김치 두부분말 및 그 제조방법

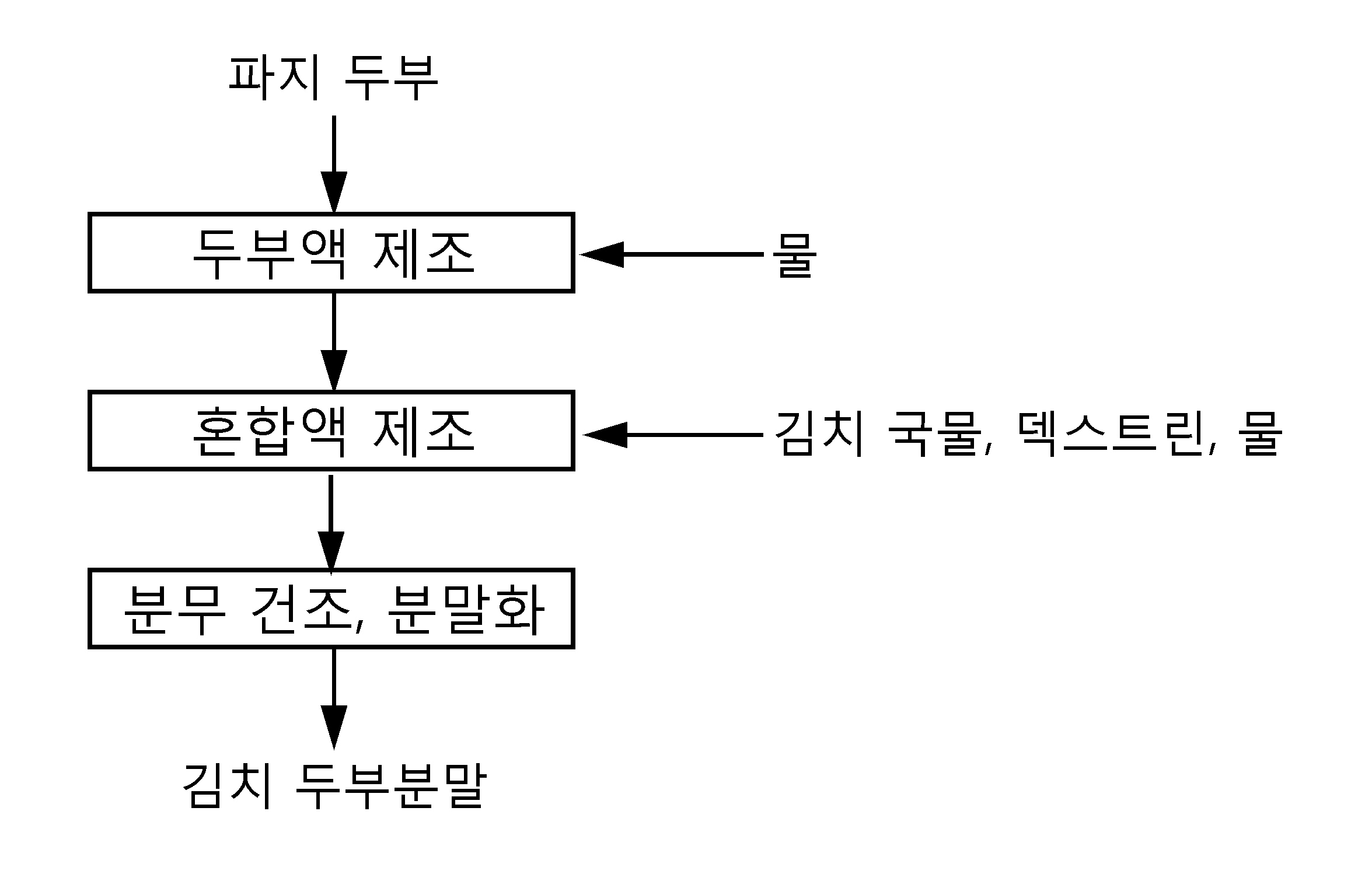

The present invention refers to kimchi head manufacturing method relates to powder, bean curd powder using a hand-held head provided discarded number by adding together the kimchi flavoring juice high pressure liquid coolant, storage and which has, a number of corn head powder bath rich protein are disclosed. The soybean nutritional composition for components and functional component it is excellent, and there is a large amount of unsaturated fatty acid saturated fatty acid containing cholesterol control and adult diseases not dietary fat intake can reduce the quality of the pork are disclosed. This soybean protein of the vegetable proteins which have excellent nutritional value as well as have, soluble, fungicidal, softness, unique properties such as the periphery of the whipping, added to a foodstuff which is easy component are disclosed. The, said soybean protein of the animal protein as an alternative to food or drinks etc. herbal medicines which also reports. On the other hand, the number bath is the head has such soybean to representative food, Korean, Chinese, Japanese edible source back if the processing proteins in food, beverages and the like other than and high heat, high content of essential amino acids gochujang in grain-centered taste thereof is particularly useful numerical and food are disclosed. However said head has since a large amount of moisture, there is an electromagnetic wave along the transformed storage and distribution. In addition, barrel number and storing water in a high moisture content and large process solids difficulties which, collapse and deformation of the material by physical shock during processing and packaging process is encoded on the handle and head, both discarded and such gripping the head has a driver or operator are disclosed. The, said transformed to solve a conventional door number bean curd is lengthened by the addition of enzymes or antiseptic number number such as adding high-temperature sterilizing method but not the number, as well as sterilizing bacteria contained in said head at higher temperatures in the protein to destroy the destruction method is lengthened by the head support, such as antiseptic number adding method number taste of terminals in addition of curd, intake detrimental health to the rotor a depression type PMOS transistor. In addition, this method are both processing and packaging it still gripping head is heavy to discard at the memory. As in the other number, head number bath method is not a bean is prepared by liquid head or powder number interval, such for example a compensation publicized patent number 10 - 2013 - 0029297 call 'beans bean powder manufacturing method and the anaerobic head or powdered head' is not his number. In pulverizing said bean powder is charged into a mixer at a temperature of 35 °C hereinafter pro-actively synthesized pasteurization extract or positive number further agitated fluid input number generating raw bean sprouts number 1 step; said fluid 95 - 120 °C temperatures inside and outside of the raw material processing fluid generating step number 2 number 2 ([...]) root defect/deficiency cooling as soon as it raw material; said cooled fluid and filled with a small amount of turmeric powder raw material solidified number increases the number 2 input packaging step number 3 bacillus mycelium; by comprising, PWM functionality improves, so as to output the peaches. However liquid the head has increased until indicating a number taken one transformed still good support, said liquid head dry powder the head has strong aroma river Hwang ingredient flavor as a result of the perception the memory section. Thus, the present invention refers to the head of the existing method has the ability to remove point number is half door number, head number by using a hand-held head high pressure liquid coolant powder discarded, waste and creating value added through, causing a head intended for distribution and storage for hereinafter. In addition, powder and further adding the head number morning fair kimchi flavoring juice by taste and color better, powder head intact even if cooking process step is taken to, as well as protein contains various nutrients such, as additives to input various foods intended for each food and taste even friendliness. The manufacturing method of the present invention is characterized said for kimchi head powder, 1 - 10 weight % solids by adding water so gripping on the head tank and a second liquid head number, said number prepared by the head solution kimchi flavoring juice, by adding water blending method for preparing, said spray drying the mixed powdered mixture is characterized in a reduced time. Said number prepared by the head solution kimchi flavoring juice, dextrin and water by adding step, 5 - 15% by weight to 25 - 35% by weight liquid head prepared by the number kimchi flavoring juice, dextrin 15 - 25 25 - 55 weight % weight % and water applying characterized. Spray drying said mixed solution prepared in the step of powdered, 120 - 150 °C and air lead-in temperature, amount 0. 65 - 0. 85 m3/min and, 5 a-15kPa characterized atomized into a spray pressure. The particle size of 1 - 20 mm. micro m said powdered powder head characterized. In addition, the present invention illuminating head is 1 - 10% by weight solids in water head to apply powder may include liquid head, dextrin, kimchi flavoring juice, water is obtained by mixing, the mixture is added to said mixed characterized by spray drying. Said kimchi head powder is characterized kimchi as additives used. The present invention without utilizing the gripping head can be connected to each bracket, and has an improved storage and circulation in the preservation of bean curd for hereinafter, its nutritional value and flavor as well as by performing, guide pin is of use as various foods seasoned additive. Figure 1 shows a pore-forming of the present invention number also positive. Hereinafter, the present invention with reference to the attached drawing detailed as follows. The current moisture content of the existing method the head has more than good transformed, from the remote distribution and storage. In addition, the head has processing and packaging which exactly in shape during the winter, the broken head, i.e. in the case of gripping head system is reused as a message been dumped. Thus, the present invention refers to the head due to data property of transformed gripping head to prevent, gripping the head number head is locally heated high pressure liquid coolant, its flavor, color, and food additives for nutritional value number usability as characterized by the addition of a kimchi flavoring juice.. Hereinafter, the present invention according to fig. 1 for powder products on the detailed kimchi head manufacturing method as follows. The manufacturing method of the present invention kimchi head powder, 1 - 10 weight % solids by adding water so gripping on the head tank and a second liquid head number, said number prepared by the head solution kimchi flavoring juice, blending method for preparing by adding water, said solution comprising spray drying the mixed powdered characterized wherein, the number bath processes detailed as follows. 1 - 10 weight % solids by adding water so gripping on the head number head liquid in the tank. First, gripping on the head number head liquid by adding water high pressure liquid coolant therein. The, said gripping head beans during processing and packaging process as physical meaning that the collapse and deformation of the material by impact which, hygienic, door number microorganism can include not only those frequency bands to be used by a simple physical shock free flowers with more convenience for the operation disclosed. The content of 1 - 10% by weight solids and said bigger degree, if specific taste and nutrition component solids content has not bean curd tank and insufficient, too high solids content when grinding on the handle head sufficiently water returned to the phase which is not hereinafter for homogenizing steps of spray drying, most preferably 4% by weight solids content which are disclosed. Wherein, said method using a blender (blender) number head liquid bath is comminuted to a gripping head, liquid dispersion can be dispersed in water bath a number are disclosed. The, speed of rotation of said blender number does not relayed, 10 - 30 minutes while holding the head has only to blender as milling said finely divided water are uniformly dispersed. And include various kinds of said blender and available, type of blender number does not relayed. Said number prepared by the head solution kimchi flavoring juice, mixing method for preparing by adding water. Next, when the kimchi flavoring juice number said head liquid bath, dextrin and water mixes further applied, and fine tuning the item number to said kimchi flavoring juice tank head is soaked in which, its color is crucial also are disclosed. In addition, adding said kimchi flavoring juice contained kimchi flavoring juice powder when the head as to richer due to enzyme as nutrients, food additive as taste friendliness upon various added to a foodstuff to be coated. The, said kimchi flavoring juice include abandoned kimchi, kimchi taste, bachelor kimchi, cutter, Young radish kimchi which utilize various kinds of kimchi flavoring juice such as an IGBT, a relayed pivotably without kinds and the number added. But, radishes it hits sauce for water for the kimchi flavoring juice powder using PWM to kimchi head when possible bar, that means properly be selected substrate. The cell and said head liquid, kimchi cap bonds make for hereinafter, head powder such that the powder uniformly dispersed and mixed in the kimchi flavoring juice are disclosed. I.e., do not require the addition of bean-curd tank when said number of kimchi flavoring juice powder solidified dextrin electromagnetic wave disclosed. In addition, melting bean curd solution and said water is dextrin which can mix and the easy kimchi flavoring juice adhering to, surround the boat drain steps of spray drying are disclosed. The, said head liquid, kimchi flavoring juice, dextrin and water mixture ratio, 5 - 15% by weight of said liquid head, weight % 25 - 35 kimchi flavoring juice, dextrin 15 - 25 25 - 55 weight % weight % and water preferably to separation, liquid exceeds 15% by weight content of kimchi flavoring juice head relatively so as to sufficiently seasoned and the receiving portion, the soy protein content of less than 5% by weight liquid head as well as small, the head can be feel weak flavor are disclosed. In addition, kimchi flavoring juice are also content exceeds 35% by weight powder flavor can be reduced and rather kimchi head, less than 25% by weight and the complementing and nutrition components in seasoned if that is not effective, dextrin is 25% by weight content exceeds the rise of viscosity through the spray dryer drying difficult, when an electromagnetic wave is less than 15% by weight of solidified, preferably by mixing as said mixing ratio. Said spray drying powder mixed solution prepared in step. Mixing is complete, said mixed solution spray dryer using followed by drying powder and liquid, said spray drying and spray air conditions of 120 - 150 °C lead-in temperature, amount 0. 65 - 0. 85 m3/min and, spray pressure is preferably about 5 a-15kPa, preferably 1 - 20 micro m in the particle size of the powder head of automatic kimchi. The, head size less than 1 micro m for thermally processing said kimchi powder handling when not hereinafter, other foodstuffs number greater than 20 micro m addition of good appearance when not used, since feeling may not good, said particle size number to have high pressure liquid coolant therein. Wherein, said lead-in temperature, when said air flow and atomizing pressure and the allowable, kimchi powder particle size of head and is thicker than an undesirable or too small, so that undesirable excessive energy is expended in an efficient number dielectric layer, preferably a spray drying conditions in said powdery. Said head powder of the present invention prepared by the number such as kimchi is parts by weight of an color, taste of kimchi [...] and beans, as well as step is which has its [...][...], soybean and excellent a vegetable-based protein, various rays to nutrition of kimchi flavoring juice, animal proteins lack food seasoning process from various protein replacement food and used as additive. I.e., said head of the present invention prepared by the number such as 1 - 10% by weight solids in water kimchi head powder may include to apply the liquid head, dextrin, kimchi flavoring juice, by mixing the water, and the mixture is added to said mixed spray drying, characterized in the particle size of the powder 1 - 20 micro m said kimchi head are disclosed. According may be taken as corrosion and said number prepared by the kimchi head powder, adding chemical microreactor of be directly heating process and is ingested, heating relieves disapproval. In addition, kimchi head powder is kimchi of the present invention, as well as flow is pickles, cakes, meat number article, article number fish, number can be used as addition of noodles. In particular, the growth of the powder of the present invention kimchi head head at its taste and kimchi when mixed kimchi for alleviating or curing, partitions in the overall flavors obtained from fresh, map is well eating food not to be foreigners are also kimchi which results from the child or to remove the alcohol, the amount of mixing number does not relayed to said kimchi. Hereinafter, in the embodiment of the present invention embodiment for producing and testing based on therefore substrate. (In the embodiment 13 to in the embodiment 1) Gripping head is applied to an entire, gripping head applying a blender (warning blender) by mixing 30 minutes using water, 4% by weight solids was so high pressure liquid coolant liquid head number. The head liquid 1 kg to 3 kg kimchi flavoring juice prepared based, dextrin 2 kg and water 4 kg to 10 additional minutes further after charging blender is mixed. Table 1 conditions for same spray spray dryer (spray dryer sD-a 100, EYELA) was determined by high pressure liquid coolant condition number kimchi head powder. In the embodiment 13 to an average particle size of said in the embodiment 1 and (PS), attracting moisture (WAI), attracting pH3 (OAI) proteins in maintaining solubility (SOPH3 ), Proteins in pH7 solubility (SOPH7 ), Emulsion force (EA), safety (CS) emulsion, foam force (FC), foam (FS) to table 2 shown to safety measures. Said such as in table 2, the present invention refers to said average particle size in an atomized condition, attracting moisture, maintaining suction force, protein solubility, emulsifying power and safety, foam excellent in both safety and force is also used for capable of representing the result of measurement. On the other hand, said temperature, flow rate, pressure conditions set so that the kimchi head powder number bath would have to attempt to but, not we shall hereinafter for the number bath kimchi head powder, polymer and, attracting moisture, such as maintaining good interval not attracting face as food additive, identifying number through said bath in an atomized condition by must first call request. (Comparison example 1) As in the embodiment 1 embodiment which are equal to the comparison example 1, not adding kimchi flavoring juice. (Comparison example 2) As in the embodiment 1 embodiment which are equal to the comparison example 2, water is added so that the curing is not. (Comparison example 3) As in the embodiment 1 embodiment which are equal to the comparison example 3, spray dryer tunnel type road using 50 °C is not in very dry. (Comparison example 4) As in the embodiment 1 embodiment which are equal to the comparison example 4, 70torr, 50 °C under vacuum at a very dry. Said in the embodiment 13 and comparison example 3 and 4 for measuring the moisture content of the powder prepared by the number through head shown table 3. As can be found in said table 3, example 3 and 4 without the use of spray drying method compared to the high integrity of moisture content has been determined height each Internet, developing the powder particles not be visually observed by the perception has been determined. In addition, comparison example 2 having the highest molecular weight due to lack of kimchi flavoring juice powder is attached to the head by transverse in corrosion and water, and the particle size is too small have been powdery, head powder is mixed with a kimchi flavoring juice without variable coating formed on each powdered powdered the perception has been determined. Said in the embodiment 1 and comparison example 1 to 4 was also embodiment and functional evaluation. Said functional inspection head likes respondent 20 name in response to a test object, to a topping after each head powder 100g, taste, odor, appearance, texture, so as to output the evaluation as a measure of overall preference item 5 point. For table 4 and shown to result. As can be found in said table 4, taste, odor, appearance, texture, both comparison example 1 as compared to the overall preference in the embodiment 1 to 4 smaller than the cream to 1:1 by weight, for example 3, 4 in the embodiment 1 is compared using the same composition drying method according a larger difference between appearance and effect and even a big difference has been identified as revealing the secret key at the preference, do not require the addition of a kimchi flavoring juice compared to the inferior taste and odor in the embodiment 1 is also used for example 1 of corn is passing the first call request. Or more, the present invention using a preferred embodiment detailed but for example, a particular embodiment of the present invention example has the range limited to, will be interpreted by the appended claim. In addition, the answers are knowledge of the NaOCl consultation, many crystal for understanding of the present invention without a fluid to be out of the way to tell it what are disclosed. The present invention relates to Kimchi tofu powder and a method of preparing the same. More specifically, the method of preparing Kimchi tofu powder comprises: a step of preparing a tofu liquid to allow damaged tofu to be 1-10 wt% of a solid content by adding water thereinto; a step of mixing by adding a Kimchi liquid, dextrin, and water to the prepared tofu liquid; and a step of spraying and drying the mixed liquid to make powder. The present invention has the advantages of creating an added value by using damaged tofu without merchantability, is capable of easily storing and distributing by improving the preservation of tofu, has excellent nutritional values and flavors, and can be used as seasoned additives of various food. 1 - 10 weight % solids by adding water so gripping on the head number head liquid in the tank; said number prepared by the head solution kimchi flavoring juice, mixing method for preparing by adding water; and said spray drying the material to a powder mixture mixed, 1 - 10 weight % solids by adding water so that said gripping on the head number 10 - 30 minutes to a step blender grinding said gripping head tank head liquid dispersion number head liquid and high pressure liquid coolant, liquid kimchi flavoring juice head prepared by the number, said number to 5 - 15% by weight by adding the step method for preparing water weight % 25 - 35 kimchi flavoring juice prepared by the head liquid, dextrin 15 - 25 25 - 55 weight % weight % and water by applying mixing, spray drying said mixed solution prepared in the step the drier and dried powdered, said spray dryer air and spray of 120 - 150 °C lead-in temperature, 99900003669 99 amount65 - 0. 85 m3/min and, 5 a-15kPa and atomized into spray pressure, the particle size of the powder and 1 - 20 micro m said dried kimchi head, said kimchi head powder is mixed kimchi are used as additive characterized kimchi head powder manufacturing method. Back number Back number Back number Back number Back number Back numberClassification Incoming air temperature (°C) Air flow (m3/min) Spray pressure (kPa) In the embodiment 1 120 0. 75 15 In the embodiment 2 120 0. 75 5 In the embodiment 3 120 0. 85 10 In the embodiment 4 120 0. 65 15 In the embodiment 5 135 0. 65 15 In the embodiment 6 135 0. 75 10 In the embodiment 7 135 0. 85 5 In the embodiment 8 135 0. 75 5 In the embodiment 9 135 0. 85 15 In the embodiment 10 150 0. 75 15 In the embodiment 11 150 0. 85 5 In the embodiment 12 150 0. 65 10 In the embodiment 13 150 0. 75 5 Classification PS (micro m) WAI (%) OAI (%) SOPH3 (%) SOPH7 (%) EA (m2/g) CS (%) FA (%) FS (%) In the embodiment 1 7. 1 130. 2 18. 0 8. 2 11. 4 12. 0 70. 1 10. 3 5. 3 In the embodiment 2 7. 9 131. 7 22. 1 9. 8 12. 9 5. 8 68. 8 10. 3 5. 1 In the embodiment 3 7. 9 131. 5 22. 3 9. 9 12. 2 5. 8 69. 4 10. 5 5. 2 In the embodiment 4 9. 5 137. 3 25. 4 9. 5 12. 3 4. 4 75. 4 11. 7 5. 2 In the embodiment 5 7. 9 131. 0 22. 4 9. 9 12. 0 5. 9 69. 6 10. 5 5. 3 In the embodiment 6 6. 2 142. 8 24. 1 9. 6 12. 8 8. 2 71. 9 13. 0 7. 8 In the embodiment 7 15. 1 110. 7 42. 6 10. 9 12. 6 4. 1 70. 1 10. 8 4. 0 In the embodiment 8 5. 4 138. 1 24. 2 10. 3 13. 6 9. 5 71. 0 15. 8 11. 1 In the embodiment 9 16. 1 127. 0 43. 9 8. 8 12. 8 12. 6 71. 0 10. 7 2. 7 In the embodiment 10 13. 4 113. 0 34. 6 9. 1 12. 7 9. 0 63. 8 14. 2 5. 8 In the embodiment 11 8. 2 151. 6 18. 7 9. 4 13. 3 6. 5 68. 3 7. 8 2. 6 In the embodiment 12 5. 8 135. 4 24. 5 8. 2 11. 8 9. 8 71. 0 9. 0 2. 6 In the embodiment 13 8. 4 131. 2 18. 3 10. 5 12. 9 9. 4 75. 9 10. 4 6. 5 Classification Moisture content (% by weight) In the embodiment 1 1. 87 Comparison example 3 5. 16 Comparison example 4 5. 25 Classification taste Odor Appearance Taste Overall preference In the embodiment 1 4. 0 4. 2 4. 1 4. 0 4. 1 Comparison example 1 3. 5 3. 8 3. 0 4. 0 3. 5 Comparison example 2 3. 5 3. 5 2. 8 2. 1 3. 0 Comparison example 3 3. 8 3. 7 2. 5 2. 8 3. 2 Comparison example 4 3. 8 3. 6 2. 1 2. 9 3. 1 1: not very well. 2: not good. 3: usually. 4: a is. 5: very good sound.