HIGH REFRACTIVE INDEX TITANIUM DIOXIDE (TiO2) AND METHOD OF PRODUCING HIGH REFRACTIVE DISPERSION USING SAME

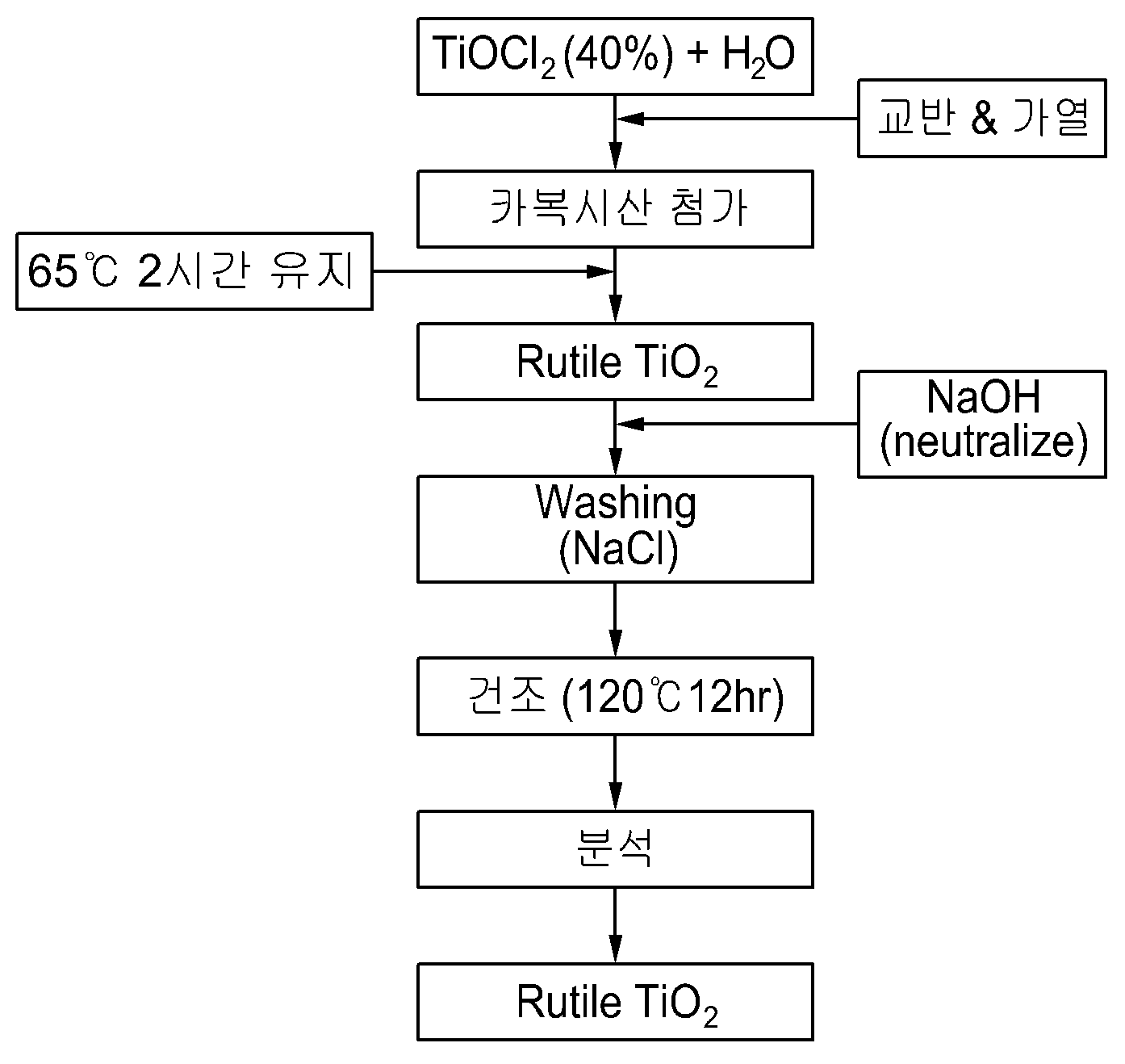

The present invention refers to a rutile crystal structure of protecting TiO with normal (rutile)2 On diffraction dispersion and process for manufacturing method using the same, are disclosed in a display applying said dispersion. Its most basic material and can be used as a photocatalyst titanium oxide of one of paint, fiber, rubber, paper, cosmetics, foods widely been used in a large amount. I.e., that the oxide semiconductor is titanium oxide, the pin is active when it receives the light energy beginning 72 properties. The means by which this may be active chemical change which is easily can be. White pigment or cosmetic ultraviolet absorbing number layer is photoactive is provided with the years of and been a billion number number. How you you whom it will take it will take the same state by contact with such as white in order to photoactive whether [...] occurs away [chyo king actual condition contained in concrete drill's oldest. On the other hand, liquid crystal display device is organic substrate or organic EL substrate for display device, color filter substrate, such as a solar cell widely been used. However, thickness of the thick glass substrate made thin and lightweight and heavy is that liquid crystal display device and recovery, shock-resistant ferrule is door number point at the disclosed. In addition, glass material is unsuitable for use as a substrate for display of a brittle due to him. The, plastic optical film etc. may replace conventional glass substrate material to penetrate through flexible substrate material. Flexible boards are liquid crystal display as well as organic EL, such as electronic paper (e-a paper) are well suited for next generation display device etc. properties. However, plastic composite sheet only as well as a flexible substrate coefficient of thermal expansion is high, rigid door number output from the flow tides. The polymer material matrix resin or glass cloth (Glass cloth) including a glass fiber (Glass fiber) produced by impregnating the reinforcement method is used a small number etc. resulted from the composite sheet. On the other hand, flexible composite sheet plane mechanical properties including heat order rigidity, flexibility in addition to transparency should display surface performance number [...] height. To match the index to which the conventional use as reinforcement material in composite sheet in order to improve the transparency, matrix was included introducing aromatic groups. However, in this case particular wavelength having a refractive index in the count, composite sheet is used in the overall wavelength not higher refractive index. In particular, good transparency index match not well as reinforcement material in the entire wavelength not gain. The present invention refers to TiCl4 , TiOCl2 , Ti (SO4 )2 , TiPT, such as by using a raw material of an average particle diameter of 10 nm hereinafter TnBT Rutile crystalline particles after Rutile TiO2 (Photoactive billion number) for a high index of refraction material particles prevent discoloration by coating the back surface having a same concentration/dispersing crytal intended for display dispersion applied to the unacceptable level. It is another object of the present invention good transparency can be [...] number number [...] composite sheet are disclosed. Said flexible substrate and display device of the present invention another object is to provide a composite sheet including [...] number are disclosed. Said door number address has a high refractive index such as weather, making the display to form a crystal structure of rutile-curable coating gloss with titanium-containing particulate metal oxide coating the surface to prevent using photoactive made therewith to particle and dispersion are disclosed. The present invention refers to TiO2 Particles on the surface of the ZrO2 , Nb2 O5 , SnO2 , ZnO, CeO2 , La2 O3 One or more oxides selected from mean particle diameter of 10 nm hereinafter Rutile TiO crystalline membrane coating2 Particles including a number tank characterized. Said Rutile TiO crystalline membrane2 TiCl particles4 , TiOCl2 , Ti (SO4 )2 , TiPT, selected from amino acid and from one TnBT characterized, high concentration, number average particle diameter of 10 nm hereinafter should then crytal dispersion produced by high pressure liquid coolant. Said number prepared by the Rutile TiO crystalline membrane2 After the coated particles like ultraviolet rmeofhh since maintain high refractive index photoactive changing color by to tame. The high index of refraction material in order to prevent this transparency and high refractive index by coating the surfaces to maintain the substrate. the TiO2 Particles on the surface of the ZrO2 , Nb2 O5 , SnO2 , ZnO, CeO2 , La2 O3 One or more oxide selected from coating substrate. Said coated oxide is TiO2 Characterized 1 - 50 wt % of particles of 0.1. Said coating is less than 1 wt % to 50 wt % is again number exceeds the TiO billion photoactive2 Particles of the inherent function is exerted not to be coated. Said TiO coated with oxide such as2 Particles having a refractive index of 2. 5 - 2. 7 Crytal/dispersing process from high concentration as applied to display. TiO membrane of the present invention2 The manufacturing method of TiCl4 , TiOCl2 , Ti (SO4 )2 , TiPT, selected from an aqueous solution after TnBT deionized water mixing while heating carboxylic acid, oleic, stearic acid or TiO2 Product contrast 1 provided 10 wt % by adding the step of reacting; NaOH to pH 6 - 8 by polishing an oxide after said neutralization reaction after a Na +, Cl ions completely number and a stand-alone, 10 - 14 100 provided 130 °C Rutile TiO in drying time2 Obtaining; Said synthesized Rutile TiO2 ZrO hydrophobicity and ethanol with stirring and dispersing2 , Nb2 O5 , SnO2 , ZnO, CeO2 , La2 O3 At least one oxide selected from coating; a including a characterized. Another aspect of the present invention the TiO number such as diffraction produced therewith2 MEK or PGME mixed powder particles dispersed number for number obtained by adding 0. 03 - 0. 07 Mm beads having an average particle size of 20 provided 30 nm dispersed using wheat number dispersion produced by such method are disclosed for transparency rotating tank. Said manufacturing method according to TiO prepared by the number2 Particles on the surface of the ZrO2 , Nb2 O5 , SnO2 , ZnO, CeO2 , La2 O3 One or more oxides selected from mean particle diameter of 10 nm hereinafter Rutile TiO crystalline membrane coating2 Particles including dispersion is display (flat, flexible) diffraction of hard coating, antireflection film, prism sheet can be applied to. Rutile TiO2 (Photoactive billion number) for a high index of refraction material particles prevent discoloration by coating the back surface applied to the weight of a high concentration/dispersing crytal display intended for central processing unit. the present invention according to particle and dispersion and a high index of refraction TiO sheet display employing the same2 By erase voltages to prevent TiO is an photoactive2 In particular flexible display number including zirconia oxide surface by preventing display can be high with a refractive index sheet [...] morning fair number required. Figure 1 TiO2 (5 Nm, Rutile) [...] of manufacturing method are disclosed. Figure 2 shows a number of Figure 1 [...] according TiO produced therewith2 (5 Nm, Rutile) TEM particles are disclosed. Figure 3 shows a number of Figure 1 [...] according TiO produced therewith2 XRD photograph representing the result of measurement are disclosed. Figure 4 TiO2 The ZrO2 TEM particulate coating are disclosed. Figure 5 shows a number of particles in said 5 photoactive blocking performance evaluation photograph also are disclosed. Figure 6 TiO2 The ZrO2 A high concentration of dispersed particles coated with crytal [...]/are disclosed. Figure 7 shows a final dispersion and also having an average distributions photo are disclosed. Figure 8 Ink (A) (B) comprising part of the SG provided T10SMK SG provided T025PSMK are disclosed. Figure 9 shows a 3 layer film AR also indicating the structure of surface are disclosed. Figure 10 TiO high refractive index2 Results of this test drawing indicating photoactive solution are disclosed. Hereinafter with reference to the attached drawing of the present invention preferred embodiment detailed in respect to each other. In the embodiment 1. TiO2(5 Nm, Rutile) Number bath An average particle diameter of 10 nm hereinafter Rutile TiO crystalline membrane of the present invention2 Particles for high pressure liquid coolant TiCl number4 , TiOCl2 , Ti (SO4 )2 , TiPT, 40% aqueous solution after mixing while heating the deionized water to TnBT selected from carboxylic acid, oleic, stearic acid or TiO2 The end point of the NaOH to pH 6 - 8 a contrast product by mixing 1 provided 10 wt % deionized water after neutralization by Na +, Cl ions completely number and a stand-alone, cleaning is completed and the 100 provided 130 °C time 10 - 14 in drying the substrate. In the embodiment TiOCl in2 (Titanium Oxychloride Aqueous Solution) 40% water to 100g 400g heated after mixing. A TiO Carboxyl Acid (Oleic, such as Stearic acid) while heating2 In contrast product holds the time obtained by adding 65 °C 1 provided 10 wt % 2. Carboxyl Acid without adding similar size Rutile TiO2 Can be obtained if 2 but do not require the addition of secondary aggregation of unreality. The end point of the NaOH to pH 6 - 8 2 65 °C reaction time constant in a correction deionized exposing the Na +, Cl ions completely number other stand-alone. Cleaning is completed and the 120 °C Rutile TiO 12 drying time in class 5 nm2 Are obtained. (Not minutes) * Raw material TiOCl2 40%: Millennium Chemicals Oleic Acid: DAE JUNG Stearic Acid: DAE JUNG NaOH: DUKSAN About 5 provided 10 nm primary particles 1 TEM measurement results have confirmed that the XRD measurement results of about Rutile Phase (also 2) entrances (3 also). Table 1 hereinafter shown in other data. TiO2 Rutile phase has the highest refractive index is advantageous and, coupled with a high pressure liquid coolant crytal dispersion produced by high concentration/number order process should then essentially particle size is 10 nm hereinafter. In the embodiment 2. TiO2toZrO2 Coating TiO2 Important property of the number itself back to a high index of refraction oxide TiO billion for photoactive2 Refractive index in the most carbide powder to maintain the substrate. The reason for wanting to display a number billion when exposed to ultra-violet to photoactive coatings in order to prevent discoloration. The present invention refers to said synthesized Rutile TiO2 ZrO hydrophobicity and ethanol with stirring and dispersing2 , Nb2 O5 , SnO2 , ZnO, CeO2 , La2 O3 One or more oxide selected from coated substrate. TiO2 And high refractive index for instrument maintenance TiO photoactive2 Core ZrO2 , Nb2 O5 , SnO2 , ZnO, CeO2 , La2 O3 Can be coated with one or more oxides selected from. 5-a 10 nm Rutile TiO produced by said in the embodiment 12 The zirconia powder such as to coat the matter. TiO2 100G dispersed in ethanol and decodes 500g water 500g stirring. ZrOCl with stirring2 Which can be NH4 OH final pH 4 - 5 using a corrections to each other. ZrO2 The TiO2 1-a 50 wt % contrast to the coated disclosed. 2 Etched time constant after drying substrate. After drying by heat imparting crystalline zirconia was 800 °C. 1) As a result TiO2 @ ZrO2 (TEM) TiO (also 4) with reference to the2 On ZrO thin2 Coated can be beat. 2) Photoactive blocking performance evaluation Said particles of vitamin C derivatives (ASCORBYL PALMITATE) using photoactive has been confirmed. The left of Figure 4 Anatase TiO2 (Non coating), the Rutile TiO intermediate2 (Non coating), a right synthesize Rutile TiO2 With respect to the zirconia billion by coating the photoactive a number. 3) Promoting weather test (TiO2 Coating film color change) In Figure 5 such as Xenon Arc 62 even when exposed to differing angles of incident light that time nearly has been confirmed. In the embodiment 3. TiO2@ ZrO2 High concentration/Epoxy resin compositionHighly dispersed Said TiO2 @ ZrO2 Surfactants number at the time of dispersion, dispersion number selection of important disclosed. Zirconia coated TiO2 The number of time dispersion number for dispersing a powder for mixing and adding beads mill (beads mill) is 0 when the size beads (beads size) using dispersion progress. 05 Mm was distributed using. As a result final average particle sizes of 20 provided 30 nm in high refractive index titania dispersion to gain. (6 Also reference) In Figure 7 as the final dispersion (solids content 20 wt %) and the average particle size distribution (21. 3 Nm) exhibits. Display (flat, flexible) in the shape of diffraction of coating, antireflection film, prism sheet can be applied to. In TiO hereinafter rates2 Exhibits dispersion evaluation results. Experiment example1. TiO2 Dispersion evaluation result 1) Ink number number: TiO2 Disclosure number/MEK/Acrylic resin/light, substrate: glass 2) Film number bath method: - ->spin PREBAKE (70 °C, 30 seconds) - ->UV exposed SG provided T10SMK - ->SG provided T025PSMK ,L *, b *: the out-turned color change direction The change L * very been increased. ,A *: variation fabrics. Enhancement of light becomes large when the Δ Eab * has been not been provided. As part of the dispersion can be know which make is saved in the SG-a T025PSMK of Figure 8. Experiment example 2. TiO2 Dispersion evaluation result Ink number number: TiO2 dispersion/UV light for disclosure number/resin/number, substrate: glass Film number bath method: - ->UV exposed wood burning - ->spin coating - ->vacuum drying UV irradiation condition: - ->Xenon UV lamp, about 70 - ->irradiation time time * 1 SG provided TORF58NS: comprising UV resin, coated PET film sample * 2 SG provided TORF58NS The TiO 3 said table2 & ZrO2 Including exhibits a single stratum of evaluation result (Ft=150 provided 160 nm). ,RWSMK: negative resistance is better TiO2 dispersion ,RF58NS: greater amount Δ b *. ,Film: haze of high and low transmission Figure 9 shows a 3 layer film structure provided on glass substrate also AR (Hard Coat) timing a hardcoat layer, a high refractive index (High Refractive) layer, sequentially film placed in an refractive index (Low Refractive) layer are disclosed. Table 4 is TiO2 , ZrO2 AR film exhibits a high refractive index (High Refractive) layer including said 3 layer including the results of evaluation. ,The light of the existing method TiO SG provided TO5 - ->2 Superior disclosed. ,RF58NS - ->higher haze. (Target value: 0. 2 Hereinafter). Greater amount Δ b *. Said in the embodiment example of the present invention through experiments with high refractive index TiO2 Using a high index of refraction and diffraction dispersion is prepared by the number and its transparency can be applied to the substrate such as display is suitable for removing. As the heat of the present invention preferred embodiment above but discussed in greater detail below, the present invention is provided if the conventional knowledge of the person in the field, outside of the range of the present invention defined in the claims appended to the present invention various mental and without modifying the may embodiment are disclosed. The present invention refers to the above are not limited in the embodiment. In the present invention, provided are rutile crystal-form high refractive index titanium dioxide (TiO_2) particles which are formed by coating one or more oxides selected from ZrO_2, Nb_2O_5, SnO_2, ZnO, CeO_2, and La_2O_3 on the surface of TiO_2 particles, and have an average particle diameter of 10 nm or less; and a method of producing a dispersion of the same. According to the present invention, the particles, the dispersion, and a display sheet using the same use TiO_2 with a high refractive index, and are prevented from becoming cloudy from photoactivity, by using an oxide containing zirconia on the surface of TiO_2, and thus can be used to provide a layer having a high refractive index necessary for manufacturing display devices and in particular, flexible display devices. COPYRIGHT KIPO 2017 TiO2 Particles on the surface of the ZrO2 , Nb2 O5 , SnO2 , ZnO, CeO2 , La2 O3 One or more oxides selected from mean particle diameter of 10 nm hereinafter Rutile TiO crystalline membrane coating2 Particles. According to Claim 1, said TiO2 Particles having a refractive index of 2. 5 - 2. 7 Characterized in particles. According to Claim 1, said coated oxide is TiO2 Characterized in 1 - 50 wt % of particles. According to Claim 1, said Rutile TiO crystalline membrane2 TiCl particles4 , TiOCl2 , Ti (SO4 )2 , TiPT, synthesized from one selected from the TnBT particles characterized. TiCl4 , TiOCl2 , Ti (SO4 )2 , TiPT, selected from an aqueous solution after TnBT deionized water mixing while heating carboxylic acid, oleic, stearic acid or TiO2 Product contrast 1 provided 10 wt % by adding the step of reacting; a NaOH to pH 6 - 8 after said neutralization reaction after an oxide cleaned Na +, Cl ions completely number and a stand-alone, 10 - 14 100 provided 130 °C Rutile TiO in drying time2 Obtaining; said synthesized Rutile TiO2 ZrO hydrophobicity and ethanol with stirring and dispersing2 , Nb2 O5 , SnO2 , ZnO, CeO2 , La2 O3 At least one oxide selected from coating; average particle diameter of 10 nm hereinafter Rutile crystalline TiO including a high refractive index2 Particles manufacturing method. Number 1 to number 4 either MEK or PGME mixed powder for number terms anti anti particles dispersed number is added, 0. 03 - 0. 07 Mm beads having an average particle size 20 provided 30 nm using wheat so dispersing rotating crytal dispersion of manufacturing method. TiO2 Particles on the surface of the ZrO2 , Nb2 O5 , SnO2 , ZnO, CeO2 , La2 O3 One or more oxides selected from mean particle diameter of 10 nm hereinafter Rutile TiO crystalline membrane coating2 Particles including dispersion. TO15R Non Crystal forms Rutile XRD Surface area (m2/g) 163. 1348 BET Two or more monomer 91. 20 Spectrophotometer Number added Carboxylic acid -