WELDLESS TRANSFER TUBE ASSEMBLY

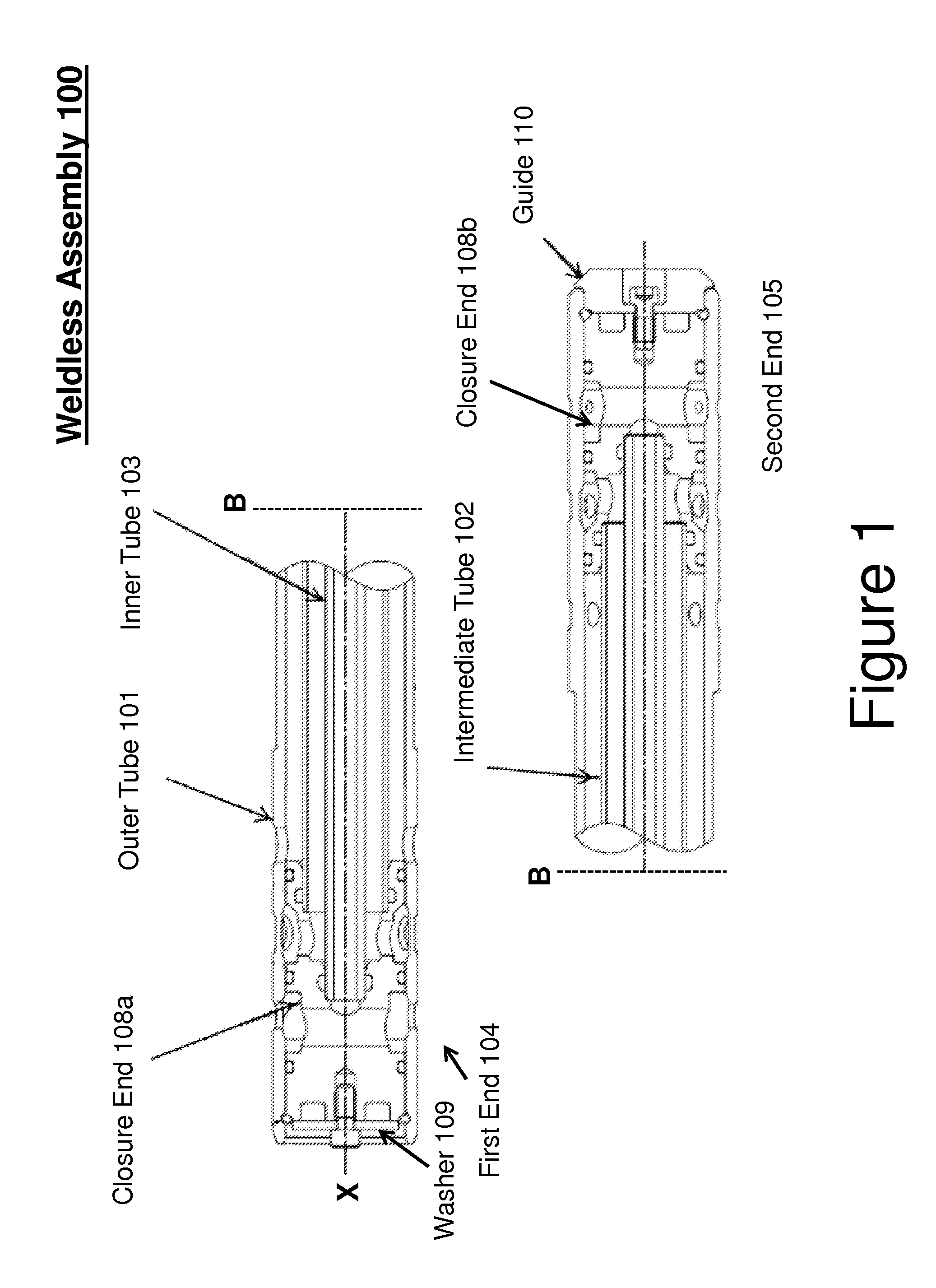

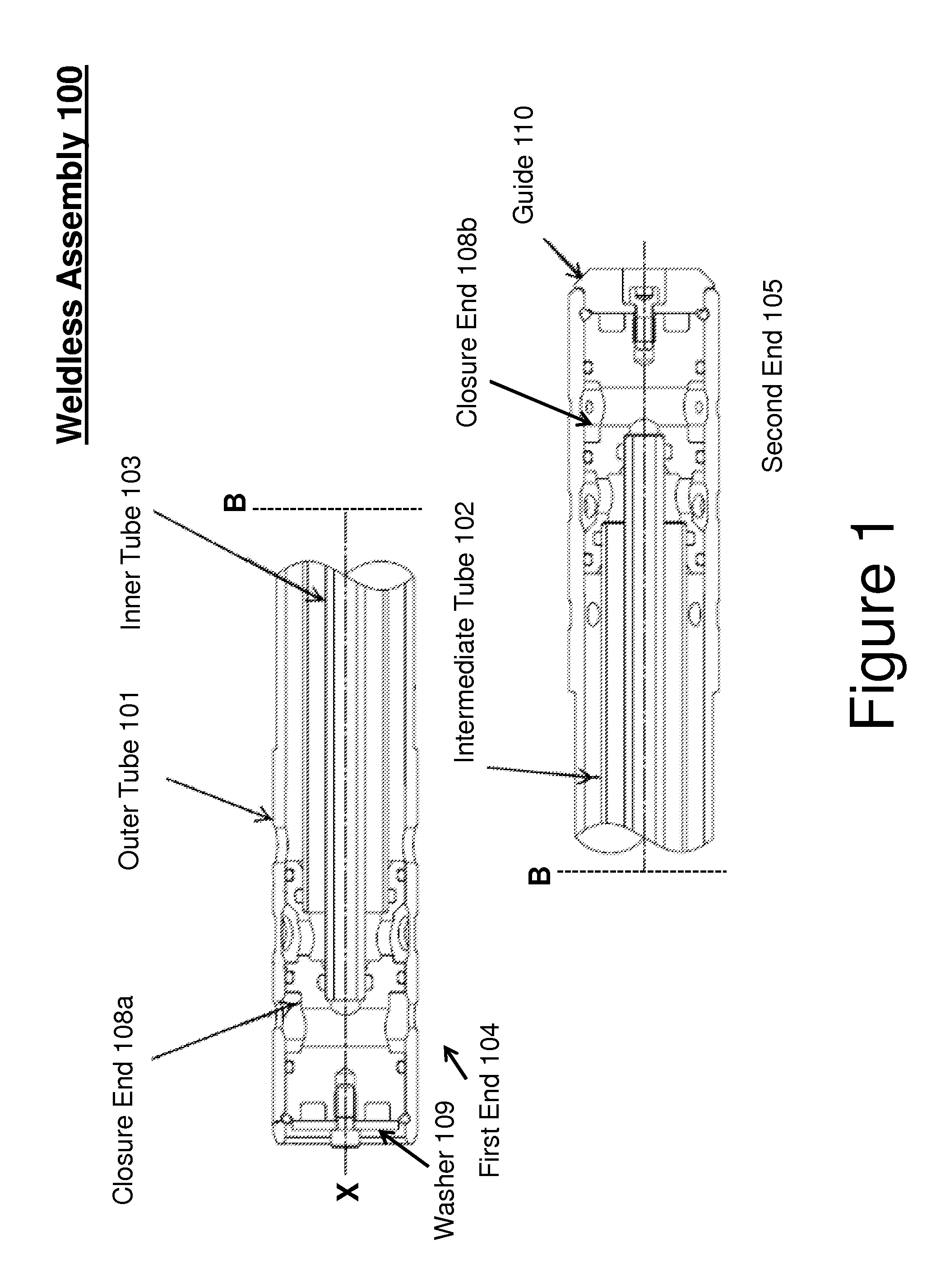

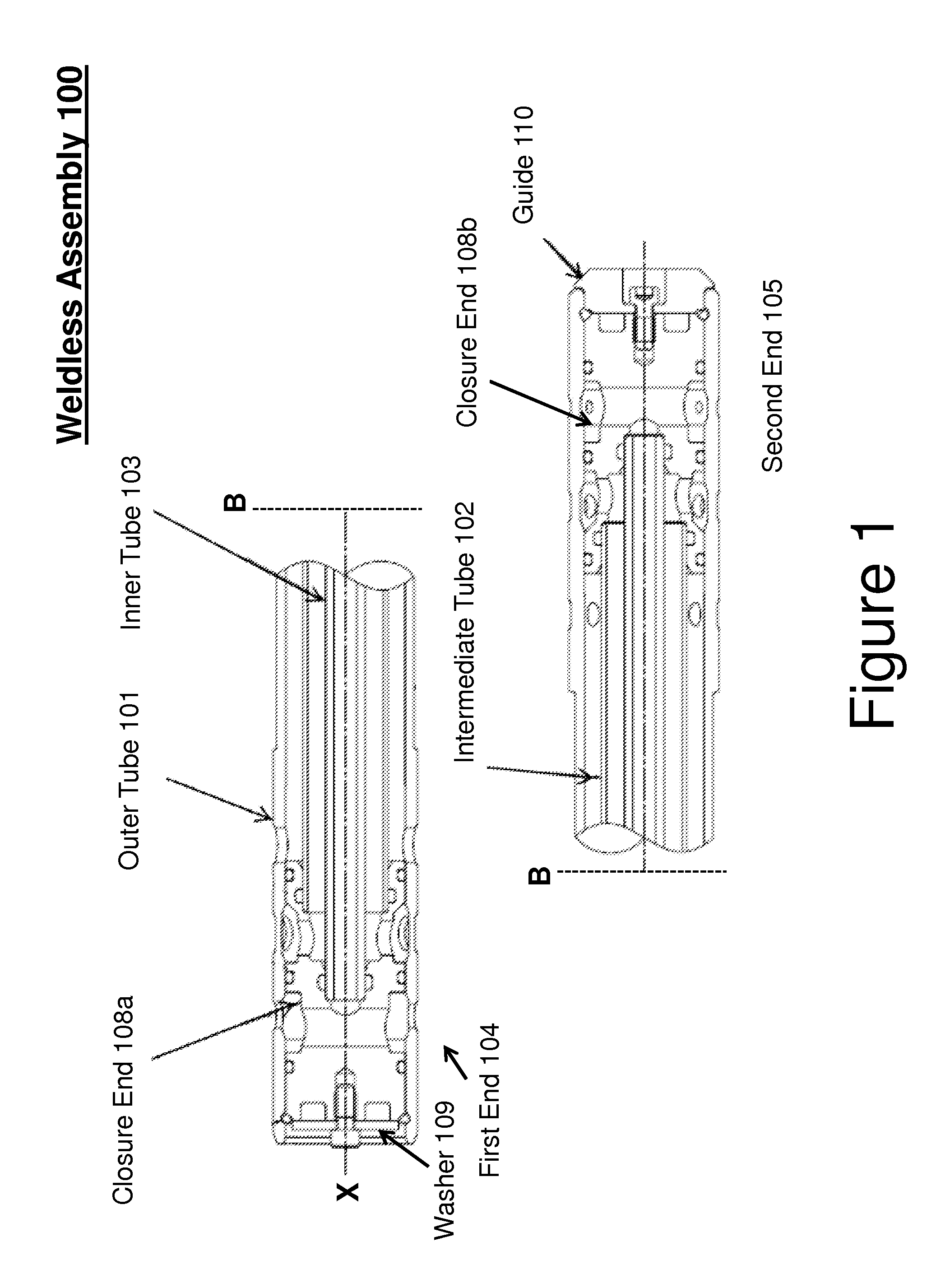

This application is a U.S. Non Provisional Application of EP No. 14306397.2 filed on Sep. 11, 2014, the disclosure of which is incorporated by reference herein in its entirety. The disclosure relates generally to transfer tube assemblies, and more specifically, to a weldless assembly that is constructed from both ends to enable increases in a final length of transfer tubes of the weldless assembly while realizing manufacturing gains. In general, present welded transfer tube assemblies contain a flange and welds that present inherent problems with respect to manufacturing, proper sealing, tube finish imperfections, nitride depths, and tube length. Further, nitriding of the present welded transfer tube assemblies to achieve particular material properties is difficult for welded structures as a result of localized inconsistencies of the material properties resulting at the welds, therefore it would be desirable to have a transfer tube assembly that does not require welding. According to one embodiment of the present invention, a weldless assembly comprises a plurality of tubes, wherein the plurality of tubes includes an inner tube, an intermediate tube, and an outer tube; a first closure end configured to cap a first side of the plurality of tubes; and a second closure end configured to cap a second side of the plurality of tubes. According to another embodiment of the present invention, a method of constructing a weldless assembly comprises inserting an inner tube into an intermediate tube, applying a first closure end onto the intermediate tube and the inner tube thereby constructing the first sub-assembly, inserting the first sub-assembly into an outer tube by forcing an end of the first sub-assembly opposite to the first closure end through the center of the outer tube, applying a second closure end onto the end of the first sub-assembly opposite to the first closure end, and applying a guide onto the second closure end thereby constructing the weldless assembly. Additional features and advantages are realized through the techniques of the present invention. Other embodiments and aspects of the invention are described in detail herein and are considered a part of the claimed invention. For a better understanding of the invention with the advantages and the features, refer to the description and to the drawings. The subject matter which is regarded as the invention is particularly pointed out and distinctly claimed in the claims at the conclusion of the specification. The forgoing and other features, and advantages of the invention are apparent from the following detailed description taken in conjunction with the accompanying drawings in which: A detailed description of one or more embodiments of the disclosed apparatus and method are presented herein by way of exemplification and not limitation with reference to the Figures. As indicated above, present welded transfer tube assemblies contain welds that present inherent problems with respect to proper sealing, tube finish imperfections, nitride depths, and tube length. Thus, what is needed is a weldless transfer tube assembly that is constructed from both ends to enable increases in a final length of the assembly. In general, embodiments of the present invention disclosed herein may include a weldless assembly that comprises a plurality of tubes, wherein the plurality of tubes includes an inner tube, an intermediate tube, and an outer tube; a first closure end configured to cap a first side of the plurality of tubes; and a second closure end configured to cap a second side of the plurality of tubes. The weldless assembly is constructed and/or manufactured via gas nitride processes or nitriding that can accommodate long tubes (e.g., three feet) via large containment chambers and that can use less heat in the application. Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case hardened surface. For the weldless assembly, each of the inner, the intermediate, and the outer tubes are separately nitrided to ensures consistent material properties (e.g., hardness properties) between the material (e.g., the steel) of the inner, intermediate, and outer tubes. That is, the separate tubes of the weldless assembly are nitrided before assembly so that the weldless assembly is treated with very little post assembly nitriding surface finishing; in contrast, nitriding before assembly is not possible with a welded tube. Thus, failures with respect to inconsistencies in the nitriding the elements of the weldless assembly are eliminated due to the weldless assembly enabling a more controlled gas nitride process on a per part basis. For example, a gas nitride process provides a straight weldless outer tube without a flange for the weldless assembly, e.g., about an inch and a half in diameter, that is produced much more accurately for final finishing (while the intermediate tube and inner tubes are also made without welds). Each tube is then assembled, secured, and further finished. Moreover, the weldless outer tube produced via gas nitride requires that one side rotate in a journal bearing that seals high pressure oil thru a lap fit. This is a rotational interface supported by oil film thickness. The opposite end is non-rotating and sealed with elastomeric seals. The opposite end has a dynamic element that requires that it be treated with close finishes and smooth surfaces (e.g., requires final finishing). The weldless assembly may be employed in many different systems, such as, a propeller systems comprising multiple actuators contained therein. In one embodiment, the weldless assembly 100 is constructed by the closure end 108 The three piece assembly is slid into the outer tube 101 by forcing an end of the three piece assembly opposite to the closure end 108 The first end 104 and the second end 105 are generally mirrored. That is, the same closure end type may be used on both ends (e.g., the first and second end 104, 105), include the same number of seals (221 Aspects of the present invention are described herein with reference to flowchart illustrations, schematics, and/or block diagrams of methods, apparatus, and/or systems according to embodiments of the invention. Further, the descriptions of the various embodiments of the present invention have been presented for purposes of illustration, but are not intended to be exhaustive or limited to the embodiments disclosed. Many modifications and variations will be apparent to those of ordinary skill in the art without departing from the scope and spirit of the described embodiments. The terminology used herein was chosen to best explain the principles of the embodiments, the practical application or technical improvement over technologies found in the marketplace, or to enable others of ordinary skill in the art to understand the embodiments disclosed herein. The terminology used herein is for the purpose of describing particular embodiments only and is not intended to be limiting of the invention. As used herein, the singular forms “a”, “an” and “the” are intended to include the plural forms as well, unless the context clearly indicates otherwise. It will be further understood that the terms “comprises” and/or “comprising,” when used in this specification, specify the presence of stated features, integers, steps, operations, elements, and/or components, but do not preclude the presence or addition of one more other features, integers, steps, operations, element components, and/or groups thereof. The flow diagrams depicted herein are just one example. There may be many variations to this diagram or the steps (or operations) described therein without departing from the spirit of the invention. For instance, the steps may be performed in a differing order or steps may be added, deleted or modified. All of these variations are considered a part of the claimed invention. While the preferred embodiment to the invention had been described, it will be understood that those skilled in the art, both now and in the future, may make various improvements and enhancements which fall within the scope of the claims which follow. These claims should be construed to maintain the proper protection for the invention first described. A weldless assembly comprises a plurality of tubes, wherein the plurality of tubes includes an inner tube, an intermediate tube, and an outer tube; a first closure end configured to cap a first side of the plurality of tubes; and a second closure end configured to cap a second side of the plurality of tubes. 1. A method of constructing a weldless assembly, comprising:

inserting an inner tube into an intermediate tube; applying a first closure end onto the intermediate tube and the inner tube thereby constructing the first sub-assembly; inserting the first sub-assembly into an outer tube by forcing an end of the first sub-assembly opposite to the first closure end through the center of the outer tube; applying a second closure end onto the end of the first sub-assembly opposite to the first closure end; and applying a guide onto the second closure end thereby constructing the weldless assembly. 2. The method of separately nitriding each of the inner, the intermediate, and the outer tubes to ensures consistent material properties between the inner, the intermediate, and the outer tubes prior to inserting the inner tube into the intermediate tube and to inserting the first sub-assembly into the outer tube. 3. The method of aligning a plurality of seals of the first closure end with the intermediate tube and the inner tube. 4. The method of aligning the intermediate tube and the inner tube during the inserting of the first sub-assembly based on champers of the outer tube catching the intermediate tube and the inner tube in place. 5. The method of utilizing a snap ring to secure the second closure end to the outer tube. 6. The method of securing the guide with a fastener to the second closure end. 7. A weldless assembly, comprising:

a plurality of tubes, wherein the plurality of tubes includes an inner tube, an intermediate tube, and an outer tube; a first closure end configured to cap a first side of the plurality of tubes; and a second closure end configured to cap a second side of the plurality of tubes. 8. The weldless assembly of 9. The weldless assembly of 10. The weldless assembly of 11. The weldless assembly of 12. The weldless assembly of DOMESTIC PRIORITY

BACKGROUND

BRIEF DESCRIPTION OF THE INVENTION

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION OF THE INVENTION