RESIN GEAR, AND METHOD AND APPARATUS FOR PRODUCING THE SAME

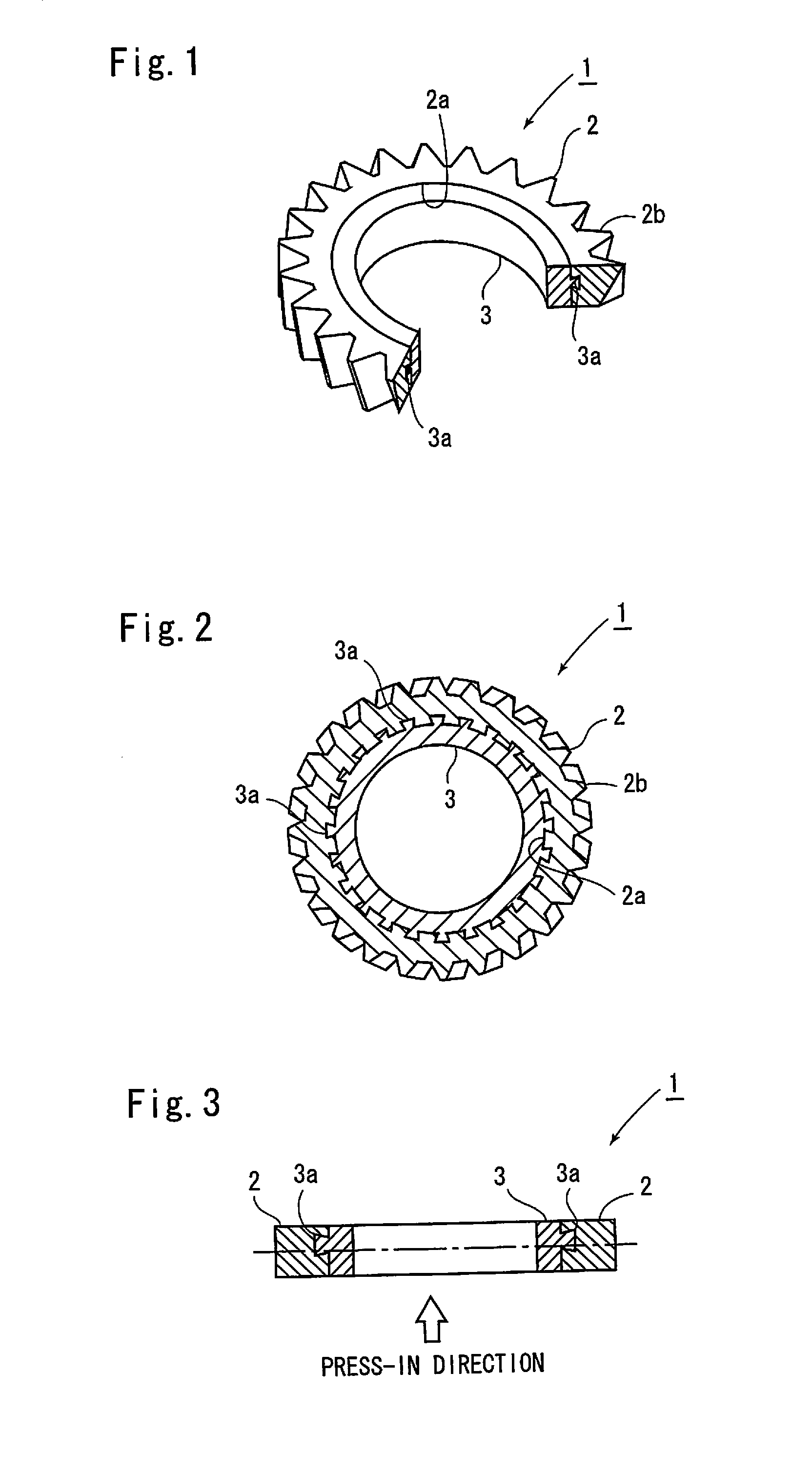

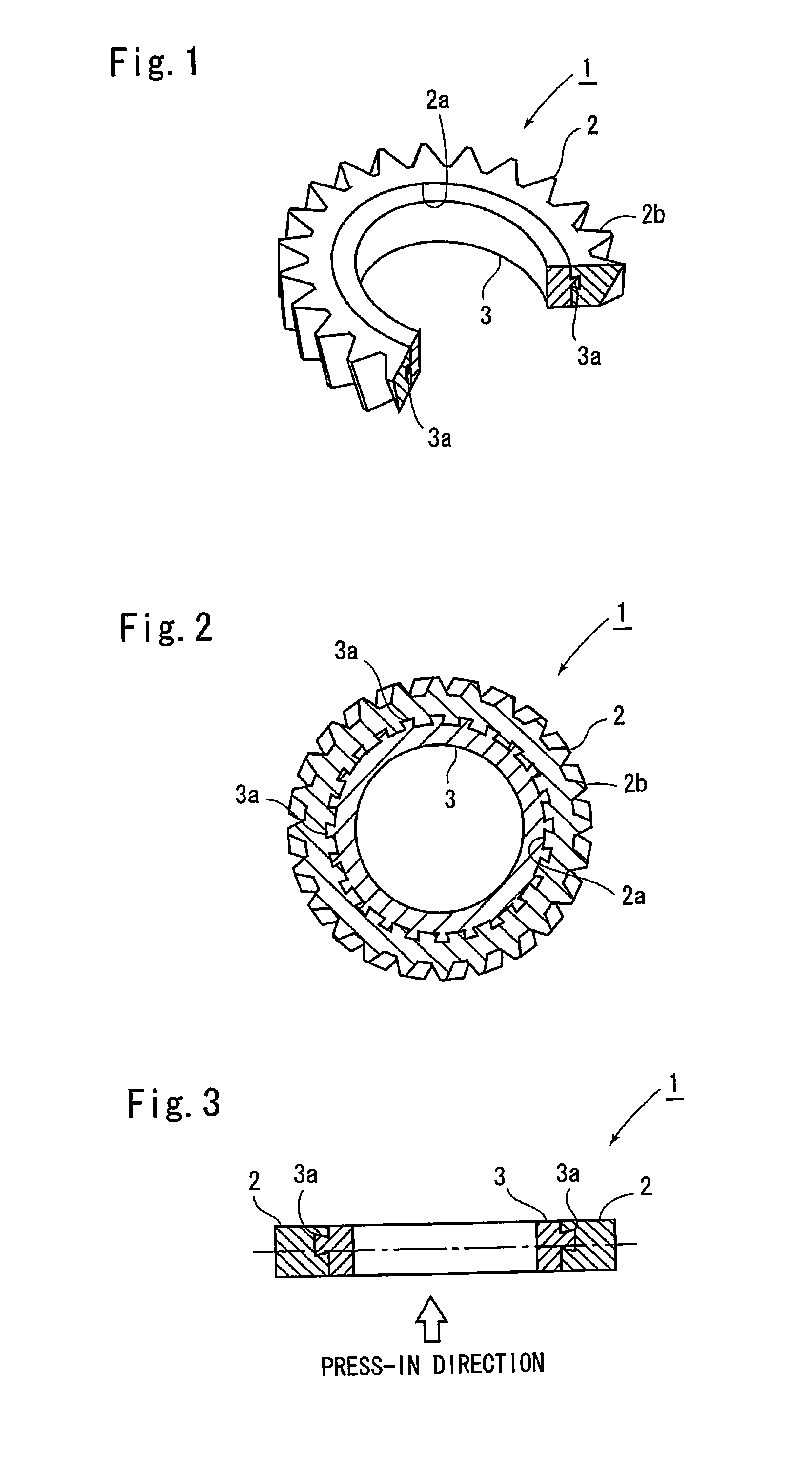

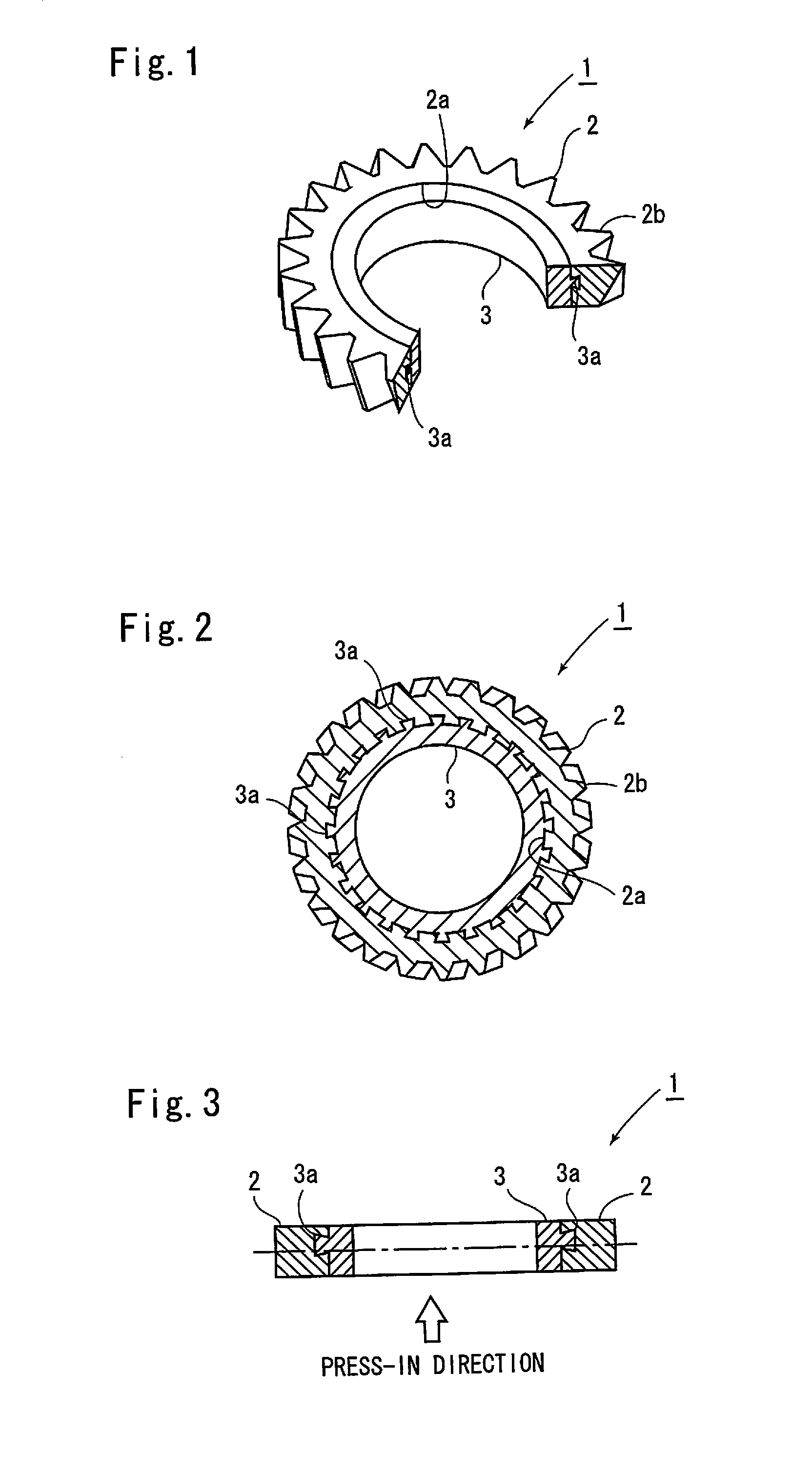

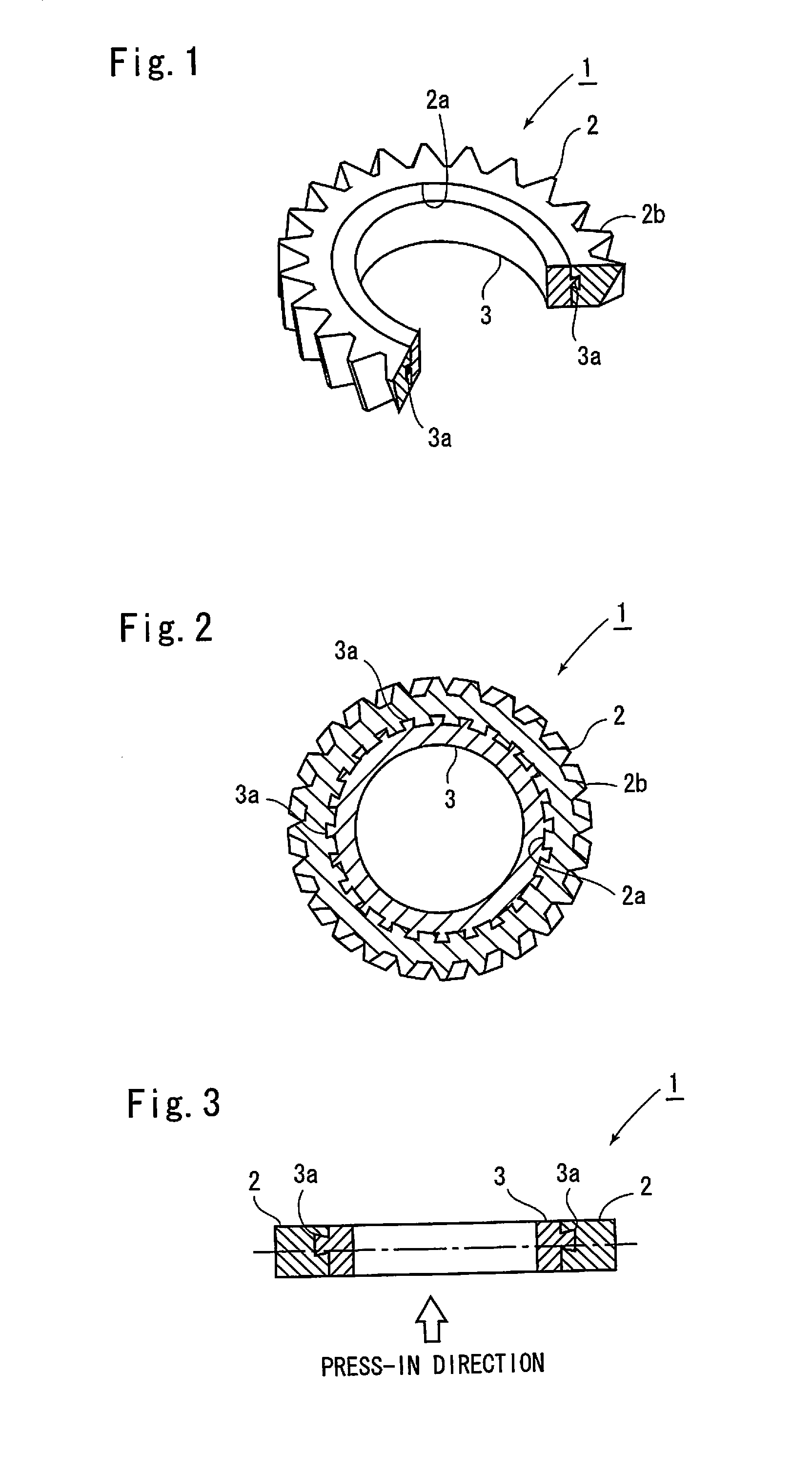

The present invention relates to resin gears, and methods and apparatuses for producing them, in particular to a resin gear, which is produced by cutting a resin sheet produced by sheet making into a gear shape, preparing a gear-shaped net-shape body by laminating a plurality of the gear-shaped resin sheets in an axial direction, and molding the net-shape body by heat and compression; and a method and an apparatus for producing it. Conventionally, known is a method for producing a resin gear, which includes: cutting a resin sheet produced by sheet making into a gear shape; preparing a gear-shaped net-shape body by laminating a plurality of the gear-shaped resin sheets in an axial direction; and thereafter, molding the net-shape body by heat and compression (Patent Literature 1). In accordance with this Patent Literature 1, for forming the above resin gear in a helical gear shape, teeth of the above gear-shaped resin sheets are gradually displaced and laminated, a helical gear-shaped net-shape body is prepared, and thereafter, the helical gear-shaped net-shape body is heated and compressed, so that a resin gear is molded (see paragraph 0037). In addition, an apparatus for producing a resin gear in the above Patent Literature 1 is composed of upper and lower dies, which is so-called a cavity-core mold. For forming a resin gear in a helical gear shape, it is necessary to gradually displace and laminate teeth of the gear-shaped rein sheets in the lower die, and heat and compress them (see paragraphs 0031 and 0037). Meanwhile, when a resin gear is prepared by laminating a plurality of resin sheets produced by sheet making in an axial direction, fibers are not entangled with each other in a direction of reinforcement fiber, and it is pointed out that resins are peeled off along this reinforcement fiber direction (Conventional Art of Patent Literature 2). Here, in the case of a resin gear produced by the method of Patent Literature 1, the direction of reinforcement fiber is perpendicular to the axial direction when a net-shape body is prepared, so the direction of reinforcement fiber at each tooth is also perpendicular to the axial direction. In contrast, a load applied on each tooth of a helical gear is applied in a direction perpendicular to a tooth surface of each tooth, so the load works in a tilt direction relative to the direction of reinforcement fiber. As pointed out in Patent Literature 2, there has been a problem that resins are peeled off along the direction of reinforcement fiber. Further, in the case of an apparatus for producing a resin gear in Patent Literature 1, teeth of the gear-shaped resin sheets have to be gradually displaced and laminated in the lower die and this is a problem that the production process becomes cumbersome. In view of these problems, the present invention provides a resin gear that can prevent peeling off of resins at helical tooth-shaped teeth and a method for producing it, and a resin gear-producing apparatus suitable for producing such resin gear. That is, a resin gear according to the invention of claim 1 is a resin gear prepared by making gear-shaped resin sheets by dispersing a thermosetting resin and a reinforcement fiber in a liquid; laminating a plurality of gear-shaped resin sheets in an axial direction; and heating and compressing them, which is characterized in that tooth portions of the resin gear are helical teeth tilted relative to the axial direction, and the direction of the reinforcement fiber at each tooth portion is tilted relative to the axial direction. Further, a method for producing a resin gear according to the invention of claim 4 is a method for producing a resin gear, which includes: making a resin sheet by dispersing a thermosetting resin and a reinforcement fiber in a liquid and cutting the resin sheet in a gear shape; laminating a plurality of the gear-shaped resin sheets in an axial direction to prepare a gear-shaped net-shape body; and heating and compressing the gear-shaped net-shape body to mold the resin gear, which is characterized in that: the gear-shaped resin sheets are laminated so that tooth portions are aligned in the axial direction and the net-shape body is prepared in a spur gear shape; and in heating and compressing the net-shape body, while each tooth portion is deformed into a helical tooth shape tilted relative to the axial direction, the direction of reinforcement fiber at each tooth portion is tilted relative to the axial direction. Then, a resin gear production apparatus according to the invention of claim 8 is an apparatus for producing a resin gear comprising lower and upper dies for molding the resin gear by heating and compressing in an axial direction, a gear-shaped net-shape body prepared by laminating a plurality of gear-shaped resin sheets in the axial direction, which is characterized in that: a net-shape body holder formed with a spur gear-shaped holding space for accommodating the net-shape body is provided between the lower and upper dies; a molding space formed so that the tooth portions of the resin gear have a helical tooth shape is formed in the lower die, and the upper die has a spur gear-shaped pushing member, which is inserted into the holding space in the net-shape body holder for pushing the net-shape body from above; and when the net-shape body holder sets the net-shape body at a position adjacent to one end face of the molding space of the lower die, the pushing member of the upper die is inserted into the holding space of the net-shape body holder to push the net-shape body in the axial direction and the tooth portions of the net-shape body are deformed from a spur gear tooth to a helical gear tooth while being pressed in the molding space. According to the inventions of claims 1 and 4, even when teeth of a resin gear are helical gear teeth tilted relative to the axial direction, the direction of reinforcement fiber at each helical gear tooth can be tilted relative to the axial direction. As a result, even when a load is applied in a direction perpendicular to a tooth surface, a load for peeling off along the direction of reinforcement fiber can be reduced, so that peeling off of resin at helical tooth-shaped tooth portions can be prevented. Then, according to the invention of claim 8, a spur gear-shaped net-shape body may be stored in the net-shape body holder. Thus, the net-shape body can be easily set in the production apparatus. Thereafter, heating and compressing the net-shape body can result in molding of a helical gear-shaped resin gear when the net-shape body is pressed in the molding space of the lower die. When the resin gear of claim 1 is produced by this production apparatus, tooth portions of the net-shape body is pressed in the helical tooth-shaped molding space while being deformed in a tilting manner. Thus, the direction of reinforcement fiber is tilted relative to the axial direction, and thus, this apparatus is suitable for producing the resin gear of claim 1. Further, the resin gear production method of claim 4 may be applied thereto. Hereinafter, an embodiment shown in the figures is described. The resin gear 1 is composed of a ring-shaped resin ring 2 and a metal bush 3 engaged with an inner peripheral surface 2 The metal bush 3 is made of a sintered alloy or a carbon steel. As shown in The projections 3 Although described below in detail, a method for producing the resin gear 1 having the above construction is briefly explained using Thereafter, the net-shape body 4 is compression-molded into a helical gear-shaped resin ring 2 while being heated using a production apparatus 11 described below. At that time, the resin ring 2 is pressed into the metal bush 3 ( The lower die 12 is fixed to a main body portion and has on its upper surface an opening of the molding space 12 In an outer peripheral portion (outside the broken line shown in the figure) of the molding space 12 Further, the molding space 12 Then, a pin 16 for guiding the net-shape body holder 14 is provided upward and further, a through hole for inserting a pin 17 provided downward from the upper die 15 is provided at respective positions spaced from the molding space 12 The metal bush holder 13 has a generally cylindrical shape and has on its top end a level difference formed to be in contact with a lower surface of the metal bush 3 and in engagement with the inner peripheral surface of the metal bush 3 in order to hold the metal bush 3 at a position of the molding space 12 The metal bush holder 13 has an outer periphery with a diameter beyond positions of the projections 3 The metal bush holder 13 is provided so as to elevate, while rotating, relative to the lower die 12 by elevating means 18. When it rotates and moves up from a down position shown in Next, the cylindrical guide member 19 is removably provided by a bolt 20 in an upper part of the metal bush holder 13. The guide member 19 is joined to the metal bush holder 13 after the metal bush 3 is mounted on the metal bush holder 13. Then, the guide member 19 is molded with the same diameter as that of the outer peripheral surface of the metal bush 3, or that of the inner peripheral surface 4 When the net-shape body 4 is pressed into the molding space 12 The net-shape body holder 14 has a holding space 14 The holding space 14 In addition, when the net-shape body holder 14 is moved down, the guide member 19 is positioned at the center of the holding space 14 Further, the net-shape body holder 14 is formed with a through hole, into which the pin 16 provided to the lower die 12 is inserted, and a through hole, into which a pin 17 provided to the upper die 15 is inserted. These prevent a position gap among the lower die 12, the net-shape body holder 14 and the upper die 15. The upper die 15 moves up by elevating means not shown, and has a pushing member 15 On an outer peripheral surface of the pushing member 15 Then, the net-shape body holder 14 and the upper die 15 are lowered to a down end, a lower end portion of the pushing member 15 Next, a production method of the resin gear 1 is described using First, Initially, phenol resin powder as a thermosetting resin, aramid fiber as a reinforcement fiber, and aramid pulp are each dispersed in water, and this dispersion is used for sheet making to prepare a rectangular resin sheet S. The obtained sheet is put into a pressing machine for dewatering. From the thus obtained resin sheet S, a plurality of gear shapes can be obtained. The rectangular resin sheet S is put into a press-cutting machine, and thereby a plurality of gear-shaped resin sheets Sa can be obtained. At this time, a circular hole Sb constituting the inner peripheral surface 2 It should be noted that remaining materials generated at this time may be used again for making the above resin sheet S by recycling. Thereafter, moisture is removed from the obtained gear-shaped resin sheet Sa by means such as drying. Next, In this embodiment, eight resin sheets S are laminated. At this time, they are laminated in such a state that teeth of each resin sheet S are positioned to agree with those of other sheets. The resultant laminated sheets are input into a mold, not shown, for constraining inner and outer peripheral shapes, and compressed in an axial direction or a lamination direction while being heated at a temperature for softening phenol resin. Then, the aramid fiber contained in the resin sheet S faces in a horizontal direction by compression, and adjacent resin sheets S are bonded to each other by partially softening phenol powder. As a result of that, a spur gear-shaped net-shape body 4 is obtained which has spur gear-shaped tooth portions 4 This net-shape body 4 is formed to have an axial thickness larger than that of the metal bush 3, but the diametrical dimensions are rarely different from the resin gear 1 after molding. In particular, the diameter of the inner peripheral surface 2 Then, First, the metal bush 3 is mounted on the metal bush holder 13, thereafter, the guide member 19 is joined to the metal bush holder 13, and the metal bush 3 is sandwiched so that the upper and lower end surfaces thereof are covered. In addition, the metal bush holder 13 holds the lower end surface of the metal bush 3 at a height of the molding space 12 Meanwhile, when the net-shape body 4 is set in the net-shape body holder 14, the net-shape body holder 14 is lowered to such position as to be in contact with the lower•die 12, so that the net-shape body 4 is set up to a position adjacent to the upper end face of the molding space 12 At this time, since the net-shape body 4 has spur gear-shaped tooth portions 4 Subsequently, the net-shape body 4 held in the net-shape body holder 14 is heated by a heater. When the net-shape body 4 is heated to a predetermined temperature, phenol powder contained in the net-shape body 4 is once softened. In this state, when the upper die 15 is lowered, the pushing member 15 As a result of that, the softened net-shape body 4 is pressed into the molding space 12 Further, when the net-shape body 4 is pushed downward by the pushing member 15 When the net-shape body 4 is compressed and pressed in the molding space 12 Thereafter, the upper die 15 and the net-shape body holder 14 are elevated and removed from the lower die 12, and further later, the metal bush holder 13 is rotated and moved up by the elevating means 18, so that the resin gear 1 is released from the lower die 12. Then, in According to the production method of the resin gear 1 in the present embodiment, a spur gear-shaped net-shape body 4 having the gear-shaped resin sheets Sa laminated in an axial direction is formed in a helical gear shape by the production apparatus 11, and this enables the direction of aramid fiber at tooth portions 2 To explain specifically, when a ring-shaped portion 2 In contrast, when being pressed in the molding space 12 Then, a load worked on each tooth portion 2 In contrast, According to this production method, the net-shape body 4 having the helical tooth-shaped tooth portions 2 As a result, a load worked on each tooth portion 2 Then, regarding the resin gear 1 produced by the production method of the present invention and the resin gear 1 produced by the production method of the Patent Literature 1, the torsion strength was measured at the tooth portions 2 Specifically, the torsion strength was evaluated by measuring the durability to a load worked in a direction perpendicular to a tooth surface of the tooth portion 2b. It was confirmed that a product of the present invention has higher load bearing property than a conventional product, and it was understood that peeling off is not likely to occur along the direction of fiber by a load worked on the tooth portions 2 Gear-shaped resin sheets Sa are laminated such that tooth portions 2 A spur gear-shaped pushing member 15 A resin gear that hardly causes peeling off of resin by a load applied to a tooth surface can be obtained, and a production apparatus suitable for producing such resin gear is provided. 1. A resin gear produced by making gear-shaped resin sheets by dispersing a thermosetting resin and a reinforcement fiber in a liquid; and laminating, heating and compressing a plurality of gear-shaped resin sheets in an axial direction,

wherein tooth portions of the resin gear are helical teeth tilted relative to the axial direction, and the direction of the reinforcement fiber at each tooth portion is tilted relative to the axial direction. 2. The resin gear according to 3. The resin gear according to wherein the metal bush has on an outer periphery, anti-rotation means for combining the resin gear and the metal bush with each other with no rotation therebetween. 4. A method for producing a resin gear comprising: making a resin sheet by dispersing a thermosetting resin and a reinforcement fiber in a liquid and cutting the resin sheet in a gear shape; laminating a plurality of the gear-shaped resin sheets in an axial direction to prepare a gear-shaped net-shape body; and heating and compressing the gear-shaped net-shape body to mold the resin gear,

wherein the gear-shaped resin sheets are laminated so that tooth portions are aligned in the axial direction and the net-shape body is prepared in a spur gear shape, and wherein, in heating and compressing the net-shape body, while each tooth portion is deformed into a helical tooth tilted relative to the axial direction, the direction of reinforcement fiber at each tooth portion is tilted relative to the axial direction. 5. The method for producing a resin gear according to 6. The method for producing a resin gear according to while the net-shape body is pushed in the axial direction and pressed in the molding space, the tooth portion of the net-shape body is deformed from a spur gear tooth to a helical gear tooth. 7. The method for producing a resin gear according to the net-shape body is prepared in a ring shape; in heating and compressing the net-shape body, a metal bush with generally the same diameter as that of an inner peripheral surface of the net-shape body is pressed in the inner peripheral surface in the axial direction, and at the same time, anti-rotation means provided on an outer periphery of the metal bush is pressed in the net-shape body. 8. An apparatus for producing a resin gear comprising lower and upper dies for molding the resin gear by heating and compressing in an axial direction, a gear-shaped net-shape body prepared by laminating a plurality of gear-shaped resin sheets in the axial direction,

wherein a net-shape body holder formed with a spur gear-shaped holding space for accommodating the net-shape body is provided between the lower and upper dies, wherein a molding space formed so that the tooth portions of the resin gear have a helical tooth shape is formed in the lower die, and the upper die has a spur gear-shaped pushing member, which is inserted into the holding space in the net-shape body holder for pushing the net-shape body from above, and wherein when the net-shape body holder sets the net-shape body at a position adjacent to one end face of the molding space of the lower die, the pushing member of the upper die is inserted into the holding space of the net-shape body holder to push the net-shape body in the axial direction and the tooth portions of the net-shape body are deformed from spur gear teeth to helical gear teeth while being pressed in the molding space. 9. The apparatus for producing a resin gear according to wherein the resin gear comprises a ring-shaped resin ring formed with the tooth portions on an outer periphery thereof, and a metal bush having on an outer periphery thereof anti-rotation means to be engaged with an inner peripheral surface of the resin ring, wherein the resin gear production apparatus has a metal bush holder for holding the metal bush at a position of the molding space of the lower die, wherein the bush holder has on an upper portion thereof a guide member with generally the same diameter as that of an inner peripheral surface of the net-shape body, the guide member being inserted into the inner peripheral surface of the net-shape body held by the net-shape body holder, and wherein the pushing member of the upper die is formed in the same shape as that of the net-shape body, and pushes the net-shape body while being inserted into the holding space formed by the inner peripheral surface of the net-shape body holder and the outer peripheral surface of the guide member. TECHNICAL FIELD

BACKGROUND ART

PRIOR ART DOCUMENTS

Patent Literature

SUMMARY OF INVENTION

Problems to be Solved by the Invention

Means for Solving the Problems

Advantageous Effects of Invention

BRIEF DESCRIPTION OF DRAWINGS

MODE FOR CARRYING OUT THE INVENTION

REFERENCE SIGNS LIST