PROCEEDED Of EXTRACTION Of AT LEAST ONE COMPOSES Of a LIQUID PHASE INCLUDING/UNDERSTANDING IONIC UNLIQUIDE FUNCTIONALIZES, AND SYSTEM MICROFLUIDIQUE FOR the IMPLEMENTATION OF CEPROCEDE.

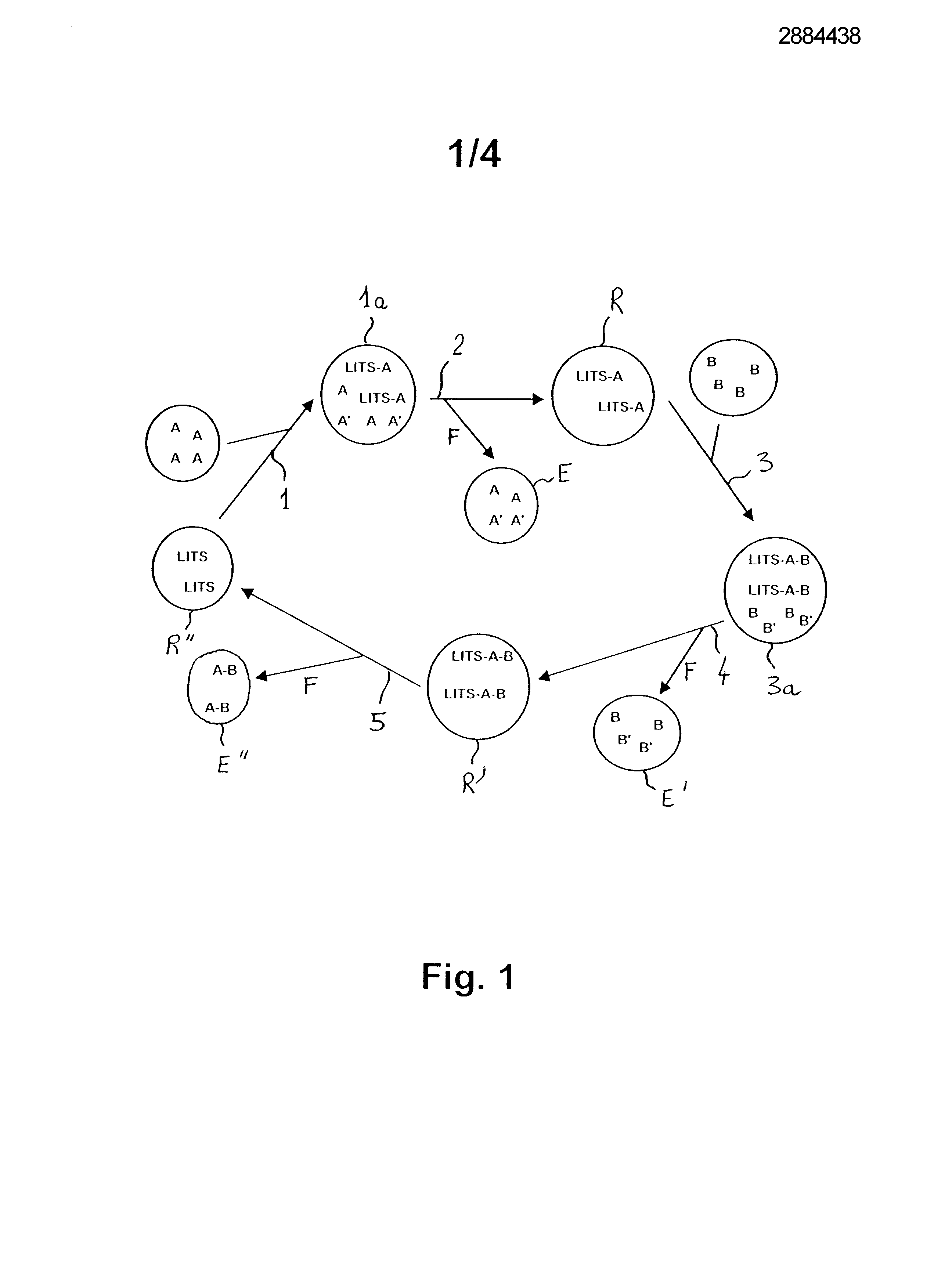

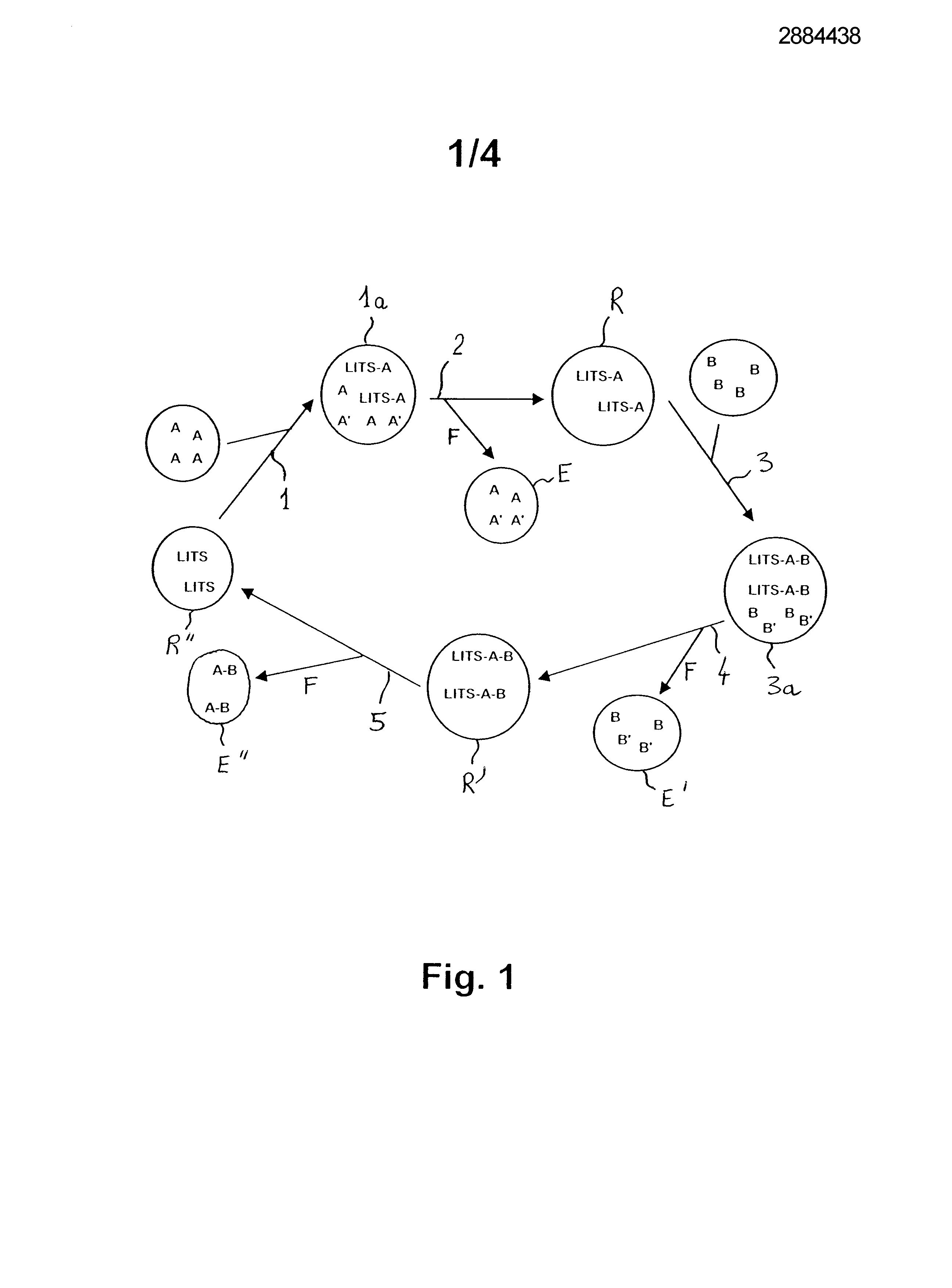

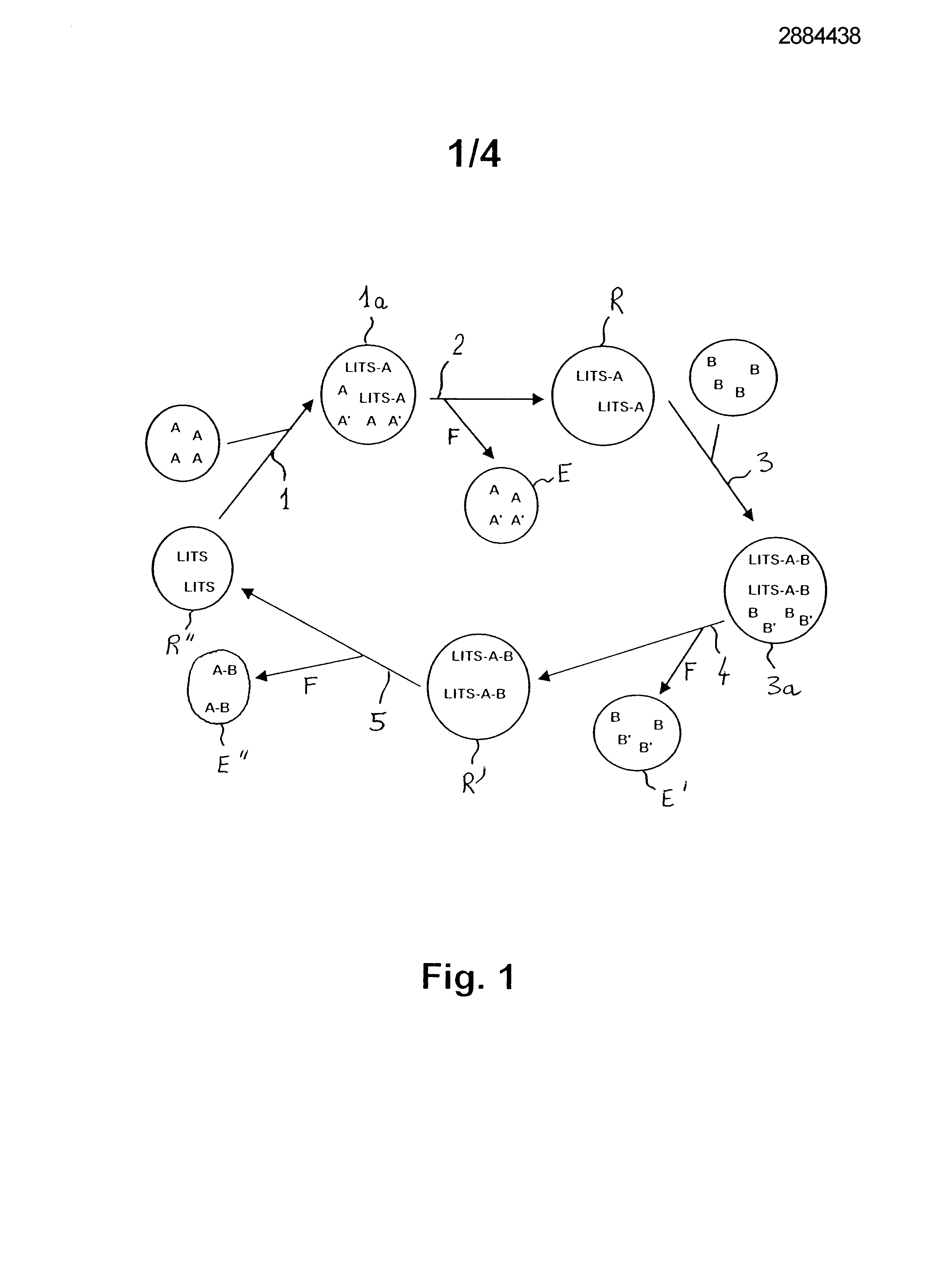

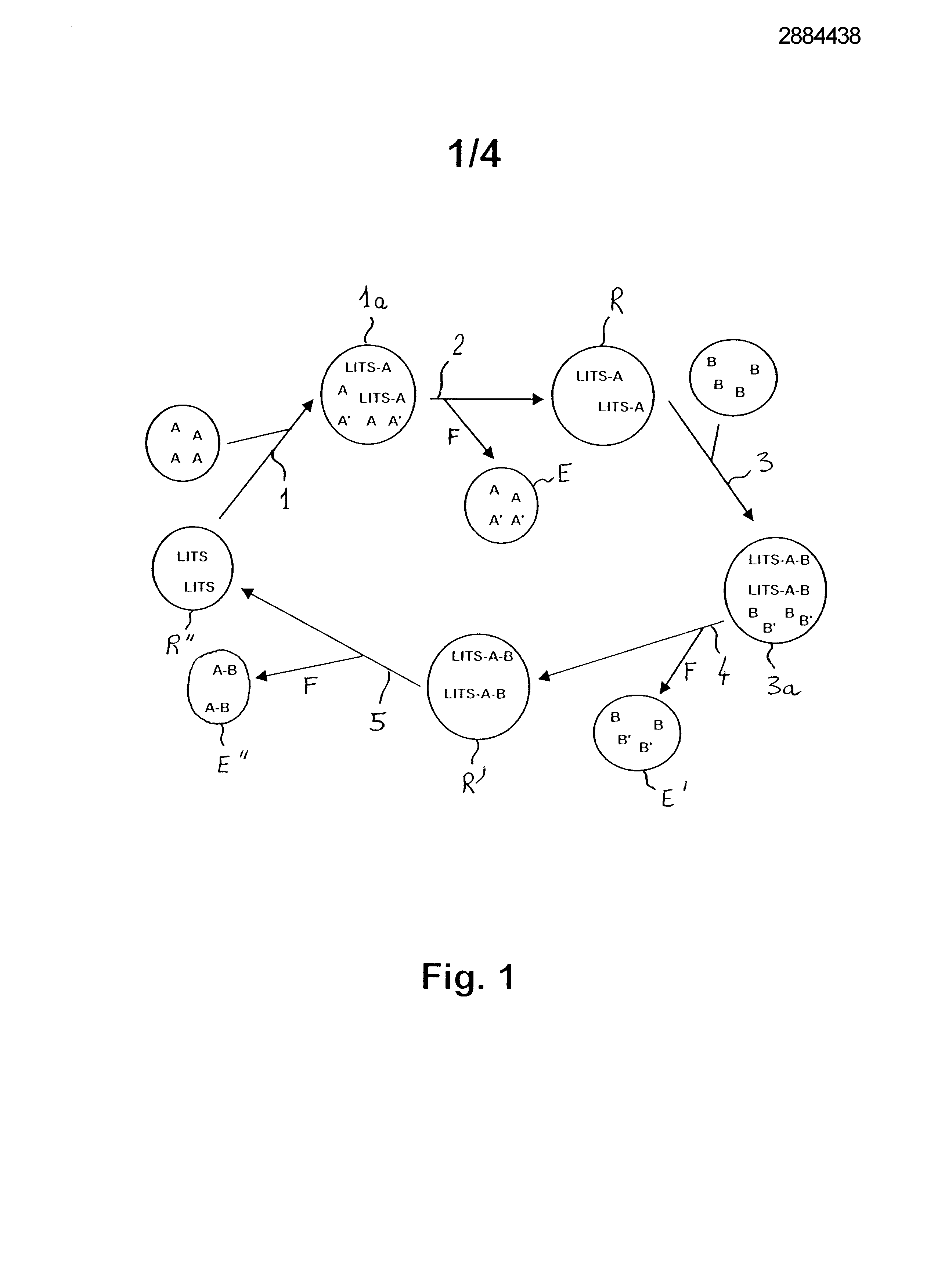

Method for extracting at least one comprises a relay device, monitoring system and method of the Society. The present invention relates to a method for extracting at least one chemical or biological compound from a liquid phase comprising at least one functionalized ionic liquid, and a microfluidic system for implementing this method. The ionic liquids at room temperature (abbreviated " [...]") or "room temperature ionic liquid" ("RTIL" abbreviated English) are increasingly used in organic synthesis due to their especially beneficial properties (see " Room Temperature [...] liquid. Solvents for synthesis and catalysis " Τ. Welton, In addition to these applications as reaction solvents, the room temperature ionic liquids have many advantages for the liquid-liquid extraction and liquid-gas. As supercritical fluids or the fluorinated solvents, these ionic liquids are generally immiscible to the volatile organic solvents ("VOS" abbreviated English) and, because of their very high vapor pressure, they can be separated by distillation directly into these solvents (see "The modem Separation techniques for the efficient in [...] Organic Synthesis" c.c. [...] and coll. It is known in the literature to use these ionic liquids as extracting fluids following during the separation process; ionic liquid-other two-phase extraction solvent or aqueous phase (see "RT ionic liquid as novel media for clean the liquid-liquid extraction" J. G. Huddleston and coll. micro-liquid extraction-liquid by means of a drop of an ionic liquid liquid chromatography (see "Ionia liquid-based liquid-phase microextraction, a new sample enrichment procedure for liquid chromatography" J. Liu and coll. separations of gaseous contaminants, liquid, sulfur in the hydrocarbons (see documents Patent WO-A- [...], and WO-A- [...] ); separation of compounds having boiling points very close (see document Patent WO-A- [...] ); and extraction of heavy metals by complexing agents in ionic liquids (see "First application of calixarenes as [...] in room-temperature ionic liquid" S. Kojiro, Letters 2004, 320-321 Chemistry). It should be noted that all of these operations separation would be to retrieve a compound with the aid of an extraction fluid consisting of an ionic liquid, i.e. migrating the compound by mass transfer of liquid gas to the ionic liquid. It is is interested recently room-temperature ionic liquids functionalized, also known as ionic liquids or dedicated to specific tasks (" [...]" abbreviated in the sequence of the present disclosure), are particularly suited for homogeneous-phase supported synthesis. Can refer to the patient to the Patent document WO-A- [...]. Functionalized The ionic liquids accumulate the advantages and liquid phase synthesis on solid support, in that they enable: -liquid phase, of achieving a large number of reactions, quickly to optimise the operating conditions and synthesize products in elevated amounts, and -on solid support, a rapid purification by repeated washing of the solid support in various solvents. The Request French Patent no. 04,07623, deposited 8 July 2004 Requester and the name of the National Center of the Research Scientific, present a microfluidic system comprising a microreactor that is comprised of a drop comprising at least one functionalized ionic liquid or not. The microreactor is without wall, the interface of the liquid (s) ion (s) with the ambient medium and with the support on which the drop is deposited define the boundaries of the microreactor. Request The Patent is also directed to methods of carrying out chemical or biochemical reactions and/or mixtures using the microreactor drop, and it provides the extraction and/or the purification of the product (s) from (s) of the reaction taking place in the drop of ionic liquid. An object of the present invention is to provide a method for extracting at least one chemical or biological compound from a liquid phase comprising at least one functionalized ionic liquid, via a liquid extracting fluid immiscible with the said (s) (s) ionic liquid (s) (s), with in particular unit operations: (i) for purifying a microdrop comprising a mixture, on the one hand, of molecules of the at least one chemical or biological compound supported by at least one functionalized ionic liquid and, on the other hand, of an excess of the compound (s) (s) unreacted molecules with the supported and/or by-products of the reaction of the ionic liquid (s) with the compound (s), for the extraction of this excess unreacted compounds and/or the by-products; and (ii) of cleavage from the support in a microdrop comprising molecules of chemical compounds or biological supported by at least one functionalized ionic liquid, for the extraction of these compounds. To this end, the extraction process according to the invention comprises moving, on a surface of a microfluidic system, of at least a microdrop of said liquid phase in a bath extraction comprises said extraction fluid and is located on said surface for recovering in outlet of said bath, under the influence of an electric field, of an extract away from said surface which is based on said extraction fluid and which is enriched in said or at least one of said compound (s), and of a raffinate moving on said surface which is based on said ionic liquid (s) (s) and which is depleted of said or at least one of said compound (s). According to another feature of the invention, moving said microdrop into said bath in the effect of said electric field, such that it moves into contact with said surface. According to another feature of the invention, is circulated by forced convection and continuously the said extraction fluid in said bath, for said raffinate obtained either comprised of said circuit or ionic liquid (s) (s) (i.e. for producing the (s) last (s) in the pure state). In the case (i) above, said extract obtained comprises a mixture of, on the one hand, said extraction fluid and, on the other hand, said excess of said one or more compound (s) unreacted and/or said one or more reaction by-products, said raffinate comprises said molecules and supported. In the case (ii) above, said extract obtained comprises then, by cleavage of the support, a mixture of said extraction fluid and said functionalized ionic compounds separated from the liquid, said raffinate and comprises the latter. For "liquid phase comprising at least one functionalized ionic liquid" which constitutes said microdrop can be used according to the invention, is meant in the present specification a mixture: -at least one chemical or biological compound, and -a pure functionalized ionic liquid, a mixture of ionic liquids pure functionalized or a mixture of one or more liquid (s) (s) functionalized ion (s) and one or more liquid (s) (s) non-functionalized ion (s) optionally with one or more solvent (s). It should be noted that said or each compound may be bound to said or each functionalized ionic liquid or be free in the mixture. The or each functionalized ionic liquid (i.e. dedicated or task-specific) that is usable in the microdrop according to the invention is liquid at room temperature, and it can be represented by the formula A/Xr, wherein: a) A/represents a cation, functional or non-functional or a mixture of cations in which either no cations is functional, is at least one of the cations is functional, b) Xi ' is an anion functional or non-functional, or a mixture of anions wherein either none of the anions is functional at least one of the anions is operative, with the proviso that c) the cation A/or/ and the anion X-i " are bearing at least one function capable of reacting with said chemical or biological compound. It is pointed out that an ionic liquid Ai+ Xi ' functionalized (i.e. comprising at least one functional ion) can be used for one hand of reaction medium and another portion dissolvable support or matrix, while an ionic liquid A/X-f non-functionalized acts solely as a reaction medium inert matrix or screw to the reactants and is able to dissolve them. Expression "functional cation" denotes a molecular moiety which has at least one chemical function, a portion of the group bearing a positive charge. Expression "functional anion" denotes a molecular moiety which has at least one chemical function, a portion of the group bearing a negative charge. Expression "non-functional cation" denotes a group free molecular chemical function, a portion of the group bearing a positive charge. Expression "non-functional anion" denotes a group free molecular chemical function, a portion of the group bearing a negative charge. In the present invention, it is possible to use as A/a functional cation or a mixture of cations which at least one is functional, and/or as a following: hydroxyl, carboxylic, amide, sulfone, primary amine, secondary amine, aldehyde, ketone, ethenyl, ethynyl, dienyl, ether, epoxide, phosphine (primary, secondary or tertiary), azide, imine, ketene, cumulene, [...], thiol, thioether, sulfoxide, phosphorus groups, heterocycles, sulfonic acid, silane, or functional aryl stannane, and any function resulting from a chemical transformation, thermal, photochemical, or microwave irradiation of the foregoing functions. with large anions such as NTf2 ', PF6', BF4 ' or CF3SO3', can be liquid at room temperature or melt at low temperature, e.g. is liquid at room temperature (Tf representing CF3 S02). Advantageously, said or at least one of said functionalized ionic liquids may be used according to the invention is selected from the group consisting of an ammonium salt, an imidazolium salt, a phosphonium salt, an onium salt and a mixture of several of these salts. Can be used a functionalized onium salt of formula A/Xf, as reaction medium comprises a functional cation and/or a functional anion ionic entity corresponding to a Y-, in other words respectively+ cationic or anionic Y- Y '-, optionally bonded via an arm L, in particular an alkyl group having 1 to 20 carbon atoms, to at least one function Fi, variant F0 Fi to Fn and n are Fi The function can in particular be chosen from the functional groups functionalized Some ionic liquids, particularly those an integer ranging from 1 to 10, the cation functional be represented as Y+- L-Fi, and the functional anion in the form Y " (L)k- Fj, k is equal to 0 or 1, and which may represent the functional anion, when k is 0, a simple anion, corresponding to Y' Fj, in particular selected from: OH ', F', CN ', RO', RS ', RS03", -RCO2, RBF3-, wherein R is an alkyl group having 1 to 20 carbon atoms, or an aryl group comprising 6 to 30 carbon atoms. The expression "functionalized onium salt" denotes ammonium salts, phosphonium, sulfonium, and all salts resulting from the quaternization of an amine, a phosphine, a thioether or a heterocycle containing one or more of the heteroatoms, and bearing at least a function Fi. Expression also designates an onium salt which " the cation as defined above is not functionalized but the anion bears a function F |. Expression may also designate a salt having the anion and cation carry a function F,. A preferred functionalized onium salt is in particular chosen from the following: m is an integer of 0 to 20. Exemplary non-functionalized ionic liquids useful in microdroplets according to the invention in combination with one or more functionalized ionic liquids, is example, onium salts selected from imidazolium cations, pyridinium NMe 3+ or- Bu Bu3 P+ Me, and anions [...]2 ', PF6' or BF4", such as 1-butyl-3-methylimidazolium tetrafluoroborate [ [...] ] [BF4], 1-butyl-3-methylimidazo! ium hexafluorophosphate [ [...] ] [PF6], 1-butyl-3-methylimidazolium bis (trifluoromethylsulfonyl) imide [ [...] ] [ [...]2], 1-ethyl-3-hexafluorophosphate [...] [ [...] ] [PF6] the [...] and bis (trifluoromethylsulfonyl) imide [ [...] ] [ [...]2]. According to another feature of the invention, the said extraction fluid used in the extraction process according to the invention can be aqueous or organic solvent type, and it comprises advantageously at least one volatile organic solvent ("VOS" English) selected from the group consisting of diethyl ether, ethyl acetate and chlorinated solvents such as dichloromethane, chloroform or carbon tetrachloride. Alternatively, the said extraction fluid may include at least one aqueous solvent, such as water subjected to a deionization. In another advantageous feature of the inventive extraction method, microdrop electrically conductive is moved into contact with said surface under the influence of an electric field, preferably by moving electro-wetting ("EWOD" to " [...] is [...]") said microdrop in both said bath and upstream and downstream thereof, via a plurality of electrodes covering said surface. The electrodes, supported by the substrate of the microfluidic system, are isolated and surface-treated for obtaining a low wetting said microdrops being bathed in the extraction fluid. Note that these microdrops are electrically conductive, of by the or each ionic liquid that they contain, while said extractor fluid has an electrical conductivity substantially zero. Advantageously, by carrying out the inventive extraction method by moving said microdrop in a continuous manner within said bath, thereby optimizing the mass transfer by diffusion forced between said microdrop to be purified and said extraction fluid. Still more preferably, microdrop is moved in said bath in a predetermined path and preferably about a center area of the bath, for example in a circular manner, thereby effectively locating said bath on said surface of the microfluidic system. According to a first embodiment of the invention, said bath and said extract are respectively obtained by at least one feed stream of said extraction fluid and with at least one of a current of extracting said bath, at least one of the feed streams and extraction is carried in a capillary which extends and opens above said surface. According to a first exemplary implementation of this first mode of the invention, the bath extraction is formed by a drop of said extraction fluid that is deposited on the said surface and which communicates with the whole ambient space above said surface, and at least one of said feed streams and extraction flows within a capillary under which is formed said drop extraction. In a second example implementation of the first mode of the invention, the bath extraction is formed by an enclosed volume of said extraction fluid which is delimited by two walls respectively formed by said lower and upper surface and a plate mounted on said surface, said volume communicating substantially with the whole side ambient space formed between said walls, and at least one of said feed streams and circulating extraction within a capillary opening into a hole of the plate and communicating with said confined volume. In a second embodiment of the invention, said bath and said extract are respectively obtained by at least one feed stream of said extraction fluid and with at least one of a current of extracting said bath, at least one of the feed streams and extending extraction in the bulk of said microfluidic system opening out on said surface. In a first example of use of this second mode of the invention, the bath extraction is formed by a drop of said extraction fluid that is deposited on the said surface and which communicates with the whole ambient space included above said surface, and at least one of said feed streams and circulating extraction within a buried channel in said microfluidic system, on which is formed said drop extraction. In a second example of use of this second mode of the invention, the bath extraction is formed by an enclosed volume of said extraction fluid which is delimited by two walls respectively formed by said lower and upper surface and a plate mounted on said surface, said volume communicating substantially with the whole side ambient space formed between said walls, and at least one of said feed streams and circulating extraction within a buried channel in said microfluidic system and flush with said surface. According to the first and second examples of the aforementioned first and second modes according to the invention: -said feed streams and extraction advantageously open into said bath substantially perpendicular to said surface, -said extract stream is recycled continuously in said feed stream, the "regeneration" the extraction fluid so as to reduce its amount used, and -said bath extraction (i.e. the said drop extraction or said enclosed volume) is open to the ambient space into at least two opposing sides thereof, for moving into contact with said surface of said microdrop upstream and downstream of said bath. According to the first example relative to the first or second modes according to the aforementioned invention, removing said drop of extracting said suction for the obtaining the same. Preferably, the microdrop consisting of said liquid phase is subjected to extraction in accordance with the invention has a volume of between 0.1 and 10 pL pL, and the volume of the microdrop is provided much less than that of the bath extraction to optimize scattering therein. A microfluidic system according to the invention for performing the extraction method as defined above is of the type having a substrate having a surface coated with electrodes adapted to move, under the influence of an electric field, microdrops from a liquid phase comprising at least one functionalized ionic liquid. According to the invention, the microfluidic channel is provided with means for bringing a fluid extraction liquid on said surface and for extraction by forced convection, to provide a bath extraction is located on said surface for extracting at least one chemical or biological compound of said liquid phase and which is open to the ambient space into at least two opposing sides thereof, for moving into contact with said surface of said microdrop upstream and downstream of said bath. As and said analysis device, include any inorganic or organic substrate and biocompatible. In connection with the said first mode of the invention, the system is advantageously such that said means for feeding and extracting said extraction fluid comprise respectively two capillaries at least one of which extends and opens above said surface and in a direction perpendicular thereto. In connection with the second said mode according to the invention, the system is advantageously such that said means for feeding and extracting said extraction fluid respectively comprise two channels, one of which at least is buried in said microfluidic system and is flush with said surface perpendicular to the latter, to communicate with said bath. In connection with said first example of the first and second modes according to the invention, said means for feeding and extracting said extraction fluid are adapted to that said bath extraction formed by a drop of said extraction fluid communicating with the entire ambient space above said surface. In connection with said first example of the second mode of the invention, said channels are adapted to forming said bath that said drop covers the respective ends of these channels. In connection with said second example of the first and second modes according to the invention, said micro-fluidic system furthermore comprises a plate which is mounted on said surface via vertical supports which defines with said surface and two respectively upper and lower walls defining an enclosed volume for said bath, which substantially communicates with the whole ambient side space formed between said walls. The plate can optionally be used to provide a counter electrode in the process of electro-wetting. Example In connection with said second said second mode of the invention, said channels are flush with said surface between vertical supports which connect the periphery of said plate to said surface, so as to form said enclosed volume forming said bath. According to another feature of the invention, said microfluidic system is advantageously such that: -the electrodes overlying the substrate, such as gold electrodes, are covered with electrical insulation, such as silica or silicon nitride ( [...]4) and -said plate is made of borosilicate glass or of a plastic material, and said supports are made of a photosensitive resin such as an epoxy resin, which is deposited on those supports via an adhesive. The above features of the present invention, as well as other, will be better understood upon reading of the following description of several exemplary embodiments of the invention, illustrative and non-limiting, said description being performed in connection with the accompanying drawings, of which: figure 1 is a process diagram illustrating synthesis examples of the applications of the method according to the invention, figure 2 is a schematic view in perspective of a microfluidic system according to a first embodiment of the invention, figure 3 is a schematic view in perspective of a microfluidic system according to an alternative embodiment of Figure 2, figure 4 is a schematic view in perspective of a microfluidic system according to a second embodiment of the invention, figure 5 is a schematic view in perspective of a microfluidic system according to an alternative embodiment of Figure 4, figure 6 illustrates schematically various stages of a method for manufacturing a substrate in cross section of a microfluidic system according to Figure 2, figure 7 illustrates schematically a method of manufacturing a counter electrode sectional view and for assembly to the substrate of Figure 6, and figure 8 a sectional schematic view of a microfluidic system according to Figure 2 obtained by assembling the counter electrode of Figure 7 on the substrate of Figure 6. Figure 1 illustrates the method are synthesized using the reaction A + B--> A-B on a support comprising at least one functionalized ionic liquid " [...]", which reaction may be chemical (creating covalent bond), biological (affinity reaction, such as hybridization, interaction antibody-antigen, protein-substrate, for example, but not limited to). The step 1 the method illustrates a first reaction between molecules of the ionic liquid [...] and molecules of a first reagent A, for producing a mixture comprising molecules 1a supported [...] -A, molecules Reagent A excess unreacted and of A ' corresponding to a by-product of the first reaction. The step 2 this method illustrates a first unit operation of separating the reagent A unreacted of the sub-product A ', by a liquid-liquid extraction of the invention applied to this mixture 1a via a removal fluid F. Therefore, an extract E comprising, in addition to the extraction fluid F, molecules of A and A ', R and a raffinate comprising the supported [...] -A molecules. The step 3 the method illustrates a second reaction between the molecules of the raffinate supported [...] -A R and molecules of a second reagent B, for producing a mixture comprising molecules 3a supported [...] -A-B, the reagent molecules B excess unreacted molecules with the supported [...] -A and B molecules' corresponding to a sub-product of this reaction. The step 4 the method illustrates a second unit operation of separating the reagent B unreacted B and the by-product ', by a liquid-liquid extraction of the invention applied to this mixture 3a via a removal fluid F. Therefore, an extract E 'comprising, in addition to the extraction fluid F, molecules of B and B', a raffinate and R ' molecules comprising the supported [...] -A-B. The step 5 the method illustrates a third unit operation "cleavage from the support" of "cleaving" and separating, by a liquid-liquid extraction of the invention applied to the raffinate R ' via a removal fluid F, separating the carrier molecules [...] (raffinate R "obtained) the reaction product A-B supported (extract E" obtained). The microfluidic system 10 according to the invention which is illustrated in Figure 2 includes a substrate 11 having a surface 12 is covered with electrodes 13 which are for example based on gold and which are coated with an electrical insulator, such as silica or silicon nitride. The electrodes 13 are adapted for moving on the surface 12, preferably by electro-wetting, microdrops 14 from a liquid phase comprising at least one functionalized ionic liquid (e.g. [...] -A) and substances free in solution (A and A '), see Figure 1. The system 10 is provided with capillaries 15 and 16 which are respectively, for feeding a liquid extracting fluid F on the surface 12 and to extraction by forced convection and which extend and open two above the surface 12 and in a direction perpendicular thereto, to provide a bath extraction 20 based on the extraction fluid which is located on the surface 12 for the extraction of at least one chemical or biological compound (A, A ' for example, see Figure 1) of the liquid phase. To this end, the system 10 comprises a plate 17, into which open the capillaries 15 and 16 via two respective ports 18 of the plate 17, so that the capillaries 15 and 16 communicate with the bath 20. The plate 17 is provided on its periphery of vertical supports 19 mounted on the surface 12, and the plate 17 with the surface 12 defines an enclosed volume of parallelepiped shape for the bath 20, in the manner of a "cover" open. As shown in Figure 2, the bath 20 substantially communicates with any ambient the lateral space between the surface 12 and the plate 17, to permit movement contact with the electrodes 13 of each microdrop 14 by electro-wetting, in the bath and 20 upstream and downstream thereof. For example in connection with the unit operation 2 of Figure 1, the system 10 is adapted for obtaining, by forcible diffusion of the microdrop 14 in the bath 20 and circulated continuously the extraction fluid F: -via the extraction capillary 16, of an extract E comprising the extraction fluid and compounds A, A ', and -via the electrodes 13, of a microdrop of raffinate R comprising the ionic liquid graft [...] -A in the pure state for further operation, e. g. another chemical or biological reaction or analysis. For the following description of other embodiments of the invention relating to Figures 3 to 5, is used of digital references increased 100 to designate elements of the corresponding microfluidic system which are the same or similar to those of Figure 2. The microfluidic system 110 of the invention which is shown in Figure 3 only differs from the system 10 of Figure 2, in that it is adapted to form a extraction bath 120 comprised of a drop deposited on the surface 112 via the drive capillary 115 112 and removed from the surface by suction via the capillary 116, such that the extraction fluid F is circulating through these capillaries 115 and 116. The drop forming the extraction bath 120 is therefore expected to be formed under the capillaries 115 and 116, and it communicates with the whole ambient space above the surface 112. For example in connection with the unit operation 2 of Figure 1, the system 110 is adapted for obtaining, by forcible diffusion of the microdrop 114 within the drop forming the bath 120 and circulated continuously the extraction fluid F: via the capillary 116, of an extract E comprising the extraction fluid F and compounds A, A ', and via the electrodes 113, of a microdrop of raffinate R is moved over the surface 112 and which comprises the ionic liquid graft [...] -A in the pure state for further operation, e. g. a reaction or analysis. The microfluidic system 210 according to the invention which is illustrated in Figure 4 only differs from the system 110 of Figure 3, in that it is provided with two channels 215 and 216 buried in the substrate 211 and 212 flush with the surface of the substrate 211 perpendicular to the latter, instead of the capillaries 115 and 116. The supply channel 215 is adapted to receive the extraction fluid F by its input 215a opening in a face perpendicular to the surface 212 and, via a bend 215b at right angles that it comprises, to provide as its output drop by 215c flush with the surface 212, to form the extraction bath 220 by deposition and suction continuously of the bead. The extraction channel 216 is adapted to remove the bath 220, via the extraction fluid F, the extract E containing, for example, the excess reactant A and the sub-product A ', by its input 212 and flush with the surface 216a, 216b via a bend at right angles that it comprises, for the removing from the substrate 211 by an output through 216c on another side of the substrate 211 perpendicular to the face 212. For example in connection with the unit operation 2 of Figure 1, the system 210 is adapted to obtaining, by forcible diffusion of the microdrop 214 within the drop forming the bath 220 and circulated continuously the extraction fluid F: via the capillary 216, of an extract E comprising the extraction fluid F and compounds A, A ', and via the electrodes 213, of a microdrop of raffinate R is moved over the surface 212 and which comprises the ionic liquid graft [...] -A in the pure state for further operation, e. g. a reaction or analysis. In a third embodiment not shown, it can be of advantage to have a capillary supply fluid from above and a capillary extraction by the substrate, without cover plate. The advantage of this combination is accumulating the advantages of each of the other two embodiments: -technology simplified because of the absence of cover; -no passage of media open to a closed environment, due to the absence of cover; -perfect positioning of the stripping zone on the microfluidic system, by centering the drive capillary on this area; -possibility of completely remove the liquid extraction the capillary provided in the substrate. In these embodiments involving motions electro-wetting, it can be advantageous to add a counter electrode to the system, e.g. in the form of a filament conductor in contact with the microdrop. Similarly, the microfluidic system 310 according to the invention which is illustrated in Figure 5 differs only the system 10 of Figure 2, in that it is provided with two channels 315 and 316 buried in the substrate 311 and the like to the channels 215 and 216 of Figure 4. Much like the channels 215 and 216 of Figure 4, the channels 315 and 316 are flush with the surface of the substrate 312 311 319 between vertical supports which connect the periphery of the plate to the surface 312 317, so as to form an enclosed volume forming the extraction bath 320. For example in connection with the unit operation 2 of Figure 1, the system 310 is adapted to obtaining, by forcible diffusion of the microdrop 314 320 in the bath and circulated continuously the extraction fluid F: -via the extraction capillary 316, of an extract E comprising the extraction fluid and compounds A, A ', and 313-via the electrodes, of a microdrop of raffinate R comprising the ionic liquid graft [...] -A in the pure state for further operation, e. g. a reaction or analysis. It should be noted that the microfluidic systems 10 to 310 provide means of recovering separately the two liquid phases consisting of the extract E and raffinate R. Therefore, for steps 2 and 4 of "purification" of Figure 1, is recovered of the microdrop [...] -A or [...] -A-B eliminating separately the extraction fluid containing the impurities F A ', B' and excess reagents A and B, while in the step 5 of "cleavage from the support", the reaction product is recovered A-B in the extraction fluid is recycled F and separately the microdrop of [...], for example for other reactions. Advantageously The out the liquid-liquid extraction process according to the invention as follows. Is moved to the microdrop 14 314 electrically conductive liquid-based ion (s) (s) (s) functionalized by the electrowetting technique called "EWOD" ( [...] is [...] ), by applying voltages of 10 to 100 V. To this end, the electrodes 13 to 313 are previously isolated and surface-treated for obtaining a low wetting microdrops to 314 14 immersed in the extraction bath 20 to 320. Unlike said microdrops 14 to 314, the extraction fluid F selected, such as a volatile organic solvent (e. g. diethyl ether, ethyl acetate, or a chlorinated solvent), has a very low electrical conductivity, so that it is not moved at the surface 12 to 312 310 to the microfluidic system 10. The the digestion of the invention at room temperature (i.e. typically between 20° and 25 C) or optionally with slight cooling the microfluidic system 10 to 310, to limit the evaporation of the extraction fluid F. In order to optimize the transfer of material by forcible diffusion between the microdrop 14 to 314 and the extraction fluid F and the location of the extraction bath 20 to 320 on the surface 12 to 312, is moved continuously in the microdrop said bath about a central point thereof. Figures 6 to 8 illustrate, as [...], the essential steps of a method of making the microfluidic system 10 according to the invention incorporating the plate 17. As shown in Figure 6, the substrate 11 is obtained according to the invention essentially by implementing the following steps: -in a first step 30, is deposited by photolithography an array of gold electrodes 13 on the substrate 11, which is for example based on glass "Pyrex" or oxidized silicon; -in a second step 40, these electrodes 13 are electrically isolated by deposition of silica or 41 If3 N4 made by "PECVD" ("Plasma Enhanced Chemical Vapour Deposition": CVD plasma), and subjecting the obtained deposition 41 to photolithography to provide clearance of contact times; and -in a third step 50, is deposited by photolithography on the substrate 11 and the treatment of "walls" 51 photosensitive resin "SU8" provided for exerting a similar function to that of the supports 19 of Figure 2, for the subsequent bonding of the counter electrode 17 on the substrate 11. As shown in Figure 7, when it is desired to a counter electrode on the plate 17, being obtained by photolithography, on a glass plate "Pyrex" or plastic with apertures 18, a coating 61 in "ITO" ("Indium Tin Oxide": indium tin oxide) on the underside of the plate which is intended to be facing the electrodes 13 of the substrate 11. Optionally, this layer of "ITO" can be covered with a layer whose hydrophobicity is controlled, to improve the slug displacement. As shown in Figure 8, are assembled the counter electrode 17 thus obtained on the "walls" 51 of the substrate 11 by the technique of "screen printing glue", by depositing a film of glue 71 homogeneous at the interface between the coating 61 and these "walls" 51. The adhesive film 71 has a thickness of less than a few micrometers, and the adhesive used is for example available from the company [...] under the name "OLED- [...] 45952". The may be, for example, refer to the Patent document WO-A- [...] for an accurate description of this technique of "screen printing glue". A method for extracting at least one chemical or biological compound from a liquid phase including at least one functionalized ionic liquid, via a liquid extracting fluid that is miscible with the ionic liquid, and a microfluidic system implementing the method. The extraction method includes moving, on one surface of a microfluidic system, at least one microdrop of the liquid phase into an extraction solution that includes the extracting fluid and that is localized on the surface to obtain in output of the solution, under effect of an electric field, an extract moving away from the surface that is rich in extracting fluid and enriched in the at least one compound, and a raffinate moving on the surface that is rich in ionic liquid and deleted in the at least one compound. 1. A process for extracting at least one chemical or biological compound (A, A 'or B, B' or A-B) from a liquid phase comprising at least one functionalized ionic liquid ( [...] -A or [...] -A-B or [...] ), through a fluid extraction liquid (F) that is immiscible with the said (s) (s) ionic liquid (s) (s), characterized in that said method comprises moving, on a surface (12, 112, 212, 312) of a microfluidic system (10, 110, 210, 310), of at least a microdrop (14, 114, 214, 314) of said liquid phase in a bath of extraction (20, 120, 220, 320) which comprises said extraction fluid and is located on said surface for recovering in outlet of said bath, under the influence of an electric field, of an extract (E, E ') away from said surface which is based on said extraction fluid and which is enriched in said or at least one of said compound (s), and of a raffinate (R, R') moving on said surface which is based on said ionic liquid (s) (s) and which is depleted of said or at least one of said compound (s). 2. A method according to claim 1, characterized in that the moving said microdrop (14, 114, 214, 314) into said bath (20, 120, 220, 320) under the effect of said electric field, such that it moves into contact with said surface (12, 112, 212, 312). 3. The method of claim 1 or 2, characterized in that the is circulated by forced convection and continuously the said extraction fluid (F) in said bath (20, 120, 220, 320), for said raffinate (R, R ') obtained either comprised of said circuit or ionic liquid (s) (s) ( [...] -A or [...] -A-B or [...] ). 4. The method of claim 2 or 3, characterized in that the is moved with electro-wetting said microdrop (14, 114, 214, 314) into contact with said surface (12, 112, 212, 312), in said bath (20, 120, 220, 320) and upstream and downstream thereof, via a plurality of electrodes (13, 113, 213, 313) covering said surface, said microdrop being electrically conductive to the difference of said extraction fluid (F) whose electrical conductivity is substantially zero. 5. A method according to any preceding claim, characterized in that the moving said microdrop (14, 114, 214, 314) according to a predetermined path, preferably around a central region said bath (20, 120, 220, 320). 6. Method according to one of claims 1 to 5, characterized in that said bath (20,120) and said extract (E, E ') are respectively obtained by at least one feed stream of said extraction fluid (F) and with at least one of a current of extracting said bath, at least one of the feed streams and extending extraction through and above said surface (12,112). 7. Method according to one of claims 1 to 5, characterized in that said bath (220,320) and said extract (E, E ') are respectively obtained by at least one feed stream of said extraction fluid (F) and with at least one of a current of extracting said bath, at least one of the feed streams and extending extraction in said microfluidic system (210,310) opening out on said surface (212,312). 8. The method of claim 6 or 7, characterized in that said feed streams extraction and open into said bath (20, 120, 220, 320) substantially perpendicular to said surface (12, 112, 212, 312). 9. Method according to one of claims 6 to 8, characterized in that said extract stream is recycled to said feed stream. 10. A method according to any preceding claim, characterized in that said extraction bath (20, 120, 220, 320) is open to the ambient space into at least two opposing sides thereof, for moving the surface (1, 112, 212, 312) of said microdrop (14,114, 214, 314) upstream and downstream of said bath. 11. The method of claim 10, which comprises applying said bath (120,220) on said surface (112,212) and removes by suction for obtaining said extract (E, E '), such that said pool substantially communicates with the entire ambient space above said surface. 12. The method of claim 10 or 11, characterized in that said extraction bath (120,220) is formed by a drop of said extraction fluid (F) which communicates with the whole ambient space above said surface (112,212). 13 A method according to claims 6 and 12, characterized in that at least one of said feed streams and extraction flows within a capillary (115 or 116) under which is formed said drop (120) of said extraction fluid (F). 14. A method according to claims 7 and 12, characterized in that at least one of said feed streams and extraction is flowing within a buried channel (215 or 216) in said microfluidic system (210) on which is formed said drop (220) of said extraction fluid (F). 15. The method of claim 10 or 11, characterized in that said extraction bath (20,320) is formed by an enclosed volume of said extraction fluid (F) which is delimited by two walls respectively formed by said lower and upper surface (12,312) and by a plate (17,317) mounted thereto, said volume communicating substantially with the whole side ambient space formed between said walls. 16. A method according to claims 6 and 15, characterized in that at least one of said feed streams and extraction flows within a capillary (15 or 16) with an opening (18) of said plate (17). 17. A method according to claims 7 and 15, characterized in that at least one of said feed streams and extraction is flowing within a buried channel (315 or 316) in said microfluidic system (320) and flush with said surface (312). 18. A method according to any preceding claim, characterized in that said microdrop (14, 114, 214, 314) of said liquid phase has a volume of between 0.1 and 10 pL pL. 19. Method according to one of claims 1 to 18, characterized in that said microdrop (14, 114, 214, 314) subjected to the extracting comprises a mixture: -of molecules ( [...] -A or [...] -A-B) said one or more compound (s) or biological chemical (s) (s) (A or A-B) supported by said functionalized ionic liquid ( [...] ), and -an excess of said compound (s) or said chemical or biological (s) (s) (A or B) unreacted molecules with said supported ( [...] -A or [...] -A-B) and/or or by-products (A 'or B') of the reaction of said functionalized ionic liquid (or [...][...] -A) (s) with the said compound (s) (s) (s) chemical or biological (s) (A or B), and wherein said extract (E, E ') comprises a mixture, on the one hand, said extraction fluid (F) and, on the other hand, said excess of said one or more compound (s) unreacted and/or said one or more reaction by-products, said raffinate (R, R') comprising said supported molecules. 20. Method according to one of claims 1 to 19, characterized in that said microdrop (14, 114, 214, 314) subjected to extracting comprises molecules of said chemical compounds or biological (LITS-A-B) (A-B) supported by said functionalized ionic liquid ( [...] ), and wherein said extract (E ") comprises, by cleavage of the support, a mixture of said extraction fluid (F) and said compounds (A-B) separated from the liquid functionalized ionic ( [...] ), said raffinate (R") comprising the same. 21. A method according to any preceding claim, characterized in that said or at least one of said functionalized ionic liquids ( [...] ) is selected from the group consisting of an ammonium salt, an imidazolium salt, a phosphonium salt, an onium salt and a mixture of several of these salts. 22. Method according to one of claims 1 to 21, characterized in that the said extraction fluid (F) comprises at least one volatile organic solvent selected from the group consisting of diethyl ether, ethyl acetate and chlorinated solvents such as dichloromethane, chloroform or carbon tetrachloride. 23. Method according to one of claims 1 to 22, characterized in that the said extraction fluid (F) comprises at least one aqueous solvent, such as water subjected to a deionization. 24. The microfluidic system (10, 110, 210, 310) for implementing a method according to one of the preceding claims, of the type having a substrate (11, 111, 211, 311) having a surface (12, 112, 212, 312) is covered with electrodes (13, 113, 213, 313) adapted to move, under the influence of an electric field, microdrops (14, 114, 214, 314) from a liquid phase comprising at least one functionalized ionic liquid ( [...] -A or [...] -A-B), characterized in that said system is provided with means (15 and 16,115 and 116,215 and 216,315 and 316) for causing a liquid extracting fluid (F) on said surface and for extraction by forced convection, to provide a bath extraction (20, 120, 220, 320) which is located on said surface for extracting at least one chemical or biological compound (A, A 'or B, B' or A-B) of said liquid phase and which is open to the ambient space into at least two opposing sides thereof, for moving into contact with said surface of said microdrop upstream and downstream of said bath. 25. System (110,210) according to claim 24, characterized in that said means (115 and 116,215 and 216) for feeding and extracting said extraction fluid (F) are adapted so that said bath extraction (120,220) is formed by a drop of said extraction fluid communicating with the entire ambient space above said surface (112,212). 26. System (10,310) according to claim 24, characterized in that it further comprises a plate (17,317) which is mounted on said surface (12,312) via vertical supports (19,319) which defines with said surface and two respectively upper and lower walls defining an enclosed volume for said bath (20,320), which communicates substantially with the whole ambient side space formed between said walls. 27. System (10,110) according to one of claims 24 to 26, characterized in that said means for feeding and extracting said extraction fluid (F) comprise respectively two capillaries (15 and 16,115 and 116), at least one of which extends and opens above said surface (12,112) and in a direction perpendicular thereto. 28. System (110) according to claims 25 and 27, characterized in that said drop forming said extraction bath (120) is provided to be formed on said surface (112) and (s) under the said capillary (s) (s) (and/or 115 116) extending and open above said surface. 29. System (10) according to claims 26 and 27, characterized in that at least one of said capillaries (15 and 16) ends in an opening (18) of said plate (17), to communicate with said enclosed volume forming said bath (20). 30. System (210,310) according to claim 24, characterized in that said means for providing and removing the said extraction fluid (F) each have two channels (215 and 216,315 and 316) at least one of which is buried in said system and is flush with said surface (212,312) perpendicular to the latter, to communicate with said bath (220,320). 31. System (210) according to claims 25 and 30, characterized in that said channels (215 and 216) are adapted so that said drop forming said bath (220) covers the respective ends (215c and 216a) of said channels. 32. System (310) according to claims 26 and 30, characterized in that said channels (315 and 316) are flush with said surface (312) between vertical supports (319) which connect the periphery of said plate (317) to said surface, so as to form said enclosed volume forming said bath (320). 33. System (10, 110, 210, 310) according to one of claims 24 to 32, characterized in that said electrodes (13, 113, 213, 313), such as electrodes gold, are covered with electrical insulation (41), such as silica or silicon nitride. 34. System (10,310) according to one of claims 26,29 and 32, characterized in that said plate (17,317) is made of borosilicate glass or of a plastic material, and that said vertical supports (19, 319, 51) are based on a photosensitive resin, such as an epoxy resin, said plate being deposited on said supports via an adhesive (71). NMe 3+ ^ OH, or orcr [...] 2 PF6 ' or'BF 4 . x Θ NMe 3+ / ^ rf ' OH, or orcr [...] 2 PF6' or BF4 3 P+ Bu Wr ' _AOE280A2AO> oh. CI- [...] PF6' or BF4