METHOD FOR MANUFACTURING POROUS METAL POWDER

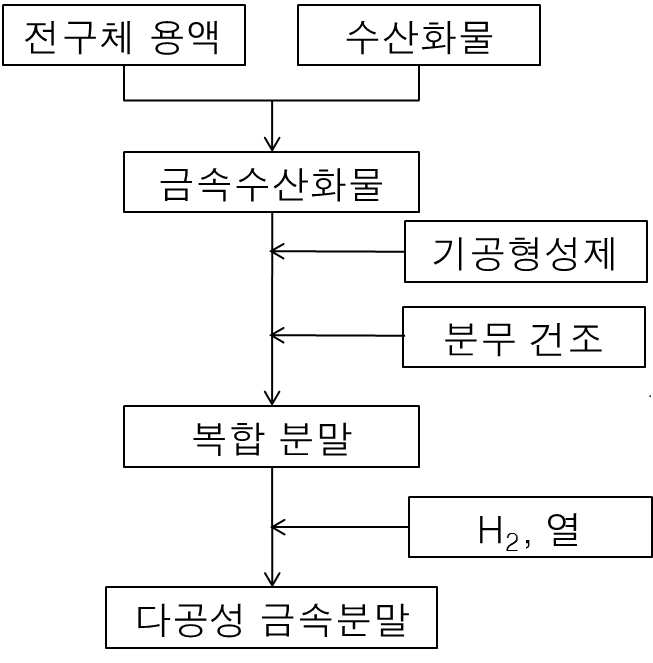

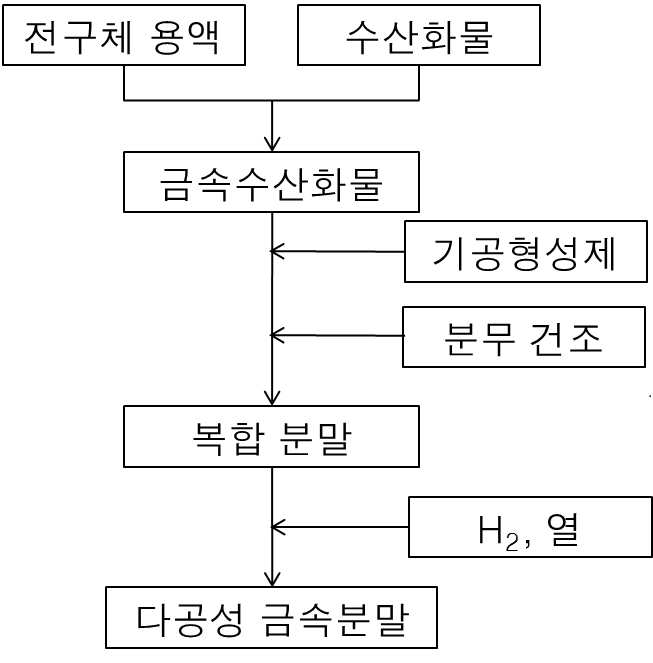

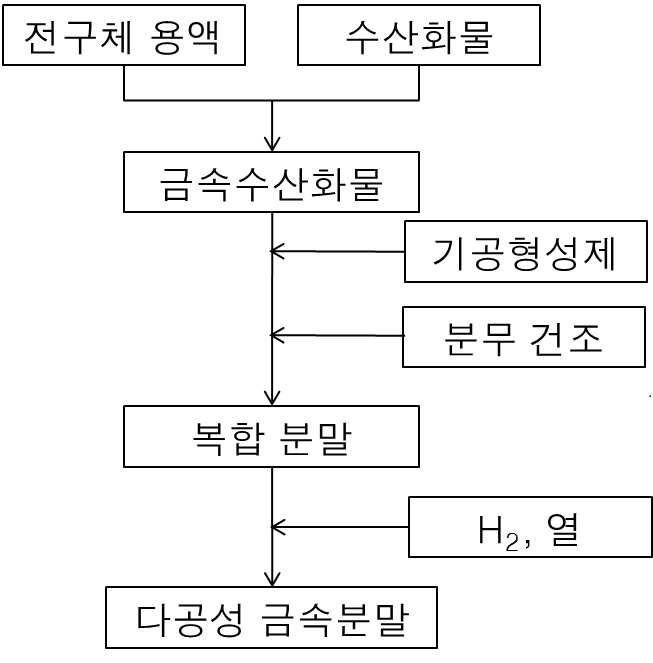

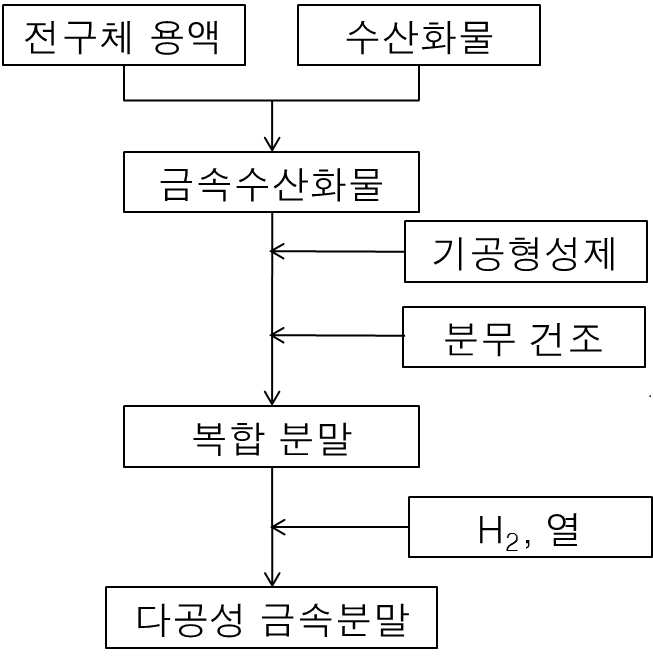

The present invention refers to a porous metal powder number bath method used in catalyst are disclosed. Hydrogenation catalyst can be used for the hydrogenation catalyst for unsaturated bond, in a broad sense include multiple myelomas are included catalyst for hydrocracking. Number VIII group element and copper is used in a metal catalyst for hydrogenation, out of oxide, sulfide or the like are used. The use of the processing advances rapidly dissolved in a temperature range of from room temperature 200 °C metal catalyst. A typical nickel catalyst but most hydrogenation catalyst to an ethylene bond, other number VIII group metal catalyst ability also having intensified state exhibits. If the raw material contains sulfur compounds including nickel sulfide, sulfide such as molybdenum sulfide catalyst are used. In the case of the hydrogenation catalyst of the representative type metal catalyst, catalytically active surface must be large increases substrate. In order to increase the surface area of metal catalyst, a metal powder in a liquid bath method been used is decomposition using existing number. I.e., metal powder after the metal salt solution from high pressure liquid coolant number, by mixing it with a polymer the pore forming number, number powder or structure and high pressure liquid coolant, and a pore-forming cooled high pressure liquid coolant to a porous metal catalyst was number number number SiB4 method alone. However, when such a high pressure liquid coolant liquid decomposition metal number, that number is used to excess cost reduction as well as expensive, difficult magnets number size and shape of metal particle surfaces disclosed. In addition, temperature and pH and a number [...], otherwise the pin is the difficulty of parameter adjustments in reaction process. If the present invention is a specific number, which does not require the temperature in the reaction process, combined with the use of reduction number excellent porous metal powder particles dispersed into a low roughness number a number [...] bath method are disclosed. In order to solve said technical and a number such as, porous metal powder of the present invention the metal salt precursor solution by mixing metal hydroxide bath method number including hydroxide step number tank; said metal hydroxide slurry in the mixing tank and the pore forming number number; said spray drying step number bath powder slurry; and heat-treating said composite powder comprising the following steps. The according to one embodiment of the invention said acids are salts, preferably zinc hydroxide or metal nitrate. The according to one embodiment of the invention said metal salt of metal is Ti, Mn, Fe, Co, Ni, Cu or Sn in preferably. The according to one embodiment of the invention said hydroxide, ammonium (NH4 OH) or sodium hydroxide (NaOH) in preferably. The (meth) acrylate according to one embodiment of the invention said pore-forming number is chosen, polymethylmethacrylate (PMMA) poly, poly [...] (PVDF), unsaturated polyester, saturated polyester, polyolefin, polyethylene, polypropylene, polybutylene, alkyd resin, epoxy polymer, epoxy resin, polyamide, polyimide, polyether-imide, polyamide-imide, polyester imide, polyester amide imide, polyurethane, polycarbonate, polystyrene, polystyrene [...], polyphenol, polyvinyl ester, polysilicon, polyacetal, cellulose acetate, polyvinyl chloride, polyvinyl acetate, polyvinyl alcohol, polysulfone, poly sulfonamides, polyether sulfone, polyketone, polyether ketone, polybenzimidazole, poly it cuts the [cu jade company it will doze, poly it cuts the [cu mote oh it will doze, poly fluorocarbons, polyphenylene ether, polyacrylate, cyano nattokinase ester polymer, their copolymers, Expancel® At least one substance selected from the group consisting of latex and preferably made. The step number according to one embodiment of the invention said slurry tank, binder, plasticizer and distributed number number number preferably further comprises a tank. The heat-treating step according to one embodiment of the invention said composite powder, preferably including hydrogen gas gas passed through the inner wall. The present invention refers to such as said, porous metal powder particles excellent, low diffusion of metal to effect uniform flow tides. Figure 1 shows a flow of porous metal powder number bath method according to one embodiment of the invention therefore are disclosed. SEM photo of cobalt hydroxide prepared by the number by PMMA composite powder Figure 2 in one embodiment of the present invention are disclosed. Figure 3 comparison process by the SEM photograph of cobalt prepared by the number PMMA composite powder are disclosed. Figure 4 in one embodiment of the present invention prepared by the porous metal powder by SEM photograph number are disclosed. Figure 5 comparison process by the porous metal powder SEM photograph number produced therewith are disclosed. The present invention refers to various modification may have various can apply in the embodiment wherein, in the embodiment example are specific detailed description and drawing the broadcast receiver. However, the present invention is defined with respect to a particular embodiment form which are not included, all changing range of idea and techniques of the present invention, including the water to replacement should understood to evenly. Number 1, number 2 including various components such as ordinal number signifies a describes an can be used but the term, such terms not defined by corresponding components. The terms distinguished from components of other components are used only one object. Any component and other components' connected 'or folder, or' connected ' referred to that when, directly connected to the other components or the carrier or may be connected, other components might lead to intermediate is present it will will be. While, any component and other components' directly connected with 'or folder, ' directly connected to ' referred to that when, intermediate will be understood to does not exist in other components. A term used in a particular application only is used to account for in the embodiment, the present invention intending to be define is endured. It is apparent that a single representation of the differently in order not providing language translators, comprising plurality of representation. In the application, " or 'includes having disclosed' specification of term articles feature, number, step, operation, components, parts or specify a combination not present included, another aspect of one or more moveable number, step, operation, component, component or a combination of these is understood to presence of or additionally pre-times those possibility should not number. Hereinafter, the present invention according to one preferred in the embodiment detailed with reference to the attached drawing as follows. Figure 1 shows a flow of porous metal powder number bath method according to one embodiment of the invention therefore are disclosed. As shown in the drawing, porous metal powder of the present invention including the metal hydroxide precursor solution by mixing metal hydroxide bath method number step number tank; said metal hydroxide slurry in the mixing tank and the pore forming number number; spray drying said slurry step number bath powder; and heat-treating said composite powder comprising the following steps. Metal hydroxide including precursor solution by mixing a metal powder having a porous metal number metal hydroxide bath and the metal salt precursor solution state dissolved, by mixing same hydroxide, metal hydroxide is generated. The metallic salt and hydrogen (M a-Cl), hydroxide (M provided SO4 ), Metal nitrogen oxides (M provided NO3 ) And the like can be used but, the number is not one. Metal salt catalyst is used can be metal (M) depending on the reaction, catalyst hydrogenation process when used, Ti, Mn, Fe, Co, Ni, Cu and Sn but selected, the number is not one. I.e., use of a metal powder or porous, catalyst prepared by the number according to porous metal powder, metal can be inexpensive price. In the concentration of the metal salt precursor solution is higher, but obtained rate can be increased, the concentration of the metal salt is too is higher, reduced or interrupted metal salt can be present as a salt is mixed with a solution precursor ion to state preferably. Mixing a metal salt of a hydroxide metal hydroxide formed therein. Hydroxide is ammonium hydroxide (NH4 OH), sodium hydroxide (NaOH) or the like can be used, depending on the type of the metal salt is a substance metal hydroxide can be produced. For example, if the precursor solution including cobalt sulfate, by mixing sodium hydroxide, cobalt hydroxide can be achieved. Metal ions of the metal salt precursor solution hydroxide ion hydroxide dissolved in 1:2 ratio precursor solution5 Such that can be evaluating the efficiency ratio of the particles. A heater including metal salt precursor solution of pH generated increased particle size. I.e., by initial precursor solution of pH, the size of the number can be [...], pH metal hydroxide creation of a heater flushing and filtering in WIPO. Precursor solution hydroxide and alkali metal hydroxide is created by mixing the particles through filtering process can be. The metal hydroxide particles into high pressure liquid coolant in the form of number if, by reduction of number of decomposition liquid sample using reduced number using pore-liquid state, reaction temperature instead of flowing to the thin film is cut. Metal hydroxide slurry by mixing particles of metal hydroxide bath step number and the pore forming number number pore-forming and mixing, is under or over a slurry state. The metal hydroxide slurry mixing and pore forming number sends, thermally treating the slurry formed porous metal powder metal degradation in the pore forming number number open pores between high pressure liquid coolant therein. The pore forming number communicates heat material as decomposed by, poly (meth) acrylate, polymethylmethacrylate (PMMA) poly, poly [...] (PVDF), unsaturated polyester, saturated polyester, polyolefin, polyethylene, polypropylene, polybutylene, alkyd resin, epoxy polymer, epoxy resin, polyamide, polyimide, polyether-imide, polyamide-imide, polyester imide, polyester amide imide, polyurethane, polycarbonate, polystyrene, polystyrene [...], polyphenol, polyvinyl ester, polysilicon, polyacetal, cellulose acetate, polyvinyl chloride, polyvinyl acetate, polyvinyl alcohol, polysulfone, poly sulfonamides, polyether sulfone, polyketone, polyether ketone, polybenzimidazole, poly it cuts the [cu jade company it will doze, poly it cuts the [cu mote oh it will doze, poly fluorocarbons, polyphenylene ether, polyacrylate, cyano nattokinase ester polymer, or a can be selected from the group consisting essential. In addition, the pore forming number is Expancel® Or be a latex. In addition, pore-forming number number step of metal hydroxide slurry tank and binder, plasticizer or number number number can be dispersed further by mixing high pressure liquid coolant. Distributed number of mixing ratio of higher concentration, improve the particulate composite powder but, in order to enhance dispersibility hereinafter for mixing and mixing chamber. Such binder, plasticizer and dispersed powder and solvent and to outside through the blending ratio of the number number, metal hydroxide and the pore forming number mixture, binder, plasticizer and distributed number number ratio of 150: (1 - 8): (0. 1 - 2): (0. 1 - 2) Can be selected from the group of mass. Spray drying the slurry bath powder slurry spray drying step number, the step number bath powder mixed with metal hydroxide and the pore forming number are disclosed. Spray drying with a hot air spray into the slurry, drying method of 1 mm hereinafter into an entrained state and while spray drying the slurry, metal hydroxide and the pore forming number composite mixed with powder form with each other. The speed of the hot air to the intake rate of the slurry by spray drying process number, complex powder particle can be a quadrature mirror filter. Composite powder composite powder into the oxidation of metal is generated, composite powder to form the pore forming number included in the sintering to produce a pore are disclosed. I.e., reducing atmosphere heat treatment powder, metal hydroxide and the pore forming number pore-forming powder mixed with thermal decomposed by number, number and wetting ability, metal hydroxide and a single metal, the porous metal powder number encoded number is present pore-forming voids are formed space about the tank. Metal hydroxide is a single metal is needed in order to reduction is carried out, this hydrogen gas passed through a heating can be accomplished. I.e., hydrogen gas is fed to reduced metal repair cargo, the resultant composite powder metal in servicing the up-and-number number is pore-forming in the wetting ability. The, door number number must be rapidly improving existing decomposition liquid can be reduced. In the embodiment of the present invention refers to a higher can be know better, in the embodiment of the present invention is to form a which is for the purpose of example, the scope of protection defined by the appended claim relayed a number that is even endured. [In the embodiment 1] When the precursor solution using 6% cobalt sulfate solution in sulfuric acid, precursor solution is mixed sodium hydroxide. The, with the hydroxide ion concentration of 1:2 pushes the cobalt precursor solution, agitating number was high pressure liquid coolant metal hydroxide at room temperature. And washed and filter the same, cobalt hydroxide-sized primary particles 1 dry weight percent. PMMA herein cobalt hydroxide formed in order to create pores number, PMMA mixture binder, binder, dispersion number, a number plasticizer is mixed. The PMMA is not to 1:1 volume ratio of cobalt hydroxide, cobalt hydroxide 150:4:1:1 PMMA mixture is mixed at a rate of mass ratio. PMMA is 3 having an average particle size micro m was used. The slurry prepared by the number Spray Air flow: 40L/min, Slurry flow: 30 ml/min, Inlet T: 200 °C, Outlet T: 100 °C conditions high pressure liquid coolant spray-dried powder which gives rise to his number. Then, 500 °C 1hr powder, 650 °C 1hr. H2 N and2 Mixing was to apply a reduction heat treatment. [Comparison example] In the embodiment on the same use in 6% cobalt sulfate solution used when the precursor solution in sulfuric acid, such as sodium hydroxide precursor solution hydrazine (N2 H4 ) By reducing number is mixed. Flushing same, filtration and drying of a metal powder in number and high pressure liquid coolant, the pore forming number PMMA after spray drying by heat-treating the porous metal powder was mixed with high pressure liquid coolant number. SEM photo of cobalt hydroxide prepared by the number by PMMA composite powder Figure 2 in one embodiment of the present invention are disclosed. Figure 3 comparison process by the SEM photograph of cobalt prepared by the number PMMA composite powder are disclosed. Figure 4 in one embodiment of the present invention prepared by the porous metal powder by SEM photograph number are disclosed. Figure 5 comparison process by the porous metal powder SEM photograph number produced therewith are disclosed. As shown in the drawing, in one embodiment of the present invention excellent in low resolution by porous metal powder particle surface unevenness does not number produced therewith. The present invention are described in the embodiment above but [...], this exemplary to avoid a and, the consultation is variable with knowledge of various deformation and uniform range of in the embodiment is enabling NaOCl will understand. The, true techniques of the present invention will be defined by the following claim protection range. According to the present invention, a method for manufacturing porous metal powder comprises the following steps of: manufacturing a metal hydroxide by mixing a hydroxide with precursor solution containing metallic salt; manufacturing slurry by mixing the metal hydroxide and a pore forming material; manufacturing composite powder by spraying and drying the slurry; and thermally treating the composite powder. COPYRIGHT KIPO 2018 Metal hydroxide precursor solution by mixing metal hydroxide bath including the step number; said metal hydroxide slurry in the mixing tank and the pore forming number number; spray drying said slurry step number bath powder; and said steps including porous metal powder powder number bath method. According to Claim 1, said acids are salts, zinc hydroxide or metal nitrate bath method characterized porous metal powder number. According to Claim 1 or Claim 2, said metal salt of metal is Ti, Mn, Fe, Co, Ni, Cu or Sn porous metal powder bath method characterized in number. According to Claim 1, the hydroxide, ammonium (NH4 OH) or sodium hydroxide (NaOH) porous metal powder bath method characterized in number. According to Claim 1, poly (meth) acrylate is pore-forming said number, polymethylmethacrylate (PMMA) poly, poly [...] (PVDF), unsaturated polyester, saturated polyester, polyolefin, polyethylene, polypropylene, polybutylene, alkyd resin, epoxy polymer, epoxy resin, polyamide, polyimide, polyether-imide, polyamide-imide, polyester imide, polyester amide imide, polyurethane, polycarbonate, polystyrene, polystyrene [...], polyphenol, polyvinyl ester, polysilicon, polyacetal, cellulose acetate, polyvinyl chloride, polyvinyl acetate, polyvinyl alcohol, polysulfone, poly sulfonamides, polyether sulfone, polyketone, polyether ketone, polybenzimidazole, poly it cuts the [cu jade company it will doze, poly it cuts the [cu mote oh it will doze, poly fluorocarbons, polyphenylene ether, polyacrylate, cyano nattokinase ester polymer, their copolymers, Expancel® At least one substance selected from the group consisting of latex and consisting of a porous metal powder characterized number bath method. According to Claim 1 or Claim 5, step number said slurry tank, binder, plasticizer and distributed number number number bath further comprises the porous metal powder bath method characterized by number. According to Claim 1, the step of heat-treating said composite powder, characterized in that hydrogen gas thereby producing porous metal powder including fixed number bath method.