Transfer machine for assembling and/or machining components

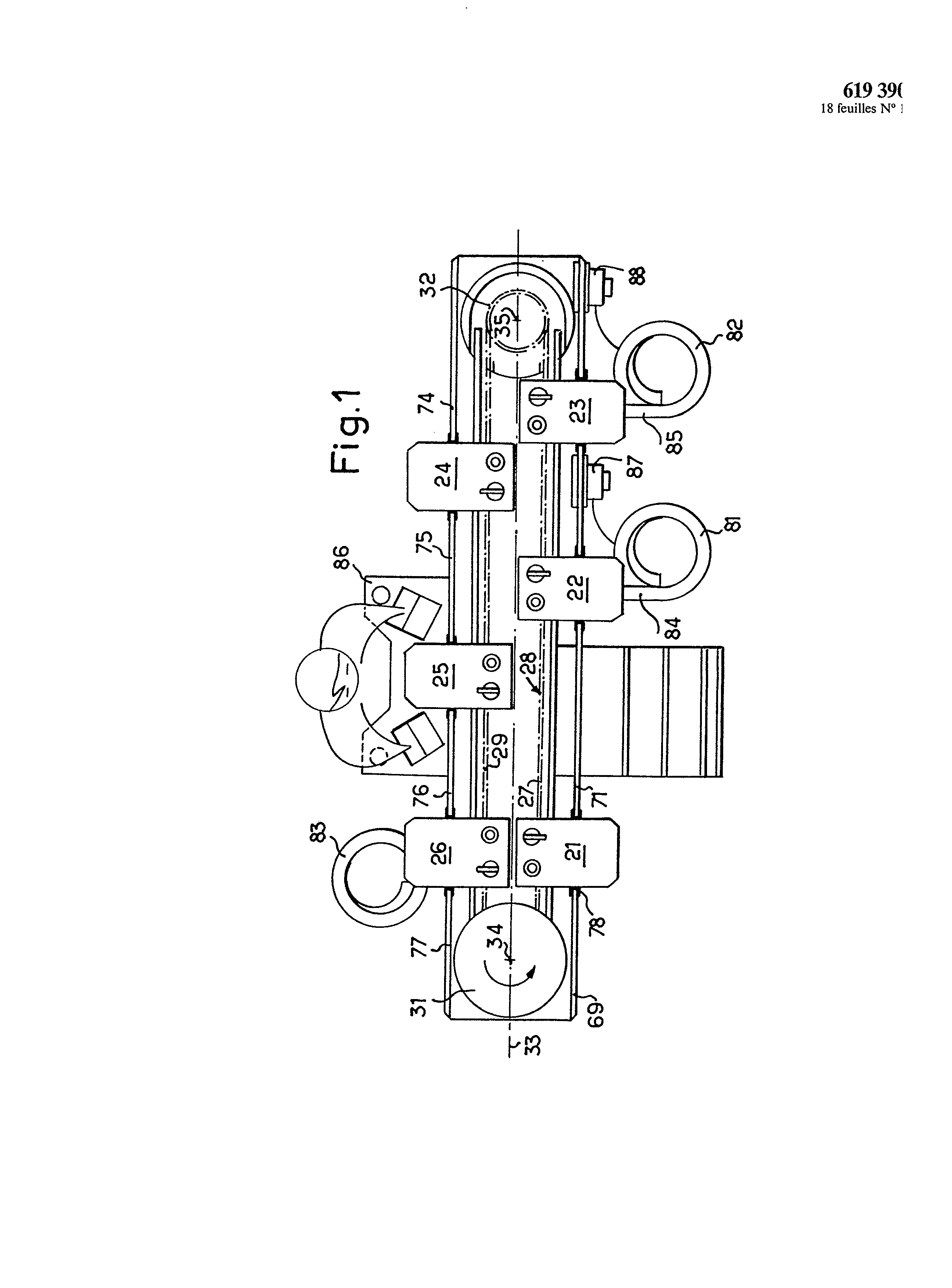

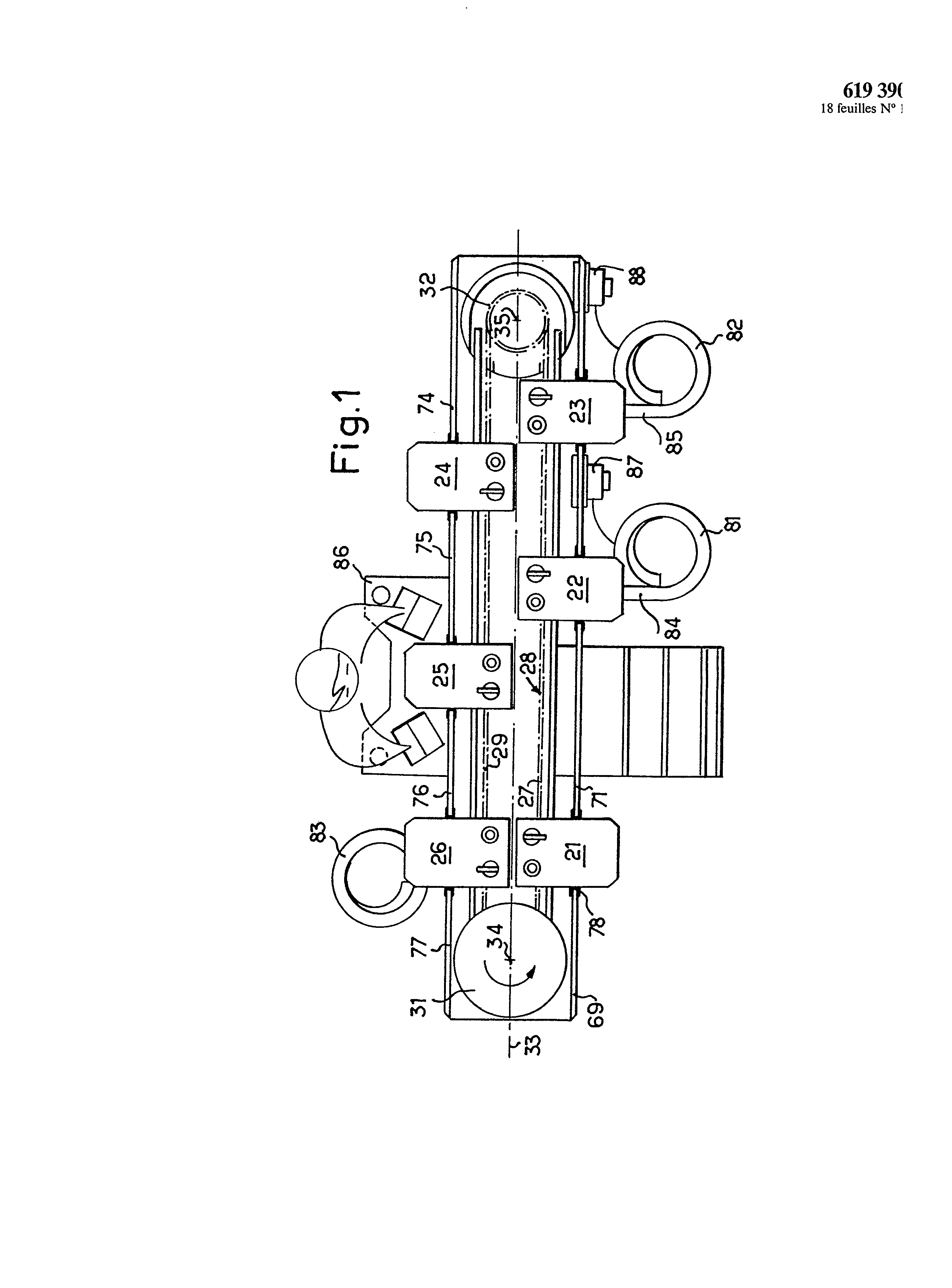

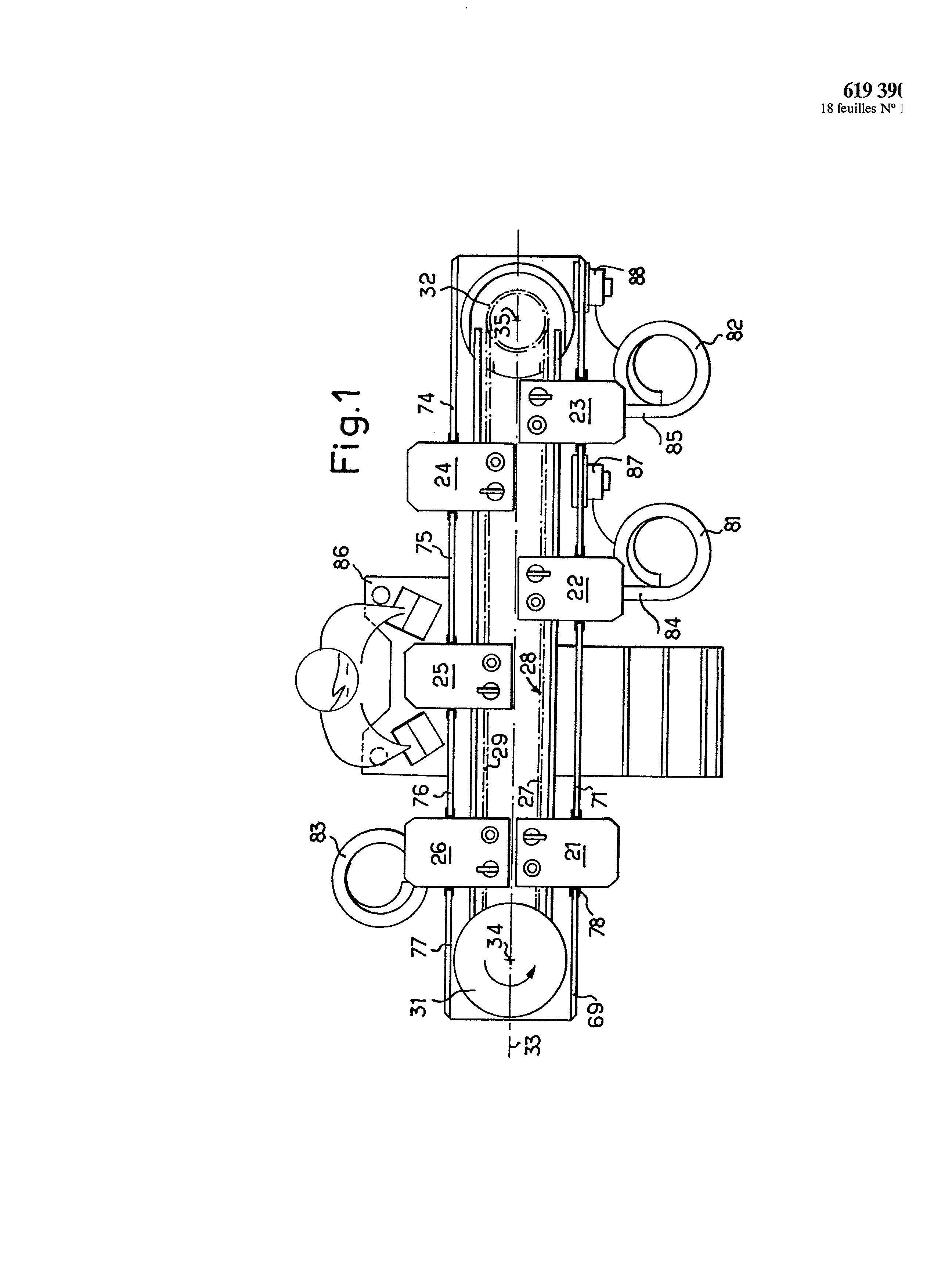

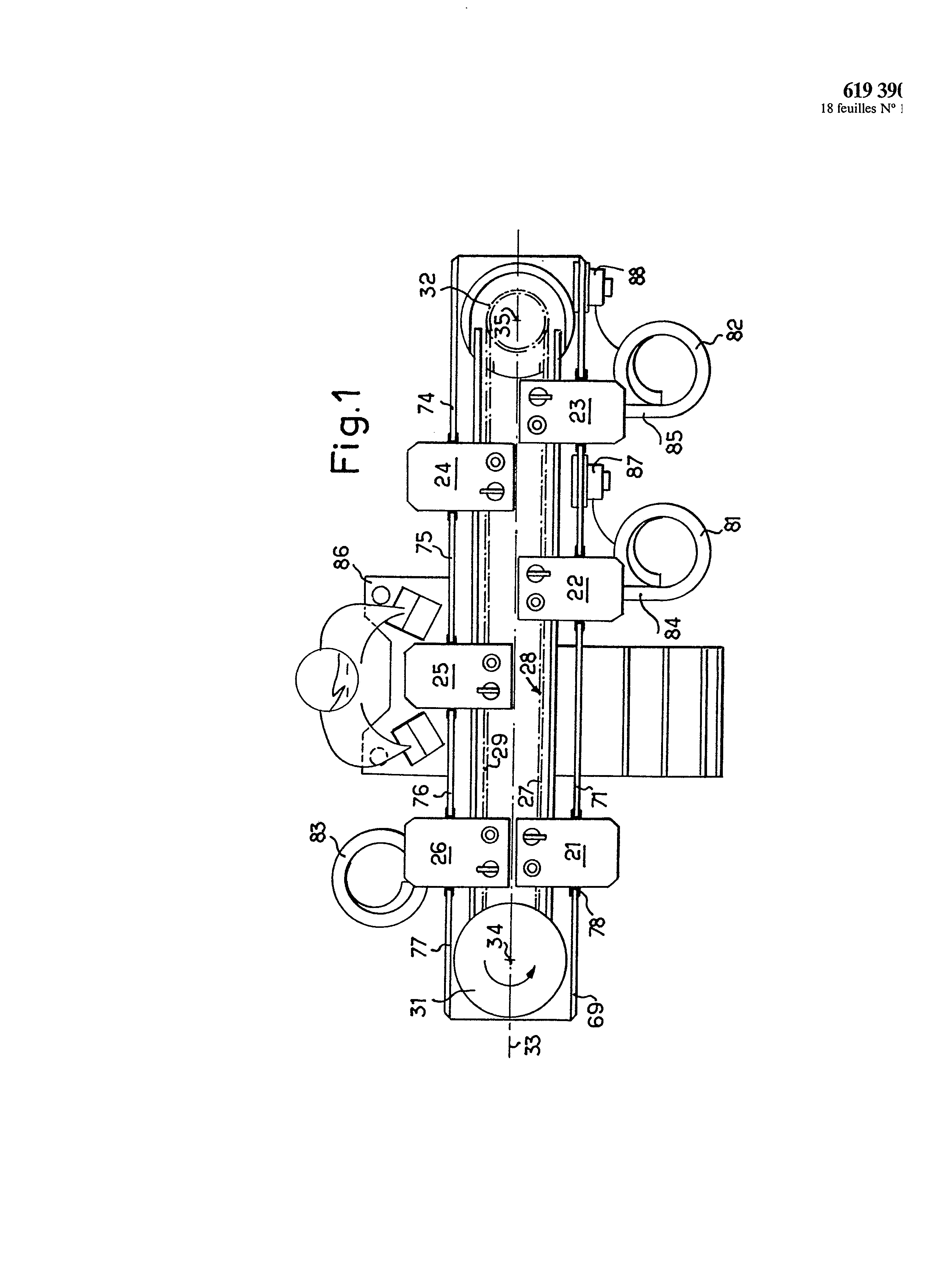

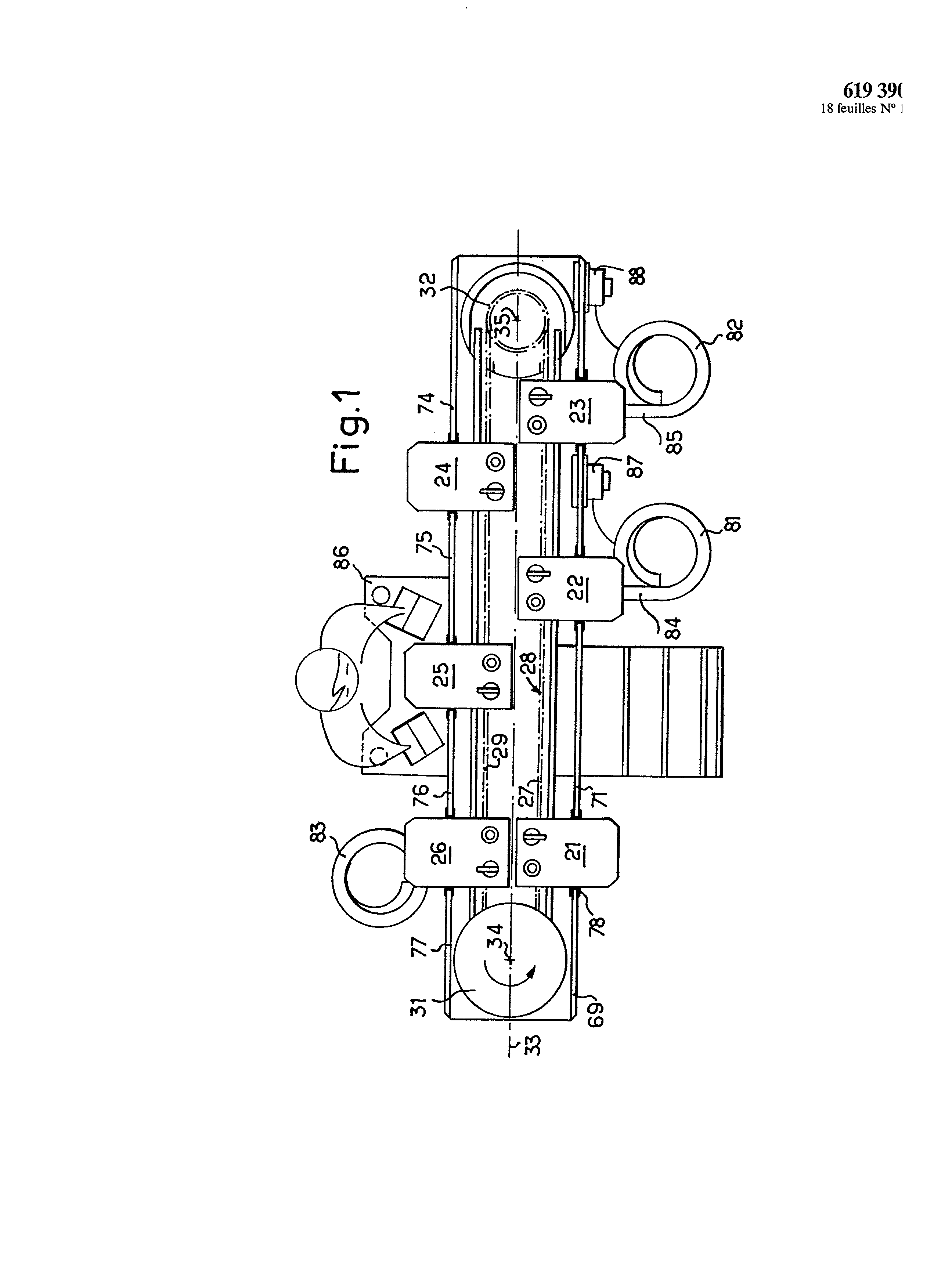

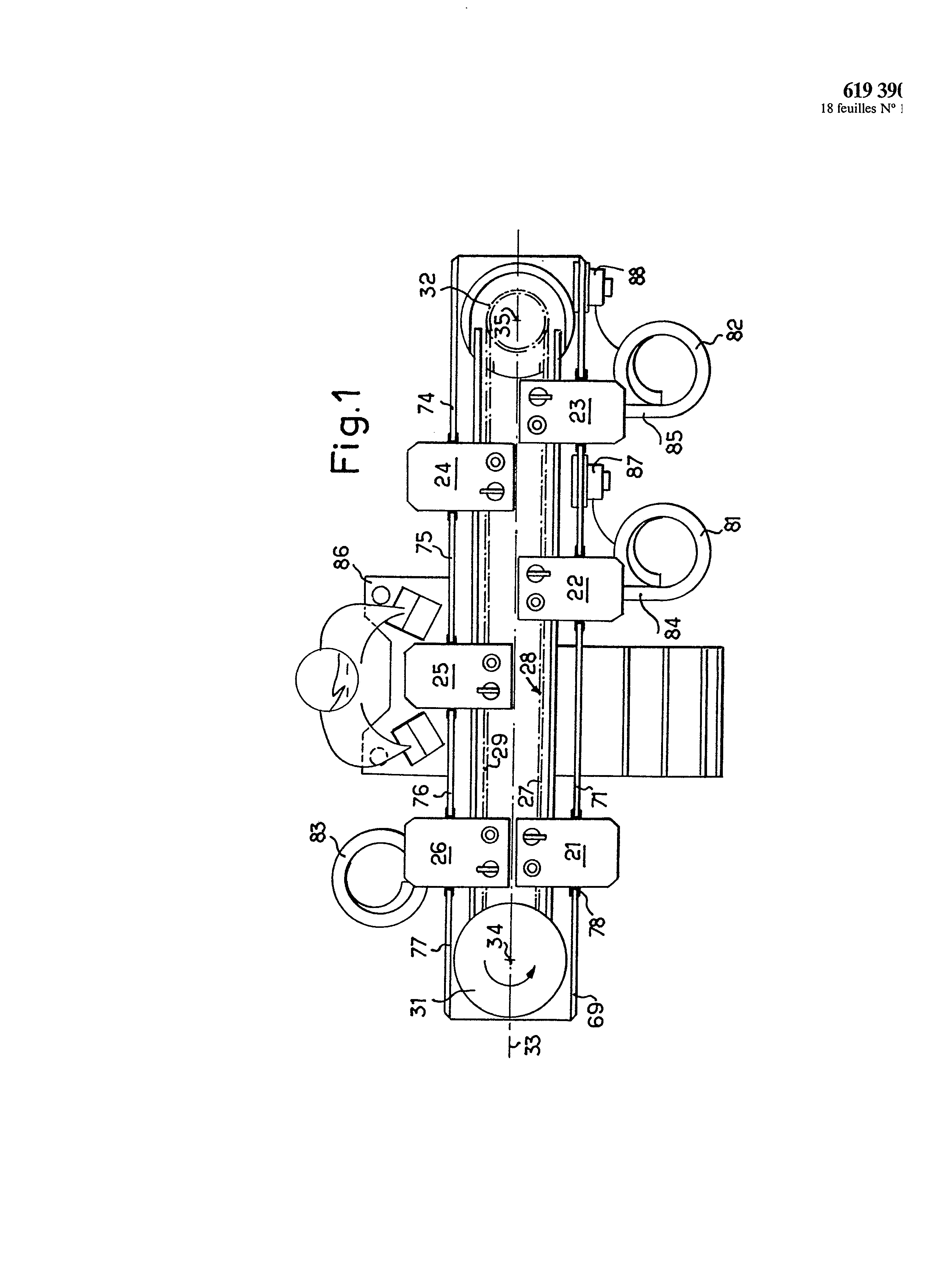

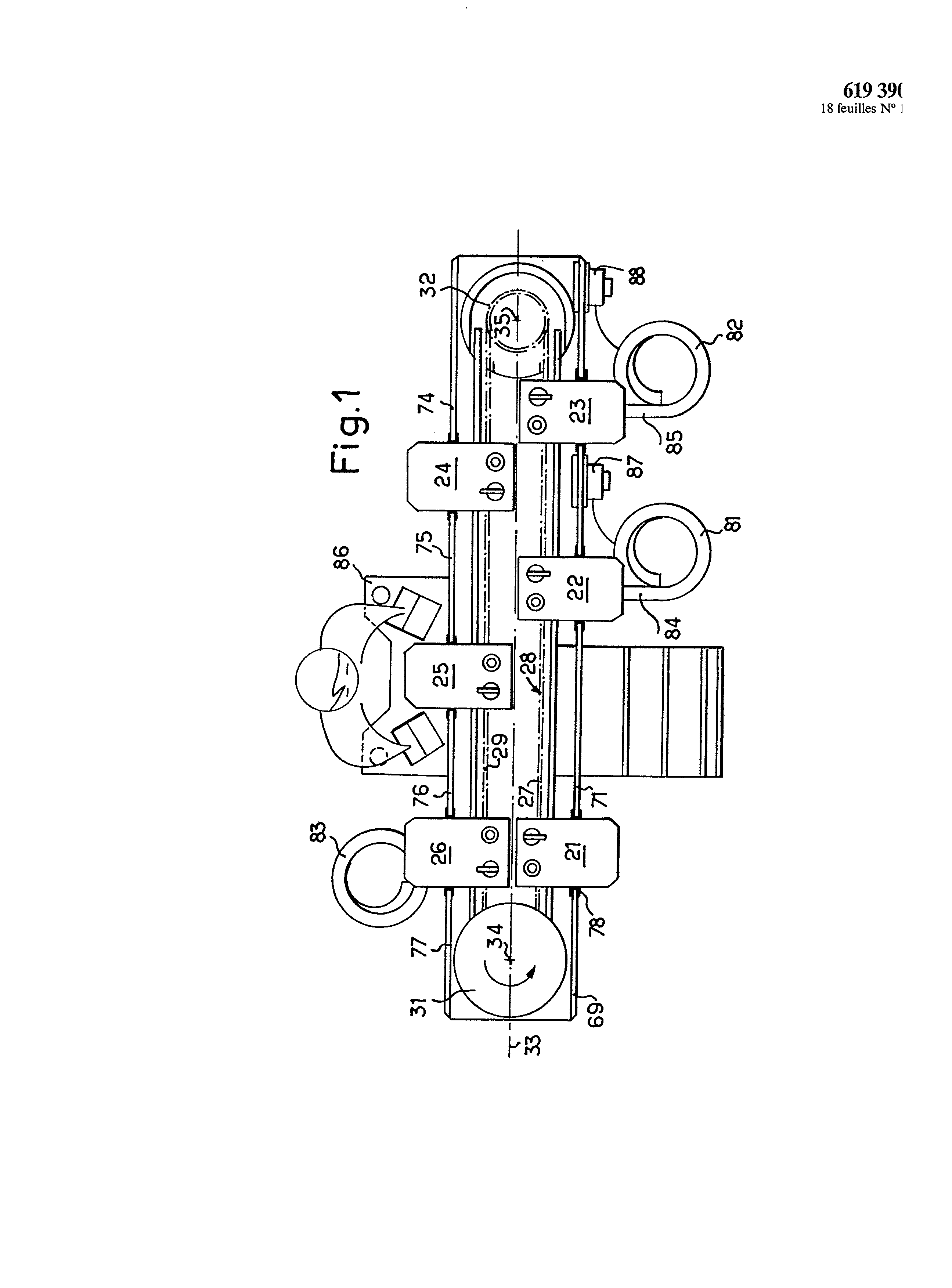

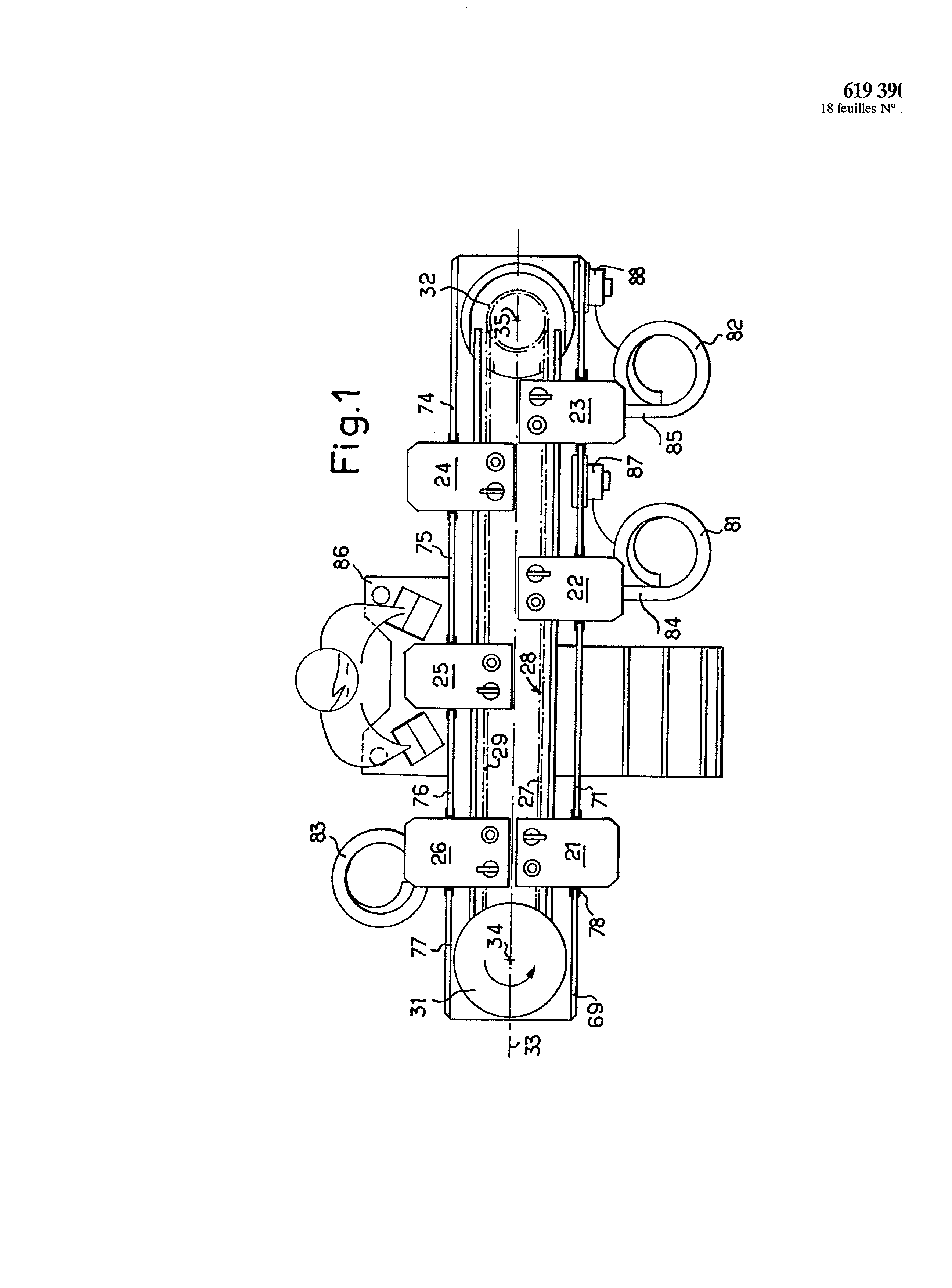

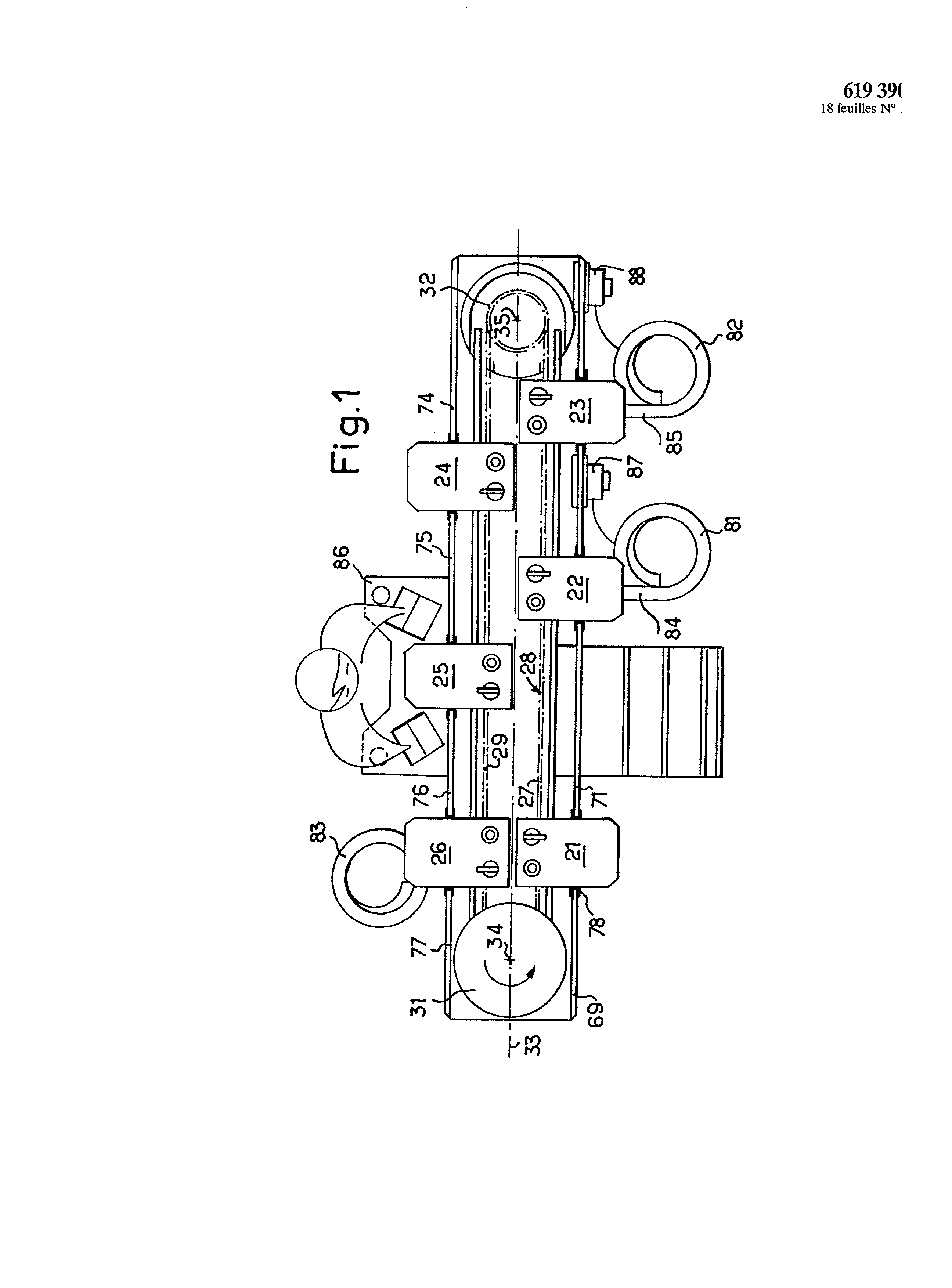

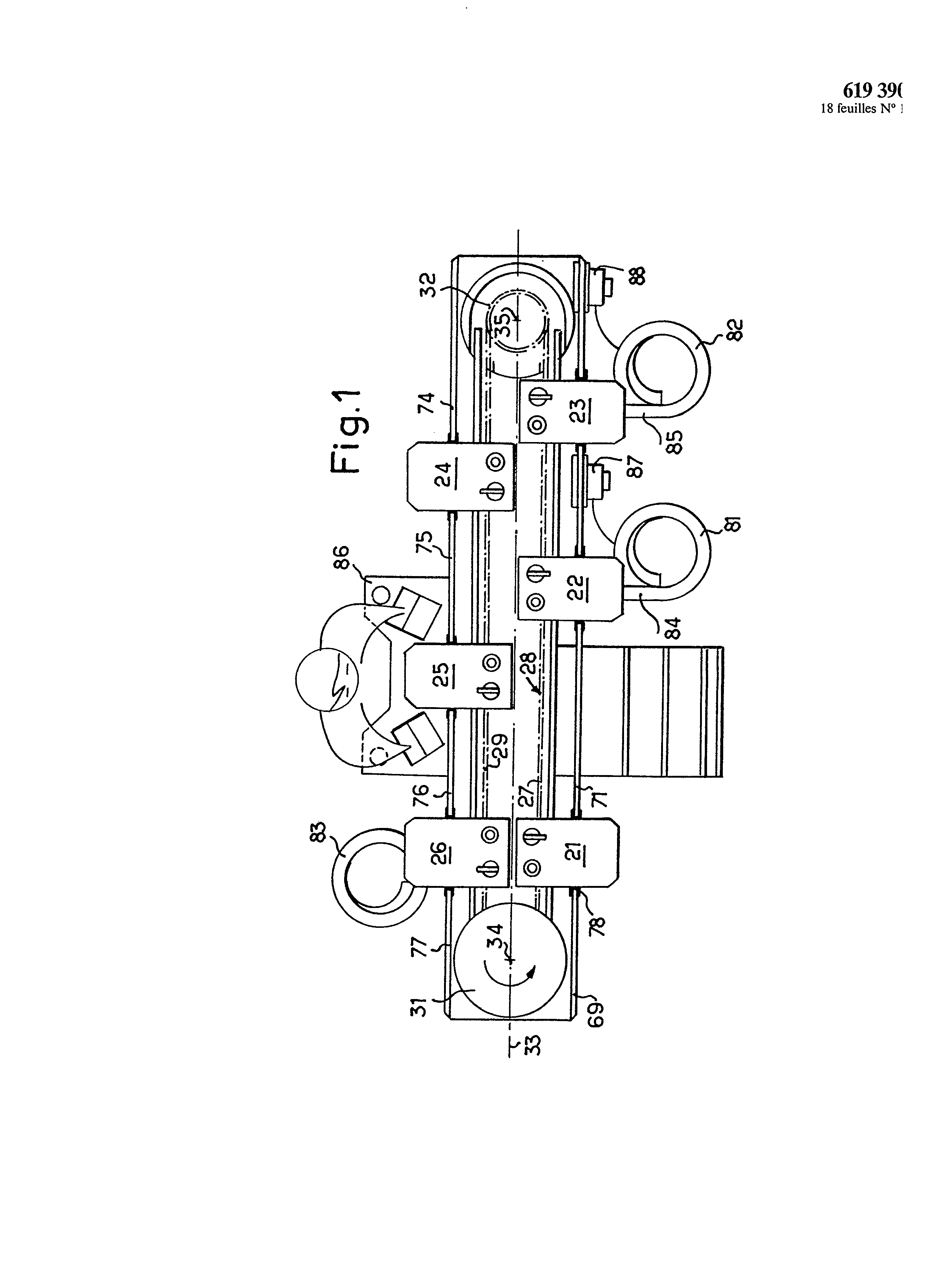

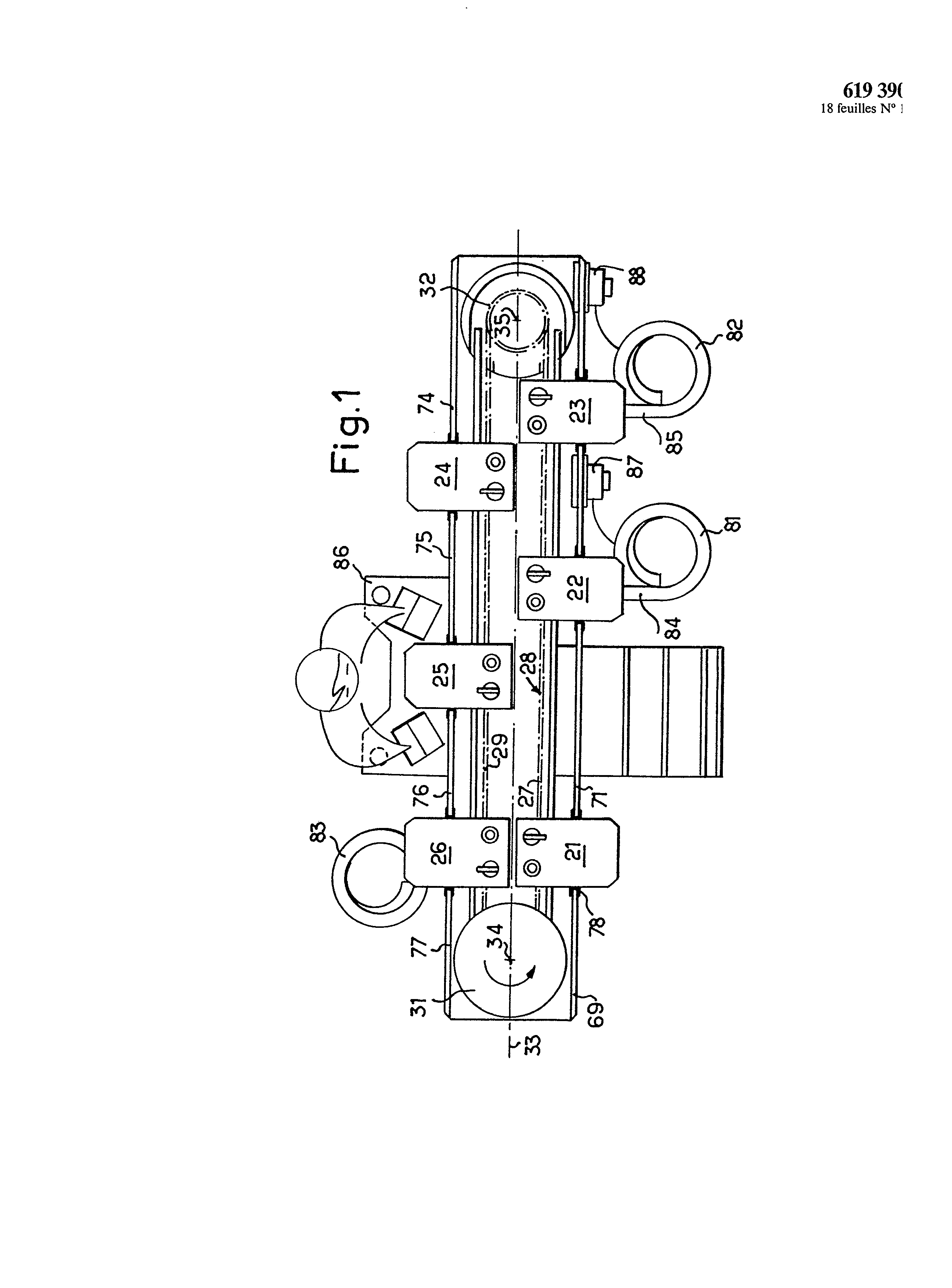

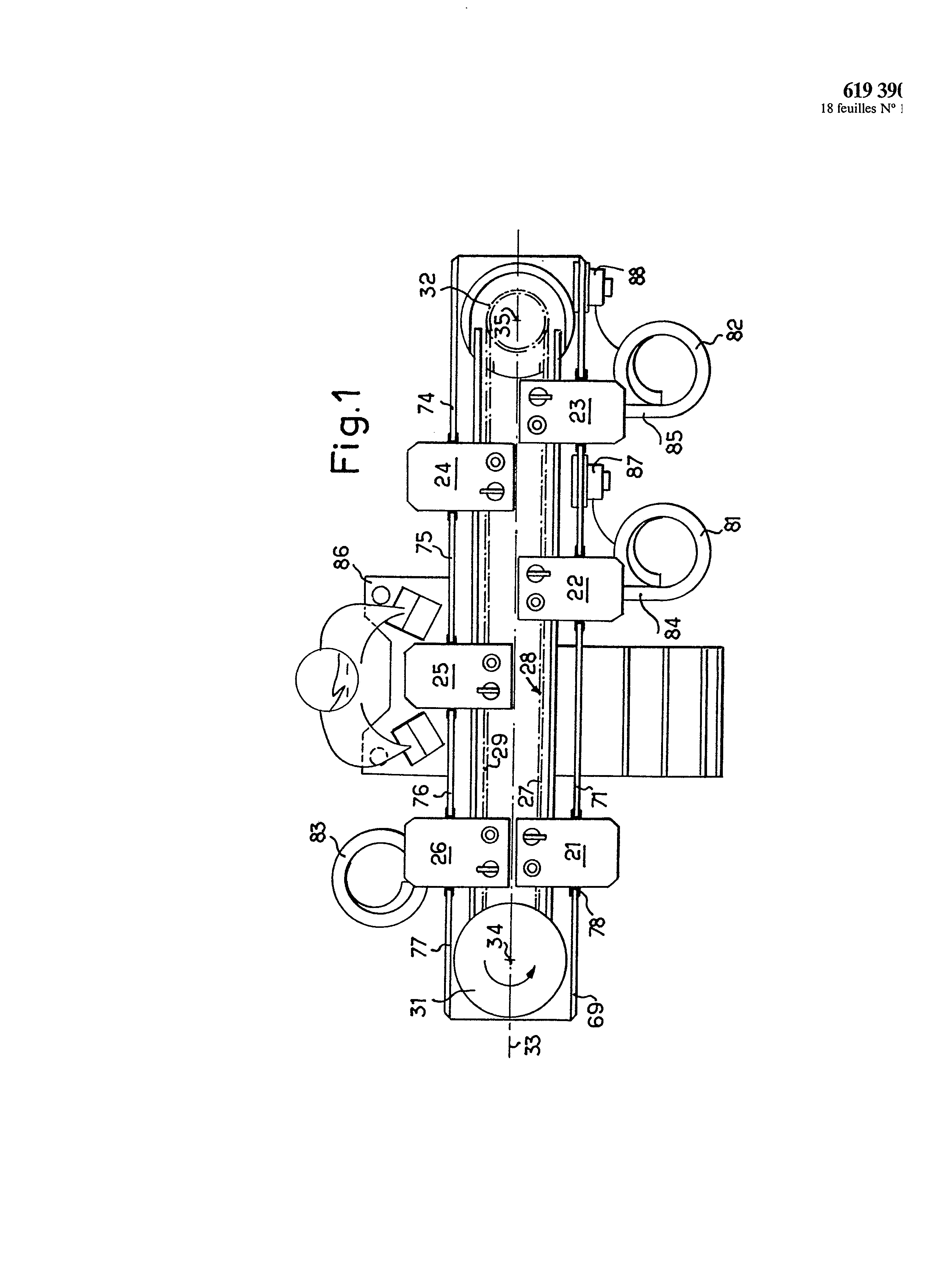

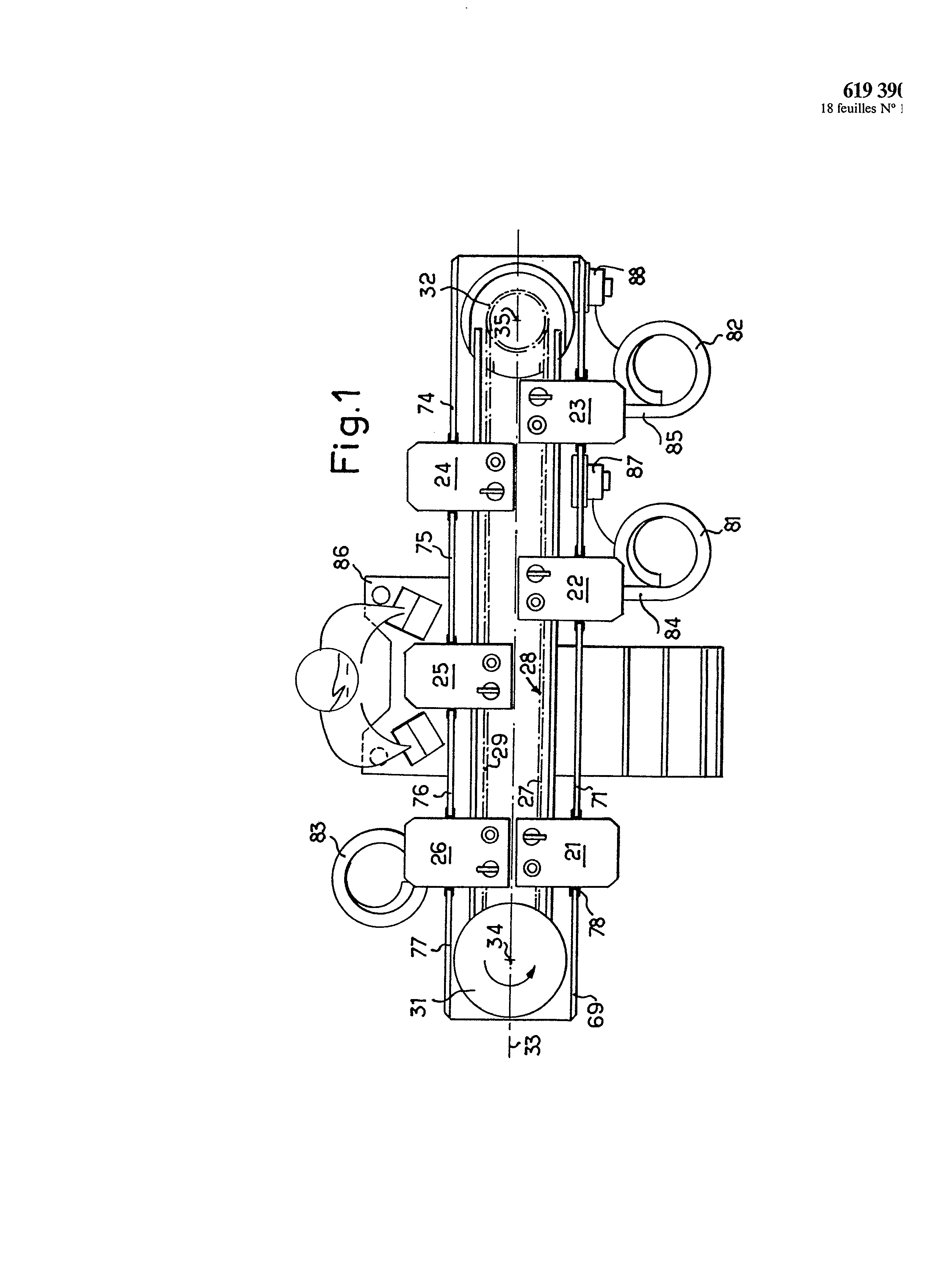

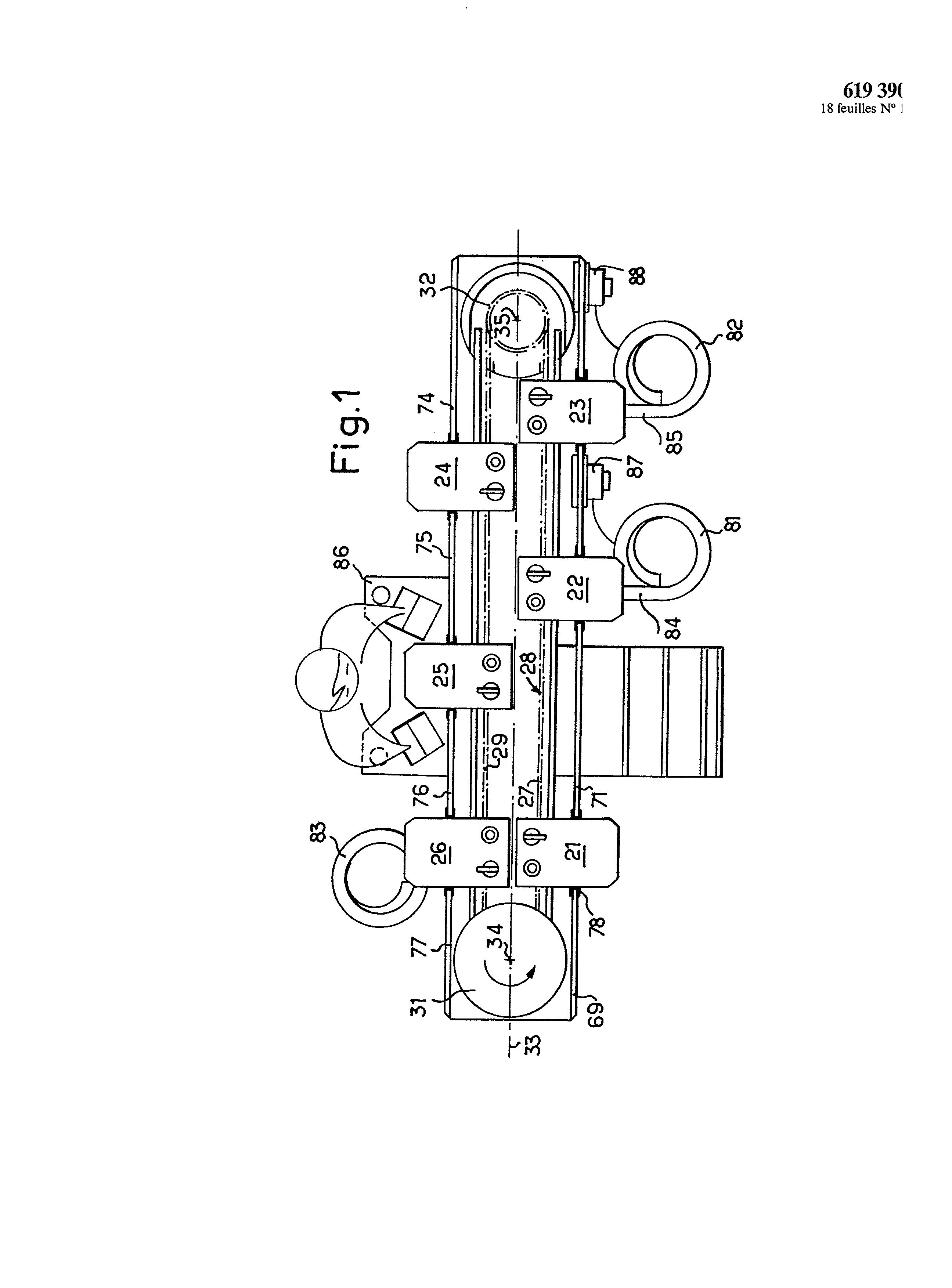

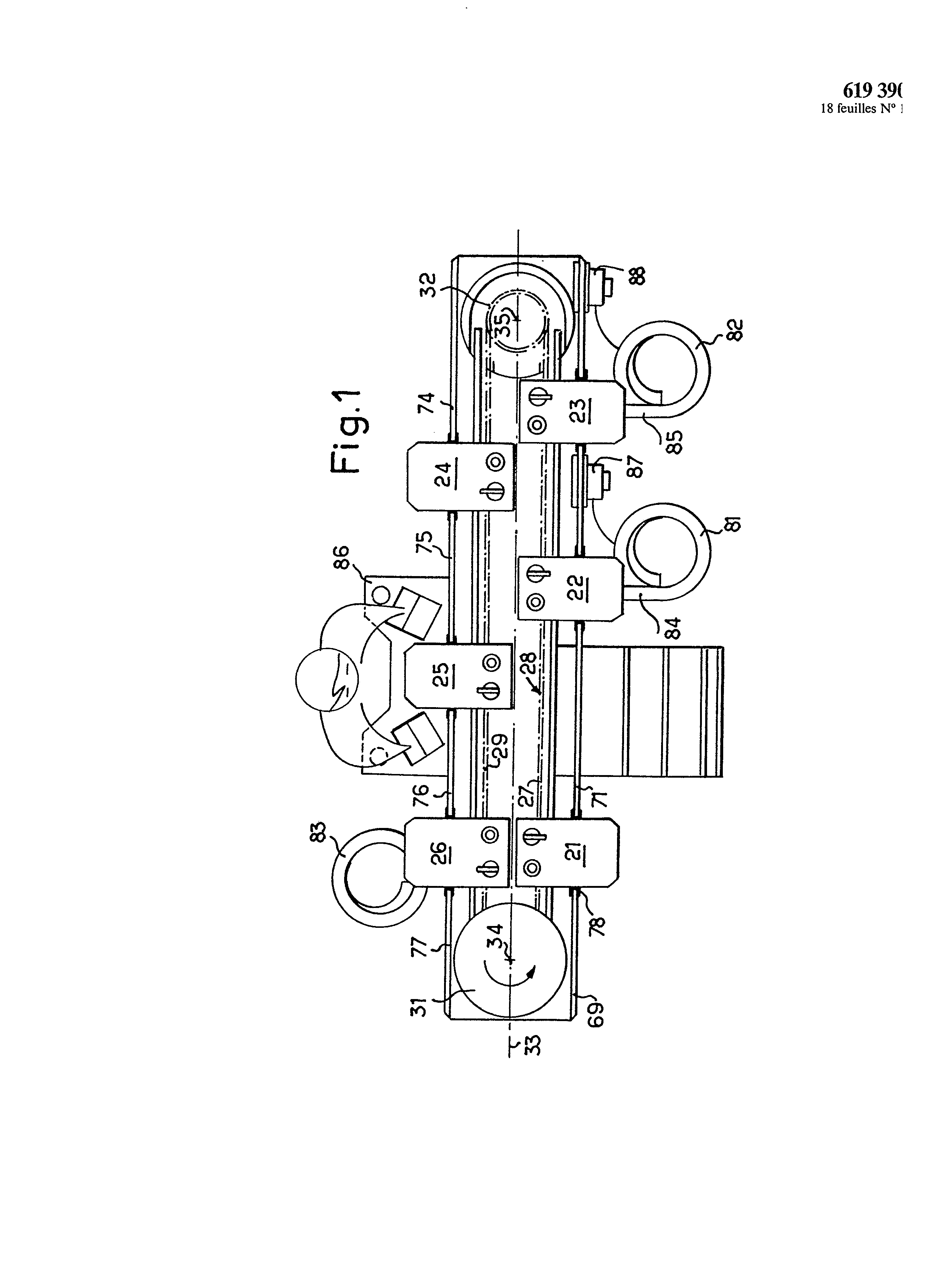

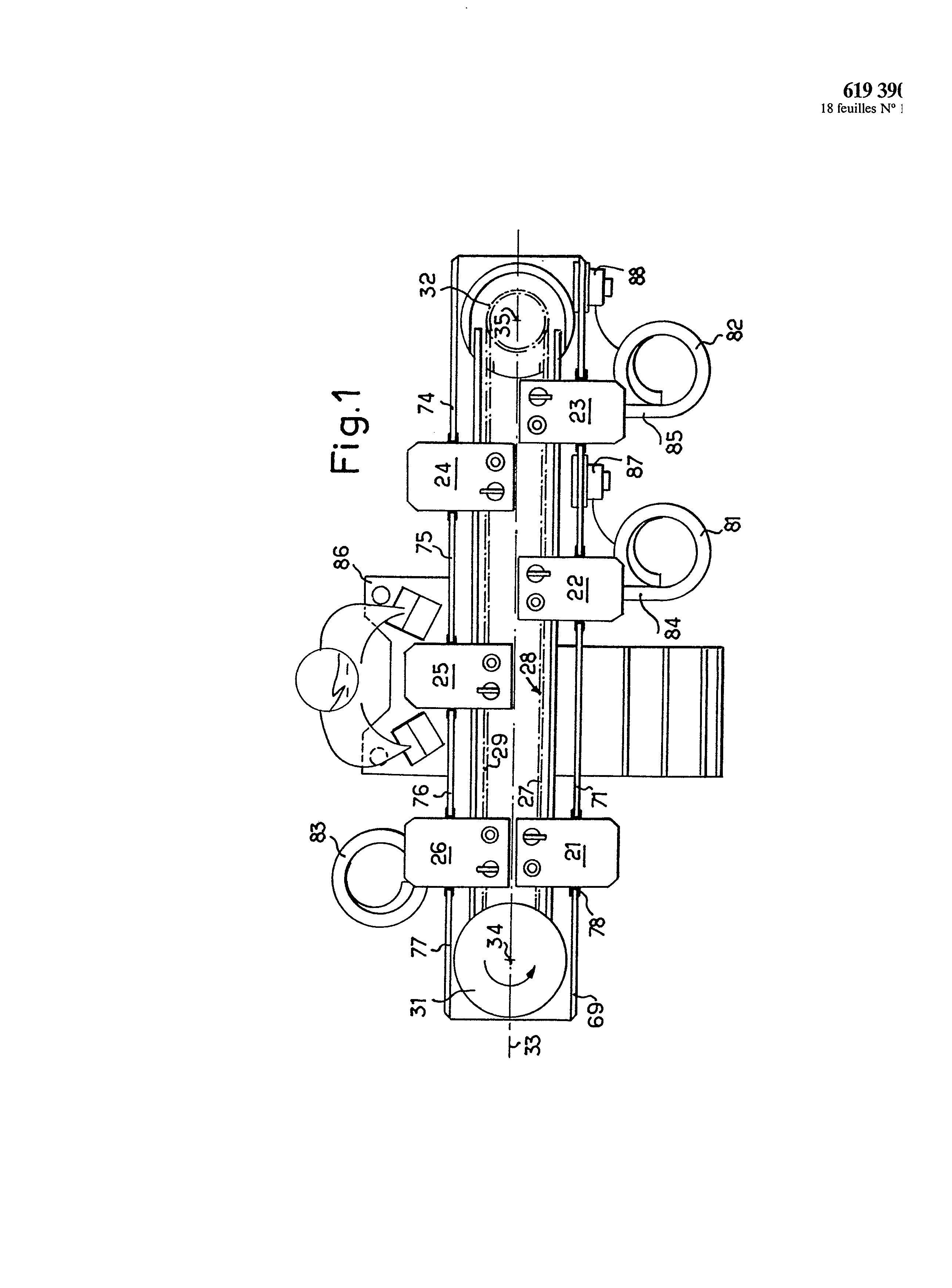

the storage area is a vertical stack, and a chañot for transversely displacing the pallets toward the station includes a flange adapted to achieve plumb with the chimney.The invention relates to machines with multiple stations for assembly and/or machining of parts.Machines are known which include various workstations, in each of them, a apparatus for assembling and/or machining of parts, and means for supplying to each station, in succession, the workpieces and/or assembling, when components are assembled and/or machined by a station then being supplied to the next station, and so on in some of these machines, stations comprise automata, c'estâ e. apparatuses to automatic operation.Multiple problems are to be solved to ensure satisfactory operation of these machines, or machine transfers, and derived in particular from the fact that the pieces should be moved from station to station, but be at each station, at least when the latter comprises an automaton, pesitionnées a highly precise manner.Further, when the peer comprises a machining apparatus, the work is to be supported for supporting the machining force.On the other hand, the peers have eadenecs may be different from each other due to the same diversity operations for which they are provided and also because a same operation does not require always exactly the same execution time.In many machine transfers, each workpiece and/or assembling is carried by a work holder or pallet, and delivery of the work pieces in succession to the various stations is obtained by snapping together the pallets of a drive means, flowing past the various stations. Said drive means, such as a necklace, stops to allow working machining or bonding apparatuses in various stations. But, in suchre uests machinery, it is the apparatus which the intervention time is the longest which controls the general rate of working, so that the efficiency of the whole machine is relatively low.To compensate for this subjection, it is possible to use a mat as drive means, so that the paddles may be temporarily away from the mat for the machining or assembly of parts carried by them, and then reductions on the mat to be transported to a station adjacent. But the degree of automation is shortened; the parts to be delivered loses accuracy and maintenance for machining or assembly is sometimes unsatisfactory.It has also proposed a machine in which a pallet, attached to a chain or the like, driven uninterruptedly, remains nevertheless maintained at a working location right sufficient time, due to relative movements of parts of chain or the like adjacent to said pallet. But, in a teile a machine, also the complication that drives the mechanical embodiment of the relative movement, it is necessary to provide chain sections or analogs of very great length, thus a considerable number of vanes, the number of parts to the job by being extremely low relative to that of the details on hold that carry the impeller affixed the strands, so that the price of the machine and its congestion exeeptionneUement are high.The transfer apparatus according to the invention is characterized in that the work locations are external to the circulating circuit, means being provided for moving a pallet carrying an assembly part or workpiece 619,390 transversely from the circulation circuit to the working position and vice versa.Along the circuit of the transfer apparatus, it is then possible to circulate pallets, while other pallets are stationary while remaining connected to the drive means.The machine may include, assigned to a work station, a stop means of a pallet, operative as long as the part carried by the pallet previous was not processed completely by the station, and the law of work of each of the stations becomes lo and thereby independent from the law of flow of plate driving means.The pallet thereby fixed in turn becomes a stop for the following pallets. In this regard, there may be applied a displacement relationship means eirculation to sinusoidal configuration, so that the contact of successive pallets occurs at zero speed, without changing element to form modified may be disturbed.In another aspect, the transfer apparatus can be characterized by the fact that the workstations themselves are placed laterally to the circulating circuit pallets, means being provided for moving a pallet arriving at right station transversely to said circuit.This allows not only completely developed a workstation with the releasing sujétionsattaehées means 22 circulation, but also the areas interventional staff attached to the machine may be completely insulated with respect to the areas where there are coins in circulation, the benefit of increased security and enhanced accessibility to pallets carrying the workpieces and/or assemble.In its general organization, the machine includes, for one embodiment, two edges parallel to the fixing apparatuses in workstations, adjustable locations, the mobility of the fastener permits, with a same assembly structure, realize machines for execution of assemblies and/or different machinings.The machine may include stations in fully automated and other using manual intervention. It provides for apparatuses which can adapt easily to one and the other general conditions of work.The drive pallets by cooperation of a link chain and sprocket mounted to friction makes the coupling and decoupling particularly easy during the transverse movement.In one embodiment, a moving circuit pallets has two parallel straight strands connected by arcs cireulaires and wherein means are provided to keep the pallets to the related effects of centrifugal force when they travel on said arcs.In another embodiment, the circuit of the movement of the pallets is circular.Slidably mounting makes possible the procedure within the housing.The panel advantageously constitutes the front end wall of the housing.A cover may be interposed between two cases sucecssifs an installation comprising a plurality of appliances and it is pivotally mounted, so as to take a position for which the track provided for shifting the workpieces to be connected and/or machining by the installation is protected by said cover and a position wherein said track is accessible.The description that follows, made by way of example, refers to the appended drawings, in which:the fig.. I is a schematic view in plan of a machinetransfert according to the invention; Figure 2 is a fixable view perspective sehématique of a portion of the machine, certain organs were omitted; Figure 3 is a cross-sectional view of a portion of the machine; Figure 4 is a 619,390 cross sectional view of the machine; Figure 5 is a plan view corresponding to the fig.. The I; the fig.. 6 is a plan view corresponding to the fig.. 3; the fig.. 7 is a plan view with partial cut of a portion of the machine; the fig.. 8 is a view in vertical section of a portion of the machine; Figure 9 is a larger scale view in vertical section of another part of the machine; Figure 10 is a diagram; lo and the fig.. 11 is an elevational view of a second embodiment; the fig.. 12 is a plan view corresponding; the fig.. 13 is a cross-sectional view; the fig.. 14 is a partial view in plan corresponding; the fig.. 15 is a cross-sectional view similar to fig.. 13, but in another state; the fig.. 16 is a cross-sectional view through a plane different from a sectional plane of the Figure. 13 and 15; the Figure. 17a, 17b and 17c are plan schematic views; the fig.. 18 is a partial view in elevation facing an automatic station; the fig.. 19 is a perspective view of a shape of the embodiment trõisième ; the fig.. 19a is a front view of a station for a fifth embodiment; the fig.. 20 is a plan view with partial sections of a fourth embodiment; the fig.. 20a is a sectional view along the line of the fig. 20a and 20a. 19a; the fig.. 21 is a plan view of the fourth embodiment; the fig.. 2la is a sectional view along the line of the fig. 21a and 21a. 19a; the fig.. 22 is a very schematic view of a set of organs from a device; the fig.. 23 is a chart showing strokes of organs and sensors; the fig.. 24 is a front view of a scoreboard; Figure 25 is a perspective view of an apparatus equipped with a control device; the fig.. 26 is a view in side elevation, partly tearing with for a sixth embodiment; the fig.. 27 is a view of the fig. plane portion. 26 and cup portion along the line 27 - 27 of the fig.. 26; the fig.. 28 is a view in side elevation, but for another position; the ñg . 29 is a view in front elevation, partly for a panel in the sealing position, and for a panel portion in raised position; the fig.. 30 is a vertical sectional view at right angles to a pallet, for another embodiment; the fig.. 31 is a view of a pinion meshed with a chain; the fig.. 32 is a perspective view of a portion of another embodiment; the fig.. 33 is a plan view with partial cut of an embodiment; the fig.. 34 is a cross-sectional view at right angles to a station for yet another embodiment; the fig.. 35 is a view similar to Figure. 34, but in another position, and the fig.. 36 is a view similar to both, but in yet another position.The transfer apparatus includes a number of workstations, six in number in the example shown in fig. 1, respectively 21, 22, 23, 24, 25, 26. The stations 21, 22, 23, are disposed along a first straight chain strand 27 28 of a drive chain link and extensions 24, 25, 26 are arranged along a strand 27 29 parallel to the strand, the strands 27 and 29 being raceordés by portions cireulaires runs over two pulleys or wheels 31 and end 32, so that the chain 28 forms a closed circuit.The entire machine is, in general, symmetrical about a vertical plane passing through the axes 33 34 31 and 32 and pulleys.The machine frame consists of two parallel beams 36 and 37 (Figure 2), symmetrical to one another relative to the plane 33, and which are similar constitutions. Said beams are supported on pedestals base 38 to 39.A beam, for example the beam 36, comprises a core 41 (Figure 3) and wings 42 and 43 which terminate in flanges 44 and to the wing 42, 46 and 47 and 43 for the wing. The flanges 44 and 46 serve to lock onto a vertical plate 48 whose longitudinal sliding allows initial fitting in position of a station along the frame. The fixing is effected by means of flanges, or claws 49, 51, clamped by screws 52 and 53 that suchre uests.The station shown in fig. 4 includes a head 55, a collet gripping a workpiece, carried by a vertically moving equipment 56 57 58 and including pistons connected by a rod 59 and housed in cylinders 61 and 62, two pin 63 being provided for guiding the upward and downward movements of the movable assembly 56. The assembly is enclosed in a casing 64 (Figure 2) which also houses the servo control means and the movement of the moving element and means that it includes. The housing 64, which extends on either side of the plate 48, project a button 66 starts and an indicator 67. The housing 64 also manual control knobs 68. It comprises an upper compartment 65 for receiving electrical circuits.Transparent panels 69, 71, 72, 73 (Figure 5), on one side of the machine, 74, 75, 76, 77 (fig.. 1), on the other side, are interposed, to the various stations, on the connection between the housings 64 and held in rebates 78 plates 48.The stations 22, 23 and 26 comprise wood supply workpieces and/or assembling, respectively 81, 82, 83, and fig. 1 shows the feed troughs 84 and 85 from bowls, 81 and 82 respectively. Cabinets of 87 and 88 are provided for control of wood supply such as 81 and 82.The station 25 is provided to be served by a person who has a work shelf 86.101 and 102 posts (Figure 2), on either side of a window 99, 103 project from the body of the plate 48 and, on said supports, is fixed, by screws 104 (fig.. 6), a teller window 105 comprising two side edges 106 and 107 connected by a crossmember antérieum 108. The facing inside faces 109 and 106 and 107 of the tape edges have grooves, respectively the I 12 and I 13. The cross member 108 also has a notch 114.To the beams 36 and 37 Parailèlement , above them and slightly offset towards the central longitudinal plane, 121 and 122 are run poutreiles (Figure 4), each beam, for example the beam 122, being attached to the adjacent beam by posts 123 124 and 125 dog cooperating with an edge of the beam 126 as 37, so as to secure fixation to the desired location of the beam.Each beam, as the beam 122, has cheruins on respective face thereof, a path 128 for attachment to the upright or leg 123 and a path 129 serves for the attachment of a sheath 131 accommodating bundles of pipes or wires, the sheath 131 being secured to its face opposite the other beam 121.The upper groove 132 of the beam 122 acts to fix any point suitable for a finger, as shown in 133, supporting at its end a sensor 134, from which is derived a wire 135 entering the housing 64 corresponding control of an automaton.On the inner flanges of the beams supéñeurs 45, 36 and 37 respectively, rectilinear rails are mounted, respectively 144 and 145 facing, respectively, 27 and 29 of the strands of the chain 28 (Figure 6).Opposite each teller, a rail, as 145, has a discontinuity limited by faces 147 and 146 (Figure 7). A rail section 148 is provided for bridging the discontinuity, its end faces 149 and 151 being initially faces opposing 146 and 147. The rail section 148 is attached to the end of a rod 161 (Figures 7 and 8) secured to the piston of a cylinder 162 156 which comprises bosses 157 and 158 tmversés 154 and 155 by pins also fastened on the section 148. On said rods is mounted to Lo eoulissement , 152 and 153 by two holes it has, a second rail section 150 and 154 and 155 around rods are threaded 162 and 163 of the springs which are supported on the faces 164 and 165 bosses from the actuator body. The ends of the second rail section 150 are integral with the tabs or protrusions 166 and 167 which cooperate with the ends of the fixed rail 168 and 169 145, adjacent sides 146 and 147 of stops.The rails 144 and 145 are provided for guiding a pallet multiplieité 181 (Figure 8). Each blade has a blade body 182, for example plastic, U-shaped in vertical cross section, 183 and 184 to two legs which cooperate by their internal faces 171 and 172, with the vertical surfaces 186 and 187 144 and 145 rails for guidance by coulissêment pallets 181.A pallet body 182 181 is integral pallet tray 188 (Figure 6). It has a generally rectangular outline with two transverse edges 189 and 191 and 192 a longitudinal edge, the connection being via 193 and 194 of fillets. The pallets are intended to receive on the top 190 (Figure 3) of their plate 188 to the hard or machining.Each pallet has, on its upper face, two receptacles and 195 196 (Figure 8) provided each for receiving a wafer made of magnetic material, said pellet being intended to cooperate with sensors 197 (fig.. 6) distributed over the length of the rails 144 and 145.On the outside faces 201 and 202 (Figure 4) 121 and 122 are joists ñxés guides stringers 203 and 204 respectively. The rods 205 (Figure 9) links of the chain are adapted to cooperate with teeth of a pinion provided on each of the vanes 206 181.A pinion 206 is mounted in a range between the body 182 of the pallet and the plate 188. Its lower face is subjected to the action of a pusher 207 208 housed in a cavity in the body 182 of the pallet and is urged by a spring 209 accommodated in said cavity.A wheel or pulley, as the device 32, includes a pulley body 211 (Figure 3) with an upper flange and a lower flange 212 213 214 rouge. Screws secure the flanges 215 212 and 213, as well as the crown 216 (Figure 9) an O pinion 217 218 and 219 toothed meshing with the rods 205 of the link chain 28 221 and 222 wafer substrates kiss 218 and 219 crowns chiller.The pulley device is part a fixed sleeve 223 (Figure 3) within which is rotatably mounted the shaft 224 which is integral with the rotatable pulley, with interposition of a ring 225. The skirt 226 223 of the sleeve is adapted to cooperate, by its inner surface 227, 228 cylindrical side face with the same radius (Figure 6) of the body 182 181 pallets.The operation is as follows:The chain 28 is driven by its engagement with the toothed sections 218 and 219 of one gear 31 and 32 following a motion whose speed law is represented by the diagram of fig.. I0. It is a sine wave-like pattern. From a time zero, the speed increases very slowly at first, the acceleration being very low, then it grows very rapidly to adopt a maximum value. It is then decreased, and then, after a slope very fast, it becomes zero after a time of very low deceleration.619,390 when a pallet 181 meshes by its pinion 206, then non-rotating and which acts as a rack with the chain 28 thus driven, advances a displacement following a law of sinusoidal type, the distance between two points where it has a zero speed being precisely equal to the length of the tray 188, c'està e. to the distance between its two transverse edges 189 and 191.On the parts of its path where it follows a circular arc, the deck support 182 is maintained on all faces.When a paddle 181 comes opposite a teller 105, it is, or not, introduced into the wicket according as the magnetic pellet that is inserted in a receptacle 195 OH in the receptacle 196 which engages a single facing the sensor 197 corresponding to said window. When placed, for example, 195 in the receptacle, said patch cooperates with the sensor 197.The hydraulic cylinder 156 is then actuated. By the action of the rod 161, the rail portion 148 which carries the pallet 181 is moved along a transverse movement. The pallet 181 engages the transverse edges of its deck 189 and 191 188 in the grooves 112 and 113 of the machine 105. Its movement continues until its longitudinal edge 192 is engaged into the groove 114 and abut against the bottom of said groove. Then the pallet is rigorously positioned relative to the apparatus, automatic, semi-automatic or non-automatic, to which corresponds the wicket.The action of the assembly or machining of the tooling of the apparatus - - in the case of the automaton shown in Figure. 4: the pickup head 55 - - then takes place exactly in the condition required for the part carried by the plate 188 of the pallet. If a force is exerted on the tray, for example by machining, it is supported by the machine 105.The end of the stroke cylinder 156, the discontinuity that was created in the rail 144 or 145 by the backflow of the rail section 148 is filled with the second rail section 150, whose correct position is effected by abutment of the wings against the ends 166 and 167 168 and 169 fixed portions of the rail 144 or 145.The arrival of the second rail section 150 in the extension portions 144 or 145 fixed rail restores the continuity of the rail, so that other pallets may continue to flow on the rail that occupies most the pallet moved transversely. They continue their stepping movement, e.g. up to arrive opposite the terminal according.There is provided, for the execution of an operation particularly long, a peer-to-two or a greater number of machines running the same operation and are thus supplied with pallets in due time, the supply of the machine stations located downstream remaining properly ensured.The machine can then perform operations of varying durations by its various machines, while operating each of them almost without interruption, thereby resulting in optimal efficiency for the machine.The machine takes into account also irregularities that may occur in the time of assembly or machining of a workpiece, for example to account for differences in time that can occur to take a part in a bowl.Provision is made to furnish some stations of a rail section provided on the cylinder rod, as shown in 150 above, but which is constituted so as to form a stop for the blade which follows that which has just been introduced into the wicket.If, during operation, a pallet by the chain 28 abuts a pallet immobilized, contact occurs at zero speed, therefore without that are motivated the parts carried by the pallets.The pulley device 32, by the cooperation that it provides between the paddle body 182 181 with the fixed skirt 223, counteracts the action of the centrifugal force, so that, despite a high rate of flow, the parts are not moved relative to the tray carrying them.619,390 on its path following a circular arc, the deck support 182 is maintained on all faces.In Figure. 4, it has been shown, facing the corridor of the feeding bowl 84 81, a receptacle 231 forming part of the station, located below the teller window 105 of said set and whose thrust flange 232 eonvenablement positions the workpiece under the head said head passes through the wicket out through the gap between the two transverse edges 106 and 107 from the machine before the pallet 181 has been introduced, grips the workpiece on the receptacle 231 and maintains the workpiece gripped in a high position, ready to be deposited on lo and the pallet, or a workpiece carried by the pallet, when it arrives in operating condition.The transparent walls 69, 71, 72, 74, 75, 76, 77 help to ensure the safety of personnel in insulating it from the elements in circulation, while permitting it to constantly observe the upstream channel.The embodiment shown in the Figure. 11 to 19 is, in the assembly, similar to that which has been described with respect to Figures 1 to 10. In this second embodiment, the machine, to rectangular configuration, comprises, supported by three legs 301.302, 303 (Figure 19) to endpieces 304, 305, 306 resting on the ground through buffers 307 of adjustable height, and two longitudinal beams 381 382 (fig.. 13) to circular cross section constituting the framework or structure of the machine on which is erected a parallelepipedic enclosure 309 2s limited by transparent walls whose members 311 - 315 (fig.. 12) are held by rebates that have plates 316 317 (fig.. 13), forming part of the frame of the machine. The machine terminates in a case or housing 308.- 381 and 382 on the beams are fixed, opposite each unit, profiles or cross-members 421, which having lands 422 and 423 semiconductor eirculaires , 381 and 382 embracing the beams, the fastening taking place with respective half-rings 424 and 425 426 clamped by screws. I. 427 and 428 ends 429 and 430 and legs that present the crossbar 421 that are fixed, by screws, the piatines 317 (Figure 14).In the embodiment shown in the Figure. 11 and 12, the machine includes, along its longitudinal sides, two stations 321 and 322 or automatic machines, with apparatuses respectively secured on the vertical walls or plates 317 and which are supplied with wood pieces from 325 and 326 respectively connecting to said appliances&327 and 328 of tracks.The other face of the platform is manually powered 331, the higher order having a shelf 332 333 enveloping a teller window. On said face is also provided an automatic station 334 which is fitted with a feeding bowl 335.A last station 336, located on the first side, depends on the discharge chute 337 parts terminated.The upstream station 323, the paddles 338, driven from the chain strand 339, were represented apart twice their length. 341 on the opposite strand of the chain, immediately upstream of the station 331, the paddles 338 are aeeolées to each other, resulting in, for example, the fact that the official has ceased its working time. Thus seen in Figure. 12 september paddles conjoined 338, and then another pallet remote from the last Ss of the row, the length of a pallet, and then another pallet remote of twice the length of a pallet, andc.With each of the stations, a pallet 338 is, for assembly or machining the workpiece that, up to be moved transversely in a wicket 333 (Figure 13) or 342. 6 the rail section 401 (fig.. 13, left portion, and Figure. 14) carrying the pallet 338 is moved from right to left under the action of the ram 402 controlled from the sensor 403, as the pallet comprises a magnetic pad. The section in the automated scrolling in front of the station. This may also be a rail section of the stop which secures the next pallet, as well as the other pallets that follow.The MAI Dang reset the circulation circuit of the pallet carrying the assembled part or machined operate by reverse movement of the cylinder 402. However, when the section 401 is again in the extension of the running rail, the pallet starts moving on the rail that after release latch that holds it on the section as long as the driving speed of the chain does not pass the value zero.In Figure. 13, it has been shown, on the left half of the condition of an automatic apparatus, for example the apparatus of the 323 station, before the introduction of the pallet 338 342 in its office. The clamp 345 forming part of the movable grips the workpiece said station 346 347 arrived in abutment with the edge of the receptacle 348 349 as part of the station and extending the infeed chute 321 327 of the bowl. I. after rising the moving equipment carrying the supply part 346 347 338 that the pallet is introduced into the wicket 342.The station includes a first portion 323 351 affected the controls and servo controls, and a second portion 352 assigned to the automatic handling of the part 347.The station 331, shown on the right hand side of the Figure. 13, served manueUement , comprises a first part 353 of same organization general that the part 351, but lacks the part 352.It is possible to employ a set as shown at 331 and arranged to be fed manually into pieces, ITU& rieurement as component of a fully automatic station, or state machine, wherein the feed of the workpieces is automatic.Optionally, the station 331 is preceded by a parking device buffer 355 in direct communication with the corridor 356 circulation pallets. The neat buffer is accommodates vanes 338 which accumulate in the upstream of the station 331 when their number exceeds a predetermined value. The screen buffer 355 general parallelepiped shape, with its inner face 357 open for communication with the hallway 356.Of facing the park 355, the rail 361 (Figure 17) guide vanes 338 is interrupted, the discontinuity being spanned by a track portion 362. When the rail portion 362 is completely occupied with pallets, the arrival and immobilization of the next pallet in line with a sensor 363 (Figure 12) provides a signal which, by comparison with a signal translating continuing the circulation of the chain, the controller causes a ram which, by its shaft, transversely moves the rail section carrying the pallets in a position schematized in 366.In this position, another rail section 367 carried by the cylinder rod comes in the extension of the ends of the rail 361 368 and 369, the arrangement being somewhat analogous to that which has been described above with reference to fig. 7.The pallets continue to arrive, the rail portion 367 is populating gradually. When fully packed, and as it was explained above for the portion 362, comparing the signal provided by the sensor 363 with a signal indicating the continuation of the drive movement causes a transverse movement of the section 367 to convey it into the park buffer, in the position schematized by the line 366, while section 362 reaches the hill in the position sehématisée via line 371. A fourth rail section 372 is then in the extension of the ends of the rail 361 368 and 369.The number of track sections can be greater or less than that which is described, based on the capacity of storage track 404, biased by the spring 405, takes the piace of the section 401, 6s parking device.the movement being limited by the stops 406 and 407. The tronLorsque working the higher order resumes, the park empties by rt. 404 may be a portion that extends beyond the running rail and a reverse operation to that described above for the pallets being thus follow the plate that has been put in its filling.In this embodiment, the cross member, the plate and the window are a subset.Whereas, in Figure. 13, the moving element 346 is shown in the down position, which is the position for gripping a corridor extending into the receptacle, it is, in Figure. 15, represented in an intermediate position. In Figure. 18, the moving element 346 is shown in a raised position, the clip 383 being over-the 342.In the station 331, the feeding mechanisms of the pallet in the machine are controlled in the same manner as it is in the 323 fully automated.The embodiment shown in Figure. 19 is very close to that shown in the Figure. 11 and 12. it has, on one side of the enclosure 309, an automatic station 391, or state machine. The panel 392 allows any time the checking for proper operation of the station. The button 393 is for the control of the manual and automatic operation and shutdown.The improved signal 394 is for warning, by its ignition, that the interval between a station, for example the station 334, and the station to AOO upstream 331, 338 is completely packed pallets placed next to one another. The ignition of the illuminant is controlled by the sensor 394 394'.The opposite side comprises an automatic station or automaton 395 with a feeding bowl 397 396 and a station having the same control means for introducing pallets in a wicket, the pallet in the wicket being within reach of an operator standing in front of the shelf 332.Referring now to fig.. 20 and 21 relating to a fourth embodiment. In this embodiment, the machine is circular and comprises a circular base 450, rests on the floor buffers 451 adjustable height and at the center of which is erected a barrel 452. The barrel depends on a central pillar 453 advantageously hollow for the passage of ducts or conductors and on which is rotatably mounted a toothed wheel whose teeth 454 454" extends only over part of the height of the wheel and cooperates with a peripheral chain 453'. The chain is double and its upper portion serves to drive pinions 452' carried by vanes 455 to 457 bifurcated body 456 and 458. The body 456 of each paddle is suspended a tray 459. The gear is integral with a disk 454 461 whose periphery has radial notches at 462 regularly distributed angularly and cooperable with said notches 463 and 464 two lugs that 465 carries a disk rotationally driven by a electric motor 466 about an axis distinct from the axis of the pillar 453 477 ã and parallel thereto.The legs 458 456 and 457 of a pallet body kiss a circular rail 467 477 centered about the axis. Facing a workstation, the rail 467 has a discontinuity bridged by a rail section 470 468 integral with a carriage, which is slidably mounted in grooves 469 and 471 that have the legs of a crossmember 472 and 473 474 radially affixed to the pillar 453 by 475 and 476 clamp halves. The carriage door 468, closer to the axis of the pillar 477 453, a second rail section 478.At 468 carriage is hitched the rod of a jack 479 481 474 radially supported by the cross member. At the end 472 and 473 branches are 482 and 483 eneastrées columns which support two platforms 484 and 485, paraUèles , forming part of a teller 486 and 487 limiting a range. The platforms 484 and 485 have inner edges provided with grooves 489 and 491.A circular plate is fixed to the pillar 490 453. It carries, at its periphery and face of each station, two stop devices 492 pneumatically actuated, comprising a cylinder and a piston 493 494 to rod the end of which forms the stop for a pallet in circulation when the piston rod is in the extended position. Each blade carries, for this purpose, a rib 495 projecting from its upper face and which is intended to interact with the 619,390 rods stop devices when they are in a protruding position.When the motor 466 rotates, it drives, by way of the studs 463 and 464, the disk and the gear 461 454 in a movement whose law is of sinusoidal type as a function of time, the distance between two sinusoids successive being equal to the width between the parallel edges 496 and 497 of a pallet.The pallets 455 are rotated when the pinion meshes with them to the top of the double chain, the pinion being frictionally mounted relative to the body of the pallet. Each of the vanes is guided by overlapping branches 457 and 458 456 of his body on the rail 467. The front edge 498 of the pallet cooperates to slip against the inner surface of a skirt extending over the entire circumference of the apparatus.When a pallet comes opposite a workstation, it is at zero velocity and its body overlaps a rail section 470. The ram 481 is on and the pallet is moved radially outwardly, its longitudinal edges engaging the grooves 489 and 491 from the machine. At the end of the movement, the second rail section 478 is in the extension rail portions of adjacent 467 and restores the continuity of the rail.A station has the same general organization than the one of the preceding embodiments. They are angularly spaced by an integer multiple of the width of the pallets.The different work stations are made from a structure which is identical for all the stations and the assignment of the station is obtained by selection of the head or working set reported 482 and 483 on the eolonnes .Referring now to fig.. 19a to 2la. In this fifth embodiment, the wicket 701 comprising the receptacle for receiving the tray 702 703 704 of the pallet is provided in a block 705 carried by the columns 706 and 707 constituting the structural members of the workstation. The latter are fixed to the end of the arms 708 and 709 711 beams interconnected by a web 712. The crew tool holder is constituted by a block 713 714 paraUélépipédique slidably mounted along a 706 and 707 columns and subjected to the action of the movable member of a jack or press 715 716 carried by a bar 717.This arrangement is particularly advantageous in case the press develops a high effort.A teile station structure is usable, that the machine is to circular plane or although the circulation circuit comprises two parallel strands of R cents etilignesraecordés therebetween.Referring now to fig.. 22 to the apparatus automatically operating, or automaton, whose operation is to be controlled, can be part of a machine having more automata. Briefly, it includes a carriage of m (Figure 22) for movement in one direction and within the other along a horizontal run of ends a and b (fig.. 23).The carriage the m carries a T-head.The ends a and b m is the stroke of the slide, the head T may separate from the carriage and vertically runs along two déplqeer , respectively an AC and BD.The head T is provided with a gripper P-able to adopt two positions, an open position shown in solid line in Figure. 22 and a closed position shown in broken line.Such a state machine is able to take a part in a bowl I, point c being within the bowl I, and then coating it on a pallet transfer F. adjacent the end of stroke'd.In each of the points has, and b, and c, d are provided three sensors cooperating respectively with the carriage of m, the head T and the clamp P. sensors corresponding to the carriage and to the head are excited when the coronary artery is to their close proximity, and the sensor associated with the clamp is excited when the latter is in one of its two conditions, for example the closed position.In the arrangement shown, the end of stroke has is to the left and at the top, that has been translated by affecting the letter G sensor carriage m to near the end of stroke has and the 619,390 letter H at T-sensor. The end of stroke b is right and top.The operation control device comprises a panel consisting of plate 515 (Figure 24) on which are tmcés of vertical lines 516 and 517 horizontal strokes defining rows and columns. Behind an appendage clear 515a of the plate 515 are, in the extension of each of the lines, placed diodes électrolnminescentes 5181, 5182, andc.The diode 5181 est MD1 connected to the sensor, the reference m lo and being used here to recall that the sensor cooperates with the slide m and the reference'd stanti used to recall that the sensor becomes operative when the carriage is in its right end position.The diode 5182 est mgs connected to the sensor, the reference ls g being used to recall that the sensor is operative when the carriage has arrived at the left end of the stroke.The diode 5183 est MC connected to the sensor, the reference T being used to recall that the sensor is arranged to cooperate with the head and the reference H for recalling that the sensor is operative when the head is in its upper position.The diode 5184 est TBs connected to the sensor, the reference b being used to recall that the sensor becomes operative when the head is in its bottom position.The diode connected to the sensors 5185 est P and being energized when the sensors cooperate with the clip P-P in its closed position.The diode is connected to the sensors 518ó P and being energized when the sensors cooperate with the clamp in its open position, another appendage s0 behind a transparent panel 515 519 are placed further LEDs 5210... 5218, horizontally aligned, the various diode 521 being respectively confronting each of the columns is limited by the vertical lines 516. sSs the diode 5210 est excited when control of the automaton corresponds to the initial position thereof, or position 0.The diode 5211 est excited when control of the AUT: ornate corresponds to position 1 thereof, and so on, and the diode 5211 which is the last in the row, is energized when the control of the automaton corresponds to position 8, the arrangement described herein is present for a cycle of operation of the automaton comprising eight positions.The vertical lines 516 and 517 delimit the horizontal strokes, by their intersections, a number of boxes rectan4çgulaires 533 some of which are transparent and other opaque depending on the expected running for the various operations of an automaton.Advantageously, the panel or plate 515 is an opaque material sheet and transparency of rectangular boxes s0 is achieved by simple punching. It has, in Figure. 24, plot of the diagonals in the transparent boxes; the bins not having diagonals are opaque.In the position shown in Figure. 24, the LED 5210 est turned on, and the other diodes 521 are turned off.The diode flashes 5210 indicates to the attendant that the automaton is in position 0.The first line or horizontal row, the diode 5181, is assigned to position to the right of the carriage the m, which is indicated to the carrier by writing word carriage enrollment in a box 522, provided as an extension of said horizontal row and by writing word straight in a bin enrollment 523, adjacent, also a continuation of said row. In front of the horizontal row immediately underlying, in the extension of the diode 5182, at block 524, 6s underlying at block 523, indicates that left. The two bins 523 and 524 are adjacent to block 522, which thus has a height twice each of the bins 523 and 524.The diode 518s, the next horizontal row terminates in a checkbox 525 high and carrying an indication that pocket is overlying a bin 526 carrying an indication low. The bins are adjacent to 525 and 526 527 a checkbox, double-height, carrying an indication head.The case immediately lower 528, of same height as at block 527, the covering lacquer clip. It is 529 and 531 two bins, the indicia bearing respectively closed and open.Squares 532, 532', 534, 535, 536, 537 are adjacent compartments comprising 523, 524, 525, 526, 529, 531 respectively, and the indications are carried therein, namely the sign + or - sign, symbolize the information contained in the bins 523, 524, andc.The letter has symbolizes the chañoto the letter b symbolizes the head.The letter C symbolizes the clamp.For the carriage, the sign + in box 532 symbolizes in its upright position and the sign - in box 532' its left position.For the head, the sign + in box 534 symbolizes the high position and the sign - in box 535 the low position. For the clip, the, sign + in box 536 symbolizes the closed position and the sign - in box 537 the open position.References with individual compartments 533, rectangnlaires , clear or opaque, have a first index that biases the rank of their column and a second index that biases the rank of their line or horizontal row. For example, the bin 533.0.1 is in the same column as the diode 5210 and in the same row as the diode 5181; the case 533.2.1 is vertically aligned with the diode 5212 and horizontally with the diode 5181.A simple glance then allows the attendant to be notified about the operation of the automaton. The only rule it has to retain, is that each phase of operation of the automaton, as shown by the lighting of the diode 21 corresponding, should light up, among the diodes 518, limited to those that are horizontally aligned with the bins transparent 533 of the column corresponding to said phase and the diodes 518 aligned horizontally with the bins non transparent column must remain éreintes . This prescription is almost intuitive and more manageable to apply.The non-firing of a di OED 518 horizontally aligned with a bin transparent column above the diode 521 ignited indicates to the attendant a faulty operation.Distinguishing the condition of transparency or opacity squares 533 may be facilitated by the presence of a light source in the panel 511 which comprises the plate 515.In Figure. 24, the diode 5210 est ignited and the other diodes are, consequently, extinguished. The attendant finds that, in the column above the diode 5210, the bins 533.0.2, 533.0.3 and 533.0.6 are transparent. It has to verify that during this phase corresponding to the diode flashes 5210, the diodes 5182, 5183 5186 and ignite. Ignition of these diodes advises that, for this phase, the state machine is in normal operation.In this phase, indeed, or phase 0, the carriage M must be left, in cooperation with the detector thus mgs, which corresponds to the ignition of the diode 1 5182; T-head must be in a high position, in cooperation with the detector MC, which corresponds to the ignition of the diode 5183; the P-clamp must be in the open condition, as sensed by the sensor ipo.If, during the phase to which corresponds the light emitting diode flashes 5210, a diodes 5182, 5183 5186 or does not ignite, the attendant is informed of an abnormal operation. If, during this phase, a diode 518, other than the diodes 5182, 5183 518ó and turns on, it pulls the same termination.When the operation is normal, what has been verified by the attendant, as indicated above, the diode électroluminestente 5210 turns off and the LED turns on 5211.The machine then begins its next operation or phase 1. check conditions of a good machine for this second phase is washed in the same manner as was indicated above for the O phase.The phase 1 of the apparatus is defined by the arrangement of the windows 533 transparent column above the diode 5211; in this phase, the carriage M must be stayed at the left end of its stroke; the head T is in its lowered position; the P-clamp must be remain open.The caretaker verifies that, in this phase where the LED 521a is turned on, to the exclusion of other diodes 521, l0 ignites the diode 5181, on the line corresponding to the transparent 5331.1 of the column 1, the diode 5183, on the line of the case transparent 5331 .a and the diode 518s, on the tigne 533ls bin, the other diodes éreintes remaining 518.The phase which follows, or phase 2, distinguishable phase 1 that Z's by the fact that the clamp closes for gripping a workpiece W in the bowl.In the next phase, or phase 3, translated by the lighting of the diode 5213, the carriage is to the left, the head to its upper position, the clip in its closed condition for holding the workpiece.The bins of the columns 4, 5, 6, 7 and 8 define, by those which are transparent, the phases 4, 5, 6, 7 and 8 of switch operation for.At any time, the operator can thus check the accuracy of the operation and, if necessary, an incident.The table 15 columns 9 and 10 carries it conforms to an automaton provided for ten operating phases, and not only eight, as described above.The panel 511 is reported advantageously on the top side of a rectangular box 541 542 enclosing the automaton.The top wall of the housing 542 541 549 bears an indicator, ignited when the apparatus is powered. Also a button 551 whose three positions correspond respectively to an automatic operation of the apparatus, to a manually operated a discount Way zero.The side wall 543 of the apparatus includes a table 544 to three-square 545, 546 and 547, respectively corresponding to the carriage, to the head and to the clamp, the symbols A, b., C. corresponding being flanked by the signs + and - respectively.Each bin 545, 546 and 547 are present buttons respectively 548aet 548a + for at block 545, 546 548bet 548b + for the bin, the bin for 548cet 548c + 547. By the operation of the buttons, is controlled manually, by the knob - 546b, movement to the left of the carriage; by the momentary 548a +, the movement toward the right, by the control of the knob - 548B , movement of the head downwardly, by the momentary 548B +, movement of the head upwardly; by the knob - 548C , release of the clamp and, by the knob 548c +, the closure of the clamp.Identifying the various components of the apparatus provided with the device for monitoring the operation that described by symbols or marks which are those that includes the control device. For example, for the head of b, the sensors associated thereto will the letter b and, depending on whether they correspond to the up position or the down position, the sign + or - sign.Also, the dispenser, the action of which control the ascent and descent of the head, is identified by the letter b and to one and the other of its positions corresponding to the ascent and descent of the head, can be read + or - respectively.The control circuit board of the dispenser is provided also with the same letter and signs + and - depending on its intervention causes the dispenser in one or the other positions which has been defined above. this eases considerably ós operator's intervention when it detects an operation abnormality through observation of the control device.619,390 the apparatus includes means for allowing the passage of an operating phase to the next phase of operation only if its members, at the end of the first phase, realized in the positions required.Referring now to fig.. 26 to 29.The automatic apparatus includes an aperture 591 to two gate body 592 and 593 tracks or guide paths providing 594 and 595. All of the members of the apparatus is enclosed in a housing formed by two sheets 601 602 and 603 which are folded along lines 604 and 605 and 606 and 607 whose edges are opposite each other. On the 592 and 593 body teller machines are mounted, by means of screws 611 and 612 to head, 613 and 614 posts, advantageously made of transparent material, such as plexiglass, the attachment being perfect 615 and 616 by studs extending through both the posts 613 and 614 that the body 592 and 593 teller. 613 and 614 the posts have vertical 617 and 618 paths provided for slidably mounting a nontransparent panel 619. The lower part 621 of said panel remains free. The top, about over two thirds of the height of the panel, receives, by gluing, a sheet 622 nontransparent material which bears at the top a table to lines and eolonnes 623.The transparent panel 619 is traversed, at its top, by a rod 624 which is integral with a knurled head 625, within reach of the operator, an elastic ring 626 layer maintaining the rod 624. The latter, in the position shown in Figure. 26, is introduced, advantageously with interposition of a rubber O ring, in a housing 628 627 that has a block fixed to the housing.Laterally to the vertical edge of the instrument panel 629 623 and in register with the various lines of the panel are located light emitting diodes 631. These diodes are advantageously fixed on a printed circuit board 632, forming part of a stack of cards, which is carried by a printed circuit board 633. 630 stores a horizontal LED borders the side hoñzontal dash upper 623.Protruding from the top wall of the housing 634, 636 635 button joystick is own apparatus is to be contained in the housing 601 in operating condition and a condition inopératoire , and an indicator light 637 shows, by its ignition, that the apparatus is out of order. A tray or pallet slide 646 645 integral with a U-shaped cross section, which serves to guide it in its movement in the installation, from a machine capable of the automatic apparatus according, is suitable for insertion into a teller window consisting of two body slides 592 and 593.On a post 641 of the apparatus is mounted, by means of a bracket 651, to rotation about an axis 652, 653 a cover made of transparent material to two branches 654 and 655 perpendicular to one another. Said cover is, at its other end, rotatably mounted on a post of another apparatus of the installation, preceding or following apparatus shown in the direction of movement of pallets 645.Inner surfaces of walls 602 and 603 are advantageously coated with an insulating layer, respectively 656 and 657.In the position shown in Figure. 26 and on the left side of the Figure. 29, the transparent panel 619 is in its normal position of use of the apparatus. By its lower part 621, it allows observation of the inner members to the housing 601.The lower edge 656 of the panel 619 is then flush with the lower ends of the uprights 657 and 658 613 and 614.If, for any reason, the operator wishes to gain access to the interior of the housing 601, it catches the knurled head 625 and exerts on the latter a tensile: by virtue of the flexibility of the constituting plate panel 619, the rod is disengaged from the housing 627 624 and the upper edge of the panel 619 659 escapes from the top wall of the housing 634. By lifting the panel 619, it moves, its lower end being guided in the 617 and 618 619,390 paths. Thus causing the panel 619 in the position which is represented on the right hand side of the Figure. 29 and in Figure. 28. This position is maintained d'elle itself due to the elasticity of the constituting plate panel 619 that applies the inner face of the panel against the anterior edge of the upper wall of the housing; the rod 624, by cooperating with said wall, prevents back in securing the panel 619 in its initial position.When it is desired to occlude again the bay 661 produced during of sliding up the panel 619, lo and it is sufficient that the attendant pulls to separate hair 625 from the position shown in Figure. 28 to disengage the rod 624 relative to the top wall of the housing and being slid 634 said panel downwardly back into its initial position.In the position shown in Figure. 26 and the left-hand portion of the Figure. 29, the cover 653 covers the portion of track or rail traffic pallets or trays 645 between two apparatuses or successive work stations. A cover 662 has been shown in the extension of the cover 653 and overhanging a track parallel to that covered by the latter.In the position shown in Figure. 28 and the right hand part of the Figure. 29, the cover 653 has been lifted: the portion of the track or rail as covered lid in the other position is thus has become accessible.In the embodiment shown in the Figure. 30 and 31, the pinion carried by a pallet 1701 1702 includes two rest pads 1703 and 1704. An elastic device supported on the holding body 1705 1706 of the pallet biases the pinion against the tray 1701 1707.1708 the teeth of the pinion are pointed to facilitate their reengagement in the links of the chain 1709 1710.In the embodiment according to fig.. 32, the structure of the machine includes a spar 1711 and 1712 est crew tool holder by the action of two rams, respectively 1713 and 1714.The organization of the station is similar to what has been described above with reference to fig.. 19a to 2la.In Figure. 33, a pallet 17021 est facing the teller 1715 by abutment against a stop its rib 17161 éclipsable 1717a.The next pallet 17022 est in abutment against a stop means 1717b.In the embodiment shown in the Figure. 34 to 36, the 1751 station includes storage means vertical pieces 1752, constituted by a chimney open at its port inféñeur 1753 1754. It is opposite a pushing device or supply 1755 1756 to cylinder and piston 1757. The carriage comprising the rail tracks 1758 1759 and 1761 has a rim i762 terminating in two fingers 1763 leaving between them a gap for the passage of the rod of the piston 1757 1764.In the position shown in Figure. 34, the clip 1760 P-takes a workpiece placed on tray 1765 of the pallet. In the condition shown in Figure. 35, the clip device actuated by the cylinder 1766 1767 has lifted the piece P. 1758 carriage has moved such that the fingers are 1763 in vertical piece e. by lowering the device gripper carrier 1766, the workpiece w comes to rest on the fingers 1763.By movement of the reverse carriage 1758, the part P and deposited on the fingers 1763 est brought opposite the lower port 1752 1754 of the chimney.In the position shown in Figure. 36, another room w 'has been brought by the tray 1765' plumb with the clip 1764. The part P is in the condition origins can be fitted into the chimney 1753 1757 the piston action.The machine equipped in this way is then able to perform work machining or assembly to one or more stations, even if one of the stations that it comprises is temporarily out of operation state.The R i8 619, 39 drawings sheets (18 n° I-sheets The transfer machine comprises six work stations (21-26). Three stations (21, 22, 23) are located along a first straight strand (27) of a link chain (28) which entrains component-carrying pallets, and the other stations (24, 25, 26) are arranged along a strand (29) parallel to the strand (27). The strands (27, 29) are connected by circular parts passing over two end pulleys (31, 32) so that the chain (28) forms a closed circuit. Three stations (22, 23, 26) comprise bowls (81, 82, 83) for supplying components to be machined and/or to be assembled. The bowls (81, 82) are provided with feed chutes (84, 85). Boxes (87, 88) are provided for controlling the feed bowls (81, 82). A station (25) is provided in order to be manned by one person, who makes use of a worktable (86). When a component carrying a pallet arrives at a work station it is displaced transversely towards the outside of the chain (28) by means of a rail. <IMAGE> 1. transfer apparatus for assembling and/is the processing of workpieces, comprising a plurality of workstations distributed along a closed circuit for circulating pallet holder, characterized in that the work locations are external to the circulating circuit, means being provided for moving a pallet carrying a work assembly part is transversely from the circulation circuit to the working position and vice versa. 2. machine according to claim 1, characterized in that a workstation comprises a set of interlocking and control at least part of which is housed inside an enclosure enclosing the circulation circuit. 3. apparatus according to claim 2, characterized in that, for a station, the affected part machining and/or assembly is external to the casing. 4. machine according to one of claims 1 or 2, comprising circulating track of pallets, characterized in that at right of a workstation, a circulating rail comprises a section movable transversely relative to the rest of the rail. Machine according to claim 4, characterized in that at right a workstation is provided a second rail section which, during the transverse movement of the first section, engages behind the [...] initially reactuated. 6. apparatus according to claim 5, characterized in that said second rail section is a section of traffic pallets. 7. apparatus according to claim 6, characterized in that the second rail section comprises a stop for the pallets arriving at the station. 8. apparatus according to claim 4, characterized in that the rail section carrying the pallet reaches the end of its stroke in a wicket cross-exterior to the enclosure. 9. apparatus according to claim 8, characterized in that the machine includes a bearing member of the pallet able to absorb the machining force. Machine according to claim 1, characterized in that it comprises, year right of a workstation, a sensor cooperating with a pallet arriving for the determination of the further movement thereof. 11. Machine according to claim 1, characterized in that the pallets are driven from a chain and are immovable tower while remaining connected to the chain, through the interposition of a pinion that comprises the pallet and arrested to friction with respect thereto. 12. a machine according to claim 11, characterized in that the drive means of the chain comprise a pallet by means becoming [...] when the driving resistance of the pallet becomes larger than a set value. 13. Machine according to claim 11, characterized in that the plate driving means are arranged to impart thereto a movement along a substantially sinusoidal law, having a period corresponding to the length of a pallet along the direction of motion is a submultiple of [...] length. 14. Machine according to claim 13, characterized in that the workstations are separated from each other by a multiple of the length of the pallets. Machine according to claim 11, characterized in that, on the chain, the pallets are spaced apart with an integer multiple of the length of the pallet, the predeterminable multiple zero. 16. Machine according to one of the preceding claims, in that a non-[...] station automatic assembly connected a workpiece supplying apparatus, means being provided for fixing the position of the assembly part relative year connecting device of the station. 17. Machine according to claim 16, characterized in that the device comprises means for bringing, along a same path, its means operative in a first engaged position of parts in a supply path, in a second position, retracted, to allow engagement of a pallet in a wicket and in a third position for the depositing of the workpiece on the pallet. 18. machine according to one of claims [...], characterized in that a vane is carried by a support LO pallet engaged to overlap on circulating track. 19. The machine of claim 18, to rail provided for circulation of the pallets, characterized in that it comprises means, in a circular path of the ratified, maintain a pallet support on its various sides. 20. Machine according to claim 19, characterized in that the outer face of the vane carrier is curved to cooperate with guide means slidably, concentric to the axis of the circular portion of the running rail. 21. Machine according to claim 1, characterized in that it comprises a set of control and servo suitable for driving the transverse movement of a pallet to a set automatic machining and/or assembling is to a shelf for assembly and/is the manual. 22. a machine according to claim 1, characterized in that the structures of the individual work stations are identical and comprise a transverse beam to the circulating circuit pallets and having two arms which are [...] columns. 23. Machine according to claim 22, wherein the means [...] transverse displacement of a pallet work site are supported by the beam. 24. Machine according to claim 22, [...] in kilos a window for receiving a vane is formed in a block fixed on the columns. Machine according to claim 22, characterized in that the machining device or assembly is carried by a slide block on the [...]. 26. The machine according [...] 25, characterized in that the machining device is removably mounted on the block. 27. Machine according to claim 25, characterized in that the bearing block of the machining device is subjected to the action of a press having the effort is directed parallel to the two columns and 4s midway thereof. 28. Machine according to claim 22, characterized in that the circulation circuit of the pallets is horizontal and circular, the machine frame having a central pillar and radial beams. oS 29. Machine according to claim 28, [...] the pallets are driven according to nn substantially sinusoidal motion by means of a notched disk cooperate with the lugs of a tray driven by an electric motor, whose axis is parallel to that of circular flow vanes. s5 30. Machine according to claim 29, characterized in that each pallet is driven by a gear meshing with and that it has a chain running around a sprocket. 31. Machine according to claim 30, characterized in that the pinion is mounted on the pallet by means of a force limiter. 32. Machine according to claim 30, characterized in that the gearwheel is surmounted by a stationary platen carrying, facing each of the workstations, [...] stops for the pallets. 33. Machine according to claim 1, characterized in that a station includes a storage area of workpieces and/or to assemble, as well as means for the supply and removal of the parts from and towards the pallets in circulation.