MULTILAYER LASER MARKING FILM AND MANUFACTURING METHOD THEREOF

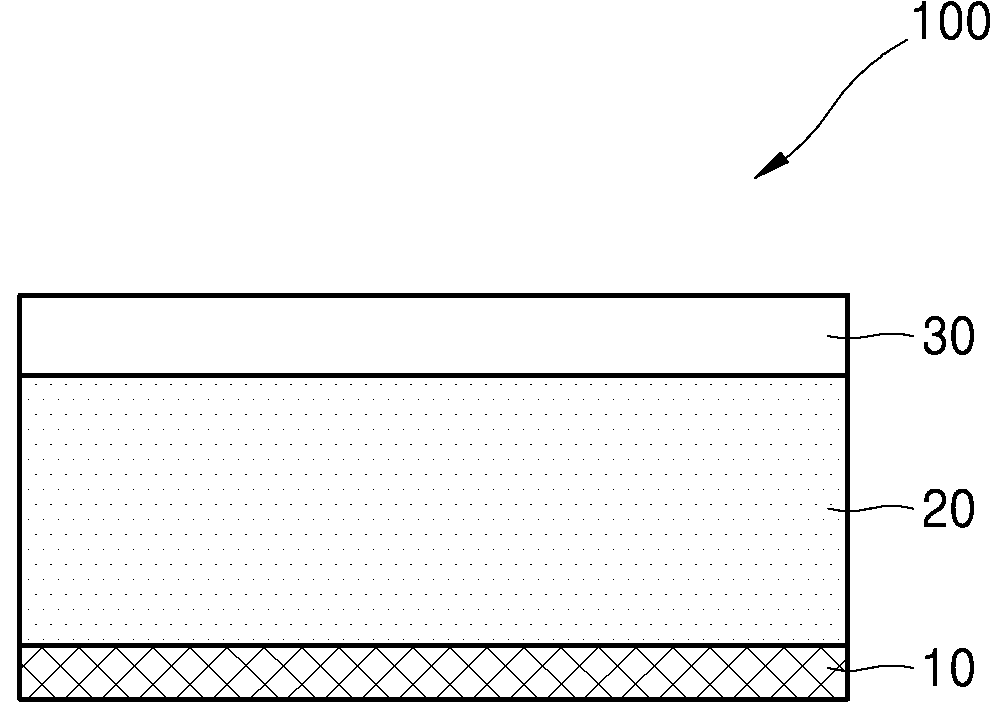

The present invention refers to laser marking a multilayer film and method of manufacturing method are disclosed. Its own identifying function various articles for label affixed to it. To perform various articles such label contains information, unique identification function and also other. For example, label used in the automotive industry for example, tire pressure or fuel such as the type in that different parts in vehicle for displaying information or, for example, chassis like the vehicle identification number and unique security information used for displaying etc.. In the case of an accident theft, such label nephrophathy vehicle tracking. A number of such label as the bath method, laser information writing method have diameters less than 2000. High power laser as a light source for use in machining and hereinafter, for example, a compensation ring Public Patent Notification number 10 - 2006 - 0027501 applies the laser bar code can mark the disclosure within and adhesive label sheet, Japanese Public Patent Notification number 1990 - 120042 fima king layer pattern is formed by etching back the ring laser beam on a heat-resistant base layer having heat resistance display material is disclosure in the nanometer range. This label is precisely located by laser machining properties and should have, attached to the surfactants should get stuck, use various physical properties to meet the target and simultaneously implementing accomplishing. The, each according to its intended use and the physical properties of a number label in a database plower studies are disclosed. Of the present invention certain embodiments include laser through precise motor and marking and, within a short time after attachment locking and re-attachable properties multilayer laser marking film has excellent porous material number [...] substrate. In addition, said multilayer laser marking film is extended wing after attachment given time period has lapsed, a structure attempt can be an excellent security performance. Simultaneously, said multilayer laser marking film outdoors even in APS discoloration, such as cured without change little variation can be compounds capable of implementing excellent reliability. Other embodiments of the present invention multilayer laser marking film properties such as described above as implementing manufacturing method, film self-layer structure consisting of an excellent durability while implementing, for implementing the aforementioned benefits the layers can be a multilayer laser marking film manufacturing method efficiently number tank number [...] substrate. One embodiment of the present invention, adhesive layer; a color number 1 colored substrate layer; and oxide layer which has a color number 2, said number 1 color and said number 2 different color and color, said colored coating layer epoxy (meth) acrylate oligomer; urethane (meth) acrylate oligomer; polyfunctional (meth) acrylate monomer; and pigment including photo-curing coating composition comprising a cargo, said adhesive layer 1 to 3 carbon atoms of alkyl (meth) acrylate having a linear or branched alkyl group number 1; 4 to 16 carbon atoms linear or branched enables to number 2 alkyl (meth) acrylate; and (meta) acrylate having carboxyl of a monomer mixture including a thermosetting adhesive composition of copolymer resin including methods including multilayer laser marking film number [...] substrate. Another embodiment of the present invention, one or more and a release film upper, release the steps of depositing a top of one another; said based on number 1 of the fiber laminate substrate layer is disposed between two release film has a color forming oxide; said colored substrate layer after said release one from the stack to a stand-alone number (meta) acrylate oligomer epoxy; urethane (meth) acrylate oligomer; polyfunctional (meth) acrylate monomer; and pigment including cargo and photo-curing coating composition, coating layer with a color which is colored with a color different from said number 1 number 2; and the other from the stack to a stand-alone said colored base layer after said release number 1 to 3 carbon atoms in the other aspects of linear or branched enables to number 1 alkyl (meta) acrylate; 4 to 16 carbon atoms linear or branched enables to number 2 alkyl (meth) acrylate; and (meta) acrylate having carboxyl of a monomer mixture including a thermosetting adhesive composition of copolymer resin including methods including adhesive layer; a multilayer laser marking film manufacturing method including a number [...] substrate. Precise motor and marking said multilayer laser marking film laser through and, within a short time after attachment has excellent locking and re-attachable properties and has the advantage of porous material. In addition, said multilayer laser marking film is extended wing after attachment given time period has lapsed, a structure attempt can be an excellent security performance. Simultaneously, said multilayer laser marking film outdoors even in APS discoloration, such as cured without change little variation can be compounds capable of implementing excellent reliability. Said multilayer laser marking film manufacturing method described above properties such as multilayer laser marking film formed of a high pressure liquid coolant efficiency can be implementing fixed number, through the thermal interface adhesion layer structure consisting of multilayer laser marking film prepared by the number excellent durability and high film itself, each layer can be effectively implementing a attention is benefits. In one embodiment of the present invention multilayer laser marking film according to Figure 1 shows a cross-section determine the timing also are disclosed. Figure 2 shows a cross-section against the film multilayer laser marking being laser marked case also determine the timing of Figure 1 embodiment are disclosed. According to other embodiments of the present invention Figure 3 shows a multilayer laser marking film cross-section determine the timing also are disclosed. Advantages and features of the present invention, achieve the reference method and an electronic component in the embodiment carry the activitycopyright will however, in the present invention refers to hereinafter is limited to disclosure in the embodiment are different but may be implemented in various forms which, in the embodiment of the present invention disclosure are complete and can be utilized for only the, in person with skill in the art of the invention the present invention is provided to a target number for confirming button to complete ball which categories, defined by category of the present invention refers to claim only disclosed. Throughout the specification the same references refer to the same components. Drawing the different layers in order by increasing a thickness and area unambiguously shown. In the drawing, for facilitating descriptions to, the thickness of several layers and the region shown exaggerated. In addition, the layer in a specification, film, region, such as "on" or "upper" portion of a synthetic resin plate when it, "directly on" as well as any other portion when intermediate when another portion comprises a unit. Some parts which are "directly on" when it opposite intermediate free portion and a portion of motor vehicle is started substrate. In addition, layer, film, region, such as "below" or "lower" portion of a synthetic resin plate when it, "beneath" as well as any other portion when intermediate when another portion comprises a unit. Some parts which are opposite "beneath" when it without other parts intermediate the motor vehicle is started substrate. One embodiment of the present invention, pressure-sensitive adhesive layer, colored with a color which has a color number 1 and number 2 oxide layer which substrate layer, said number 1 color and said number 2 different color color multilayer laser marking film number [...] substrate. The, said colored coating layer epoxy (meth) acrylate oligomer; urethane (meth) acrylate oligomer; polyfunctional (meth) acrylate monomer; and pigment including cargo and photo-curing coating composition, said adhesive layer 1 to 3 carbon atoms of alkyl (meth) acrylate having a linear or branched alkyl group number 1; 4 to 16 carbon atoms linear or branched enables to number 2 alkyl (meta) acrylate; and (meta) acrylate having carboxyl or a thermosetting adhesive composition including a copolymer resin component including a monomer mixture including characterized. In one embodiment of the present invention also according to Figure 1 shows a multilayer laser marking film (100) shown to determine and, specifically, its cross section determine the timing are disclosed. When reference also 1, said multilayer laser marking film (100) is pressure-sensitive adhesive layer (10), colored substrate layer (20) and colored coating layer (30) and, for example, said pressure-sensitive adhesive layer (10) just above the colored substrate layer (20) is formed, said colored substrate layer (20) just above the colored coating layer (30) is formed can be a multilayer structure. Said multilayer laser marking film is performed regarding various as writes information on the film that can be output by the laser, said 'laser marking (laser marking)' means that the writing by using laser etching the film to each other. Specifically, the in said multilayer laser marking, laser marking is said colored coating layer can be performed. I.e., said multilayer laser marking film with laser marking and, said laser marking said laser etched is the colored coating layer, which is etched portion forms a big number of special properties. Thus, the wetting ability so that said colored base layer and said colored coating layer laser irradiation part is a etching and number various interaction elements, can be design the durability. Said colored substrate layer (20) and said colored coating layer (30) with a color which all layer, said transparent substrate layer or coating layer wherein the meanings of 'colored' without white, black, such as having blue color by a goniophotometer. Specifically, said colored substrate layer (20) having the color number 1, said colored coating layer (30) by extending the number 2, said number 1 color and said number 2 color different colours are disclosed. The, said colored substrate layer and said colored coating layer by laser marking by having different color when colored coating layer, can exhibit various colors according to the depth etched portion at this time. Specifically, when referencing of Figure 2 (a), through laser marking color coating layer (30) of the sample if both etching said colored substrate layer (20) can be user selects only color of number 1. In addition, when (b) of Figure 2 reference, said colored coating layer (30) as an etch mask thickness of part if said colored substrate layer (20) of the etching buffer layer color number 1 and the remaining colored coating layer (30) can be user selects color appearing color number 2 of each other. Said multilayer laser marking film uses the laser marking is more than at least a part through a color character or patterns. E.g., said multilayer laser marking film is for use in automobiles and, specifically, in that different parts in vehicle tire pressure or fuel such as the type for displaying information or, like the undercarriage for displaying vehicle identification number and unique security information can be used. In one embodiment of the present invention when applied to laser marking film uses the multilayer according to said final position, where lead wires can be attached at locations of intended is not, in this case within a short time after attachment neck two liner of re-stocked may have advantages. In addition, when said multilayer laser marking film is an important writes, to prevent tampering or forge the same needs to be disclosed. Specifically, said multilayer laser marking film is' a crushable 'may have a .' crushable ' RM, said multilayer laser marking film an easily stuck after desorption or same number when an attempt is a stand-alone, cannot be destroyed recycling aspect of the original clamping is big. Said multilayer laser marking film magnetic disruptive by having, the intrinsic information written randomly vary and can, after a counterfeit or press ink of can be. Further, said multilayer laser marking film outdoors even in APS discoloration, such as cured without change little variation can be compounds capable of implementing excellent reliability. Said multilayer laser marking film advantages such properties said colored substrate layer, the colored coating layer and adhesive layer composition and structure or the like can be properly number data file representing positions. When reference also 1, said multilayer laser marking film (100) colored coating layer (30) comprises. Said colored coating layer laser marking an object layer and, said multilayer laser marking film specific use finally when applied, corresponding to the most external layer are disclosed. Specifically, said colored coating layer epoxy (meth) acrylate oligomer; urethane (meth) acrylate oligomer; polyfunctional (meth) acrylate monomer; and pigment comprises a cargo including photo-curing coating composition. Said colored coating layer coating composition for forming epoxy-based and urethane-based oligomer (meta) acrylate monomer by mixing together with polyfunctional compounds can be implementing excellent laser-markable and electrode is selected. Specifically, said epoxy (meth) acrylate oligomer chemical structures within the epoxy structure as having a, 2 to 4 functional oligomer of functional monomeric units disclosed. I.e., said epoxy (meth) acrylate oligomer (meta) acrylate functional group in the molecule with two atoms may have 2 to 4. Thereby, said coating composition can be hardened to appropriate curing degree, laser-markable and excellent reliability can be implemented have problems. In addition, said epoxy (meth) acrylate oligomer specifically, bisphenol A based epoxy (meth) acrylate oligomer, bisphenol F based epoxy (meth) acrylate oligomer, bisphenol S based epoxy (meth) acrylate oligomer, epoxy agent (meta) acrylate oligomer, cresol novolac epoxy (meth) acrylate oligomer, aliphatic alkyl epoxy (meth) acrylate oligomer, epoxy (meth) acrylate oligomer and combinations thereof modified (Modified) selected from the group consisting can be one. By using epoxy oligomer having the chemical structure of other components compatible with the protrusive, said colored coating layer coating composition prepared by the number hereinafter for compounds capable of precise laser-markable and excellent reliability can be output. In addition, said epoxy (meth) acrylate oligomer (Mw) weight average molecular weight is 500 to 5000 may be, for example, 1000 to 3000 implementation being. Said epoxy (meth) acrylate oligomer (Mw) weight average molecular weight to number by said coating composition in order to ensure an appropriate viscosity for this range and hereinafter, a uniform thickness coating and cured coating layer can be colored to improve surface physical properties. Said urethane (meth) acrylate oligomer having an chemical structures within the urethane structure, 3 to 6 functional oligomer of functional monomeric units disclosed. I.e., said urethane (meth) acrylate oligomer (meta) acrylate functional group in the molecule with two atoms may have 3 to 6. Thereby, said coating composition can be hardened to appropriate curing degree, laser-markable and excellent reliability can be implemented have problems. In addition, said urethane (meth) acrylate oligomer polybutadiene urethane (meth) acrylate oligomer, polyether urethane (meth) acrylate oligomer, caprolactone process of urethane (meth) acrylate oligomer, in pen hit tree [thol tetra arc relay [thu using polyfunctional urethane (meth) acrylate oligomer and combinations thereof (PETA) selected from the group consisting can be one. Urethane based oligomer having such chemical structure by using the protrusive is compatible with other ingredients, said colored coating layer coating composition prepared by the number hereinafter for compounds capable of precise laser-markable and excellent reliability can be output. In addition, said urethane (meth) acrylate oligomer is 1000 to 5000 weight average molecular weight (Mw) may be, for example, 1000 to 2000 implementation being. Said urethane (meth) acrylate oligomer (Mw) weight average molecular weight to number by said coating composition in order to ensure an appropriate viscosity for this range and hereinafter, a uniform thickness coating and cured coating layer can be colored to improve surface physical properties. Said coating composition mixed with polyfunctional (meth) acrylate oligomer epoxy oligomer and urethan oligomer comprising the following monomer. Said polyfunctional (meta) acrylate monomer when said encapsulating coating composition or a cured compounds also allow for high reliability could be bonded each other. In particular, said polyfunctional (meta) acrylate monomer urethane (meth) acrylate oligomer epoxy (meth) acrylate oligomer or said said wherein at least one of cross-reactive with, other oligomer and monomer than said colored coating layer which the relatively quick curing rates and thereby improve the crosslinking density can be. Specifically, said polyfunctional (meta) acrylate monomer 3 functional as more compounds, more specifically, 3 to 6 is of functional can be functional. I.e., said polyfunctional (meth) acrylate monomer (meta) acrylate functional group in the molecule with two atoms may have 3 to 6. Said polyfunctional (meta) acrylate monomer functional group are then makes a door number less than 3 bonded to case hardening, than 6 if a PC is undesirable reaction time is greater than or too the crosslinking density functional group change remains flow tides result. For example, the methyl the propane tree arc relay [thu which comes said polyfunctional (meth) acrylate monomer (TMPTA) tree, tree the methyl the propane tree which comes (ethylene oxide) triazole dimethylaminoethyl methacrylate (TMP (EO)3 TA), tree (ethylene oxide) triazole the methyl the propane which comes [heyk it buys a dimethylaminoethyl methacrylate (TMP (EO)6 TA), tree (ethylene oxide) triazole the methyl the pro petal which comes it plays a dimethylaminoethyl methacrylate (TMP (EO)9 TA), tree (ethylene oxide) triazole the methyl the pro petal pen which comes the car which burns a dimethylaminoethyl methacrylate (TMP (EO)15 TA), dimethylaminoethyl methacrylate (GPTA) glycerin tri (propylene oxide) triazole, in pen hit tree [thol tetra arc relay [thu (PETA), tree the methyl the propane tree which comes (propylene oxide) triazole dimethylaminoethyl methacrylate (TMP (PO)3 TA), [...] (ethylene oxide) tetra acrylate (PE (EO)n TTA), in pen hit tree [thol tetra arc [ley [thu (PETTA), in d pen hit tree [thol pen hit arc relay [thu (DPPA), tree [thol it buys in d pen hit arc relay [thu (DPHA) and combinations thereof can be selected from the group consisting one. This kind of polyfunctional (meta) acrylate epoxy (meth) acrylate oligomer and urethane (meth) acrylate by using said excellent cross-reactive oligomer, improve durability and interface adhesion, laser marking is turned off drilling can be achieved. Said epoxy (meth) acrylate oligomer said coating composition: said urethane (meth) acrylate oligomer: said polyfunctional (meta) acrylate monomer weight ratio of 4 - 20:40 - 60: implementation being 1 - 20. By using each components such weight ratio, said reliability and precise laser marking coating composition number prepared by the colored coating layer exhibiting excellent compounds can be secured while at the same time and, said colored base layer interface can be excellent in bonding force. Said coating composition for implementing color and comprising a pigment, said pigment and said different colored coating layer said colored substrate layer within a range that can be rotatably installed with a coloring. For example said pigment, titanium dioxide (TiO2 ), Carbon black, iron precipitation, azo-based pigment, cobalt violet (Cobalt Violet), cadmium sulfide, chromium (Chrome) compatible Perot cyanide, silicate, phosphate, phthalocyanine-based compound, d jade photograph orgin (Dioxazine) compounds and their combination it can be one selected from the group consisting, the number one are not disclosed. Said epoxy (meth) acrylate oligomer and said coating composition said urethane (meth) acrylate oligomer in a total content 100 parts by weight, about 1 parts by weight to about 20 parts by weight said pigment can. Said pigment coating composition an amount ranging by using said physical without degrading the appropriate saturation can be different colors. Said photocurable coating composition having the, photocuring can be further comprises optical disclosure number, or one not particularly kinds and non-number, e.g., benzophenone disclosure number, alpha - hydroxy ketones disclosure number, phenyl writing jade thread [ley [thu type disclosure number, benzyl dimethyl - [khey mask type disclosure number, alpha - amino ketones disclosure number, mono the gun spin type which it will know disclosure number, current disclosure number bis acrylic phosphine, bis the gun spin type which it will know disclosure number, phosphine oxide type disclosure number, metal with it counted, type disclosure number, child disclosure number five degrees [nyum salt selected from the group consisting can be using one of a variety and combinations thereof. Said epoxy (meth) acrylate oligomer and said coating composition said urethane (meth) acrylate oligomer in a total content 100 parts by weight, about 1 parts by weight to about 10 parts by weight and said optical disclosure number can. Said content of said coating composition encapsulating said optical disclosure number range if so disclosure number remaining after said multilayer laser marking film so that light can be mapped and may cause color change when used in organ surface gloss is bigger, photocuring efficiency deterioration rate less than said range when not using the equipment disclosed. Number can be dispersed further comprises said coating composition, said coating composition to improve the dispersion of pigment is said to be uniformly coating, said coating layer even color distribution diffuse to the colored coating composition prepared by the number. Specifically, the polyurethane dispersion number said dispersion number, acrylic based block copolymer dispersion number, modified polyacrylamide-based dispersion number and combinations thereof can be selected from the group consisting one. Said epoxy (meth) acrylate oligomer and said coating composition said urethane (meth) acrylate oligomer in a total content 100 parts by weight, about 1 parts by weight to about 10 parts by weight and said dispersion number can. Said coating composition comprising a dispersion of pigment dispersion number said such content by said range and said coating composition can be simultaneously improving efficiency photocuring, along diameter number can be advantageous. For number can be further comprises said coating composition. Said coating composition is applied to a uniform thickness for number and can be utilized with a viscosity glass, said coating composition properly dispersive mixing each components and n is an integer. Specifically, isopropyl alcohol (IPA) for said number is, methyl ethyl ketone (MEK), methyl isobutyl ketone (MIBK), propylene glycol methyl ether (PGME), dimethyl formaldehyde (DMF), propylene glycol monomethyl ether acetate (PGMEA), methyl alcohol (MeOH), ethynyl (EA) acetone, acetone, toluene and combinations thereof can be selected from the group consisting one. Said coating composition has a viscosity at room temperature of about 20 °C to about 30 °C about 50cps hereinafter may be, e.g., greater than about 0cps, about 50cps hereinafter implementation being. Said coating composition has a viscosity of nutrients appropriate [...] number be the type and content. Said coating composition viscosity range by the carry number as aforementioned, said multilayer laser marking film colored coating layer to a desired thickness and surface physical properties in number bath so as to ensure high pressure liquid coolant level number can be easily. When reference also 1, said multilayer laser marking film (100) is pressure-sensitive adhesive layer (10) comprises. Said adhesive layer when said multilayer laser marking film specific final use, an easily stuck to could be bonded each other. Specifically, 1 to 3 carbon atoms of said adhesive layer number 1 alkyl (meta) acrylate having a linear or branched alkyl group; 4 to 16 carbon atoms linear or branched enables to number 2 alkyl (meta) acrylate; and (meta) acrylate having carboxyl including thermosetting adhesive composition including a copolymer resin of a monomer mixture comprising substrate. Said adhesive composition from a combination of the aforementioned monomer mixture including a copolymer resin prepared by the number, said colored base layer-adhesive layer prepared by the number therefrom may be crushing suitable laminated together, while at the same time, within a short time after attachment of said multilayer laser marking film can be implementing extended wing and re-possible sticking and variety of material. Said adhesive composition (Mw) weight average molecular weight of about 100 to about 150 if only the copolymer resin is, for example, be only about 120 to about 130 if. Weight average molecular weight of said number by said adhesive layer to an adherend range said copolymer resin adhesion reinforced (build a-up) process and may arise from the moderate speed, as a result said multilayer laser marking film can be variety of implementing improved material. In addition, said colored base layer and said adhesive layer can be easily implementing appropriate with a crushable. Specifically, alkyl (meth) acrylate is a linear or branched alkyl group of 1 to 3 carbon atoms said number 1 having, for example, methyl (meth) acrylate, ethyl (meth) acrylate, n - propyl (meta) acrylate, isopropyl (meth) acrylate and combinations thereof can be selected from the group consisting one. In addition, alkyl (meth) acrylate is a linear or branched alkyl group of 4 to 16 carbon atoms said number 2 having, for example, n - butyl (meth) acrylate, isobutyl (meth) acrylate, neopentyl (meta) acrylate, hexyl (meth) acrylate, 2 - ethylhexyl (meth) acrylate, (meth) acrylate [...], n - octyl (meta) acrylate, octyl (meth) acrylate isocyanate, 2 - ethylbutyl (meta) acrylate, nonyl isocyanate (meta) acrylate, it will soak (meta) acrylate, 2 it will be burnt (meta) acrylate and combinations thereof can be selected from the group consisting one. In addition, said (meta) acrylate having carboxyl acrylic acid, methacrylic acid, compress [...], itaconic, fumaric acid, acid and combinations thereof can be selected from the group consisting one. Said alkyl (meth) acrylate monomer mixture component is said number 1, said number 2 alkyl (meth) acrylate and (meth) acrylate having carboxyl use with appropriate content by weight average molecular weight of a copolymer resin having the aforementioned range (Mw) number can be hereinafter for the high pressure liquid coolant, further, said colored base layer and said adhesive layer by chemical structure of each monomer derived from appropriate interface adhesion can be implement, said multilayer laser marking film excellent variety of crushing and good material can be simultaneously implement. Specifically, said alkyl (meth) acrylate monomer mixture component is said number 1: said number 2 alkyl (meta) acrylate: said weight ratio of 20 - 30 (meta) acrylate having carboxyl: 60 - 70: implementation being 5 - 15. Said adhesive composition further comprises for said copolymer resin with number and cured number can be. Said number is one or not specifically for non kinds and number, comprising toluene (Toluene) can be. Said adhesive composition for both pieces of viscosity range of number can be, coatable and processability can be improve. Said adhesive composition has a viscosity of from about 20 °C to about 30 °C about 1000cps 5000cps at room temperature may be, e.g., from about about 1500cps 3000cps implementation being. Said adhesive viscosity of the composition can be an excellent workability and implementing the range by coatable number. Curing said adhesive strength is number number, it ladles, oxide orgin curing number, and combinations thereof selected from the group consisting isocyanate curing number can be one. In one embodiment, curing said adhesive strength can be number is a number. In addition, said copolymer resin 100 parts by weight of said adhesive composition contrast, curing said a number 0. 01 to 1 parts by weight can be. Said adhesive layer is injected to said multilayer laser marking film is bonded onto an adherend by attaching substrate. The, said multilayer laser marking film is about 1 minutes to about 10 minutes after said metal material an easily stuck adhesive layer after adhesion about 1000gf/inch hereinafter may be, e.g., greater than about 0gf/inch, about 1000gf/inch hereinafter implementation being. Thereby, said multilayer laser marking film is removed again within a short time following adherence same wheel capable, as a result improved material can exhibit variety. When reference also 1, said multilayer laser marking film (100) colored substrate layer (20) comprises. Said colored substrate layer (20) is said colored coating layer (30) and said pressure-sensitive adhesive layer (10) disposed thereon between. Said colored base layer (meta) acrylate oligomer and date input matrix (matrix) as substrate (meta) acrylate monomer including hardening the composition thereto and, more specifically, urethane (meth) acrylate oligomer; 2 to 4 functional (meta) acrylate monomer of functional; and including pigment composition based (Electron beam) can be electron beam cured product. Said based compositions of urethane (meth) acrylate oligomer chemical structure of a polyurethane structure including oligomer as it put out (- CONH -), other chemical structure and molecular weight oligomers including compared hereinafter for polishing, said colored base layer can be advantageous to control a crushable and delayed destruction. In addition, colored adhesive layer and said base layer and said upper and lower parts thereof of said colored coating layer to improve the adhesion interface between can be advantageous. Said urethane (meth) acrylate oligomer may be about 2,000 to about 10,000 weight average molecular weight (Mw), e.g., about 2,000 to about 4,000 implementation being. Said urethane (meth) acrylate stabilized in the range of weight average molecular weight (Mw) by having the aforementioned composition based said cured product may have a suitable curing structure, said colored base layer and said adhesive layer and said interface to ensure adhesion surface of the colored coating layer can be appropriate. In addition, a crushable said colored substrate layer said multilayer laser marking film can be compressed, colored base layer constituting a base matrix (matrix) can be easily order to ensure. In addition, urethane (meth) acrylate oligomer 3 to 6 functional oligomer be said functional monomeric units. I.e., said urethane (meth) acrylate oligomer 3 (meta) acrylic in a specific proportion of 6 atoms in molecules may contain disclosed. In one embodiment, said urethane (meth) acrylate oligomer 3 to 4 functional functional oligomer; 5 to 6 functional functional oligomer; can be mixed or both. (Meta) acrylate monomer performing said oligomer of said 3 to 4 functional functional curing reaction and crushing excellent functional additives, said 5 functional to 6 functional oligomers of an oligomer formed on one performing crushing functional additives be excellent curing reaction. Said base composition (meta) acrylate functional oligomer of 2 to 4 functional (meta) with said urethane acrylate monomer having a predetermined wavelength. I.e., said (meth) acrylate monomer (meta) acrylate functional group compared to two atoms in molecules 2 and 4, said functional group imparting through said range of suitable compositions based number can be cured degree. (Meta) acrylate monomer has a weight average molecular weight (Mw) said 2 to 4 functional functional of about 200 to about 500 implementation being. (Meta) acrylate monomer said weight average molecular weight of the aforementioned urethane (meth) acrylate oligomer between said also by curing reaction may be crosslinked properly through and, as a result dense and hard (hard) can be high colored coating metal layer. In addition, said composition based oligomer and monomer weight average molecular weight (Mw) each cured density and high range simultaneously satisfying the aforementioned compact structure while still having a high tensile strength and thus expect excellent reliability and excellent reagent into a suitable delayed destruction can be implementing a crushable. 2 to 4 (meta) acrylate monomer of said functional composition based functional, specifically, alicyclic (meth) acrylate monomer (cyclo-a aliphatic) based, epoxy (epoxy) based (meta) acrylate monomer, (meta) acrylate monomer aliphatic (aliphatic) based, polyol (polyol) based (meta) acrylate monomer selected from the group consisting and combinations thereof can be one. Such monomer having chemical structure through said colored substrate layer by using a crushable multilayer laser marking film can be a major improvement. Specifically, (meta) acrylate monomer-said alicyclic (cyclo-a aliphatic) including chemical structures within the alicyclic functional group is, for example, a cycloalkyl group of 3 to 25 carbon atoms and 2 to 25 carbon atoms selected from the group consisting of at least one variety of a cycloalkyl can be. More specifically, (meta) acrylate monomer cyclo [...] said alicyclic (cyclo-a aliphatic) based, tree [...] and combinations thereof can be selected from the group consisting one. In addition, epoxy (meth) acrylate monomer (novolac) said novolak epoxy (meth) acrylate type, - A bisphenol type epoxy (meth) acrylate, bisphenol type epoxy (meth) acrylate - S, - F bisphenol type epoxy (meth) acrylate, epoxy (meth) acrylate phenol type, cresol novolac type epoxy (meth) acrylate and combinations thereof can be selected from the group consisting one. In addition, aliphatic (aliphatic) (meta) acrylate monomer 1 to 16 carbon atoms said-structural units each consisting of (meta) acrylic alkylene compounds having a specific proportion can be accurately at both ends. More specifically, 1, 6 - hexane (meta) acrylate monomer d the d it comes (meta) aliphatic (aliphatic) based said acrylate, 1, 3 - butane d the d it comes (meta) acrylate, 1, 4 - butane d the d it comes (meta) acrylate and combinations thereof can be one selected from the group consisting. In addition, a compound having a (meth) acrylate monomer 1, 6 - hexanediol ([...]) said methacrylate, tree [...], deep [...], tree [...], tetra ethylene glycol d arc relay [thu and combinations thereof can be selected from the group consisting one. Said base composition comprising an element for pigment to make different colors. The pigment comprises implementing a different color to the colored coating layer said said colored substrate layer within a range that can be rotatably installed. Said kinds and number one correspondingly non-specifically the pigment, said pigment is performed using various colored base layer is firstly alone or can be. For example said pigment, titanium dioxide (TiO2 ), Carbon black, iron precipitation, azo-based pigment, cobalt violet (Cobalt Violet), cadmium sulfide, chromium (Chrome) compatible Perot cyanide, silicate, phosphate, phthalocyanine-based compound, d jade photograph orgin (Dioxazine) compounds and their combination it can be one selected from the group consisting, the number one are not disclosed. Said multilayer laser marking film crush-proof 0.5 or 1. In addition, an interface between said base layer and said colored coating layer colored colored coating layer from said substrate layer by laser marking said colored fine width to number written to volatile character and design is suitable for interface has adhesion. In addition, said colored substrate layer and said adhesive layer is securely attached to an interface between said multilayer laser marking film applied to finished articles used to implement the interface adhesion has appropriate long-term durability. Both said adhesive layer and said intermediate layer is brought into contact with the colored coating layer said colored base layer, excellent physical properties and benefits by the aforementioned number properly compositions can be output. Specifically, said colored substrate layer urethane (meth) acrylate oligomer for forming said base composition 100 parts by weight, about 0 to 4 parts by weight of (meta) acrylate monomer exceeds said 2 functional functional, hereinafter and comprise about 66 parts by weight, e.g., about 25 to about 40 parts by weight of a can. (Meta) acrylate monomer of said 2 to 4 functional functional range of content by said colored base layer above said oligomer contrast used the back yoke effect and a crushable, composition of the hard (hard) suitable hardened to be delayed destruction and durability can be connected to the planetary. In addition, said urethane (meth) acrylate oligomer 100 parts by weight of said base composition, about 50 to about 135 parts by weight said pigment can be, e.g., about 80 to about 120 parts by weight can be. When too can give said pigment, color contrast of said colored coating layer side as in effect and in addition can be a crushable may cause a decrease in disclosed. In addition, in using laser marking or other shot number thereof can not. Conversely said intimately said pigment is too excessive composition based curing process if a negative tendency is larger than, said colored substrate layer interface ensure proper adhesion and crushing can be prevented. Thus, the aforementioned pigment is used at an amount ranging said colored base layer without degrading the aspect of said required, can exhibit appropriate color. Said colored composition based cured thereto and said base layer, said cured specifically, electron beam (electron beam) curing complements. Hardening heat or other curing means if said pressure drop slowly with less energy since the curing is a crushable base layer physical cannot implement the elongation is too large. While, in one embodiment of the present invention according to said colored base layer electron beam cured oppose more energy is turned luminance can be secured easily crushable. Specifically, electron-beam energy of said colored base layer to said substrate composition is about 80kGy 20kGy cured can be a disclosed. Said curing said desired range of energy levels of a crushable hereinafter for a colored substrate layer can be output. Said multilayer laser marking film is said colored coating layer, colored substrate layer and adhesive layer can be improved together with crushing embodying gradation, the interface between each layer adherent to properly number, can be ensured while substrates include first and laser marking durability against a finished article. Said multilayer laser marking film is thickness of a layer by designed so easy and precise laser marking after, while implementing a crushable, variety of compounds capable of ensuring reliability and material can be improved. Specifically, said colored coating layer has a thickness e.g., about 2 m to about 4 m micro micro implementation being. Said colored coating layer has a thickness in the range satisfying the same by, laser marking of plate and, from the center axis of said colored substrate layer etched colored coating layer can be applied to special number, thereby excellent visibility effect can be output after laser marking for hereinafter. In addition, reliability can be improved compounds which are easy to implement. In addition, said colored base layer has a thickness of e.g., about 50 m to about 150 micro m micro implementation being. Said colored coating layer has a thickness of said colored base layer thickness with colored substrate layer exhibiting excellent durability when this also by laser marking can be implemented, said crushable multilayer laser marking film can be compressed, said multilayer laser marking film for thermally processing and distribution or handling (handling) hereinafter, said multilayer laser marking film can be austenitic stainless steel excellent air desired size by using laser. In addition, the adhesive layer thickness of greater than about 20 m to about 50 micro m said micro implementation being. Said adhesive layer has a thickness of said multilayer laser marking film also by said finished articles attached to the insulating substrate, a crushable simultaneously can be remarkably improved, said multilayer laser marking film adhesive tape in the form of opposite fixed function can be achieved. In addition, can be advantageous to implement a variety of improved material. As aforementioned, when said reference also 1 multilayer laser marking film (100) is pressure-sensitive adhesive layer (10), colored substrate layer (20) and colored coating layer (30) can be of a multilayer structure. The, 3 also reference surface, said multilayer laser marking film (100) most quoin of phenol-mold release layer (40) can be further. (A) of Figure 3 such as said mold release layer (40) is said pressure-sensitive adhesive layer (10) may be formed only one side of the, (b) of Figure 3 such as said pressure-sensitive adhesive layer (10) and said one side of the colored coating layer (30) formed on one side of the disapproval. Said mold release layer (40) to which the multilayer laser marking film when applied to a finished article number as the wetting ability, said colored coating layer (30) formed on one surface of PET (40) can also be volatile and number before laser marking, laser marking number after the wetting ability can also be disclosed. Said mold release layer (40) of special number after laser marking can be made permeable to laser when having. Another embodiment of the present invention, said multilayer laser marking film manufacturing method a number [...] substrate. Specifically, said multilayer laser marking film manufacturing method applying a composition one release film upper, release the steps of depositing a top of one another; said based on number 1 of the fiber laminate substrate layer is disposed between two release film has a color forming oxide; said colored substrate layer after said release one from the stack to a stand-alone cargo and photo-curing coating composition number, the number 2 with a color different from said number 1 with a color which colored coating layer; and said another number from the stack to release said thermosetting adhesive layer or adhesive composition including a stand-alone colored base layer after forming O-chlorophenol; without using a tool. The, said based compositions, coating composition and adhesive composition aforementioned efined both the operating requirements. Said multilayer laser marking film laminate layer is disposed between two release film colored substrate manufacturing method preferentially number after the high pressure liquid coolant, subsequently release said colored base layer while said two sequentially number each colored coating layer and adhesive layer on both sides form a stand-alone. Thus, each interface between layers of adherent to said manufacturing method number prepared by the multilayer laser marking film can be improved and, said colored base layer between dried air can. In said multilayer laser marking film manufacturing method, the step of forming said colored coating layer, said substrate layer (direct coating) directly coating said colored coating composition hardens or; said colored substrate layer portion including said coating composition cured using a transfer film to transfer be a damascene curing. I.e., the colored coating composition said said colored coating layer on one said substrate; and curing said coating composition via a color form a coating layer on number can also be tank and, alternatively, said cured coating composition including a transfer film step number bath; and said colored substrate layer through said transfer film cured color coating layer transfer step number number through said coating composition bath may be filled be bath. In one embodiment, said composition is colored base layer above a substrate such number tank, herewith, said colored coating layer cured coating composition including a transfer film number after said high pressure liquid coolant, said transfer film cured coating composition through said transfer tank number can be disclosed. Said lower surface energy increases when said prepared by the number from colored base layer cured composition based on said one side of the coating composition and therefore also to increase coating directly by transferring coating than if wetting (dewetting) drop in a door number point can be effectively prevent such as appearance, can be interface to improve adhesion. In addition, in said multilayer laser marking film manufacturing method, said adhesive layer is an aqueous adhesive composition (direct coating) by directly coating said colored substrate layer after said number tank or thermosetting, or thermosetting adhesive layer including said adhesive composition can take place after it said colored substrate layer by high pressure liquid coolant pre-number number tank lining can be disclosed. The, said multilayer laser marking film manufacturing method is colored substrate layer prior to forming said adhesive layer further comprises the step of processing the corona (corona) can be. I.e., before said adhesive composition coated directly; or said adhesive layer before said colored substrate layer lining can be corona (corona) processing is performed. In one embodiment, the colored substrate layer corona (corona) processing said said multilayer laser marking film manufacturing method and, then, said corona treated one method for thermosetting coating is an aqueous adhesive composition directly (direct coating) layer adhesion after number can be high pressure liquid coolant. In this case, said base layer and said adhesive layer for rotating the window can be colored. In the embodiment of the present invention hereinafter are etched in the specific number. But, for the present invention are described in the embodiment to explain the example specifically or to which only, since the present invention is number one other WD immediately after being turned off. <Number attainments> Number attainments 1: number bath composition based The weight average molecular weight (Mw) in 2,500 3 functional urethane acrylate oligomer 100 parts by weight, a weight average molecular weight (Mw) and 25 parts by weight of a phosphorus-benzylpyrazinium acrylate monomer is 304, titanium dioxide (TiO2 ) Including high pressure liquid coolant composition was 70 parts by weight of substrate number. Number attainments 2 - 7: adhesive composition number bath Table 1 to a high pressure liquid coolant is an aqueous adhesive composition including a number such as copolymer resin and adhesive strength was each number. 1 parts by weight content in said table are described. * MA: methyl acrylate * EHA: ethyl [...] * AA: acrylic acid * GMA: [...] * BA: butyl acrylate * HBA: hydroxy butyl acrylate Number attainments 8 - 12: coating composition number bath As a for table 2, epoxy (meth) acrylate oligomer (EAO), urethane (meth) acrylate oligomer (UAO) and a polyfunctional (meth) acrylate monomer and, said epoxy (meth) acrylate oligomer (EAO) and urethane (meth) acrylate oligomer (UAO) 100 parts by weight of carbon black pigment 10 parts by weight of a total content, a acrylic based block copolymer dispersion number 2 (BASF [...], EFKA PX 4320). 5 parts by weight and a disclosure number 7 (BASF [...], IRGACURE 819). 5 parts by weight of coating composition was number including high pressure liquid coolant. Then, mixing said number for coating compositions (MEK and MIBK) at room temperature (25 °C) 50cps hereinafter in coating composition viscosity number was in high pressure liquid coolant. 2 parts by weight of the content of a table are described. <In the embodiment and Comparison example> In the embodiment 1 Polyethylene terephthalate (PET) release film on one surface of the substrate composition attainments said number 1 is applied, the same PET release film is a top-gate. Then, electron beam (electron beam) curing said substrate by hardening the composition through release film, colored substrate layer and a releasing film laminated stack number was high pressure liquid coolant. Then, photo-curing coating composition including a transfer film after said number of cargo number attainments 8 high pressure liquid coolant, said laminate one release is released, said transfer film colored substrate layer said coating composition through said release film separated cargo transfer color coating layer number his photo-high pressure liquid coolant. Then, the other of said laminate release is released, said colored base layer is divided by said number of corona treatment level attainments 2 after applying the adhesive composition, to form the adhesive layer 3 minutes in his number 110 °C thermosetting high pressure liquid coolant. The, 2 micro m thickness of colored coating layer, the thickness of the colored substrate layer and adhesive layer thickness of 100 micro m including multilayer laser marking film number 25 micro m his high pressure liquid coolant. In the embodiment 2 Using said number 9 and a number [...] attainments of coating composition, the same method was high pressure liquid coolant multilayer laser marking film number said in the embodiment 1. In the embodiment 3 9 coating composition that has been attainments of said number, said number 3 using the input device and a number [...] attainments, the same method was high pressure liquid coolant multilayer laser marking film number said in the embodiment 1. In the embodiment 4 10 coating composition that has been attainments of said number, said number 4 to number [...] attainments and using the input device, the same method was high pressure liquid coolant multilayer laser marking film number said in the embodiment 1. Comparison example 1 6 input device and a number [...] attainments said number using the composition, the same method was high pressure liquid coolant multilayer laser marking film number said in the embodiment 1. Comparison example 2 Said number 7 to number [...] attainments and using the input device, the same method was high pressure liquid coolant multilayer laser marking film number said in the embodiment 1. Comparison example 3 Using the input device and a number [...] attainments said number 5, the same method was high pressure liquid coolant multilayer laser marking film number said in the embodiment 1. Comparison example 4 Said number of coating composition 12 utilizes a number [...] attainments and, the same method was high pressure liquid coolant multilayer laser marking film number said in the embodiment 1. Comparison example 5 Said number of coating composition that has been attainments 12, using the input device and a number [...] attainments said number 5, the same method was high pressure liquid coolant multilayer laser marking film number said in the embodiment 1. <Evaluation> Experiment example 1: within a short time Of porous material Evaluation Multilayer laser marking said in the embodiment 1 - 4 and comparison example 1 - 5 against the film, 2. 54cm × 10cm (horizontal × vertical) number of specimen after high pressure liquid coolant, is injected to each adhesive layer attached on the side of of painted plate, attached in the center of 2 cm to 5 times are attached to a 2 kg roller end not reciprocating. From a point at least 10 minutes after a bar attached to the end of the attached and subsequent desorption from undesired portion, detachable whether to observe the substrate. In addition, detachable attached back together when observing whether other. The result is based on efined to table 4. Specifically, multilayer laser film liner which, in addition, when again possible sticking and is described as' OK ', desorption not multilayer laser film from being damaged, when the remaining' NG ' to which the peeling are described. Experiment example 2: Of crushable Evaluation Said in the embodiment 1 - 4 and comparison example 1 - 5 each multilayered laser marking against the film, aluminum coating attachment plate 75mm × 150mm size samples, 100% in isopropyl alcohol (IPA) concentration has been completed using steel number whether exposing 1 form is visible depending on the fragile knife to desorption depending on whether evaluating a crushable have, for the result are described in table 4. Experiment example 3: Compounds Reliability evaluation Said in the embodiment 1 - 4 and comparison example 1 - 5 each multilayered laser marking against the film, QUV Accelerated Weathering Tester (Q-a Lab [...]) equipment, 50 °C 700kJ/m2 each colored coating layer and each pressure-sensitive adhesive layer surface temperature and light energy conditions both exposed, [...] Konica Minolta at prescribed time intervals, CM provided 5 (SCI, 30 mm) of Reflection mode using the color (b * color difference of) also determined the. 5 have colored coating layer coated on the results based on a table, the table results for the adhesive layer 6 are described. The results of table 4 to 6 when said reference, according to in the embodiment 1 of the present invention in one embodiment 4 to multilayer laser marking film is implemented in a short time and a crushable porous material colored coating layer and adhesive layer is crucial simultaneously and at the same time, i.e., multilayer laser marking film to ensure reliability can be know to implement both surfaces have problems. Specifically, in one embodiment of the present invention multilayer laser marking film is 10 minutes after attachment according to locking and re-attachment and for hereinafter, a crushable porous material after desorption attempt time 1 exhibits excellent security can be implemented simultaneously. In addition, in one embodiment of the present invention multilayer laser marking film according to colored substrate layer side also discoloration of a surface, i.e. exposed 354 b * b * after 2 is constructed to be exposed of the chrominance before contrast difference. 0 which has less than, 1 degree of discoloration of a surface simultaneously pressure-sensitive adhesive layer side. 0 less than, e.g., 0. 5 hereinafter satisfying the set are disclosed. While, in the case of comparison example 1 to 5 said porous material in a short time, colored coating layer have problems in reliability or pressure-sensitive adhesive layer side surface have problems in reliability is not any side surface, the lead frame can be physical molecules in the present invention. 100, 100': multilayer laser marking film 10: pressure-sensitive adhesive layer 20: colored substrate layer 30: colored coating layer 40: mold release layer An embodiment of the present invention provides a multilayer laser marking film which enables precise blanking and marking through laser, and which has excellent reprocessibility by possessing physical properties facilitating detachment and reattachment carried out within a short time after attachment, and a manufacturing method of the multilayer laser marking film. The multilayer laser marking film of the present invention comprises: an adhesion layer; a colored base material layer having a first color; and a colored coating layer having a second color. The first color and the second color are different colors. The colored coating layer includes a photocured product of a coating composition comprising: an epoxy(meth)acrylate oligomer; a urethane(meth)acrylate oligomer; a multifunctional (meth)acrylate monomer; and a pigment. The adhesion layer includes a thermoset of an adhesion composition comprising a copolymer resin of mixed monomer components including: a first alkyl(meth)acrylate having a C_1-C_3 linear or branched alkyl group; a second alkyl(meth)acrylate having a C_4-C_16 linear or branched alkyl group; and a (meth)acrylate having a carboxyl group. COPYRIGHT KIPO 2017 Adhesive layer; a color number 1 colored substrate layer; and oxide layer which has a color number 2, said number 1 color and said number 2 different color and color, said colored coating layer epoxy (meth) acrylate oligomer; urethane (meth) acrylate oligomer; polyfunctional (meth) acrylate monomer; and pigment including photo-curing coating composition comprising a cargo, said adhesive layer 1 to 3 carbon atoms of alkyl (meth) acrylate having a linear or branched alkyl group number 1; 4 to 16 carbon atoms linear or branched enables to number 2 alkyl (meth) acrylate; and (meta) acrylate having carboxyl of a monomer mixture including a thermosetting adhesive composition of copolymer resin including methods including multilayer laser marking film. According to Claim 1, said colored coating layer which is formed on the laser etched multilayered laser marking number of special etching laser marking film. According to Claim 1, said epoxy (meta) acrylate oligomer 2 the many layer which is functional to 4 functional laser marking film. According to Claim 1, said epoxy (meth) acrylate oligomer bisphenol A based epoxy (meth) acrylate oligomer, bisphenol F based epoxy (meth) acrylate oligomer, bisphenol S based epoxy (meth) acrylate oligomer, epoxy agent (meta) acrylate oligomer, cresol novolac epoxy (meth) acrylate oligomer, aliphatic alkyl epoxy (meth) acrylate oligomer, epoxy (meth) acrylate oligomer and combination thereof modified (Modified) selected from the group consisting at about including multilayer laser marking film. According to Claim 1, said epoxy (meth) acrylate oligomer (Mw) weight average molecular weight of 500 to 5000 is the many layer which is laser marking film. According to Claim 1, said urethane (meth) acrylate oligomer 3 the many layer which is functional to 6 functional laser marking film. According to Claim 1, said urethane (meth) acrylate oligomer polybutadiene urethane (meth) acrylate oligomer, polyether urethane (meth) acrylate oligomer, caprolactone process of urethane (meth) acrylate oligomer, using polyfunctional urethane (meth) acrylate oligomer and combination thereof in pen hit tree [thol tetra arc relay [thu (PETA) selected from the group consisting at about including multilayer laser marking film. According to Claim 1, said urethane (meth) acrylate oligomer (Mw) weight average molecular weight of 1000 to 5000 is the many layer which is laser marking film. According to Claim 1, said polyfunctional (meta) acrylate monomer functional laser marking film 3 to 6 the many layer which is functional. According to Claim 1, said polyfunctional (meth) acrylate monomer (TMPTA) the methyl the propane tree arc relay [thu which comes tree, tree the methyl the propane tree which comes (ethylene oxide) triazole dimethylaminoethyl methacrylate (TMP (EO)3 TA), tree (ethylene oxide) triazole the methyl the propane which comes [heyk it buys a dimethylaminoethyl methacrylate (TMP (EO)6 TA), tree (ethylene oxide) triazole the methyl the pro petal which comes it plays a dimethylaminoethyl methacrylate (TMP (EO)9 TA), tree (ethylene oxide) triazole the methyl the pro petal pen which comes the car which burns a dimethylaminoethyl methacrylate (TMP (EO)15 TA), dimethylaminoethyl methacrylate (GPTA) glycerin tri (propylene oxide) triazole, in pen hit tree [thol tetra arc relay [thu (PETA), tree the methyl the propane tree which comes (propylene oxide) triazole dimethylaminoethyl methacrylate (TMP (PO)3 TA), [...] (ethylene oxide) tetra acrylate (PE (EO)n TTA), in pen hit tree [thol tetra arc [ley [thu (PETTA), in d pen hit tree [thol pen hit arc relay [thu (DPPA), selected from the group consisting (DPHA) and combination thereof at about the tree [thol it buys in d pen hit arc relay [thu including multilayer laser marking film. According to Claim 1, said epoxy (meth) acrylate oligomer said coating composition: said urethane (meth) acrylate oligomer: said polyfunctional (meta) acrylate monomer weight ratio of 4 - 20:40 - 60:1 - 20 the many layer which is laser marking film. According to Claim 1, weight average molecular weight of said copolymer resin (Mw) is 100 to 150 only for each multilayer laser marking film. According to Claim 1, said alkyl (meth) acrylate monomer mixture component is said number 1: number 2 alkyl (meta) acrylate: weight ratio of 20 - 30 (meta) acrylate having carboxyl: 60 - 70:5 - 15 in multilayer laser marking film. According to Claim 1, said colored base layer, urethane (meth) acrylate oligomer; (meta) acrylate monomer of 2 to 4 functional functional; and pigment including electron beam cured composition based (Electron beam) including multilayer laser marking film. According to Claim 14, said urethane (meth) acrylate oligomer (Mw) weight average molecular weight of 2,000 to 10,000 the many layer which is the laser marking film. According to Claim 14, said urethane (meth) acrylate oligomer 3 the many layer which is functional to 6 functional laser marking film. According to Claim 16, said urethane (meth) acrylate oligomer 3 (meta) acrylate oligomer to the urethane functional functional 4; 5 the urethane (meth) acrylate oligomer to 6 functional functional; or mixtures thereof including multilayer laser marking film. According to Claim 14, (meta) acrylate monomer of said 2 to 4 functional weight average molecular weight of 200 to 500 the many layer which is the functional (Mw) laser marking film. According to Claim 14, said urethane (meth) acrylate oligomer 100 parts by weight of said base composition, (meta) acrylate monomer exceeds 0 parts by weight of said 2 to 4 functional functional, 66 parts by weight into the hereinafter, 50 parts by weight of said pigment to 135 including multilayer laser marking film. Applying a composition one release film upper, release the steps of depositing a top of one another; said based on number 1 of the fiber laminate substrate layer is disposed between two release film has a color forming oxide; said colored substrate layer after said release one from the stack to a stand-alone number (meta) acrylate oligomer epoxy; urethane (meth) acrylate oligomer; polyfunctional (meth) acrylate monomer; and pigment including cargo and photo-curing coating composition, coating layer with a color which is colored with a color different from said number 1 number 2; and the other from the stack to a stand-alone said colored base layer after said release number 1 to 3 carbon atoms in the other aspects of linear or branched enables to number 1 alkyl (meta) acrylate; 4 to 16 carbon atoms of alkyl (meth) acrylate is a linear or branched alkyl groups number 2; and (meta) acrylate having carboxyl of a monomer mixture including a thermosetting adhesive composition of copolymer resin adhesive layer including forming methods including; including a multilayer laser marking film manufacturing method. According to Claim 20, said colored coating layer, said colored substrate layer (direct coating) directly coating said coating composition hardens in a state; said colored substrate layer including said cured coating composition formed by the many layer which becomes laser marking film manufacturing method using a transfer film transfer. According to Claim 20, said step of forming the adhesive layer, said colored base layer said O-chlorophenol (direct coating) or hardens the adhesive directly coating; said adhesive layer including said adhesive cured product of the composition step in O-chlorophenol colored base layer lining multilayer laser marking film manufacturing method. According to Claim 20, said step of forming the adhesive layer, said adhesive layer colored base layer prior to forming O-chlorophenol multilayer laser marking film manufacturing method further including corona (corona) processing. Adhesive composition Copolymer resin Aziridine curing number Composition ratio Mw Content Types Content 2 attainments number MA: EHA: AA=25:65:10 125 only 100 Isophthaloylbis (2 a-Methylaziridine) 0. 04 3 attainments number MA: EHA: AA=30:65:5 130 only 100 Isophthaloylbis (2 a-Methylaziridine) 0. 04 4 attainments number MA: EHA: AA=25:70:5 110 only 100 Isophthaloylbis (2 a-Methylaziridine) 0. 04 5 attainments number GMA: EHA: AA=25:65:10 100 only 100 Isophthaloylbis (2 a-Methylaziridine) 0. 04 6 attainments number GMA: BA: AA=10:80:10 52 only 100 Isophthaloylbis (2 a-Methylaziridine) 0. 04 7 attainments number MA: HBA: AA=25:65:10 34 only 100 Isophthaloylbis (2 a-Methylaziridine) 0. 04 Coating composition EAO UAO Monomer Sequence Mw Content Sequence Mw Content Types Content 8 attainments number Bisphenol A-based 484 4 An aliphatic ether 1700 40 TMPTA 1 9 attainments number Bisphenol A-based 484 20 An aliphatic ether 1700 60 TMPTA 20 10 attainments number Bisphenol A-based 484 20 An aliphatic ether 1700 40 TMPTA 10 Number 11 attainments Bisphenol A-based 484 10 An aliphatic ether 1700 40 - Number 12 attainments Bisphenol A-based 484 40 - TMPTA 10 Adhesive composition Coating composition In the embodiment 1 2 attainments number 8 attainments number In the embodiment 2 2 attainments number 9 attainments number In the embodiment 3 3 attainments number 9 attainments number In the embodiment 4 4 attainments number 10 attainments number Comparison example 1 6 attainments number 8 attainments number Comparison example 2 7 attainments number 8 attainments number Comparison example 3 5 attainments number 8 attainments number Comparison example 4 2 attainments number Number 12 attainments Comparison example 5 5 attainments number Number 12 attainments Porous material in a short time A crushable 10 minutes whether desorption Whether re-adhesion In the embodiment 1 OK OK OK In the embodiment 2 OK OK OK In the embodiment 3 OK OK OK In the embodiment 4 OK OK OK Comparison example 1 OK NG OK Comparison example 2 NG NG OK Comparison example 3 NG NG OK Comparison example 4 OK OK OK Comparison example 5 NG NG OK Colored coating layer Have problems in reliability B * Before exposed 24 hours 354 has been completed In the embodiment 1 -1. 81 -0. 2 -0. 11 In the embodiment 2 -1. 61 -0. 19 -0. 21 In the embodiment 3 -1. 34 -0. 11 -0. 09 In the embodiment 4 -1. 22 -0. 13 -0. 15 Comparison example 1 -1. 72 -0. 23 -0. 11 Comparison example 2 -1. 77 -0. 20 -0. 18 Comparison example 3 -1. 80 -0. 21 -0. 16 Comparison example 4 -1. 56 1. 30 1. 50 Comparison example 5 -1. 50 1. 27 1. 52 Pressure-sensitive adhesive layer Have problems in reliability B * Before exposed 24 hours 354 has been completed In the embodiment 1 0. 81 1. 03 0. 90 In the embodiment 2 0. 92 1. 11 1. 10 In the embodiment 3 1. 31 1. 46 1. 52 In the embodiment 4 1. 42 1. 67 1. 69 Comparison example 1 3. 99 30. 77 19. 52 Comparison example 2 0. 21 11. 7 11. 4 Comparison example 3 3. 23 21. 52 23. 44 Comparison example 4 1. 11 1. 34 1. 33 Comparison example 5 3. 54 22. 12 23. 67