Presse mit einem blech und ein blech aus stahl

The invention has a press with a sheet metal from steel, e.g. Pressplatte, in particular volume, as well as a sheet metal endIosen for a press to the article.

For the production yon essentially flat-parallel plates with smooth Oberfl iche from plastic masses are well-known different devices. At floor presses loosely preformed plates are used, whereby between an upper and lower stamp a situation of the masses of the product, on it following a Pressplatte, which can be produced, again a situation of the masses of the product etc. which can be produced are then arranged in each case. These plastic masses are then solidified with heat effect and pressure. The production takes place here intermittent.

During a further device for the production of particle boards, plastic foils od. such.

into the gap between endless Bindery of a double volume press those are brought thermally to solidifying masses. Such Bender possesses e.g. a width of 2,0 m and a Linger of 14,0 M. the gleichfSrmige movement of the upper and lower volume betr igt m/min. The W rmeeinbringung both of the lower and upper volume cuber W takes place rmeleitung to and via the upper and lower volume. At least one of the blind exhibits a smooth Oberfl che with a middle roughness of some few IJm, whereas the other volume can exhibit a structuring, with which w it-ends the Pressvorganges a Oberfl& che is igt and solidified gepr.

Stampings exhibit a particularly high Oberfl ichenqualit it, whereby both against the flatness and against the roughness particularly high AnsprL che is placed. In the course of production k6nnen by Inhomogenit Sch that iten at the Pressplatten develop in the press property.

Such Inhomogenit iten is for example due to metallic EinschlL sse in the HSIzern, Produktanh iufungen and such. Thus the stampings, which exhibit a relatively small thickness, beginning with 1 mm up to 2 mm, are deformed Iokal. This Iokalen deformations k6nnen only to be however heavily aligned, so that it is necessary, the equivalent ...... Blechbereicha_uszutau. A such exchange can either by the exchange of a metal strip, which itself (J6er those-entire-broad of the sheet metal extended or also via exchange of a round range take place. Here in accordance with il% EP-A-0 820,833 an appropriate range is removed mechanically or by plasma cutters from the sheet metal.

This distance takes place via FShrung of the plasma cutter or a mechanical gumption mechanism along one at the sheet metal 0ber electromagnets or vacuum August elements, which are connected with a source of vacuum, F0hrung held. After distance of a Ronde out of the sheet metal a treatment of the Schnittfl takes place ichen in the sheet metal, whereby the working on tool, is moved a Bruiser, again along the F fastened to the volume hrung 0ber an electrical engine. The Bearbeitungssp ine od. such is caught in a cup, which is arranged underneath the endless volume. Then one einzuschwei end to Ronde begun, which is specified again more ber a mounting plate in the erw0nschten position. Then again more ber the mechanical F (Jhrung and an electric motor a Schwei mechanism, and zw. a TIG Schweil%ger t, become moved. In such a way received Schweil%naht can mechanically, e.g.

by deformation at low temperatures to be worked over again. Such Schwei n§hte was in such a manner produced the fact that the same a substantial 0berstand approximately (Jber of the adjacent uninfluenced Stahlbandoberfl che exhibit, so that in the anschlie ends to treatment one mSglichst gleichm l ige even adjustment of the Schweil approaches and anschliel ends ranges was reached, however must the penetration be removed, whereby a further recess took place when sharpening, e.g. with an angle sander.

Described in the EP 0,031,613 a2 a procedure for the production of a Pr igegravur on one by a Schwei approaches connected metallic continuous volume. In order Inhomogenit iten with the Schweil%naht to avoid, the continuous volume with galvanically separated metal-laminated are provided. This galvanic laminates Qbernimmt however due to gleichm& r igen separating the same mechanical points of discontinuity up.

3 RK 413,679 B in the EP 0,113,813 is likewise a metallic continuous volume with structured Oberfl che descriptive. The metal band consists rtbaren or by W irmeoder radiation treatment of one ausscheidungsh in the KristallgefiJge inderlichen metal alloy. The alloy of the Schweil approaches soil with the metal structure of the ungeschweil3ten of base material ident its, whereby with the structuring no differences between Schweil3naht are to arise and ungeschweil to tem material. Like this to be reached soil, can not be taken from this patent application.

In the EP 0,402,377 B1 a procedure for the production of a metallic continuous volume more igemuster provided with a Pr is descriptive. The task consists of producing different EndIosb Indian with the same Pr more igemuster. Here yon a casting is taken to an endless volume in form of an endless flexible plastic volume, on which by Aufgalvanisieren a metal-laminated is separated on the Abdruckfl iche of the plastic volume. Thus a reproduction of a work vertic. stabil. can become iche f0r an endless volume durchgef0hrt, however this procedure is on certain metals, and zw. such, which is electrolytically separated kSnnen, eingeschr inkt, so that with in such a way received volume a shorter life span is to be expected.

In the DE 41 34 976 A1 for the avoidance of Inhomogenit itsstellen by the Schweil3naht a certain steel alloy is suggested to metallic compacted strip, which is treated before the galvanic structural giving in a S iurebad. Here it is necessary that the entire Aul becomes polished enund Innenfl iche of the press volume on one gleichm IL ige material thickness. Here a particularly high work expended is thus present.

Is set to the available invention to the goal of creating a sheet metal and a press with sheet metal into which plastic masses is thermally subjected, whereby Schweil n did not ihte, which is due for example to exchange of besch digten ranges of the sheet metal, optically perceptible Inhomogenit itsstellen in the produced product causes.

endless volume, with a thickness of 1.0 mm up to 3.0 mm and an averaged Rautiefe from 1,0 IJm to 4.0 pm for the thermal shaping and solidification of plastic masses, e.g. f0r particle boards, plastic foils, and a heating mechanism, which introduce {3ber a level of work of the sheet metal W irme into the plastic masses, which approaches a more einoder multi-layer stumpfgeschweil Te Schweil from kind-same material, in particular identer composition, to the steel exhibits, exist essentially in the fact that a Oberfl the iche Schweil approaches in a gekn3mmten Fiche lies, which is appropriate for this gegeneberliegenden level of the sheet metal, which one grSl ten normal distance, in particular from 30 pm to 50 in particular between the level of work and one IJm, to the level of work of the sheet metal exhibits, and the fact that a cut curve of the Oberfl the iche Schweil approaches and on both sides to the level of work anschliel ends ranges with one normal level on the level of work of the sheet metal is constant, and a further Oberfl the che tail approaches at that the level of work gegenLiberliegenden side of the sheet metal in a Fiche lies, which removes maximally 20 tJm from the level, in particular in the level, the sheet metal lies and the Schweil approaches a minimum thickness exhibits, which is smaller at least 50 pm than the thickness of the sheet metal.

It was quite Liberraschend that a Arbeitsfl& che, a such Unregelm il%igkeit, like it the gegen0ber of the 0brigen Oberfl the iche lowered Schweil3naht represents, to optical Inhomogenit did not iten with the produced product f0hrt. This d0rfte on the fact zur0ckzuf0hren its that the Inhomogenit tsstellen, which so far with Schwei n ihten arose is conditioned on a W lacking irmeleitung by the steel sheet into the product. By the training of the Schweil it approaches can on the one hand be achieved that no identation places at the work vertic. stabil. iche of the volume arise, whereby the life span of the sheet metal can be substantially erhSht and on the other hand the range of the Schweil can approaches than such is kept particularly small there the boundary regions are only smaller melted to m0ssen. By the 4 RKs 413,679 B specific training of the Schweil3naht at that the work vertic. stabil. iche gegenLiberliegenden Oberfl iche of the stamping or volume it is reached that the W approaches rmeLibergang from the heating mechanisms in the press on the volume and/or stamping in approximately equal as outer erhalb the Schwei take place can.

Schliel3t the Oberfl the che Schweil3naht and the anschliel3enden of ranges with the level of work an angle avon maximally 4 ' in particular maximally 2 ', then knows on the one hand a particularly small mechanical treatment of the Schwei approaches and anschlie to end ranges take place, whereby the product in its optical manifestation not beeintr& is chtigt.

Is if the Schweil approaches in itself closed, then also a substitution of small flat steel bar can chen the sheet metal to take place, whereby an optical Beeintr can be avoided also here chtigung the produced product.

Betr igt those width of the Schweii%naht with that reciprocally anschliel3enden ranges, which are lowered more gegenLiber the level of work, alas 40bis 70-fache, in particular 50bis 60ofache, the thickness of the sheet metal, then is a particularly good process of the Uberganges between Schwei - approaches and the level of work of the sheet metal given, whereby further the Bearbeitungsfl& chen are relatively small held.

Is if the Schweil approaches in the cross section doppeI-V-f6rmig, then a particularly good W& can; rmeQbergang between sheet metal and w units irmeQbertragenden guaranteed its, whereby further a particularly high firmness is it-performed gew.

The cut curve of the Oberfl& points; the che Schweil3naht and that on both sides the same anschlieI nden ranges at that the level of work gegenLiberliegenden level with one normal level on the level of work at least per a point of discontinuity to each side of the Schwei approach up, then knows a particularly high Planit it the Schweil3naht at that the level of work gegenQberlie…. gen_den level to be reached, whereby the two points of discontinuity Qberraschenderweise no Beeintr& chtigung to e European Union aenden product causing,--however on the other hand erm6gli….

it chen that the treatment of the Schweil%naht and the adjacent ranges can be kept particularly small, so that particularly even training can be achieved.

Invention in accordance with 13e the sheet metal from steel, e.g. Stamping, in particular endless volume, with a thickness between 1.0 mm and 3.0 mm, an averaged Rautiefe of 1,0 pm to 4.0 pm and two flat-parallel levels, of which one serves as level of work, which exhibits a Schweil3naht from kind-same material, in particular identer composition to the steel, exists essentially in the fact that a Oberfl the iche Schweil3naht lies in a gekr0mmten Fiche, which in particular between the level of work and this gegen0berliegenden is appropriate level of the sheet metal, which one gr) for i%ten normal distance, in particular from 30 pm to pm, to the level of work of the sheet metal exhibits, and that a cut curve of the Oberfl the che Schwei approaches and on both sides to the level of work anschlie ends Ranges with one normal level on the level of work of the sheet metal is constant, and a further Oberfl the che Schwei approaches the level of work at that gegenLiberliegenden side of the sheet metal into a flat steel bar iche lies, those maximally 20 IJm far away of that level, in particular in the level, the sheet metal lies, and the Schwei approaches a minimum thickness exhibits, which is smaller at least 50 IJm than the thickness of the sheet metal. With a such sheet metal it can be achieved that to these Fiche products which can be casted obtains an optically homogeneous impression, whereby Schweil3n& hte, which are necessary from different GrQnden, not st6rend in the optical general impression of the product which can be produced is. The Oberfl& che of the sheet metal however quite points an optical Inhomogenit& t up, and it was 0berraschend that by producing a Inhomogenit itsbereiches can be achieved on the Oberfl che of the volume a homogeneous product.

Schliel%en the Oberfl& the che Schweil3naht and the anschliel3enden of ranges with the level of the level of work an angle of maximally 4 Winkelminuten, in particular RK 413,679 B like that is at the sheet metal an optical Inhomogenit it due to the different Retiexionswinkel of the optical jets given to 2 Winkelminuten, however no Inhomogenit itsstelle is recognizable and this with photographic showed with the produced product.

Is if the Schweil approaches in itself closed, thus k6nnen also smaller Inhomogenit itsbereiche to be exchanged, whereby no optical centring takes place on the substituted range in the product, but an optical adjustment to more anschlier end ranges is present.

Betr igt those width of the Schweil approaches with that reciprocally anschliel ends to ranges, those in the gekrGmmten Fl& che are appropriate, the 40bis 70-fache, in particular for 50bis 60-fache, the thickness of the sheet metal, then a particularly favourable adjustment of the Oberfl is the iche Schweil approaches and the anschliel%enden ranges under Ber icksichtigung the total thickness of the Schweil approaches given, so that both che under Ber is carried for the firmness and the training of the work vertic. stabil. cksichtigung the W irmeBbertragung regarding the optically particularly homogeneous training of the sheet metals calculation.

If the Schweil3naht is in the cross section doppeI-V-f6rmig, then a particularly homogeneous 0bergang is along the entire thickness of the sheet metal between Schweil approaches and sheet metal given, whereby the total width of the Schweil3naht can be kept smaller due to the double-sided Schweil ung.

If the cut curve of the further Oberfl exhibits the iche Schweil3naht and that on both sides the same anschliel3enden of ranges at that the level of work gegeniJberliegenden level with one normal level on the level of work at least per a point of discontinuity to each side of the Schweil approaches, then particularly even training that knows the work vertic. stabil. che gegenGberliegenden side of the Schweil approaches to be caused, whereby it was berraschend quite L that the two points of discontinuity bezL resembled the W irmeleitung the sheet metal on the level of work none unerwL nschten effects exhibit and the points of discontinuity further none ...... negative influence on the life span of an endless volume exhibit.

In the following the invention becomes on the basis the design n& ago erl& utert.

Show:

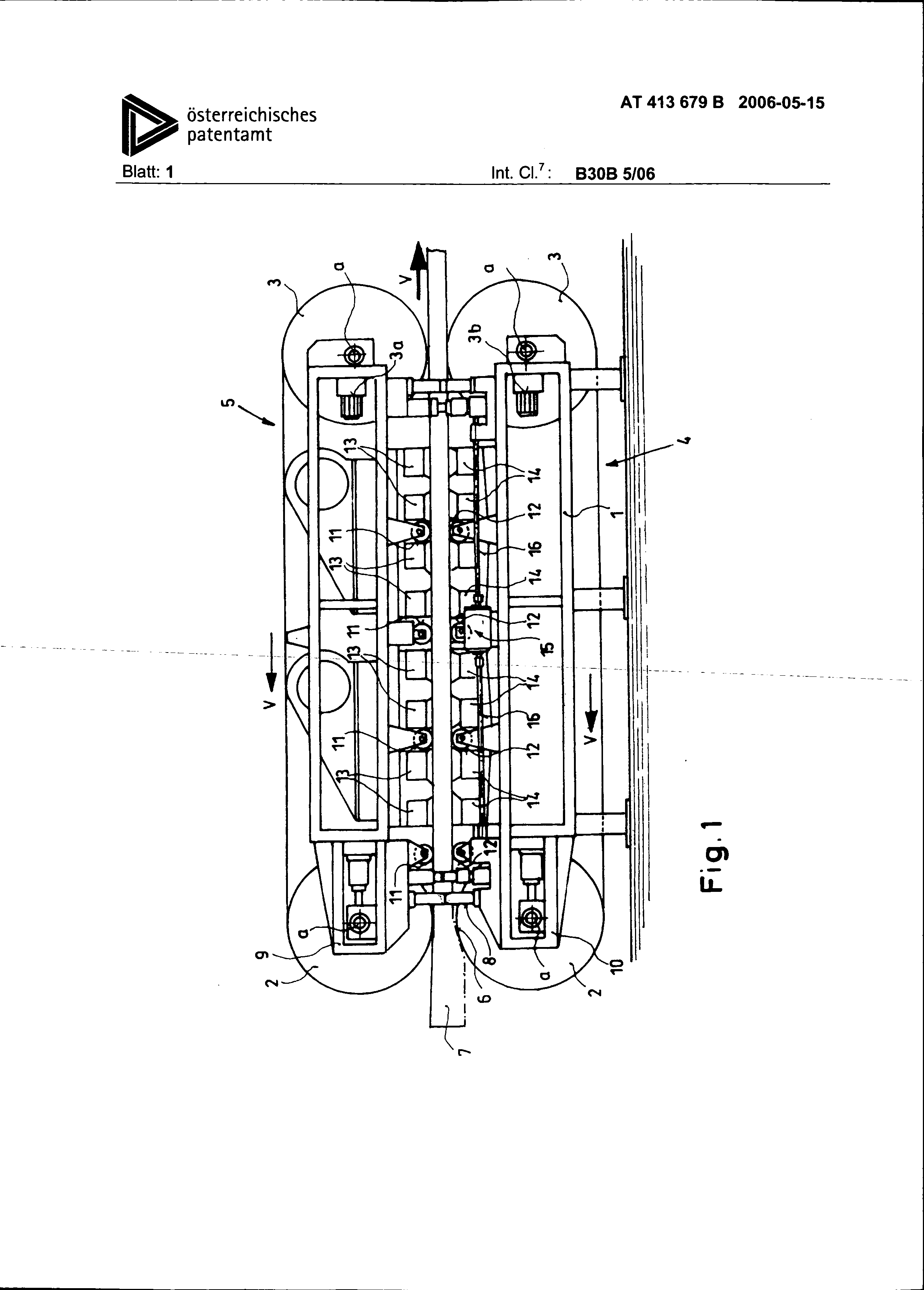

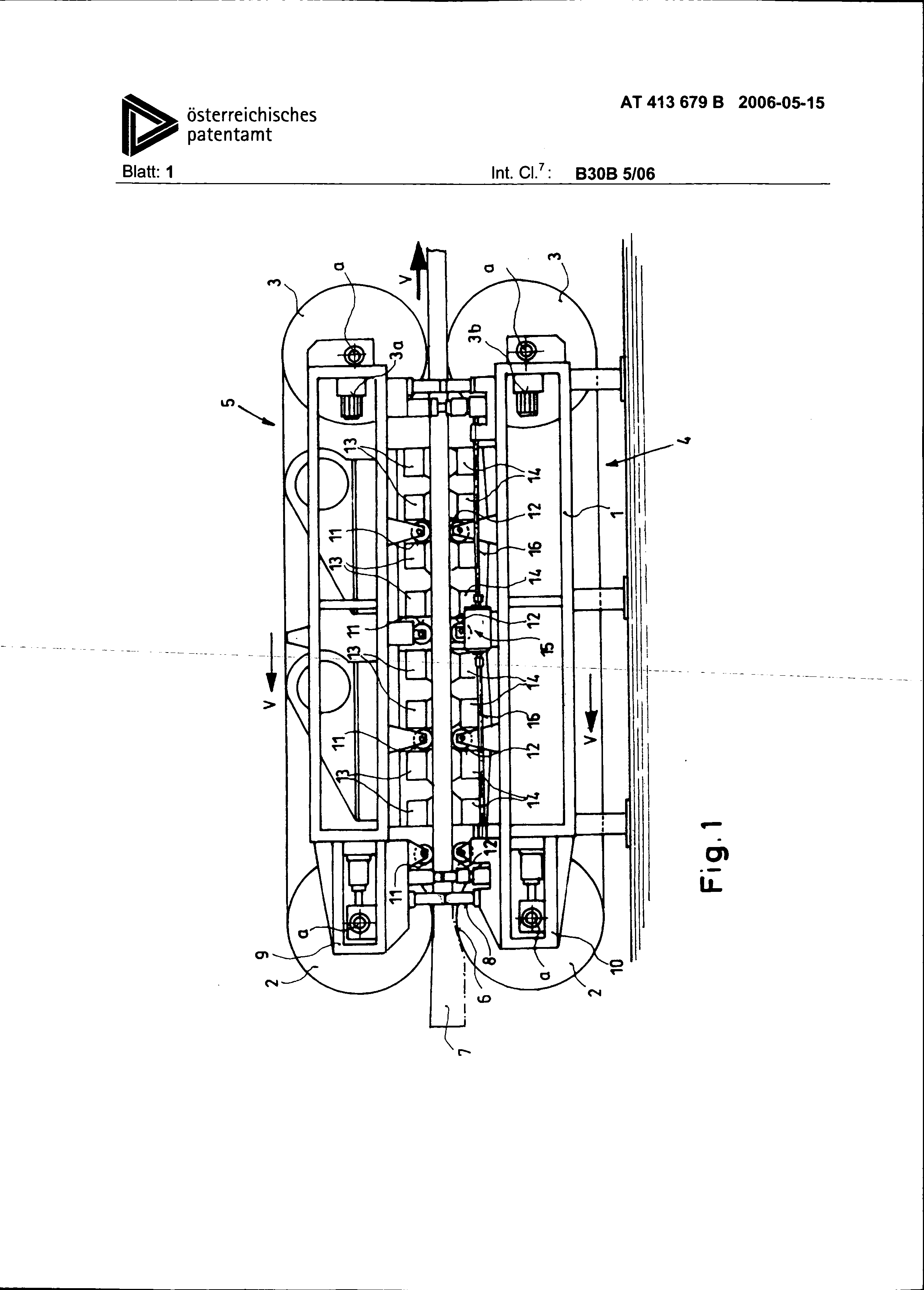

Fig. 1 a double volume press in schematic representation, Fig. 2 the cut by a sheet metal from steel with a Schweil%naht.

In Fig. 1 represented double volume press exhibits a framework 1, which igt the entire mechanism, in particular the guide rollers 2 and driving pulleys 3, tr. L ingsabstand the axles A of the roles betr igt 720 mm. A lower volume 4 and an upper volume 5 with a width are moved by these roles by 1,950 mm from highly polished steel toward the arrow v with same speed. By the two guide rollers 2 with a diameter of 1,800 mm and the upper and lower Bender 4, cooperated with them, 5, a gap 6 is formed, which is only in the range of the guide rollers, into which a pre-product 7 from vividly ductile masses is brought. The exact distance of the guide rollers 2 is regulated by hydraulic stamps 8, the one distance between the upper trigger 9 {Jber the guide rollers 2 and the lower Tr& adjusts more ger 10 f0r the lower guide rollers 2. In direction of motion of the Bender seen an upper and lower supporting roller 11, 12 after the intake gap, which the Bender 4, 5 to carry, is. The driving pulleys 3 exhibit in each case their own driving motor 3a and 3b. The supporting rollers exhibit a common drive 15, fLir the synchronous movement of this concern tract. In the Gest Inge 16 of the common drive 15 represented flexible disks are not intended, around geringf0gige Unfluchtigkeit of the Gest& nges to adjust and zw. the waves to each other. If necessary, k6nnen other joints, as for example universal joints, to the employment arrive. The upper roles of 11 and the lower roles of 12, those trained in the horizontals and vertical one 6 RKs 413,679 B relocatable its k0nnen to keep have the task to carry the upper and/or lower volume and easily aligning if necessary toward on the other hand volume. By the upper heating mechanism 13 and lower heating mechanism 14 W irme by direct contact 0ber of sharpening elements is introduced to the upper volume 5 and the lower volume 4.

In Fig. a thickness d1 exhibits 2 on average represented endless volume 4 yon 2.6 mm, which averaged Rautiefe determines according to DIN M 1115, betr igt 1.5 pm. The Schwei approaches 17 is trained doppelV fSrmig and exhibits a thickness d2 of 2.550 mm. The volume 4 exhibits an upper level of work 18 and one this gegen0berliegenden level 19. The Schnittfl chen both the volume 4 and the Schwei approaches 17 lies in one normal level on the level of work 18. The Oberfl che 20 lies in a gekr0mmten flat steel bar che 21, which exhibits and also asymmetrically be trained can a grSI3ten normal distance x of 50 pm to the level of work 18. The Oberfl che 20 the Schweil approaches 17 as well as the two anschliel ends ranges 22 and 23 exhibits a maximum angle A, which of that is included gekr0mmten flat steel bar che 21 with the level of work 18, of 2 Winkelminuten. The gekr0mmte Oberfl iche 21 extends 0bet 150 mm and betr igt from there the 58-fache of the thickness d1 of the sheet metal. The gekr0mmte flat steel bar che 21 is constant on average and constantly goes into the level of work 18 0ber, whereby the angle A is constantly removing trained.

At the lower surface of the sheet metal a further level is 19, whereby the Fl& che 24 the Schweil3naht in the level 19 to lie comes. The flat steel bars che 24 can a maximum distance to the level 19 of pm exhibit. On both sides the Schweil3naht are intended identation places 25 and 26, the points of discontinuity on average are.

During inserting a Blechronde into the endless volume one proceeds as follows.

The Inhomogenit tsstelle in the volume is determined and planned in the center the same a drilling by the volume. By this drilling a centering pin gef0hrt, 0ber which one ....... electromagnets at the volume FLihrung along is a_ngeordnet. On the other side a cup is arranged at the centring tiff. Along the Fi] hrung becomes more ein=PlasrfiaSchneider with one elektri….

schen tension of 380 V, compressed air with 5,5 bar and with a speed 2 m/min gef0hrt. After a Blechronde with 300 mm in diameter was cut out and removed, a Freshen of the lip takes place, whereby the cut ran essentially normally for the level of the volume. It then a Blechronde with a lip, which is normal to the level of work, their Aul enabmessungen inserted with cut C) ffnung 0bereinstimmt, whereby below both the sheet metal and the Blechronde a mounting plate from copper was intended. The Blechronde was held zus itzlich 0ber for electromagnets in its situation. With a TIG burner electrical tension 220 V and 7 litres argon per minute was put through to melt opens of the sheet metal and the Blechronde a Schweil3naht, whereby the Blechronde before the actual Schweil procedure was filed into the sheet metal.

The Schweil procedure becomes with a speed of 140 mm/min on the one side durchgef0hrt, on which the F0hrung at the other page is situiert and a Schweil procedure as described, however with a smaller depth took place again. After completion of the Schweil of procedure a deformation at low temperatures took place via H mmern, on which on the side and on the gegen0berliegenden level the SchweiP approached the level of work with a grinding wheel, which was pneumatically claimant and exhibited a rubber plate with a diameter of 75 mm and first with grinding wheels K 80, K 120 and anschliel3end was worked on and/or polished with a fleece. Sharpening and polishing were accompanied by a measuring procedure, so that in Fig. 2 represented configuration to be kept could do. By cold deforming knew the Schweil approaches and the adjacent ranges at that the level of work gegen0berliegenden side into the level of the sheet metal to be put. The total thickness amounted to 2.550 mm. An automatic manufacturing is likewise m6glich.

A further Ronde likewise with a TIG Schwei more ger it eingeschweil3t, whereby those were kept above angef0hrten parameter and a Schweil wire with identer Zusammen7 RK 413,679 B setting came to the sheet metal to the employment. The treatment of the Schweil approaches as was above ausgefLihrt.

With endless volume, which exhibited three eingeschweil Te Ronden with 300 mm in diameter, whereby two erfindungsgem& l were out-arranged and a further Ronde with 300 mm, with which the Schweil approached the thickness of the sheet metal exhibited, whereas the two penetration ranges on both sides the Schwei approaches with angle sander was processed, so that on both sides the Schweir approaches in for instance ringf6rmige hollows with a depth of 50 pm was present, and which Schweil approached was likewise coldly worked on, so that the root the same came to likewise lie in lo the level of the sheet metal, continuously a centralclose fiber board with 9 mm was produced. It could be determined by markings at the volume in each case whether with the appropriate range of the volume also invention in accordance with l eingeschweir ten Ronden or with one not invention in accordance with IL eingeschweil ten Ronde the range concerned of a plate one manufactured. Ever three disk samples then bluntly in addition, as actually admits, subjected after a sharpening procedure under a beam of light of 30°von seven persons of an optical investigation, whereby from all persons ringfSrmige Verf does not irbungen with the fiber boards manufactured with Ronde ter invention in accordance with i eingeschweil be observed could, however with the fiber boards invention in accordance with eingeschweil ten Ronden by no person a Verf rbung to be manufactured also determined could.

PatentansprLiche:

1. Press with a sheet metal (4, 5) from steel, e.g. Pressplatte, in particular endless volume, with a thickness (d1) of 1.0 mm up to 3.0 mm and an averaged Rautiefe from 1,0 IJm to 4.0 pm for the thermal shaping and solidification of plastic masses (7), e.g.

fiJr particle boards, plastic foils, and a heating mechanism (13, 14), a ber level of work (18) of the sheet metal (4, 5) Warmed into the plastic masses introduces, which approach one ........... in or multi-layer stumpfgeschweil Te Schweil (! it exhibits 7) from kind-same material, in particular identer composition, to the steel, g-ekenn-zeidhrfet thus that….

a Oberfl che (20) the Schweil approaches (17) in one gekr {Jmmten Fl& che (21) lies, which is appropriate for these in particular between the level of work (18) and one approximately {Jberliegenden level (19) of the sheet metal, which one grSl ten normal distance (x), in particular yon 30 IJm to 50 pm, to the level of work (18) of the sheet metal (4, 5) it exhibits and that a cut curve of the Oberfl che (20) approaches the Schweil (17) and on both sides to the level of work (18) anschliel ranges (22, 23) with one normal level end on the level of work (18) of the sheet metal (4, 5) is constant, and a further Oberfl iche (24) the Schweil approaches (17) at that the level of work (18) gegenLiberliegenden side of the sheet metal (4, 5) in a Fiche lies, which removes maximally 20 pm of that level (19), in particular in the level (19), the sheet metal (4, 5) lies and the Schwei approaches (17) a minimum thickness (d2) exhibits, which is smaller at least 50 IJm than the thickness (d1) of the sheet metal.

Press by a sheet metal according to requirement 1, by the fact marked that the Oberfl iche (20) approaches the Schweil (17) and anschliel ranges (22, 23) with the level of work (18) end an angle (A) of h6chstens 4 Winkelminuten, in particular from h6chstens 2 Winkelminuten, einschliel to EN.

3. Press by a sheet metal according to requirement 1 or 2, by the fact marked that the Schwei approaches (17) is self-contained.

Press by a sheet metal after one the Anspr che 1, 2 or 3, by the fact marked that those approaches width of the Schweil (17) with that reciprocally anschliel ends ranges (22, 23), which more gegenLiber the level of work (18) is lowered, the 40bis 70-fache, in particular the 50bis 60-fache, the thickness (d1) of the sheet metal (4, 5) betr igt. The invention relates to a press, comprising a steel plate (4, 5) with a thickness (d1) of between 1.0 mm and 3.0 mm and a surface roughness of between 1.0 mu m and 4.0 mu m and comprising a heating device (13, 14). Said heating device introduces heat into the plastic materials using a working plane of the steel plate (4, 5). The plate has a single-layer or multi-layer, butt-welded welding joint (17), whereby the surface (20) of said welding joint (21) is located in a concave surface which is located at a maximum normal distance, in particular, between 30 mu m and 50 mu m from the working plane (18) of the steel plate (4, 5). A surface intersection curve of the welding joint (17) and the adjacent areas of the working plane which lie on either side, is continuous with a normal plane, in relation to the working plane (18) of the steel plate (4, 5). The surface (20) of the welding joint (17) which is on the opposite side of the steel plate to the working surface, lies in a surface which is located at a maximum distance of 20 mu m from the plane (19) of the steel plate. The welding joint (17) has a minimum thickness (d2) which is at least 50 mu m lower than the (d1) of the steel plate. setting to the sheet metal to the employment came. The treatment of the Schweil approaches as was above ausgefLihrt.

With endless volume, which exhibited three eingeschweil Te Ronden with 300 mm in diameter, whereby two erfindungsgem& l were out-arranged and a further Ronde with 300 mm, with which the Schweil approached the thickness of the sheet metal exhibited, whereas the two penetration ranges on both sides the Schwei approaches with angle sander was processed, so that on both sides the Schweir approaches in for instance ringf6rmige hollows with a depth of 50 pm was present, and which Schweil approached was likewise coldly worked on, so that the root the same came to likewise lie in lo the level of the sheet metal, continuously a centralclose fiber board with 9 mm was produced. It could be determined by markings at the volume in each case whether with the appropriate range of the volume also invention in accordance with l eingeschweir ten Ronden or with one not invention in accordance with IL eingeschweil ten Ronde the range concerned of a plate one manufactured. Ever three disk samples then bluntly in addition, as actually admits, subjected after a sharpening procedure under a beam of light of 30°von seven persons of an optical investigation, whereby from all persons ringfSrmige Verf does not irbungen with the fiber boards manufactured with Ronde ter invention in accordance with i eingeschweil be observed could, however with the fiber boards invention in accordance with eingeschweil ten Ronden by no person a Verf rbung to be manufactured also determined could.

PatentansprLiche: 1. Press with a sheet metal (4, 5) from steel, e.g. Pressplatte, in particular endless volume, with a thickness (d1) of 1.0 mm up to 3.0 mm and an averaged Rautiefe from 1,0 IJm to 4.0 pm for the thermal shaping and solidification of plastic masses (7), e.g.

fiJr particle boards, plastic foils, and a heating mechanism (13, 14), a ber level of work (18) of the sheet metal (4, 5) Warmed into the plastic masses introduces, which approach one ........... in or multi-layer stumpfgeschweil Te Schweil (! it exhibits 7) from kind-same material, in particular identer composition, to the steel, g-ekenn-zeidhrfet thus that….

a Oberfl che (20) the Schweil approaches (17) in one gekr {Jmmten Fl& che (21) lies, which is appropriate for these in particular between the level of work (18) and one approximately {Jberliegenden level (19) of the sheet metal, which one grSl ten normal distance (x), in particular yon 30 IJm to 50 pm, to the level of work (18) of the sheet metal (4, 5) it exhibits and that a cut curve of the Oberfl che (20) approaches the Schweil (17) and on both sides to the level of work (18) anschliel ranges (22, 23) with one normal level end on the level of work (18) of the sheet metal (4, 5) is constant, and a further Oberfl iche (24) the Schweil approaches (17) at that the level of work (18) gegenLiberliegenden side of the sheet metal (4, 5) in a Fiche lies, which removes maximally 20 pm of that level (19), in particular in the level (19), the sheet metal (4, 5) lies and the Schwei approaches (17) a minimum thickness (d2) exhibits, which is smaller at least 50 IJm than the thickness (d1) of the sheet metal.

Press by a sheet metal according to requirement 1, by the fact marked that the Oberfl iche (20) approaches the Schweil (17) and anschliel ranges (22, 23) with the level of work (18) end an angle (A) of h6chstens 4 Winkelminuten, in particular from h6chstens 2 Winkelminuten, einschliel to EN. 3. Press by a sheet metal according to requirement 1 or 2, by the fact marked that the Schwei approaches (17) is self-contained.

Press by a sheet metal after one the Anspr che 1, 2 or 3, by the fact marked that those approaches width of the Schweil (17) with that reciprocally anschliel ends ranges (22, 23), which more gegenLiber the level of work (18) is lowered, the 40bis 70-fache, in particular the 50bis 60-fache, the thickness (d1) of the sheet metal (4, 5) betr igt.

8 RKs 413,679 B RST press by a sheet metal after one the AnsprGche 1 to 4, by the fact marked that the Schweil approaches (17) in the cross section is doubly V-fSrmig.

Press by a sheet metal after one the AnsprGche 1 to 5, by the fact marked that the cut curve of the Oberfl lche (24) approaches the Schweir (17) and on both sides the same anschliel ranges at that end to that to the level of work (18) gegenGberliegenden side with one normal level on the sheet metal (4, 5) at least per a point of discontinuity (25, 26) to each side of the Schwei approaches exhibits.

Sheet metal (4, 5) from steel, e.g. Stamping, in particular endless volume, with a thickness (d1) between 1.0 mm and 3.0 mm, an averaged Rautiefe of 1,0 pm until 4.0 IJm and two flat-parallel levels (18, 19), of which one as level of work (18) serves, a Schweil approaches (17) from kind-same material, in particular identer composition to the steel, exhibits, by the fact characterized that a Oberfl& che (20) the Schweil approaches (17) in one gekr {3mmten Fl& che (21) lies, those in particular between the level of work (18) and this gegenGberliegenden level (19) of the sheet metal (4, 5) lies, which one gr (5 ten normal distance (x), in particular of 30 pm to 50 pm, to the level of work (18) of the sheet metal (4, 5) it exhibits and that a cut curve of the Oberfl iche (20) approaches the Schweil (17) and on both sides to the level of work (18) the anschlie ends ranges (22, 23) with one normal level on the level of work (18) of the sheet metal (4, 5), and a further Oberfl che (24 is constant) the Schweil approaches (17) at that the level of work (18) gegenGberliegenden side of the sheet metal (4, 5) in a Fl& che is appropriate, which removes maximally 20 pm of that level (19), in particular in animal level (19), the sheet metal (4, 5) lies, and the Schweil approaches (17) a minimum thickness (d2) exhibits, those at least 50 pm than the thickness (d1) of the sheet metal (4, 5) is smaller.

Sheet metal (4, 5) from steel according to requirement 7, by the fact characterized that the Oberfl& che (20) the Schweil approaches (17) and anschlier ranges (22, 23) with the level of the acre end ...... beitsebene (t-8) a Winkel_ (o) _von to h6chstens 4 W nke m slots, in particular h chstens 2 Winkelminuten, einschliel EN. - ............... 9. Sheet metal (4, 5) from steel according to requirement 7 or 8, by the fact characterized that the Schweil approaches (17) is self-contained.

Sheet metal (4, 5) from steel according to requirement 7, 8 or 9, by the fact characterized that those approaches width of the Schweil (17) with that on both sides anschliel ends ranges (22, 23), which into the gekrOmmten flat steel bars che (21) lies, the 40bis 70-fache, in particular 50bis 60-fache, the thickness (d1) of the sheet metal (4, 5) betr gt. 11. Sheet metal (4, 5) from steel after one the AnsprLiche 7, 8, 9 or 10, by the fact characterized that the Schweil approaches (17) in the cross section is doppeI V fSrmig.

Sheet metal (4, 5) from steel after one the AnsprGche 7 to 10, by the fact characterized that the cut curve of the further Oberfl che (24) approaches the Schweil (17) and to that on both sides the same anschlie ranges at that end to the level of work (18) gegenLiberliegenden level (19) with one normal level on the level of work (18) at least one point of discontinuity each (25, 26) to each side of the Schweil approach (17) exhibit.

so Hiezu 2 sheets designs