PROCESS AND APPARATUS FOR MAKING ALTERNATE S/Z TWIST PLIED BRAID OR JOINED ALTERNATE S/Z TWIST PLIED YARNS

This invention relates to an improved method and apparatus for producing an alternate twist plied braid and joined alternate twist plied yarns. The invention further relates to alternate S/Z twist plied braid and joined alternate S/Z twist plied yarns obtained with the method. The concept of producing alternate twist plied yarns using the alternate twist, self-twist phenomenon is now rather well known in the art. Documents in which the general principles of alternate twisting and self-twisting are described include the following: “Self-Twist Yarn”, D. E. Henshaw, Merrow Publishing C° , Ltd., Watford, Herts, England, 1971; RE 27,717 Breen et al; U.S. Pat. No. 3,225,533 Henshaw; U.S. Pat. No. 3,306,023 Henshaw et al.; U.S. Pat. No. 3,353,344 Clendening, Jr.; U.S. Pat. No. 3,434,275 Backer et al.; U.S. Pat. No. 3,443,370 Walls; U.S. Pat. No. 3,507,108 Yoshimura et al.; U.S. Pat. No. 3,717,988 Walls; U.S. Pat. No. 3,775,955 Shahand and U.S. Pat. No. 3,940,917 Strachan. For purposes of convenience, some general comments concerning producing plied yarn by these techniques will be described. It is possible to form a plied yarn by alternate twisting two or more single yarn strands, attaching the strands to each other and then permitting the strands to wrap about each other using the release of forces stored by the alternate twisting to accomplishing the plying, hence the term “self-twist”. The alternate twisting itself, in simplified form, involves holding spaced points of a yarn strand and twisting the strand in one direction at a point intermediate the held points, e.g., the center. This produces twists on one side of the center in one direction and on the other side of the center in the opposite direction. The center of the twisted strand constitutes a point of twist reversal and is called a “node”. Clearly, forces are stored in the strand in the twisting step. When two strands similarly alternate twisted are brought together in side-by-side juxtaposition with their ends held and permitted to act against or with each other by releasing a central node, the stored forces cause the strands to ply, i.e., to wrap around each other spontaneously. The process is enhanced and the product made more stable if the nodes of the two strands are aligned and are joined or joined together before release and plying. As will be recognized, the torque or twist force exerted by each strand is roughly proportional to the amount of twist therein and that such force decreases as the strands ply. The plying step itself therefore continues until the stored twist forces in each strand decrease to a point at which the remaining twist forces are exactly counterbalanced by the resistance to further twisting in the plied yarn. Thus, if one begins with individual strands and then alternate twists the strands and plies them, each strand will end up, in the plied yarn, with some degree of residual twist which can be thought of as some remaining stored potential energy, the force exerted thereby being too small to cause further ply twisting against opposing forces in the plied yarn. In a stable plied yarn formed in this fashion, the amount of applied singles twist always is greater than the amount of ply twist. Generally speaking, this remaining stored force or energy may not be particularly disadvantageous, depending upon the type of fabric to be produced from the plied yarn. However, when the yarn is to be used to produce certain products such as pile or tufted carpet, the existence of the residual twist in the singles yarn becomes highly significant because of the appearance of the product produced therefrom. Consider, for example, a plied yarn formed from two singles yarns in which the value of applied singles twist is equal to 1.4 times the value of ply twist (S=1.4 P). In this circumstance it has been found that the fibers in the individual strands are substantially parallel with the axis of the plied yarn. A tufted carpet made from yarn of this description exhibits two significant disadvantages, one of these being the fact that relatively minor variations in the manufacturing process, such as small variations in twist between spindles, causes large changes in the light reflectance characteristics of the carpet tufts, and the carpet can have a highly noticeable streaky appearance which is unacceptable. The second major problem is that with S=1.4 P or more , the individual yarn strands tend to retain their identity as individual strands, even though plied, and tend to split at the tuft tips into separate singles strands which are visible and which give the carpet surface an undesirable “stringy” appearance. It is also known, as shown in aforementioned U.S. Pat. No. 3,443,370, Walls, to produce a yarn by alternate twisting a number of strands greater than two or more assembled threads or yarns, and plying steps with the previously plied yarns to form what can be termed a braid. In forming a braid from previously plied strands, the various forces interact in each plying process in such a way that it is difficult to predict the degree of twist which will exist after all of the steps, and it is therefore a rather complicated process to arrive at an end product which has twist relationships which meet desired specifications. However, U.S. Pat. No. 4,246,750 describes that by inserting specified degrees of twist in singles yarns, joining the nodes of the yarns, permitting them to ply together to form alternate twist plied strands, alternate twisting selected ones of the strands, joining nodes of the strands and permitting the strands to ply together into a braid, a product having predictable and consistent twist relationships can be obtained. U.S. Pat. No. 4,246,750 further describes that joining a plurality of plied alternate twisted strands together at the nodes permits a dramatic increase in the number of strands which can be heat set in a given interval with little increase in energy input, thereby significantly increasing the production rate of such yarns and reducing the cost per unit length of the heat-setting operation. Additionally, it describes that heat setting braided or joined alternate twisted plied strands results in a product which can be used as it is in producing, for example, tufted carpets; or which can be separated into plied strands which have predictable desired characteristics and can individually be used in carpet manufacture. U.S. Pat. No. 4,246,750 describes a method of forming stable twisted yarn products comprising the steps of providing a plurality of singles yarns in a plurality of groups and maintaining the yarns in each group separated from each other, imparting alternate twist to at least one of the singles yarns in each group to form in the yarn a sequence of twist regions having longitudinally spaced regions of alternating S and Z twist separated by nodes of twist reversal, placing the yarns in each group in closely spaced relationship with each other, joining the yarns in each group to each other at the locations of the nodes, permitting the yarns in each group to self-twist to form a plurality of alternate twist plied strands wherein twist torques are at substantial equilibrium, imparting additional twist to each of the alternate twist plied strands to form therein a sequence of unbalanced twist regions of alternating S and Z twist separated by the joined nodes, placing the strands in closely spaced relationship with each other with the nodes thereof longitudinally aligned, joining the plied strands to each other at the node locations, and heating the joined plied strands to a temperature sufficient to heat-set the twist characteristics thereof. But U.S. Pat. No. 4,246,750 remains silent on how to join the plied strands to each other at the node locations, especially in a continuous process, whereby the singles yarns, the twist plied strands and the final braid are processed at a continuous process speed, i.e. without stopping them for making joints. Such joining is very difficult in a production environment, because the yarn tensions are high after the imparting of additional twist, and because the filaments have low entanglement capabilities due to the prior joining of the nodes in the yarns. The reliable and reproducible joining of the nodes of the alternate S/Z twist plied yarn has in practice proven impossible. U.S. Pat. No. 5,644,909 discloses a method and apparatus for making alternate twist plied yarn and product. Connections are formed nearby a node. Yarns are connected by ultrasonic bonding. These yarns have small pieces of solid, hard plastic, where the ultrasonic bonding has taken place. This is disadvantageous as it may cause discomfort, itching and scratching. In the method disclosed, the production is stopped at intervals. This is disadvantageous for the production speed and apparatus capacity. The ply reversal of the second or doubled plied end is unbounded. Therefore, there is a need in the art for improvements. The present invention aims to provide a solution or improvement to at least one of the above mentioned problems. The objective of the invention is to provide an improved method and apparatus that enable the reliable joining of the plied strands while processing them at a continuous process speed. In a first aspect, the invention thereto provides a process for making an alternate S/Z twist plied braid, comprising the steps of:

In a preferred embodiment, the alternately S/Z twisted strands (7, 7 In a preferred embodiment, combining the alternate S/Z twist plied yarns (12, 12 In a second aspect, the invention provides a process for making joined alternate S/Z twist plied yarns, comprising the steps of:

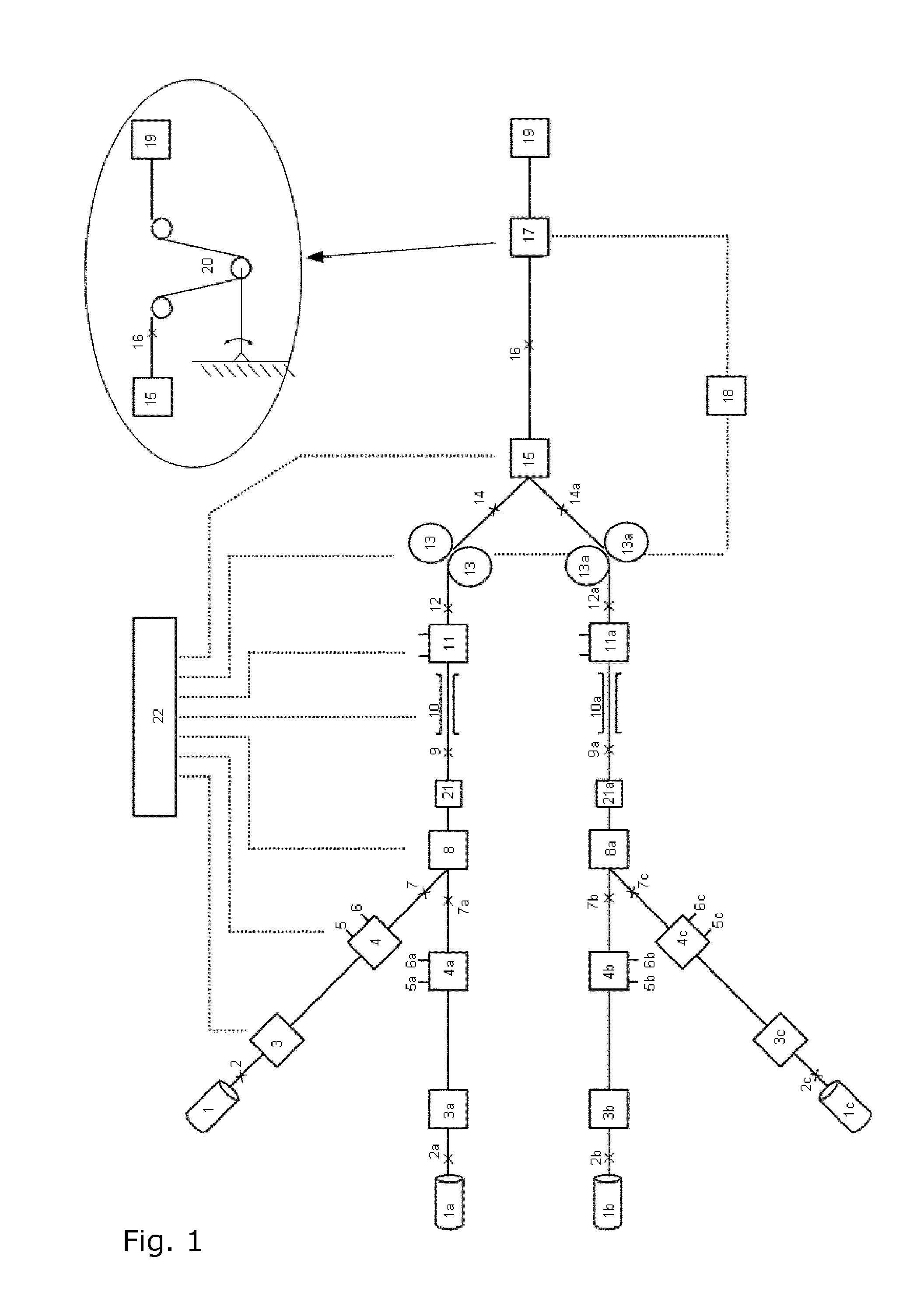

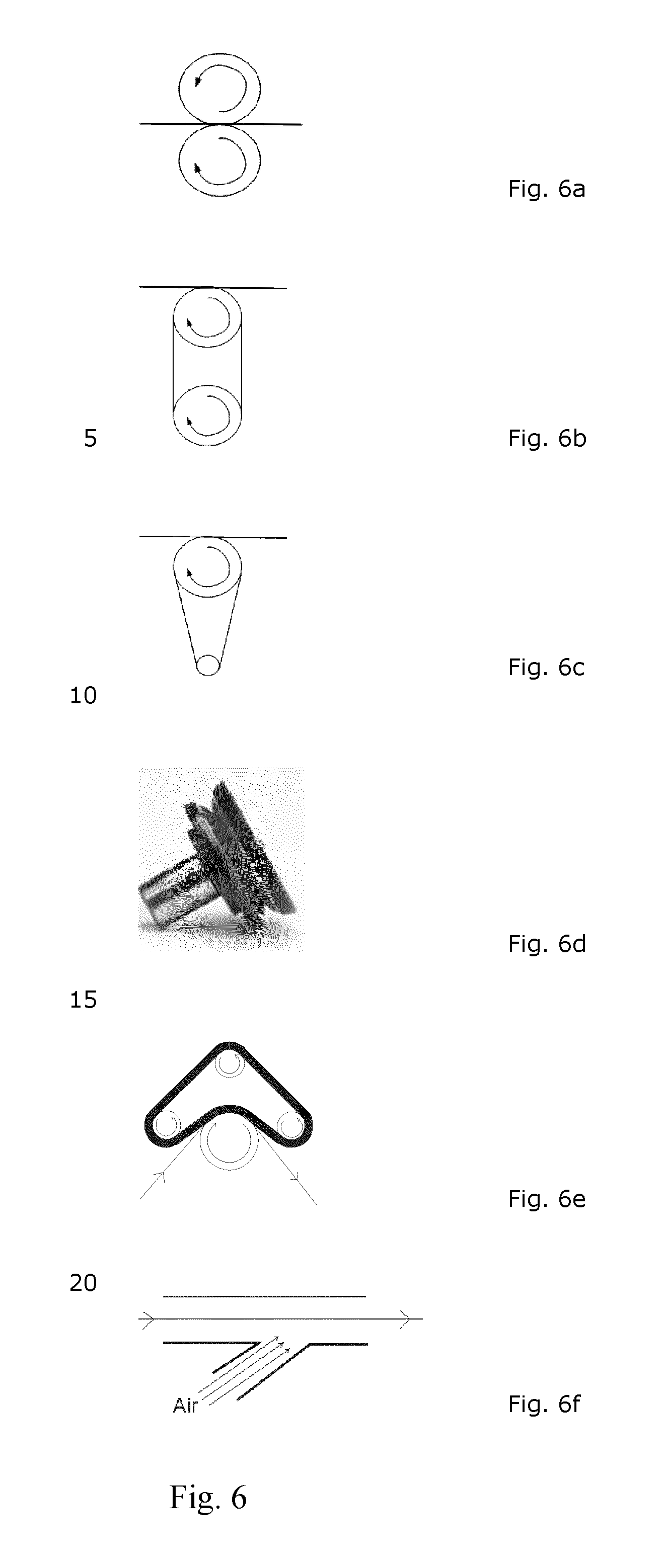

By reducing the tension at the location where the nodes of the alternate S/Z twist plied yarn are to become entangled, entanglement is facilitated and improved. Fewer nodes are missed. A reliable and reproducible process is obtained. The movement of yarn through the process is not stopped. In a preferred embodiment, the alternately S/Z twist plied strands (7, 7 In a preferred embodiment, combining the alternate S/Z twist plied yarns (12, 12 In a preferred embodiment, the tension of the alternate S/Z twist plied yarns (12, 12 In a preferred embodiment, the tension of the alternate S/Z twisted yarns is reduced in a controlled manner with a closed circuit system on the basis of the amount of yarn between the step of connecting the nodes of the alternate S/Z twist plied yarns (h, r), and the step of leading away the yarn produced (j, s). In a preferred embodiment, the fibers or filaments of the alternate S/Z twisted yarns are preheated prior to imparting additional alternate twist to said yarns. Preheating further facilitates and improves the entanglement of the nodes. In a preferred embodiment, the fibers or filaments of the alternate S/Z twist plied yarns are heated using a hot fluidum at the imparting of additional alternate twist of said yarns. In a preferred embodiment, the fibers or filaments of the alternate S/Z twist plied yarns are heated using a hot fluidum when connecting their nodes. In a preferred embodiment, inter-fiber or -filament friction of the alternate S/Z twist plied yarns is reduced by the addition of liquid additives prior to or during imparting additional alternate twist of said yarns. In a preferred embodiment, inter-fiber or -filament friction of the alternate S/Z twist plied yarns is reduced by the addition of liquid additives during the connection of their nodes. In a third aspect, an apparatus is provided for making an alternate twist plied braid or joined alternate twist plied yarns formed from a plurality of at least four strands, comprising: a source of supply for the separate feeding of individual strands (2, 2 a first twisting means (4, 4 a first fixation means (8, 8 a second torsion means (11, 11 a second fixation means for connecting the alternately S/Z twist plied yarns (9, 9 a means to remove the yarn produced; a steering means (22) for the coordinated control of all the above mentioned means, characterized in that the means (13, 13 In a preferred embodiment of the apparatus of the invention, a means for measuring the tension of the yarn (17) is provided after the second fixation means (15). In a preferred embodiment of the apparatus of the invention, a means for yarn accumulation (20) is provided after the second fixation means (15). In a preferred embodiment of the apparatus of the invention, a means for heating the alternate S/Z twist plied yarn (9, 9 In a preferred embodiment of the apparatus of the invention, a means (21, 21 In a preferred embodiment of the apparatus of the invention, a means is provided for the addition of liquid additives to the second torsion means (11, 11 In a preferred embodiment of the apparatus of the invention, a means is provided for addition of liquid additives in the second fixation means (15). In a final aspect, the invention provides an alternate S/Z twist plied braid and a joined alternate twist plied yarn obtained with a process according to an embodiment of the invention. These products display an improved entanglement of fibers at the nodes. Consequently the S/Z twist can be maintained. Product quality is improved. The fixation of the nodes is sturdier. The processing properties of the braid and yarn are improved. Unless otherwise defined, all terms used in disclosing the invention, including technical and scientific terms, have the meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. By means of further guidance, term definitions are included to better appreciate the teaching of the present invention. As used herein, the following terms have the following meanings: “A”, “an”, and “the” as used herein refers to both singular and plural referents unless the context clearly dictates otherwise. By way of example, “a compartment” refers to one or more than one compartment. “About” as used herein referring to a measurable value such as a parameter, an amount, a temporal duration, and the like, is meant to encompass variations of +/−20% or less, preferably +/−10% or less, more preferably +/−5% or less, even more preferably +/−1% or less, and still more preferably +/−0.1% or less of and from the specified value, in so far such variations are appropriate to perform in the disclosed invention. However, it is to be understood that the value to which the modifier “about” refers is itself also specifically disclosed. “Comprise,” “comprising,” and “comprises” and “comprised of” as used herein are synonymous with “include”, “including”, “includes” or “contain”, “containing”, “contains” and are inclusive or open-ended terms that specifies the presence of what follows e.g. component and do not exclude or preclude the presence of additional, non-recited components, features, element, members, steps, known in the art or disclosed therein. The recitation of numerical ranges by endpoints includes all numbers and fractions subsumed within that range, as well as the recited endpoints. The invention is an improved method and apparatus for braiding or joining alternate twist plied yarns. The invention was previously described in application BE2010/0650 filed on 3 Nov. 2010, which is herein incorporated by reference. In particular, the invention provides a process for making an alternate twist plied braid formed from a plurality of at least four strands, comprising the steps of:

The invention further provides a process for making joined alternate twist plied yarns from a plurality of at least four strands, comprising the steps of:

In a preferred embodiment the number of strands is four and the number of groups two, providing two groups of two strands each. In a preferred embodiment of a process according to the invention, the tension of the alternate twist plied yarns is reduced in function of the tension of the yarn produced. In a preferred embodiment of a process according to the invention, the tension of the alternate twist plied yarns is reduced in function of the amount of accumulated yarn produced. In a preferred embodiment of a process according to the invention, the process further comprises the preheating of the twist plied yarns prior to the said imparting of additional alternate twist. In a preferred embodiment of a process according to the invention, a hot fluidum is applied to the twist plied yarns for the said imparting of additional alternate twist. In a preferred embodiment of a process according to the invention, hot fluidum is applied to the twist plied yarns for the said joining of the nodes. In a preferred embodiment of a process according to the invention, interfilament friction is reduced by the application of fluid additives prior to or during the said imparting of additional alternate twist. In a preferred embodiment of a process according to the invention, interfilament friction is reduced by the application of fluid additives prior to or during the said joining of the nodes. In a preferred embodiment of a process according to the invention, the process further comprises the step of heat-setting the alternate twist plied braid. In a preferred embodiment of a process according to the invention, the process further comprises the step of heat-setting the joined alternate twisted yarns. The invention also provides an apparatus for making an alternate twist plied braid or joined alternate twist plied yarns formed from a plurality of at least four strands comprising:

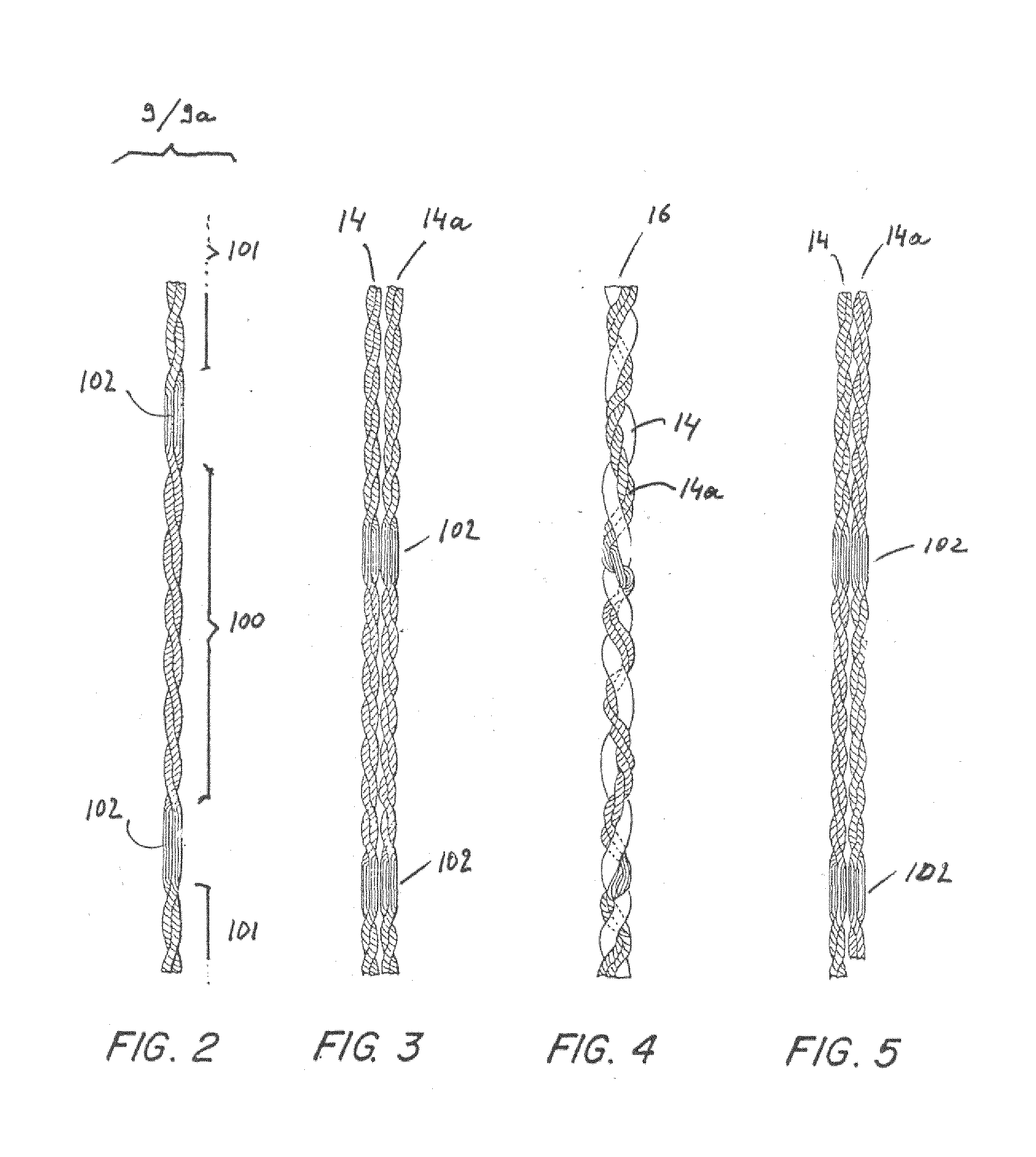

In a preferred embodiment of an apparatus according to the invention, the apparatus comprises a means for measuring the tension of the alternate twist plied braid, or of the joined twist plied yarns. In a preferred embodiment of an apparatus according to the invention, the apparatus comprises a means for measuring the amount of accumulated alternate twist plied braid, or the amount of joined twist plied yarns. In a preferred embodiment of an apparatus according to the invention, the apparatus comprises a means for the preheating of the twist plied yarns prior to the said imparting of additional alternate twist. In a preferred embodiment of an apparatus according to the invention, the apparatus comprises a means for the application of fluid additives to the yarns, positioned upstream of the second twisting means. In a preferred embodiment of an apparatus according to the invention, the apparatus comprises a means for the addition of fluid additives to the fluid of the second twisting means. In a preferred embodiment of an apparatus according to the invention, the apparatus comprises a means for the addition of fluid additives to the fluid of the second joining means. Preferably, the apparatus includes a means for measuring the tension of the alternate twist plied braid, or of the joined twist plied yarns, or a means for measuring the accumulated amount of alternate twist plied braid, or joined twist plied yarns. Preferably also, the apparatus includes a means for heating the twist plied yarns at the upstream side of the second joining means. Preferably also, the apparatus includes a means for the application of lubricants to the filaments of the yarns. In a final aspect, the invention provides an alternate S/Z twist plied braid and a joined alternate twist plied yarn obtained with a process according to an embodiment of the invention. These products display an improved entanglement of fibers at the nodes. The fixation of the nodes is sturdier. The invention is illustrated in a number of non-limiting examples. The invention will be explained further by reference to the general schematic provided in As shown in Yarns 2, 2 Yarns 2, 2 Twist jets suitable for use in the invention are for instance disclosed in U.S. Pat. No. 4,074,511. The twist jets have central openings through which yarns 2, 2 Hence, by the application of pressured air to the air inlets 5 and 6 (respectively 5 As the alternate twisted strands 7, 7 The alternate twisted strands 7, 7 Preferably this joining process is also applied to strands 7 The alternate twisted strands 7, 7 It will be recognized that in order for the yarns to ply, it is necessary that jets 4 and 4 Yarns 9 and 9 At this point, it may be helpful to refer to Z-twisted singles strands the Z twist having been imparted by jets 4 and 4 At the outlet of twist devices 11 and 11 In twist jet devices 11 respectively 11 Imparting additional alternate twist to the strands 9, 9 The inventors have found that this problem can be advantageously addressed as follows. Between twist jet devices 11 respectively 11 After the node fixator 15, a composite strand 16 is produced, which is conducted to the next process 19, which can be a heat-setting process in which the twist characteristics imparted to the various components are set. The heat-set device can be any conventional heat-setting apparatus utilizing steam, infrared energy, or other forms of elevating the yarn to the necessary level to heat-set the characteristics thereof. Generally speaking, with synthetic yarns, it is necessary to elevate the temperature of the yarns to the glass transition temperature, or second order transition temperature, at which the stresses in the yarns are relieved. The characteristics of the composite yarn will be further described in connection with If this yarn is then released and permitted to ply after node joining, the plied strands will again ply or “cable” around each other, forming a yarn such as that illustrated in Alternatively, if devices 4 If the unbalanced S/Z twist plied yarns 14 and 14 If the unbalanced S/Z twist plied yarns 14 and 14 In a preferred embodiment of the invention, a system 18 controls yarn feed systems 13 and 13 In another preferred embodiment of the invention, the alternate twist plied yarns 9 and 9 In another preferred embodiment of the invention, a hot fluidum like hot air or steam is used in the twist jets 11 and 11 In another preferred embodiment of the invention, a hot fluidum like hot air or steam is used in the node fixator 15, in order to make the filaments weaker and therefore further facilitate and improve the entanglement of the nodes in the node fixator 15. In another preferred embodiment of the invention, additives can be applied on the filaments in order to reduce friction between the filaments, and therefore further facilitate the entanglement of the nodes in the node fixator 15. The additives are preferably certain liquid additives. These additives can be applied by applicator means 21 and 21 Finally, for each of the embodiments described, a control system 22 is required for the coordination of all the actuators. The examples provided above and The process described is a continuous process: meaning that the strands provided and yarns produced move continuously through the process. Preferably the process runs at a speed of 200-700 m/min, more preferably at least 700 m/min. No intermittent stops are made. This provides for cost-effective manufacturing. The present invention provides an improved method and device for producing an alternate S/Z twist plied braid and joined alternate S/Z twist plied yarns. The invention further provides an alternate S/Z twist plied braid and joined alternate S/Z twist plied yarns produced according to a process of the invention. 1. A method for making an alternate S/Z twist plied braid, comprising the steps of:

a) separately providing at least four strands, divided over at least two groups; b) alternately applying S and Z twist to the strands; thereto zone of S- twist are alternated with zones of Z-twist and vice versa, with an intervening zone with approximately no twist, wherein these reversal zones are called “nodes”; c) per group the alternately S/Z twisted strands, are brought together via a narrowing; d) connecting the nodes of all strands within a group; e) allowing the strands of a same group to self-twist thereby providing an alternate S/Z twist plied yarn; f) alternately imparting additional twist to the alternate S/Z twist plied yarn, wherein the alternation of the direction of twist coincides with the nodes of the alternate S/Z twist plied yarns; g) combining the alternate S/Z twist plied yarns via a narrowing; h) connecting the nodes of the alternate S/Z twist plied yarns; i) allowing the alternate S/Z twist plied yarns, to self-twist, thereby providing an alternate S/Z twist plied braid, j) leading away the braid produced, wherein, tension of the alternately S/Z twist plied yarns is reduced between the step f) of imparting additional alternate twist to the alternately S/Z twist plied yarns and the step g) of combining these yarns. 2. The method according to 3. The method according to 4. A method for making joined alternate S/Z twist plied yarns, comprising the steps of:

k) separately providing at least four strands, divided over at least two groups; l) alternately applying S and Z twist to the strands, wherein zone of S-twist are alternating with zones of Z-twist and vice versa, with an intervening zone with approximately no twist, wherein these reversal zones are called “nodes”; m) then subsequently per group the alternately S/Z twist plied strands, are brought together via a narrowing; n) connecting the nodes of all strands within a group; o) allowing the strands of a same group to self-twist thereby providing an alternate S/Z twist plied yarn; p) alternately imparting additional twist to the alternate S/Z twist plied yarn, wherein the alternation of the direction of twist coincides with the nodes of the alternate S/Z twist plied yarns; q) combining the alternate S/Z twist plied yarns, via a narrowing; r) connecting the nodes of the alternate S/Z twist plied yarns, thereby providing joined unbalanced alternate twist plied yarns comprising at least two unbalanced alternate S/Z twist plied yarns, connected with each other in the nodes, s) leading away the yarns produced, wherein, tension of the alternately S/Z twist plied yarns is reduced between the step p) of imparting additional alternate twist to the alternately S/Z twist plied yarns and the step q) of combining these yarns. 5. The method according to via a narrowing, in phase: all nodes coinciding, and with zones of equal twist direction next to each other. 6. The method according to 7. The method according to 8. The method according to 9. The method according to 10. The method according to 11. The method according to 12. The method according to 13. The method according to 14. An apparatus for making an alternate twist plied braid or joined alternate twist plied yarns formed from a plurality of at least four strands, comprising:

a source of supply for the separate feeding of individual strands, at least four, spread over at least two groups; a means for tensioning each strand; a first twisting means for alternatingly applying a S respectively Z twist in at least one strand of each group thereby obtaining alternate S and Z twisted strands; a first fixation means for combining the alternately S/Z twisted strands of each group and connecting these at their nodes; a second torsion means for imparting additional alternate twist to at least one of the alternately S/Z twisted strands; a second fixation means for connecting the alternately S/Z twist plied yarns with each other; a means to remove the yarn produced; a steering means for the coordinated control of all the above mentioned means, characterized in that the means for reducing the tension in the alternate S/Z plied yarns is provided between the second torsion means and the second fixation means. 15. Apparatus according to 16. Apparatus according to 17. Apparatus according to 18. Apparatus according to 19. Apparatus according to 20. Apparatus according to 21. An alternate S/Z twist plied braid obtained by the method of 22. A joined alternate twist plied yarn obtained by the method of TECHNICAL FIELD

BACKGROUND

SUMMARY OF THE INVENTION

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION