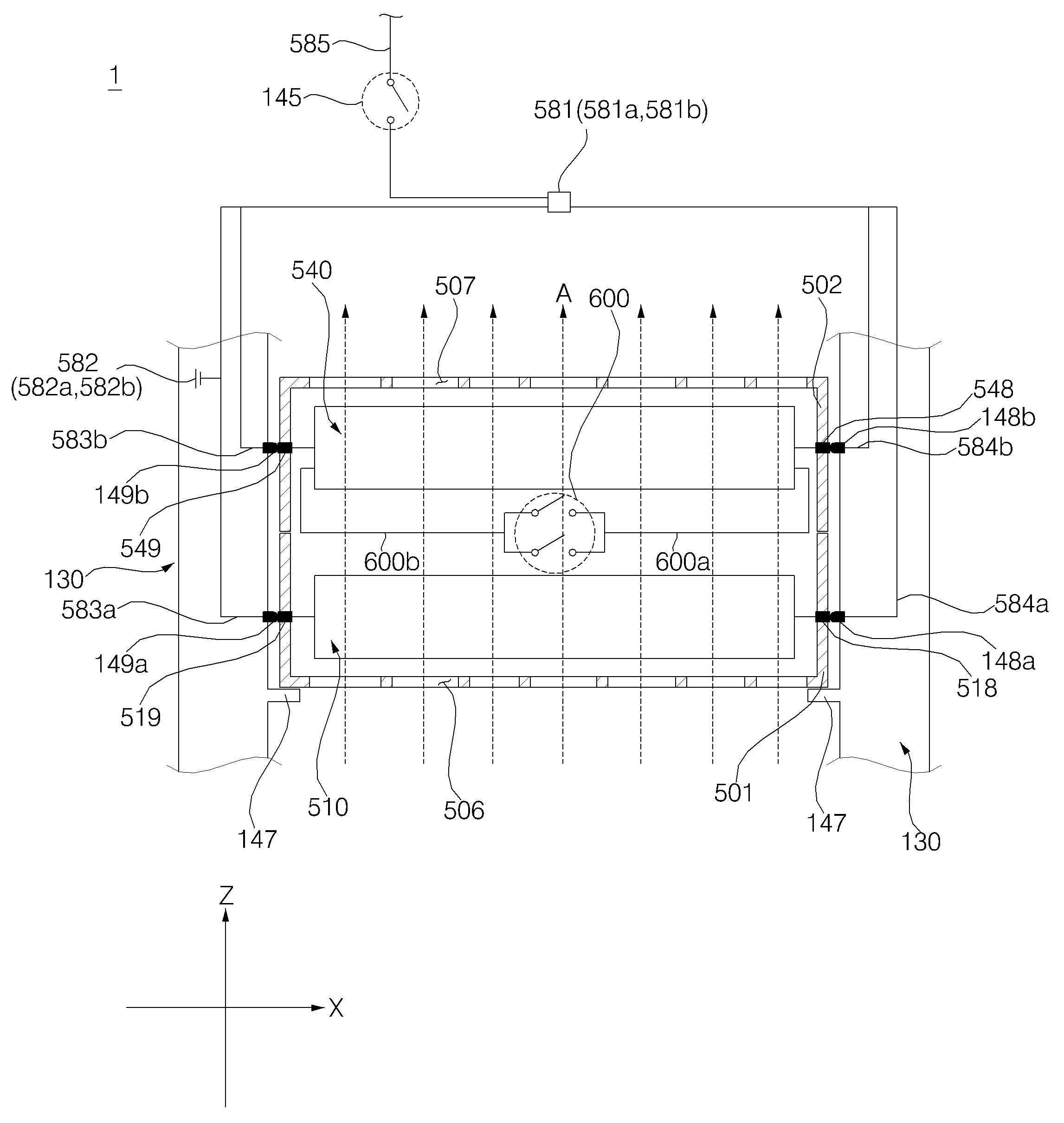

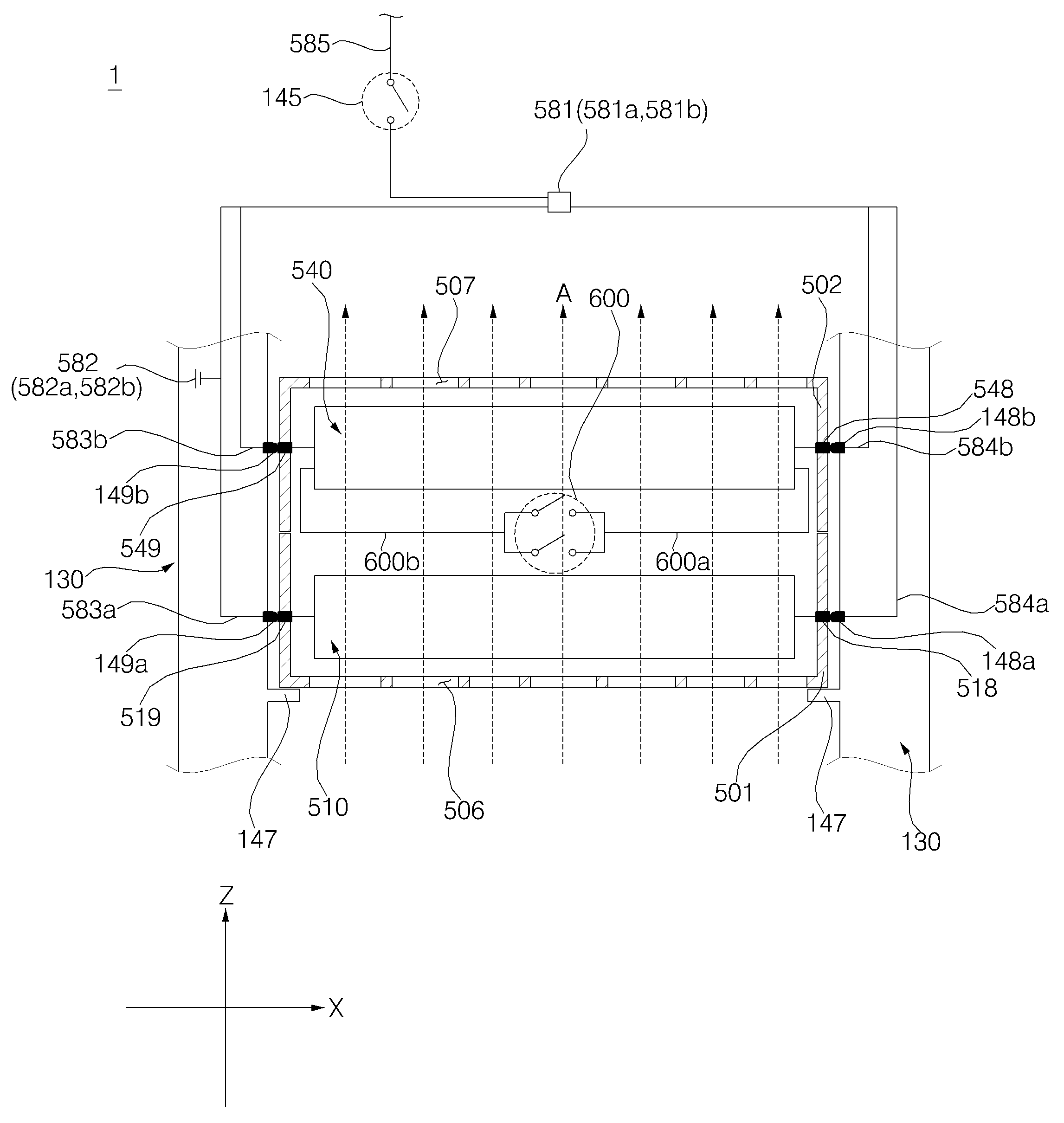

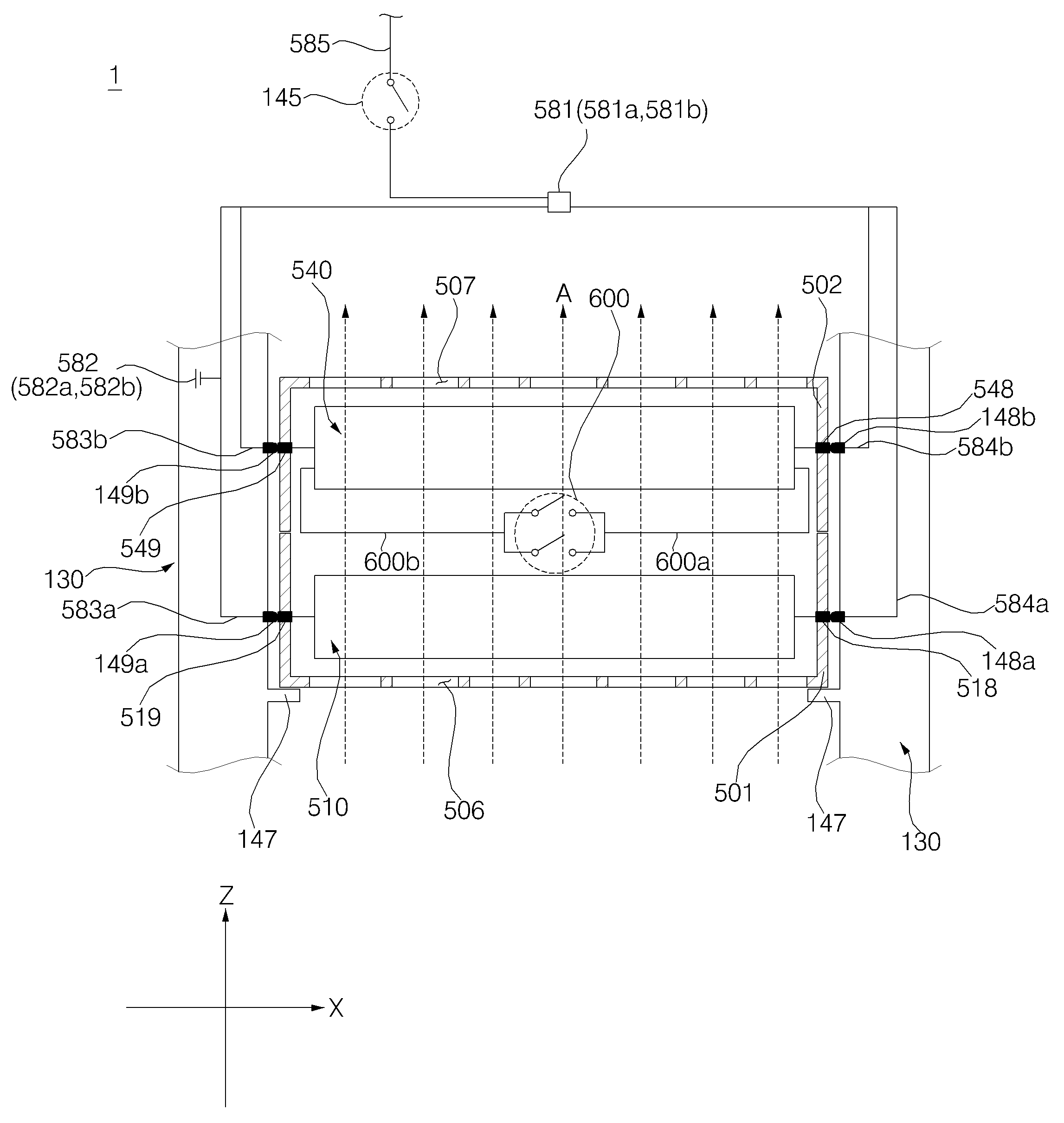

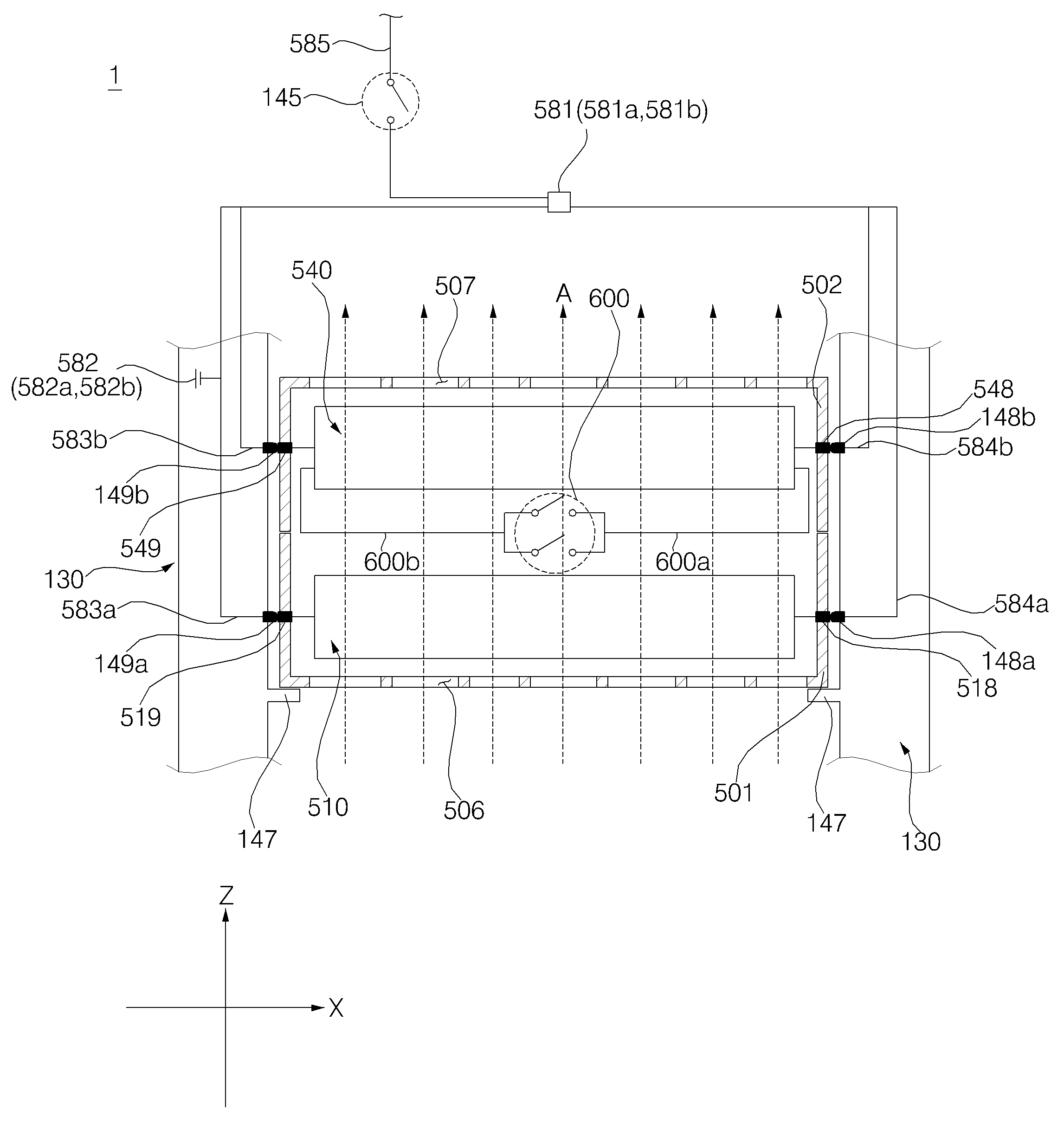

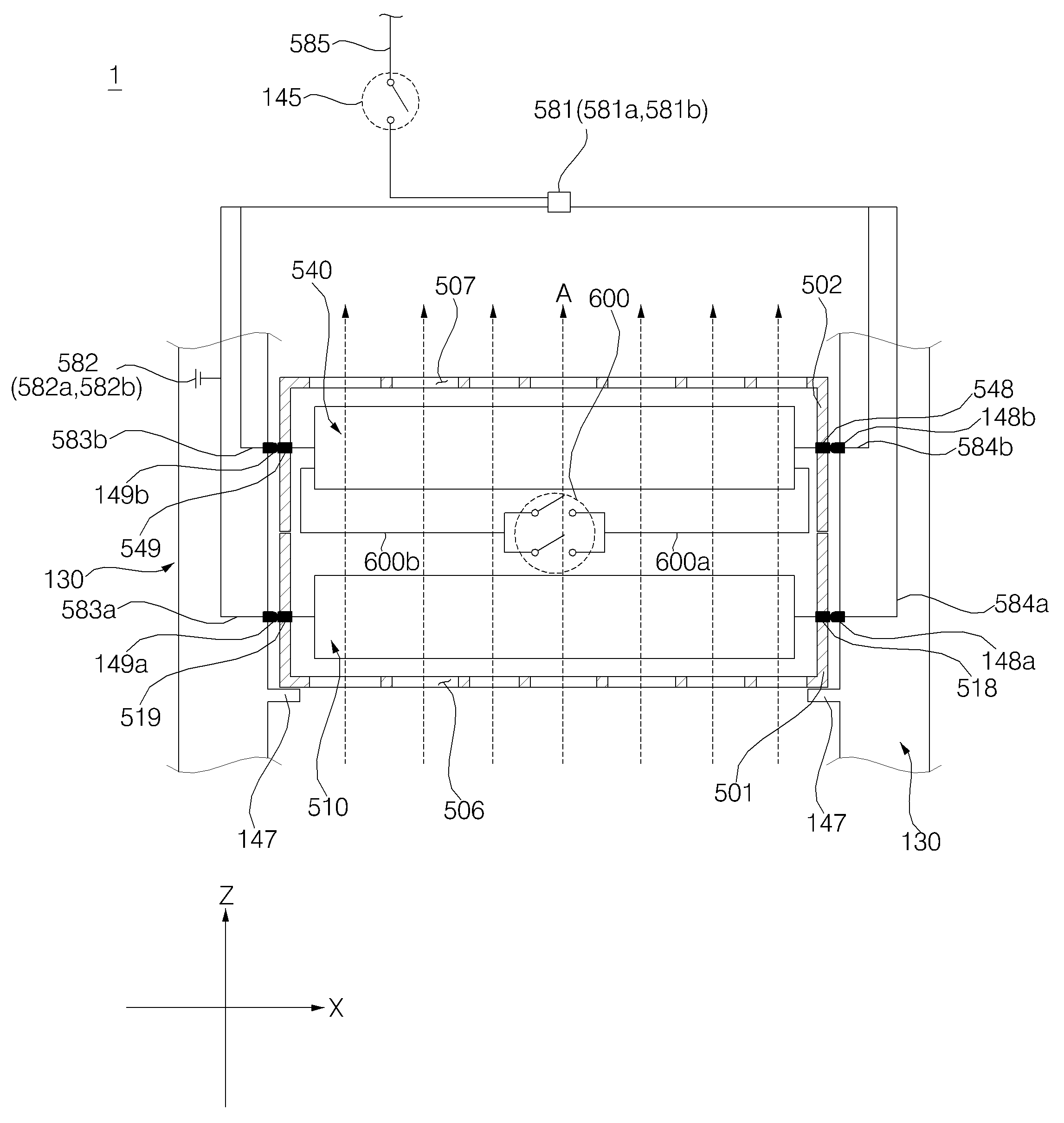

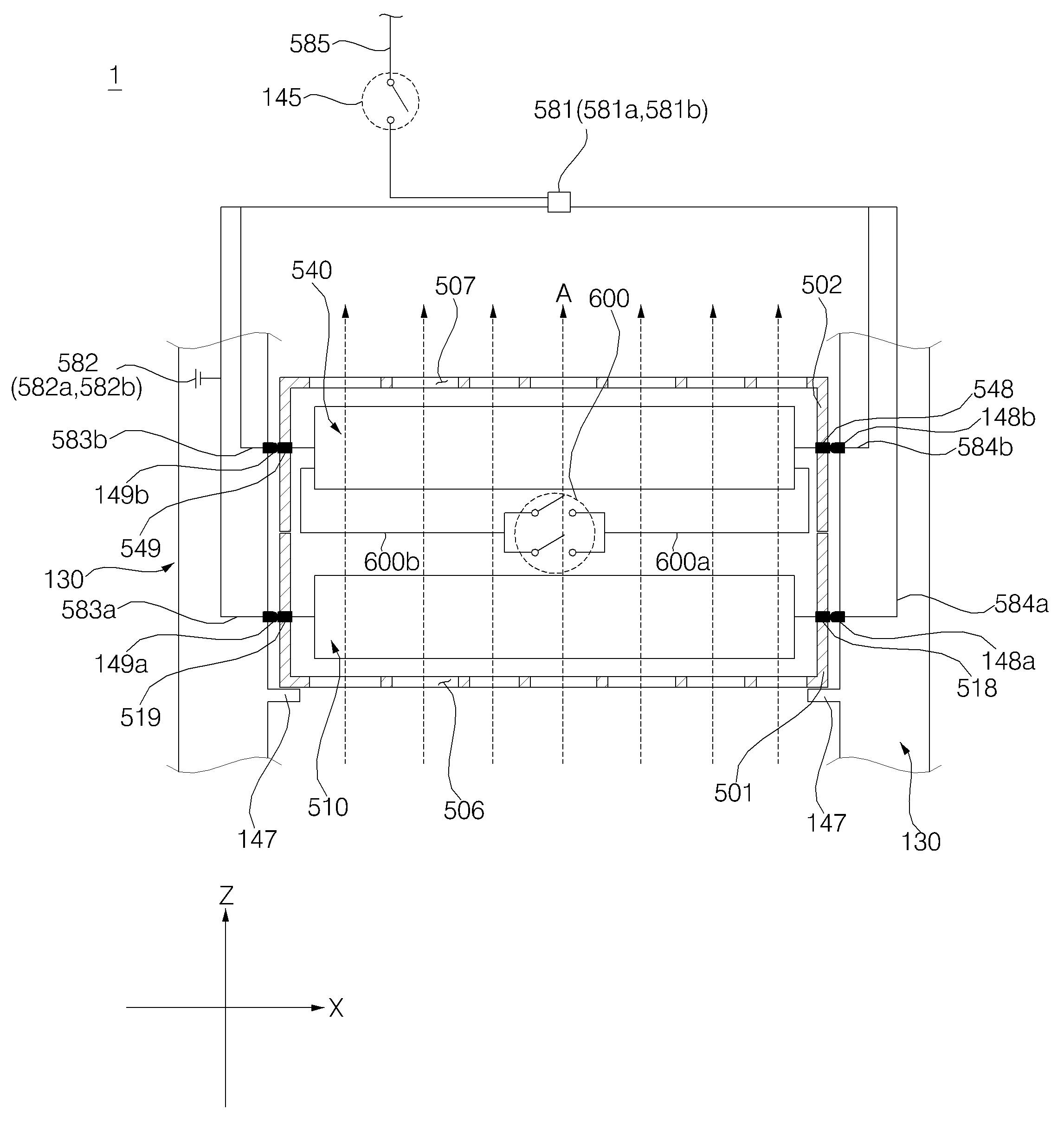

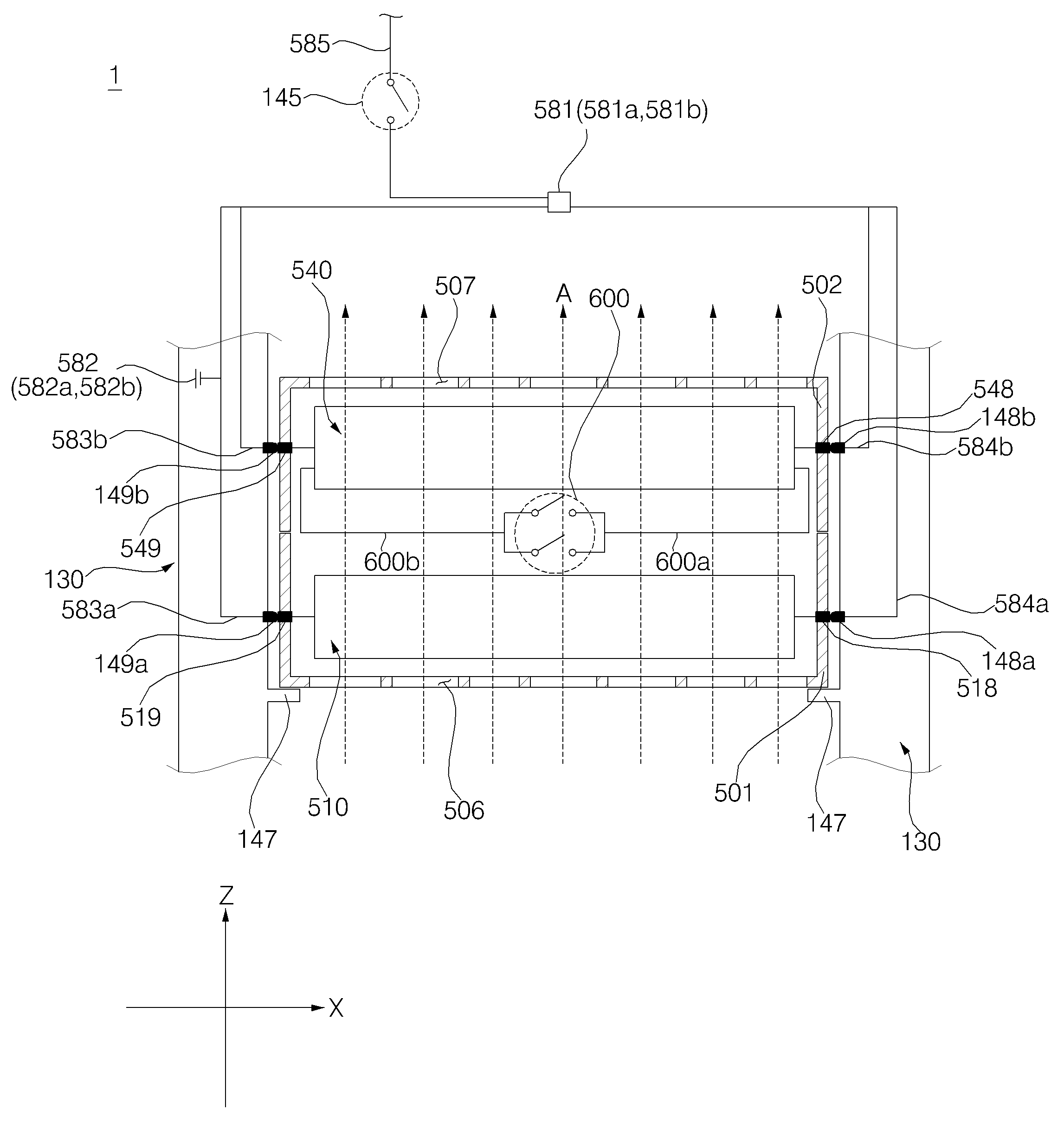

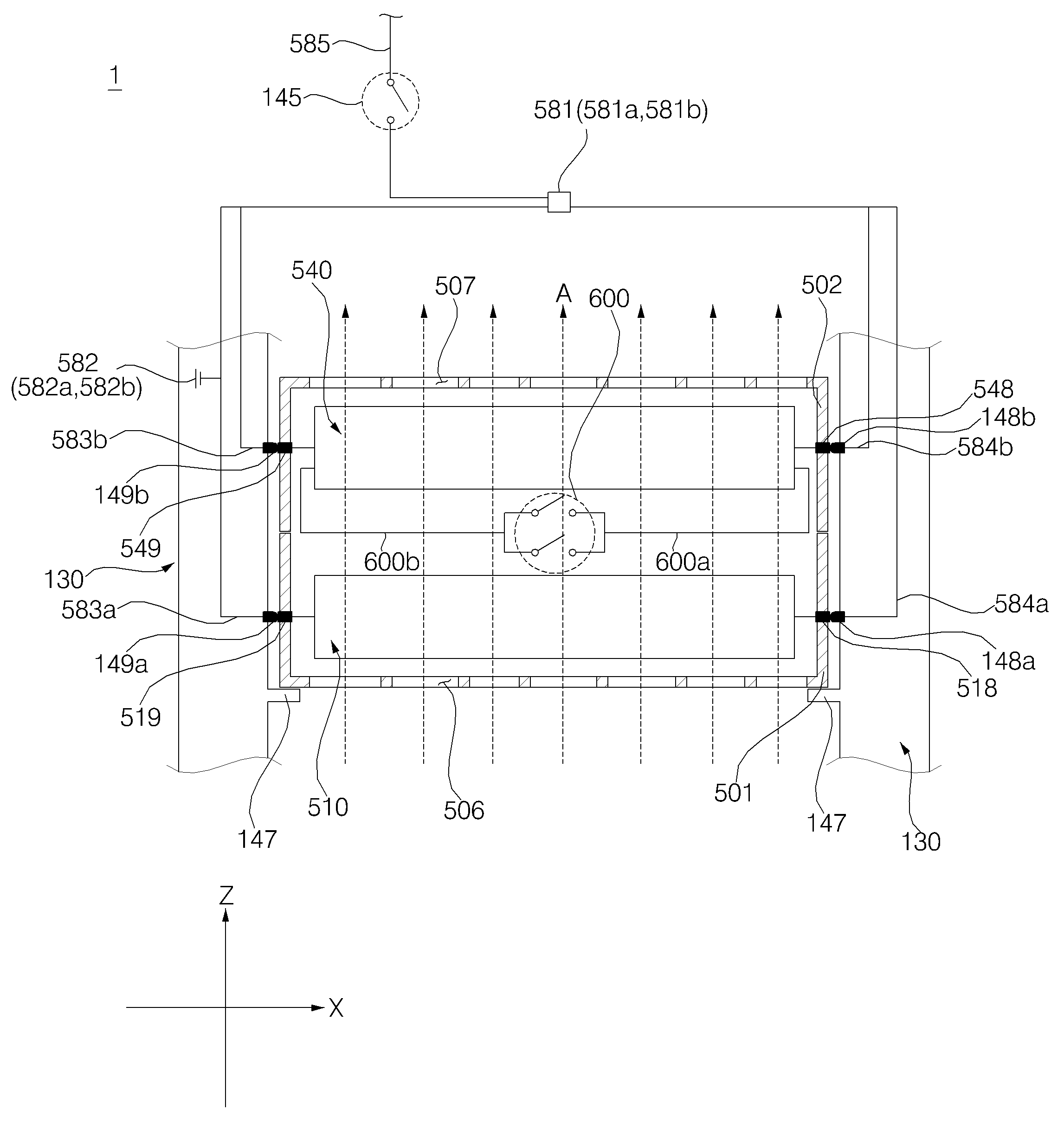

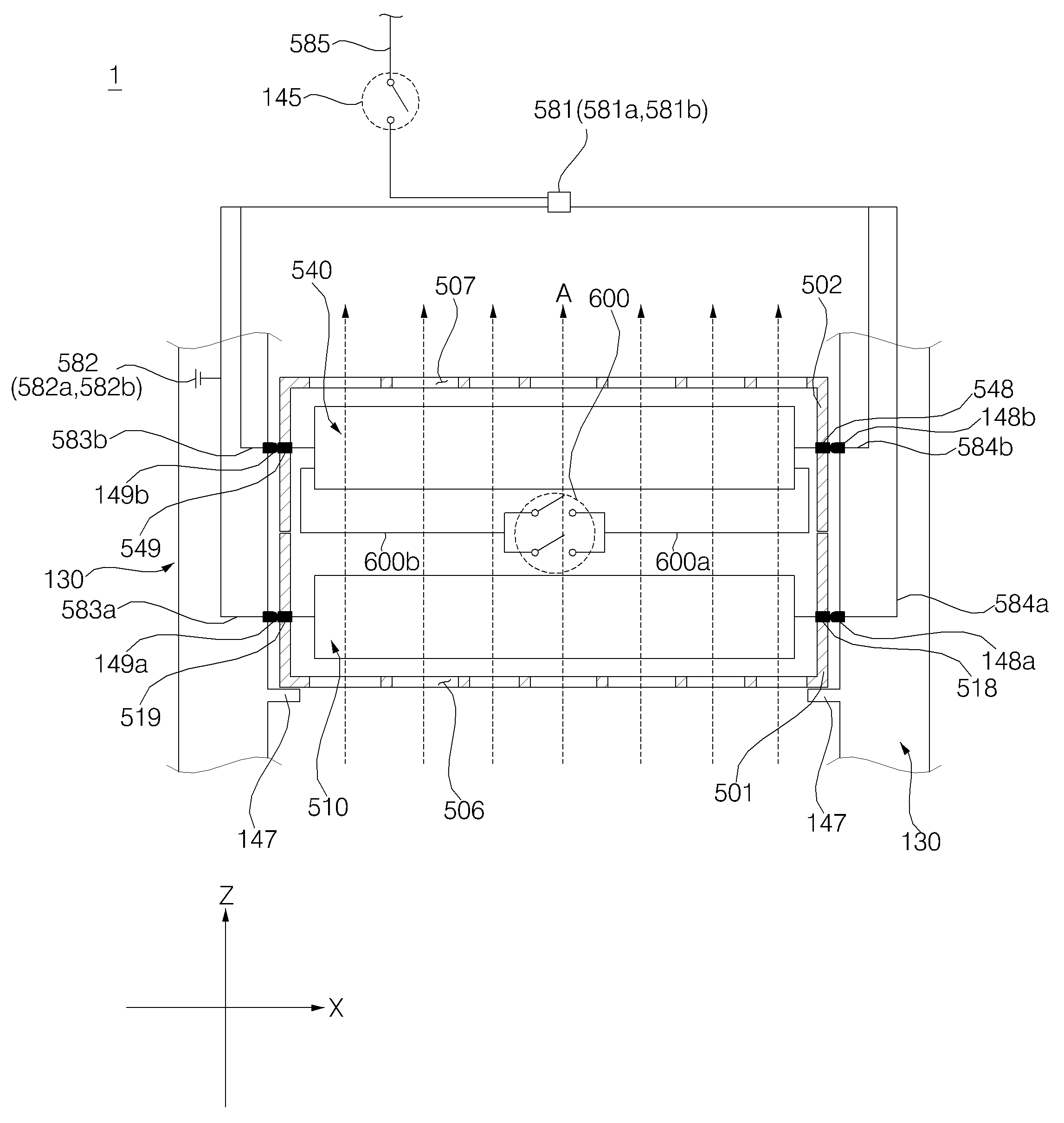

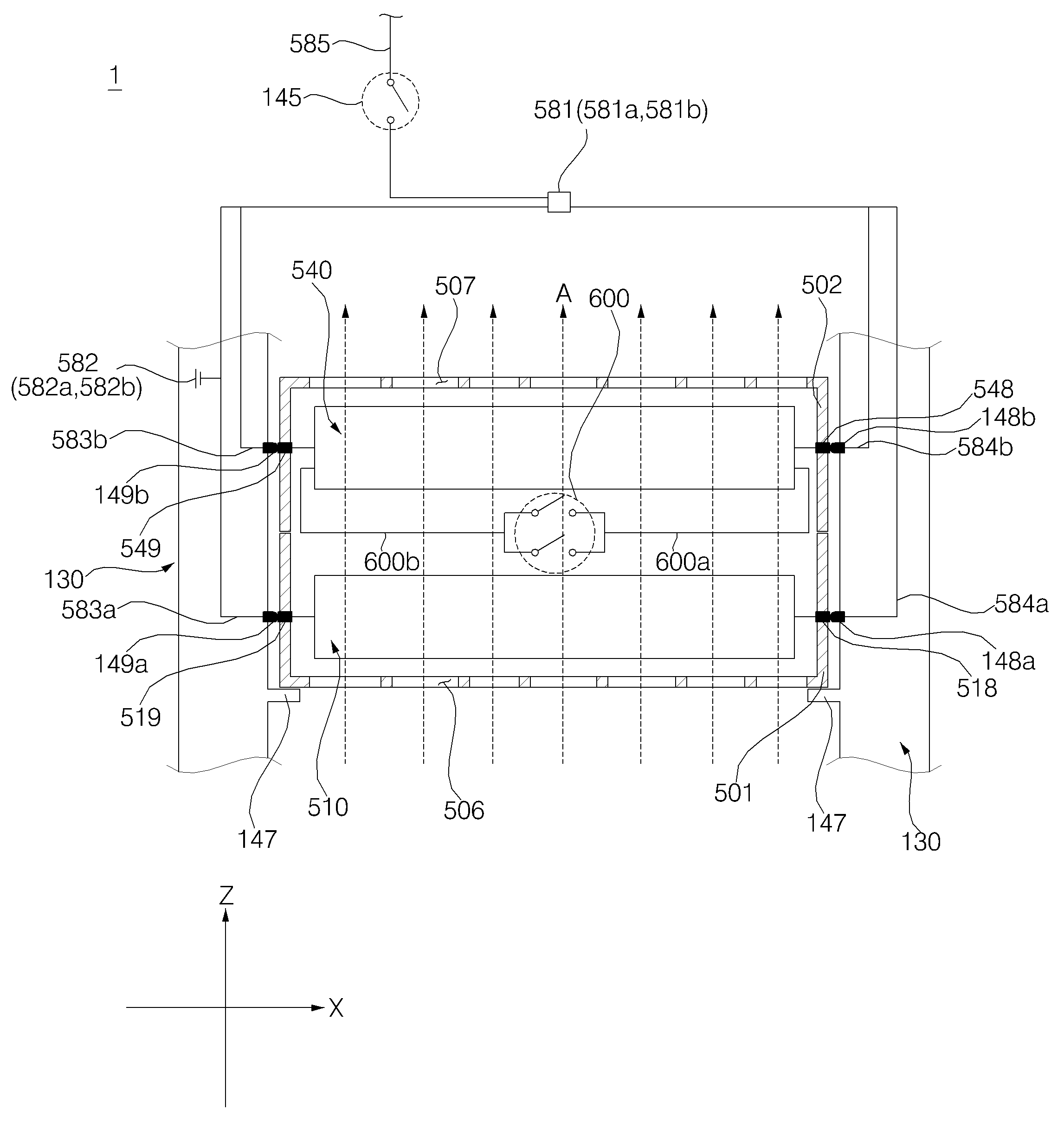

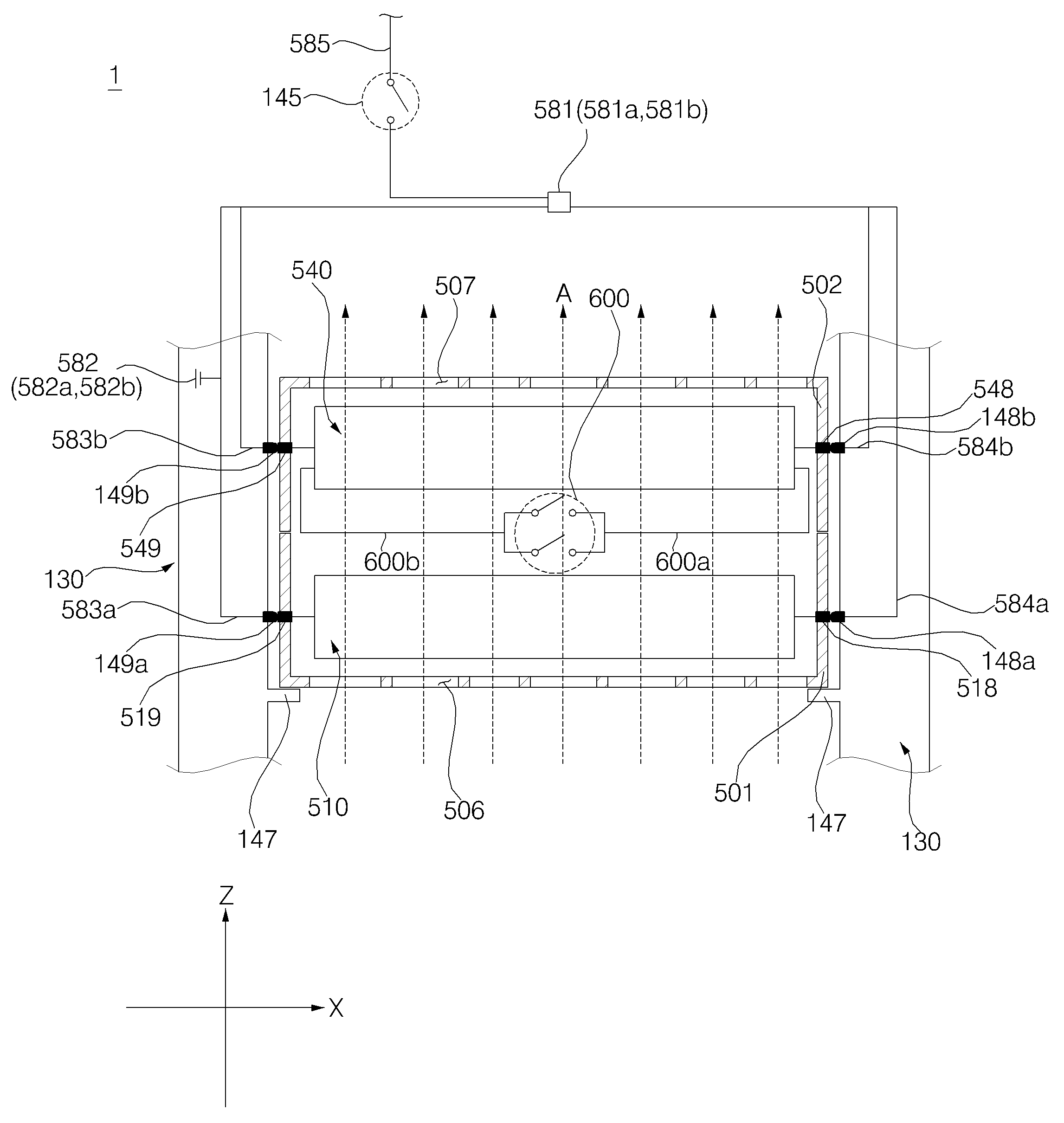

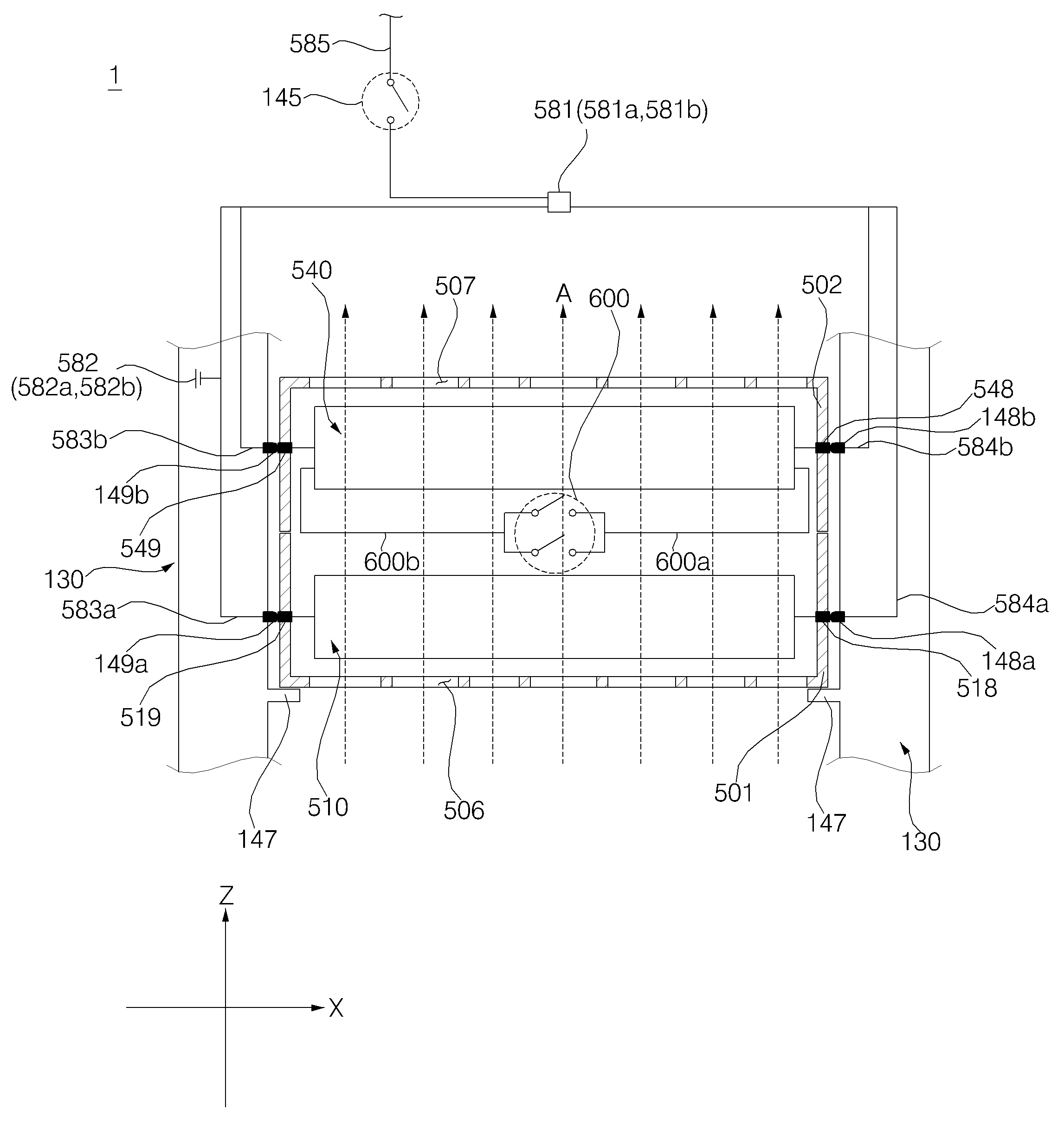

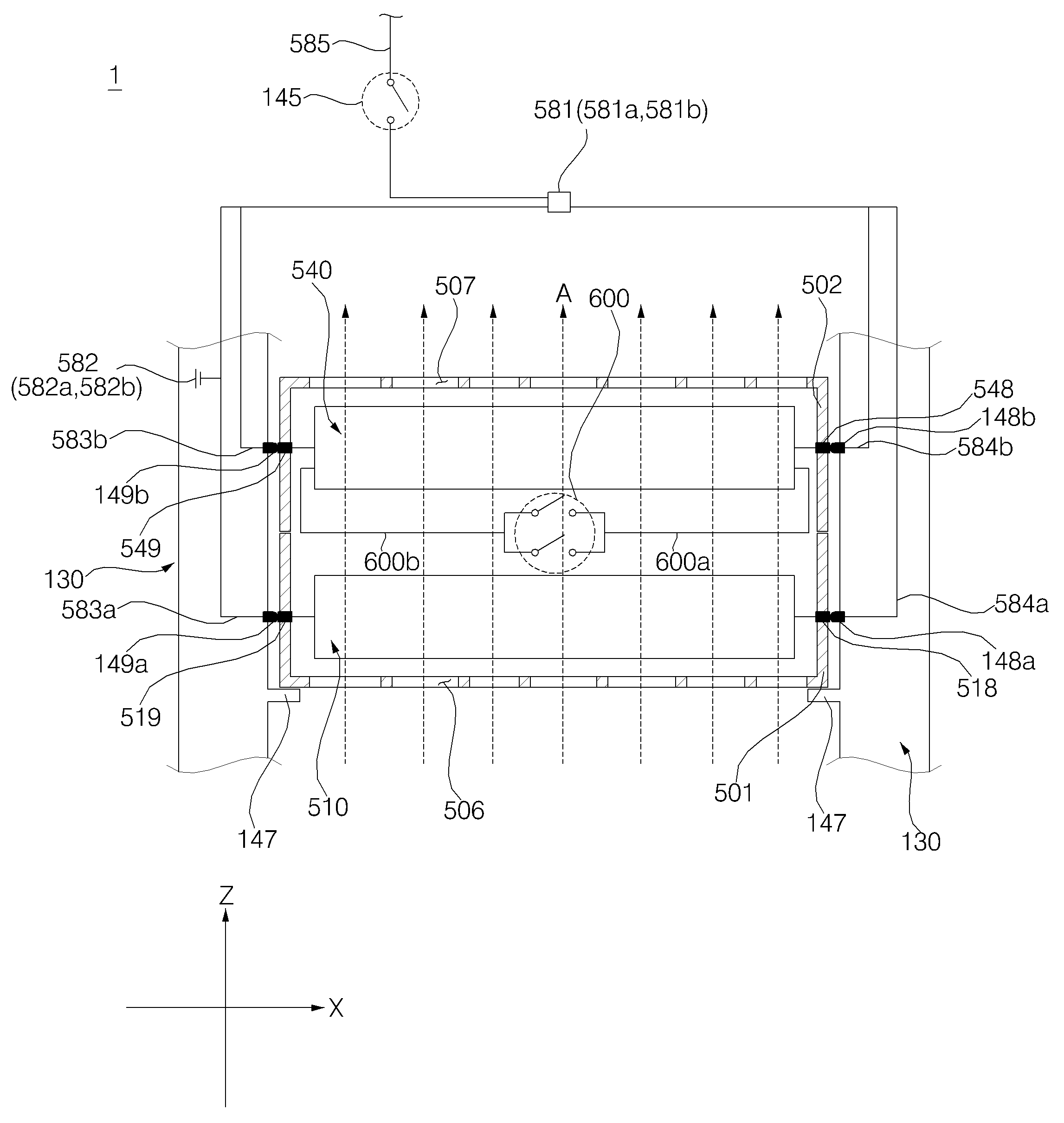

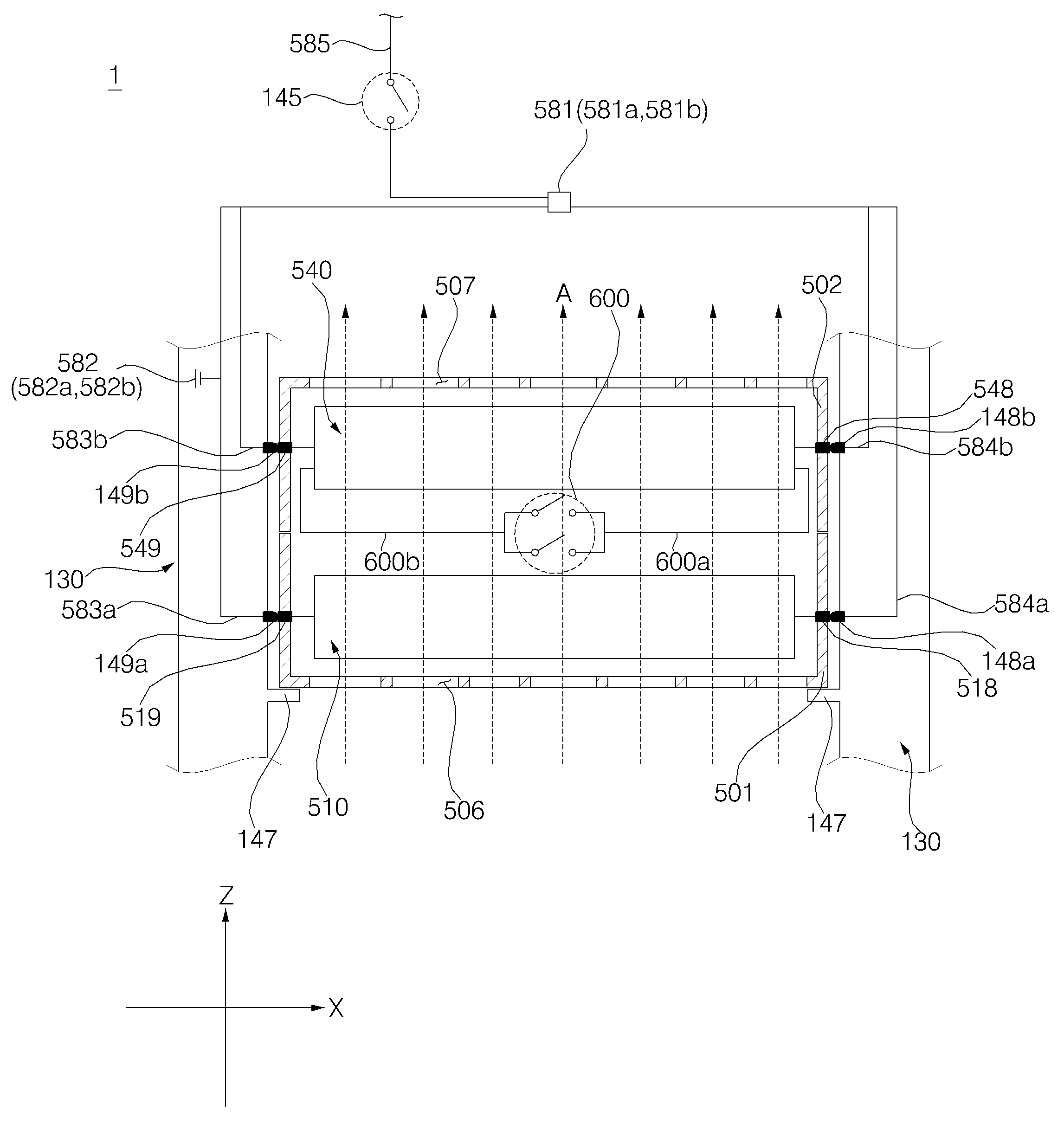

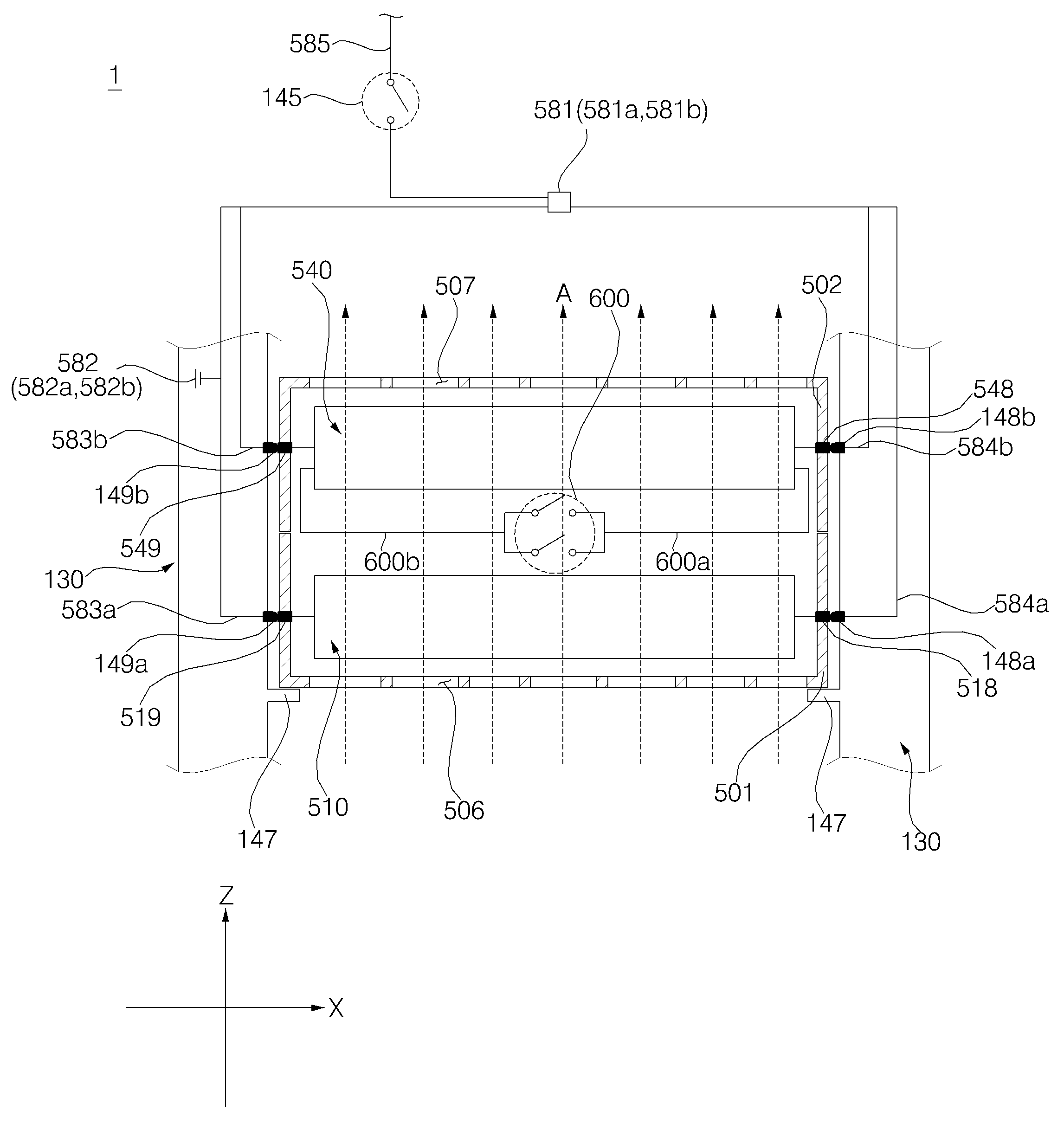

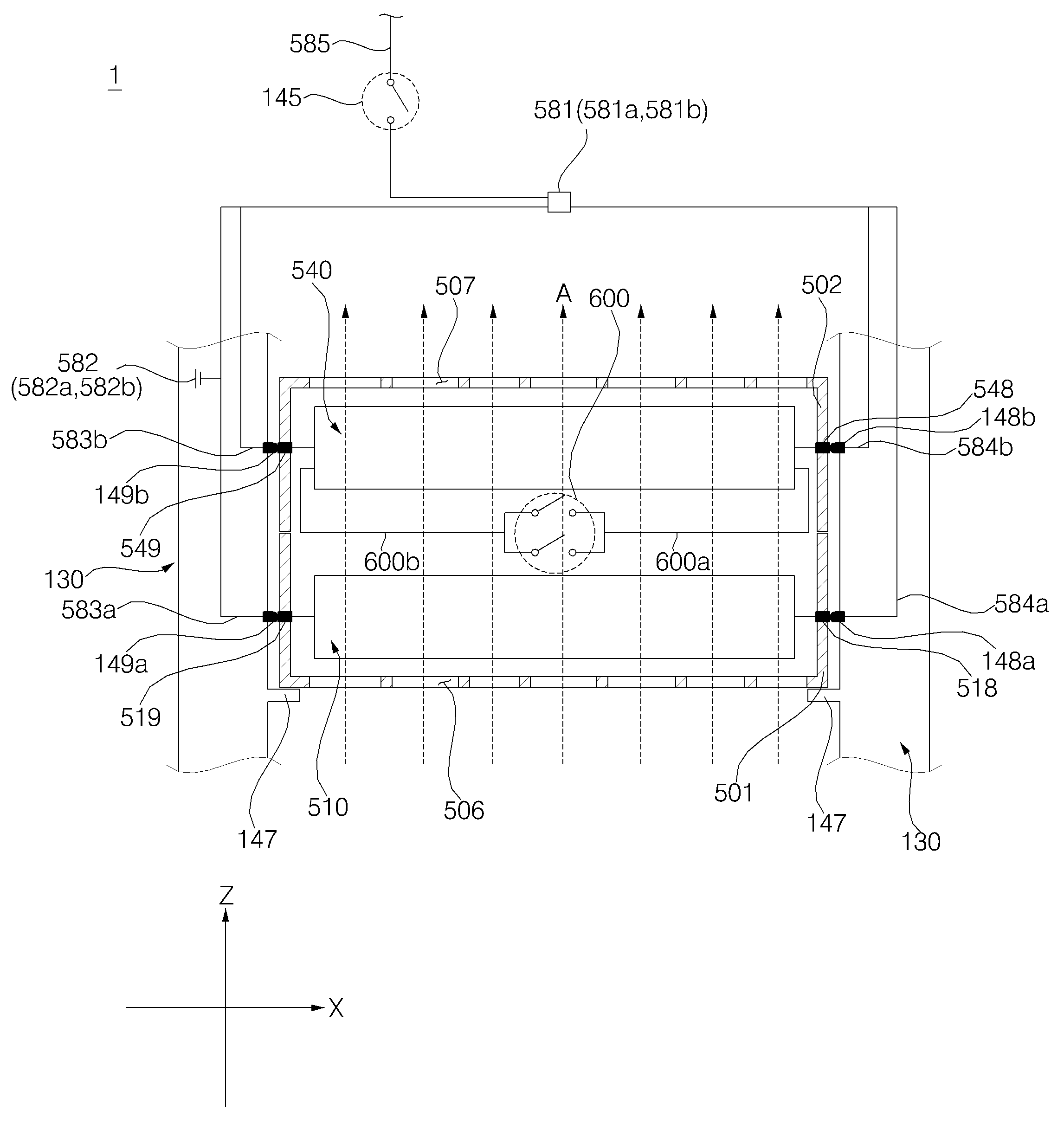

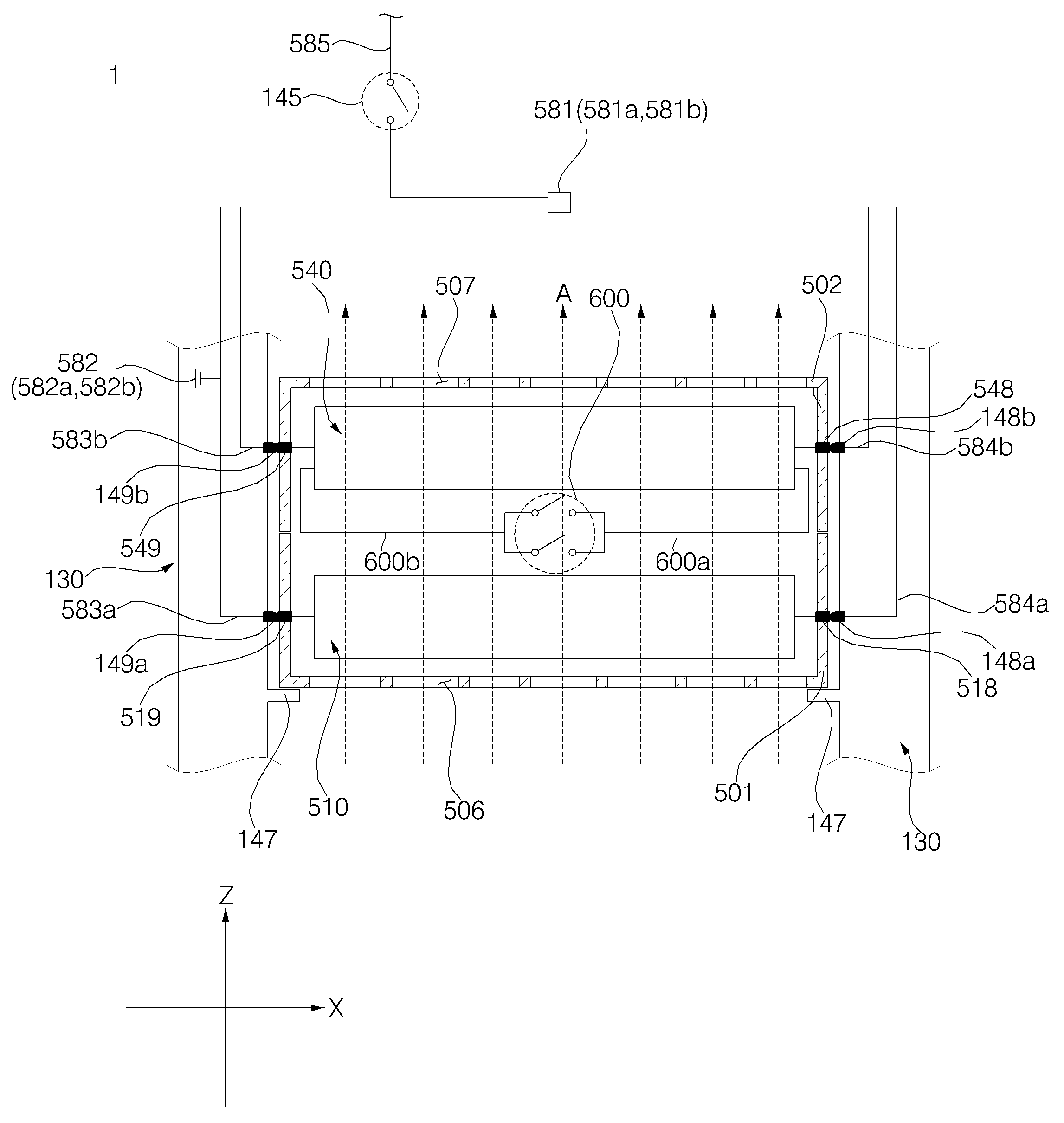

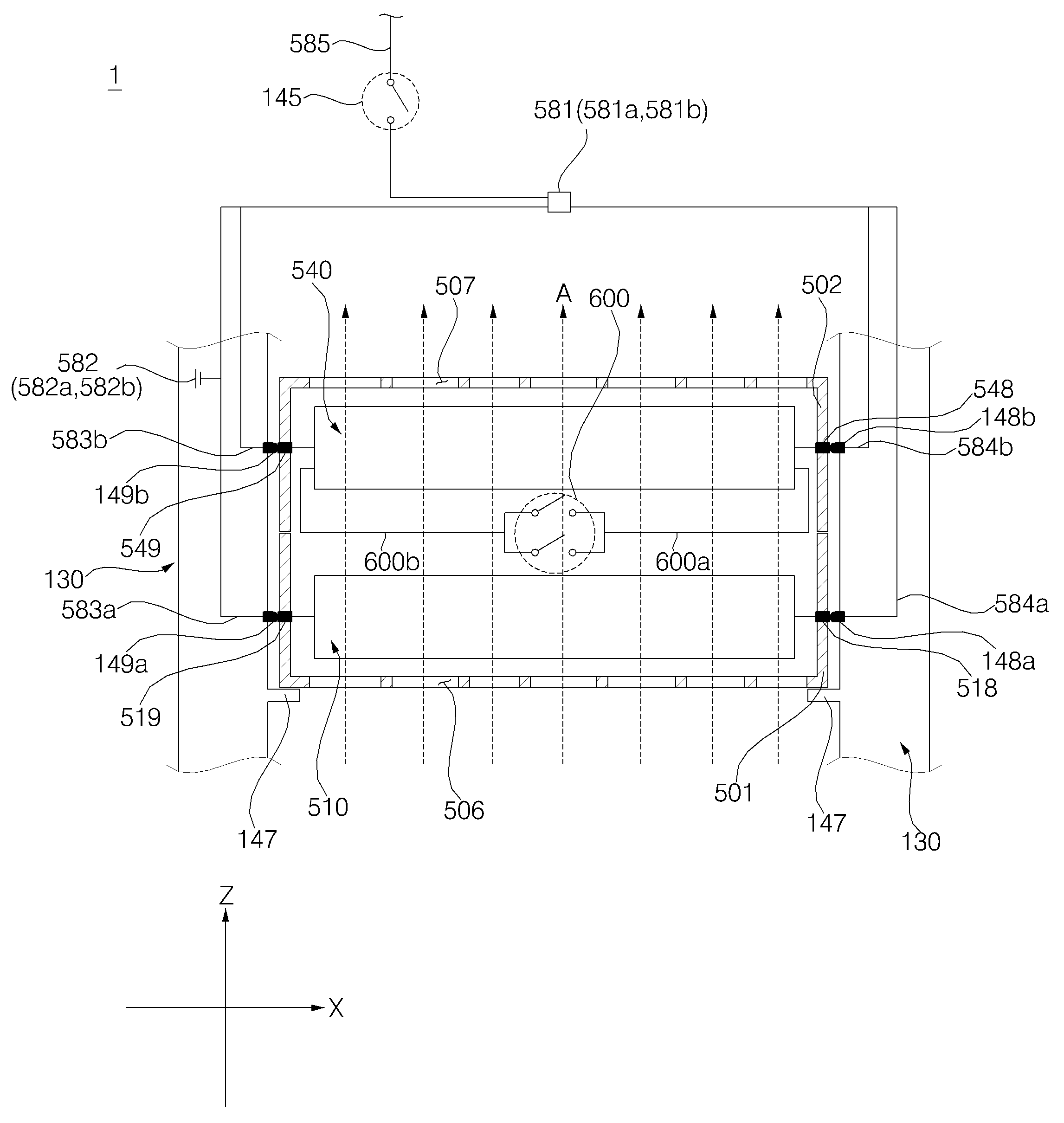

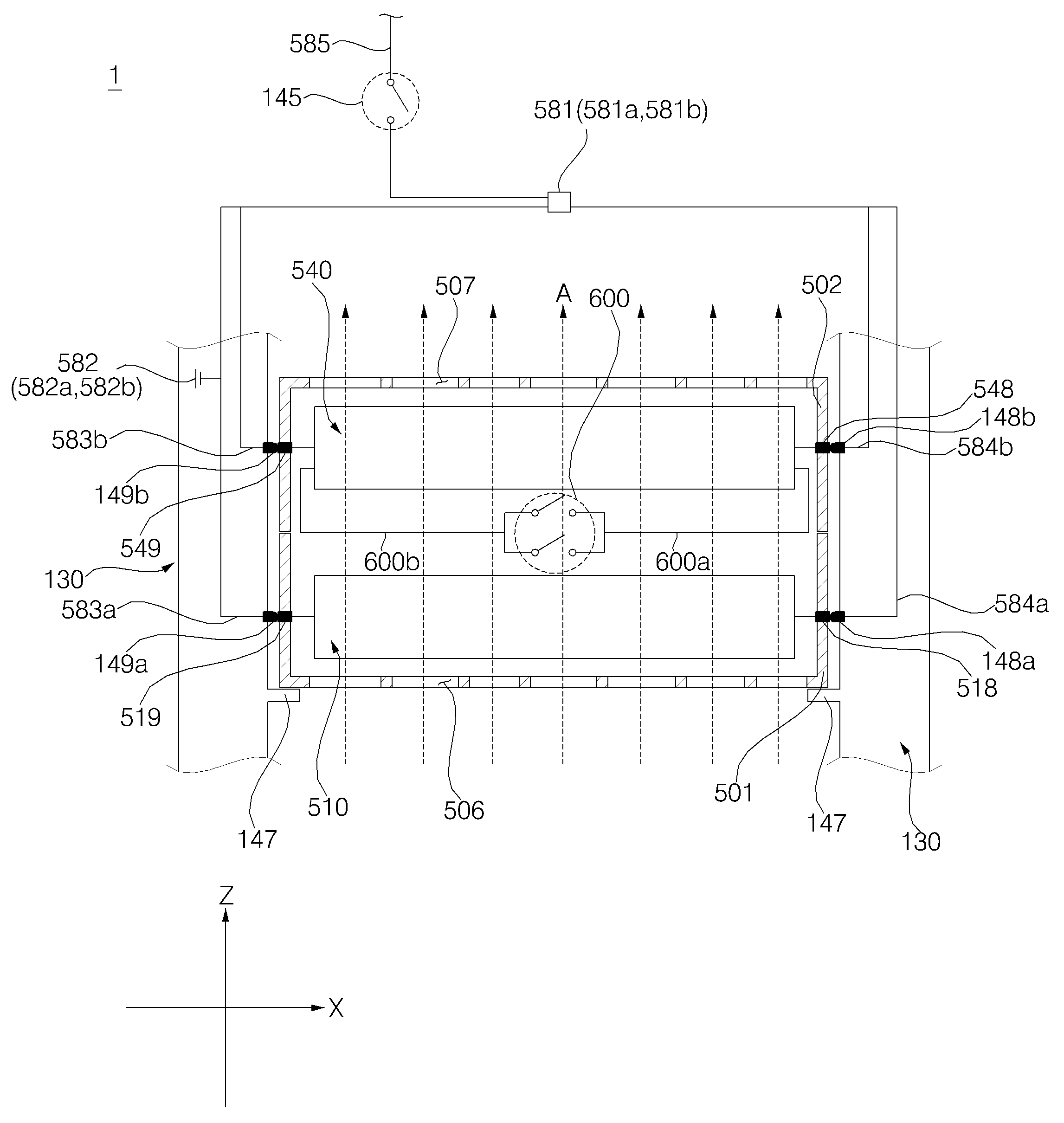

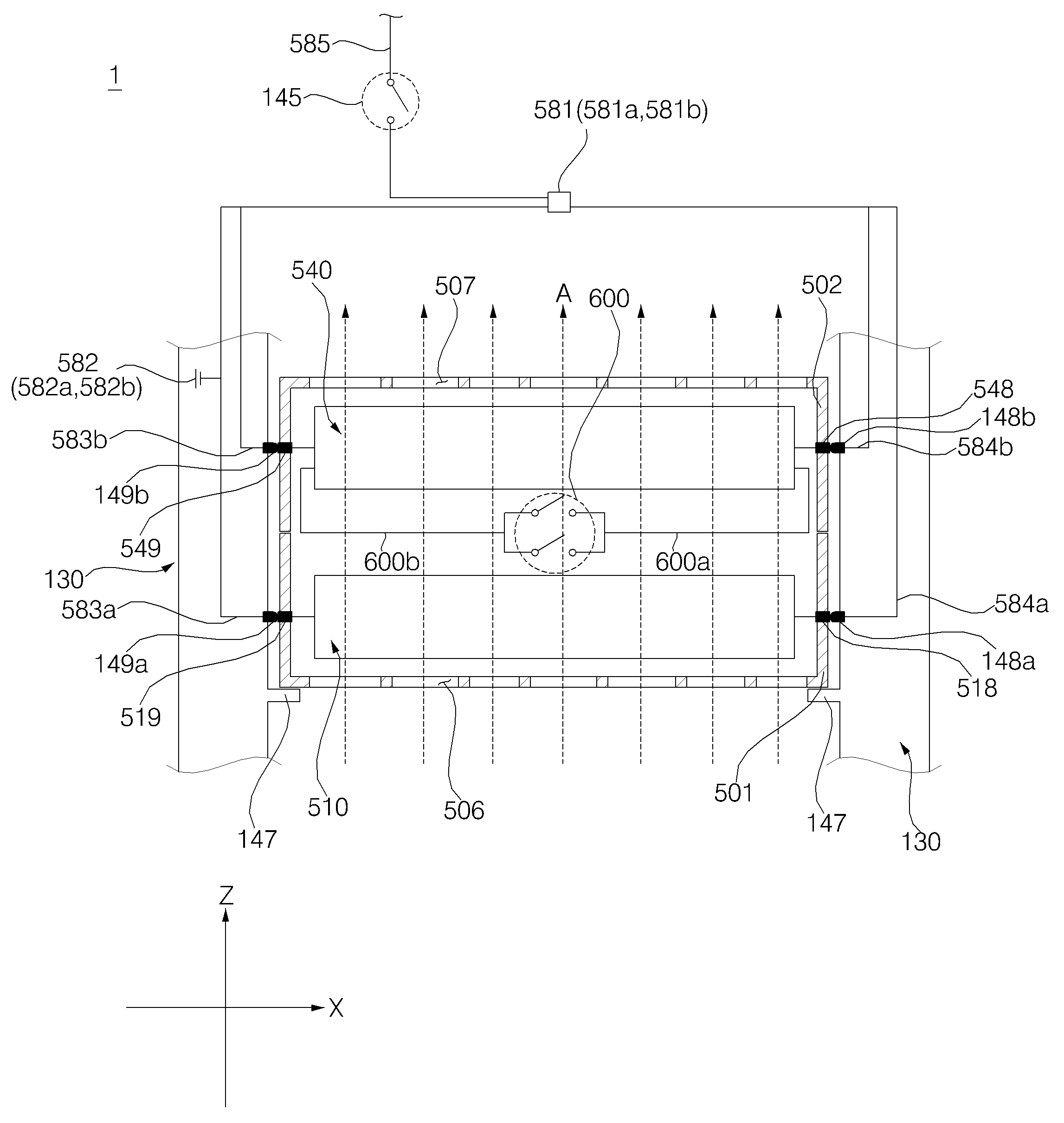

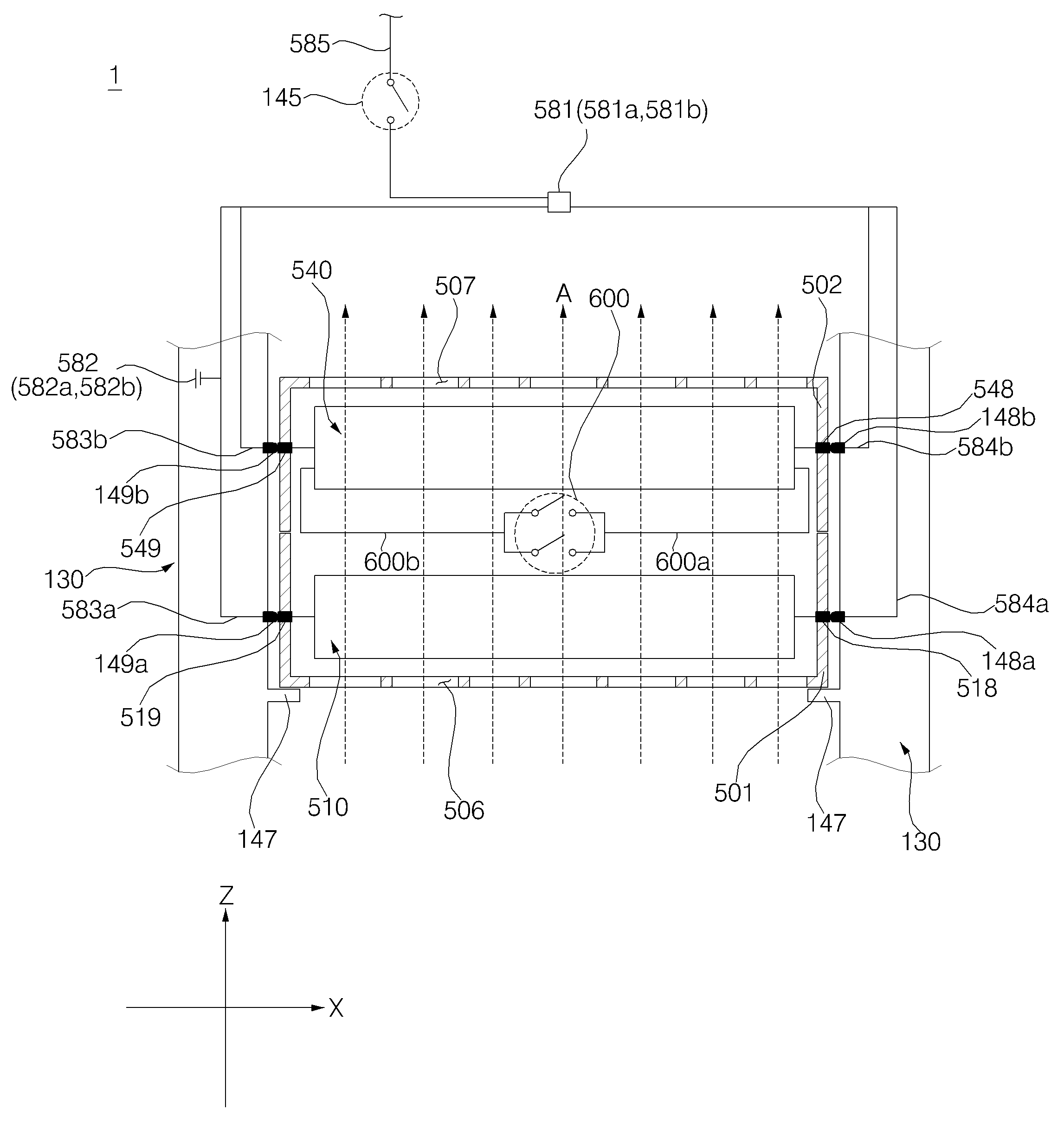

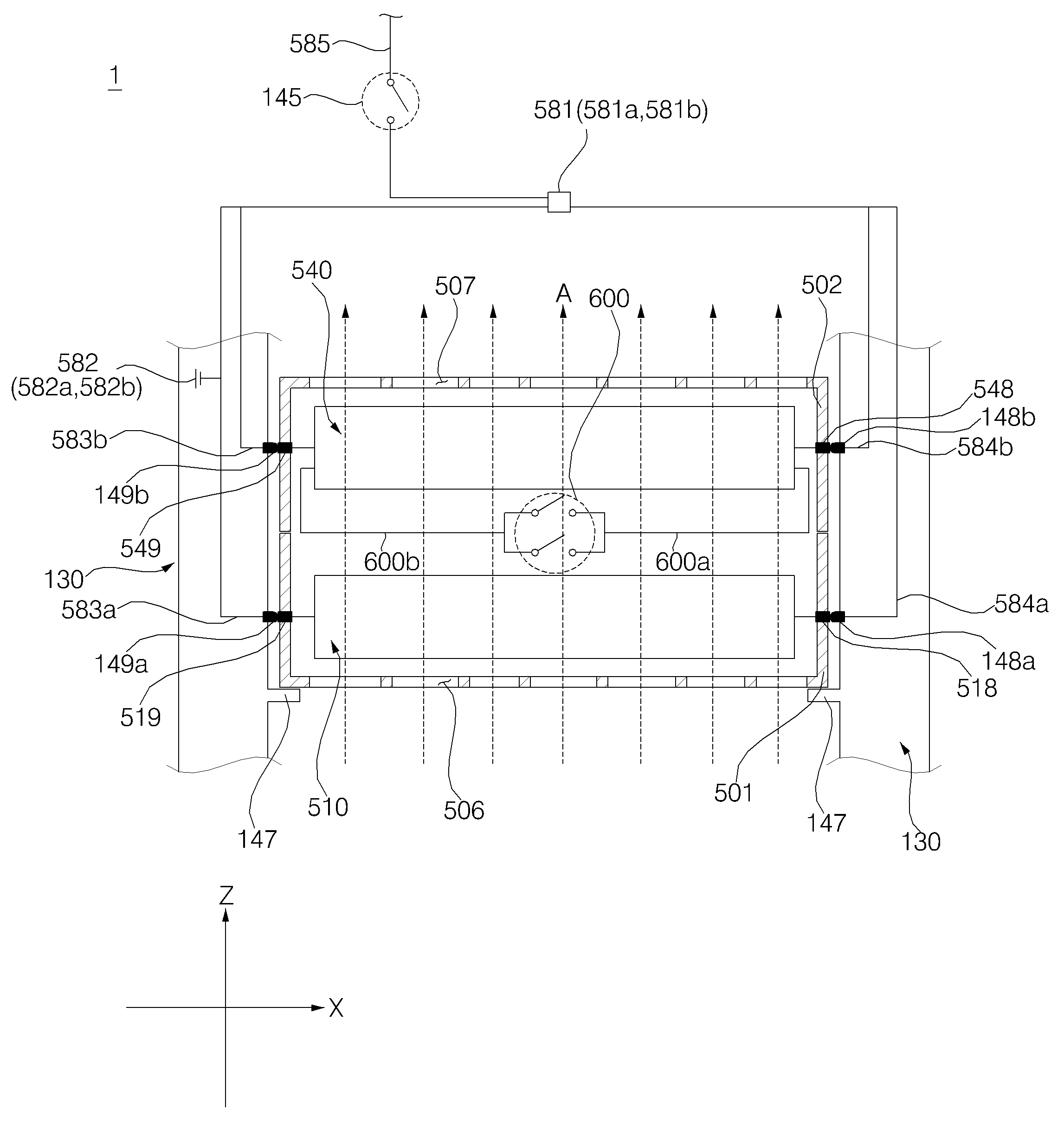

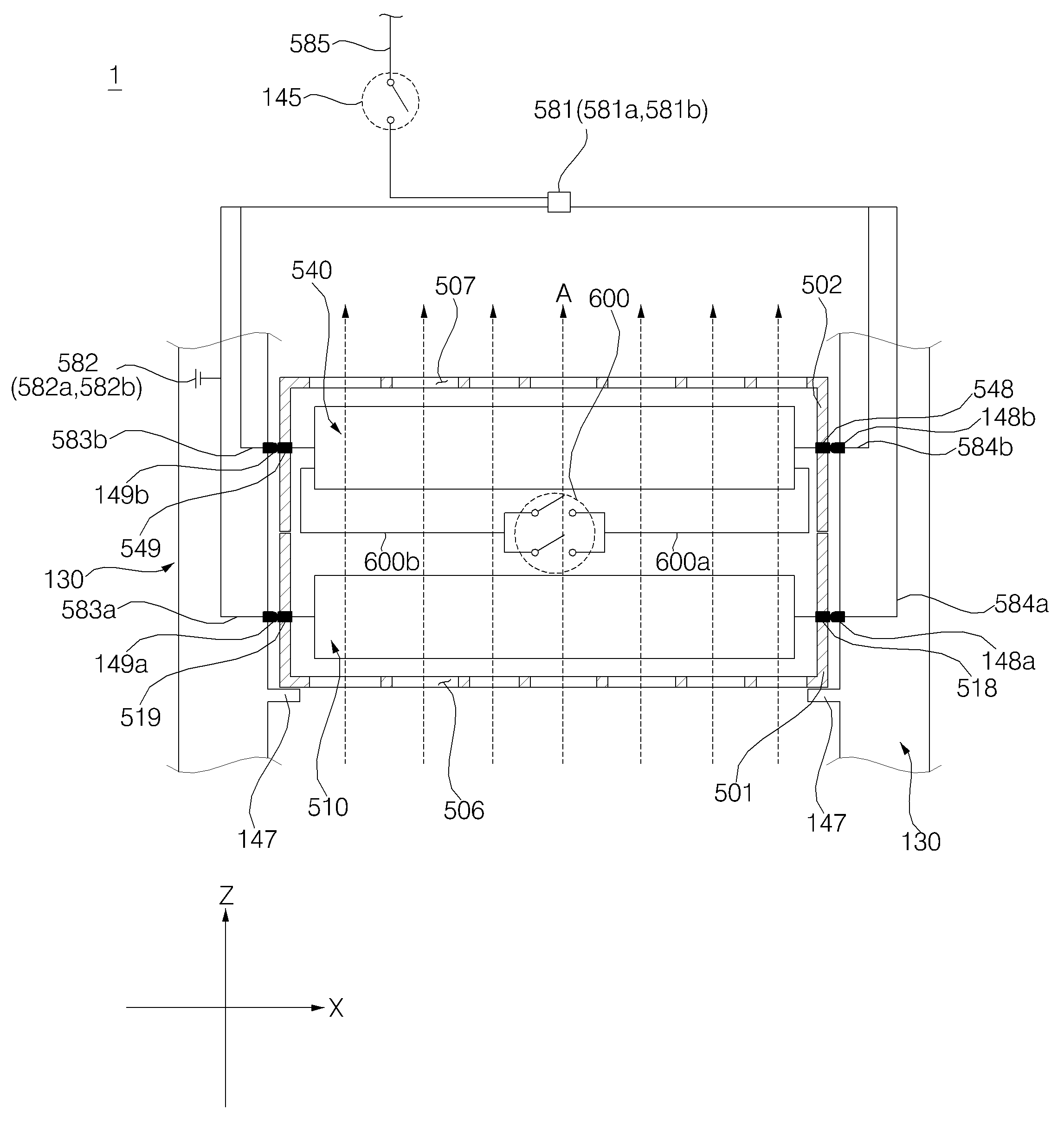

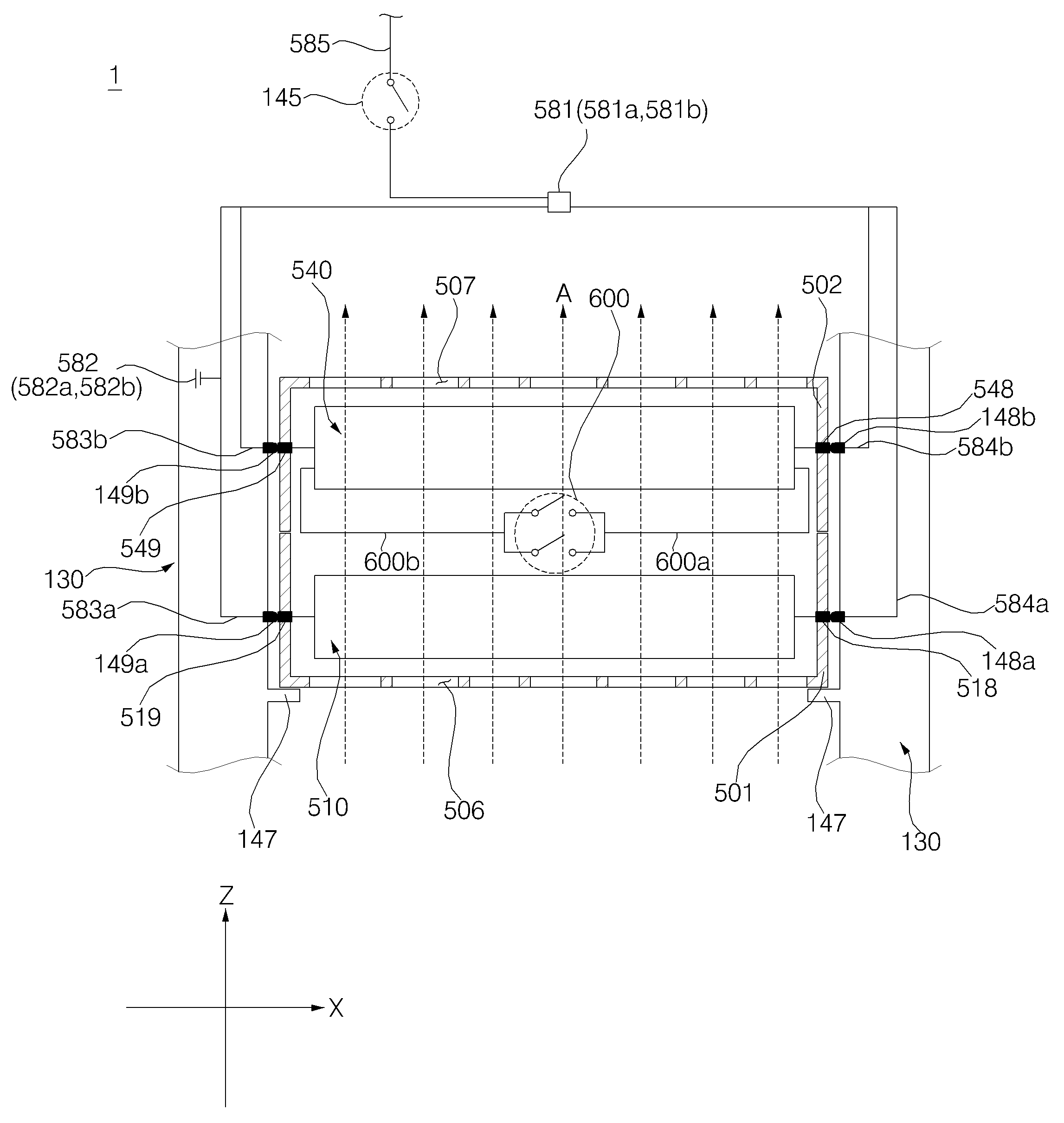

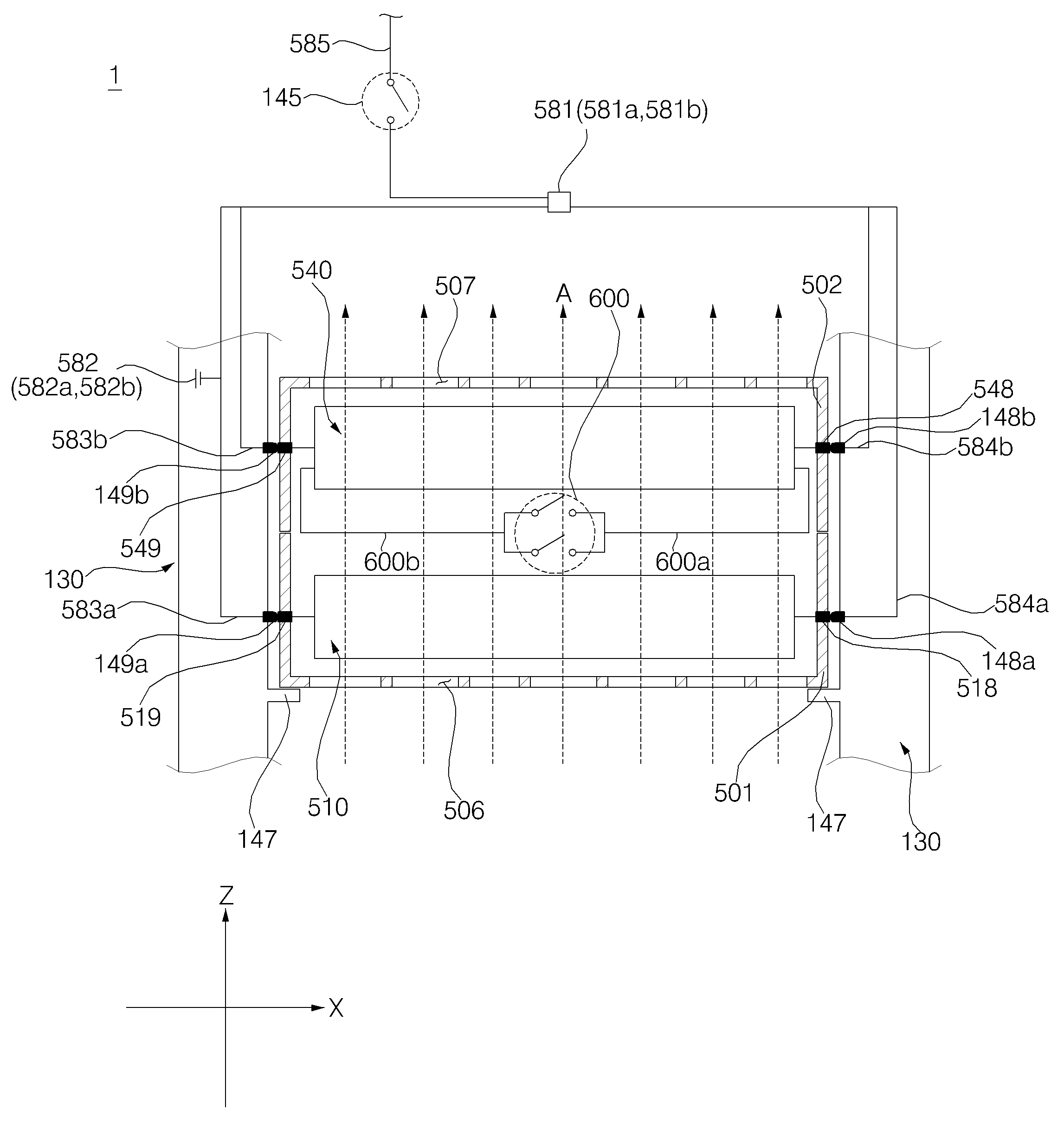

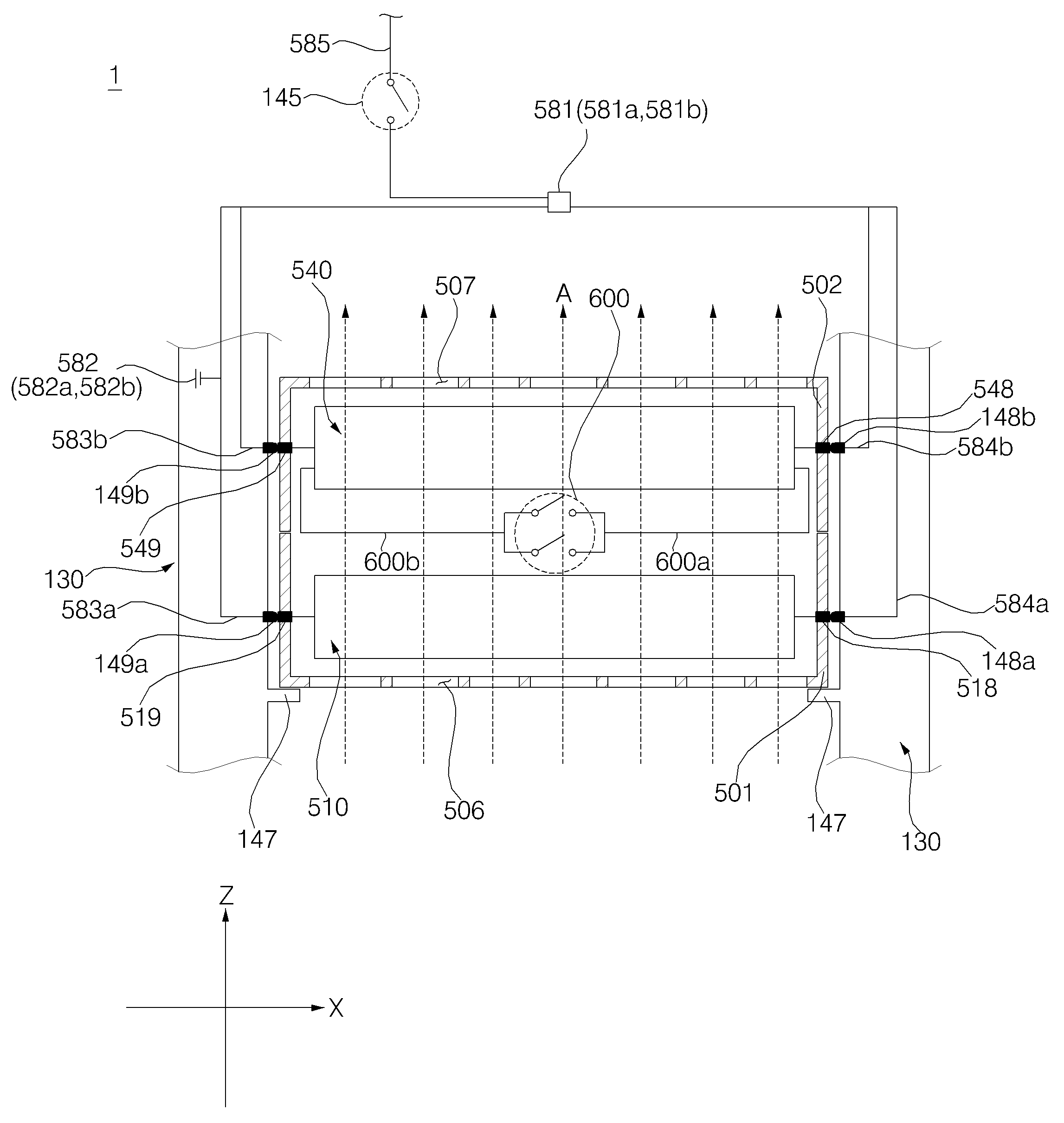

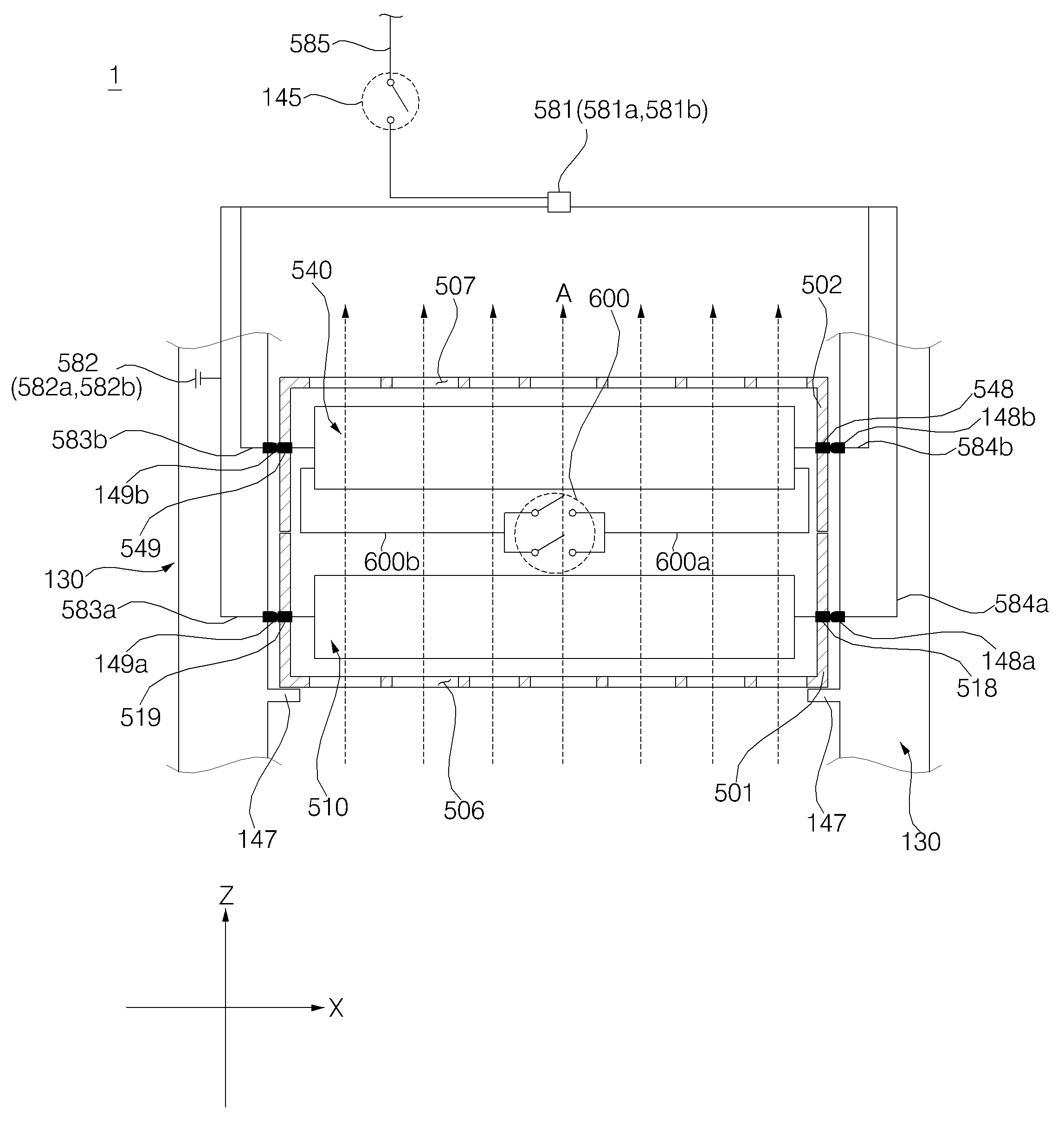

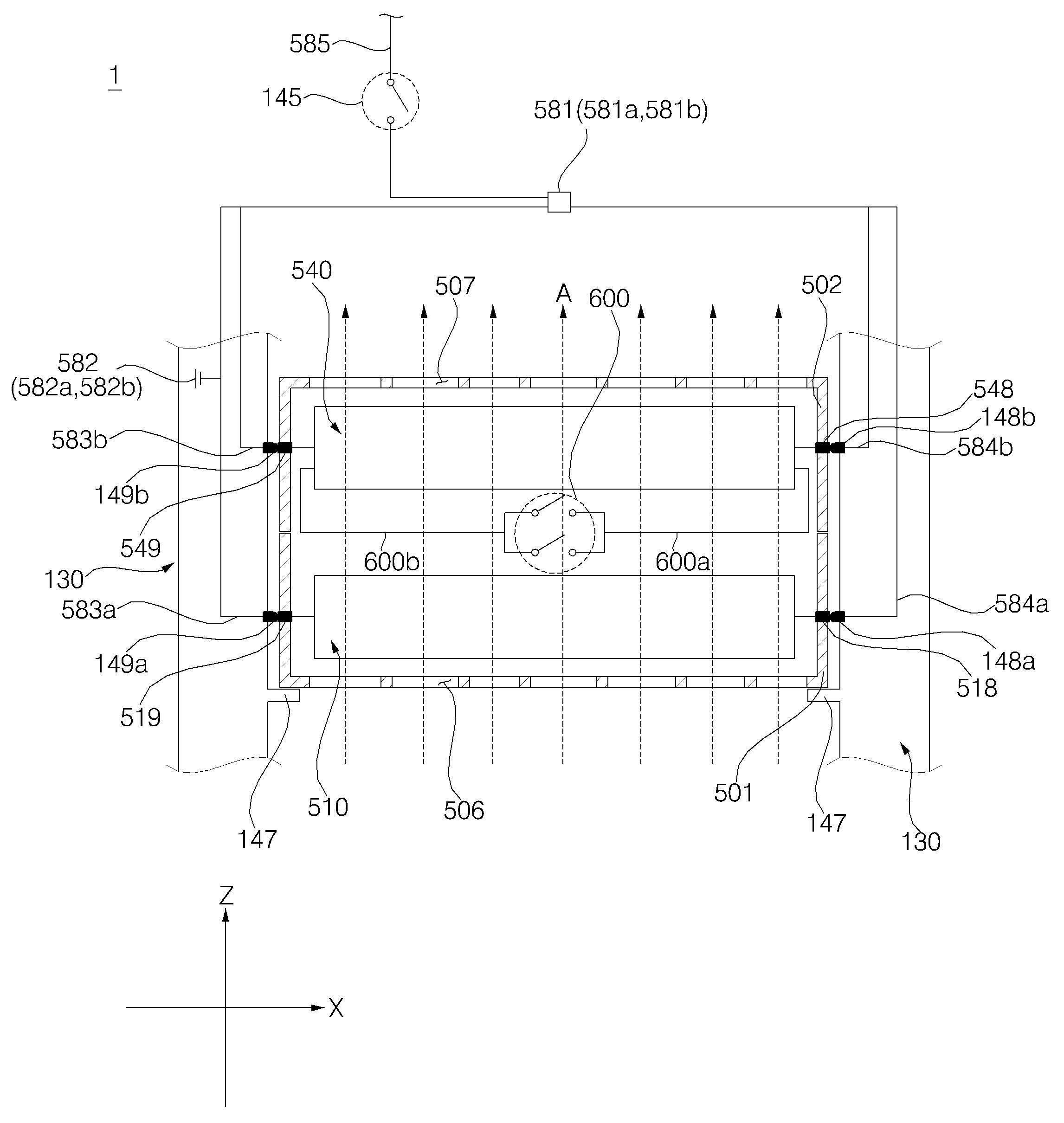

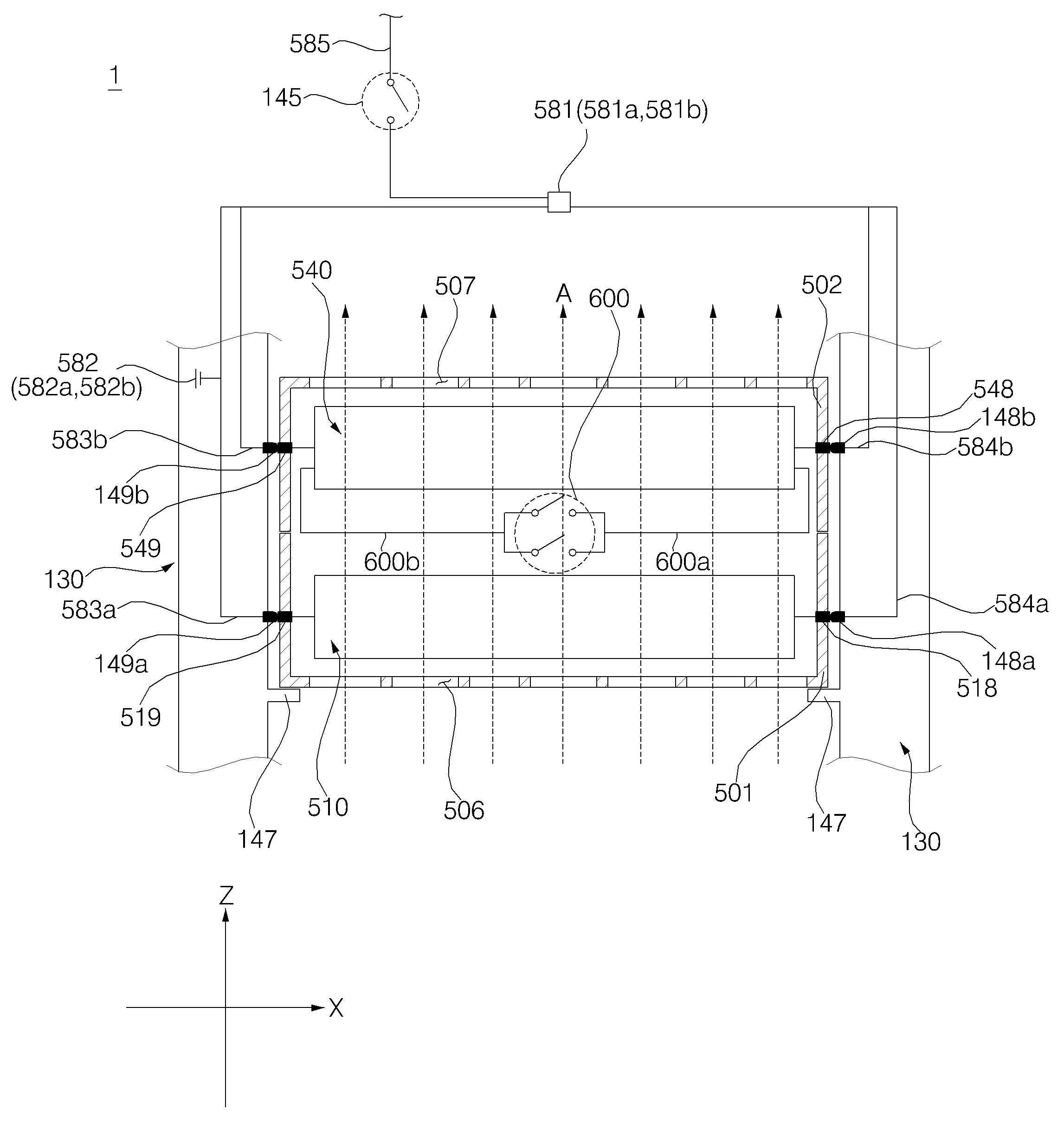

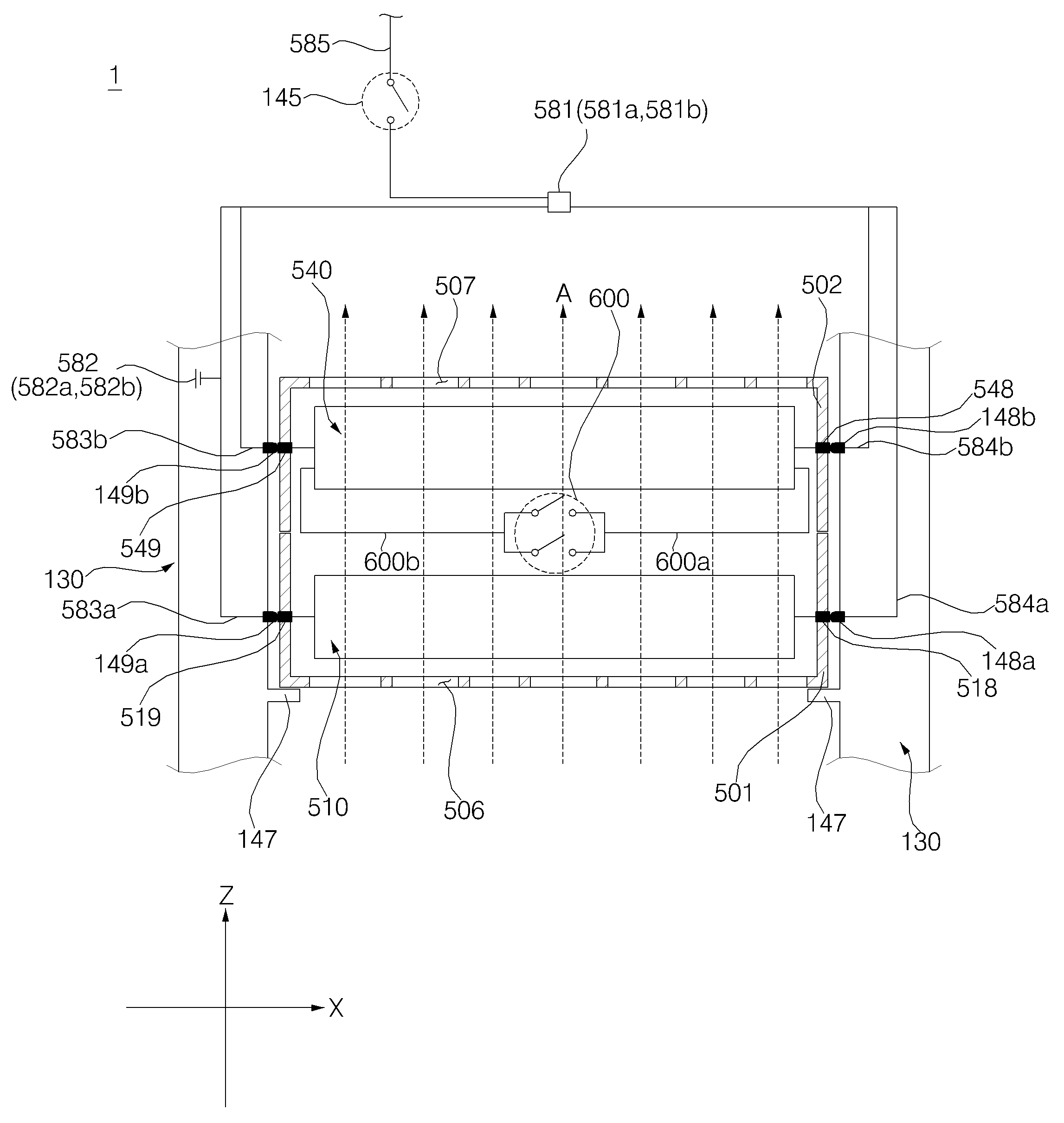

ELECTRIC DUST COLLECTION DEVICE AND MANUFACTURING METHOD THEREOF