PROCESS FOR PREPARING FISH BONE POWDER

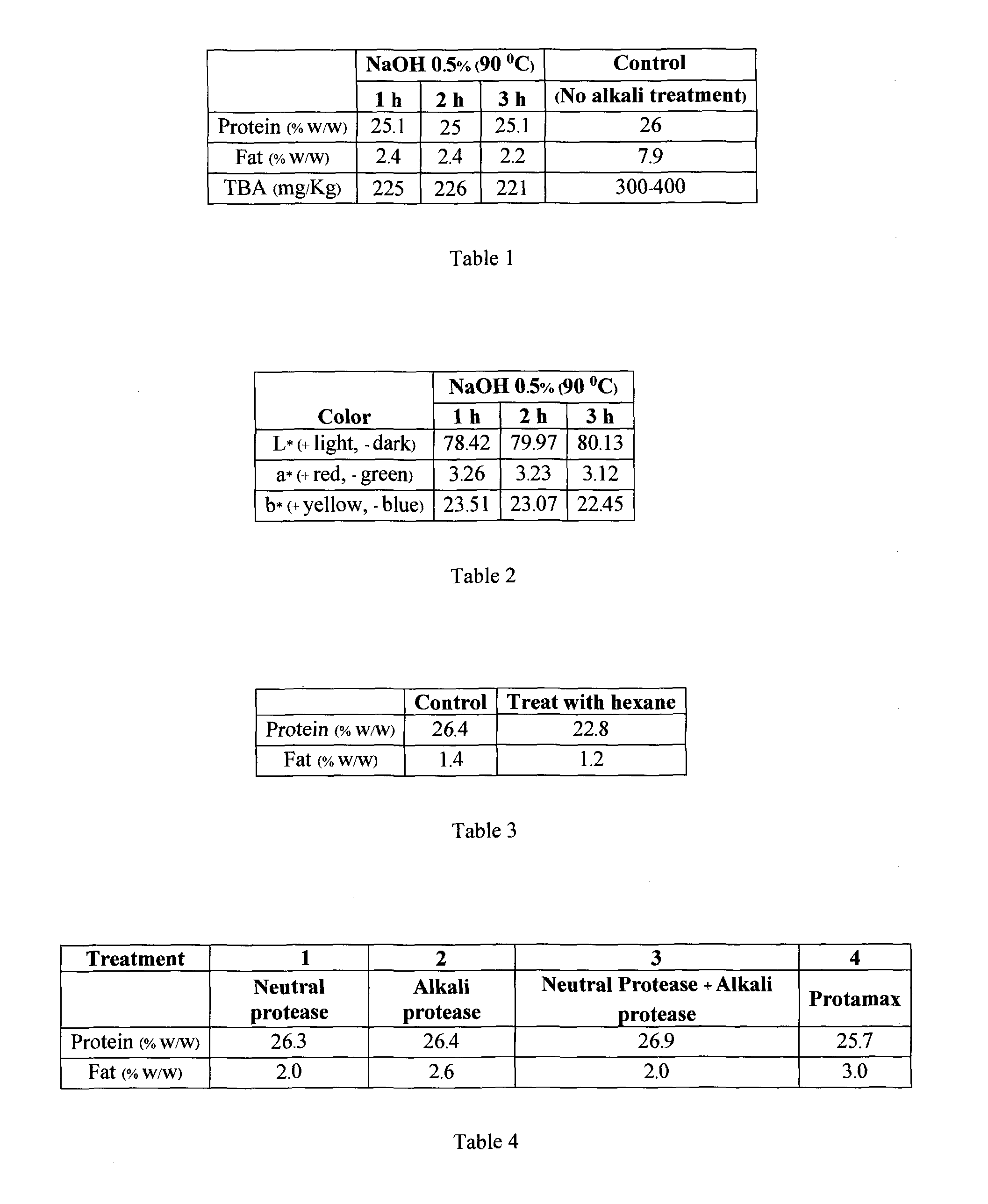

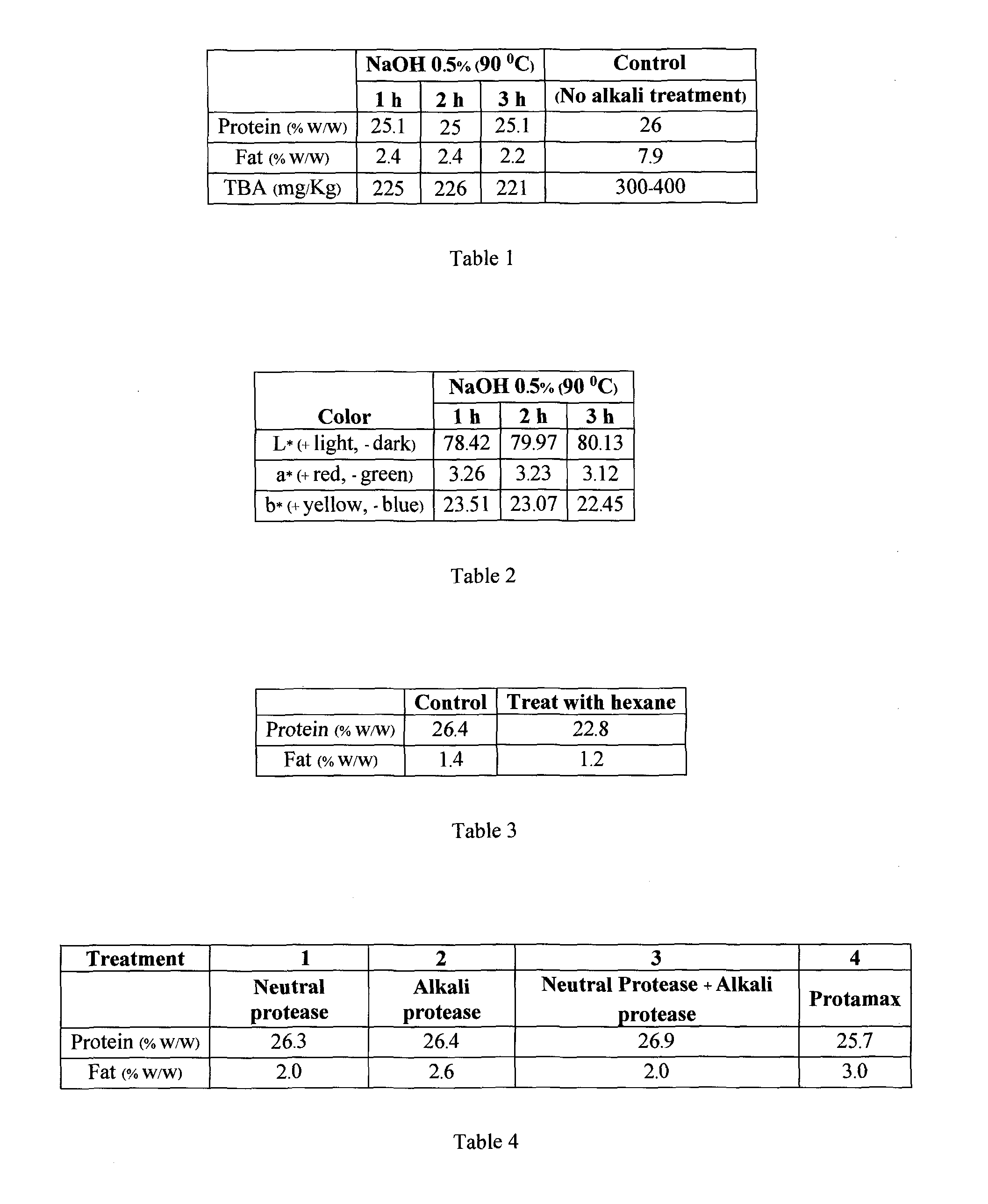

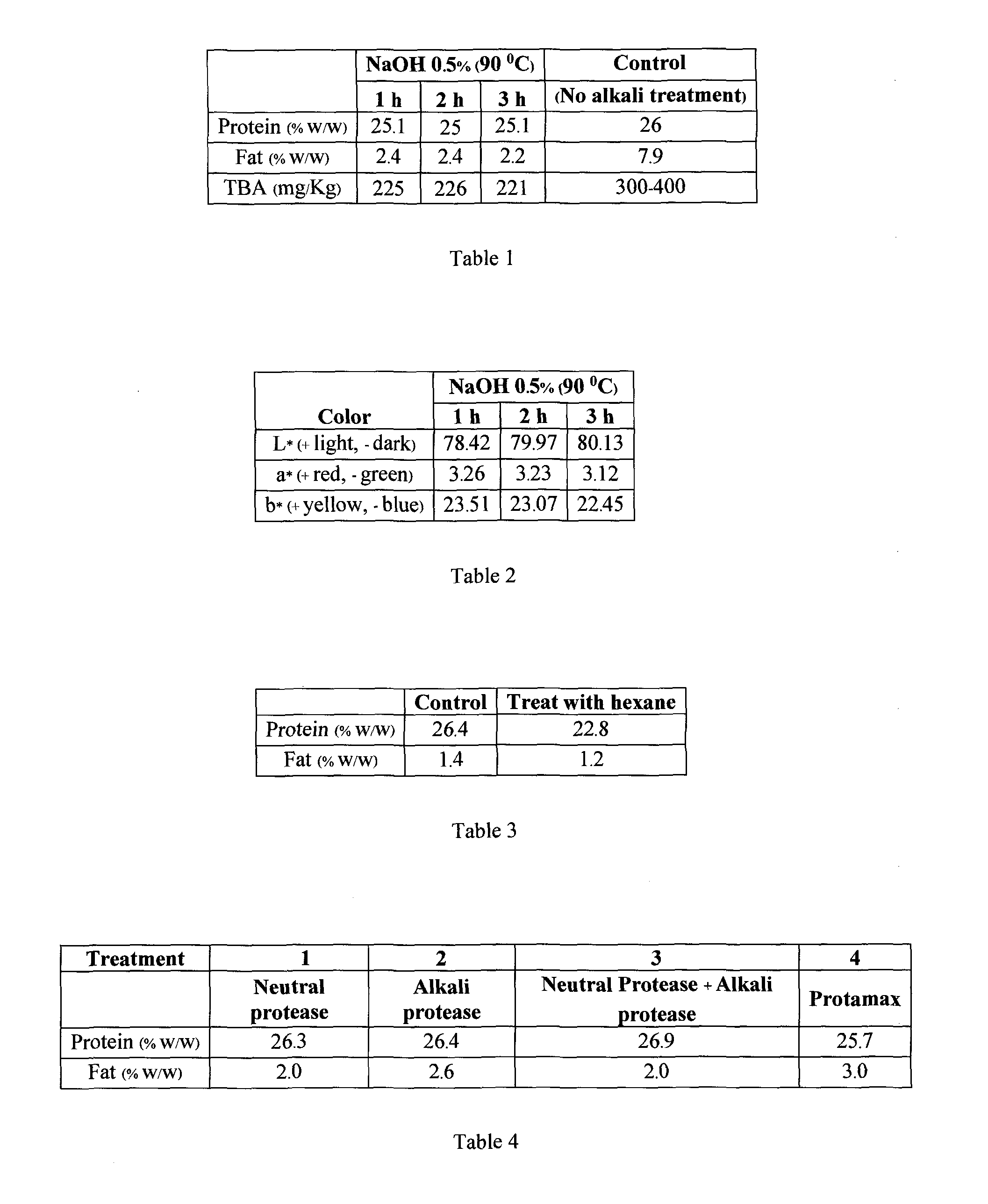

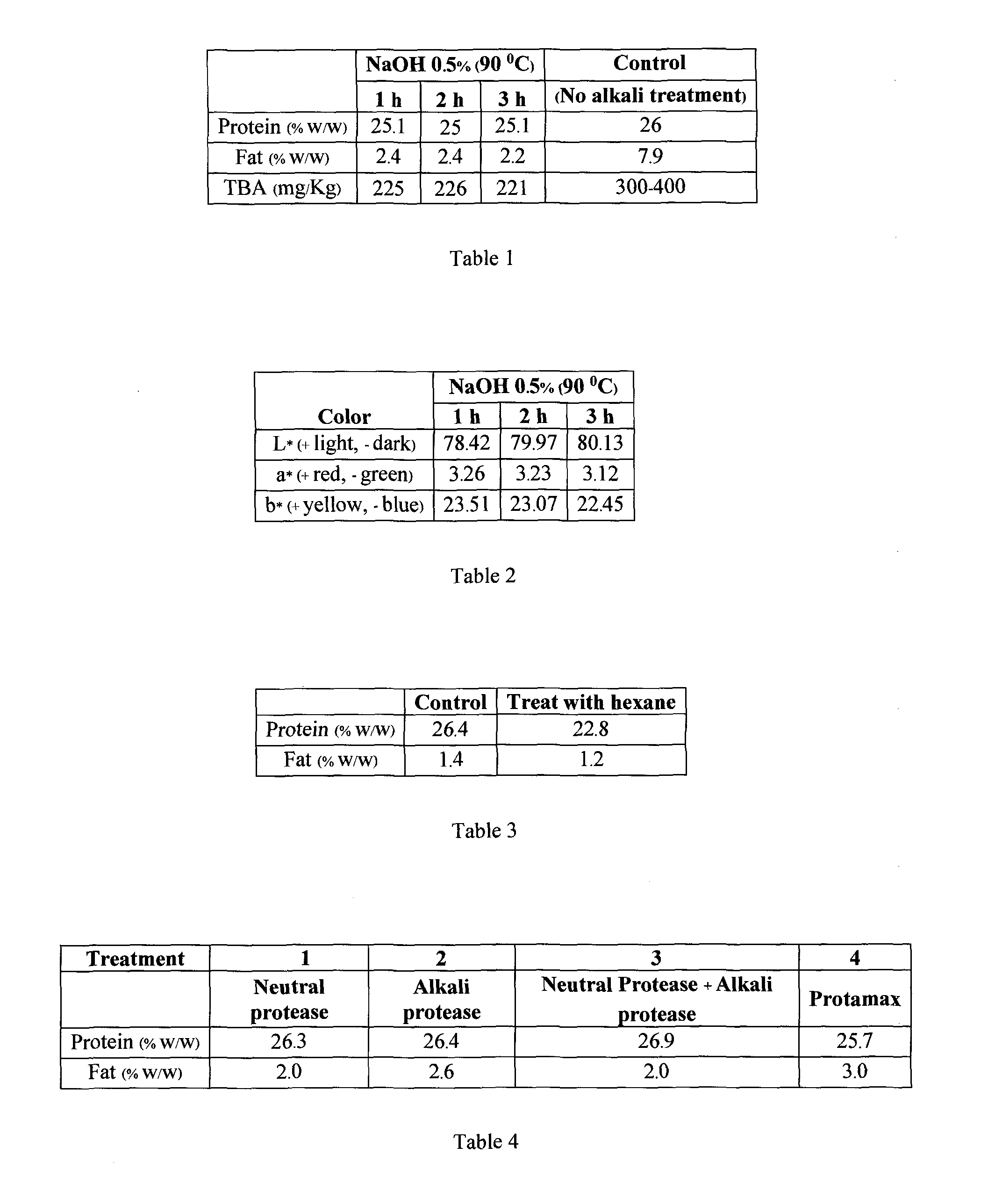

The field relates to the food processing science and technology, especially in the field of the production of fish bone powder, preferably the calcium powder production. Calcium is the fifth most abundant element in the human body. It plays an important role in many physiological processes, including nerve and muscle functions. Furthermore, calcium is required for a normal growth and the development and maintenance of the skeleton which provides strength and structure of the body. Over 99% of total body calcium is found in the teeth and bones. As bone contains a high proportion of the body calcium, it is the major reservoir for calcium in most invertebrates and the main component of bone calcium is hydroxyapatite. Fish bone is known to be a good source of calcium which is normally consumed in the form of a whole fish or the fish stock. Larden et al (2000) reported that the intake of whole small fish with bone can increase calcium bioavailability and the small fishes may be an important source of calcium. Tuna bone, similar to any other animal bones, is mainly compose& of calcium and phosphate in the form of hydroxyapatite Ca10(PO4)6(OH)2crystal and other ions. The organic phase of the bone is composed of collagen fibers, and ground substances formed by glycoproteins and proteoglycans (Prentice et al. 2003).This makes tuna bone and the partial composition thereof the preferred sources of natural calcium used for the addition or fortification in the seafood products. The need for potential sources of calcium which has high calcium content and less undesirable components has been increased due to the global market demand for healthy foods. Previously, the processes for removal of undesirable component from the animal bones focused on the certain aspects as reviewed in the following references. A patent document EP2075231A1 disclosed the biphasic calcium phosphate and method for obtaining same from fish bones. This method includes the steps of calcination and grinding of the fish bones wherein the calcination is carried out at a temperature comprised between 600 and 1200° C., preferably between 900 and 950° C. Furthermore, this invention also disclosed the process for obtaining the biphasic calcium phosphate wherein the laser beam is applied on fish bones that are not ground, and then subjected at the same time to a temperature comprised between 200 and 400° C. A patent document CN104342474A also disclosed the method wherein the waste from tuna fish was treated with alkaline protease enzyme to be separated from the fish bones, the supernatant liquid was centrifuged and the supernatant was removed from the precipitation. Precipitation was separated in order to isolate the fish bones. A patent document CN103156186B disclosed the invention regarding calcium tablet using deep-sea fish bone as raw material and preparation method thereof. The process of preparing the fish bone according to this invention includes the following steps; 1) the fish bones from deep-sea fish were cleaned, degreased, dried and then pulverized to a particle size of 300 mesh or powder; 2) the pulverized bone meal was treated with 0.5˜1.5 mol/L sodium hydroxide solution in a 1:4 to 1:6 mass ratio and soaked for 24-36 hours. The mixture was filtered and washed with distilled water until the fish bone meal has neutral pH. The fish bone meal was then immersed in 50-70% (w/w) ethanol solution for 12-18 hours wherein the mass ratio of bone meal and fish ethanol solution of 1:4 to 1:6. After washing with distilled alcohol, the solid phase was removed by filtration and dried to a moisture content of 9-11% (w/w) of the fish bone meal; 2) prepared fish bone meal and distilled water in a 1:0.5-1:1.5 mass ratio in a container, 2 to 3% of enzyme papain was added to fish bone meal and stirred, the solution was then heated until the center temperature reached 40-45° C., holding the said temperature for 1-2 hours, filtered, washed with distilled water fish bone meal, dried to a moisture content of 9-11% (w/w); 3) prepared fish bone meal set by mixing with citric acid and hydrochloric acid at the ratio of 1:9-1:11 and soaked for 36-60 hours. The solid phase was removed, washed with distilled water to a neutral pH and dried to a moisture content of 9-11% (w/w); 4) fish bone meal was mixed with skimmed milk powder, lactitol and aspartame. Calcium according to this invention has both high solubility and bioavailability characteristics which can promote the body's absorption of calcium. A patent document CN101032311A disclosed the invention regarding Fish bean curd including high dietary calcium. The high calcium fish bean curd is made with refined crushed fish, fish soup and jellied bean curd, and the making process includes the following steps: making fish soup with fish bones through cooking and filtering, crushing fish meat, making jellied bean curd with soybean and halogen, adding calcium lactate into jellied bean curd, mixing fish soup, jellied bean curd and crushed fish meat in a pan, steaming in a steam kettle, packing and freezing. A high calcium fish, tofu, which is made late and refined fish soup with bean curd made, characterized by making approach is to turn the fish bones and skulls of impurities inside the fish, take fish bones and fish skull 10 kg innocence boiled soup from refined fish wrapped into the pot, and then boiled old soup, add a little sugar, white pepper and vinegar and fresh, refined fish broken into late spare, old soup filtered to remove impurities from the water After soaking soybeans ground into a paste 12-15 kg of water to boil and cooked into a halogen into bean curd, bean curd 500-600 grams of added calcium lactate, take the old Stir soup, add a little starch, refined fish with broken end and curd Calibrating mix into the dish, put the pot boiling steam, finished packaging, frozen storage. Patent document U.S. Pat. No. 5,905,093A disclosed fish scale extract as a calcium supplement. The present invention is directed to a calcium rich preparation which is prepared by soaking fish scales in an acidic solution for a defined period of time. This fish scale extract can be used as food supplement to prevent or reduce the risk of bone loss or other calcium deficiency. The calcium form in this fish scale extract can be readily absorbed by the skin. A patent document CN101971970B disclosed the invention relates to a processing method for fishbone sauce, and belongs to the technical field of fish byproduct processing. The fishbone sauce is characterized by comprising the following components in percentage by mass: 60 to 80 percent of fishbone paste, 4 to 6 percent of edible salt, 3 to 5 percent of soft sugar, 0.3 to 0.5 percent of cooked white sesame seed, 0.5 to 2 percent of red chili powder, 1 to 2 percent of cooked ground peanut, 1 to 3 percent of fermented soy sauce, 0.2 to 0.4 percent of thickener, 0.1 to 0.5 percent of dried shallot powder, 0.1 to 0.5 percent of dried ginger powder, 0.1 to 0.5 percent of five spice powder, 5 to 8 percent of wheat meal, 3 to 10 percent of soybean flour and the balance of water. The processing method comprises the following steps of: 1) processing raw materials; 2) removing fishy smell of the fishbone, and adjusting pH; 3) performing vacuum centrifugal defatting; 4) crushing, and homogenizing under high pressure; 5) seasoning; 6) heating and pressurizing for sterilization; and 7) cooling and packaging. The processing method has the advantages that: the fish resources can be fully utilized, and deteriorated fishbone is prevented from polluting the environment. The fishbone sauce produced by the technology has fine and smooth mouth feel, unique flavor, a little sediment and uniform color, and is easy to store. A patent document CN101480251B disclosed the invention regarding a production raw material and a production technology of a natural bone calcium capsule which is mainly prepared by natural bone calcium, CPP, harp seal meat bone powder, VD3, lactose, VC, maltitol, VE, seadragon powder, VA and glycin according to a certain proportions. The invention has a reasonable formula according to the needs of human bodies, adds various vitamins and glycine, is favorable to the synthesis of collagen, is easy to absorb and is safe and nontoxic. A patent document CN104222216A disclosed the invention relates to high-calcium biscuit and a manufacturing method thereof. The high-calcium biscuit is made of low-gluten flour, fishbone broom corn millet, water, butter, white sugar, salt, sodium bicarbonate and vanilla powder. The high-calcium biscuit has the advantages that on the basis of raw materials of common biscuit, the fishbone broom corn millet is added, calcium content of the biscuit is increased, resources are effectively utilized, and the biscuit has unique seafood flavor. A patent document CN102551108A disclosed a high-calcium fish ball and a manufacture method thereof. The fish ball is made of minced fillet, fishbone paste, egg white, refined salt, monosodium glutamate, white ground pepper, garlic powder and the like according to fixed proportion. The manufacture method comprises the steps of 1) pretreating fish heads or fish bones, rinsing fresh chub heads or fish bones with ozone water, and washing the fresh chub heads or the fish bones with tap water; 2) manufacturing bone paste with the fish heads or the fish bones, and sequentially grinding the washed fish heads or the washed fish bones with a bone paste machine to obtain fish bone paste of certain particle diameter; 3) chopping and stirring, and placing weighted raw materials in a chopping and stirring machine to be chopped and stirred, continuously adding icy water to control temperature; 4) forming, and placing the chopped and stirred materials in a ball machine to be stirred to be formed; 5) heating to form, placed formed fish balls in water, and fishing the fish balls in tap water to be cooled when the fish balls float up; and 6) refrigerating, freezing the cooled fish balls with a double spiral quick freezer, and placing the fish balls in a refrigerator to be refrigerated. The high-calcium fish ball and the manufacture method are reasonable in formula, the raw materials are easy to obtain, production cost is low, and the manufacture method is easy to use, convenient to operate and suitable for industrialized production. A patent document CN102948820A disclosed the invention relates to a high-calcium freshwater fish ball and a preparation method of the high-calcium freshwater fish ball, belonging to the technical field of the processing and the producing of food. The minced fillet and the fishbone mud are taken as raw materials. The preparation method comprises the following steps of: adding shop fat with a certain quantity and the other auxiliary materials, chopping in a mixing way, forming fish ball, curing fish ball and the like. On the basis that the peculiar taste of the fish ball is guaranteed, the high-calcium freshwater fish ball provided by the invention is rich in elasticity, and has the loose, soft, fine and smooth mouth feel when being eaten, and the pursuing of modern people to nutrition health can be met. The problems that the calcium is sufficiently ingested by people, and the problem that the fish bone generated when the freshwater is deeply processed is not well used in the prior art can be solved. The additional value of the fish bone can be improved, a feasible technical scheme can be provided for the treatment of the fish bone, and the considerable economic benefit can be brought to the enterprises. A patent document CN1215797C disclosed a method for preparing whole fish calcium protein products will include scales and fishbone whole fish into fish flesh finely ground paste, then add protein-rich, organic calcium, phosphorus, iron, raw materials, then add spices natural thickeners, and into the dough, tablet molding, baked. The method overcomes the disadvantages of the prior art, science and technology and reasonable, comprehensive nutrition rich. A patent document CN103704757A disclosed a high calcium sausage consists of fish bones 8-10% (w/w). A patent document CN103932288A disclosed a high-calcium sesame paste and a preparation method thereof. The high-calcium sesame paste is characterized by being composed of the following raw materials in parts by weight: 100 to 110 parts of black sesame, 3 to 4 parts of radix Based on the fish bone compositions which contain inorganic substances 60-70%, mainly calcium phosphate and hydroxyapatite and the remaining organic component i.e. collagen. In order to produce calcium source for enrichment of food products, the bone must be treated and changed to an edible form by softening the bone structure, remove impurity such as protein and fat to get the good quality calcium to apply in food and supplement products. The methods for protein and fat removal vary from physical, chemical and biological processes. This invention provides the process for preparing fish bone powder. Wherein a calcium-rich powdered product can be obtained from the above process. The calcium powder according to this invention can be used as an ingredient and calcium supplement in food products, especially seafood. Specific implementations of the invention will now be described with reference to the following tables, which are provided by way of example, and not limitation. Table 1 is showing protein, fat and TBA contents of dried tuna calcium after alkali soaking at different time; Table 2 is showing color of dried tuna calcium after alkali soaking at different time; Table 3 is showing protein and fat content of dried tuna calcium after treated with hexane; Table 4 is showing protein, fat and TBA contents of dried tuna calcium after treated with different protease enzymes; Table 5 is showing protein, fat and TBA contents of dried tuna calcium after treated with the combination process of soaking with alkali and protease enzyme treatments; Table 6 is showing protein, fat and TBA contents of dried tuna calcium with the combined processes of soaking with alkali and enzymatic treatments with protease Table 7 is showing protein, fat and TBA contents of dried tuna calcium pretreated with cooking with hot water and steam and treated with Protease enzyme in comparison to the combined process of soaking with alkali and enzymatic treatment with protease; Table 8 is showing color and appearance of dried tuna calcium pretreated with cooking with hot water and steam and treated with Protease enzyme in comparison to the combined process of soaking with alkali and enzymatic treatment with protease; Table 9 is showing analysis result of major component of tuna calcium; Table 10 is showing composition of tuna calcium compared with normal fish frame and percent on dry basis thereof; and The removal of non-polar components from the pre-treated bone with the alkali solution comprises the following steps;

The preferred solvent used for removal of non-polar components from the pre-treated bone is isopropanol or hexane. In another embodiment, a process of preparing fish bone powder comprises the following:

Furthermore, the removal of protein components from the pre-treated bone with an enzyme or the combination of enzymes comprises of the following steps;

Wherein the protease enzyme can be selected from the group of proteases derived from plants, animals or microorganisms, preferably, the enzyme is Protamex enzyme (protease complex: serine endopeptidase E.0 3.4.21.62 and metalloendopeptidase E.0 3.4.24.28, Novozyme)

The calcium product obtained from this invention has a particle size of less than 100 microns (micrometers) or in the range of 0.1 to 30 microns, but most preferably at 10 microns, and experiments below are the examples of the embodiments according to this invention. This experiment shows the effect of the alkali soaking time on final fat, protein, TBA contents and color of dried tuna calcium. The main frame of tuna bone was crushed to size 1-2 cm then soaked the crushed bone in sodium hydroxide solution (0.5%) with the ratio of crushed bone: NaOH solution at 1:1 at the temperature between 90-95C, for 1 hour. The alkali-treated bone was rinsed with tap water until the pH of alkali-treated bone is neutral before drying in hot air oven at 90 C for 1 hour. The dried crushed bone is referred to as dried tuna calcium in this invention. It is clearly shown that alkali treatment can significantly reduce the fat content and the TBA value of crushed bone as shown in Table 1. The results in tables 1 and 2 show that alkali treatment can remove muscle protein and the increase of alkali soaking time slightly reduces fat and TBA content of the dried tuna calcium. It also helps to improve the color of tuna calcium. This experiment shows the fat removal by using solvent. The main frame of tuna bone was crush to size 1-2 cm then soaked crushed bone in sodium hydroxide solution (0.5%) with the ratio of crushed bone: NaOH solution at 1:1 at the temperature between 90-95° C., for 1 hour. The alkali-treated bone was rinsed with tap water until the pH of alkali-treated bone is neutral before drying in hot air oven at 90 C for 1 hour. The dried tuna calcium is mixed with hexane with the ratio 1:5 (dried tuna calcium: hexane) before incubation of the mixture at 58-60° C. for 30 min. in a shaking water bath. Filter the solvent extracted, dried tuna calcium and dry the said material with hot air oven at 37° C. for 48 hr to remove solvent residue. The result shows that hexane extraction helps to reduce the fat content of dried tuna calcium. This experiment shows the bone cleaning process by using protease enzyme. The main frame of tuna bone was crush to size 1-2 cm. The crushed bone is mixed with water at ratio 1:1 and protease enzyme at dosage 2 g/Kg was added to the crushed bone. Incubate the said mixture at the temperature of 50-55° C. for 60 mins in a water bath shaker. Heat the mixture to 90° C. for 60 min in order to inactivate the enzyme activity. Separate the solid part by filtration and rinse the remaining bone with water. The said bone is dried in hot air oven at 90° C. for 1 hour. This experiment shows the bone cleaning process by using the combination of alkali soaking and protease enzyme. The main frame of tuna bone was crush to size 0.5-1 cm then soaked the crushed bone in sodium hydroxide solution (0.5%) with the ratio of crushed bone: NaOH solution of 1:1 at 90°-95° C., for 1 hour. The treated crushed bone was rinsed with tap water until the pH of alkali-treated bone is neutral before drying. The treated bone is mixed with water at the ratio of 1:1. Protease enzyme was added at dosage of 0.2 g/100 g crushed bone and incubate the said mixture at 50-55° C. for 60 mins in water bath with agitation. Heat the said mixture to 90° C. for 60 min to inactivate enzyme activity then filter the remaining bone and rinsed by water. The bone is dried in hot air oven at 90 C for 1 hour. The results show that bone cleaning by alkali soaking followed by enzymatic treatment with protease can reduce fat and TBA contents of tuna calcium. The Alkali protease (P6) and Protamex show lowest fat and TBA content among 4 treatments. This experiment shows the effects of pretreatment of tuna bone with hot water and steam on the removal of fat and TBA content of dried bone before the alkali soaking and enzymatic treatments. The main frame of tuna bone was treated with hot water and steam at 95° C. for 45 min before crushing the said bone to size 0.5-1 cm. The crushed bone was then soaked in sodium hydroxide solution (0.5%) with the ratio of 1:1 at 90-95° C., for 1 hour and rinsed with tap water to remove alkali residue. The treated bone was mixed with water at ratio of 1:1. Protease enzyme was added at dosage of 0.2 g/100 g crushed bone and incubate the mixture at 50-55° C. for 60 mins in water bath with agitation. The mixture was heated at 90° C. for 60 min in order to inactivate the enzyme activity. Filter the solid part and rinsed with water. The remaining bone is dried in hot air oven at 90° C. for 1 hour. This experiment shows the effect of cooking tuna bone by hot water and steam before crushing on fat and TBA contents of dried tuna calcium treated with protease enzyme in comparison to the combined process of soaking with alkali and enzymatic treatment with protease. The main frame of tuna bone was cooked with hot water and steam at 95° C. for 45 min before crushing to size 0.5-1 cm. The precooked and crushed bone was soaked in sodium hydroxide solution (0.5%) with the ratio of 1:1 at 90-95° C., for 1 hour and rinsed with tap water to remove alkali residue. The alkali treated bone was mixed with water at the ratio of 1:1. Protease enzyme was added at dosage of 0.2 g/100 g to the crushed bone and incubate at 50-55° C. for 60 mins in water bath with agitation. The mixture was heated to 90° C. for 60 min in order to inactivate the enzyme activity. Filter the solid part and rinsed with water. The remaining bone is dried in hot air oven at 90° C. for 1 hour. The result shows that pretreatment by cooking with hot water helps to reduce the fat content better than cooking with steam. Soaking the crushed bone with alkali also helps to improve the appearance of the tuna calcium. Protease enzyme further helps to lower the fat content and reduce oxidation (TBA value) of tuna calcium. The fish bone powder obtained from the processes according to this invention contain the component as shown in table 9. As mentioned above, the most preferred fish bone powder comprises the following components: protein 20-30%, fat 0.5-2% and ash 50-70%. And mineral contents of the said fish bone powders comprising calcium 18-22 g/100 g, phosphorus 5-15 g/100 g, sodium 0.5-1.5 g/100 g, magnesium 0.1-0.5 g/100 g and potassium 0.01-0.1 g/100 g. The element analysis shows that ratio of Ca/P of tuna calcium is 1.86 which is within the range of natural calcium found in bone (Ca/P 1.6 -2.0). A process for preparing fish bone powder according to this invention generally comprising at least 4 steps: pre-heating, removing of impurity, drying and milling to derive a calcium-rich bone powder product that contains calcium in the range of 18-22 g/100 g of the final product. In addition, the bone powder particle size obtained is less than 100 microns and contains high levels of protein, fat, and essential minerals, such as sodium and phosphorus. The source of bone can be obtained from any fishes, preferably from tuna. 1. A process for preparing fish bone powder comprises following steps:

a. pre-treatment of fish bone; b. removal of non-polar components from the pre-treated bone obtained from step a with alkali solution or solvent wherein the alkali concentration is in the range of 0.2-1% (w/v); c. drying of the alkali or solvent treated bone from step b; and d. milling or pulverizing of the dried bone from step c. 2. The process for preparing fish bone powder according to 3. A process for preparing fish bone powder comprises the following steps:

a. pre-treatment of fish bone; b. removal of protein components from the pre-treated bone obtained from step a with an enzyme or the combination of enzymes wherein the ratio between pre-treated and water is in the range of 1:1-2; c. drying of the bone obtained from step b; and d. milling or pulverizing of the dried bone obtained from step c. 4. A process for preparing fish bone powder comprises the following steps:

a. pre-treatment of fish bone; b. removal of non-polar components from the pre-treated bone obtained from step a with alkali solution or solvent wherein the alkali concentration is in the range of 0.2-1% (w/v); c. removal of protein components from the pre-treated bone obtained from step a with an enzyme or the combination of enzymes wherein the ratio between pre-treated or alkali treated bone and water is in the range of 1:1-2; d. drying of the bone obtained from step c; and e. milling or pulverizing of the bone obtained from step d. 5. The process for preparing fish bone powder according to 6. The process for preparing fish bone powder according to a. pre-treatment of fish bone; b. removal of impurities from the pre-treated bone obtained from step a with boiling water at 100° C.; c. drying of the bone obtained from step b; and d. milling or pulverizing of the dried bone obtained from step c. 7. The process for preparing fish bone powder according to a. removal of blood meat from the bone; b. pre-heating the bone at 80-120° C. for 50-90 minutes; c. reducing the size of the pre-heated bone to 0.5 cm; and d. washing the bone obtaining from step c. with water. 8. The process for preparing fish bone powder according to a. mixing the said pre-treated bone with the alkali solution at the concentrations of 0.2-1% (w/v) and the ratio between the said crushed bone and the said alkali solution is in the range of 1:1-2 (w/v); b. heating the mixture obtaining from step a at the temperature between 70-100° C. for 45-120 minutes; and c. Washing the bone obtaining from step b with water. 9. The process for preparing fish bone powder according to a. mixing the pre-treated or alkali treated bone with water at the ratio of pre-treated or alkali treated bone and water between 1:1-2; b. adjusting the pH of the mixture obtained from step a to 8.0-8.5 with NaOH or KOH; c. adding the enzyme or the combination of enzymes selected from the group of protease (dosage 0.2%) to the said mixture; d. incubating said mixture with enzymes at the temperature between 50-55° C. with the agitation speed between 1000-1500 rpm for 0.5-1.5 h; e. inactivating the enzymes by heating said mixture at the temperature above 90-95° C. for at least 1 hour; f. filtrating said mixture to separate the remaining bone materials and the aliquot; g. washing said bone material with water until the pH of the said bone is 7.0; h. drying said bone; and i. keeping the dried bone in the cool and dry place. 10. The process for preparing fish bone powder according to 11. The process for preparing fish bone powder according to 12. The process for preparing fish bone powder according to 13. The process for preparing fish bone powder according to 14. The process for preparing fish bone powder thereof according to 15. The process for preparing fish bone powder according to 16. The process for preparing fish bone powder according to 17. The process for preparing fish bone powder according to calcium 18-22 g/100 g, phosphorus 5-15 g/100 g, sodium 0.5-1.5 g/100 g, magnesium 0.1-0.5 g/100 g and potassium 0.01-0.1 g/100 g. 18. The process for preparing fish bone powder according to any claim of the previous claims 19. The process for preparing fish bone powder according to 20. The process for preparing fish bone powder according to FIELD OF THE INVENTION

DESCRIPTION OF THE RELATED ART

SUMMARY OF THE INVENTION

BRIEF DESCRIPTION OF THE DRAWING

DETAILED DESCRIPTION OF THE INVENTION

Experimental 1:

Materials and Method:

Experimental 2:

Material and Method:

Experimental 3:

Material and Method:

Experimental 4:

Materials and Method:

Experimental 5:

Material and Method:

Experimental 6:

Materials and Method: