Einrichtung zum zerkleinern und mischen von einrichtung zum zerkleinern und mischen von abfällen, insbesondere von biologisch abfällen, insbesondere von biologisch abbaubaren abfällen abbaubaren abfällen

The invention refers to a mechanism for cutting up and mixing Abf llen, in particular yon bielogisch, to each other parallel lying F6rderschnecken extending degradable striking with a trough-like Beh more lter, into in L ngsrichtung the Beh lters swivelling stored is. whereby within the near-surface range of the Beh lters at least two F6rderschnecken lying next to each other are intended and at least a further pair F rderschnecken (3berliegend is arranged and the trough-like Beh more lter at least one filling ffnung and at least a Entleerungs6ffnung exhibits.

A mechanism of this kind is well-known from the EP-0536767 A1. The trough-like Beh more lter is from the top fed, and in the ground of the Beh lters a Entleerungs6ffnung with a Verschlul3klappe is to be planned, by the soft cut up and mixed property be unloaded can. Biologically degradable Abf lle is, which concerns its processing and processing, difficult basic materials. It cut up mixed in the Beh more lter dutch the F rderschnecken and form thereby a smudgy and sticky mass. After the release of the emptying ffnung it lasts from there for a very long time until this smudgy and sticky mass is yielded to the Graze by these in the ground of the Beh lters EntleerungsSffnung present. Will in local Abfallaufbereitungsantagen used mechanisms of this kind, incoming goods day for day grol3e quantities erw ihnten Abf lle to be resulted, mSglichst rapidly prepared the m ssen, thus it deposited k6nnen. It is from there of substantial importance, dal3 the processing and the associated work within short time to be completed k6nnen. With that erw before-well-known mechanism usually take up the emptying more time than cutting up and mixture of the biological Abf lle hnten here.

In this connection also the Mischbeh is more lter to US 3,797,807 A and US 3,995,836 A too erw hnen, which are used in agricultural enterprises. With these mechanisms fodder cereals and addition materials are blended. The material which can be mixed is drying and rieself hig. The trough-like Beh more lter is fed yon above and possesses in one of its two Seitenw a nde Entleerungs6ffnung, which by means of one pray hydraulically tigbaren flap to 6ffnen and is to be schlieSen. To this EntleerungsSffnung schlier3t a FSraerband on, L] more ber that the mixed fodder cereals to be delivered Kant. Those once [Jckige wave of that F rderschnecke, which this Entleerungs5ffnung lies neighbouring, tract within the range of the Entleerungs6ffnung paddle-like shovels, those the emptying procedure lowest braids.

DarL berhinaus is subdivided carried the screw volume by the einstSckigen wave of these F6rderschnecke, in the Wise, da/J upward gradients directed each other opposite exhibit the two parts of the screw volume, which run to the two sides of the Entleerungs6ffnung, which a screw volume thus rechtsg ngig, which is ngig other one linksg, so dab this F6rderschnecke too both sides of the EntleerungsSffnung the lying schLittund rieself hige fodder cereals directly to these paddle-like shovels f6rdert. For the processing of biologically degradable striking such fodder mixers are however suitable, since on the one hand the Entleerungs6ffnung neighbouring lying FSrderschnecke with its paddle-like shovels Mischund Zerkleinerungsvorgang is chtigt beeintr and the smudgy and sticky mass, which this cut up biological Abf lle forms, from the Beh are more lter delivered not upward kSnnen.

Outgoing yon the invention did not place itself the task to this state of the art to be developed further and improved a mechanism of the kind initially specified in such a way, dab after AbschluB Zerkleinerungsund of mixture course the smudgy and sticky mixture property m5glichst from the Beh more lter be delivered at short notice can, thus da/J the emptying of the Beh lters any more time in requirement takes than a mixing and a cutting up, preferably even less. To the L6sung of this task schl the invention gt forwards, dab the Entleerungs6ffnung in a front wall of the Beh lters is intended and at least the near-surface arranged FSrderschnecken jewels in L ngsrichtung seen of two Wellenabschnitten to consist and each of the Wellenabschnitte of the F6rderschnecken its own drive is assigned and the verschlie! 3bare EntleerungsSffnung within the front range of these near the surface arranged F6rderschnecken is intended. Zweckm 13ige arrangements of the invention are held in the Unteranspr Jchen.

In order to illustrate the invention, a AusfShrungsbeispiel of nether er6rtert becomes in the enclosed design, without which invention thereby on this AusfQhrungsbeispiel shown einzuschr nken. Show:

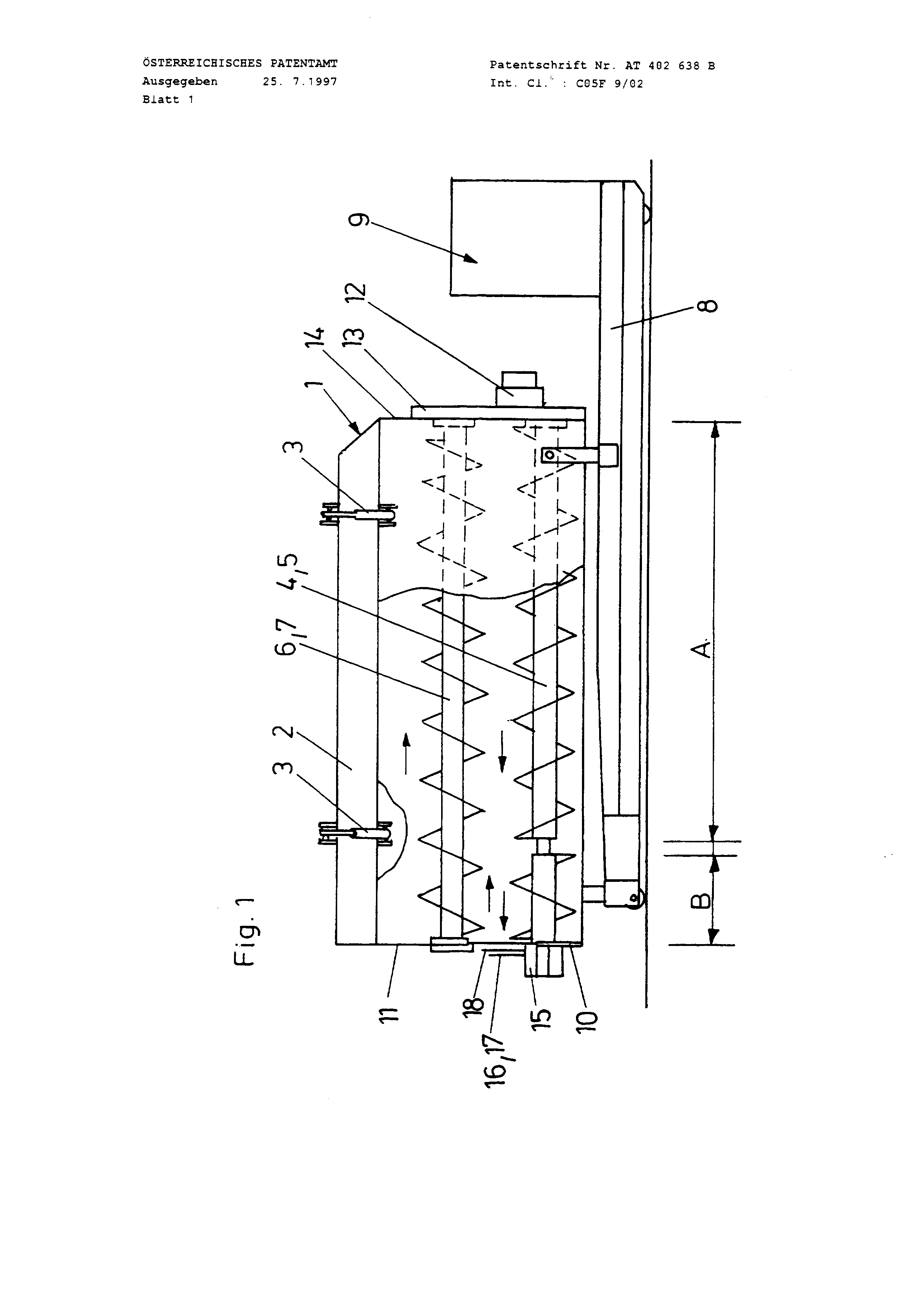

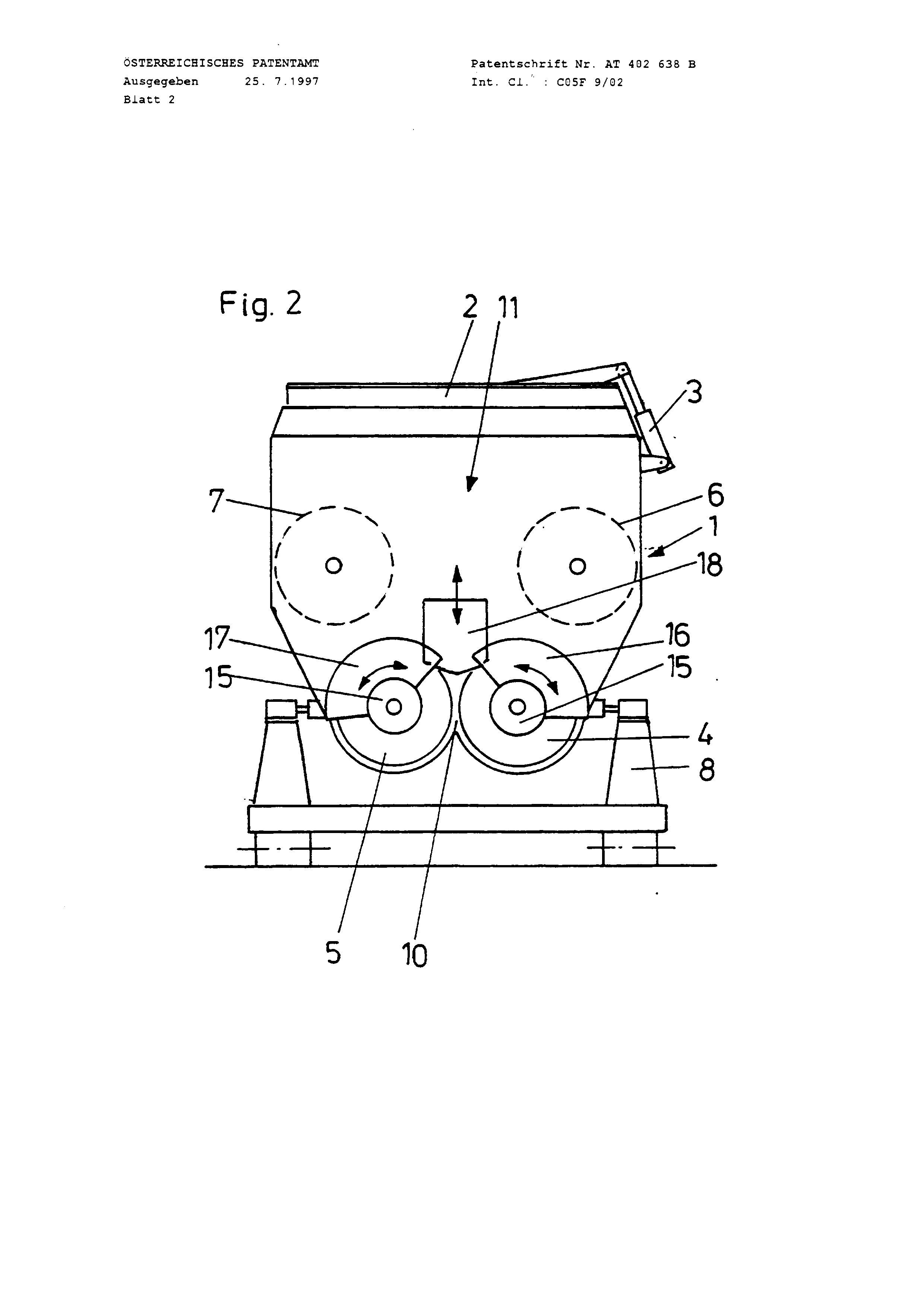

Fig. 1 a side view of the mechanism, partially broken; Fig. 2 a Stirnansicht of the mechanism in a gegenLJber Fig. 1 vergrSr3erten mA! 3stab.

A trough-like, elongated Beh more lter 1 is verschlieBbar with a cover 2 above, which is lowerable mittens piston cylinder units 3 around to L a ngsachse of the Beh lters 1 parallel axle hebund.

L ngswandungen the Beh: lters 1 k6nnen at least partially clam-shell trained its, whereby by these clam-shell wall parts a W is leadable rmetr germedium, in order to heat the mixture property anzuw rmen and. In the enclosed designs this clam-shell arrangement of the Beh is however not shown lterwand. AIs W rmetr germedium kSnnen for example the exhaust gases of a driving motor RK 402,638 B to be used, for the enterprise of the mechanism diet. In this Beholder 1 two FSrderschnecken 4 and 5 are swivelling stored in the near-surface range. These two near-surface FSrderschnecken 4 and 5 lie together close, and the neighbouring ground range of the Shelters 1 is partially the extent outline of these two Ferderschnecken 4 and 5 angepaBt (Fig. 2). Above these two FSrderschnecken 4 and 5 a further FSrderschneckenpaar 6 and 7 is intended. This Beh more lter 1 is stored on a chassis 8, also a drive unit 9 tr igt with a hydraulic pump, which develops the necessary hydraulic pressure for the enterprise of the hydraulic motors, with which the F rderschnecken is propelled. Hydraulic driving motors are f [Jr the invention not compellingly. Reason tzlich w RH it mSglich to use driving motors of other kind here.

The EntleerungsSffnung 10 is intended in a front wall 11 of the printing-like Beh lters 1, in the front range of the two near-surface Ferderschnecken 4 and 5. the waves of these near-surface Ferderschnecken 4 and 5 are split, related to its L ngserstreckung. Some a Wellenabschnitt A extends [Jber grS the 3ten Tell of the lung of the trough-like Beh lters 1, the short Wellenabschnitt B umfal3t only few Schraubenwindungen and is for example 60 to 100 cm long. Each other turned ends of the two Wellenabschnitte A and B a Ferderschnecke 4 or 5 are into one another gefiJhrt and into one another stored in each case.

The two Ferderschnecken 6 and 7 as well as the long Wellenabschnitte A more cler near-surface F lying above rderschnecken 4 and 5 by a hydraulic motor 12 are propelled here and a reduction gear 13, which is flanged on to a front wall 14 of the trough-like Beh lters 1. The reduction gear 13 is laid out for dal3 now in such a way, with betriebsm the 13igen employment the long Wellenabschnitte A of the near-surface Ferderschnecken 4 and 5 ven right to the left (Fig. 1) transport, against what the Ferderschnecken 6 and 7 lying above pushes the mixture property to the right into the opposite direction, thus yon left. For the short Wellenabschnitte B the near-surface F rderschnecken 4 and 5 is arranged at the front wall 11 its own driving motor 15 in each case. These driving motors 15 of the two Wellenabschnitte B are reversible to be laid out, daB these short Wellenabschnitte B both in as well as against the clockwise direction be thus propelled kSnnen.

The EntleerungsSffnung 10, in whose boundary region the turning camps of the short Wellenabschnitte B of the near-surface F rderschnecken 4 and 5 lie, is bar by a multipart slidegate valve verschlie. This multipart slidegate valve consists of the two tiltable stored slidegate valves 16 and 17, their drag axes coaxially lies with the axles of the near-surface F rderschnecken 4 and 5, and a slidegate valve lying between them 18 that is linear adjustable. To pray tigung this slidegate valve 16, 17 and 18 k nnen for example piston cylinder units to be planned.

The screw spirals of the Wellenabschnitte A and Bder both near-surface Ferderschnecken 4 and know run in the same direction or against-intimately. In the following description of the function animal mechanism provided, dab these screw spirals of the two Wellenabschnitte A and B ran in the same direction.

This mechanism works now as follows, whereby is presupposed, dal] the slidegate valves 16, 17 and 18 into its SchlieBstellung drove: 0ber the engine! 2 and the reduction gear 13 now, after with raised cover 2 the Beholder 1 was from the top fed, the long Wellenabschnitte A of the near-surface F rderschnecken 4 and 5 in such a way propelled, dab it from right to left (Fig. 2) ferdern, the short Wellenabschnitte B however are in such a way propelled, dal3 them into opposite direction fSrdern. The upper Ferderschneeken 6 and 7 is in such a way propelled, there it from left to right ferdern.

Thus the mixture property and by the against-intimately transporting, short Wellenabschnitte B beer within the range of the front wall 11, lying in the ground range, is transported concerns to the left for the time being iuft and up GET [] FCS, thus dab it into the range of the upper F rderschnecken 6 and 7 arrives and yon these is now pushed again to the right. The brought in property is converted so for a long time in this way in the Beh more ilter 1, until it sufficiently cut up and mixed is. The Sehraubenwendeln of the Ferderschnecken is ckt zweckm igerweise with friction measurers bestL], that are replaceable arranged.

Zerkleinerungsund mixing process is to be terminated and soil now alas usually smudgy and sticky mixture property be delivered, then the slidegate valves become 16, 17 and 18 into their Offenstellung getahren, and the driving motors 15 of the two short Wetlenabschnitte B of the near-surface FSrderschnecken 4 and 5 who that now switched, thus dab these short Wellenabschnitte B yon to likewise transport right to the left, exactly the same as the long Wellenabschnitte A. thereby, shoved out dab alas mixture property is erreieht now obligatorily by the emptying ffnung, which takes only few minutes.

The emptying procedure with a Beh ilter same GrSI3e and same structure lasts during the mechanism after the initially described state of the art up to three quarterly hours, against what with invention in accordance with Ben the mechanism of the Beh more lter in few minutes is vSIlig emptied. Since mechanisms RK 402,638 B ndlichen kind with local waste disposal facilities is used and such mechanisms in a multi-shift operation to usually run, by invention in accordance with fJe arrangement gegenst the mechanism a completely substantial and substantial time saving obtained with the consequence, dab within the intended work time of more Mischvorg nge by the mechanism is interspersed k nnen, when this is with the well-known plant the case. Waste material, partic. biologically decomposable waste is comminuted in a trough-like vessel (1) with sealable lid (32) contg. parallel screw feeders (6, 7) and further ≥ 2 parallel feed screws (4, 5) near the base comprising two shaft sections (A, B) in the longitudinal direction, each having its own drive. The discharge opening (10) of the vessel in the end face of these feeds screws. Pref. the shaft section (B) adjacent to the discharge opening is shorter than the other shaft section. Displaceable or pivotable slide valves (16, 17, 18) are provided for closing the discharge opening. 1, mechanism for cutting up and mixing yon Abf llen, in particular from biologically degradable Abf llen with a trough-like 8eh more lter, to each other parallel lying F6rderschnecken extending into in L ngsrichtung the Beh lters swivelling stored is, whereby within the near-surface range of the Beh ilters at least two F lying next to each other rderschnecken are intended and minaestens a further pair F6rderschnecken dar0berliegend is arranged and the trough-like Beh exhibits more lter at least a Beschickungs6ffnung and at least a EntleerungsSffnung, thereby characterized, dab the Entleerungs6ffnung (10) in a front wall (11) of the Beh lters intended is and at least the near-surface arranged FSrderschnecken (4th 5) jewels in L ngsrichtung seen from two Wellenabschnitten (A, B) exist and everyone of the Wellenabschnitte (A, B) of the F6rderschnekken (4, 5) its own drive and the verschlieBbare EntleerungsSffnung (10) is assigned irn front range of this near the surface arranged F (4, 5) rderschnecken is intended. 2. Mechanism according to requirement 1, by it characterized, dab the emptying ffnung (10) neighbouring lying Wellenabschnitt (B) of the near-surface F rderschnecken (4, 5) is more kLirzer than the other Wellenabschnitt (A) of these split FSrderschnecken (4, 5).

3, mechanism according to requirement 1 or 2, by it characterized, da£ to oversleep-young the EntleerungsSffnung (10) several in to each other parallel levels verschiebbzw. tiltable slidegate valves (16, 17, 18) are intended.

Mechanism according to requirement 1, by it characterized, dab the turning camps of the near-surface F rderschnecken (4, 5) in the boundary region of the EntleerungsSffnung (10) are intended.

5° 7, 8° mechanism according to requirement 3, by it characterized, dab the drag axes of the tiltable slidegate valves (16, 17) coaxially by the axles of the FSrderschnekken arranged within the near-surface range (4, 5) lie.

Mechanism according to requirement 1, by it characterized, dal3 each other turned ends of the respective two Wellenabschnitte (A, B) of a near-surface FSrderschnecke (4, 5) into one another gef Jhrt and are into one another getagert.

Mechanism according to requirement 3, thus, dab between the two tiltable slidegate valves (16, 17) at animal EntleerungsSffnung' (10) a linear adjustable slidegate valve (18) gekennzelchnet is intended.

Mechanism according to requirement 1, by it characterized, dab at least the drive (15) of the short Wellenabschnitte (B) of the F6rderschnecken (4, 5) is reversibly trained.