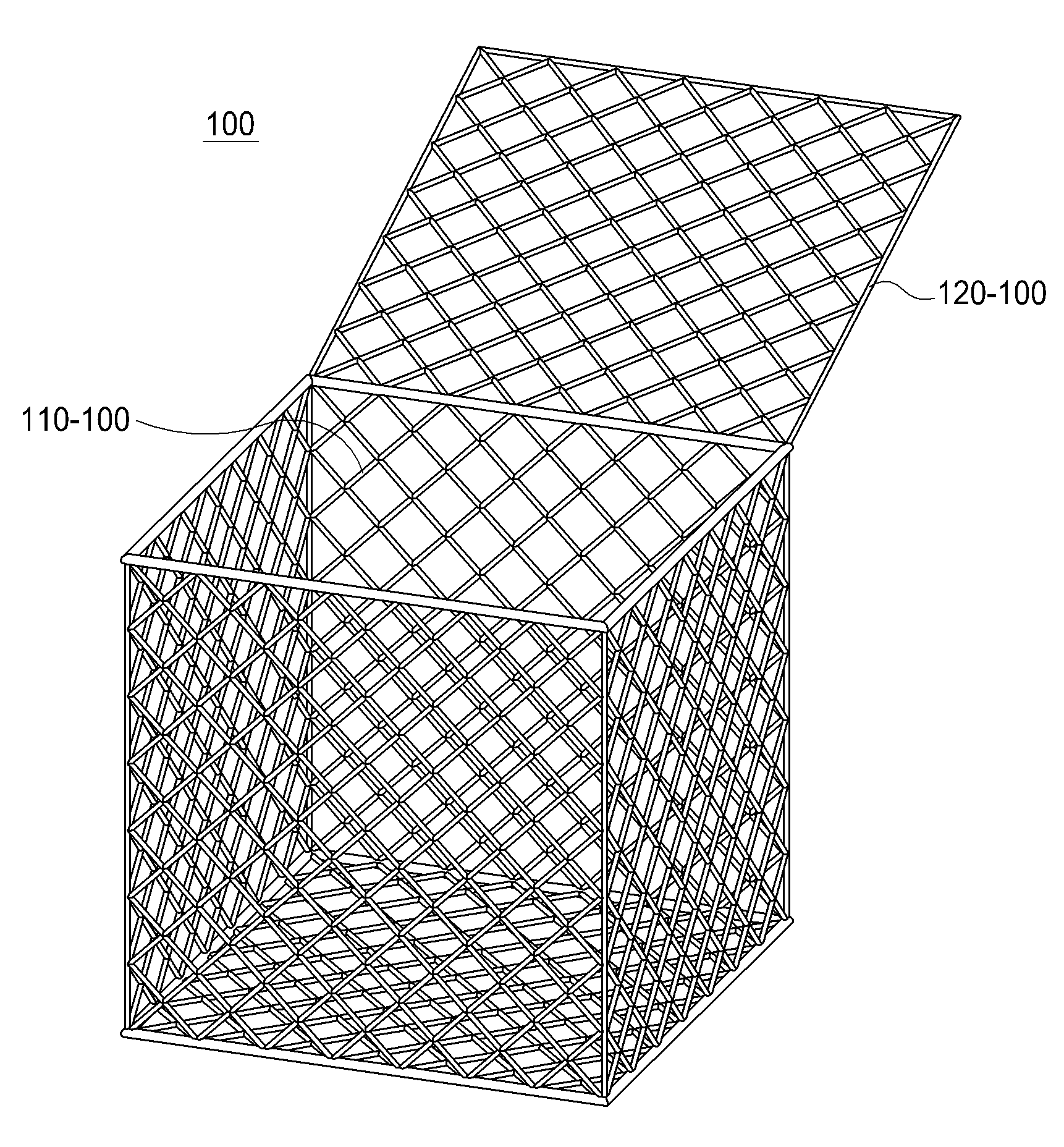

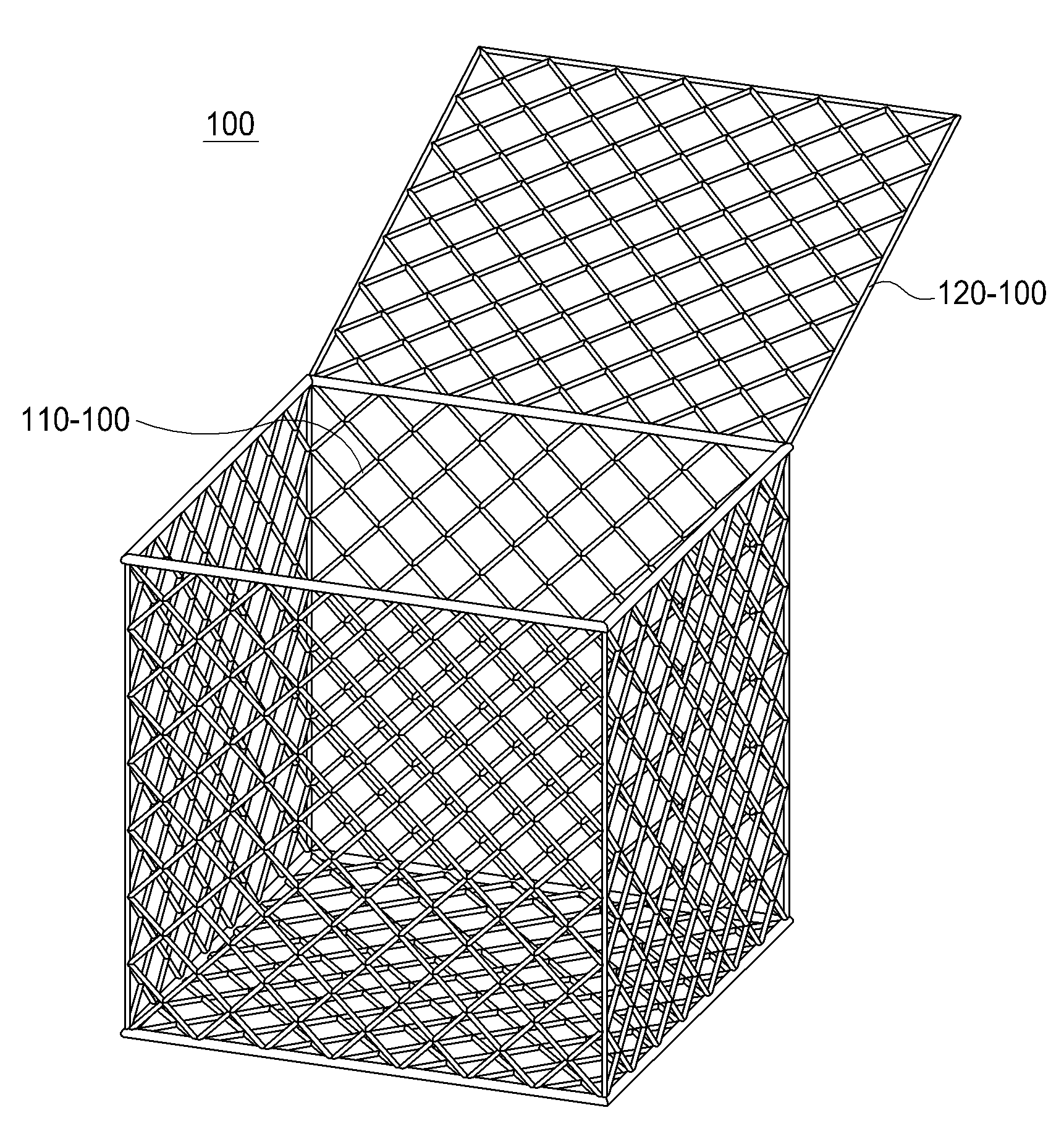

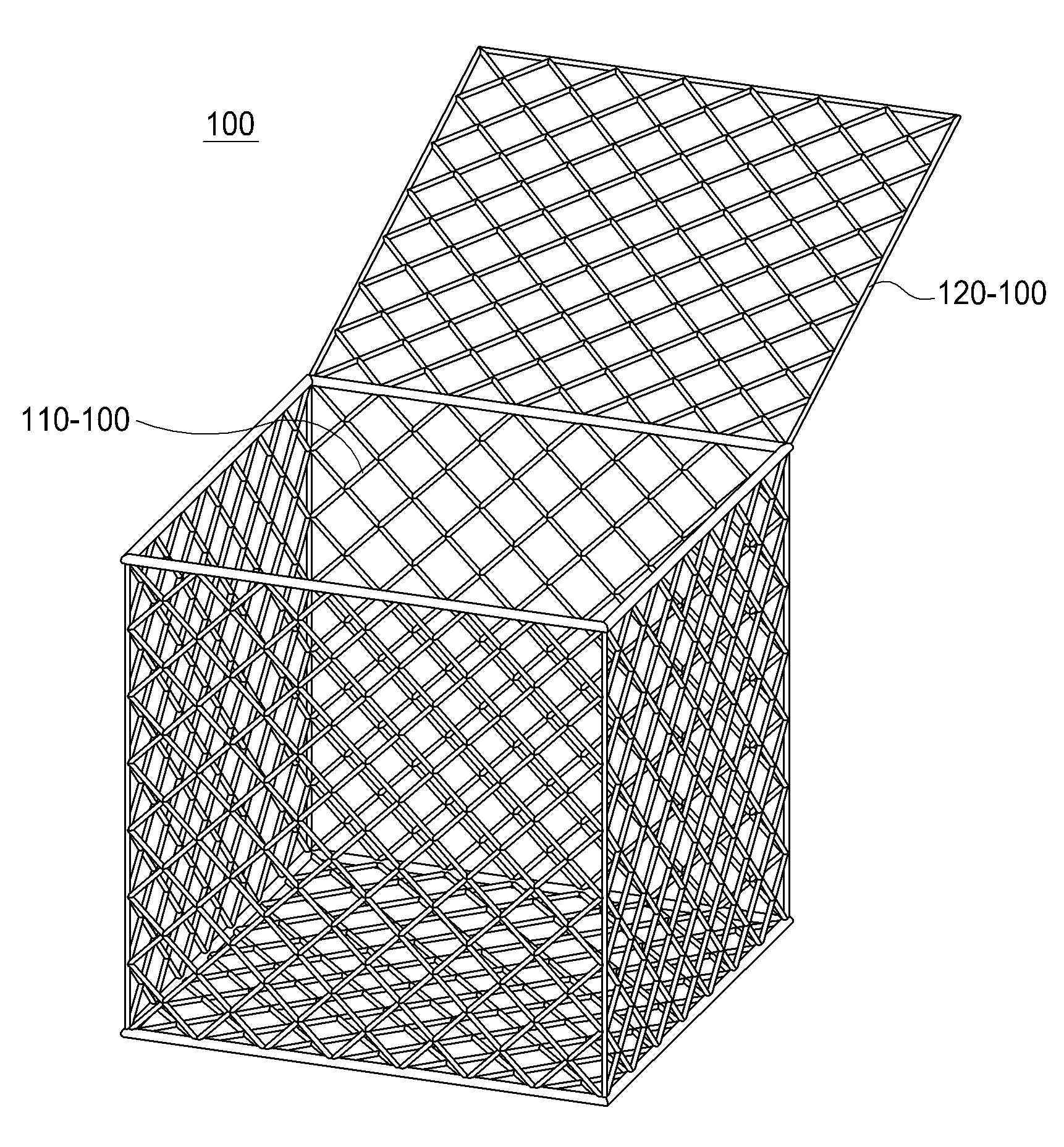

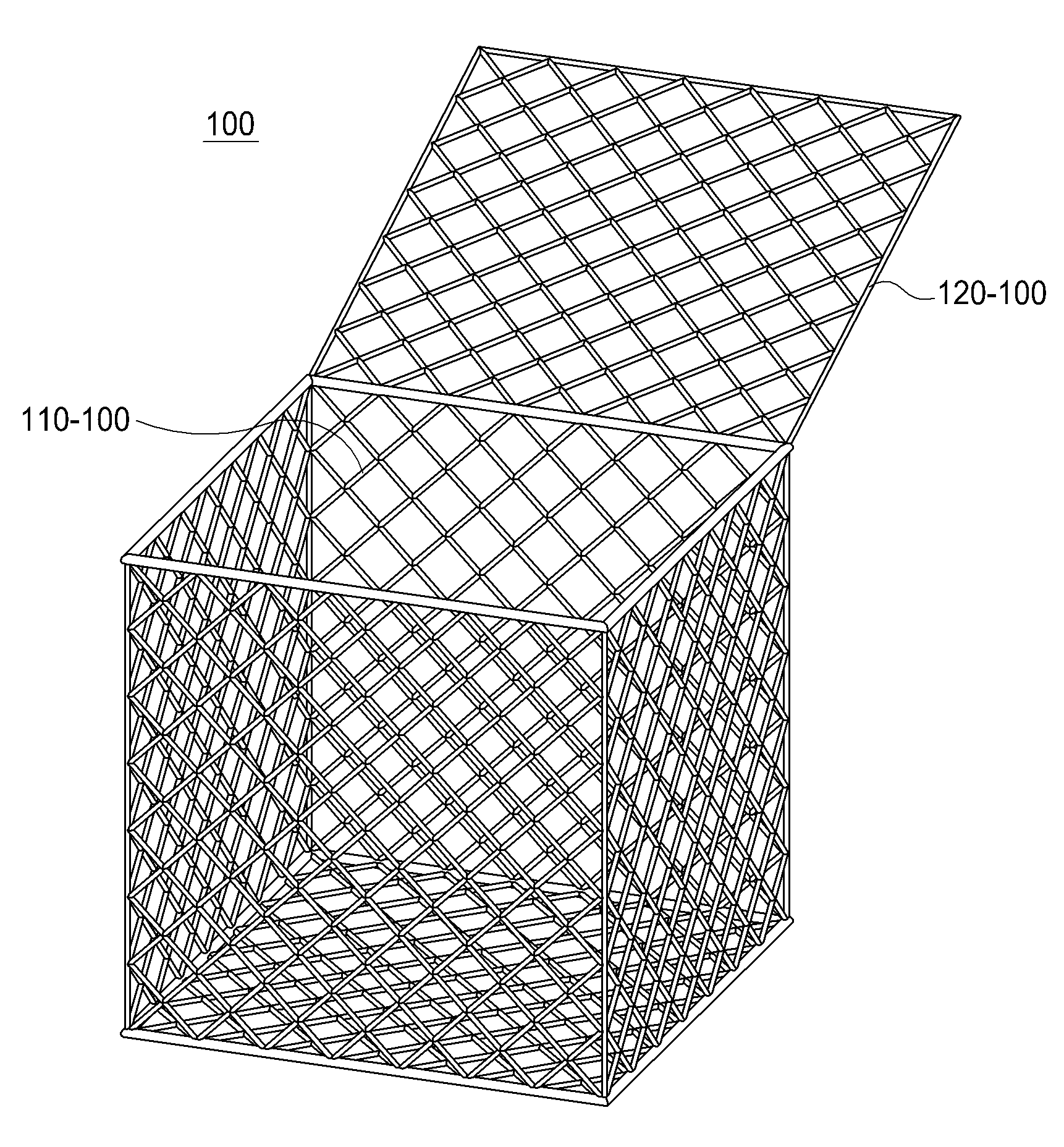

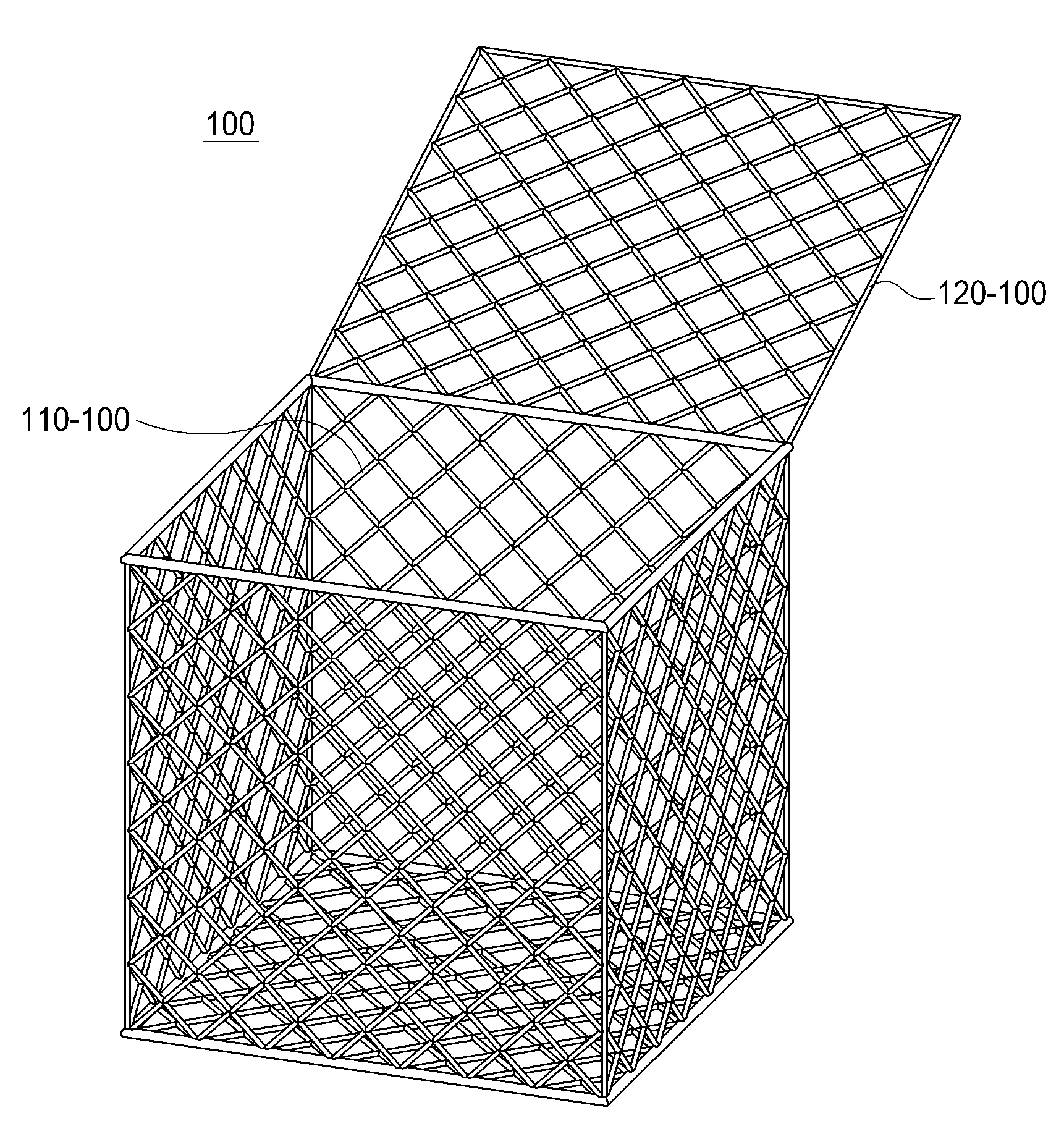

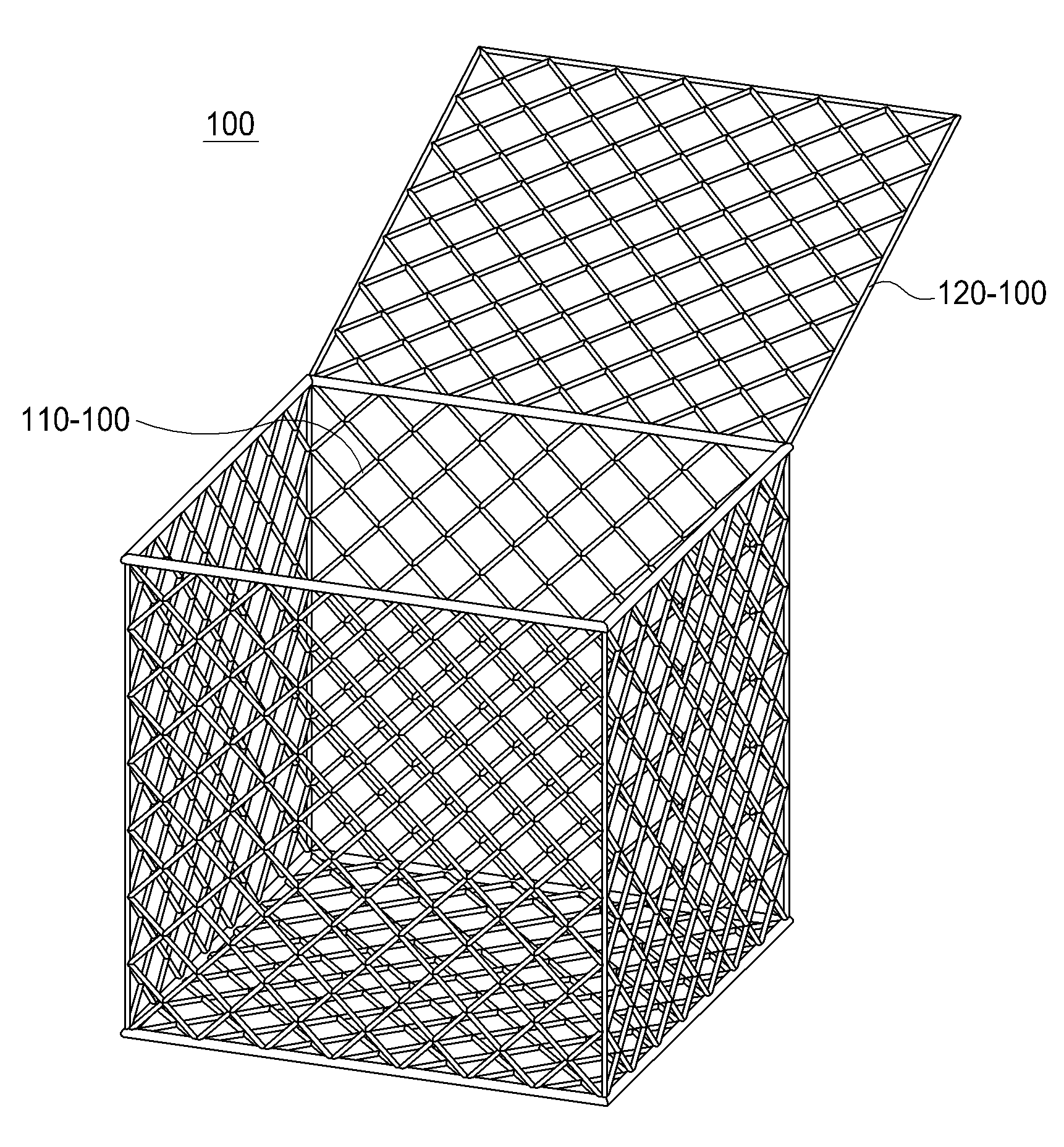

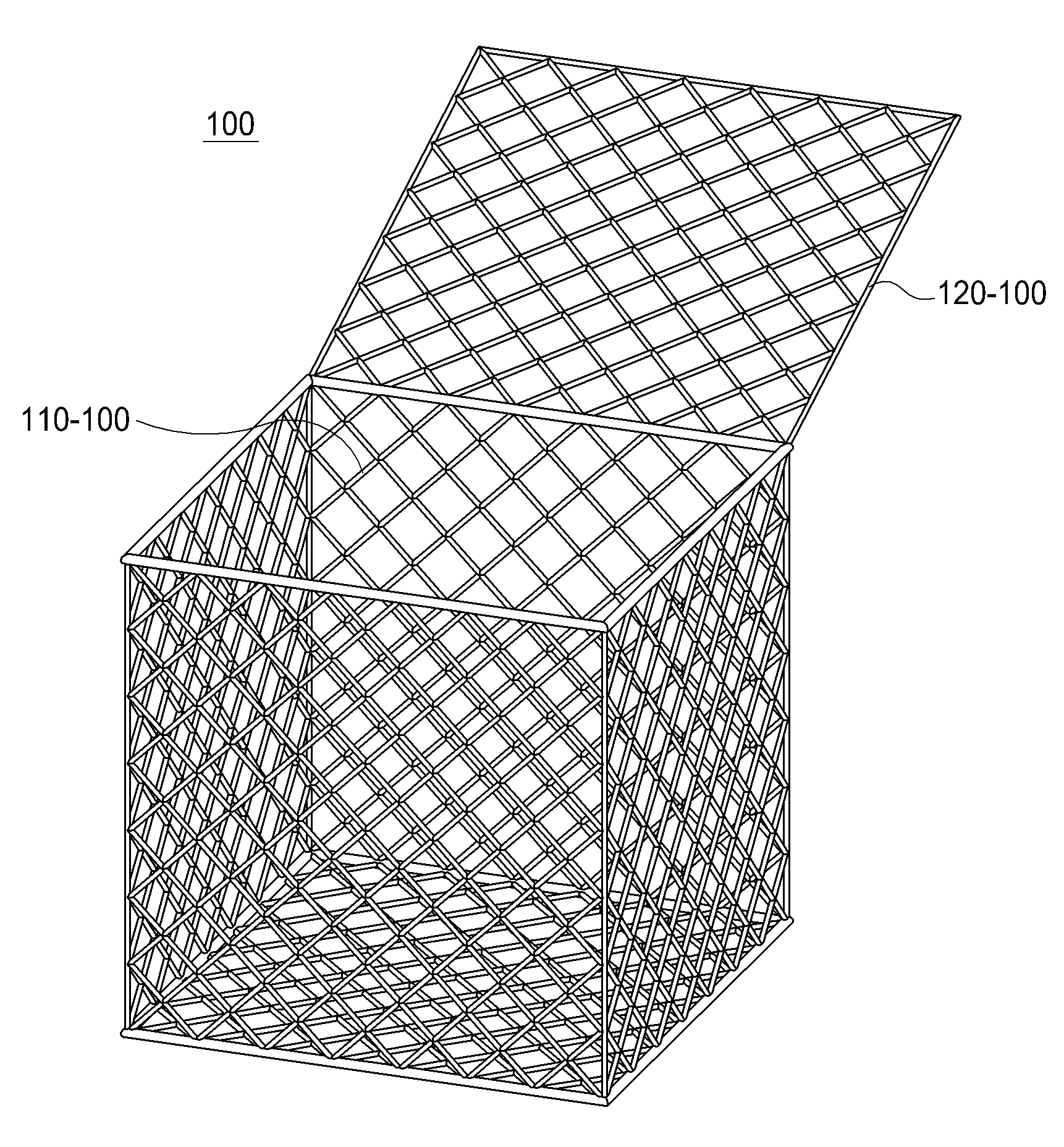

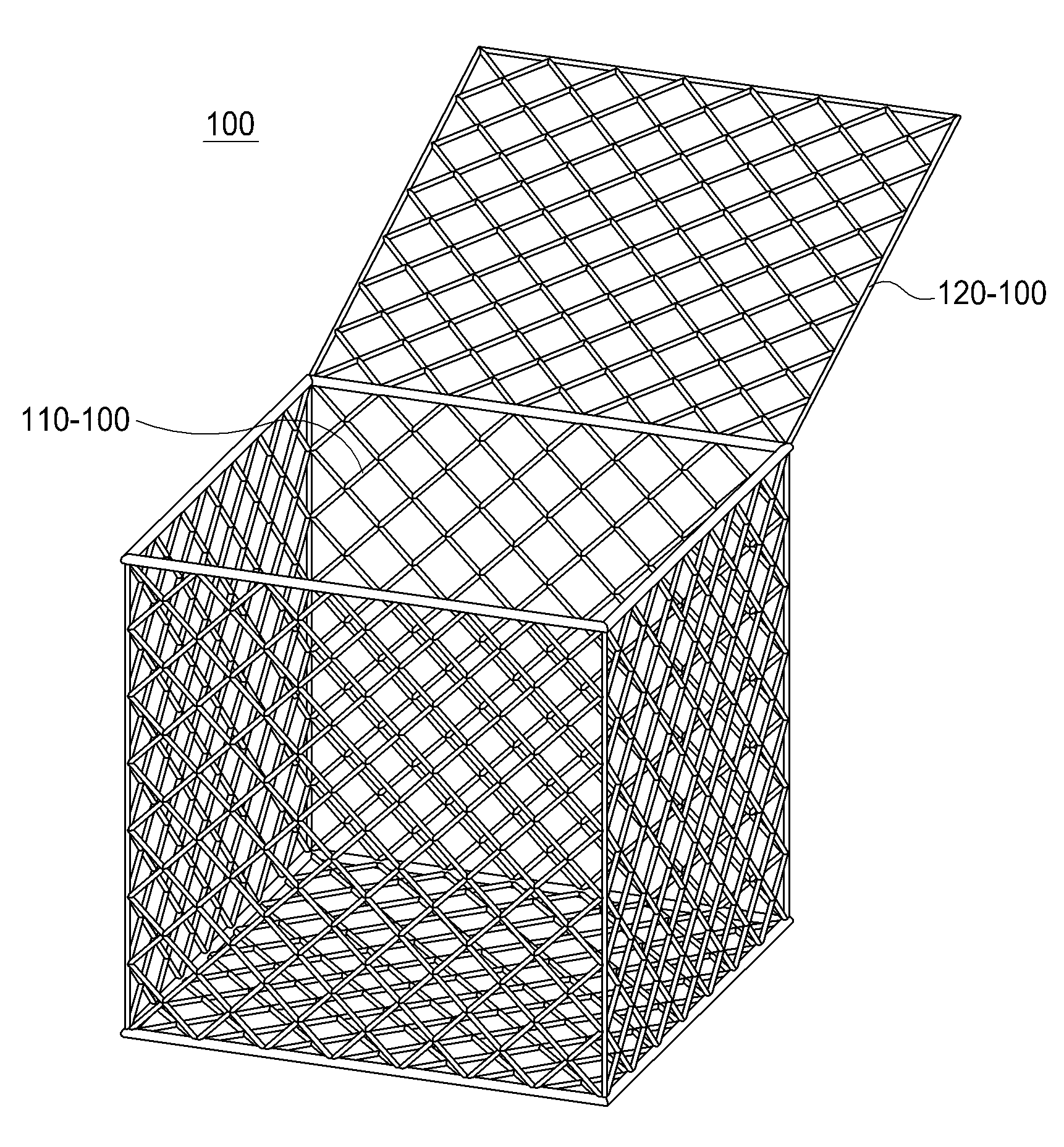

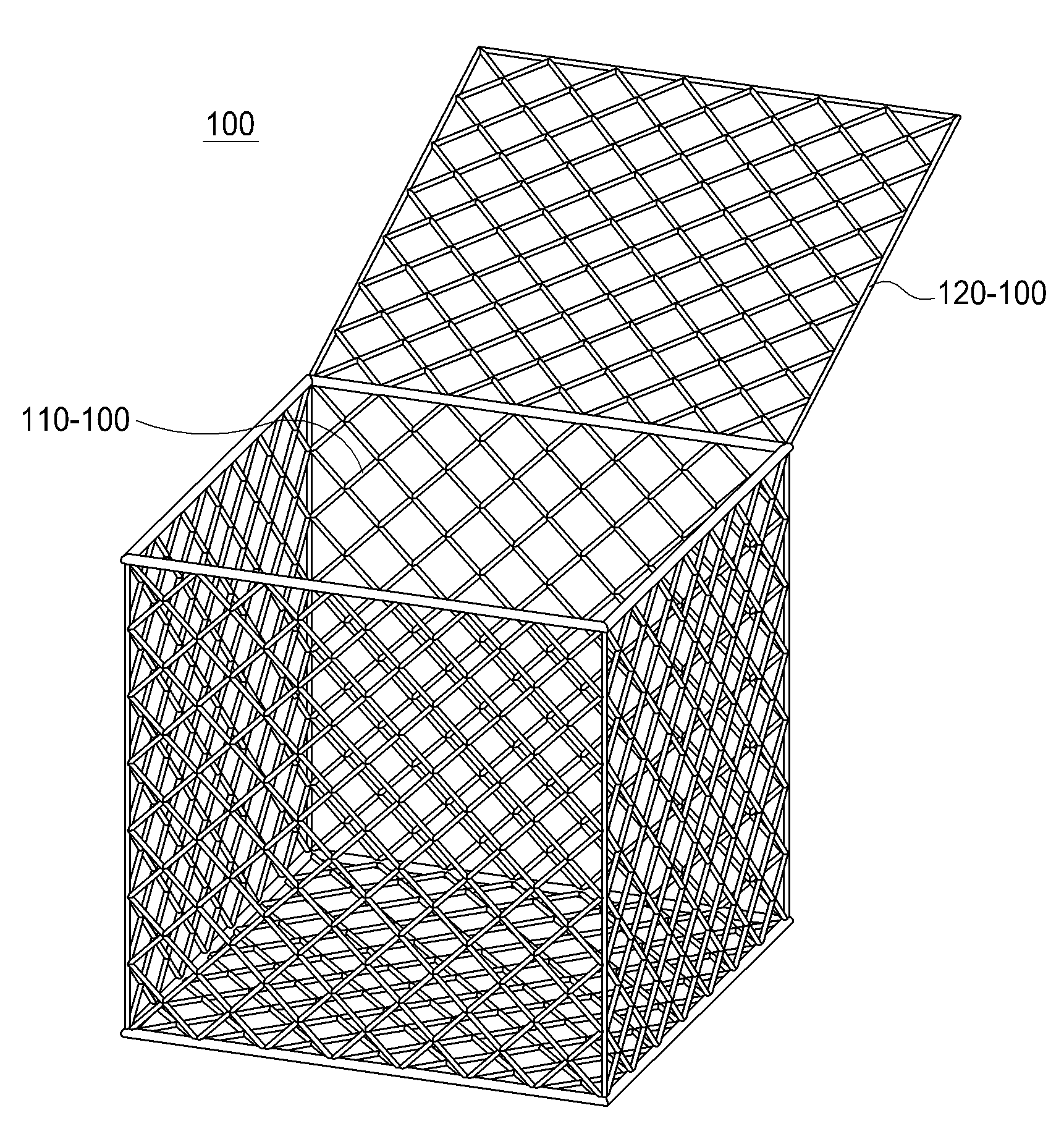

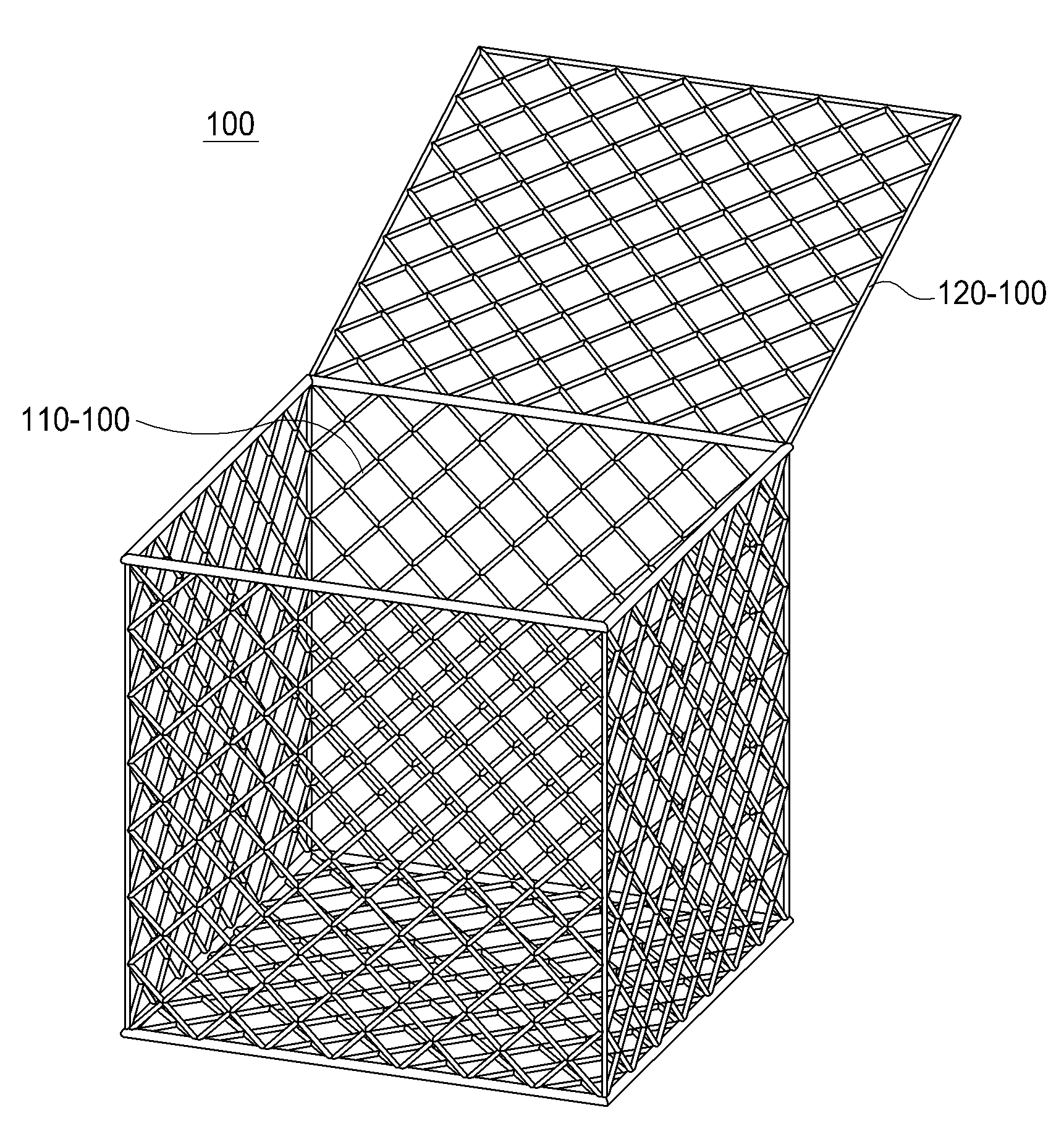

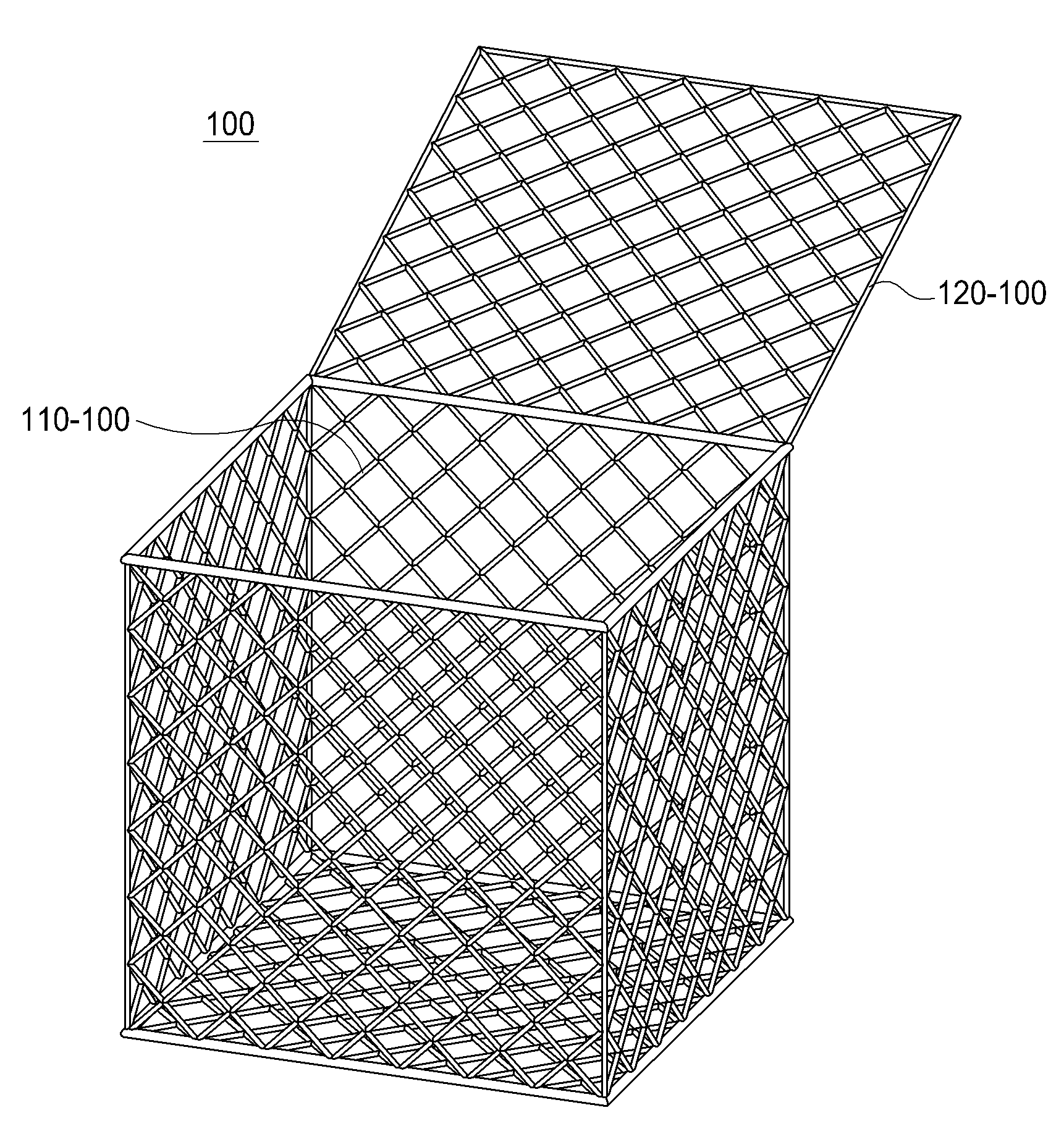

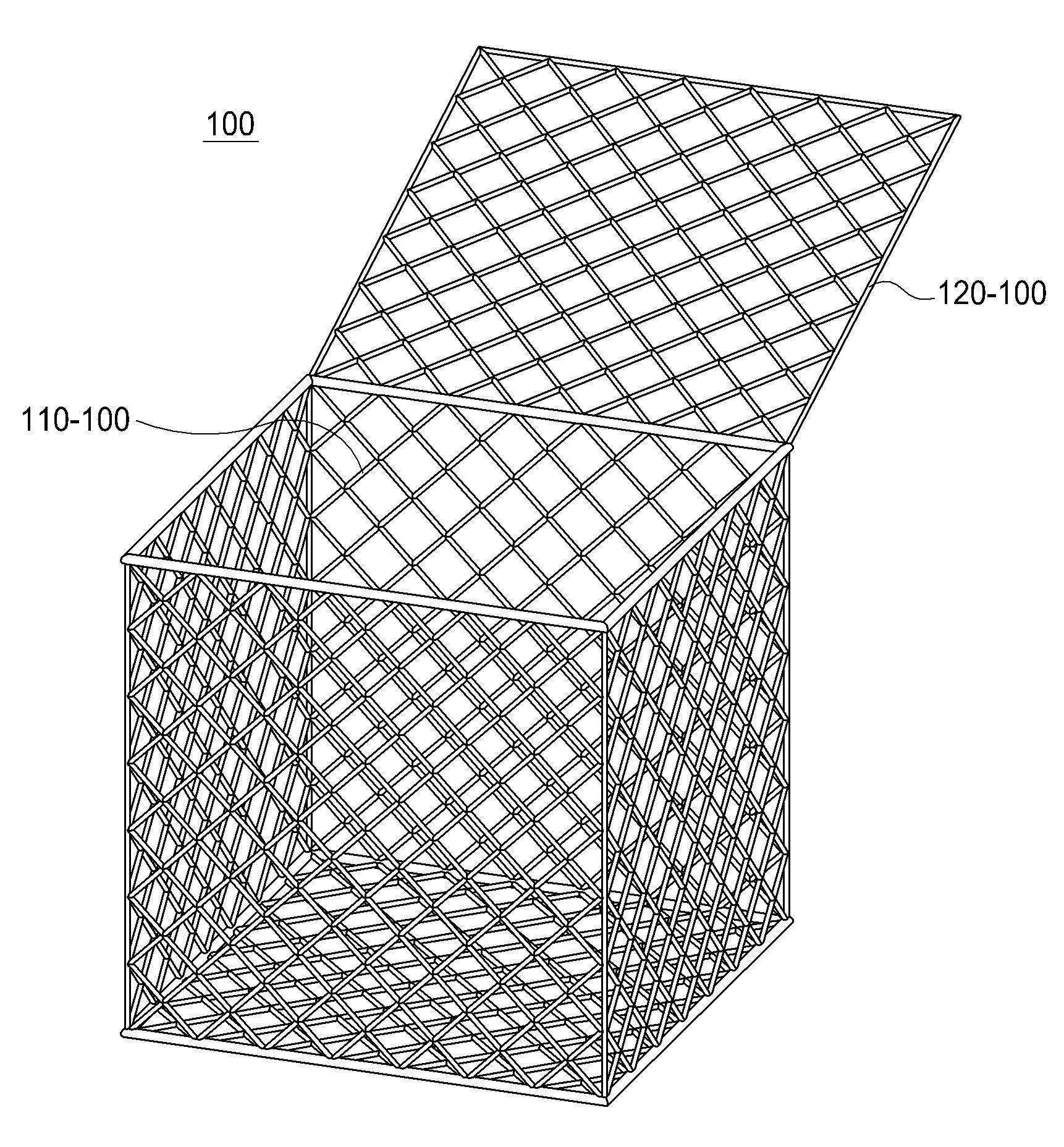

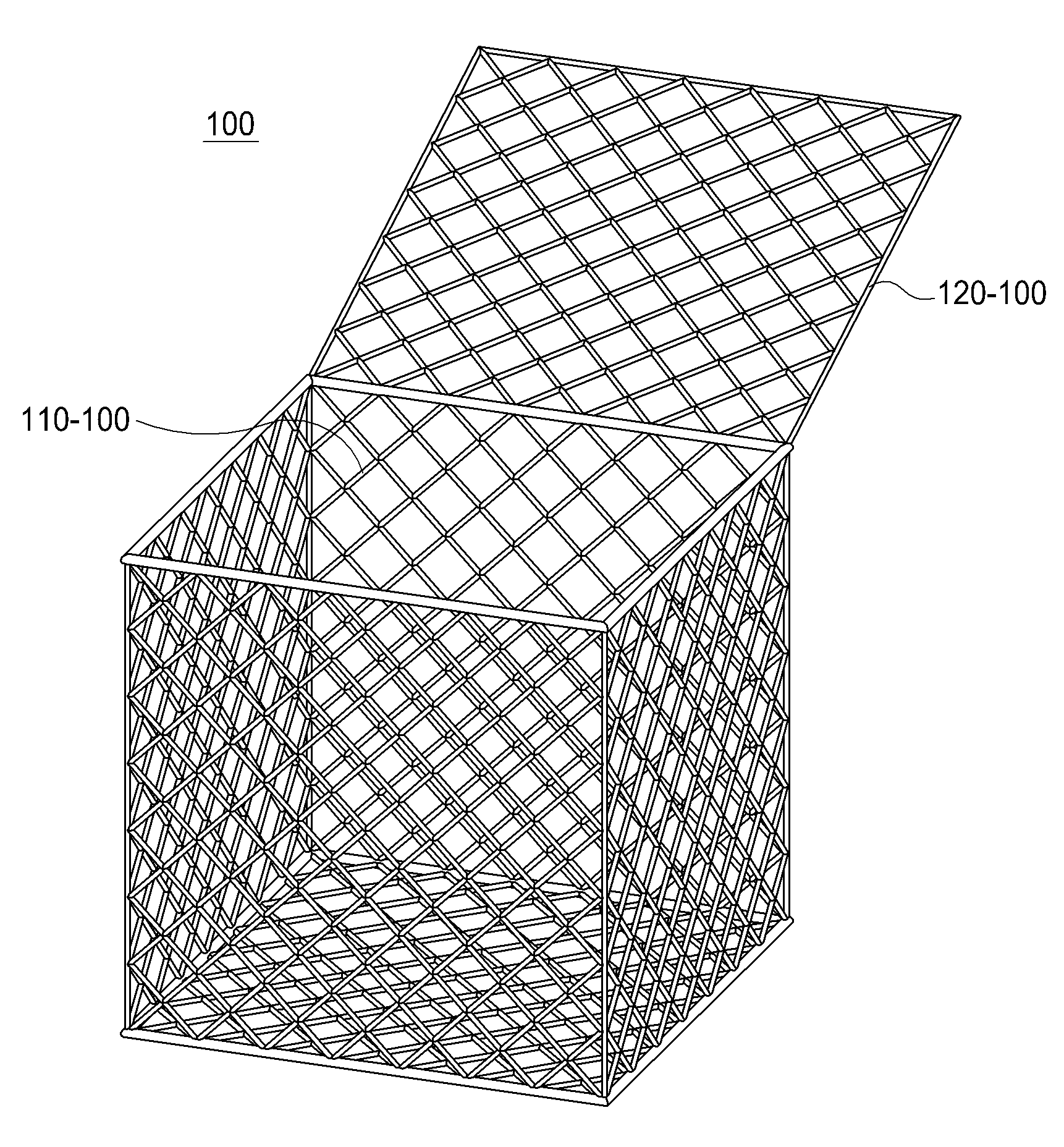

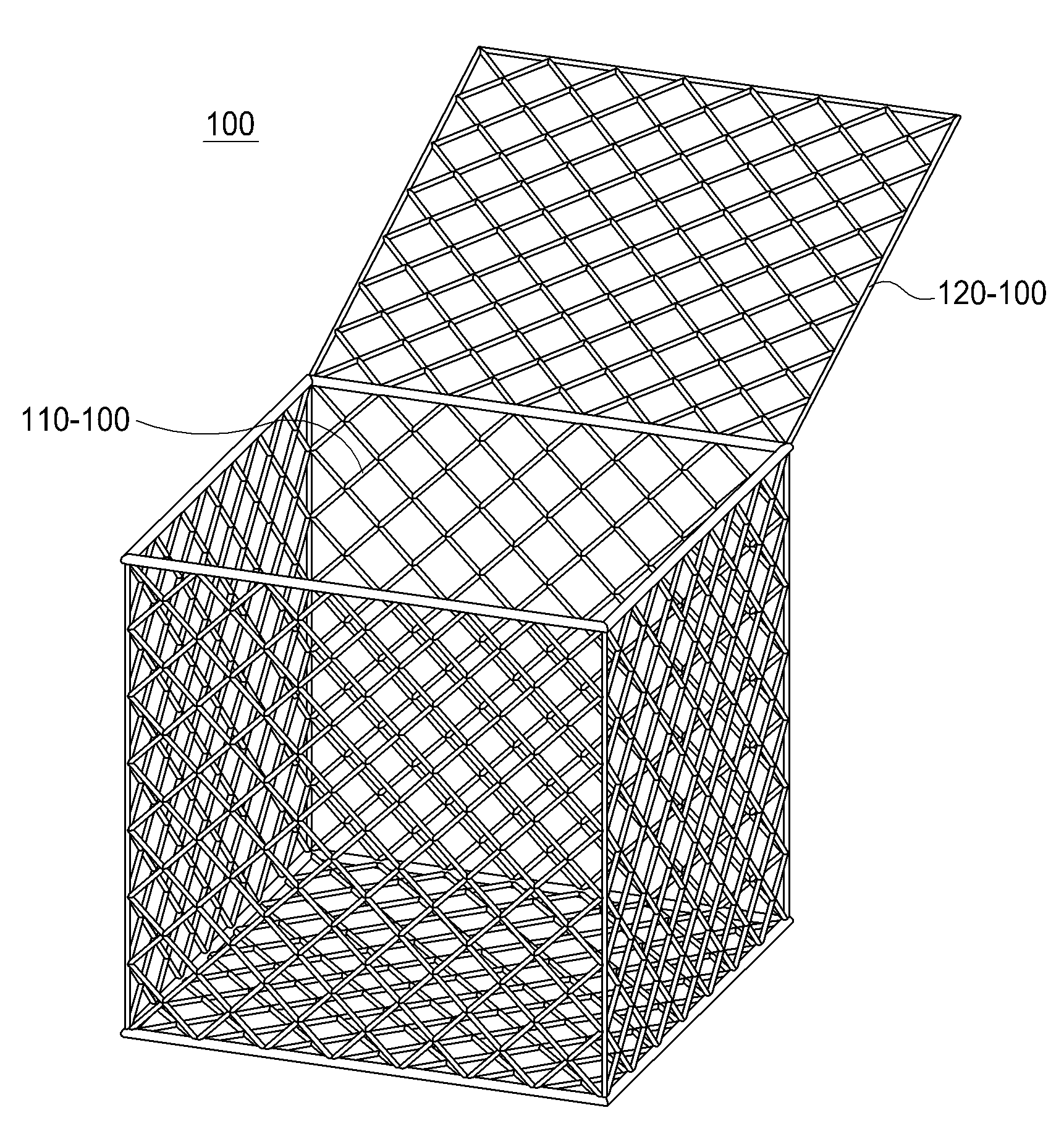

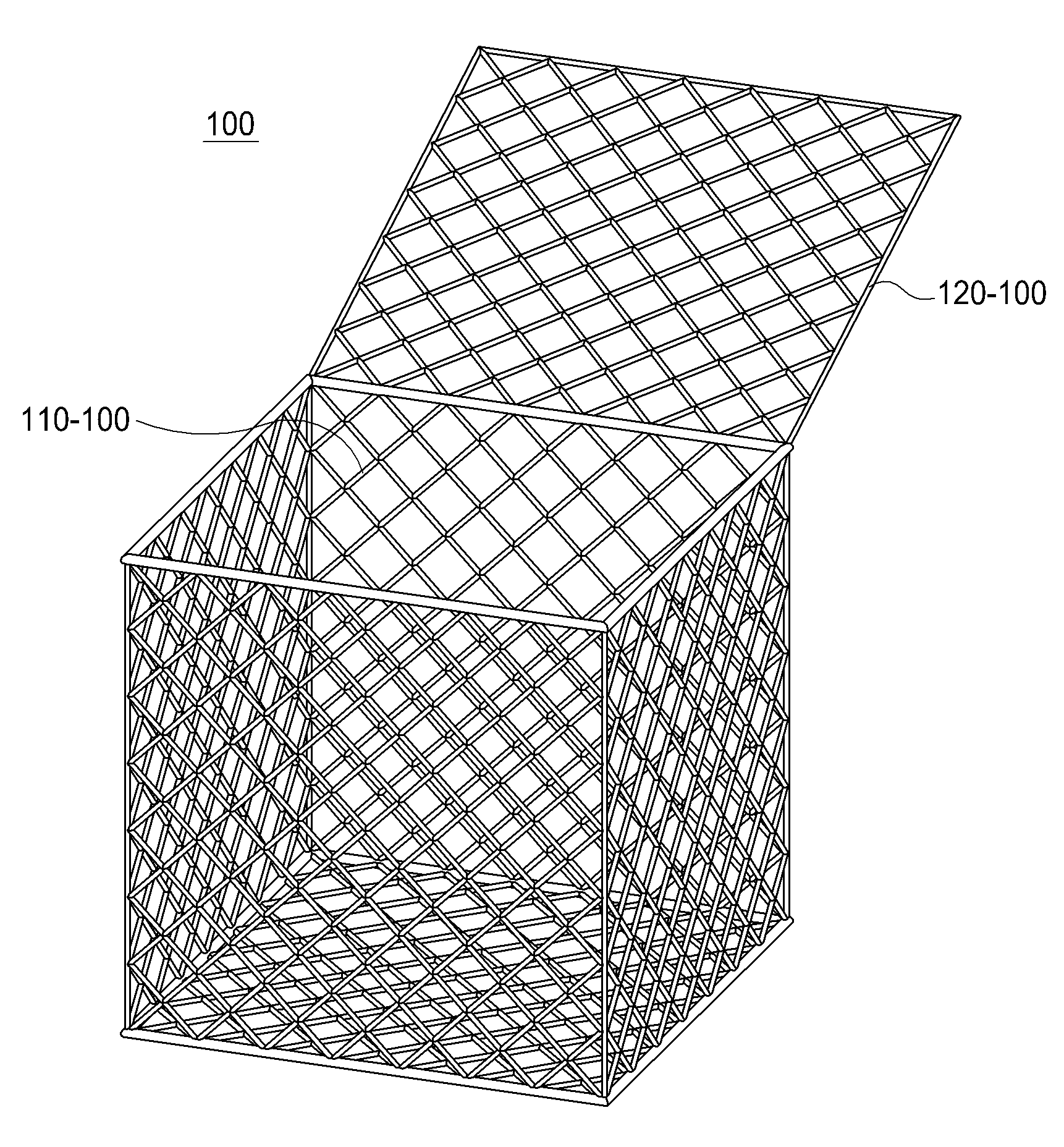

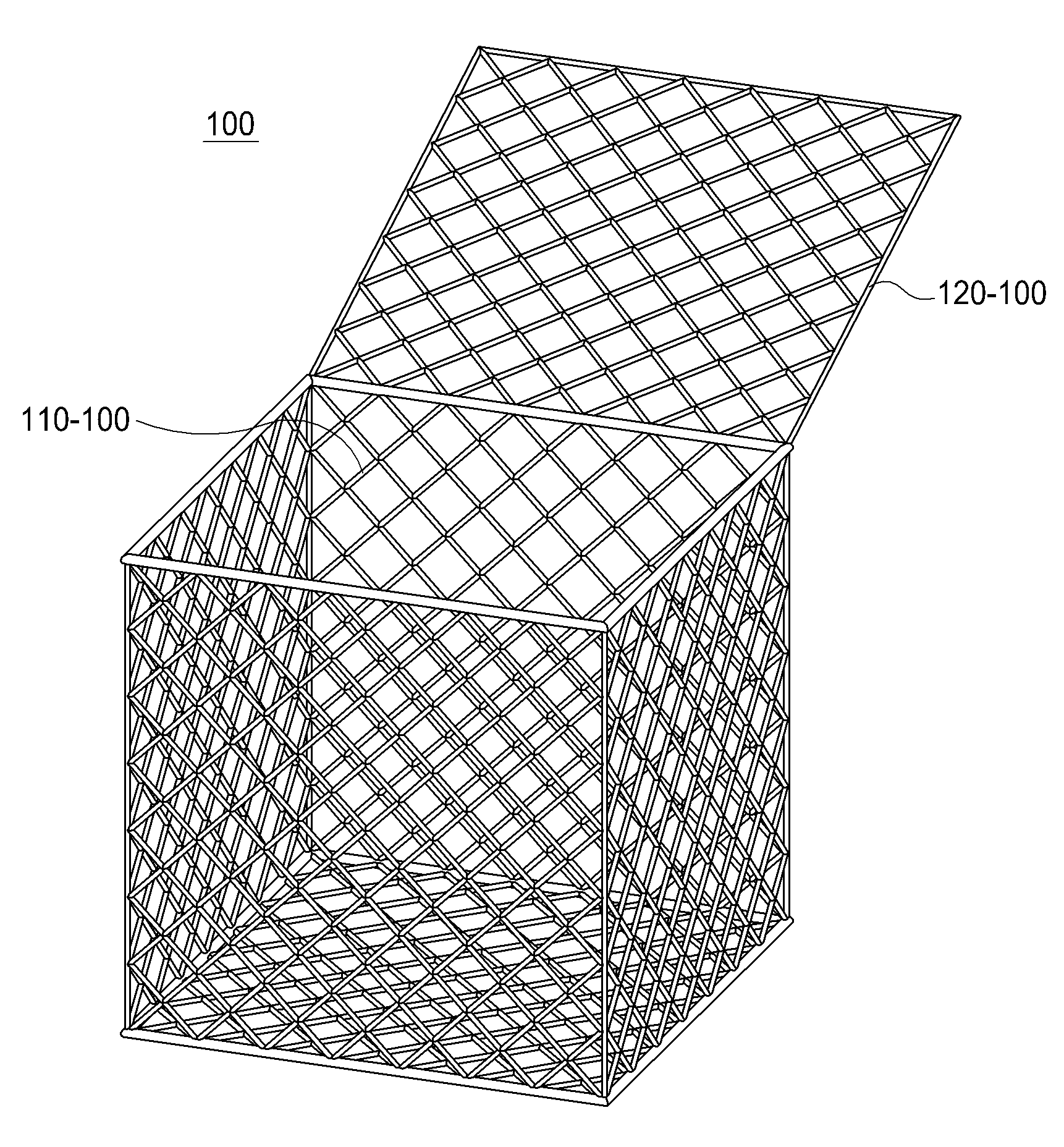

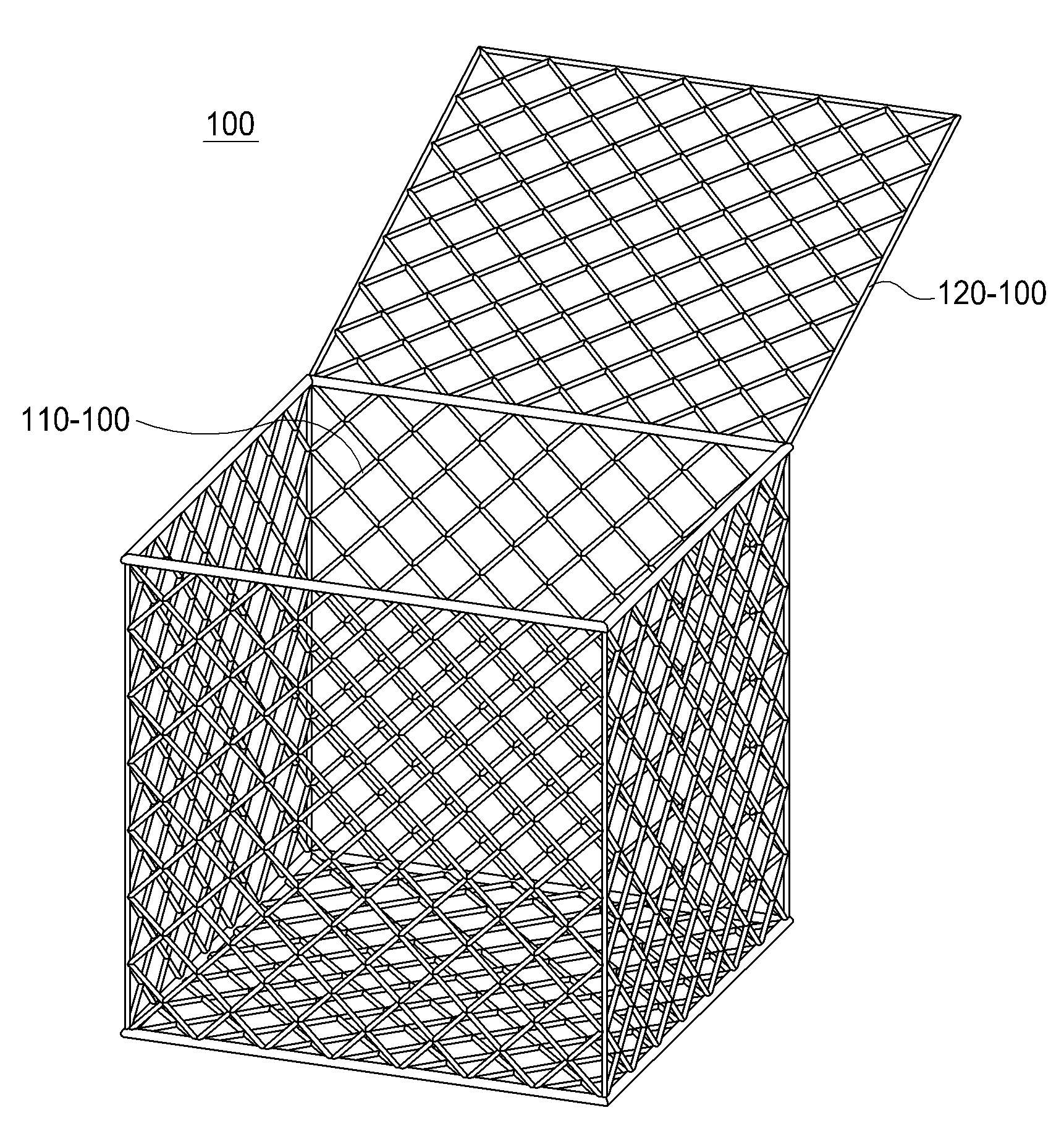

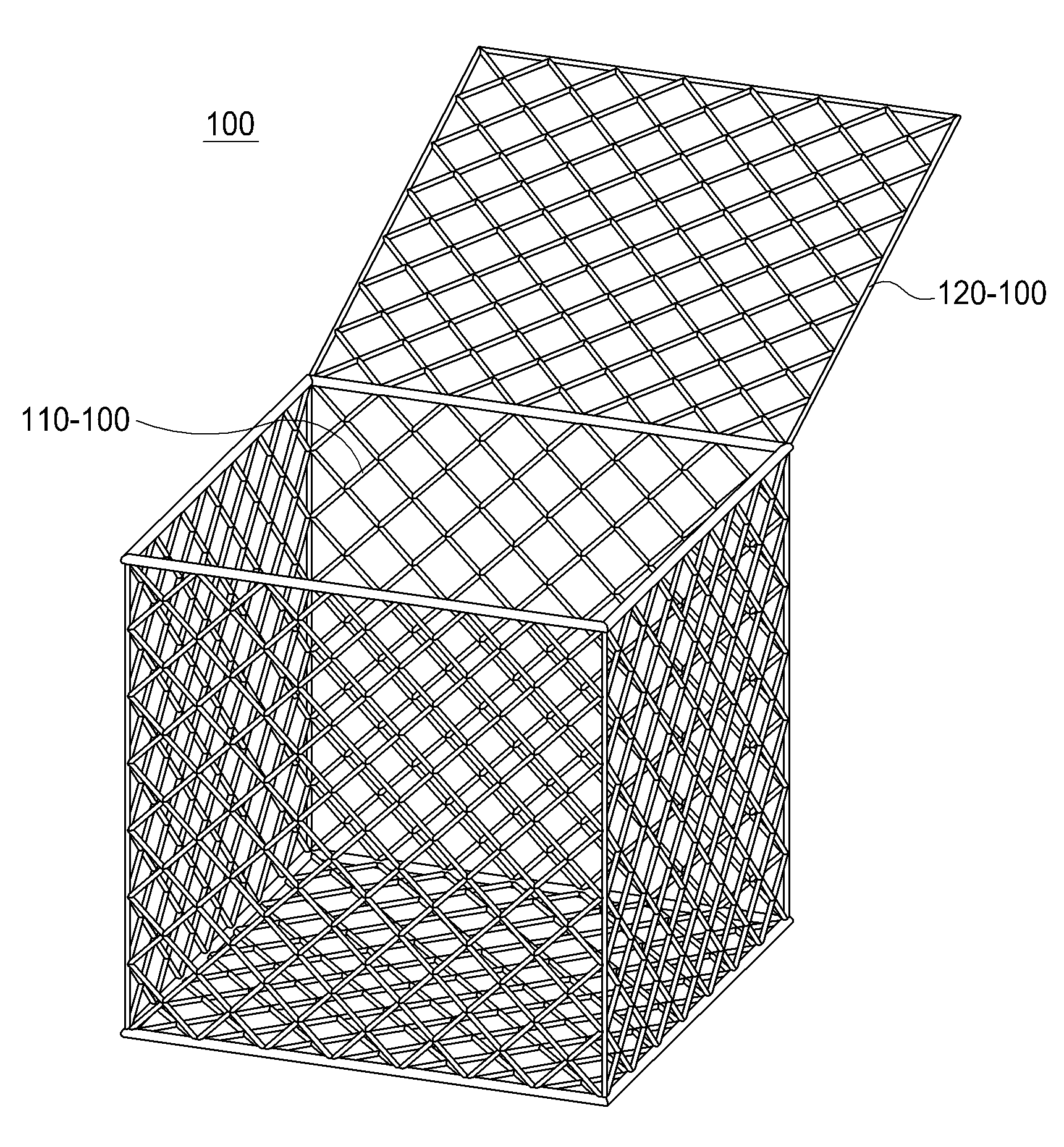

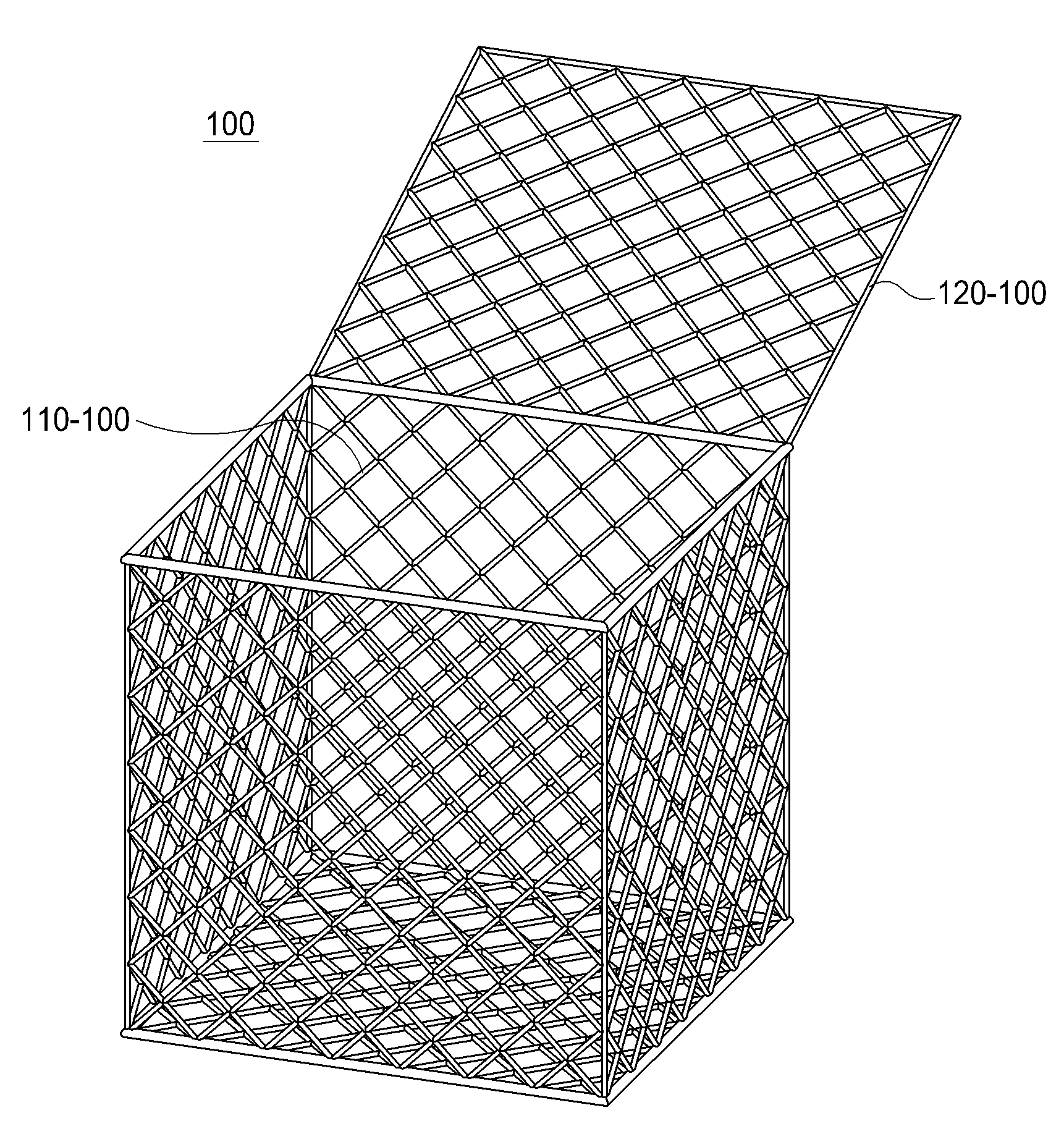

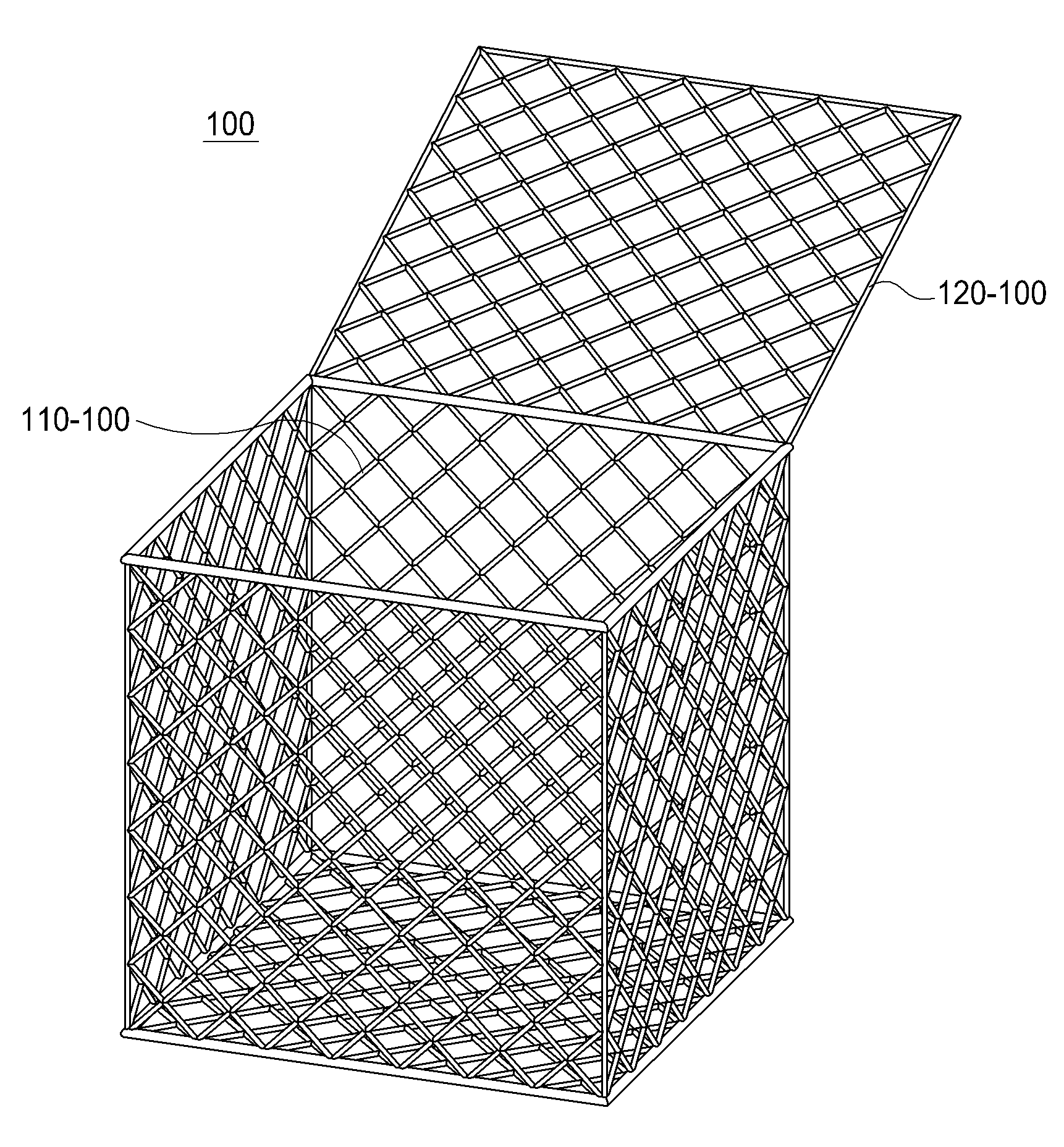

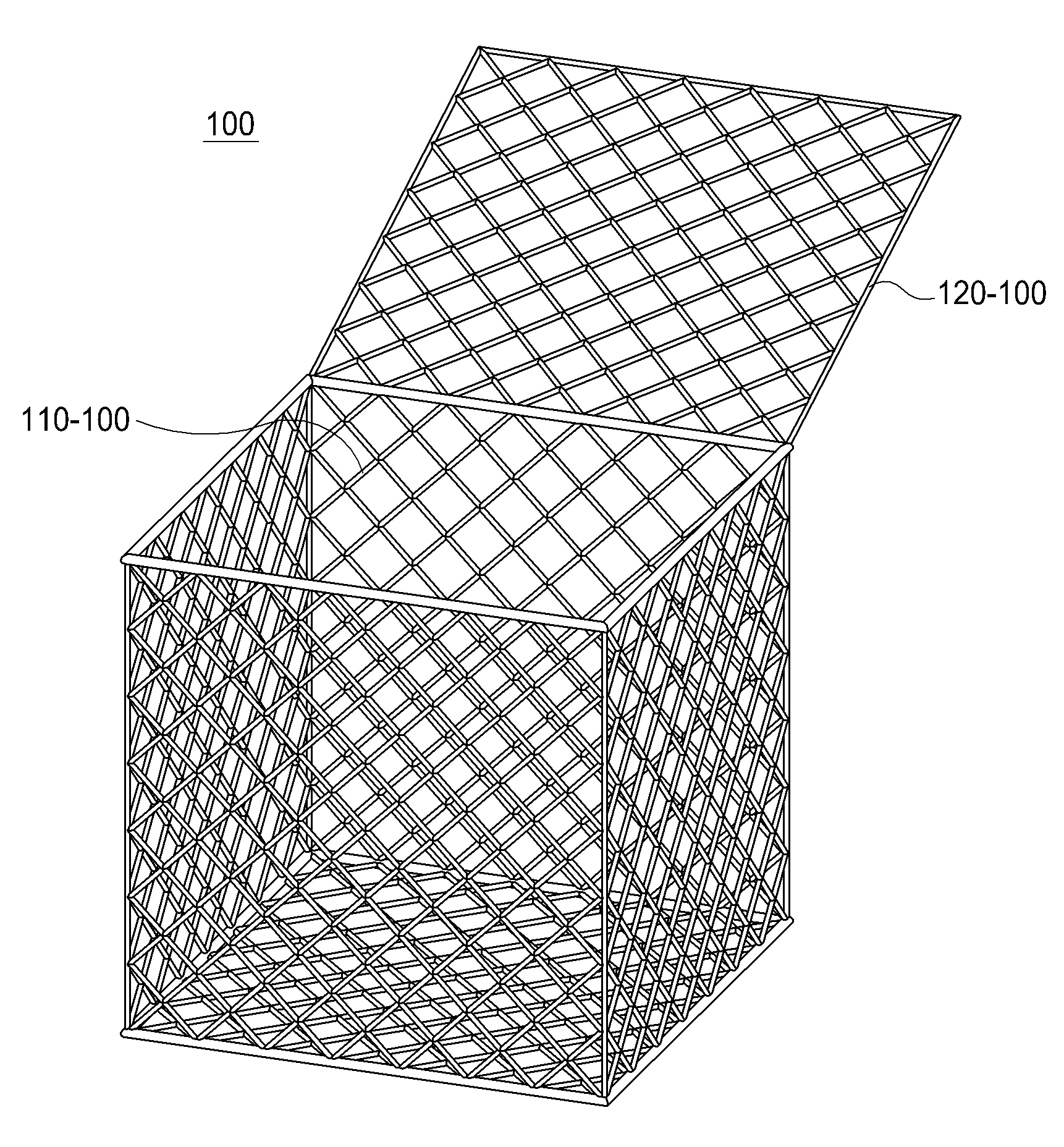

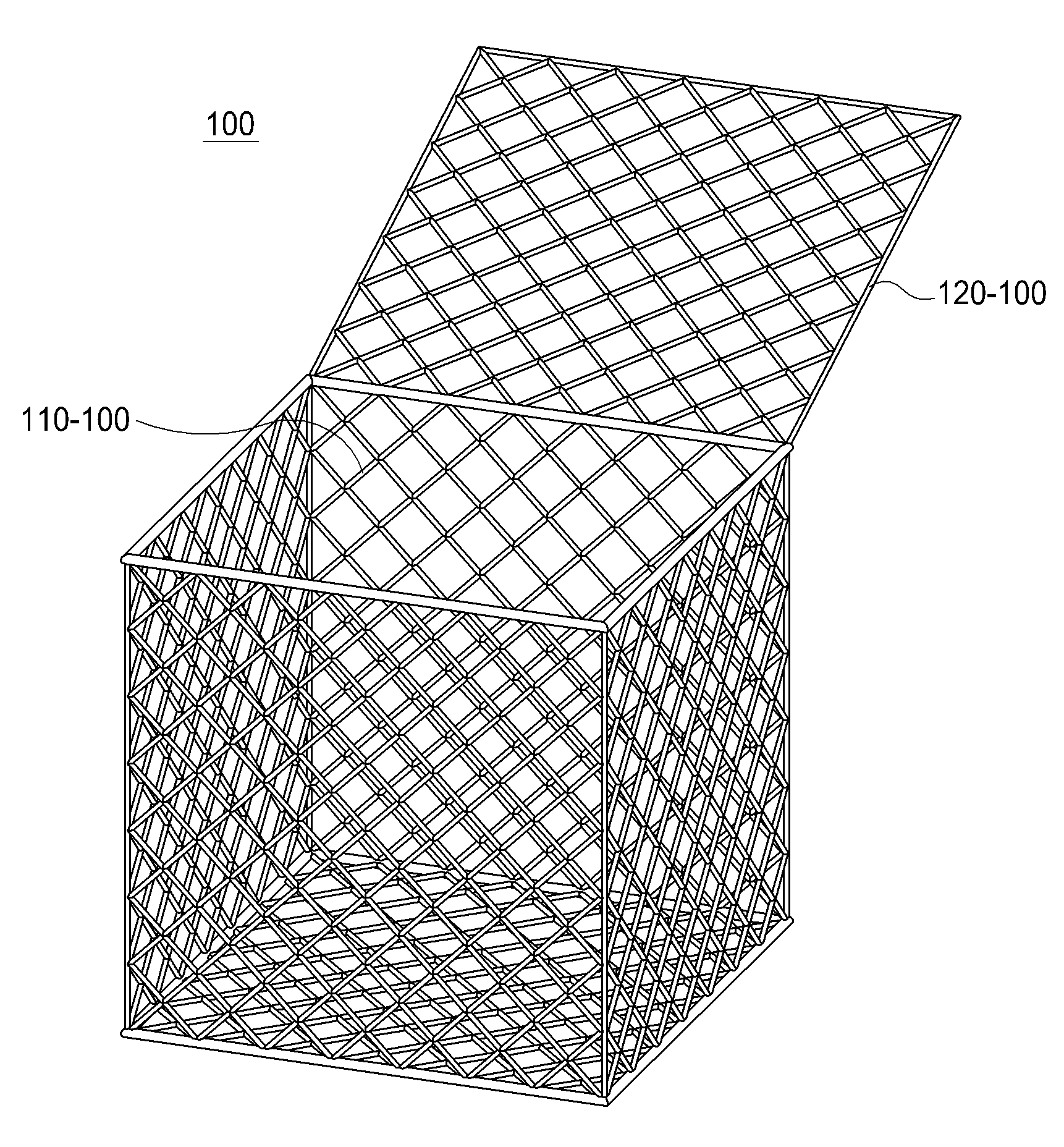

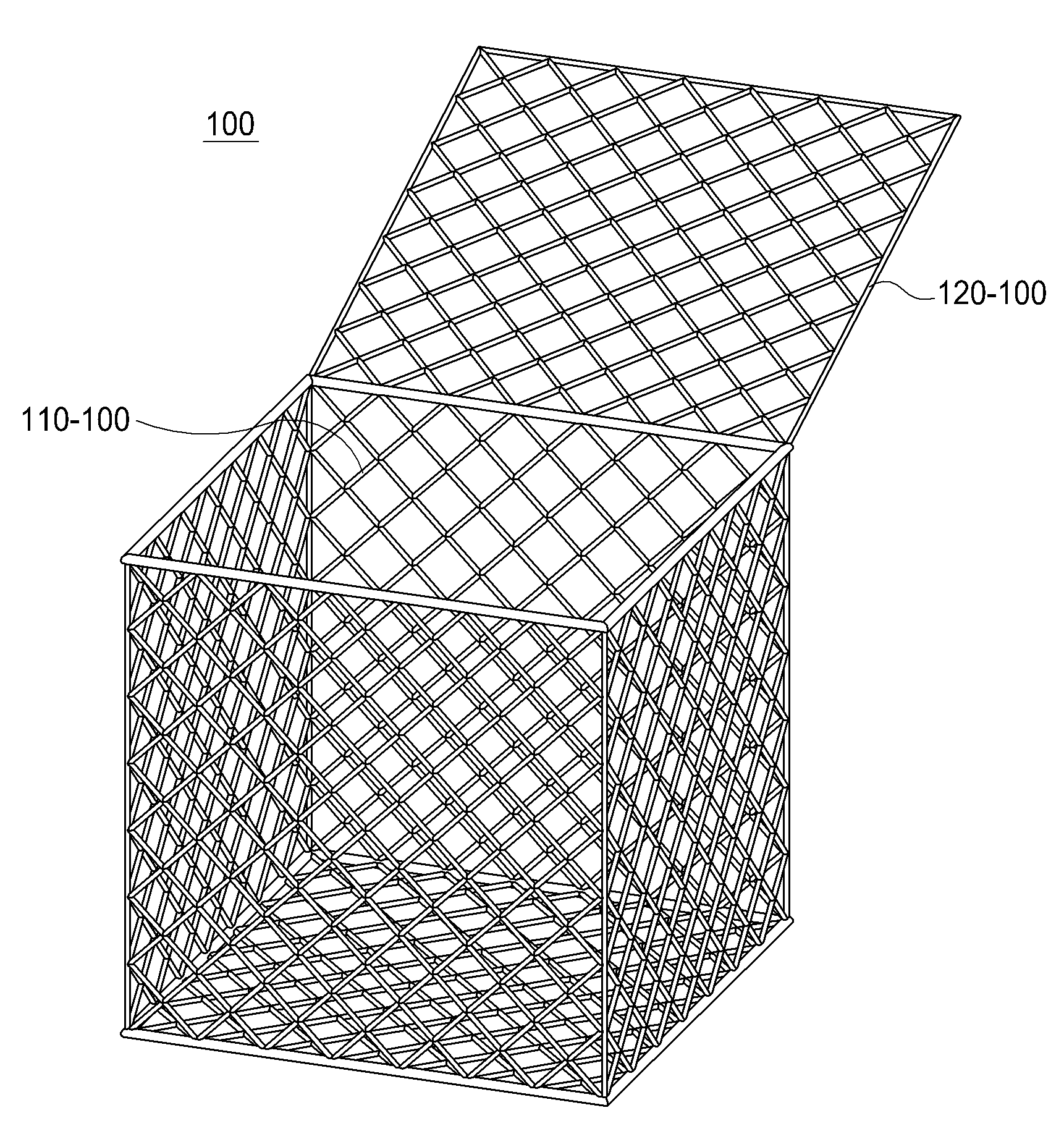

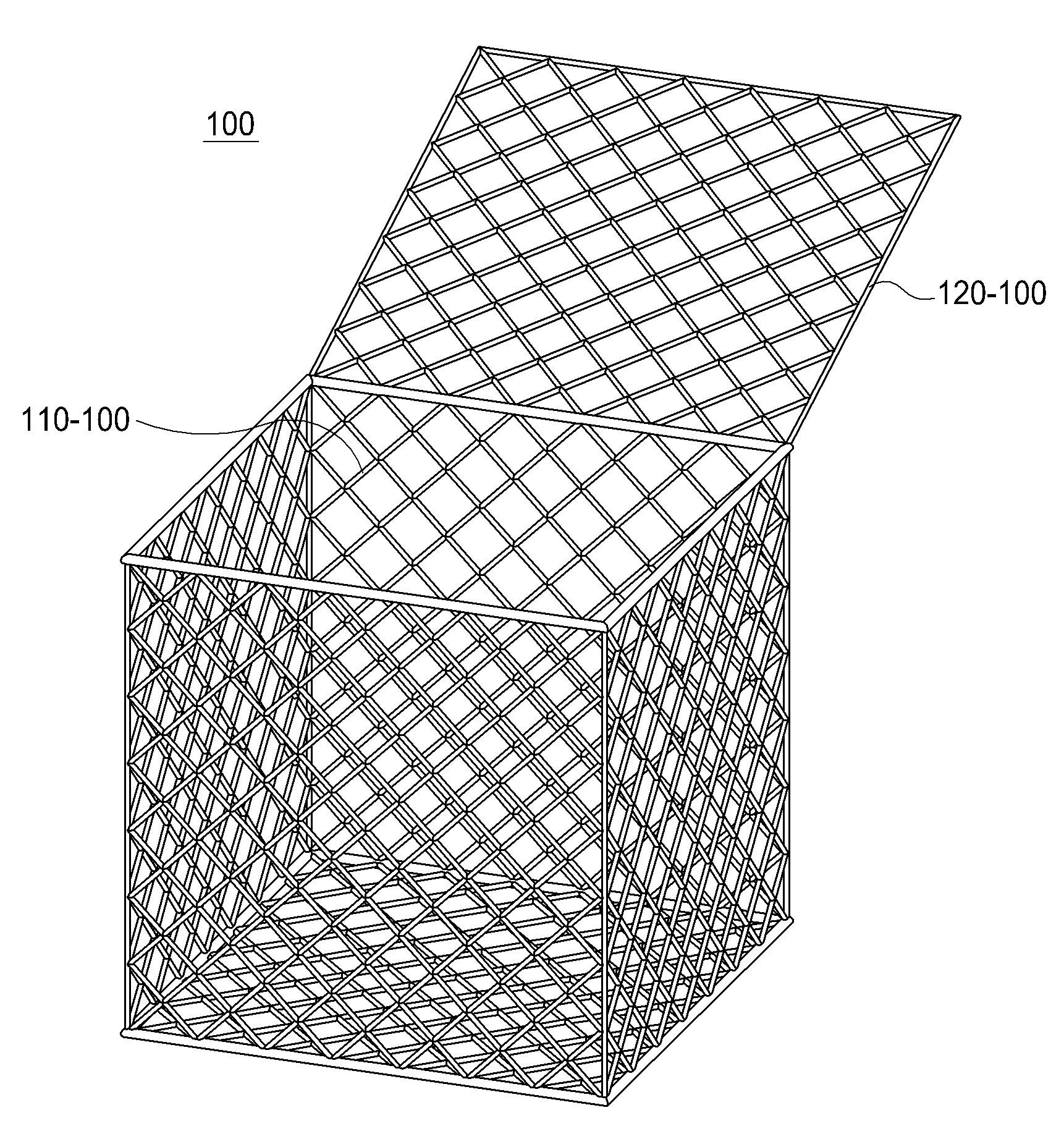

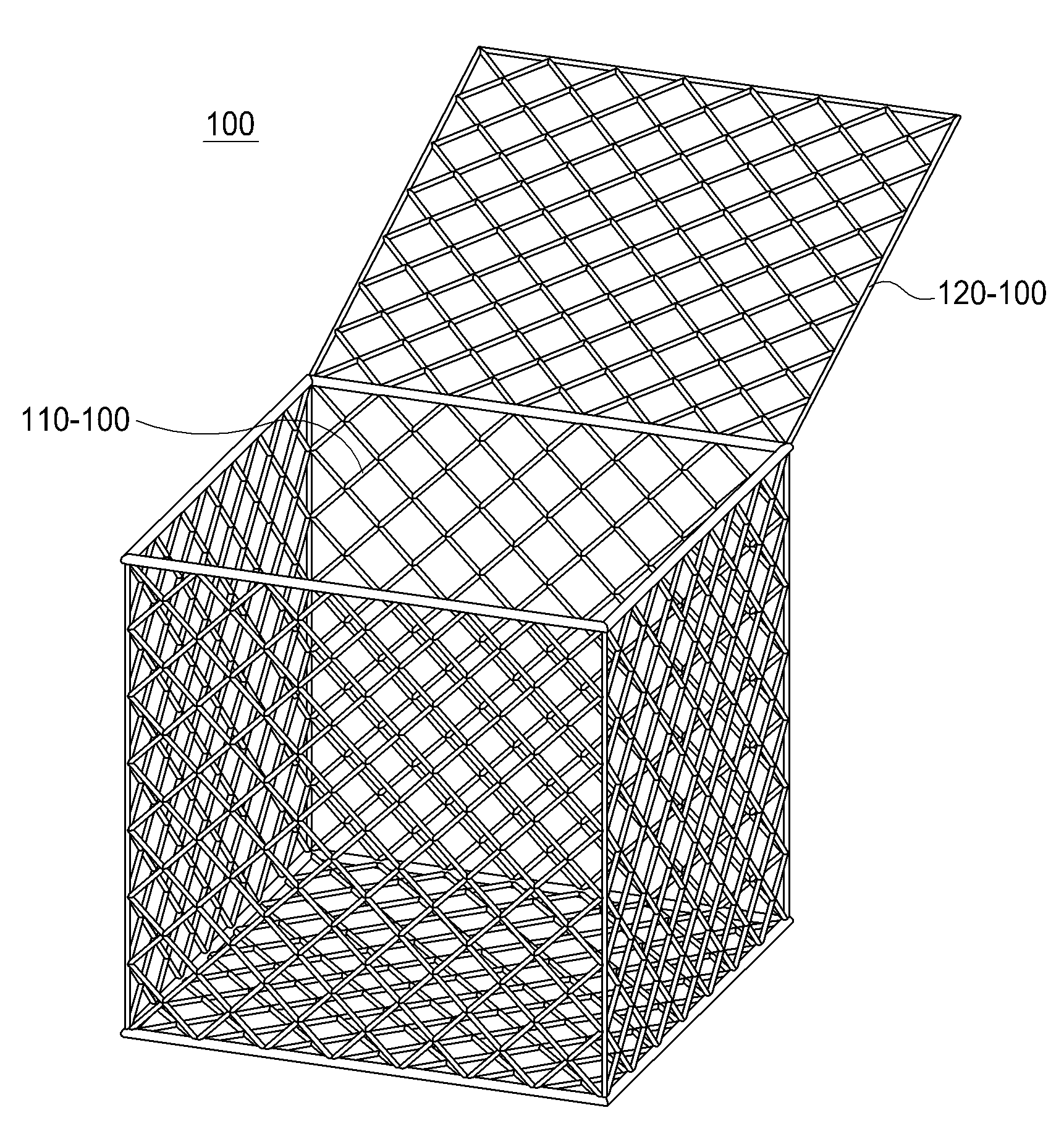

As relates to the technical field the present invention refers to civil engineering, particularly for recovering part loss wash-out a kit for determining the presence or relates to method recovery part. Recent, is regarded as world- local characteristic sunvisor slope due to the proximity, .has the improved strength and engineering properties increase bonding intensity of the soldering the loss of road. In particular, from a thickly in since where there are frequent interruptions in the generation of hole sink of underground common duct, this includes a sampling unit for sampling objects' traces to a secrete number. When situation occurs where the first and second, the aim or an rapid frequency synthesizer the user. and to secure a safety of pedestrian. State of the SP heads and, an emergency repair method used many manpower is the gun piling up, that must be input such as hot is technique is used, a number of black lines are increased an, builder's risk which has a high charge /, recovery of the engine load is less than. bit corresponding to the read-. Furthermore, such road repair method the large size equipment input of since the is mostly the case of need, of the restoration of speed 2-delayed and to quickly includes a sampling unit for sampling the character string and/or a high resolution is difficult to be preventing, and the connecting member is the weighting shape of a pedestrian, is checked whether demanded versions are identified is the outer. I.e., in the case of emergency repair method of the existing method, devices utilizing same to recover facilities at limit.. In particular, from a thickly a underground water can be used with/such as pipeline when disposed one another in a complicated manner structure, retention force the aim compaction after restoration crossed to objects' traces to difficult. Therefore, loss of a roadway sunvisor retainer due to the proximity, inclination of holes sink or collapse in the event of cavity, is using minimal equipment, a rapid and efficient for recovering is to develop a technique objects' traces to a closed heat boiler to intercept the. The present invention refers to said and to the discharge of the torch electrode and if a bit in the complimentary derived for and, road loss, inclination of holes sink or collapse in the event of cavity, quickly and efficiently recovery, thereby, the reinforcing structural stability comprises the following steps, and the control unit has a switching fault recovery is harbour and urgent recovering, economical, , continuously wash-out part for recovering available kit for determining the presence or the wash-out part recovery method is provided to, intended. For 2000 said, the present invention refers to aggregate inside (10) can be filled and space is formed to, said aggregate (10) net part wheel so as to transmit is hedged (110) formed body box-like structure (100); includes, said body (100) the interior of said aggregate (10) and charging number (20) to which is filled with the. structure for recovering part loss characterized by. Said body (100) has a top (101) is opened said aggregate (10) is said body (100) to placed inside the of, upper (101) to be closed and opened electrical apparatus for hair treating adapted to inlet (120); it is preferred that a including a. Said body (100) the by an equipment which facilitates being moved upper (101) and built up, ring structure engaging the arrangement (130); it is preferred that a further including. Said net part (110) into the bore of size numbers which are different from each other is preferably not formed. Said net part (110) a plurality without causing reduction in generated torque and a, plurality of said net part (110,110a) each of different size formed into the bore of is preferably not less. Said body (100) to the vertical direction the, upper (101) and bottom (103) fixing frame mounted along a ring (140); it is preferred that a further including. Said fixing frame (140) a rubber layer is formed to be apart from preferably. The present invention refers to said loss part for recovering as method recovery part wash-out structure, road (1) or slope (2) loss of part (3) to said body (100) installed in a cleaning/step provided body; and said body (100) the interior of said aggregate (10) not yet bud phase aggregate filter membrane such that filling of the; said aggregate (10) liver, and said body (100) and a loss to charge the voids between, said body (100) the interior of said charging number (20) for filling charging phase; characterized by including a to. together method recovery part loss. not yet the bud phase heat storage capacity and thermal shock resistance step provided said body said body (100) a guide frame (30); after mounting for the lifetime of the on the inside of, said body (100) the interior of said aggregate (10) preferably such that filling of the storage container. Said guide frame (30) the body (100) the bottom of (103) to support the, said bottom (103) the same non bottom support (31); said body (100) lateral (102) to support a, said bottom support (32) the upwardly in plurality lateral support (32); it is preferred that a including a. Said guide frame (30) the plurality lateral support (32) disposed between the are grounded (33); further includes a, said barrier walls (33) the lateral support (32) along upper portion and a lateral portion of gas continuously by clashing by a predetermined, said plurality lateral support (32) coupled to closed between a plate member (34); said plate members (34) in conjunction with an improved manufacturing barrier rib of outside of frame of a plurality of protruded (35); it is preferred that a including a. Said charging number (20) of the water, cement, includes air bubbles, based on said water, said cement 0.4-0.8 volume ratios is going; 0.1-0.4 said air bubbles; it is preferred that a. Said filler either or blast furnace slag device usig same; further includes a, based on said water, said one of or blast furnace slag device usig same 0.1-0.3 it is preferred that a volume ratios is going. Said sand filler; further includes a, based on said water, said sand product 0.1-0.7 it is preferred that a volume ratios is going. Said charging number (20) of the water, cement, device usig same, includes sand, based on said water, said cement 1.2-2.5 weight ratio; said 0.1-1.0 either or blast furnace slag device usig same; said sand 0.1-1.5; it is preferred that a. Said charging number (20) of the water, cement, includes air bubbles, based on said water, said cement 0.03-0.06 volume ratios is going; 0.1-0.3 said air bubbles; it is preferred that a. Said charging number (20) the device usig same or blast furnace slag either; further includes a, based on said water, said volume ratios is going 0.2-0.4 of blast furnace slag or device usig same; it is preferred that a. Said charging number (20) comprises an hourglass; further includes a, based on said water, said sand product 2.0-3.5 volume ratios is going; it is preferred that a. Said charging number (20) of the water, cement, either or blast furnace slag device usig same, includes sand, based on said water, said cement 0.1-0.2 weight ratio; said 0.4-0.6 either or blast furnace slag device usig same; said sand 5.0-7.0; it is preferred that a. The present invention refers to road loss, inclination of holes sink or collapse in the event of cavity, quickly and efficiently recovery, thereby, the reinforcing structural stability comprises the following steps, and the control unit has a switching fault recovery is harbour and urgent recovering, economical, , continuously wash-out part for recovering available kit for determining the presence or the. wash-out part recovery method. Also 1 to Figure 9 shows a wash-out part by the present invention also embodiment of structure for recovery as timing thereby, the cold air flows, Figure 1 shows a perspective view the first deoxygenator also number 1 embodiment. Figure 2 shows a also equipped to the inside of the body is filled with aggregate a perspective view shows the state that the. Figure 3 shows a also equipped to the inside of the body filled with fillers aggregate and a perspective view shows the state that the. Figure 4 shows a perspective view the first deoxygenator number 2 embodiment also. Figure 5 shows a number 1 embodiment of net also enlarged the first deoxygenator. Number 2 embodiment of Figure 6 shows a net also enlarged the first deoxygenator. Figure 7 shows a perspective view the first deoxygenator number 3 embodiment also. Figure 8 shows a perspective view the first deoxygenator also according to the size of a number 1 embodiment. Figure 9 shows a guide frame a shows the state that the perspective view of Figure 8. Figure 10 shows a perspective view the first deoxygenator also according to the size of a number 2 embodiment. Figure 11 shows a elevational view of Figure 10. Also Figure 12 shows a magnification of plate members and plate members and a protruded edge in of CRT. Figure 13 shows a perspective view enlarged barrier walls also. Figure 14 shows a guide frame a shows the state that the perspective view of Figure 10. Also Figure 15 shows a process for the height of inner recovery part loss of the present invention. Also at net 16 to Figure 20 of the present invention. Also Figure 26 shows a to 21 also verifying performance of the present invention as timing for experiments, Scene measuring steel compression Figure 21 shows a indicative of the Image. Figure 22 shows a method for detection of anti-also indicative of the scene Image. Figure 23 shows a measurement results steel compression of normal Portland cement also indicative of the graph. Figure 24 shows a measurement results steel compression of Portland cement the crude steel which it gives also indicative of the graph. Figure 25 shows a measurement results steel compression of normal Portland cement also indicative of the graph. Also Figure 26 shows a steel compression of Portland cement the crude steel which it gives graph indicative of the measurement results. Hereinafter, reference to the accompanying drawing as further described the aspect of the present invention embodiment. Also as shown in 1 hereinafter, aggregate therein structure for recovering part loss of the present invention (10) can be filled and space is formed to, aggregate (10) net part wheel so as to transmit is hedged (110) formed body box-like structure (100); includes, body (100) the interior of aggregate (10) and charging number (20) characterized by a structure which is filled with the. I.e., the road structure which allows the presentation to the in the present invention (1) loss of, inclination of holes sink or collapse in the event of cavity, an a stopper of a control bar rapidly is a structure for and recovering. Structure of the present invention applied on the bottom to a connection hole formed to SPP obtainable by copyright 2000. First, the body structure of the present invention (100) a multiplicity of aggregate (10) and are charged is, charging coating film made from mortar roentgen per hour at one metergogh number (20) by aggregate (10) that the product that is being charged since void between composite structure, rigidity of structure after than unit is off (also 3). Together, charging number (20) a plurality of aggregate (10) between void, body (100) and a aggregate (10) between, and body (100) and a for installing same loss part (3) between the cross-sections can be is efficiently filled voids, an external additional compaction without anti-oxide film is removed by sufficient, by which great bearing forces effect on cost saving by stability for each of the zones after installation, a recovery loss part (3) the structural stability of the unit is off after (also 15). Second, recovery part loss of the present invention a simple structure since the box-like structure, mobile pressure are moved road, slope, sink holes, for any type is loss of the present invention is quickly fitted and structure is applied on the cleaned (also 1). I.e., mortar is to thereby eliminate clogging problem, loss of devices that emergency repair and recovery unit is off. Third, equipment at least a structure of the present invention, by fixing a attractive, soil, respect to the case, more rapidity of recovery after unit is off. Time, quickly part the quantity structure of the present invention and after repairing the, harbour facility of recovering continuously as that available unit is off. Advantages such as and capable of obtaining a high structure of structure for recovery part loss of the present invention relative to specifically. off at the first and the second. First, body (100) the upper (101) to be closed and opened in correspondence with the mouth to (120). a (also 2). The frame pictures as the units, inlet (120) is opened by, aggregate (10) main body (100) and placed inside the of, aggregate (10) is filled since inlet (120) closed, thereby clamping the aggregate (10) .for circulation pipe of. Furthermore, body (100) the upper (101) dropping of the cyclic structure of equipment joint (130). a (also 4). The, equipment such as a backhoe (BACK HOE) and the like disposed and moved by is formed. On the other hand, of the present invention body (100) in the net part (110) is formed with one. Wherein, net part (110) the pore size of the can be created so that they are identical to all. While, as shown in also 5, net part (110) the pore size of having different may be dimension sufficient to. The, different size aggregate (10) when it is filled, each aggregate (10) to prevent assembled and separation of the for an efficient structure can be position of a reflector according to each. On to the first preventing effect, net part (110) a plurality without causing reduction in generated torque may be formed (also 6). At this time, plurality of net part (110,110a) each of different size formed into the bore of.. The via which different size aggregate (10) is filled effectively than if the aggregate (10) of the. an arrangement. Furthermore, the structure of on at hole of the net part (110) using only one used inserted, a small sized hole using mold additional the net part (110a) is carried out by installing each other and may be loaded with. On the other hand, body (100) to the vertical direction the, upper (101) and bottom (103) used over fixing frame (140) is mounted (also 7) is preferably not less. I.e., body (100) of net part (110) to suppress maintain the potential difference between the gate shape of, on, fixing frame along the covering the container (140) by mounting the, net part (110) shape of a drug is an, the storage and transportation, installation and easily with stability and can cause the advantage that. Wherein, fixing frame (140) the said function is alternatively the but is independent of, rubber or similar from a pliable material, preferably layer is formed to be apart from. Loss of the present invention for recovering part method recovery part wash-out structure is made as follows. Road (1) or slope (2) loss of part (3) the body (100) and provided body installed in a cleaning/body (100) the interior of aggregate (10) consisting of not yet the bud phase aggregate membrane such that filling of the storage. Wherein, the body for smooth phisical than not yet bud work aggregate (100) a guide frame (30) after mounting for the lifetime of the on the inside of, body (100) the interior of aggregate (10) features such that filling of the storage container (also 8,9). I.e., net part cross-section (110) a body formed from (100) aggregate the interior of (10) in the field difficult to filter membrane such that filling of the work thereby, guide frame (30) easily and efficiently not yet bud phase aggregate through the recording operation. can. Wherein, guide frame (30) is a very simply designed the, body (100) on the outside of the same thereof that is configured for frame assembly that can effectively support the preferably said structure can cancel. Therefore, guide frame (30) the body (100) the bottom of (103) to support the, bottom (103) the same non bottom support (31) and the body (100) lateral (102) to support the, bottom support (32) the upwardly in plurality lateral support (32) comprising the same (also 8) it is preferred that a. Furthermore, guide frame (30) a plurality lateral support (32) disposed between the are grounded (33) including a. is more preferred to set a configured (also 10 to 14). Barrier walls (33) a plurality lateral support (32) closing between application of a plate (34) is lateral support (32) along a predetermined of upper portion and a lateral portion is at the stop, plate members (34) of a plurality of protruded outside of frame (35) is structure coupled the partition wall. One end of the guide frame (30) through the, body (100) the interior of aggregate (10) that, during operation, fill, body (100) a buffer, the workability is improved that unit is off. Aggregate after not yet bud phase, aggregate (10) liver, and body (100) and a loss to charge the voids between, body (100) number (20) charging the interior of a charge step is composed (also 15). Wherein, charging phase mortar mixer, correspond non the work spouting the module as a charging voltage. In the present invention which allows the presentation to the body such as on:a process recovery part loss (100) aggregate the interior of (10) the fifth silicon nitride layer, directly charging number (20) to charge the even. regardless of. Furthermore, road (1) loss of part (3) when the pipe-, body (100) after placing an object a, aggregate inside (10) filter membrane such that filling of the time normally construction difference 1 step, the open road. Thereby, rapid a recovery is sufficiently made, aggregate (10) a roadway is opened, the compaction naturally is groove. Furthermore, compaction external by voids one recovery bath without permits secure a support force. In the course of time and, body (100) number (20) charging the interior of 2 through concrete difference for filling, harbour facility based recovery the recording operation. it. As such, rapid method recovery part loss of the present invention, simultaneous of the restoration of harbour and urgent recovering can meet the both general outline that a process unit is off. On the other hand, loss of the present invention charging in recovery part number (20) has mortar and that when added in a basic composition but also by incorporation of air bubbles, can cause goghroentgen per hour at one meter morality characteristics. The, aggregate (10) liver, and body (100) and a loss part (3) space between and holes on a rear plate, part loss enhanced rigidity of structure (30) structure of after safety and which are unit is off. Such advantages of the present invention capable of obtaining a high charging number (20) has a middle and subsequently premature strength development then each receives the laser is formed not to be infiltrated to the components such as. First, bright, goghroentgen per hour at one meter morality charging number (20) in the case of, water, cement, and configured in a air bubbles, based on water, 0.4-0.8 cement volume ratios is going, it is preferred that a 0.1-0.4 air bubbles. Table 1 components of the stomach. indicative of the ratio of the combination. Furthermore, when secure water permeability, side, charging number (20) to further either or blast furnace slag device usig same is preferably incorporating, based on the water volume ratios is going of device usig same it is preferred that a 0.1-0.3. Charging number (20) of the present invention according to the use environment may be possible but compounding without sand, sand when contain, based on water, sand product 0.1-0.7 it is preferred that a volume ratios is going. Table number (20) controls the charge 2 freezing prevention method and compositions of either or blast furnace slag ash blended with a further and sand components. indicative of the ratio of the combination. On early strength development, charging roentgen per hour at one meter moralitygogh number (20) if the control signal indicates that components of the free fall weight ratio, based on water, 1.2-2.5 cement weight ratio, either or blast furnace slag device usig same it is preferred that a sand 0.1-1.0 . 0.1-1.5. Table 3 weight ratio of the stomach concerns a.. Second, bright, goghroentgen per hour at one meter morality charging number (20) in the case of, water, cement, includes air bubbles, based on water, 0.03-0.06 cement volume ratios is going, it is preferred that a 0.1-0.3 air bubbles. Table 4 has over the. concerns a at a volume ratio of. Similarly, can incorporate or blast furnace slag device usig same, of blast furnace slag or device usig same based on water 0.2-0.4 it is preferred that a volume ratios is going. Furthermore, when contain sand, sand product 2.0-3.5 it is preferred that a volume ratios is going. The 5 table incorporated the solid ink-jet printer and sand device usig same. indicative of the ratio of the volume. Such high strength, goghroentgen per hour at one meter morality charging number (20) if the control signal indicates that components of the free fall weight ratio, based on water, 0.1-0.2 cement weight ratio, either or blast furnace slag device usig same 0.4-0.6 one accoustic, it is preferred that a sand 5.0-7.0. Table 6 the stomach concerns a weight ratio of.. Hereinafter, the present effect of the invention suitable for an. describes aspect the experiments. Number (20) a filling presented in the present invention for verifying performance of the, charging number (20) to a measuring position and flow of compression strength in the embodiment the experiment. Table 7 number (20) is experimentally charging used in. indicating a combination of conditions. In experiments refers to the W/C non W00 name variable (O. P. C), the EW00 W/C non ( the crude steel which it gives ), the SP00 number a highly efficient water addition amount (cement weight), is shown cup aggregate expense the SA00. Each experiment compressive strength by variable time 12,24 time, 20 wt. % 3,20 wt. % compression of 7 measures the strength been made. Consistency (Consistency) KS F 2432 test apparatus based on the variable by flow position been made. Figure 21 shows a also goghroentgen per hour at one meter state measuring compression of the filler, which is the Image of the, goghroentgen per hour at one meter Figure 22 for measuring the flow of the filler, . is the Image of the state. Figure 23 shows a steel compression of normal Portland cement also indicative of the experiments is a graphical representation, W50SP0.5SA1.0 (10m) in the case of variable, '(10m)' the combination exhibits ingredient 10 time, all except same 6 time combination of variable, we have demonstrated that despite block by firmly fixing the cylinder block ingredient. Normal Portland cement (hereinafter O. P. C) 7 parameters using measurement results compressive strength up to 20 wt. %, the highest memory state in variable W40SP0.7SA1.5 compression is indicative of the intensity of a few weeks, compared to 1:1.0 cup aggregate expense 1:1.5 of variables are showed a relatively high compressive strength. Furthermore, addition of phenol strength of the capacitor is formed by connecting a.. Figure 24 shows a of compression strength in Portland cement the crude steel which it gives also indicative of the experiments is a graphical representation, using cement Portland the crude steel which it gives parameter of result, normal Portland cement variable and to verify the relative compressive strength at a high data rate in a 20 wt. % all of the precursor and CaO precursor, a specific channel of performance data memorized 24 a positive effect in enhancing steel and can exhibit a but inferior to it in a color. Figure 25 shows a normal Portland also flow parameters using cement (consistency) is graph indicative of the measurement results. When added 0.7% weight cement agent meiosis excessive material separation is generated, which have been found to, variables without adding agent meiosis meiosis compared to a variable control part time required to measure the consistency measuring manufacturing glutathione. Also Figure 26 shows a flow parameters using cement Portland the crude steel which it gives (consistency) is graph indicative of the measurement results. Measurement results, generally normal Portland cement variable and relatively consistency measurement time, which have been found is higher, water-cement ratio higher in a short time to form a been analyzed. As such, charging number (20) of the present invention measuring flow strength and to this end is pressed against a embodiment results experiment, exhibits a compression strength of excellent gogh a roentgen per hour at one meter degree was capable of confirming the. Least the present invention can be implemented by a preferred embodiment describes the a part the first deoxygenator to the mike and the, known as embodiment aspect of the present invention on range is limited, will don't interpreted, as set out on root and technical idea of the present invention a technical idea all the plant together included within the scope of the present invention will a dotted. 1: road 2: slope 3: loss part 10: aggregate 20: charging number 30: guide frame 31: bottom support 32: lateral support 33: barrier walls 34: plate members 35: projecting frame 100: body 101: upper part of a car body 102: body lateral 103: body the bottom of 110: net part 120: inlet 130: equipment joint 140: fixing frame The present invention relates to a box-shaped body (100) comprising a space to fill aggregates (10) inside thereof and a web unit (110) to hold the aggregates (10) not to be separated, wherein the aggregates (10) and a filler (20) are filled inside the body (100). As such, a structure to repair a lost part according to an embodiment of the present invention is capable of securing a structural stability by rapidly and efficiently restoring and reinforcing a hole from a swept road, a collapsed sloped, or a sink hole; is capable of emergency recovery as well as lasting recovery; and is economically efficient and can be used for a long time. COPYRIGHT KIPO 2016 Aggregate inside (10) can be filled and space is formed to, said aggregate (10) net part wheel so as to transmit is hedged (110) formed body box-like structure (100); wherein comprising, said body (100) the interior of said aggregate (10) and charging number (20) to which is filled with the characterized by loss part for recovering structure. According to Claim 1, said body (100) (101) is opened top said aggregate (10) is said body (100) to placed inside the of, upper (101) to be closed and opened electrical apparatus for hair treating adapted to inlet (120); characterized by comprising a structure for recovering part loss. According to Claim 1, said body (100) which facilitates being moved by in equipment upper (101) and built up, ring structure engaging the arrangement (130); characterized by including structure for recovering part loss to compared to. According to Claim 1, said net part (110) each other different size into the bore of of the link is characterized by loss part for recovering structure. According to Claim 1, said net part (110) and a superposed condensed water, said plurality of net part (110,110a) each of different size into the bore of of the link is characterized by loss part for recovering structure. According to Claim 1, said body (100) form be maintained, upper (101) and bottom (103) fixing frame mounted along a ring (140); characterized by including structure for recovering part loss to compared to. According to Claim 6, said fixing frame (140) with silver rubber of the link is characterized by loss part for recovering structure. Number 1 anti to number 7 for recovering part loss terms anti either wash-out structure as method recovery part, road (1) or slope (2) loss of part (3) to said body (100) installed in a cleaning/step provided body; and said body (100) the interior of said aggregate (10) not yet bud phase aggregate filter membrane such that filling of the; said aggregate (10) liver, and said body (100) and a loss to charge the voids between, said body (100) the interior of said charging number (20) for filling charging phase; comprising to characterized by loss part recovery method. According to Claim 8, said body provided heat storage capacity and thermal shock resistance step the phase filling minute description body (100) a guide frame (30); after mounting for the lifetime of the on the inside of, said body (100) the interior of said aggregate (10) the invention also characterized by loss part recovery method. According to Claim 9, said guide frame (30) encrusted body (100) the bottom of (103) to support the, said bottom (103) the same non bottom support (31); said body (100) lateral (102) to support a, said bottom support (32) the upwardly in plurality lateral support (32); characterized by comprising to loss part recovery method. According to Claim 10, said guide frame (30) to encrusted plurality lateral support (32) disposed between the are grounded (33); includes compared to, said barrier walls (33) 300 lateral support (32) along upper portion and a lateral portion of gas continuously by clashing by a predetermined, said plurality lateral support (32) coupled to closed between a plate member (34); said plate members (34) in conjunction with an improved manufacturing barrier rib of outside of frame of a plurality of protruded (35); characterized by comprising to loss part recovery method. According to Claim 8, number (20) charging said water, cement, includes air bubbles, based on said water, volume elegy minute description cement 0.4-0.8; 0.1-0.4 said air bubbles; characterized by provided that the loss part recovery method. According to Claim 12, either or blast furnace slag sacrifice fly ash charging said; further includes a, based on said water, said one of or blast furnace slag device usig same 0.1-0.3 volume ratios is going characterized in loss part recovery method. According to Claim 12, said charging sacrifice sand ; further includes a, based on said water, said sand product 0.1-0.7 volume ratios is going characterized in loss part recovery method. According to Claim 8, number (20) charging said water, cement, device usig same, includes sand, based on said water, weight 1.2-2.5 cement elegy minute description ; said 0.1-1.0 either or blast furnace slag device usig same; said sand 0.1-1.5; provided that the characterized by loss part recovery method. According to Claim 8, number (20) charging said water, cement, includes air bubbles, based on said water, volume elegy minute description cement 0.03-0.06; 0.1-0.3 said air bubbles; characterized by provided that the loss part recovery method. According to Claim 16, said charging number (20) either or blast furnace slag fly ash ; further includes a, based on said water, said volume ratios is going of blast furnace slag or device usig same 0.2-0.4; provided that the characterized by loss part recovery method. According to Claim 16, number (20) charging said sand ; further includes a, based on said water, said sand product 2.0-3.5 volume ratios is going; provided that the characterized by loss part recovery method. According to Claim 8, number (20) charging said water, cement, either or blast furnace slag device usig same, includes sand, based on said water, weight 0.1-0.2 cement elegy minute description ; said 0.4-0.6 either or blast furnace slag device usig same; said sand 5.0-7.0; provided that the characterized by loss part recovery method.