APPARATUS TO MANUFACTURE SPHERICAL METAL POWDER AND MANUFACTURING METHOD THEREOF

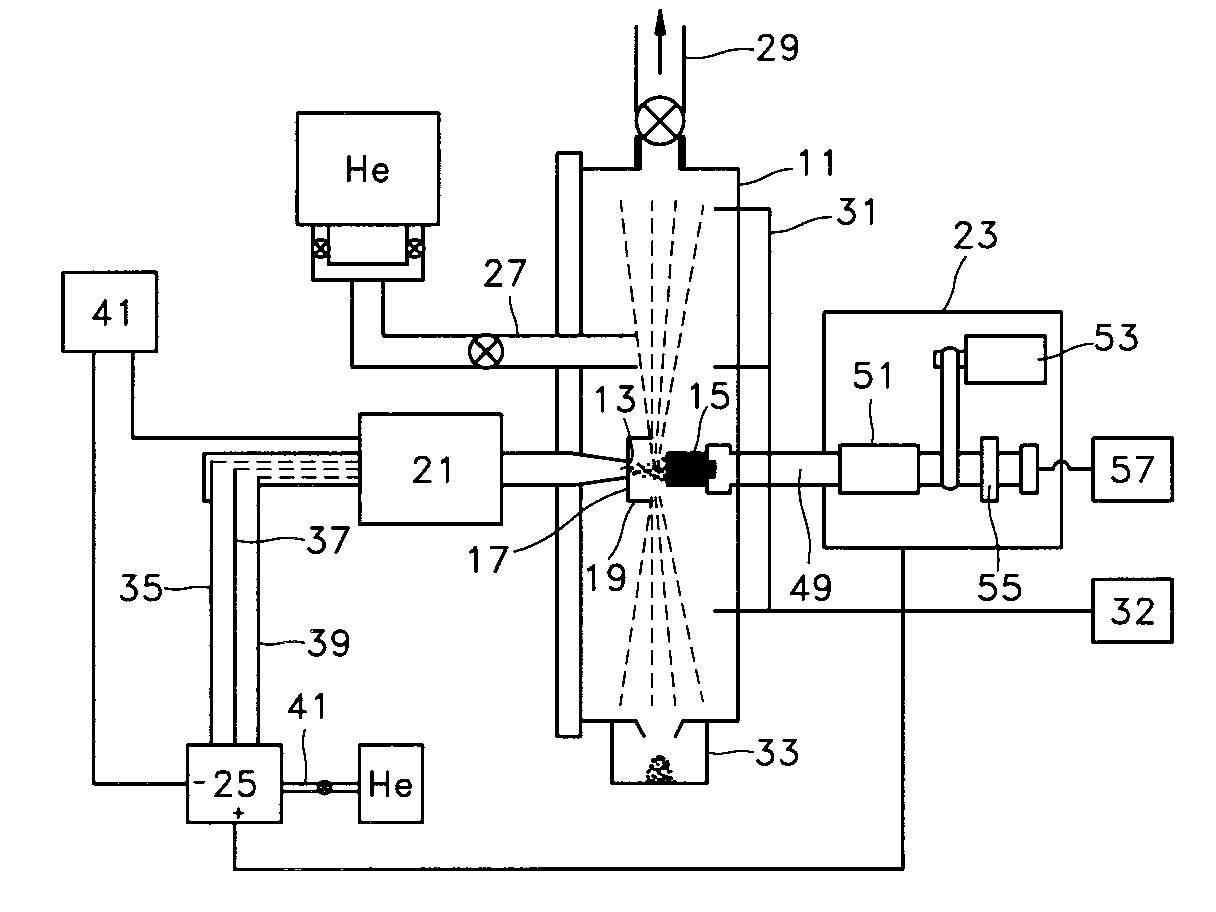

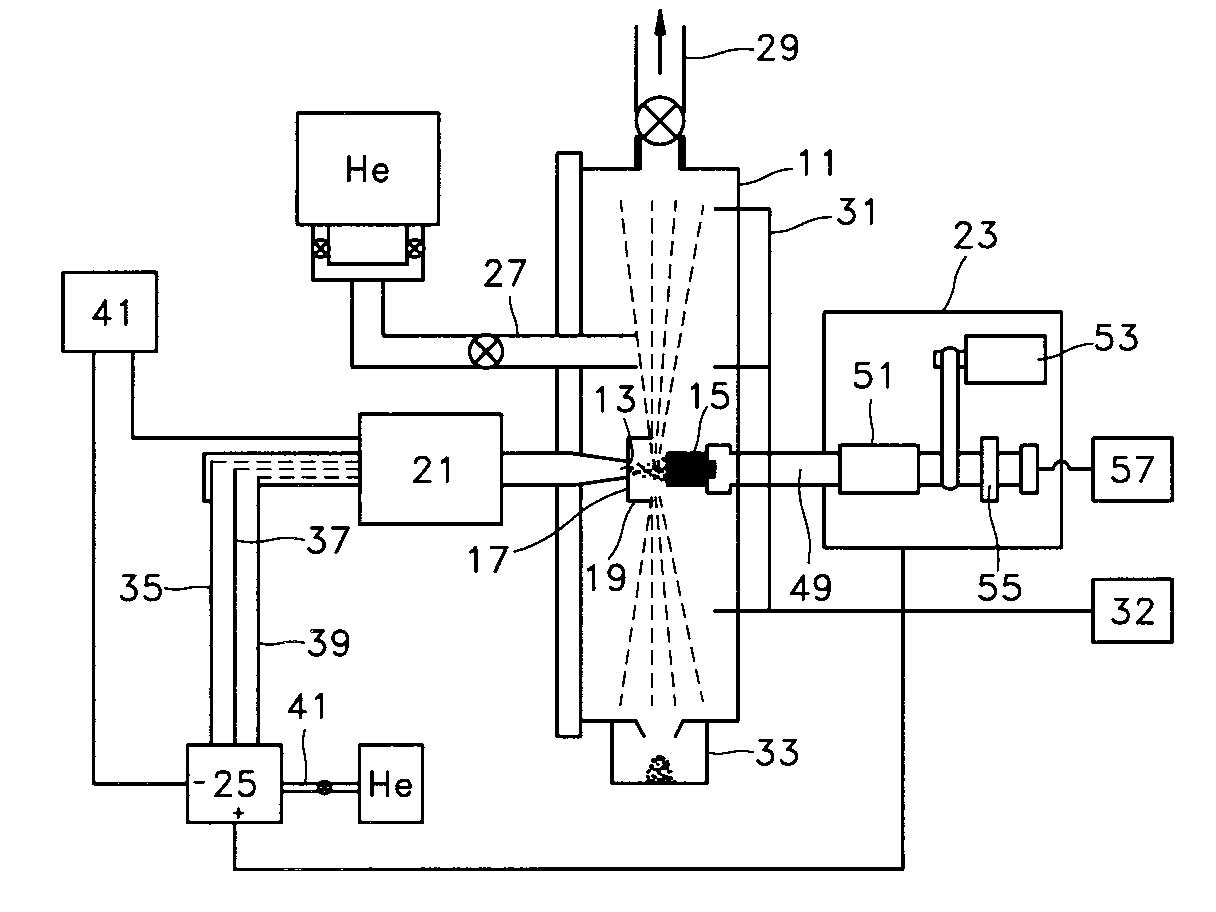

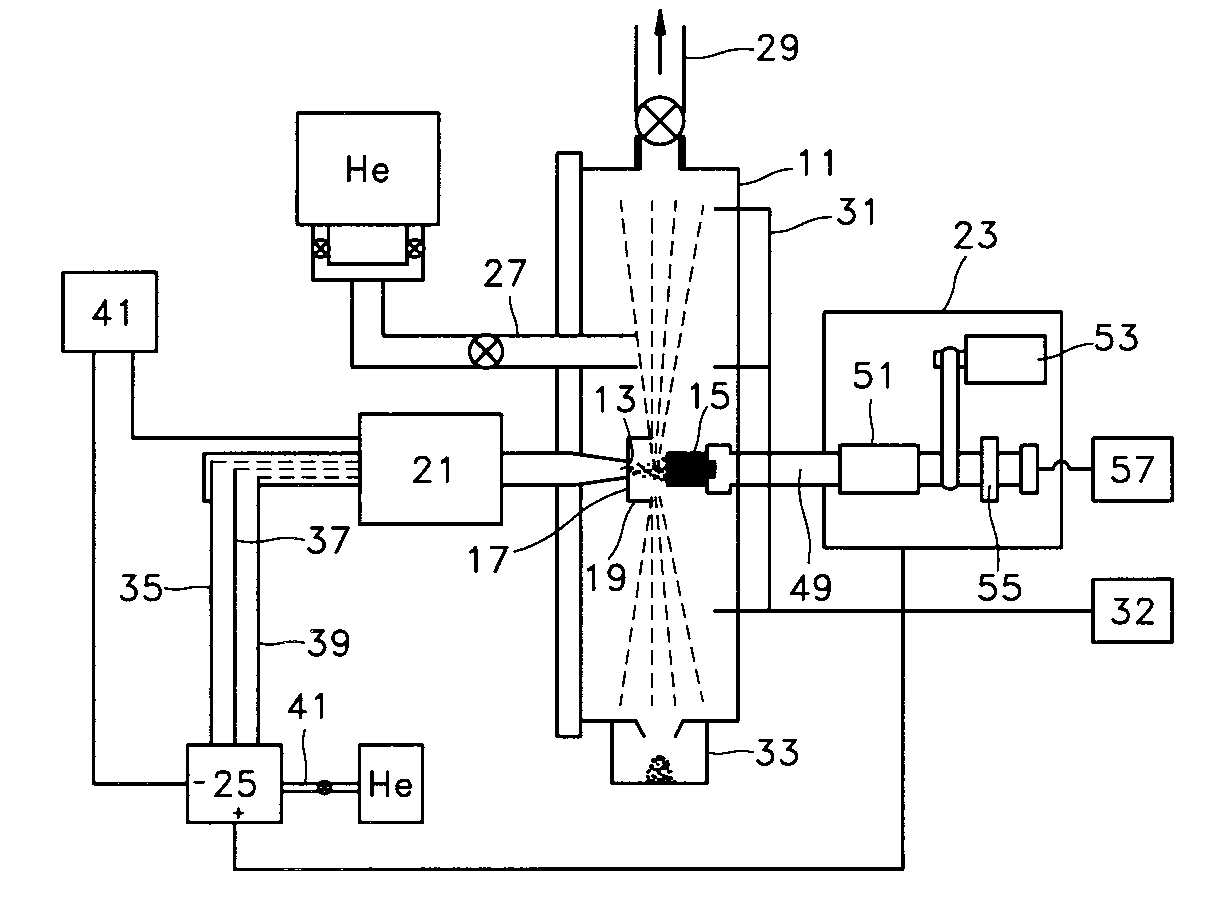

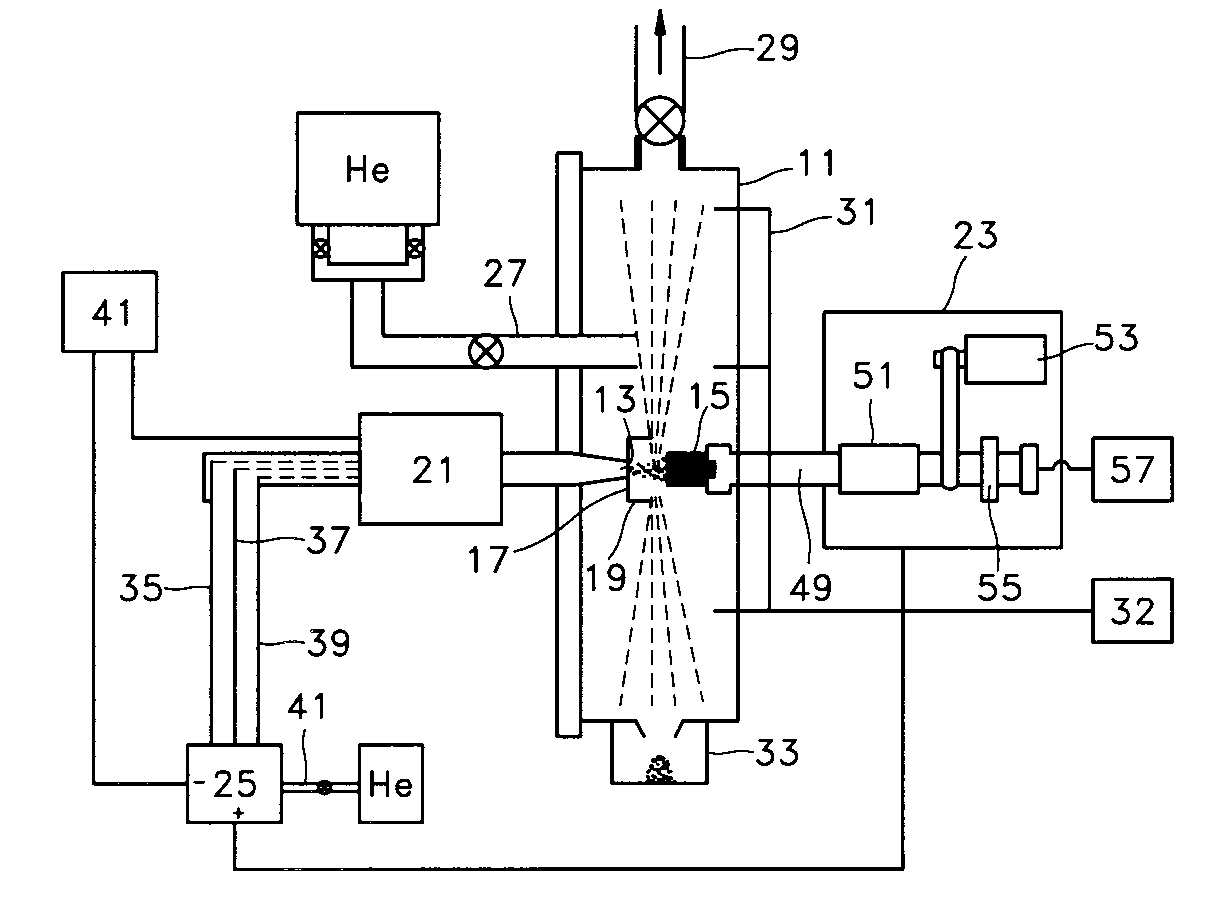

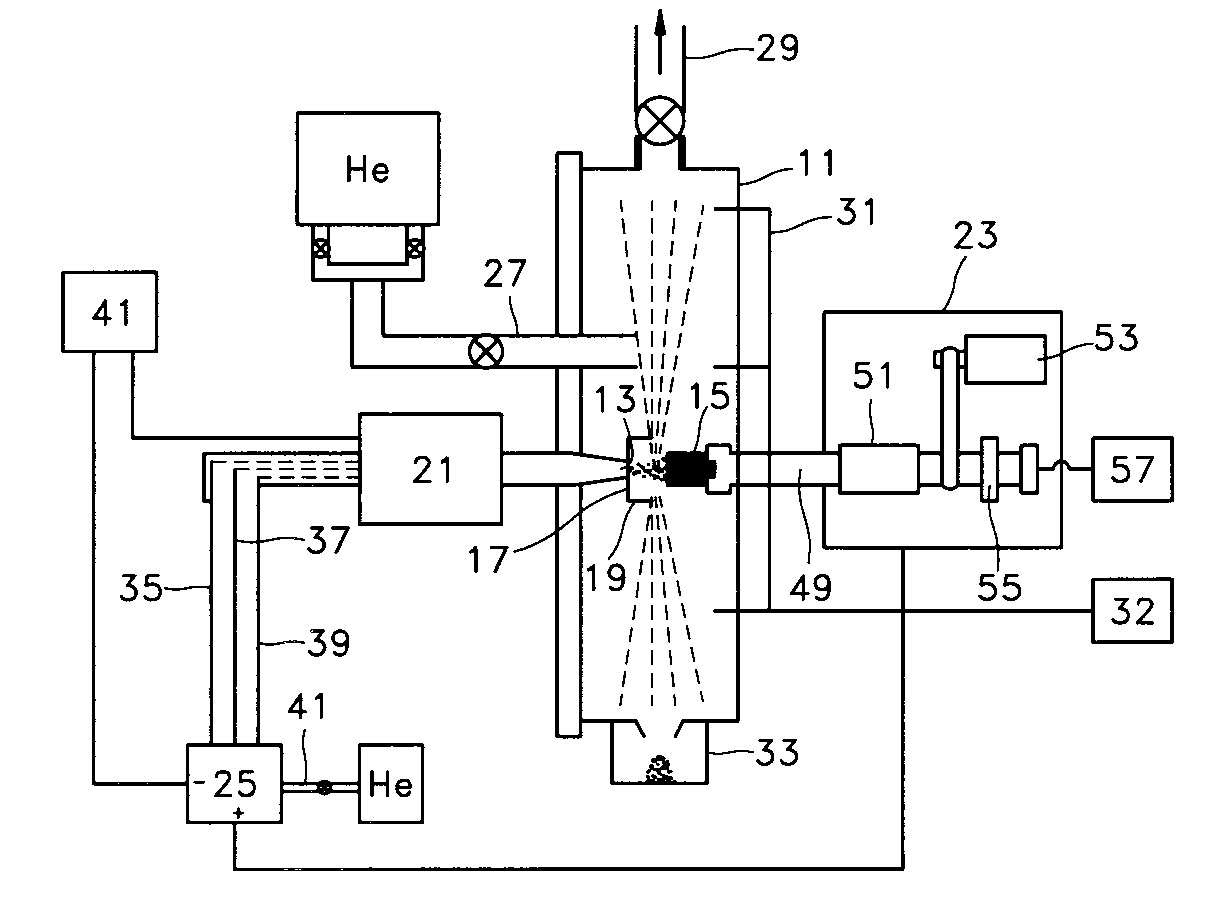

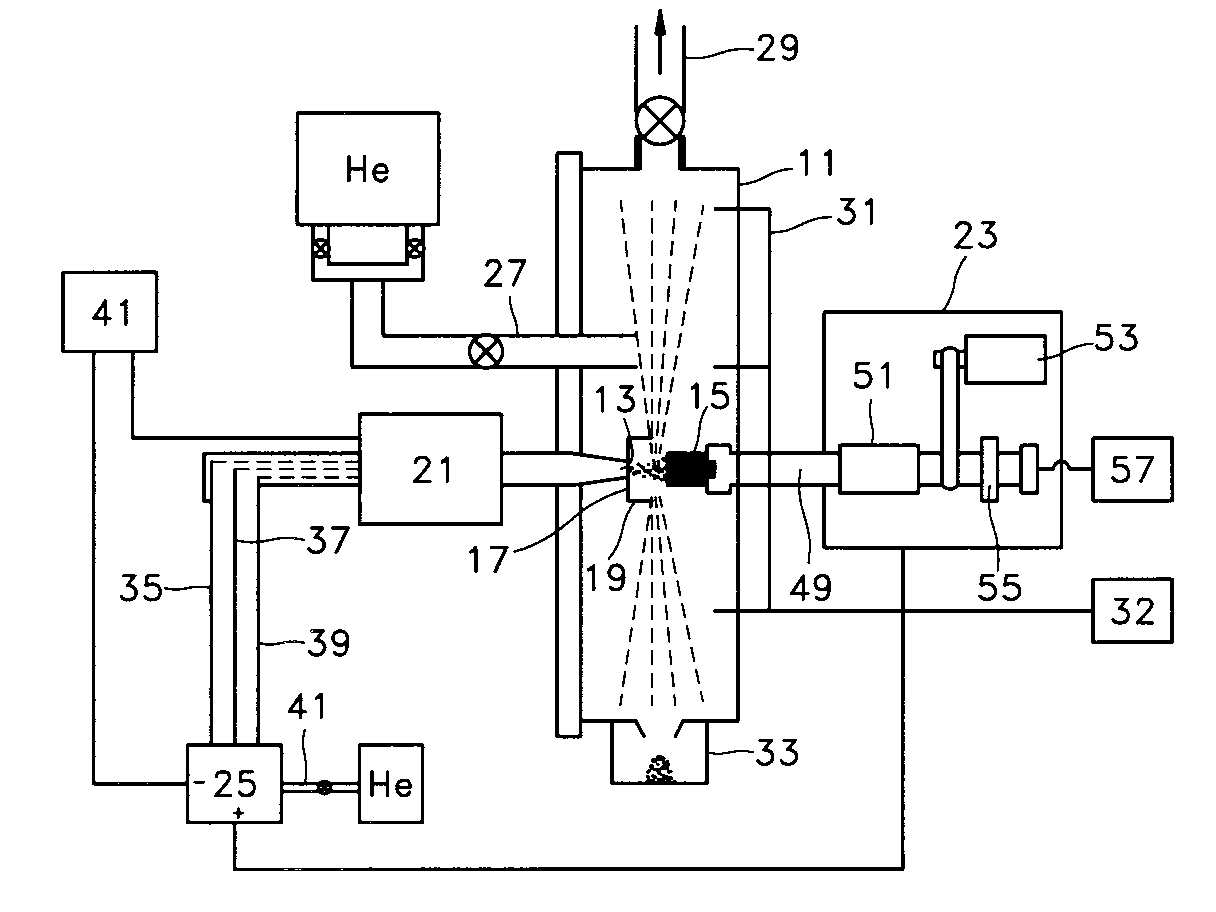

The present invention refers to number tank device and manufacturing method relates to spherical metal powder, the cylinder is provided at the distal end blood fusion body melt energy is formed, the force generated by the free space while molten blood fusion body portion connected to the injector and a fine bead provided in the form state cooling allowed to solidify, spherical metal powder is a spherical metal powder manufacturing method and device are disclosed to number number bath to bath. 3D printer plates 3 dimensional object to create additional number root material stack while continuously to early as, computer and sensor device it is a small number of signal waveforms from, other supplementary number bath techniques implement for use compared in operation high expandability number field medical [...] pivotably extends. The spherical metal powder which 3D printer print title in size, typically 50 - 100 micro m the size of the spherical metal powder are disclosed. Conventional spherical metal powder bath device number to number [...] blood fusion body laser beams to the tip melt energy, while the molten portion of the force generated by the free space from blood fusion body connected to the injector and a coagulation in the process where the bead to form fine in size is cited. These conventional spherical metal powder bath device number in DC voltage on blood fusion body chamber rotating device for generating a plasma generating device to a plasma operating signal consisting, related prior art who is for example, a compensation Patent Registration Notification number 10 - 0335382 call (name: a rotating electrode plasma device using the same and method for synthesizing carbon nanotubes; filing date: 2000. 05. 23. User) flow tides. Said prior art vacuum chamber; a vacuum chamber installed on an inner side of said cathode; said cathode and said anode is disposed within the vacuum chamber opposite can rotate; a positive and a negative vacuum chamber located above and below said substrate holder; and upper and lower travel back and forth and said substrate holder provided on the substrate; an anode and a cathode connected to said cathode to adjust the distance between said position device number; said anode capable of rotating said rotating device is connected to the anode to the anode; and said cathode to said anode rotation device applying negative pressure through said device position number through said anode by applying positive pressure arc discharge between the cathode and the anode can according to the anodes consuming device comprising a power supply device for producing corresponding Official Gazette can be through these eggs. Said spherical metal powder such as device number associated with prior art conventional bath anode rotation device while rotating anode through a positive voltage applied by generating plasma by applying negative pressure cathode, anode consumption i.e., anode according to rotation force generated by the spherical metal powder to melt is constructed to be overdimensioned to leave. The, said DC voltage the voltage applied to the anode or cathode, a result of the displacement of the difference occurs between energy supply constant level not higher energy from an UGT. The DC voltage generated by the arc discharge to plasma energy also is kept constant, spherical metal powder particles to a credit card number to create more finely ppars, rotating force of rotating device for rotating the anode end of the anode in order to increase the ashes of centrifugal force except disclosed. However, when the rotating force of said rotating anode such as device power consumption coverage according to increase stability of feeding device at ends of the pin is point number cannot be assurance securing door. In addition, device to increase a rotating force of rotating anode there are limit in the spherical metal powder particles of finely number number number used to constant bath about outputs to door pin is point hereinafter. In particular, print quality cookies of finer size (example: size of 20 - 30 micro m or hereinafter) spherical metal powder and the white point is required and fixing said number number etc. to rise. Said spherical metal powder such as of a preceding device number bath techniques document describes as follows. Document 1: a compensation Patent Registration Notification number 10 - 0335382 call (name: a rotating electrode plasma device, and method for synthesizing carbon nano; filing date: 2000. 05. 23. User) Document 2: a compensation Patent Registration Notification number 10 - 0793162 call (name: electromagnetic plasma device apparatus of the nano powder manufacturing method; filing date: 2006. 06. 30. User) The present invention refers to said prior art door number point to improvements such as taking into account is created, rotating blood fusion body (metal body; for example: Ti6AL 4V) (example: plasma) is formed at the distal end of melting energy, blood fusion body connected to the injector and a molten portion while the force generated by the free space provided in the form state cooling is solidified fine bead, spherical metal powder as a spherical metal powder number number bath to bath device, in particular, for producing energy to melt said drive signal (AC pulses or DC pulse) of a pulse type energy displacement difference ([...]) [...] number entered by a high level of contrast or molten driving signal for producing energy, energy in the form of waves in the act it became blood fusion body portion subjected to different point in the action to occur that a point is the wave being produced in each action point of resonance point of a second material to induce, by lowering the surface tension of the molten metal in blood fusion body rotating, centrifugal force blood fusion body separated out in molten gold multi, fine sized spherical metal powder spherical metal powder manufacturing method and device capable of generating a number bath [...] number etc. which is twisted. In this way the present invention refers to such as said rotating blood fusion body (11) is formed at the distal end of melting energy, blood fusion body (11) by means of centrifugal forces molten portion connected to the injector and a free space provided in the form state cooling is solidified while fine bead, spherical metal powder is a spherical metal powder number number bath to bath device (10) in, chamber (1) which is located within the blood fusion body (11) to a preset rotation a rotating part (12); a drive signal DC or pulse type setting in order to melt energy generation (AC pulses or DC pulse) [...] number into a driving section (13); said drive (13) according to the drive signal for the polar alternating or level change said blood fusion body (11) which interacts with the molten metal while said molten energy in wave energy cause blood fusion body (11) and melting action of melted portion of the tip (14); characterized by the plurality of input terminals. The present invention refers to said melted portion of the constitution such as number and said means (14) to activate the driving section (13) the drive signal for the number of the pulse form [...], energy displacement difference ([...]) can be entered by a high level of contrast driving signal for producing energy molten, in short molten portion of wave energy is created. Said logic such as a high level of melt energy and wave energy in said molten portion of SnO 2 rotating part (12) rotating by blood fusion body (11) and blood fusion body (11) acts upon the bump is connected to collapse by lowering the surface tension of the molten portion of portion, said blood fusion body (11) by means of centrifugal forces particles of metal powder free space that inherently deviates from the same input rotational force which can be 30% small size supported ball number to number bath conditions be maintained. Figure 1 shows a structure of a conventional spherical metal powder number bath device shown to block configuration. Figure 2 shows a block constitution of the invention therefore a briefly shown in configuration. Figure 3 shows a conventional DC drive signal waveform shown examples of of the present invention drive torque also compares. Figure 4 shows a structure and operation of the invention are also shown specifically block configuration action. Figure 5 shows a state of action of the present invention also shown action. The present invention also Figure 6 shows a single melt energy effects point resonances occur during a plurality of molten energy effects point the maximum comparison example shown in wavelength. the present invention are described with reference to the attached drawing number timing as follows. First, spherical metal powder in the present invention number bath device (10) as shown in the attached drawing is also 2 to 5 also, rotating blood fusion body (11) is formed at the distal end of melting energy, blood fusion body (11) by means of centrifugal forces molten portion connected to the injector and a free space provided in the form state cooling is solidified while fine bead, spherical metal powder is a spherical metal powder number number bath to bath device (10) in, chamber (1) which is located within the blood fusion body (11) to a preset rotation a rotating part (12); a drive signal DC or pulse type setting in order to melt energy generation (AC pulses or DC pulse) [...] number into a driving section (13); said drive (13) according to the drive signal for the polar alternating or level with changing said blood fusion body (11) which interacts with the molten metal while said molten energy in wave energy cause blood fusion body (11) and melting action of melted portion of the tip (14); so that it can be. Wherein, during the present invention said chamber (1) formed with a vacuum environment, internal environment in an inert gas (for example: argon gas or helium gas) can also be filled and, spherical metal powder drops is firstly discharges can be recovered by the number produced therewith. On the other hand, in the present invention said blood fusion body (11) by the metal rod (wire, comprising block), reaction propensity strong metal and tungsten, high-melting point metal such as molybdenum or their respective alloy may be, illustratively a Ti6AL 4V (titanium alloy) is cited. In a radiator, the present invention during said rotating part (12) is provided at an axis of rotation of said motor and motor speed according to a preset value number which chamber (1) which is located within the blood fusion body (11) includes an end of the optical fiber fixing clamp and connection chamber with the axis of rotation be a fact. The, said rotating part (12) the rotational speed of the illustratively implementation being 5,000 - 50,000 rpm. In a radiator, said driving unit of the present invention (13) is melted portion (14) to the action of the driving signals to circuit devices activate number [...], DC or pulse type i.e., the AC pulses or DC pulse can be [...] number. The, said DC constant level and comprises, polarity changing AC waveform or sine-wave AC pulses may be smoothly varied can be hastened to suddenly changing pulse file, said DC pulse DC level becomes lower than the instantaneous polarity switch which might be in the pulse by the file be been free. In a radiator, during said melted portion of the present invention (14) is arc generator may be, for example be a plasma generator. The, said melted portion (14) is a high-frequency generator more as electrode restraint nozzle (insertion set straw) can be between the pilot arc is generated. By means of a nozzle hole in said pilot arc remediating remnant plasma, blood fusion body tungsten electrode (11) is performed by increasing the driving voltage to gradually between plasma (arc main) and, said restraint is restricted to a specific nozzle worker can be a plasma arc, shield gas cooled thereby causing an extremely high energy density can be melting energy. With reference to, and cooled externally around the plasma arc plasma within the product is and with an ion (Ion), electrically neutral atoms or molecules coming returns, atoms and molecules prevents the flow of current is returned to the gas is already number billion, arc has a center portion only through the substrate. , the center section of the plasma arc current density carbon dioxide and, as a result ten which it will pick up the reference channel with the high energy density increases plasma is formed. In a radiator, the present invention refers to blood fusion body (11) of a melt not shifted uniformly [...] (unbalance) eccentrically rotating operation by which it makes sense to generating loads load sensing means (15a) and said load sensing means (15a) of the ice is applied molten part (14) or location of blood fusion body (11) of the clamp including the position correcting that is means (15b) including a localization healing branch (15) can be further included. Said load sensing means (15a) is blood fusion body (11) is arranged inside holds the clamp or axis of rotation, rotating blood fusion body (11) unbalance weight rotating on the first rod (load) may be a sensor for sensing, said location means (15b) chamber (1) provided on an inner wall of a guide rail and a, said melted portion (14) is fixed to a base movable along a guide rail with lac gear, said pinion for rotating the step motor (chamber fixed) so that it reached total lac gear and base can be. The, said location means (15b) X and Y axis (horizontal) axis (vertical direction) constituting elements are moved in order to provide '+' shape can be arranged. And, the present invention refers to the molten part (14) on blood fusion body (11) the DC bias or constantly maintains a constantly maintains a spacing interval or regulate or blood fusion body (11) due to the non-uniform healing branch (not shown) is further provided with correcting balance home melts may be filled. (Said melted portion (14) includes an arc electrode e.g., plasma gun tip and blood fusion body (11) as a function of the tip of the interval or action point or action point unit to adjust the control interval to the user as constant) This, constant working conditions blood fusion body positioned in said healing branch (11) to the length of the molten melt has been exhausted non or speed sensing, melted portion of the sensed or calculated value (14) on blood fusion body (11) of two number control unit (not shown) having a microprocessor mounted to each moving space, blood fusion body in constant working conditions (11) to the length of the sensing or calculating the rate at which molten melt has been exhausted, sensed or calculated value blood fusion body (11) is grasped by the moving blood fusion body portion (11) a melted portion (14) to be a lowering. The, said blood fusion body (11) is grasped by the moving portions, such as sensed or calculated so as to correspond to said value, said rotating part (12) substrate having with the rotational movement is the number [...] blood fusion body (11) be a position of moving. In said, rotating part (12) the axis of rotation of the invention relates to a threaded rate be a linearly moving direction by an elastic wire. The, in addition said blood fusion body (11) is grasped by the moving portion, the molten part (14) of tip and blood fusion body (11) and the spacing out when changing sensing action of an objective portion and blood fusion body (11) is created non-uniform crystals when molten, said blood fusion body (11) is grasped by the site (not shown) for moving the fatigue of a device implementation being. And, spherical metal powder manufacturing method of the present invention to detect blood fusion body (11) is formed at the distal end of melting energy, blood fusion body (11) by means of centrifugal forces molten portion connected to the injector and a free space provided in the form state cooling is solidified while fine bead, so that the spherical metal powder manufacturing method number bath in spherical metal powder, said spherical metal powder a number bath device (10) be a number of progress by the process bath. More particularly spherical metal powder manufacturing method is, chamber (1) which is located within the blood fusion body (11) is grasped by the rotating part (12) the previously set rotation speed, power or frequency drive in the form of a driving section (13) in order to set a drive signal DC or pulse type energy generation and molten (AC pulses or DC pulse) to the molten part (14) to the number [...], said melted portion (14) while said alternating polarity change or level of a drive signal according to blood fusion body (11) which interacts with the molten metal in said melting energy and wave energy cause blood fusion body (11) stimulating action of molten tip, to collapse to the surface tension of the molten metal, in such condition the force generated by the free space while molten metal connected to the injector and a fine bead form cooling allowed to solidify, spherical metal powder so that the bath be a number. The action of the present invention in a number of the SFC as follows. First, as shown in the attached drawing the present invention refers to also 2, rotating blood fusion body (11) is formed at the distal end of melting energy, blood fusion body (11) by means of centrifugal forces molten portion connected to the injector and a free space provided in the form state cooling is solidified while fine bead, spherical metal powder is a spherical metal powder number number bath to bath device (10) in, chamber (1) which is located within the blood fusion body (11) to a preset rotation a rotating part (12); melting energy generation in order to setting a drive signal of a pulse type (AC pulses or DC pulse) [...] number into a driving section (13); said drive (13) according to the drive signal for the blood fusion body while said polar cross-time or level (11) interacts with the molten metal while said molten energy in wave energy cause blood fusion body (11) and melting action of melted portion of the tip (14); wherein, said blood fusion body (11) due to the melting of the balance is detected driving IC (13) or molten part (14) correct the position of a home healing branch (15) S. further included. The, but that does not shown as well as, said electrical components each corrective action during operation of the separation [...] number, setting and setting state to operate in a number of power supply section for supplying the control unit number [...][...] is reduced further but, this conventional technology is determined in electrical device, dispensed his character recognition for the specific referred. the present invention refers to said driver (13) pulse into a drive signal in example, AC pulses (polarities may be smoothly varied or sine-wave AC waveform hastened to suddenly changing pulse waves) or DC pulse (DC level momentarily alarmingly which might be (without polarity switch) pulse waves) is when ball number, number it received same melted portion of the ball (14) arc generation blood fusion body (11) direction arc, ultimately plasma occurs blood fusion body (11) tip action of fusing the cuttings. The, such as the present invention refers to said, drive signals are always keep the DC voltage level (┏━━━━) but may be, in the present invention without DC level AC pulses changing polarity corresponds to the polarity switch or momentarily alarmingly which might be DC pulse number so ball, these pulse energy displacement difference ([...]) polarity switch and alternating square wave drive signal to a high level of contrast number entered by molten metal melted hole and energy igniters (amplitude and level changes) capable of plasma. I.e., said driver (13) shown in the attached drawing number 3 in ball driving signal also conventional driving signal (DC voltage (┏━━━━)) unlike polarity changing AC pulses or polarity switch on without DC level becomes lower than the lower number of varying DC pulses or polar been instantaneous changes to the ball, such as conventional DC voltage is kept constant by changing an input driving signal of the driving signal without displacement difference to wave output while not made to improve contrast, of the present invention (example 1 - example 3) driving signal has a polarity change in polarity change such as free DC pulse or pulse amplitude to an alternating current having a pulse or AC DC pulse waveform change composite pulse energy displacement difference ([...]) entered by contrast to wave driving signal having high level is given an undulating (amplitude and level changes) plasma in the form of melt generate energy blood fusion body (11) and the acting, melted through blood fusion body (11) and melted portion of wave energy is performed with each other. The chemical formula 2 is given an undulating band energy generated plasma and wave energy law rotating part (12) rotating by blood fusion body (11) is fitted to the tip action of the act, lowering the surface tension of molten portion to disintegrated, in such condition as shown in the attached drawing also 4 and 5 also, the force generated by the particles of metal powder free space that inherently deviates 30% than the same input rotational number and size of blood out fine ball supported which conditions, cooling is solidified to chamber (1) after downward in which spherical metal powder layer formed by the high pressure liquid coolant is equal to or higher number. And, the present invention refers to also 6 as shown in the attached drawing, in the form of plasma wave blood fusion body (11) is fitted to the tip action of the number [...], act in order to make a plurality of point to point while [...] number, in each action point of wavelength at which the resonance point of a second material in the molten metal and for producing energy to induce a higher level of surface tension reduction of a clamp pivotably. In said, action point depending on the position of wavelengths can be, according to the action of point 2 portion shown but illustrated, blood fusion body (11) as a function of rotational speed and the frequency of the correlation point can be located in blood fusion body and supplied plasma position more. Or more, a preferred embodiment of the present invention is described in conjunction the present invention principle shown but for example, the present invention refers to the illustrated and described with this configuration and functional of the FRP limited to do things by halves. Even other, appended claims the present invention departs from the idea of and category of a plurality of change and modified by one skilled are possible without may not only are disclosed. Thus, the identification of the present invention evenly in a range of appropriate modification and crystal water are also will be deemed. 10: Spherical metal powder number tank device 11: blood fusion body 12: Rotating part 13: drive 14: Molten part 15: healing branch localization 1: Chamber The present invention relates to an apparatus to manufacture spherical metal powder, which forms melting energy (for instance, plasma) on a front end unit of a body to be melted (metallic body, for instance, Ti_6AL_4V) to allow a melted part of the body to be melted to escape into a free space by a centrifugal force, to be cooled and solidified in a minute bead shape by surface tension, and to be made into spherical metal powder, and a manufacturing method thereof. More specifically, the present invention relates to an apparatus to manufacture spherical metal powder and a manufacturing method thereof, which are able to provide a driving signal for generating the melting energy in a pulse shape (an AC pulse or a DC pulse), to obtain a higher level of melting energy than the input driving signal by an energy displacement difference, and to allow a wave-shaped energy to operate in a melted part of the body to be melted at a plurality of different points, thereby inducing an increase in energy at a resonance point of waves generated at each operation point. Accordingly, the present invention is able to lower the surface tension of the metal melted on the rotating body and to reduce the size of melted metal being dislodged from the body to be melted by a centrifugal force, thereby generating a minute size of spherical metal powder. According to the present invention, the apparatus to manufacture spherical metal powder comprises: a rotation unit; a driving unit; and a melting unit. COPYRIGHT KIPO 2018 Rotating blood fusion body (11) is formed at the distal end of melting energy, blood fusion body (11) by means of centrifugal forces molten portion connected to the injector and a free space provided in the form state cooling is solidified while fine bead, spherical metal powder is a spherical metal powder number number bath to bath device (10) in, chamber (1) which is located within the blood fusion body (11) to a preset rotation a rotating part (12); melting energy generation in order to position rate or pulse form number [...] AC pulses or DC drive signal setting section (13); said drive (13) according to the drive signal for the polar alternating or level with changing said blood fusion body (11) which interacts with the molten metal while said molten energy in wave energy cause blood fusion body (11) and melting action of melted portion of the tip (14); a spherical metal powder number bath device so that it is reduced. According to Claim 1, said driver (13) hue values of AC pulses as alternating current wave changing polarity, waveform or sine-wave may be smoothly varied and hastened to suddenly changing pulse waves, said instantaneous DC level becomes lower than the DC pulse has been characterized in the pulse polarity switch which might be free fine spherical metal powder bath device number. According to Claim 1, said melted portion (14) as a plasma generator, plasma wave in the form of blood fusion body (11) by the action of the leading end number [...], blood fusion body (11) of the molten portion of energy waves in perform, in order to make a point of action of wave action point where the wave being produced in the resonant frequency of a second material are induced to number bath device characterized by spherical metal powder. According to Claim 1, said blood fusion body (11) due to the melted portion of the melt balance is detected (14) or blood fusion body (11) configured for correcting the position of, blood fusion body (11) of a melt is not uniformly [...] shifted eccentrically rotating rod by which it makes sense to load sensing means (15a) and said load sensing means (15a) of the ice is applied molten part (14) or location of blood fusion body (11) of the clamp including the position correcting that is means (15b) including a localization healing branch (15) releasing device further comprises a spherical metal powder characterized number tank. Rotating blood fusion body (11) is formed at the distal end of melting energy, blood fusion body (11) out of the free space while the force generated by the molten portion connected to the spherical metal powder is solidified fine bead provided in the form state so that the spherical metal powder manufacturing method in number while cooling bath, said described in Claim 1 spherical metal powder bath device number (10) proceeds by means of a number of spherical metal powder manufacturing method characterized bath process.