Washing machine with water supply through the drum back.

[0001] the invention relates to a washing machine according to the preamble of claim 1. [0002] known from EP 1,700,943 is a washing machine having a tub, in which a drum is arranged rotatably about a horizontal axis. A user door closes the tub from front. [0003] in the door is a water nozzle bellows, supplying water to the drum process. With a special nozzle shape is attempted, the water on the laundry is as uniform as possible to distribute, although in the region of the bellows for the nozzle door little space is present. [0004] of the present invention is the provision of a washing machine of the type named above, wherein a good distribution of the water supplied by the water nozzle process is possible. [0005] from the washing machine according to claim 1 this task is fulfilled. [0006] accordingly has the following components washing machine: - A tub: the tank forms a space for receiving the process water. - About a substantially horizontal axis of rotation in a tub arranged drum: the drum serves to accommodate the laundry to be cleaned. - A user door: this user from the tub and it has the user closes (when the door is opened) access to the interior of the drum. - At least one stationary first water nozzle: this water nozzle is arranged, it can be introduced into the drum that process water. Under "stationary" I mean, not that the water nozzle rotates with the drum. [0007] to the drum at the opposite rear wall further has at least one non-axial opening arranged user door on. The water nozzle is so arranged, that it can be sprayed over water from the outside rear wall, such, that at least a portion of said process water (i.e. the water from the first water nozzle process) passes through the filling opening into the drum. [0008] a "non-axially arranged" in filling opening is a filling opening, which lies outside the axis of rotation of the drum and this is not allowed. Preferably including a filling opening is to understand, radially spaced from the drive shaft of the drum is arranged. [0009] the term "syringe" it circumscribes the transportation of water through an air gap, wherein the this process generating water pressure depending on requirements (in particular depending on the beam direction and desired water speed) may be very low. [0010] the invention is based on the idea, the drum water supply through the filling opening on the rear side. Since the filling opening is arranged non-axially, this happens over said first water nozzle, which injects the water towards the rear wall. By this measure can in particular be well wetted in the rear region of the laundry drum. [0011] on the rear wall is advantageously provided a filling chamber, which communicates with the interior of the drum through the filling aperture (s). It is so positioned, process water from the first water nozzle and temporarily collected in that it receives. The filling chamber thus acts almost as short-term memory for the process water, whereby the water flow between the first water nozzle and the drum interior can be improved. [0012] the proposed technology can be applied in particular at a drum, the drum on which compensation for balancing tank are arranged, on the rear side thereof and a plurality of filling rings are provided for filling the tank preferably individual. [0013] in this case can the filling chamber through a radially outside annular region, between or within the filling rings are filled. This area is located radially outside the filling rings advantageously, since it in this case a higher surface has the same radial expansion, what makes it easier, a relatively large amount from the rear into the filling process water drum. [0014] a large process to ensure water flow, advantageously more fill openings are provided on the rear wall of drum. [0015] in addition to the first water nozzle can be provided a stationary second water nozzle, with which process water can be injected into the drum from the front. The water can still be uniform in entry. [0016] additional embodiments, advantages and applications of the invention result from the dependent claims and from the following description with reference to the figures now. This show: Figure. 1 a schematic section through a first embodiment of the washing machine, Figure. 2 a schematic section through a second embodiment of the washing machine, Figure. 3 execution of the rear wall of the drum from the drum interior seen, Figure. 4 a first inclined section view of figFig. 3 the drum rear wall, Figure. 5 a second oblique view of the drum of figFig. 3 rear wall, Figure. 6 the filler ring arrangement of the rear wall of the drum of FIG. 3 viewed from the front side, Figure. 7 cut along line a-a by the filling ring assembly of FIG. 6, Figure. 8 a section along line b b by the filling ring assembly of FIG. 6, Figure. 9 a oblique view the rear side of the filling ring assembly and Figure. 10 a oblique view the front side of the filler ring arrangement. [0017] concepts such as "front", "rear", "front", "back", "before" and "rear" are to understand from user view, i.e. the user door is arranged at the front and the back of the device is of the door apparatus opposite side formed. [0018] under a "substantially horizontal axis of rotation" is understood to mean an axis of rotation, which mounting of the washing machine intended not more than 30 °, in particular not more than 10 °, is inclined to the horizontal. [0019] the terms "radially" and "tangentially" are relative to the axis of rotation of the drum to understand. [0020] Figure. 1 shows some important components of a washing machine in this context. In particular the washing machine having a tub 1, a space for receiving the process defined water. In the vat 1 is a drum 2 disposed, which is rotatable about a substantially horizontal pivot axis 3. [0021] the tub is in known manner in a housing of the washing machine can be deflected elastically and damped (not shown) arranged. [0022] the drum 2 is rotatably mounted in the tub 2 via a drive shaft 4. A drive motor (not shown) at 4 on the drive shaft engages, with which the drum for rotation about the axis of rotation 3 2 can be driven. [0023] on the front side of the drum 2 and of the tub 1 is a user door 5 arranged, via an elastic bellows 6 which is sealed against the tub 1. [0024] on the underside of the tub 1 is a drain 7 provided, with which process water can be supplied to a pump assembly 8. With the pump assembly 8 can the process water in the drain or be conveyed e.g. circulates. For circulation of process water the pump arrangement has a circulation pump 8, with which the process water (depicted only schematically in the figFig. 1) via a circulation line 9 a first and a second water nozzle 10, 11 can be supplied. [0025] the first water nozzle 10 is arranged on the rear wall 14 of the drum 2 and fixed stationary tub 1. It serves, process water into the drum above the rear wall 14 to table. This is more particularly described below. [0026] the second water nozzle 11 is arranged in a stationary manner in the region of the bellows 6 and also serves, injecting water into the drum 2 from the front. [0027] 9 may be provided on the circulation line 15 heating, the process water, which is circulated, to heating. [0028] figFig. 1 as further seen from, the rear of the drum 17 further nozzles 2 are arranged, via which water in filling rings 18 on the drum back can be injected. This water is on pipe joints in countervailing tank 19 on the drum 2 guided and serves, balancing the drum when centrifuging the laundry. Corresponding arrangements are e.g. from EP and EP 2,944,717 1,693,500 skilled in known and are described in more detail here. [0029] the processes in the apparatus are controlled by a control 20, which in particular the operation of the pump assembly 8, the heater 15 and the water nozzles 10, 11 and 17 controls. [0030] the first water nozzle 10 serves, as mentioned, the supply of process water from the rear into the drum it is arranged 2nd thereto, by filling openings 22 in the rear wall 14 to process water can make. [0031] in the execution according to Figure. 1 my filling chamber 24 is arranged on the rear wall, into which the water nozzle 10 injects the process water. From there the water runs through the openings 22 into the interior of the drum 2 process. [0032] a large amount of process water can collect as possible, the filling chamber 24 forms a radially inner and a radially outer pocket or pocket 25a/25b. Depending on the rotational speed of the drum and the drum 2 can place one or both of process water pockets 25a, 25b to the filler openings 22 are collected and guided. [0033] in the execution according to Figure. 1 the first water nozzle 10 the water injected in the axial direction from the rear into the filling chamber 24 a. [0034] extending 360° about said axis of rotation via the filling chamber 24 advantageously 3 2nd water drum, which is not directly with the first water nozzle 10, i.e. above, entry into the drum 2, so that the filling chamber 24 can run down along and filler openings 22 into the drum 2 by lying below occur. [0035] in operation the washed laundry in the drum 2, not shown in the tub water through a process by first inflow 1 is introduced. The drum 2 is rotated only with relatively lower speed, and at the same time the process water from the effluent to the circulation pump via the circulating line 9 7 to the water nozzles 10, 11 guided, via which it fore and aft of the laundry is conveyed, so that a uniform wetting of the laundry can be achieved. [0036] after completion of the actual pumping of the process water and the laundry washing process can optionally be centrifuged. At this stage the drum 2 is rotated at high rotational speed and can be balanced in known manner, on the nozzle 17 into the balancing tank 19 by water is introduced. [0037] Figure. 2 shows a second embodiment of the invention. This is different from the first configuration characterized in, that the water from the first water nozzle 10 into the filling chamber 24 and there injected radially from the radially inner pocket 25a is collected. In this case the water nozzle 10 behind and radially outside the drum 2 is arranged, for example on the casing wall of the tub 1. [0038] in Figure. 3a 10 on the basis of the execution of the washing machine is a specific third components on the rear wall 14 of the drum 2 represented. [0039] Figure is first on. 3 - 5 referred, the rear wall 14 of the drum which show, as well as a shaft attachment 30, the drive shaft 4 and a filler ring assembly 31. [0040] the rear wall 14 is formed for example of a mold plate, wherein said non-axial inlet openings 22 are arranged. Such openings are provided in the present example 3x4. This number, as well as the shape and size, the inlet openings 22 may vary. A plurality of inlet openings 22 are advantageously provided but, which rotationally symmetrical about the axis of rotation of the drum are distributed 3 2. [0041] on the rear wall 14 is fixed to said shaft attachment 30, which in turn carries the drive shaft 4. The shaft attachment 30 according to this embodiment has three mounting arms 32, which are connected with the rear wall 14 and meeting at the center, to form around the base for the drive shaft 4. [0042] in the fixing arms 32 33 for supplying water to the balancing tank 19 extend tubes and for away-drove water from the same. [0043] the filling ring assembly 31 forms the filling chamber 24 and the filling rings is a plastic injection molded part advantageously 18th. Its structure is hereinafter with reference to Figure. 6 - 10 more particularly described. [0044] in the middle of the filler ring assembly 31 is an opening 34 for receiving the driveshaft 4 provided. Extending around the three filling rings 18, 19 through which water in the compensating tank can be filled. Each filler ring 18 (figFig. 6, 9) is connected with a pipe section 37, which in turn each with one of the tubes 33 (Figure. 5) communicates. [0045] the filling chamber 18 is arranged radially outside the filling rings 24, which in this design a radially inner pocket 25a for receiving the process water (figFig. 7, 8) forms. [0046] 14 towards the rear wall of the drum 2 is in the filling chamber 24 in three 38 (figFig. 4, 6, 9) hydrants away, preferably on the rear wall 14 which sealingly abut. The hydrants 38 are arranged, that each thereof each a group with the filling chamber 24 connects each filler openings 22. [0047] in the filling chamber 24 (in the embodiment shown in the connecting sleeve 38) 40 (figFig. 6, 9) are provided guide walls, which extend transversely to the tangential direction and with which the water can be diverted to the filler openings 22 towards. [0048] in the aforementioned embodiments above the water with the water filling tank 24 can thanks to the circumferential nozzle 10 permanently, i.e. over an entire drum rotation, are introduced. But is grateful, the controller 20 and the water nozzle 10 is arranged, the process water of the drum supplying pulsed, in particular always exactly then, if a filling opening and/or a group of filling openings and/or a filling tank section 24 just prior nozzle 10 is water. [0049] in the above embodiment three balancing tank 19 provided on the drum are. It may also be e.g. six balancing tank, a distributed to compensate for unequal axial load, as indicated in the EP 2,944,717 is described. The invention may also be used drums, none have the compensating tank, in which case more space for supplying the process water available from behind. [0050] while in this application are described preferred embodiments of the invention, attention is clear, that the invention is not limited within the scope of the following claims and otherwise also can be performed. On the rear wall (14) of the drum (2) arranged a washing machine non-axial feed openings (22) allow, by means of a first water nozzle (10) into the interior of the drum from the back side to process water (2) introduce. A second water nozzle is additionally (11) in the region of the user door (5) of the drum (2) provided, for process water into the drum from the front (2) inject. In this way a omnidirectional, uniform wetting of the laundry results. 1. washing machine with a tank (1), in a vat (1) about a substantially horizontal axis of rotation (3) rotatably mounted drum (2) for receiving laundry, a user door (5), which the tub (1) over which a user closes the interior of the barrel and (2) is accessible, and at least one stationary first water nozzle (10) for supplying process water in the drum (2) characterized in that the drum (2) on one of the user door (5) opposite rear wall (14) at least one non-axially arranged filling opening (22) has, and wherein the first water nozzle (10) for spraying process water from the outside rear wall (14) is arranged, such that at least a portion of said process water through the filling opening (22) into the drum (2) passes. 2. washing machine according to claim 1, wherein on the rear wall (14) for the temporary accommodation of process water from the first water nozzle (10) a filling chamber (24) is arranged, which through the filling aperture (s) (22) with the interior of the drum (2) communicates. 3. washing machine according to claim 2, wherein the filling chamber (24) around 360° about the axis of rotation (3) of the drum (2) extends. 4. washing machine according to claim 2 or 3, wherein the drum (2) compensating tank (19) for balancing the drum (2) are arranged, and wherein on the rear wall (14) several filling rings (18) for filling the compensation tank (19) are arranged, wherein the filling chamber (24) via an annular region radially outside, between or within the filling rings (18) can be filled, and especially wherein the annular region radially outside the filling rings (18) is. 5. washing machine according to claim 4, wherein the filling rings (18) and the filling chamber (24) of a filling ring assembly (31) are formed, mounted at the back of the rear wall (14) is mounted. 6. washing machine according to any of claims 2 to 5, wherein the filling chamber (24) a radially inner pocket (25a) for receiving process water forms. 7. washing machine according to any of claims 2 to 6, wherein the filling chamber (24) a radially outer pocket (25b) for receiving process water forms. 8. washing machine according to one of the preceding claims, wherein in the rear wall (14) more fill openings (22) are arranged. 9. washing machine according to one of the preceding claims, wherein additionally a stationary second water nozzle (11) is provided, with which process water from the front into the drum (2) is injected. 10. washing machine according to any preceding with a circulation pump, process water from a region below the tub to (1) for water nozzle (10) or to the water nozzles (10.11) to promote, and/or wherein the first water nozzle (10) on the tub (1) is arranged.Description

Field of the invention

Background

Disclosure of the invention

Brief description of drawings

Ways to carry out the invention

Definitions:

About, first execution:

Second configuration:

Third execution:

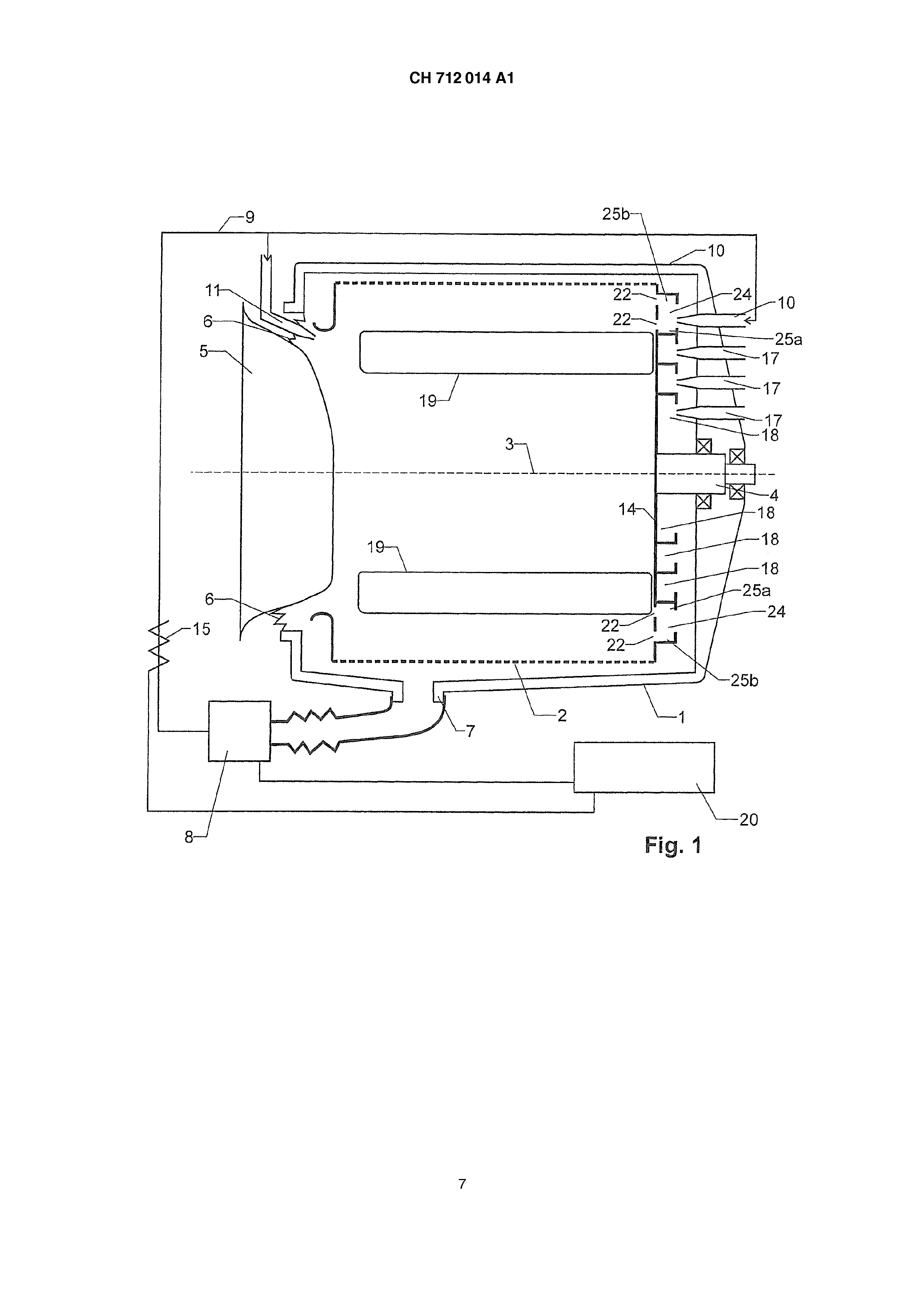

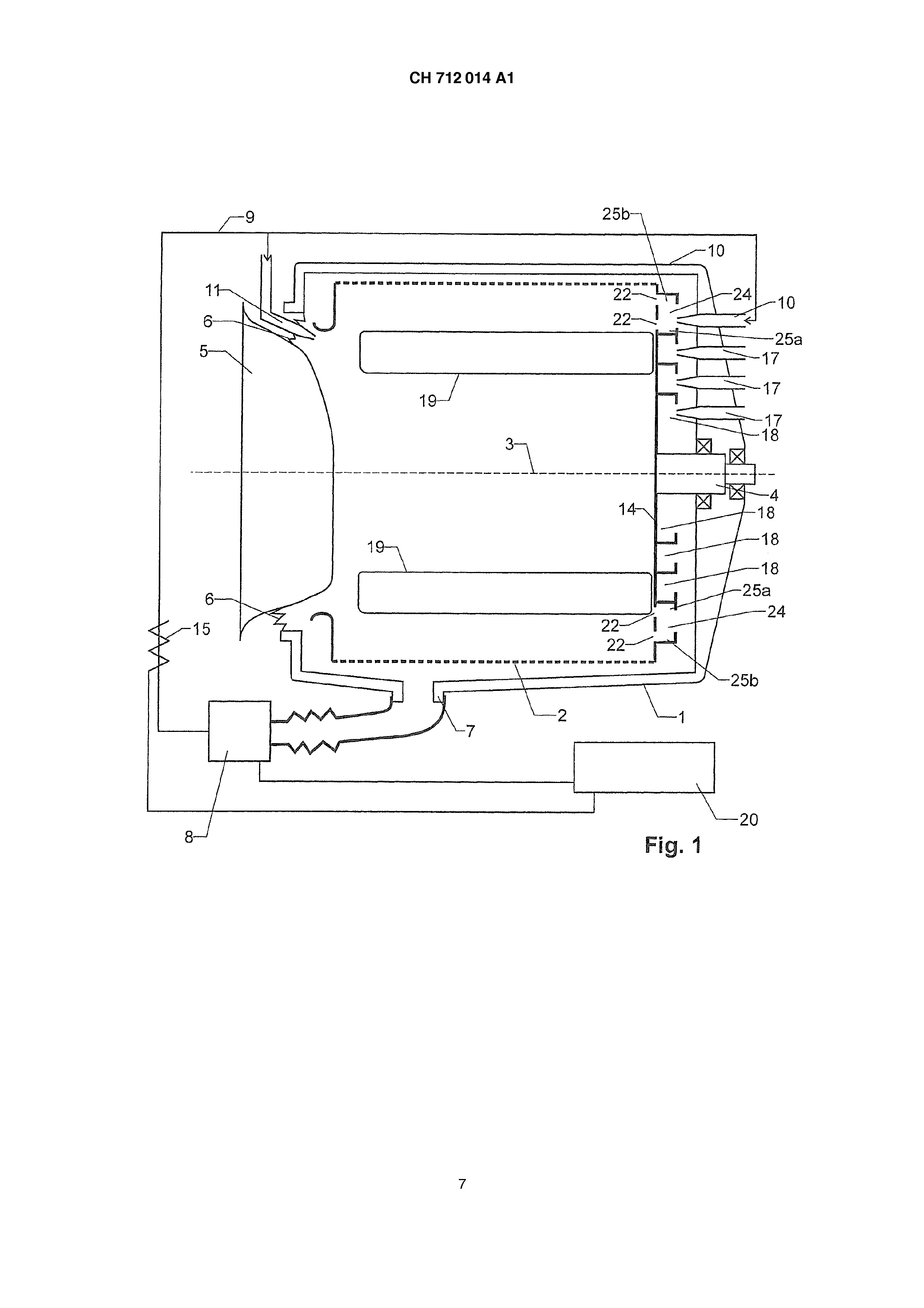

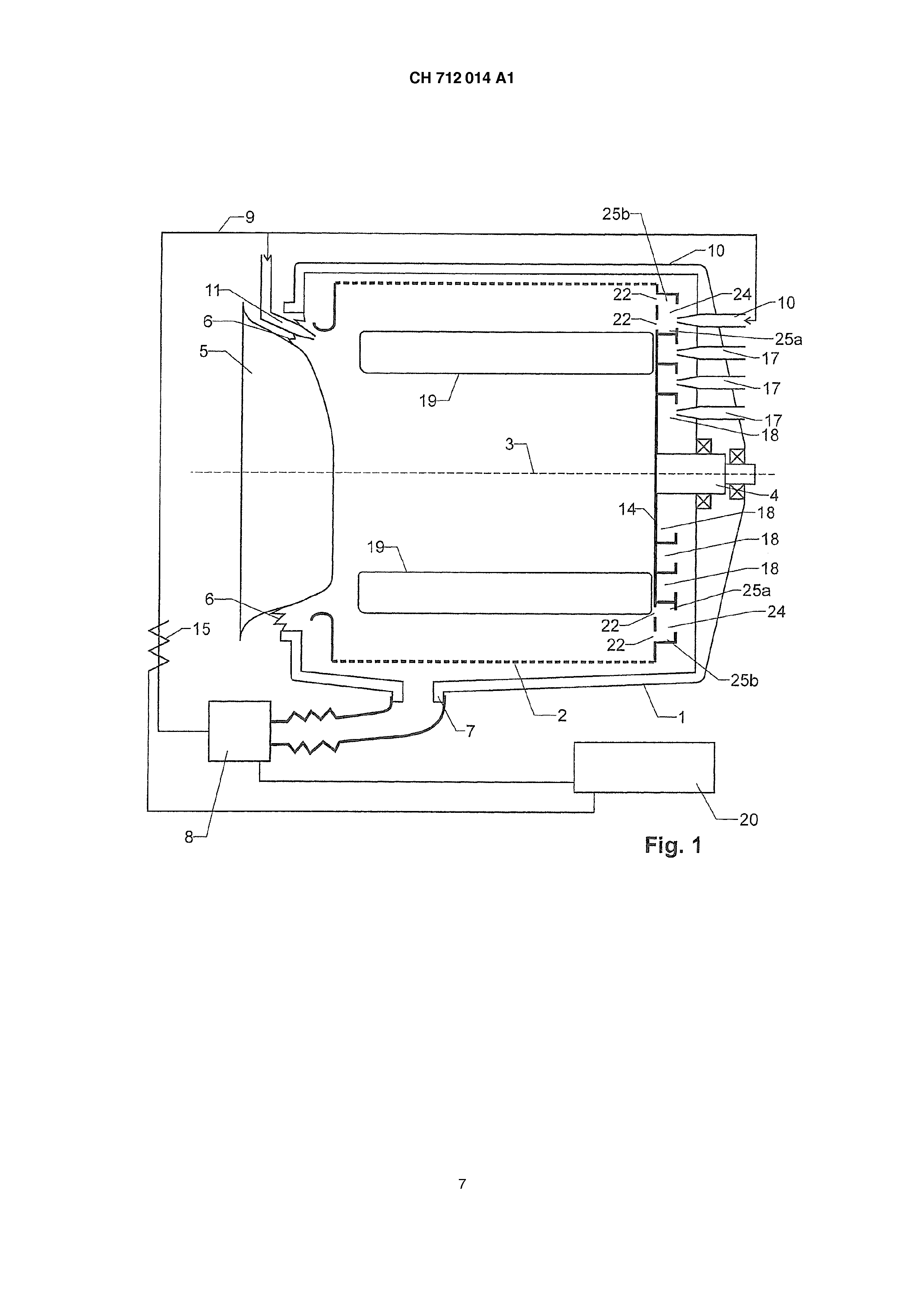

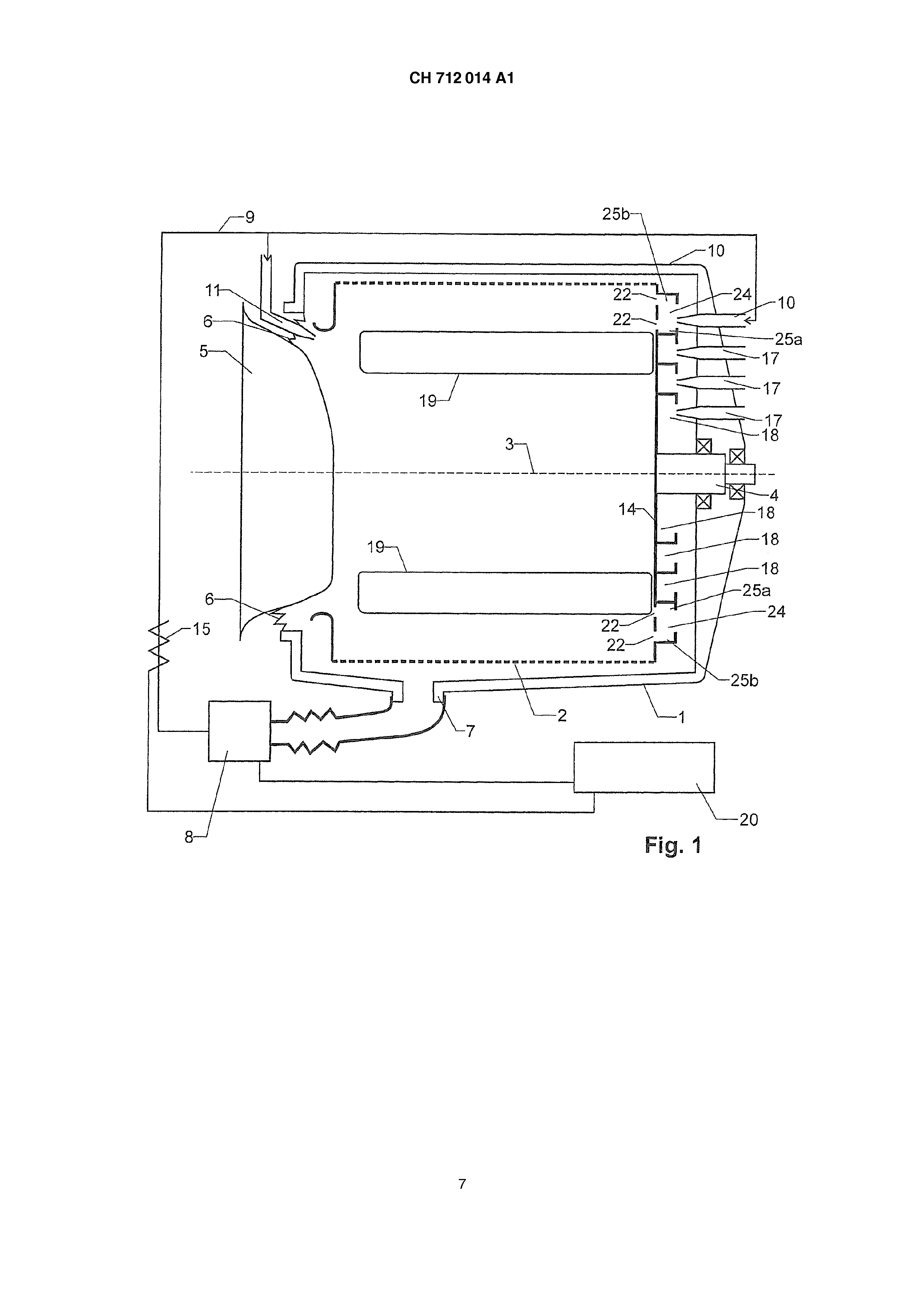

Comments: