Behälter und verpackungseinheit

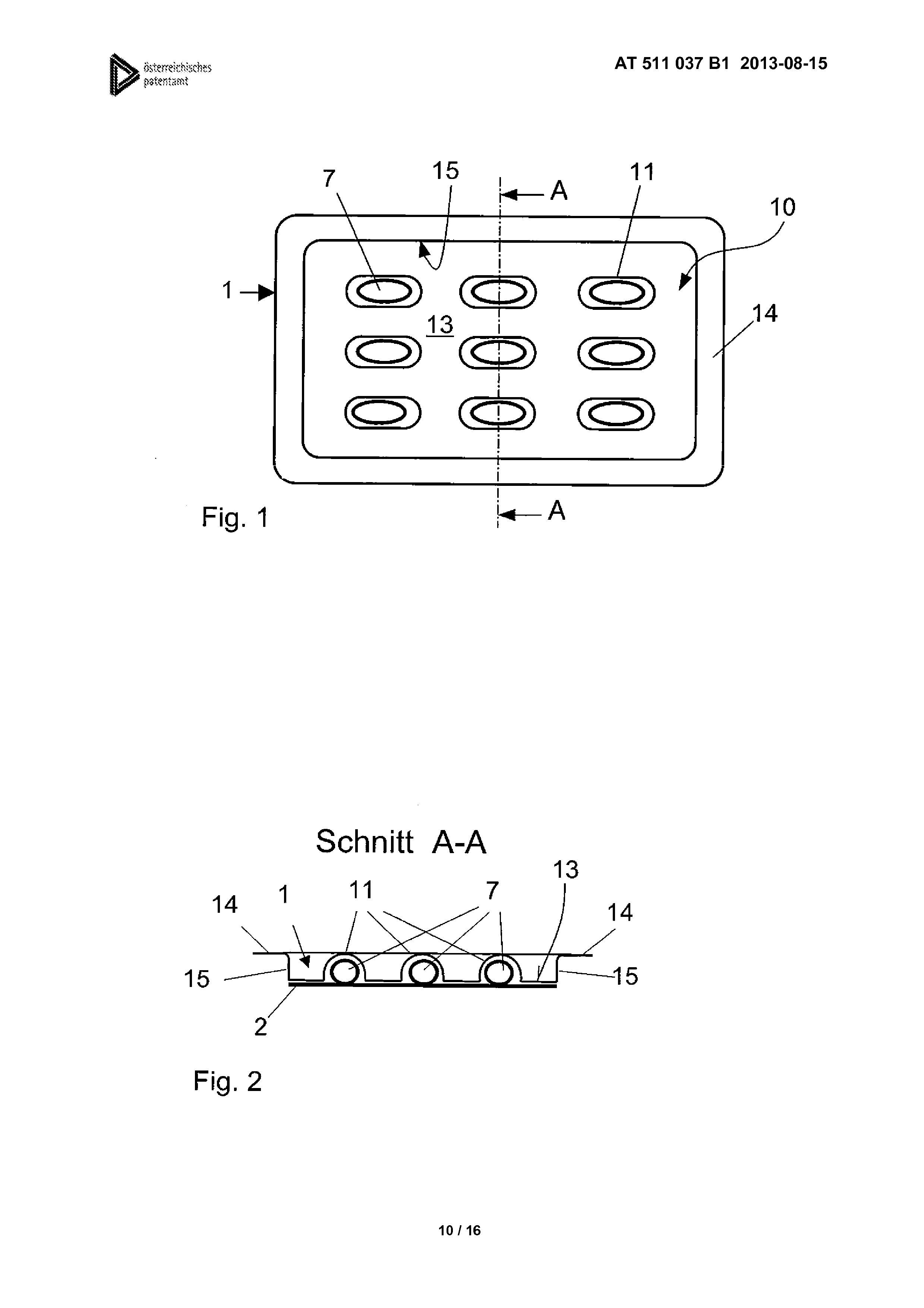

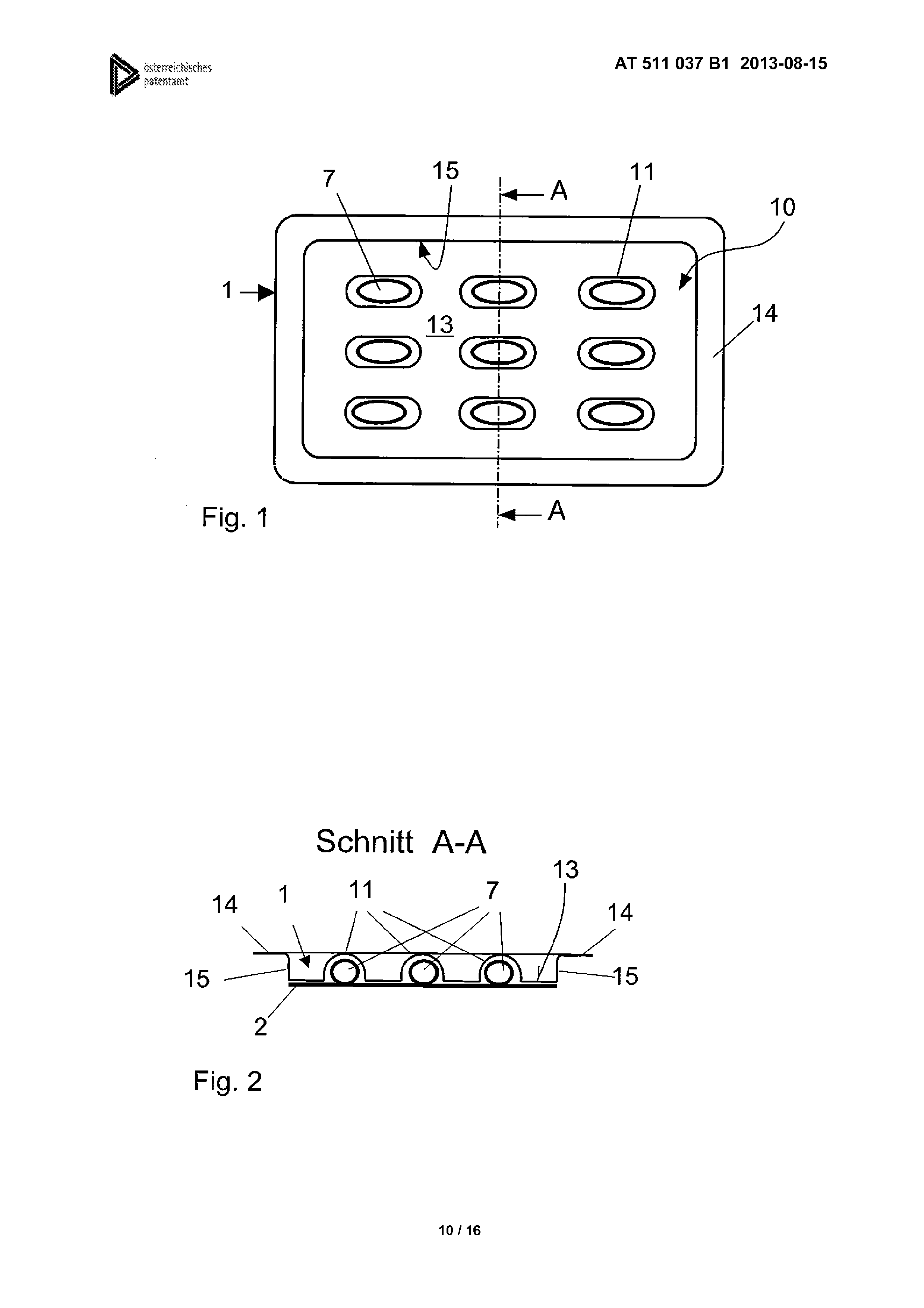

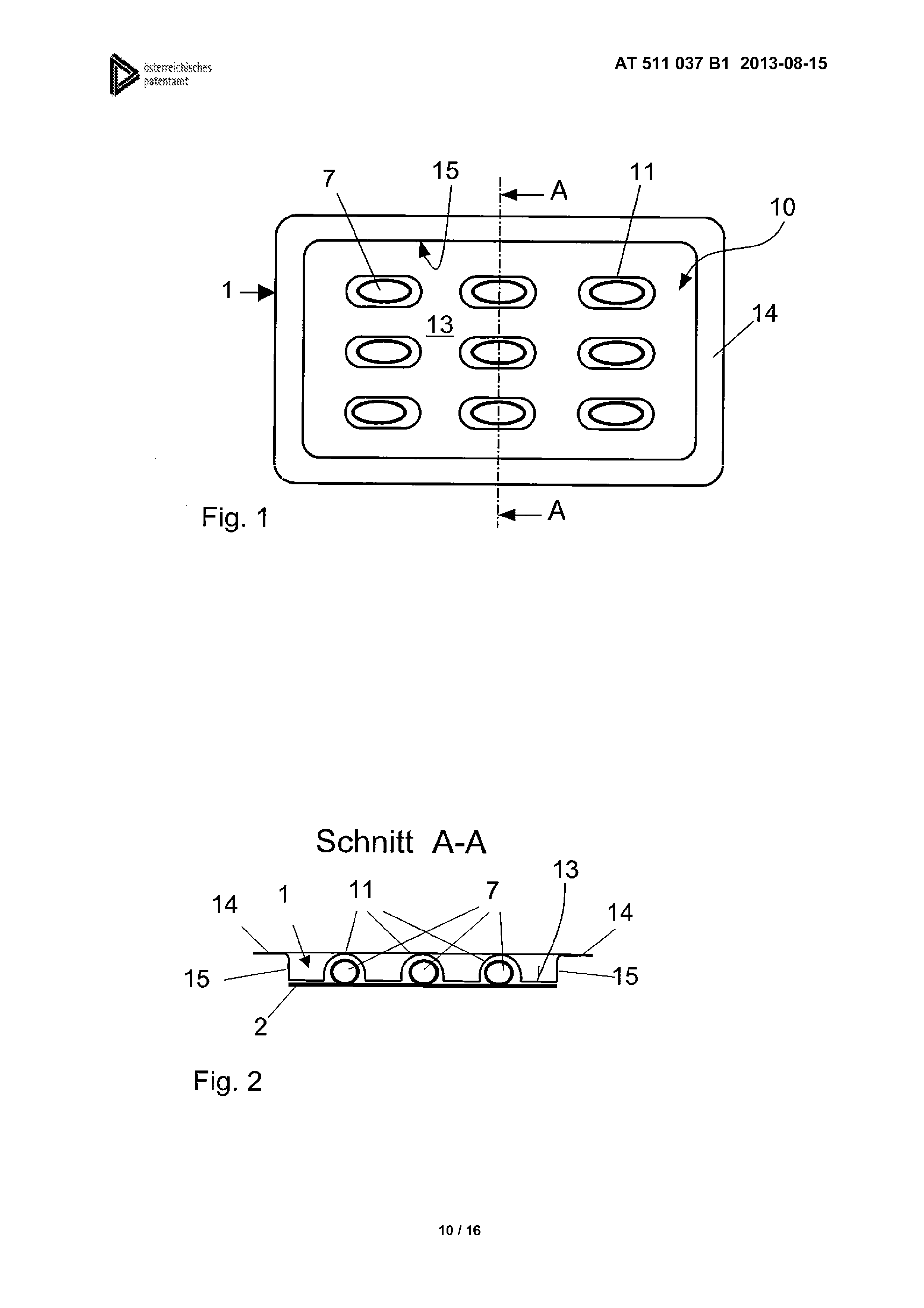

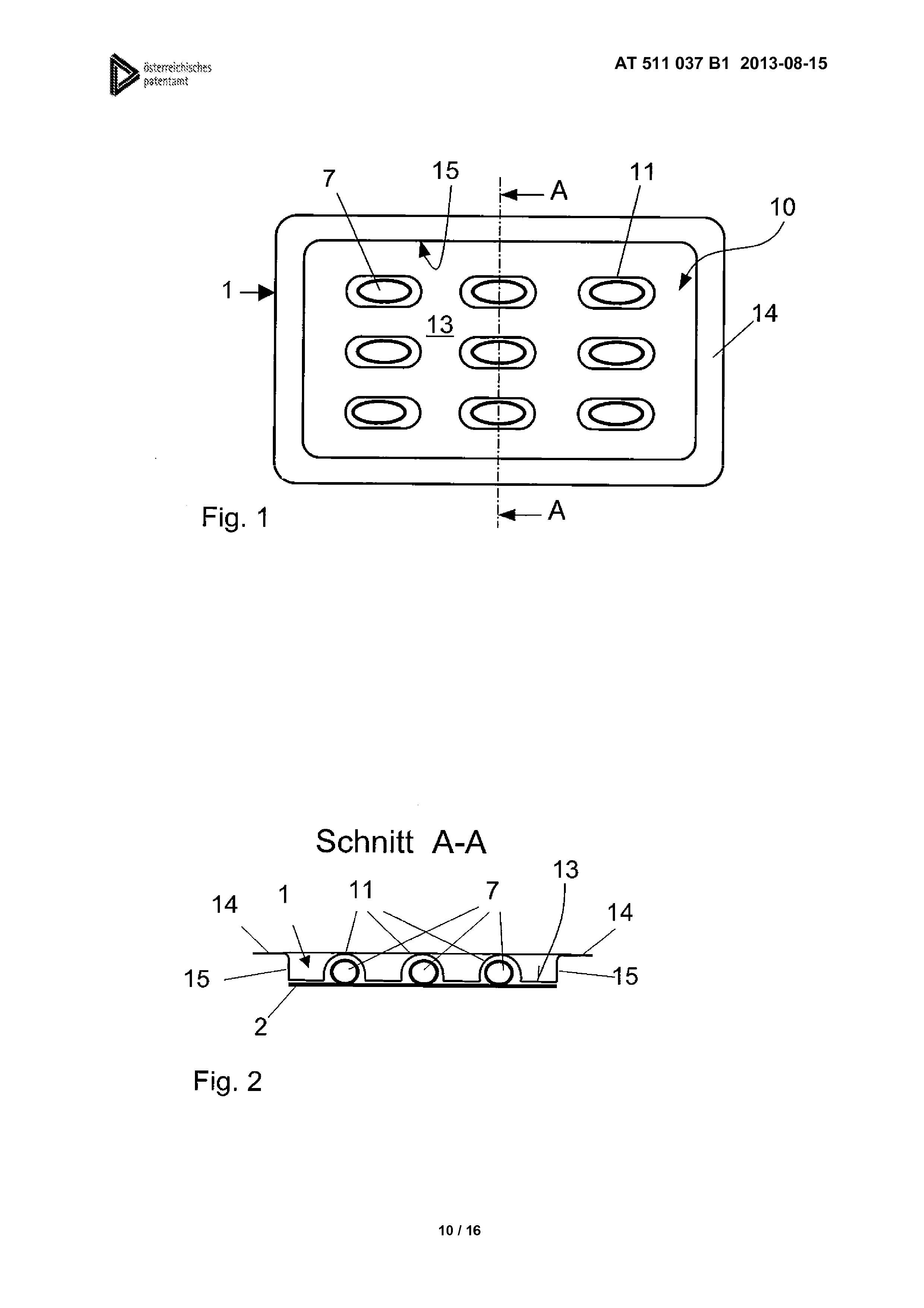

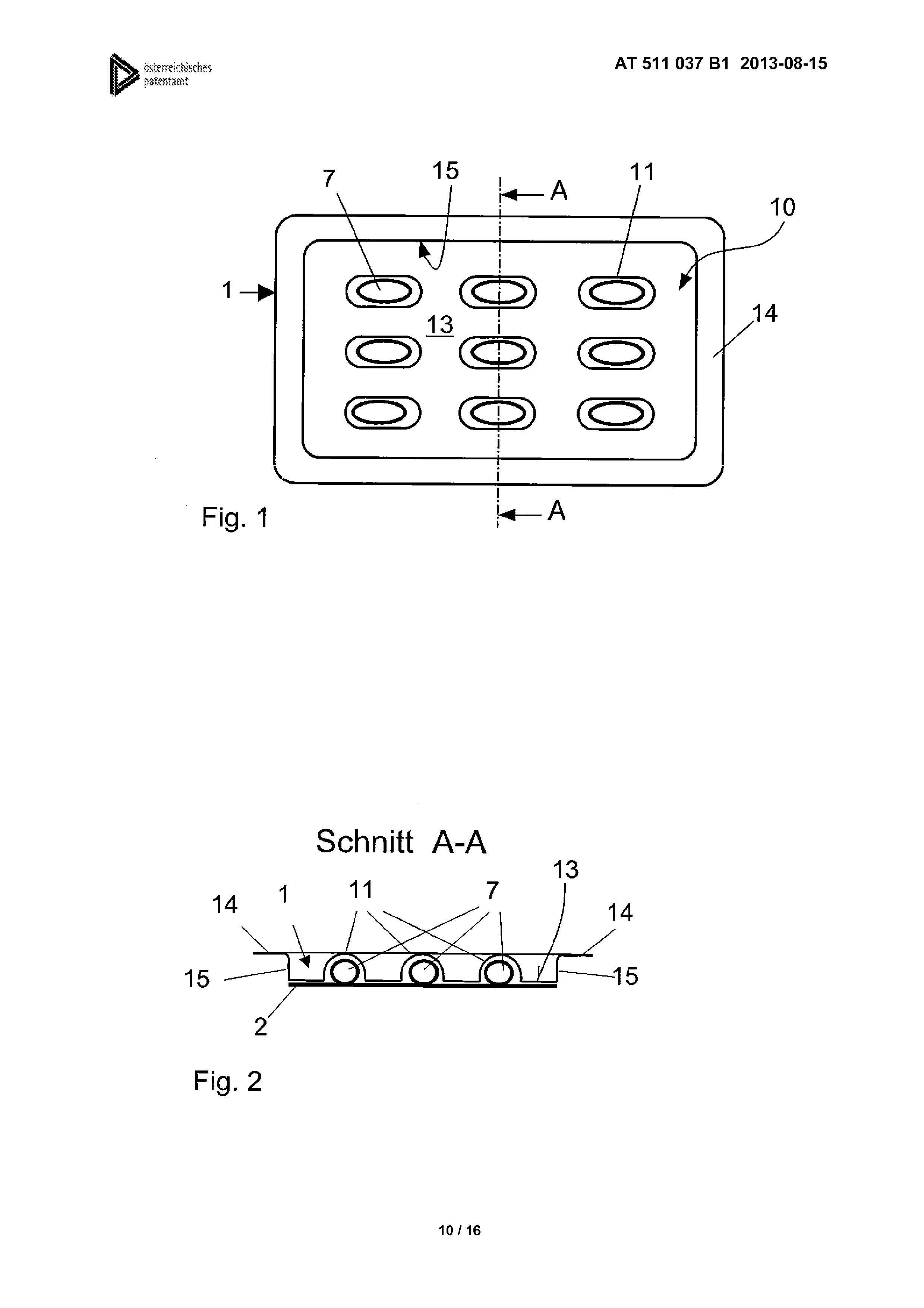

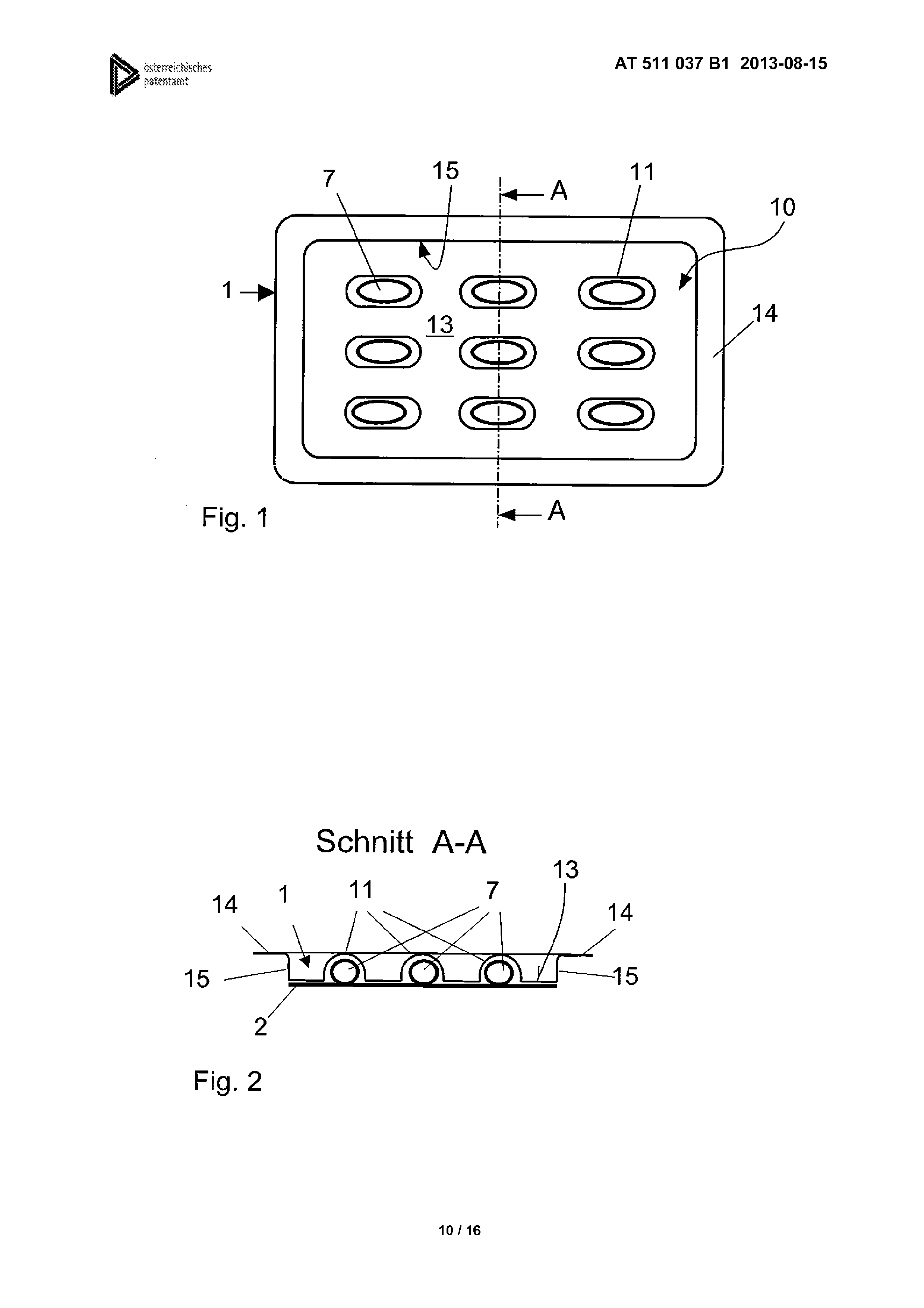

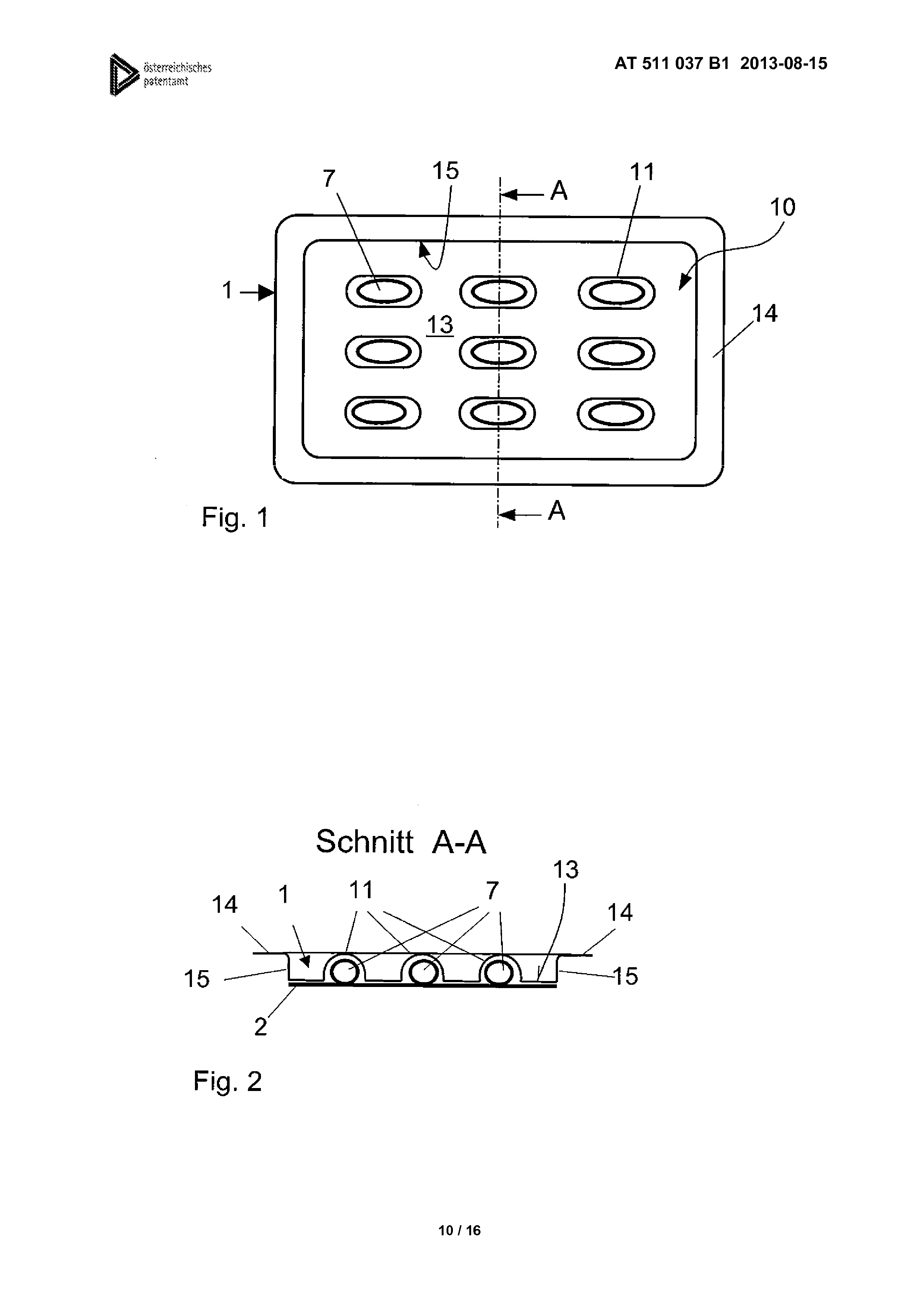

[0001] The invention concerns a container in accordance with the generic term of the patent claim 1. Furthermore the invention concerns an adhesive label in accordance with the generic term of the patent claim 12 as well as a packing unit in accordance with the generic term of the patent claim the invention favourable-proves in the range of the packing by drugs used which, after equipment with appropriate additional components, in further consequence for the monitoring of the medicine income to be used to be able. From the conditions of the technology a multiplicity of different drug packing is well-known, on which data over the dosage, which effect, which production, which packing of the respective in the packing drugs present, about tablets are stored. From the international patent application WHERE 2009/000425 are represented a system for the identification and verification of the authenticity of a pushing through packing and for the installation or activation from software to the support of control the one by a medicine income by a patient. From the international patent application WHERE 2007/076176 a2 are a blister pack from a not leading base from plastics, which is locked with aluminum foil, well-known. The blister pack possesses a central range, within which a Blister is taken off by dry film resist and an outside range, which surrounds the central range circularly and by the dry film resist beabstandet and released is. This outside range is attached a coil, which surrounds the central range circularly. From the international patent application WHERE 2006/007867 A1 is a blister pack from a not leading base from plastics well-known, is locked for which with aluminum foil. Fig. it shows 7 that the distance corresponds to the transponder circuit of the aluminum foil of the height of the Auswölbungen, whereby the height of the blister packs amounts to typically 1 to mm. The carrier range is transferred in relation to the base line. From the US patent application US 2006/202830 A1 is well-known a blister pack from a not leading base from plastics, is locked for which with aluminum foil. The blister pack represented in D3 exhibits a coil, which surrounds the blister pack circularly and by the metal foil beabstandet and shielded is. From the European patent application EP 2009793 a blister pack from a not leading base is well-known, which is locked with aluminum foil. During this blister pack the coil is attached in a range, which is not covered by the aluminum foil. Thus the coil exhibits a distance from the aluminum foil. There is with well-known medicine containers frequently the problem that during the selling of the medicine, approximately by the packman, the pharmacist, the physician or nursing homes additional information is stored and the patient to be available to be supposed. With the fact the problem exists that the effect of antennas, which make a wireless energy transmission possible on the container, by which electrically or magnetically conductive metallic foil, which serves the catch of the container, strongly is reduced. The task of the invention is it to create a container favourably wireless Datenund energy transmission on a chip applied on the container made possible, which covers in particular on one side a metallic and/or electrically or magnetically conductive foil. The invention solves this task with a container of the kind initially specified with the characteristic of the patent claim 1. One is according to invention electrical and/or magnetically conductive foil with a container comprehensively an electrically not leading base with Auswölbungen for the admission of small articles and, which is laminar applied on the base and which locks Auswölbungen, so that between the Auswölbungen and the foil final cavities for the articles are trained, intended that the base exhibits a carrier range for carrying one of the foil beabstandeten and released coil. This has the substantial advantage that a launching of radio signals is possible into a coil applied on the carrier body of the container. It can besides be planned that the carrier range is exempted from the foil and beabstandet. This makes a particularly simple arrangement for a coil possible within the range of the carrier body with high stability. Alternatively or additionally it can be intended that the carrier range is connected circularly and is beabstandet at each point of the foil. Thereby alternative training of the carrier body as the admission of the coil with a favourable linking of electromagnetic signals is reached. A further aspect of the invention plans that the carrier range exhibits the form of a closed volume. Thereby a good linking of electromagnetic signals is obtained. For the decrease of materials requirements necessary for the production of the container it can be intended that the carrier range exhibits at least a supporting element, in particular a number of supporting elements, for supporting a coil running in form of a closed volume on the supporting elements. And a mechanically stable arrangement of the invention which can be manufactured particularly simply plans that the base from it flattens electrically not leading piece of material is formed, from which the Auswölbungen is formed out and is away from a footpoint of the base and that the carrier range is trained along the edge of the base and is released in relation to the footpoint, whereby a crease range in the angle, adjacent on the carrier range, runs and/or normally to the footpoint and connects the carrier range with the footpoint. One structurally and geometrically favourable arrangement of the invention plans that the carrier range is transferred after that direction in relation to the footpoint, into which the Auswölbungen from the footpoint is away. Linking a signal can be improved, if the distance between the foil and the carrier range amounts to or the foil and the coil 1 mm up to 10 mm. Particularly simply to manufacture is a container, if on the carrier range a circulating coil is arranged, which is beabstandet of the foil. A economical kind for the production of a container is present, if the coil is imprinted on the carrier range. A particularly robust and error free producible execution form of the container is characterized by one, preferably in the base integrated, in particular within the carrier range arranged or cast in, electronic circuit, which is attached to the coil and which makes communication possible with an external communication unit, whereby communication is attainable over radio or inductive coupling, whereby the coil as if send and/or receiving antenna is controllable. For the further improvement of linking the electromagnetic field of the communication unit into the coil it can be intended that the minimum distance between the foil and the carrier range is in such a manner selected or the foil and the coil that the electronic circuit is supplied with energy during a given signal achievement of the external communication unit sufficiently. An adhesive label can particularly favourable be begun, it is intended with which that the adhesive label is trained in form of a volume and the coil rotates along the volume, whereby a circuit attached to the coil is integrated in the adhesive label, whereby in particular it exhibits a hole in the internal area covered by the coil. By gluing such an adhesive label on a container according to invention information can later be assigned the container and be held to the call by the consumer for the order. For the favourable distribution of containers as well as to the mistake of containers with information a packing unit is suitable, whereby the containers are in such a manner arranged that the minimum clearance between in each case two coils of the containers is maximum. A particularly space-saving and transmission-technically favourable packing unit with two containers is characterised by it that with both containers the carrier range is transferred after that direction in relation to the footpoint, into which the Auswölbungen from the footpoint is away, whereby the two containers are so arranged in the packing that the two footpoints are turned with the side carrying the respective foil each other. Several remark examples of the invention are represented on the basis in the following the represented designs without restriction of the general inventive thought. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. a first execution form of a container according to invention from above shows. points to Fig. 1 represented container in a cutaway view along the cut line A-A. a further execution form of the invention from above shows. a special execution form of a container according to invention with a coil and on the container an arranged and with the coil shows in electrical Verbinung stehenen electronic circuit and/or a microchip located on the container. points to Fig. 1 represented container in a cutaway view along the cut line B-B. an adhesive label according to invention shows. points to Fig. 7 represented adhesive label, glued on in Fig. 1 represented execution form. shows a cut by in Fig. 7 represented adhesive label along the cut line CC. shows a cut by in Fig. 7 represented adhesive label along the Schittlinie D-D. an alternative container with a coil and an electronic circuit show and/or a microchip containing adhesive label in accordance with Fig. 7, that on a base in Fig. 3 represented execution form is glued on. points to Fig. 10 represented container in a cutaway view along the cut line E-E. Fig. a special kind of the packing of two containers shows in a common packing unit. Fig. points to Fig. 12 represented manner of packing in a cutaway view along the cut line FF. Fig. a first remark example of a container according to invention 1. the container 1 shows magnetically not leading base 10 of one electrically and made. The base 10 is present before the production process as even bodies from plastic, which is brought by deep-drawing under thermal effect into its final form. In this special execution form by deep-drawing a number of Auswölbungen 1 1 was provided, those from a footpoint 13 formed by the base 10 after a direction is away (Fig. 2). This Auswölbungen 1 1 forms ranges for the admission of small articles 7, as about of medicines 7 in firm form, tablets or caps. The represented execution form of the invention covers six Auswölbungen, in which the medicine 7 is inserted in each case and welded or stuck together afterwards with a foil 2 hermetically. The foil 2 is mostly designed as multi-layer sandwich foil, whereby one or more situations of the foil can be electrical and/or magnetically conductive. The tablets 7 are thus limited and hermetically locked by the range between the Auswölbungen 11 and the foil 2. In Fig. 1 represented execution form exhibits further along its edge from the metallic foil 2 released a carrier range 14, on the one in Fig. 1 not represented coil to be applied can. The carrier range 14 runs continuous along the edge of the base 10, whereby with this special execution form of the carrier bodies 14 by deep-drawing from the footpoint 13 is exempted. The carrier body 14 is essentially evenly or planar trained, whereby the surface trained by the carrier body 14 runs essentially parallel to the footpoint 13. Alternatively however also alternative developments of the carrier range are possible, which make a better linking of signals for an external communication unit possible. The carrier range 14 is connected circularly. The carrier range 14 is beabstandet at each point of the metallic foil 2. By the manufacture procedure of the deep-drawing between the carrier body 14 and the footpoint 13 a crease range 15, represented in Fig. 2, trained, which attaches at the outside edge of the footpoint 13 and toward the Auswölbungen 11 from the footpoint 13 is away. The crease range 15 attaches 14 to the internal boundary region of the carrier body. In the available favourable execution form the Auswölbungen exhibits 1 1 a maximum height regarding the footpoint 13 of the container 1. This height essentially corresponds the height of the crease range to 15 and/or the distance of the level formed by the carrier range 14 from the footpoint 13. Favourable geometry with a good space utilisation is obtained by this constructional measure. The height and/or the distance between the level formed by the carrier range 14 and the footpoint 13 amounts to depending upon size of the tablets 7 between 1 mm and 10 mm, in particular between 3 mm and 5 mm. With one in the Fig. to 1 to 2 represented execution form of a container 1 medicines 7, approximately in the form of tablets, can be sold, whereby the complexity of the production of the containers 1 corresponds for instance to the complexity of the production of containers after the state of the art, which for the admission of a coil 3 does not exhibit a carrier range released in relation to the footpoint 13. For the manufacturers of containers, in particular medicine packing, results thus no disadvantages. The space requirement of the containers 1 is not increased in relation to well-known containers 1. With in Fig. 1 represented container 1 results additionally the advantage that with large printing effects to a number of stacked superimposed containers I a majority of the pressure is derived over the crease ranges 15 and the carrier ranges 14. An alternative execution form of a container according to invention 1 is in Fig. 3 represented. The two containers 1 are essentially identically developed, whereby in the following only with the differences between the two execution forms one deals. Contrary to in Fig. 1 represented execution form points in Fig. 3 represented containers 1 a carrier range 14 up, which is trained by a multiplicity of individual supporting elements 16. The supporting elements 16 give like also the carrier range 14 represented in the first remark example a geometrical form and/or design, along which a coil favourable-proves 3 for signal transmission between the container 1 and external Sendeund receiver can be arranged. In this execution form the carrier range 14 as well as the individual supporting elements 16 exempted from the metallic foil 2 are and beabstandet. The distance amounts to like also in the first remark example depending upon height of the Auswölbungen II between 1 mm and 10 mm. By the individual supporting elements the 16 for carrying a coil the form of a closed volume exhibits 3 formed range. In place of a deep-drawing procedure also in principle different procedures for the figuration and production of plastic parts, available after the conditions of the technology, can be consulted. Fig. an execution form of a container according to invention 1 with on the container 1 applied and/or into the container a 1 integrated coil 3 and/or a 1 electronic circuit 4 integrated located on the container 1 into the container, which can also contain or several of microchip, shows 4. Fig. 5 shows in Fig. 4 represented execution form of the invention on average along the cut line B-B. From Fig. 5 clearly that between the coil 3 and that is intended electrically and/or magnetically conductive foil 2 an intermediate range, the one electromagnetic coupling between the coil 3 and Sendeund receipt coil is to be recognized or - antenna of an external, not represented communication unit makes possible. It exists thus favourable-proves the possibility that from the communication unit delivered electromagnetic waves and/or magnetic fields will receive 3 in sufficient measure by the coil, so that all components of the electronic circuit 4 are supplied sufficiently with electricity, without the foil 2 weakens the electromagnetic field of the communication unit in such a manner by mutual induction that a sufficient power supply of the electronic circuit 4 is prevented. Fig. 6 an execution form of a container according to invention 1 shows to the one adhesive label 40 glued on is, the coil 3 as well as the electronic circuit 4 and in it if necessary contained of microchip covered. The adhesive label 40 and the carrier range 14 of the container 1 exhibit essentially identical form. The adhesive label 40 exhibits on the carrier range 14 turned side a sticking layer, by means of those it with the carrier range 14 stuck together. In the adhesive label 40 an electronic circuit 4 as well as a coil 3 are integrated, whereby the electronic circuit can contain 4 or several of microchip. The coil 3 is simply or several times wound and with the adhesive label 40 connected along the carrier range 14. In this special execution form of the invention the coil 3 is arranged and imprinted on the adhesive label 40 on the sticking and the carrier range 14 turned side of the adhesive label. Alternatively the coil can be 3 also inside the adhesive label 40 arranged or embedded. Further alternatively the adhesive label 40 can is more zweioder in multiple layers trained, whereby the individual situations stuck together with one another and whereby the coil 3 and/or the circuit 4 between different situations are arranged. The body 48 of the adhesive label 40 is favourable-proves of paper, cellulose or from a foil from plastic manufactured. In the available remark example the range of the adhesive label 40 inside the carrier range 14 before gluing on the carrier range 14 was punched out or cut out. The adhesive label 40, in however position represented in Fig. 7, either during the production of the containers 1 directly the container 1 can be applied or later be glued on however with the prescription or the expenditure by a pharmacist or a physician the manufactured container 1. In a special advanced training of the invention the 40 can be supplied with to individual adhesive labels together also in a packing unit. While the expenditure of the container 1 the physician can or pharmacists by means of an external communication unit information about the coil 3 for circuit 4 transfer, in which these information is stored and held to the inquiry by the consumer for the order. The consumer ordered likewise a communication unit, by means of those it the information to select knows and thus in particular information over the dosage and the time of the income of the medicines in the container 1, about tablets 7, receives. The transmission of the information from the external communication unit to the electrical circuit 4 and of the electrical circuit 4 to the communication unit effected wirelessly via electromagnetic coupling between the antenna of the external communication unit and the coil 3. the external communication unit can in particular into a commercial mobile phone in an integrated way or as independent Lesebzw. Recorder conceived its. The selection of the distance of the footpoint 13 of the carrier range 14 is certain with the indicated remark examples of the invention also by the fact that for the maintenance of the possibility Informationsund energy transmission between the coil 3 and/or the circuit 4 and an external communication unit the minimum distance between the foil 2 and the carrier range 14 or the foil and the coil 3 is given. This is in such a manner selected that during a given signal achievement delivered by the communication unit the circuit 4 is supplied with energy sufficiently. Fig. 8 and 9 shows in each case a cross section by the adhesive label 40 along the two cut lines CC and D-D. In Fig. a connection between the coil 3 and the circuit 4 is represented 9. The adhesive label 40 exhibits a body 48, which exhibits a hole 49 in the center. The hole 49 serves in particular for the fact that also after applying the adhesive label 40 on the container 1 still another unhindered withdrawal of the tablets 7 from the container 1 can take place. An alternative execution form of a container according to invention 1 exhibits on the carrier range 14 of the container 1 imprinted or integrated coil 3 and an electronic circuit 4 welded into the container 1. Such an execution form is particularly suitable for direct storing of the production and the durability as well as the authenticity of the medicines 7 data concerned in the container 1. The possibility for the manipulation of data and the falsification of medicines 7 are strongly made more difficult by such a measure. Besides the electronic circuit 4 can offer the possibility that concerning further information the dosage, income, prescription, side effects etc. additionally to be stored to be able. This is possible again with the fact that the physician or pharmacist has with the expenditure of the medicines 7 an appropriate communication unit, which transmits data over the coil 3 to the electronic circuit 4, on which the electronic circuit 4 stores and as further inquiries by the patient for the order regards the data. Further the possibility exists with this execution form that the physician or pharmacist examines on a microchip of the electronic circuit 4 stored information, in particular the durability and the authenticity of the medicine and spends the medicine if necessary at the patients. By gluing on into the Fig. 7 to 9 of represented adhesive label 40 on one in Fig. 3 represented execution form of a container 1 can be achieved a further special execution form of the invention, those in Fig. 10 from above seen and in Fig. 11 in a sectional view is represented. A special execution form of the invention, represented in Fig. , the storage and packing concerns 12 and 13 of containers 1, on which in the course of its packing a coil 3 as well as an electronic circuit 4 were applied. This can have taken place either via gluing an adhesive label 40 on or but via production of the alternative execution form described before. In the available remark example two containers 1 in common packing 20 are packed. A packing 20 is selected, which is permeable for electromagnetic fields and waves. In particular the packing for electromagnetic fields and waves should be permeable in the frequency range of 13.56 MHz, which are used typically for RFID. If necessary however also another suitable frequency can be used. With this execution form a packing from cardboard is selected, whereby the packing is quaderförmig trained. Into the packing 20 two become in Fig. 4 or Fig. 6 or Fig. 10 represented container 1 with medicines 7 brought in, whereby the two containers 1 are in such a manner arranged that the distance between in each case two coils 3 is maximum the container 1. In the available case this is reached by it that with both containers 1 the carrier range 14 in relation to the footpoint 13 is transferred after that direction, into which the Auswölbungen 11 from the footpoint 13 is away, whereby the two containers 1 are so arranged in the packing 20 that the two footpoints are turned to 13 with the respective foil 2 basic side each other. The two footpoints 13 fit together, whereby the foils can affect 2 each other. The two coils 3 of the two containers 1 exhibit in it a sufficiently large distance to each other. Further the two coils 3 exhibit also to that electrically or magnetically conductive foils 2 a sufficiently large distance. By this kind of the packing it is very simply possible to transfer during the production process or immediately after the production process data to container 1 which is already packed. Besides it is possible that a physician or a pharmacist transmits data to container 1, which is packed, without this must open the packing 20. In the represented remark examples the represented containers 1 or on the respective container 1 glued on adhesive labels 40 in each case the 4 exhibit a coil 3 as well as an electronic circuit. The electronic circuit 4 contains or several of microchip, in particular a memory chip for storing data, which stand with the medicines 7 in the container 1 in connection. To the letter on the memory chip a communication connection with an external communication unit can be developed. This exhibits an antenna and develops the data communication connection with the electronic circuit 4 by electromagnetic coupling to the coil 3 connected with the circuit 4. Apart from the data communication it is intended in the represented examples that also an energy transmission takes place, so that the electronic circuit 4 needs to have even no constantly available energy stores. The communication unit of a physician, a pharmacist or a manufacturer is in principle suitable for writing or reading from data from that and/or into the memory chip in the electronic circuit 4. By transmission according to coded instructions accomplishes the electronic circuit 4 the appropriate memory call and transfers if necessary the queried memory value to the communication unit. Also the patient has an appropriate communication unit, about a RFID reader, which is integrated in its mobile phone. On the mobile phone runs an application, which activates the RFID reader for selection in the circuit of the respective container. Normally the patient has only read access, not however write access on in the memory chip the circuit 4 stored data. It can be desired with special applications however also possible, and/or that the patient receives write access on a subrange of the memory also. osterreicfectes pstesnäffii The present invention relates to a container comprising - an electrically non-conductive basic body (10) with bulges (11) for receiving small objects (7) and - an electrically and/or magnetically conductive film (2) which is applied in a sheet-like manner onto the basic body (10) and closes the bulges (11), thus forming sealed cavities for the objects (7) between the bulges (11) and the film (2). According to the invention, the basic body (10) has a carrier region (14) for carrying an exposed coil (3) spaced apart from the film (2). 1. Container comprehensively an electrically not leading base (10) with Auswölbungen (11) for the admission of small articles (7) and one electrically and/or magnetically conductive foil (2), which on the base (10) is laminar applied and which locks Auswölbungen (11), so that between the Auswölbungen (11) and the foil (2) final cavities for the articles (7) it are trained - whereby the base (10) a carrier range (14) to carrying one of the foil (2) beabstandeten and released coil (3) exhibits, in the fact characterized that the base (10), out of that those is formed out of a flat, electrically not leading piece of material Auswölbungen (11) are formed out and by a footpoint (13) of the base (10) it is away and that the carrier range (14) along the edge of the base (10) is trained and in relation to the footpoint (13) is released, whereby a crease range (15) in the angle, adjacent on the carrier range (14), runs and/or normally to the footpoint (13) and the carrier range (14) with the footpoint (13) connects. 2. Container according to requirement 1, by it characterized - that the carrier range (14) from the foil (2) exempted and beabstandet is and/or - that the carrier range (14) is connected circularly and at each point of the foil (2) is beabstandet. 3. Container according to requirement 1 or 2, by the fact characterized that the carrier range (14) exhibits the form of a closed volume. 4. Container after one of the preceding requirements, by the fact characterized that the carrier range (14) exhibits at least a supporting element (16), in particular a number of supporting elements (16), for supporting one in form of a closed volume on the supporting elements (16) running coil (3). 5. Container after one of the preceding requirements, thereby characterized that the carrier range (14) is transferred after that direction in relation to the footpoint (13), into which the Auswölbungen are away (1 1) from the footpoint. 6. Container after one of of the preceding requirements, by the fact characterized that the distance between the foil (2) and the carrier range (14) or the foil (2) and the coil (3) 1mm to 10mm amounts to. 7. Container after one of the preceding requirements, by the fact characterized that on the carrier range (14) a circulating coil (3) is arranged, which of the foil (2) is beabstandet. 8. Container after one of of the preceding requirements, by the fact characterized that the coil (3) on the carrier range (14) is imprinted. 9. Container after one of of the preceding requirements 7 or 8, characterized by one, preferably in the base (1), in particular within the carrier range (14) arranged or cast in, electronic circuit (4), attached to the coil (3) and one communication with an external communication unit integrated is made possible, whereby communication is attainable over radio or inductive coupling, whereby the coil (3) as if send and/or receiving antenna is controllable. 10. Container after one of of the preceding requirements, by the fact characterized that the minimum distance between the foil (2) and the carrier range (14) or the foil (2) and the coil (3) is in such a manner selected the fact that the electronic circuit (4) during a given signal achievement of the external communication unit is sufficiently supplied with energy. 1 1st adhesive label for gluing on a container, which a coil (3) covered, in particular after one of of the preceding requirements, by the fact characterized that the adhesive label (40) is trained in form of a volume and the coil (3) along the volume rotates, whereby one to the coil (3) attached circuit (4) in the adhesive label (40) is integrated, whereby in particular it in the coil (3) covered internal area a hole (49) exhibits. 12. Container, which an adhesive label (40) is glued on according to requirement 1 1. 13. Packing unit by one packing (20) and at least two containers (1), in each case after one of the patent claims 9, 10 or 12, by the fact marked that the containers (1) is in such a manner arranged the fact that the minimum clearance between in each case two coils (3) the container (1) is maximum. 14. Packing unit according to requirement 13 by two containers (1), by it marked that with both containers (1) the carrier range (14) in relation to the footpoint (13) is transferred after that direction, into which the Auswölbungen (11) is away from the footpoint (13), whereby the two containers (1) in the packing (20) is so arranged that the two footpoints (13) each other with the respective foil (2) basic side is turned.