Tool for the machining of surfaces.

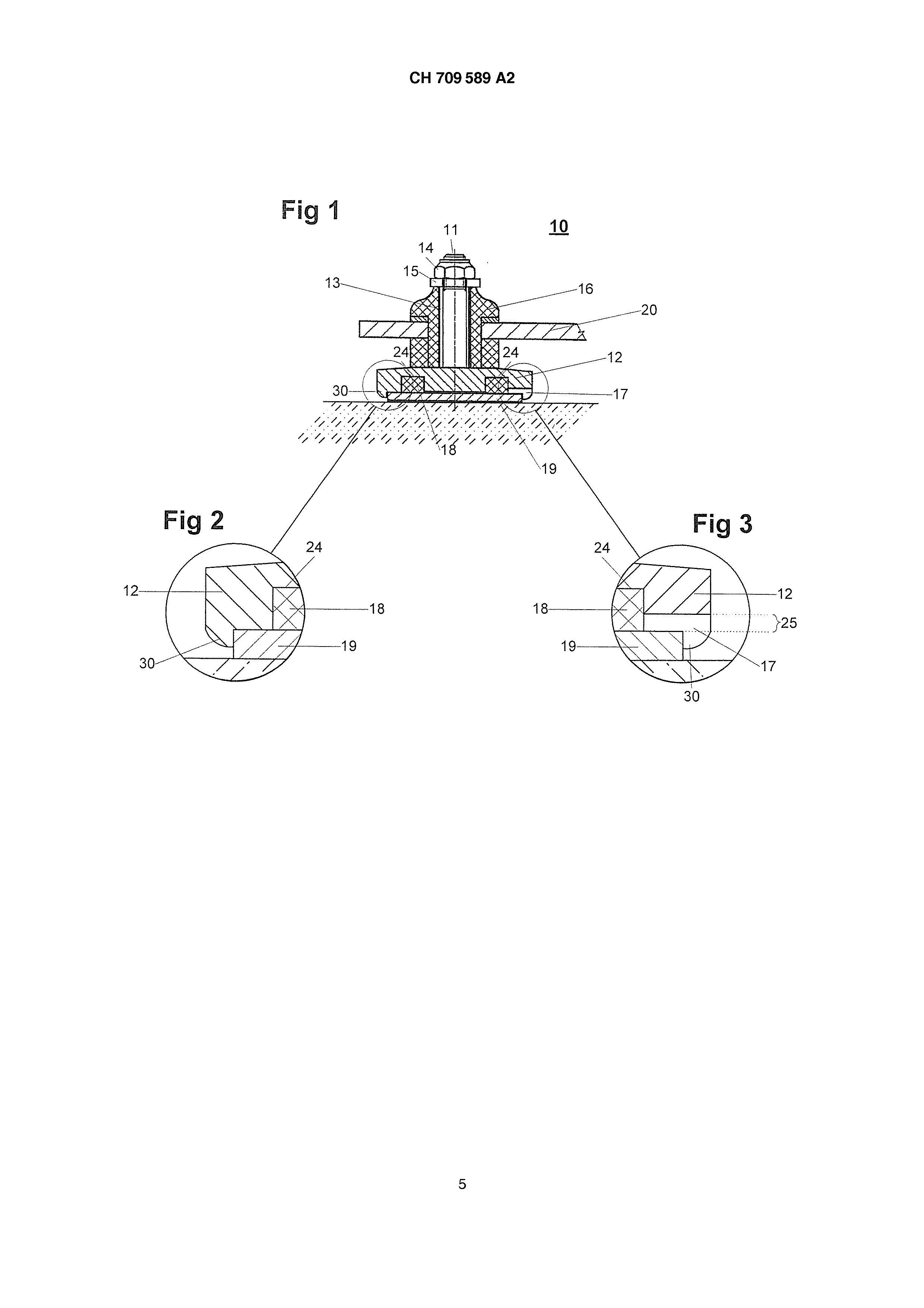

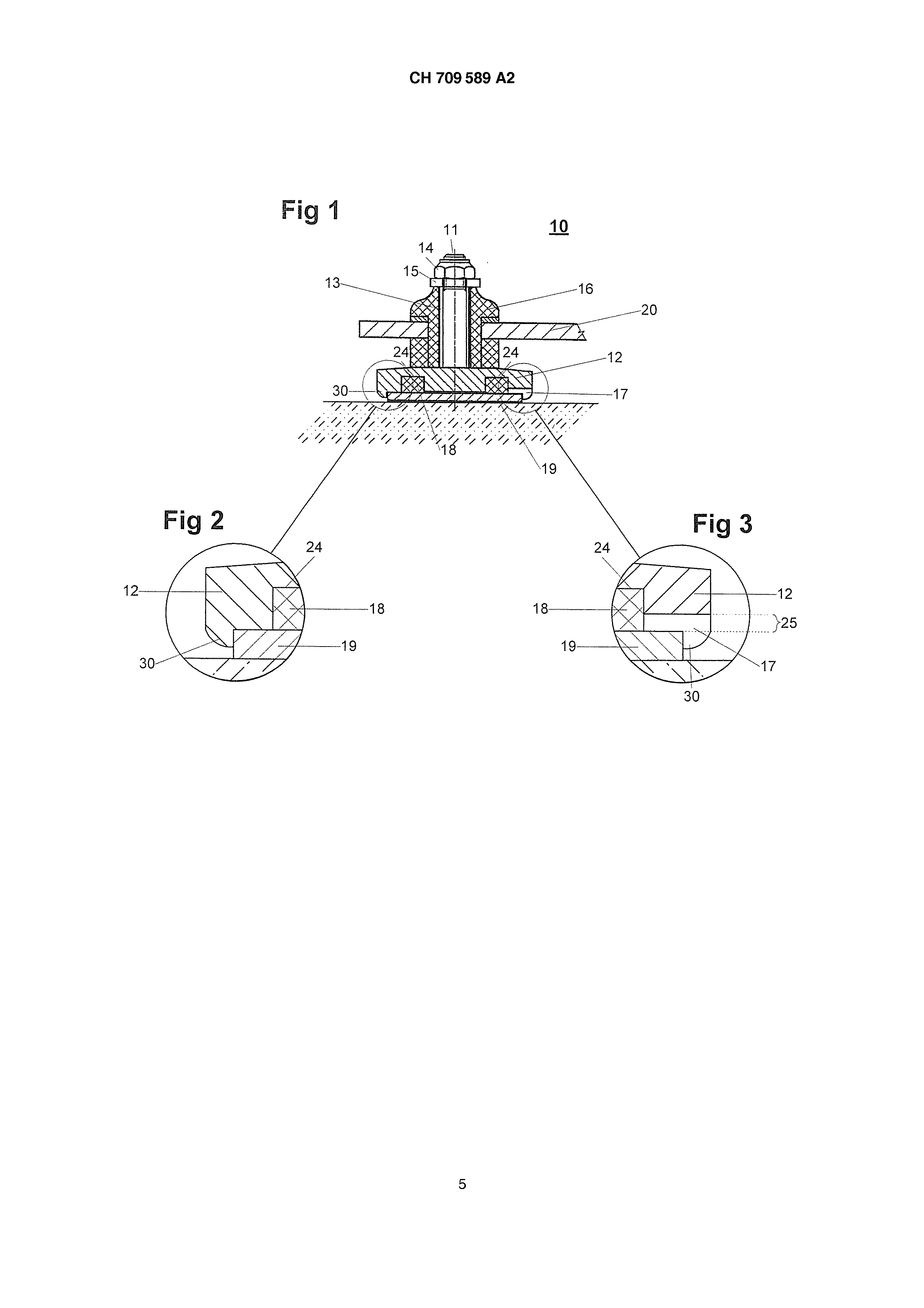

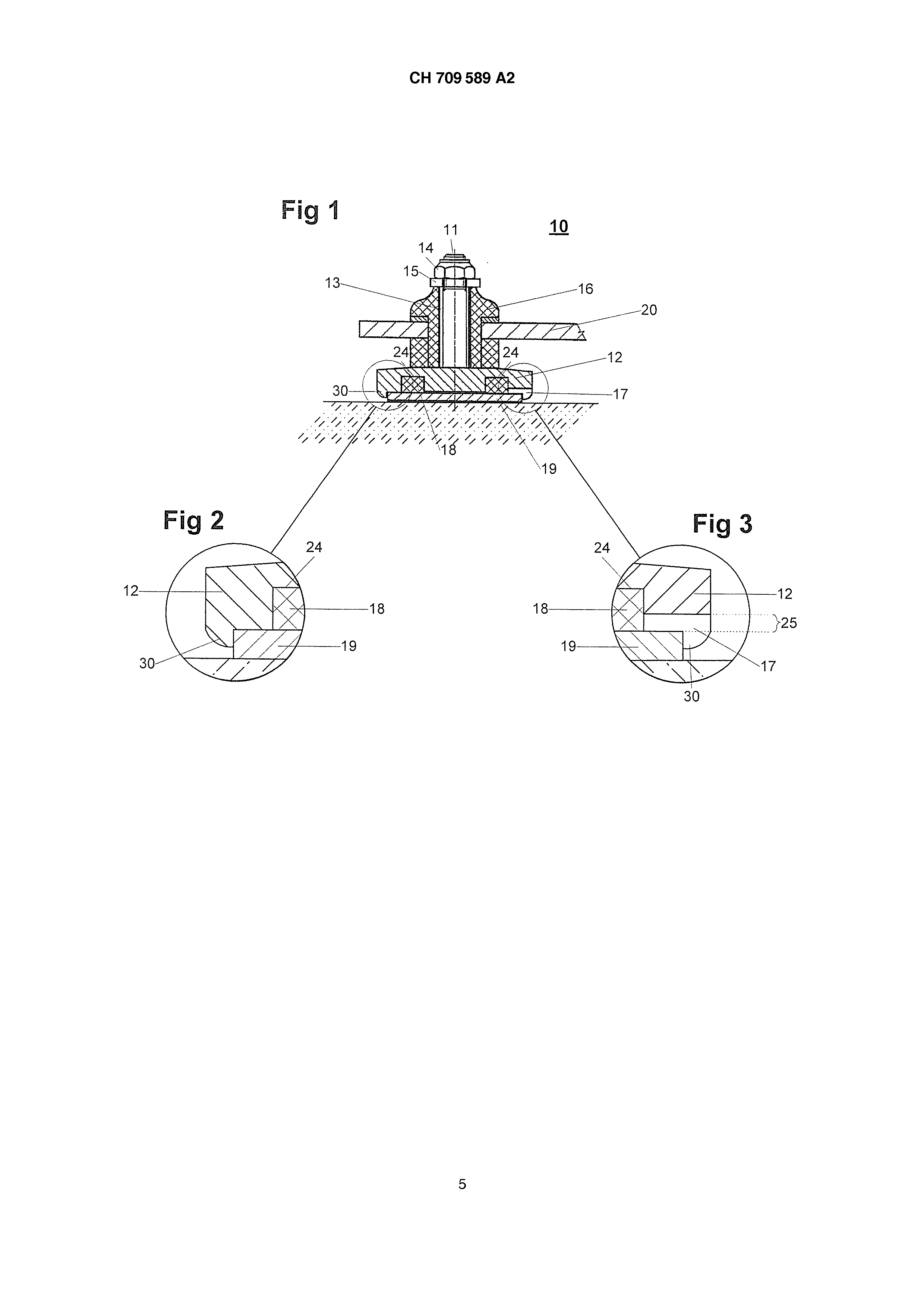

[0001] The present invention relates to a tool for the machining of surfaces according to the preamble of claim 1. [0002] Instead of conventional tiles today often so-called design materials are laid. This so-called design materials consist of a base, a binder and a Design additive. The base can of cement, concrete or mortar are made. If the base not already includes cement or concrete, a binder is added, e.g. a hardening Bicomposite adhesive,. The Design addition a e.g. a color can, pebbles or coarse sand grains, etc., just be a decorative element. Design soils can with pattern, images or other free decorative means are designed. [0003] You such building materials for base plate and wall coverings a. They are popular in interior designers, because the mixtures are very freely selectable for design purposes. Any wall and each bottom may be unique. Another advantage is the laying of such linings. With the corresponding skill this is with known techniques to make readily. Wall coverings and floor coverings are cast and planed facade renderings applied as are. The latter also come into question as a conclusion on a support provided with floor heating for example. [0004] While for a living surface structure has also very much like to wall coverings, one wishes for floor coverings possible flat, [...] surfaces. That is to say by means of a suitable tool after the casting in such linings and a surface machining planed must, be ground and polished. An example of such a known from EP 1,806,206 A1 is Cultivation device. [0005] In the renovation is made by default on wooden floors, natural stone floors of marble, granite, basalt [...]etc. Even tiles of artificial stone on epoxy base and other such as concrete, mastic asphalt, floors, etc. is found before. This are usually dirty and partially worn away by the use. In pores and joints subject to some time to accumulate dirt, which are no longer with the normal cleaning to remove. One has then the choice, the whole bottom by a new lining on the ground as to replace the existing floor covering or to Edit that these dirt Removing together with as little as possible proportion of the floor covering. [0006] In principle, all floor coverings are recognized, of course, than surfaces, even though the individual elements, e.g. at a bottom of the is covered with tiles, have different heights for nuances. Each is gaining ground, moreover, a better structure and acts more lively, but also have ground planks or plates in minimal differences in height when one another. The differences in height are dangerous and are thus not form [...] Two such changes, but unevenness in the range of up to 0.1-0.2 mm. [0007] Up surface treatment machines and tools for the equalization newly potted soil known, or the purification, renovation of old stone grounds art portion of natural or synthetic rubber, are usually provided with diamond tools, are mounted on rigid plates. [...]cast stone grounds point but, as described above, depressions and asperities on. In thereby deeper locations and unequal heights can not engage on a flat and rotating plate fixed diamond tools, or are at such height differences on. [0008] At worst, they lie slightly higher damage parts. [0009] Conventional systems are therefore either rigidly, as in the patent publication No EP 1,806,206 A1, or they are presented as (to) movable in No US 2005/0 172 428. [0010] The present invention a tool for the machining of surfaces is a challenge to improve of the kind discussed above that the benefits of the known surface treatment machines be maintained, with the apparatus but also to the widest possible variety of materials such as wood and also inhomogeneous, natural or artificial stone, as well as other surfaces can be processed. [0011] This task is solved by a device having the features of the above claim go from the dependent claims and their 1st Further according to the invention features are explained advantages in the following description. [0012] in the drawing shows: Fig. 1 Tool Fig. 2 Detail board of the tool Fig. 3 Detail opening of the rim and free space Fig. 4 carrier plate with tools, supervision Fig. 5 carrier plate with tools, cut AA Fig. 6 soil-working machine [0013] Figures shall constitute embodiments, which are explained in the following description. [0014] 11 (1 Fig.) A mandrel, which is connected in a form-fitting manner with a plate 12 in an operative and the centrepiece 10. The mandrel has, on the opposite side form of the tool for connection to the plate 12, on a thread. A sleeve 13 and 15 are slipped over the mandrel and a backing via the thread 14 secured with the nut tightened. The sleeve 13 ensures that the distance between plate 12 and support 15 is defined and remains. This sleeve is an elastic holder 13 16 arranged in order. Parts of this holder 16 can be fixedly connected with the sleeve for example by vulcanization or with adhesive. This holder 16 in a support plate 20 is positively anchored Am outside diameter. [0015] The elastic holder 16 can e.g. made of rubber, but also from other resilient material, be made. To increase the elasticity and flexibility can be tapered To of the resilient retainer 16 shown, this on the opposite side to the plate 12 that is, on the side of the nut 14, as in 1 Fig.,. Also the carrier plate 20, depending on the desire of the mobility of the tool 10 can closer or further away from the plate 12 are arranged. The greater the distance between plate 12 and support plate 20 is, the more moving the tool 10 is held in the support plate 20. To this distance to be adjusted and the mounting of the tool 20 in the support plate 16 to allow the holder 10 consists of at least two parts. Selecting the materials for the holder 16 is also influenced the mobility of the tool. [0016] The plate 12 has a round recess 23 on, which is limited by a board 30 at the external diameter (4 and 1.2 Fig.). In this recess 23 a groove-shaped, circular recess 23 screwed is (Fig. 1-3). 23 is used for receiving a ring-shaped magnet 18. This This recess is press-fitted into the recess 23 either, or by means of binder so anchored that it becomes stuck in an operative and in a form-fitting manner. The dimensions are chosen such that after pressing of the magnet 23 whose free surface corresponding approximately with the plane of the recess, a small amount, max. 0.3 mm projects. [0017] In of the recess 23 will take place then a disc 19 made of magnetic material (1 Fig.) place. This wafer 19 is held in the recess 23 and then from the magnet 30 secured against horizontal shifting from the board. The disc 19 is made of magnetic material and is provided on a surface with an abrasive coating. Depending on the application with a coarse or a fine can That area diamonds or [...] splinters be provided covering, which are connected firmly with the disc 19 as far as possible. [0018] In a carrier plate 20 are installed usually six tools 10. Between the tools 21 are in the carrier plate 10 approximately at the same radius (Fig. 4) arranged recesses. This serve suction removal of the dust, as produced by the abrasion with the tools 10. The center of the support plate 22 is disposed a Entraining opening 20, into which the drive shaft 20 by means of screw connection with which the carrier plate 7 engages and is 6 Fig. connected. [0019] The 23 held firmly in the recess 18 with the magnets 19 must be exchanged during the entire work process disk. These 19 wears because the abrasive lining of the discs on the one hand, but also then again, because for the scale from a coarse grade abrasive during the process of machining surfaces to a fine granular form and so that the discs 19 are changed, so as to be able to bring the surface of a rough grinding up to the finished fine structure, possibly, to for matt glossy form. The end of the work process is used a disc 19 with a multiple very fine Covering. Especially when a question with one image to Edit design ground is a, it is essential that the surface is ground and polished even-moderately and matt glossy really. [0020] on the construction site with simple means 10 The tool can be operated is to. Therefore the board 30 is provided at a location with an opening 17. This is as wide that with a screwdriver can engage in opening 17. It was so that the disc 18 from the magnet 25 is now a free space 19 can solve (Fig. 3) provided, so that with the screwdriver out-weighted can be gripped and 19 under the disc. [0021] 20 with the tools 10 thereon is Same as above described the carrier plate, via a drive shaft 1 connected with a soil-working machine (6 Fig.) 7. This 1 consists of a chassis 2 and a carriage 3 Cultivation device, which are connected with each other by means of lever 5. A 4 allows height adjustment, adjusting the distance between carriage 3 and chassis 2. With the chassis 7 are 2 drive shaft, support plate 20 and thus the tools 10 connected. This Cultivation device 1 allows, finely adjust the distance to the floor surface to be treated. [0022] 7 on a motor connected to the drive shaft 6 can be adjusted the rotational speed. Usually, 400 rpm for the machining of these varies can e.g. 1800 rpm between concrete and wooden floors and to stone be adjusted for. It makes possible the deep rotational speed of 400 rpm Only that can be processed with this tool 10 also wooden floors. It is a tool for the machining of surfaces presented, which is incorporated in a flexible and resilient support plate 20. The tool 10 consists of a plate of 12, wherein a magnet is installed in a recess 18, which consists of magnetic material, a disc 19 retains 30 in the recess between a board. The disc 19 points to a surface on a abrasive coating, by means of which a bottom made of wood, concrete or design material coarsely and finely to for polishing can be processed. 1. tool for the machining of surfaces, consisting of a mandrel (11) with a plate (12) is solid and on the other end has a thread connected, wherein over the mandrel (11) a sleeve (13) is placed, which is made with a support (15) by a nut (14) is held fixedly, wherein the sleeve (13) of a holder (16) is surrounded, which in turn in a support plate (20) is anchored, characterized in that the holder (16) of elastic material and consisting of at least two parts and positively around the sleeve (13) is arranged, wherein said retainer (16) externally in a support plate (20) is held. 2. tool according to claim 1, characterized in that the plate (12) has a round recess, where on the outer diameter of this recess a board (30) will conclude it all around. 3. tool according to claim 2, characterized in that in the board (30) and the round recess (23) a recess (21) is mounted. 4. tool according to claim 3, characterized in that in the depression (23) a groove (24) is incorporated, in which an annular magnet (18) is non-positively and positively anchored. 5. tool according to claim 2 and 4 characterized in that in the depression (23) a disk (19) is used. 6. tool according to claim 5, characterized in that the disk (19) made of magnetic material. 7. tool according to claim 4, 5 and 6, characterized in that the disc (19) by the magnet (18) in the recess (23) is held. 8. tool according to claim 2 and 5, characterized in that the board (30) and the recess (23) of the plate (12) an opening (17) has, wherein between the plane of the recess (23) and the opening (17) a groove-form free space (25) is present. 9. tool according to claim 3, characterized in that the disc (19) has an abrasive coating on a surface. Description