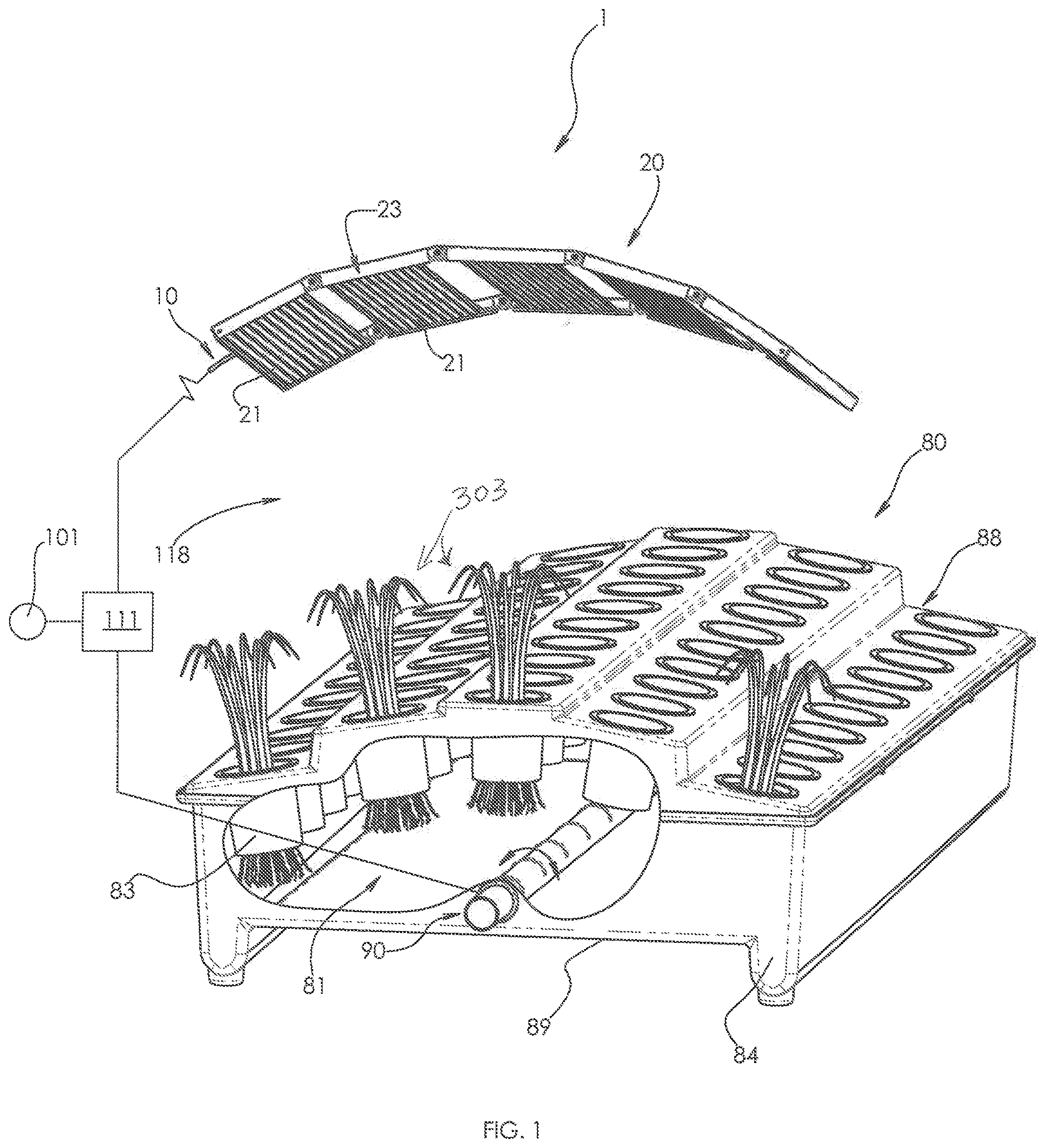

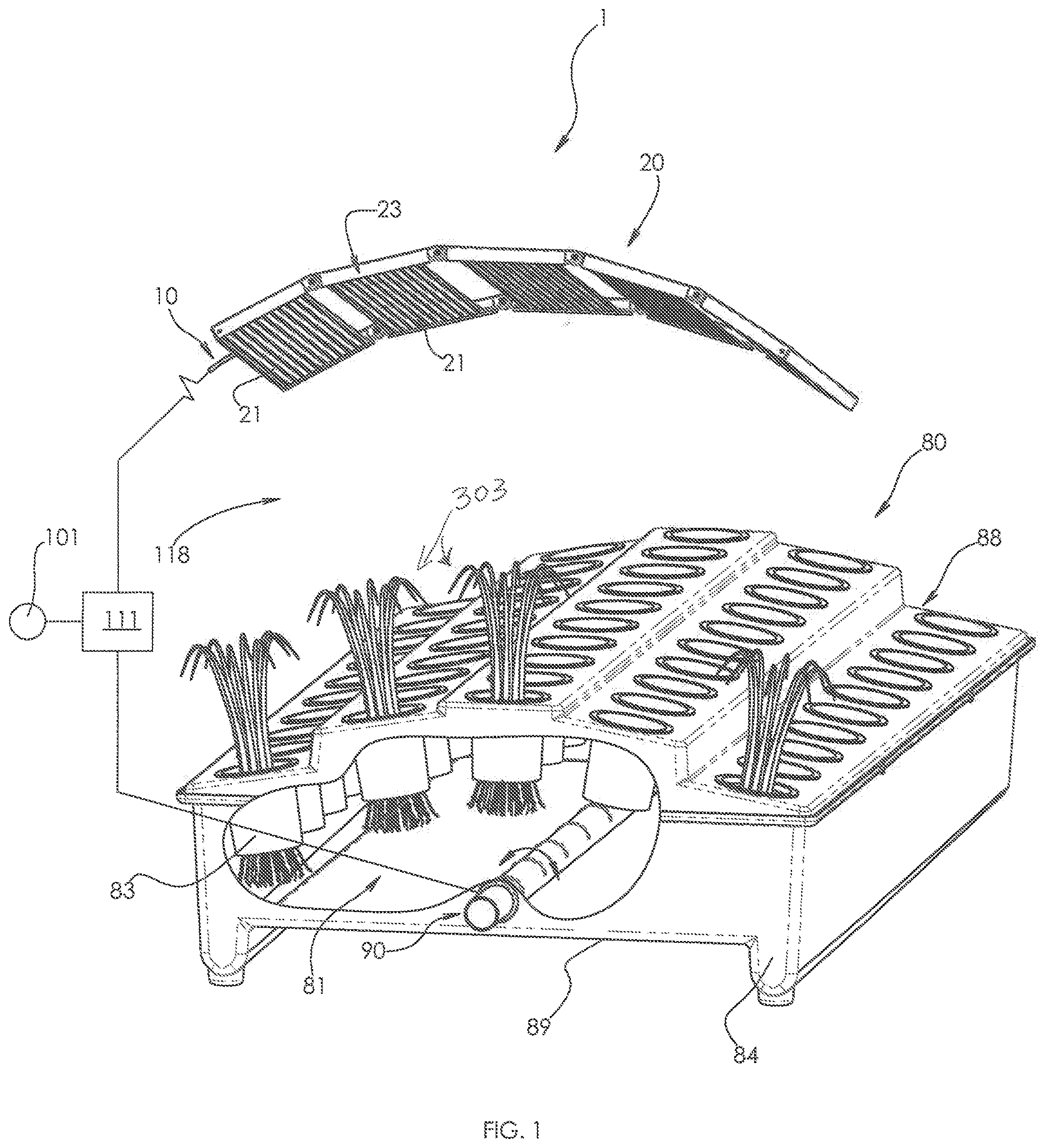

Horticulture Grow System for Horticulture

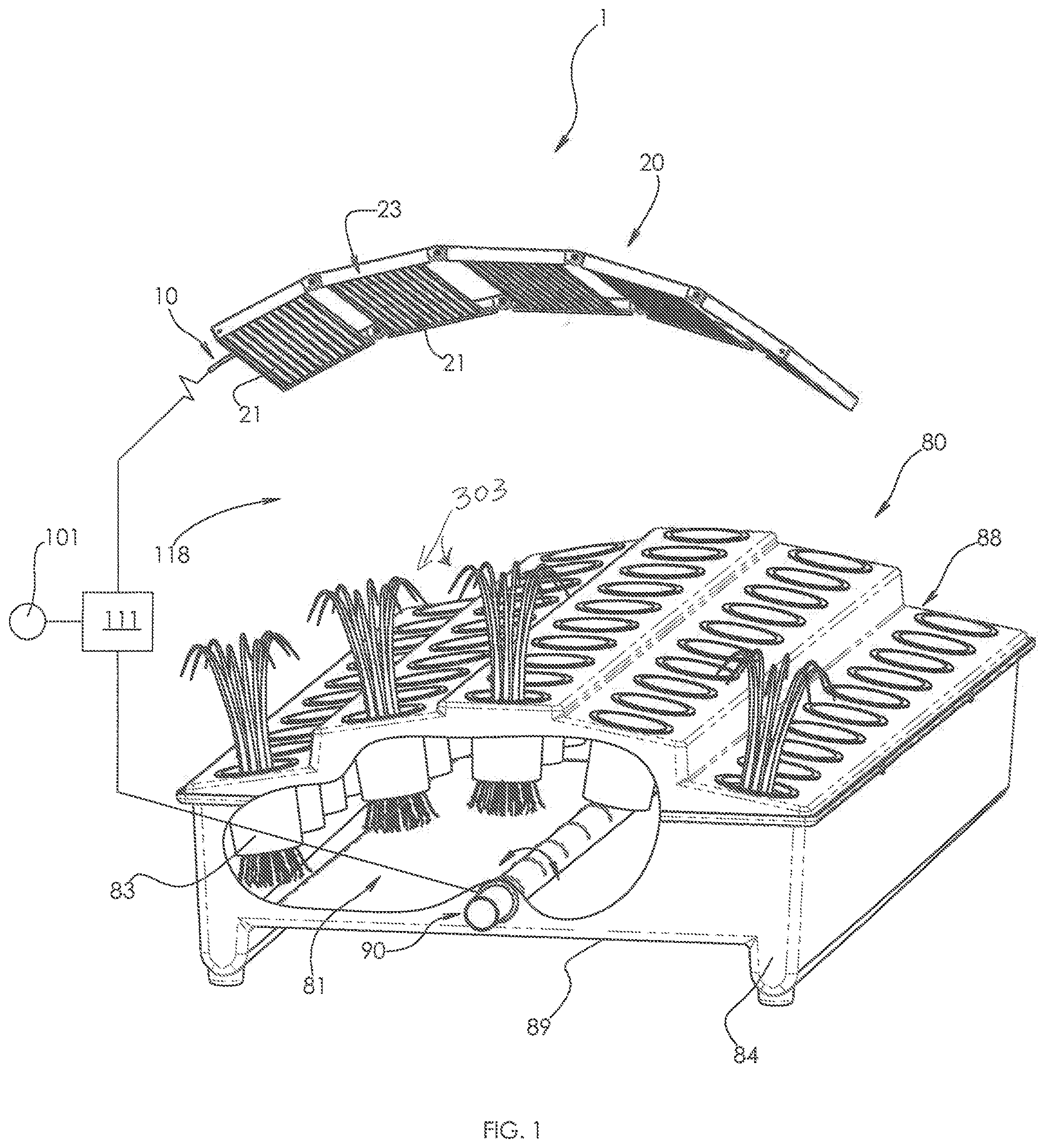

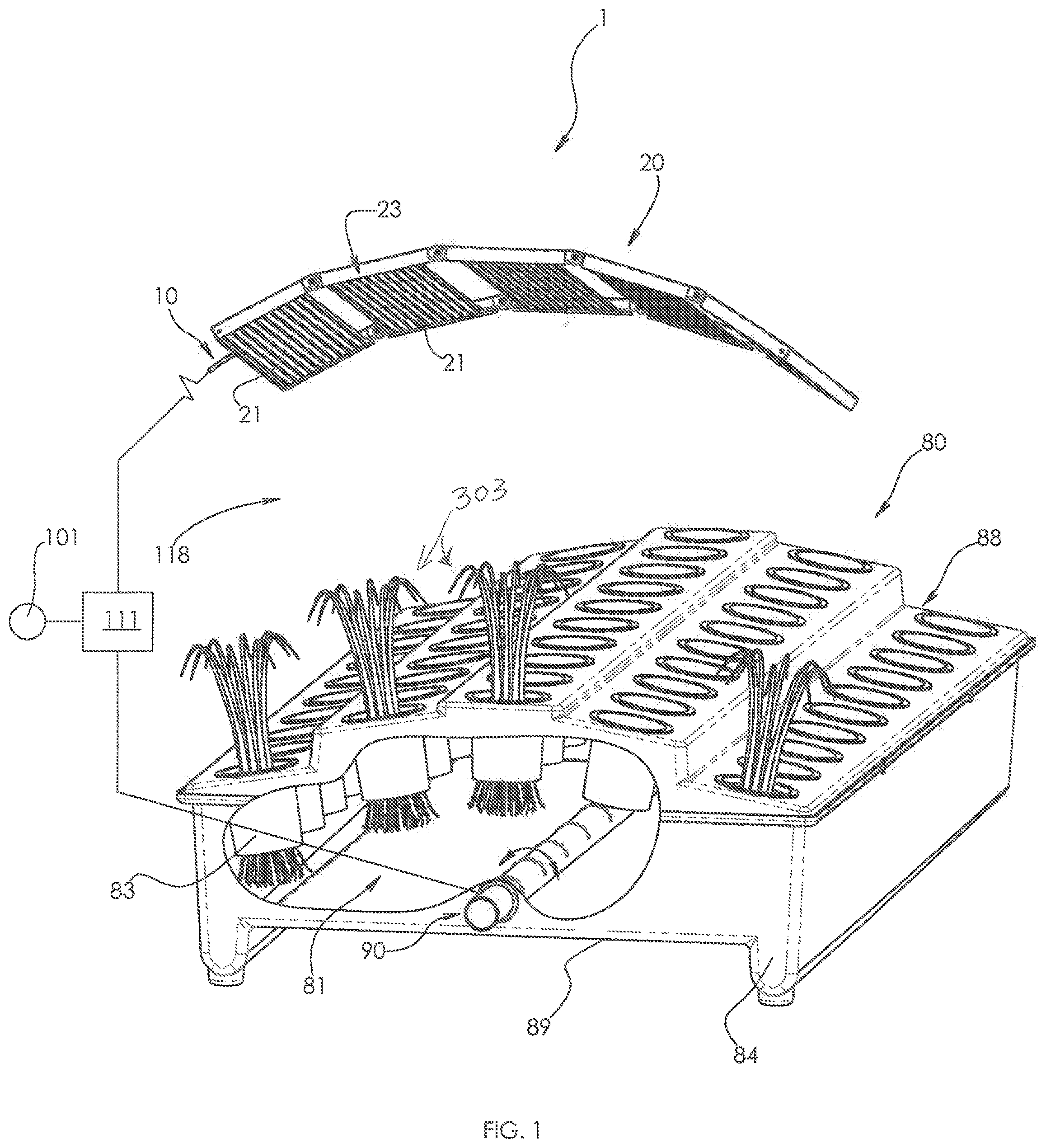

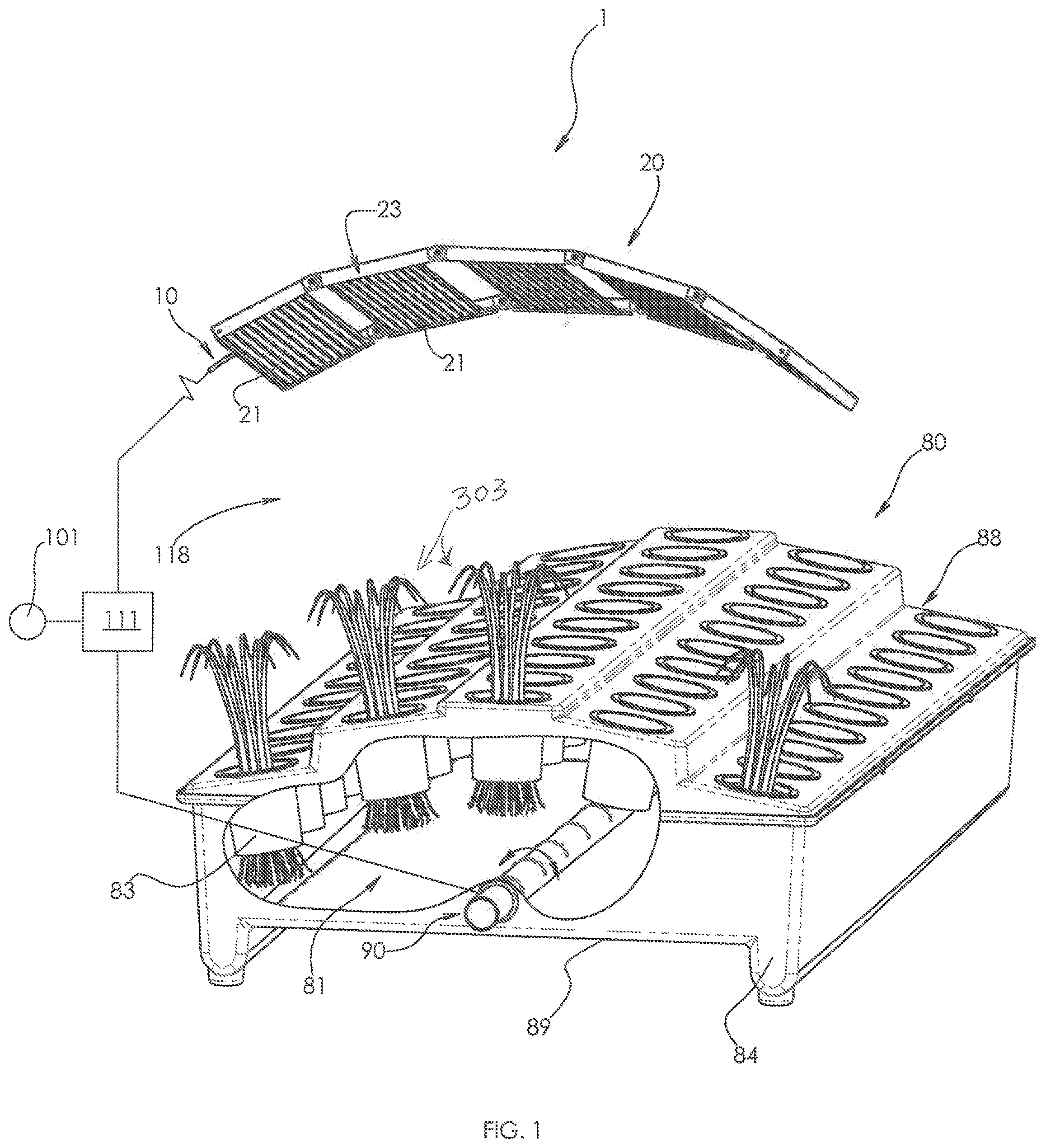

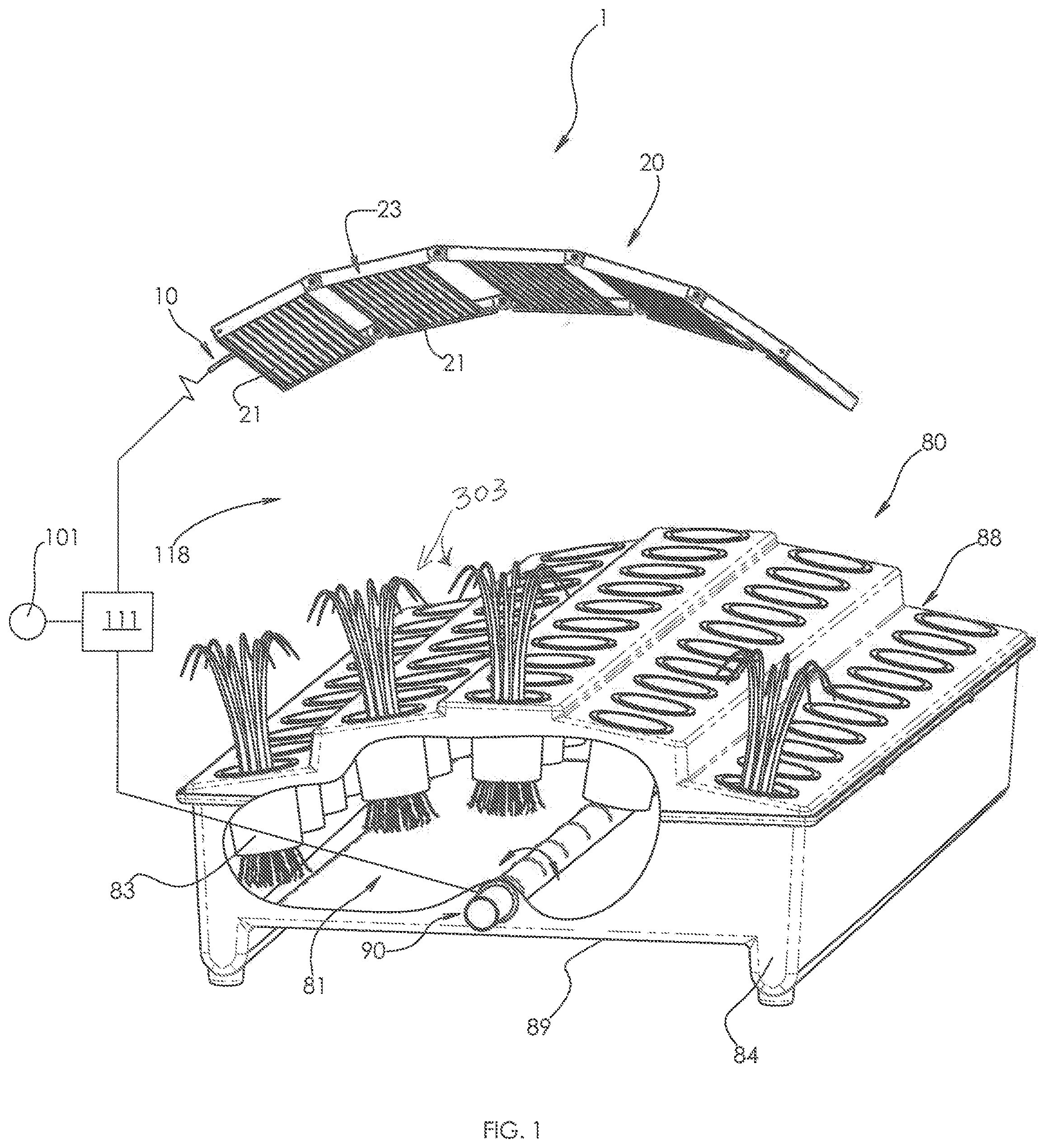

This application claims priority to U.S. Provisional Application No. 62/851,109 entitled “Pyramid Semi Circle Horticulture Grow System” and filed May 22, 2019 and to U.S. Provisional Application No. 62/873,786 entitled “Pyramid Curved Horticulture Grow System” and filed Jul. 12, 2019. Both of the above applications are hereby incorporated by reference in their entireties. Implementations described herein relate to a horticultural grow system that includes at least a plant substrate system and a luminaire. In particular, some implementations relate to a grow system that includes at least that includes at least a plant substrate system and a luminaire that is configured to be powered with direct current. Recently there has been an increase in indoor growing of plants for markets. Among the plants grown in grow rooms indoors are lettuce, some salad greens, strawberries, mint, basil, and The following summary introduces at a high level a limited number of topics described in the Detailed Description. This summary is not intended to identify key or essential features and should not be used for that purpose. In addition, this summary is not intended to be used as a guide to the scope of the claims. Instead, this Summary is provided as an introduction for the reader. In an exemplary first implementation, a horticulture grow system for plants includes at least a plant substrate system. The horticulture grow system for plants of the first exemplary implementation further includes at a luminaire positioned adjacent to the plant substrate system, the luminaire includes a plurality of grow light panels, a lighting frame, and at least one luminaire connector, the lighting frame includes a plurality of frame members, the at least one luminaire connector is coupled between one frame member and another frame member adjacent to the one frame member, the luminaire connector adjusts the spatial position of the plurality of frame members that define the lighting frame and shape of the luminaire. The horticulture grow system for plants of the first exemplary implementation further includes at a plant canopy zone, defined between the plant substrate system and the light canopy rendered in a curvilinear configuration, and whereby the plant canopy zone defines a curvilinear space for illuminating the plants. In a second exemplary implementation, a horticulture grow system for plants includes at least a plant substrate system. The horticulture grow system of the second exemplary implementation further including at least a light canopy positioned adjacent to the plant substrate system, the light canopy includes a plurality of grow light panels, a lighting frame, and at least one canopy connector, the canopy connector adjusts the spatial position of frame members that define the lighting frame and curvilinear shape of the light canopy. In a third exemplary implementation, a method of illumination includes a plurality of steps, including at least disposing plants hydroponically on a plant substrate system. The method of illumination of the third exemplary implementation further includes at least positioning a light canopy adjacent to the plant substrate system to define a plant canopy zone, the light canopy includes a plurality of grow light panels, a lighting frame having a plurality of frame members, and at least one canopy connector; The method of illumination of the third exemplary implementation further includes at least adjusting the spatial positions of frame members of the plurality of frame members to render the light canopy in a curvilinear shape; and The method of illumination of the third exemplary implementation further includes at least supplying light to the plants within the plant canopy zone with the light canopy rendered in a curvilinear shape. Some implementations are now described with reference to the above-described drawings. All implementations discussed in this detailed description and in the drawings are merely examples and not meant as limitations on the scope of the description or the claims. The drawings are simplified drawings. Some details are omitted to avoid unnecessary clutter that could obscure the principles described herein. In addition, the drawings are not necessarily to scale. At various places in this description, there is reference to “some implementations.” These multiple references to “some implementations” are not necessarily describing the same implementations and some implementations may be alternatives to one another. Similarly, multiple references to “one embodiment” or “one exemplary embodiment” are not necessarily referring to the same embodiment. In addition, no attempt is made to exhaustively describe all possible implementations. Instead, based on the following description those of ordinary skill in the art will be appraised of certain concepts and principles which will then enable them to imagine additional or alternative implementations to those described herein. The indoor horticulture described in this disclosure includes use of a variety of different mediums. Some example grow systems use at least one of aeroponics or hydroponics. Aeroponics is a process of growing plants with their roots in air rather than in soil or other medium. Aeroponics is a subset of hydroponics in that in aeroponics nutrients are carried via water. Examples of other plant substrates used in a plant substrate system are soil, coco, or peat moss. Some implementations described herein include a plant substrate system that supports plants in a pyramid-shaped configuration in which they occupy less horizontal space in a grow chamber. In some implementations the plant substrate system includes grow decks for supporting plants, the grow decks arranged in the pyramid-shaped configuration. The plants supported on the grow decks extend roots below the grow decks into a grow chamber defined under the pyramid configuration of grow decks. In some implementations the roots can then be irrigated with a nozzle system disposed in the grow chamber. Some plant substrate systems may not include one or more of the above features. Some implementations include a luminaire that is positioned to provide light through a plant canopy zone onto plants disposed on a plant substrate system. The luminaire is both light weight and flexible so it can be deployed over plant substrate systems of different configurations—including the pyramid-shaped configuration discussed above. In some implementations, a plurality of grow light panels is arranged on a lighting frame of the luminaire. And the flexibility is due at least in part to luminaire connectors that connect frame members of the lighting frame. These luminaire connectors allow the lighting frame to be arranged in different configurations as needed. Thus, the luminaire, and its grow light panels, can be arranged in shapes dependent on the shape of the plant substrate system that the luminaire is disposed over. Possible luminaire shapes include at least curvilinear, flat, concave, irregular, and other shapes. In some implementations the panels can be wired to each other without the need for luminaire connectors. In some implementations, the luminaire includes a plurality of grow light panels powered by direct current with the direct current being distributed among the plurality of grow light panels in series. The use of direct current distributed in series allows for reduced wiring which requires less weight and less space. Thus, the installed cost of the luminaire is reduced compared to other light structures. Further, powering light panels with direct current allows the power equipment to be located in its own room far from the grow chamber, which reduces the amount of HVAC needed to maintain a grow chamber environment. In some implementations, the luminaire connectors discussed above are configured with a passage for a direct current power line, such as discussed above. The different frame members are associated with different ones of the plurality of grow light frames. And the power line may pass through the interior of the frame members and then pass from frame member to frame member via passages in the luminaire connectors. Thus, the luminaire connectors enable a low weight direct current power line to be threaded from frame member to frame member to service the grow light panels associated with the different frame members. When panels in a luminaire are wired in series, a failure of LED or one string of LEDs does not affect the other LEDs in the luminaire to the same extent as if the panels were wired in parallel. Specifically, In one exemplary embodiment, the luminaire comprises either a light emitting diode (LED) light; a curved light; an LED light; a curved LED grow light; or a curved LED lighting frame. Referring to Opposing, In Referring back to Shown in Further referring to In Referring now to Shown in In one embodiment, each adjustment portion 45 is rounded having a corresponding centerline. In operation, the fastener 47 joins the two halve portions 41 defining the luminaire connector 29 at the centerline. According, in one exemplary embodiment, the fastener 47 further provides a pivot point for independent rotations of the two halve portions 41 relative to one another. In this description and appended claims the term “luminaire connector” is defined to include among others hinges; and adjustable hinges. In one embodiment, shown in In one embodiment, the luminaire connector 29 further includes an actuator 880, such as a worm gear or pneumatic actuator. As such, the luminaire connector 29 includes a first half portion and a second half portion. The actuator 880 is positioned between the first half portion and the second half portion and coupled to the supply line 10. The actuator 880 receives control signals from the supply line 10 to render the first and second half portions from a first spatial position to a second spatial position. In some implementations a horticulture grow system for plants includes at least a plant substrate system. For example, referencing The horticulture grow system further includes at least a luminaire positioned adjacent to the plant substrate system, the luminaire includes a plurality of grow light panels, a lighting frame, and at least one luminaire connector, the luminaire connector adjusts the spatial position of frame members that define the lighting frame and shape of the luminaire. And wherein the lighting frame includes a plurality of frame members, and wherein the at least one luminaire connector is coupled between one frame member and another frame member adjacent to the one frame member. In some implementations a luminaire may include a variety of structures, such as a grow light or an led luminaire. In some implementations a luminaire connector includes a variety of structures, such as hinges or adjustable hinges. And in some implementations, a grow light panel may include a variety of structures, such as lighting panel. And in some implementations, a lighting frame may include a variety of structures, such as a curved led lighting frame. For example, referencing In some further implementations a horticulture grow system further includes at least a power line, the power line coupled to the luminaire, the power line passing through at least one luminaire connector. For example, referencing In some further implementations the power line passes in series through the luminaire. For example, in In some further implementations the power line provides direct current, DC. For example referencing Thus, in some implementations, a horticulture grow system 1 for plants 303 includes at least a plant substrate system 80, a luminaire 20 positioned adjacent to the plant substrate system 80, the luminaire 20 includes a plurality of grow light panels 21, a lighting frame 23, and at least one luminaire connector 29, the luminaire connector 29 adjusts the spatial position of frame members 28 that define the lighting frame 23 and shape of the luminaire 20 and a power line 12, the power line 12 coupled to the luminaire 20, the power line 12 configured for direct current and passing at least one luminaire connector 29 in series through the luminaire to power one or more grow light panels. An exemplary method is now described. Preliminarily it is noted that the method includes a plurality of “steps” which are described in a ordered fashion. The order of the steps is merely exemplary and are not intended to limit either this disclosure or the claims. In various implementations, the steps may be performed in different orders and sequences that are different from that described below. Additionally, in the description below, certain elements from the drawings are called out as examples of structure that could, in some implementations, be used to perform the method steps. These called out elements from the drawings are not intended to be limiting. Referencing The exemplary method 1200 includes at least disposing plants on a plant substrate system (e.g. plant substrate system 80 of In some implementations the exemplary method 1200 further includes at least positioning a luminaire (e.g. luminaire 20) adjacent to the plant substrate system (e.g. plant substrate system 80) to define a plant canopy zone (e.g. plant canopy zone 118 of In some implementations, positioning a luminaire per Process block 1204 includes at least positioning a luminaire (e.g. luminaire 20) that includes a plurality of grow light panels (e.g. grow light panels 21), a lighting frame (e.g. lighting frame 23) having a plurality of frame members (e.g. frame members 28) and at least one luminaire connector (e.g. luminaire connector 29). In some implementations the exemplary method 1200 further includes adjusting the spatial positions of frame members (e.g. frame members 28) of the plurality of frame members to render the luminaire (e.g. luminaire 20) in a shape (See, e.g. shape of luminaire 20 in Drawing 5 And in some implementations, the exemplary method 1200 further includes supplying light to the plants within the plant canopy zone (e.g. plant canopy zone 118 of In some implementations, supplying light to the plants per process block 1208 includes at least passing a power line (e.g. power line 12) in series through the lighting fame (e.g. lighting frame 23) to illuminate the plurality of grow light panels (e.g. grow light panels 21). In some further implementations, as shown in It will be understood by those skilled in the art that the terminology used in this specification and in the claims is “open” in the sense that the terminology is open to additional elements not enumerated. For example, the words “includes” should be interpreted to mean “including at least” and so on. In addition, articles such as “a” or “the” should be interpreted as not referring to a specific number, such as one, unless explicitly indicated. At times a convention of “at least one of A, B, or C” is used, the intent is that this language includes any of A alone, B alone, C alone, A and B, B and C, A and C, or all of A, B, and C. The same is indicated by the conventions “one of more of A, B, or C.” Similarly, the phrase “A, B, and/or C” is intended to include any of A alone, B alone, C alone, A and B, B and C, A and C, or all of A, B, and C. With parentheticals such as (e.g. A, B, C). It is intended that this refer to any or all of A alone, B alone, or C alone and to any combination thereof that is applicable in the particular context. And as previously indicated elements, components, or operations should not be regarded as essential unless they are so explicitly described. The teachings contained herein may be adapted to a variety of implementations arranged and composed in a wide variety of ways. The above description of various implementations is intended to be illustrative not exhaustive and is not intended to limit this disclosure, its application, or uses. Those skilled in the art will be able to imagine implementations not described but that are consistent with the principles and teachings described herein. Therefore, the above description of exemplary implementations is not intended to limit the scope of this disclosure, which should be defined only in accordance with the following claims and equivalents thereof. In some implementations, an indoor grow system for plants includes at least a plant substrate system; a luminaire positioned adjacent to the plant substrate system, the luminaire includes a plurality of grow light panels, a lighting frame, and at least one luminaire connector, the lighting frame includes a plurality of frame members, the at least one luminaire connector is coupled between one frame member and another frame member adjacent to the one frame member, the luminaire connector adjusts the spatial position of the plurality of frame members that define the lighting frame and shape of the luminaire; and a plant canopy zone, defined between the plant substrate system and the luminaire rendered in a curvilinear configuration, and whereby the plant canopy zone defines a curvilinear space for illuminating the plants. 1. A horticulture grow system for plants comprising:

a plant substrate system; a luminaire positioned adjacent to the plant substrate system, the luminaire includes a plurality of grow light panels, a lighting frame, and at least one luminaire connector, the lighting frame includes a plurality of frame members, the at least one luminaire connector is coupled between one frame member and another frame member adjacent to the one frame member, the luminaire connector adjusts the spatial position of the plurality of frame members that define the lighting frame and shape of the luminaire; and a plant canopy zone, defined between the plant substrate system and the luminaire, and whereby the plant canopy zone defines a space for illuminating the plants. 2. The horticulture grow system for plants of 3. The horticulture grow system for plants of 4. The horticulture grow system for plants of 5. The horticulture grow system for plants of 6. The horticulture grow system for plants of 7. The horticulture grow system for plants of 8. The horticulture grow system for plants of 9. The horticulture grow system for plants of 10. The horticulture grow system for plants of 11. The horticulture grow system for plants of 12. The horticulture grow system for plants of 13. The horticulture grow system for plants of 14. A horticulture grow system for plants comprising:

a plant substrate system; a luminaire positioned adjacent to the plant substrate system, the luminaire includes a plurality of grow light panels, a lighting frame, and at least one luminaire connector, the luminaire connector adjusts the spatial position of frame members that define the lighting frame and shape of the luminaire; and

a power line, the power line coupled to the luminaire, the power line configured for direct current and passing at least one luminaire connector in series through the luminaire to power one or more grow light panels. 15. The horticulture grow system for plants of 16. A method for illumination comprising the steps of:

disposing plants on a plant substrate system; positioning a luminaire adjacent to the plant substrate system to define a plant canopy zone, the luminaire includes a plurality of grow light panels, a lighting frame having a plurality of frame members, and at least one luminaire connector; adjusting the spatial positions of frame members of the plurality of frame members to render the luminaire in a shape; and supplying light to the plants within the plant canopy zone with the luminaire rendered in a shape. 17. The method for illumination of PRIORITY APPLICATIONS

TECHNICAL FIELD

BACKGROUND

SUMMARY

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION

First System Implementation

Second System Implementation

Exemplary Method