휠 로더

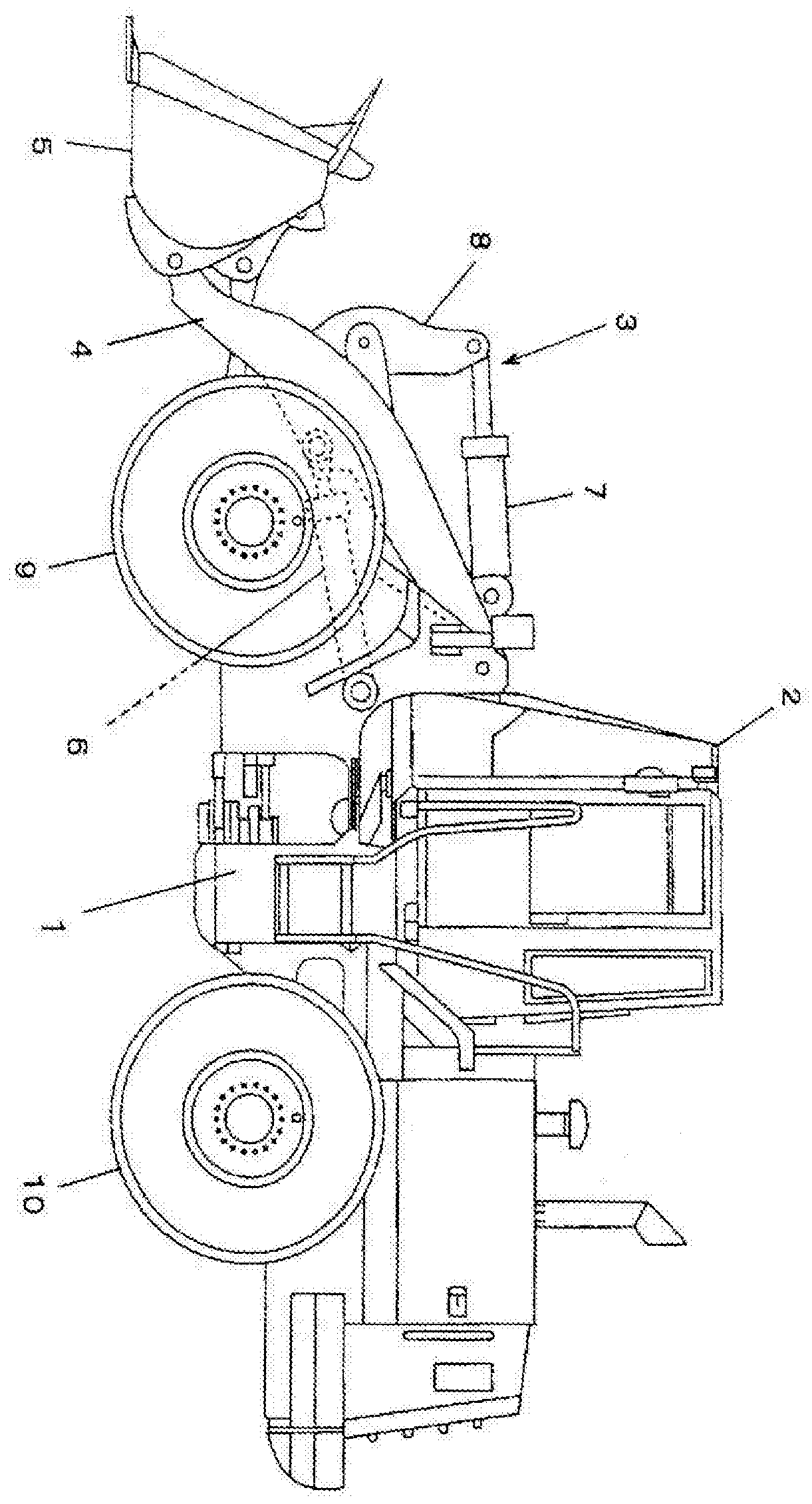

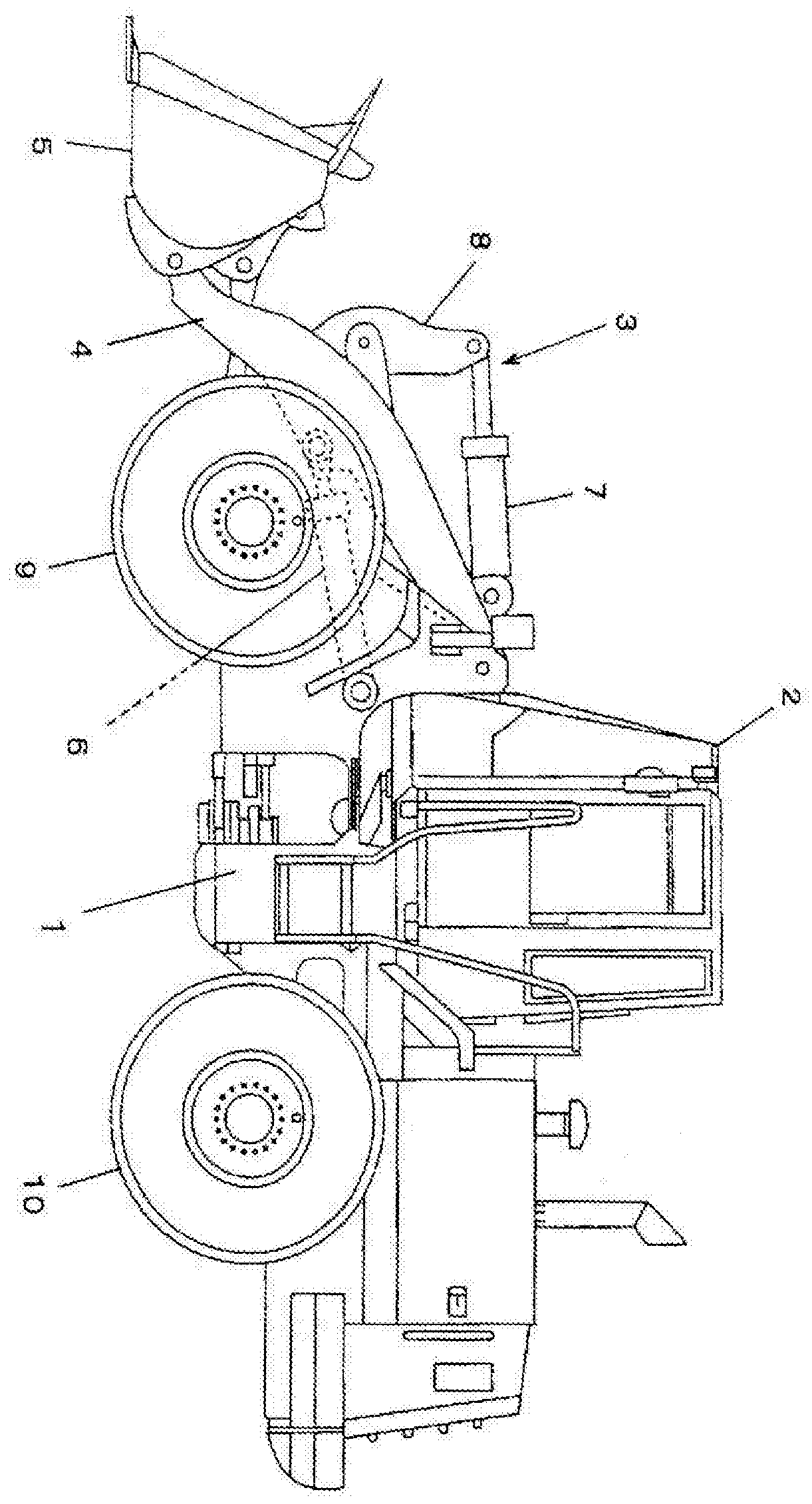

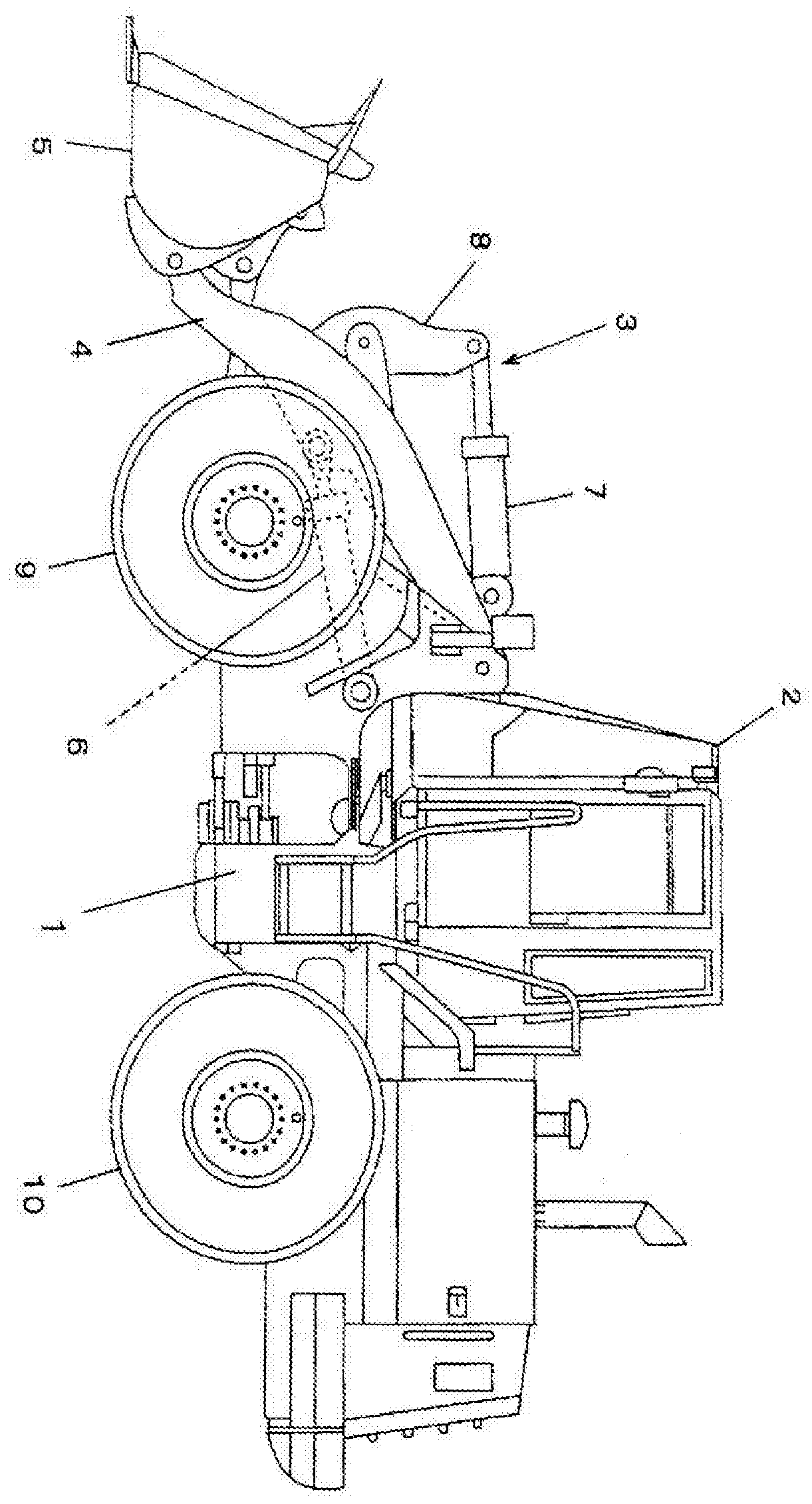

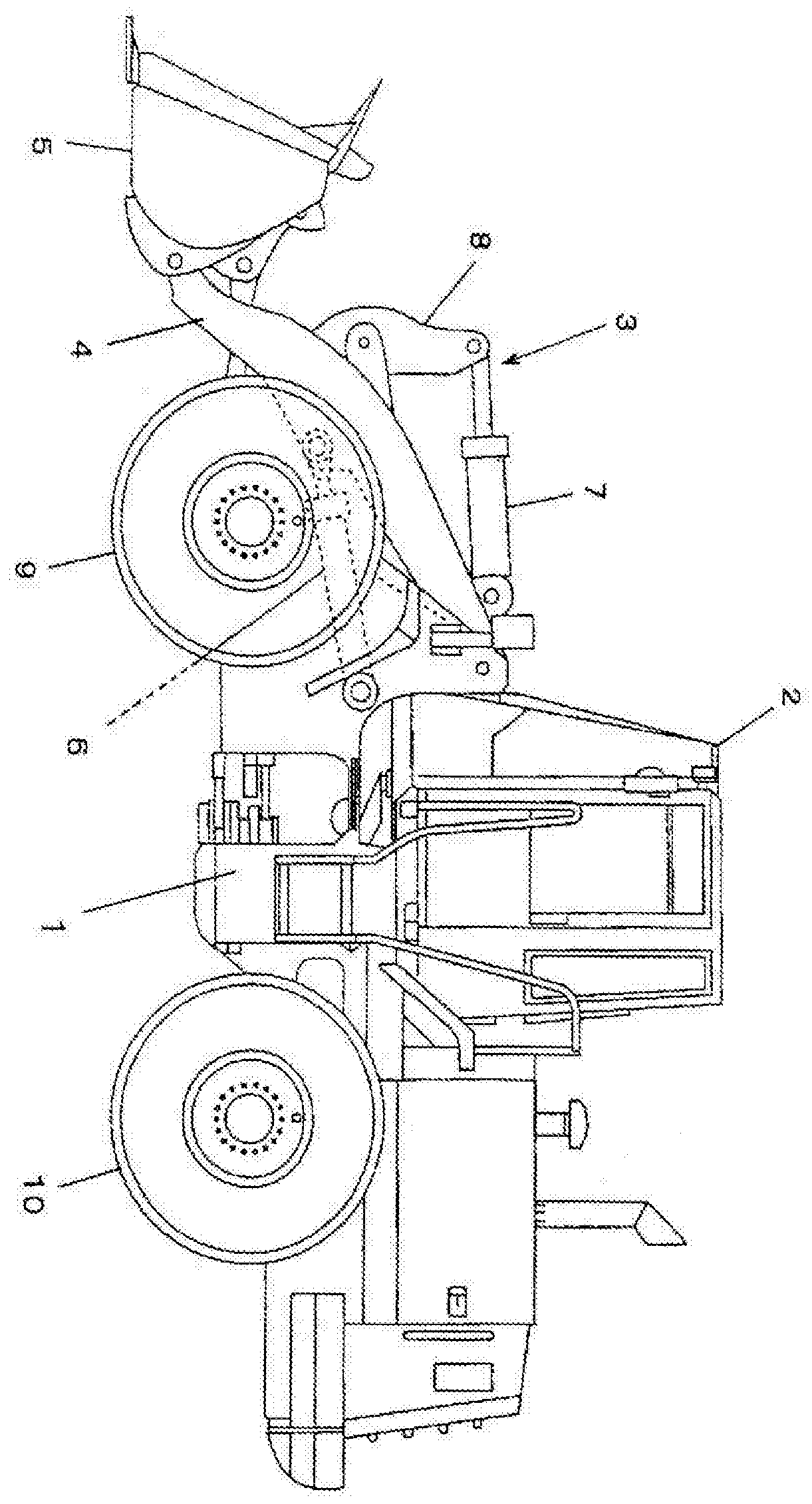

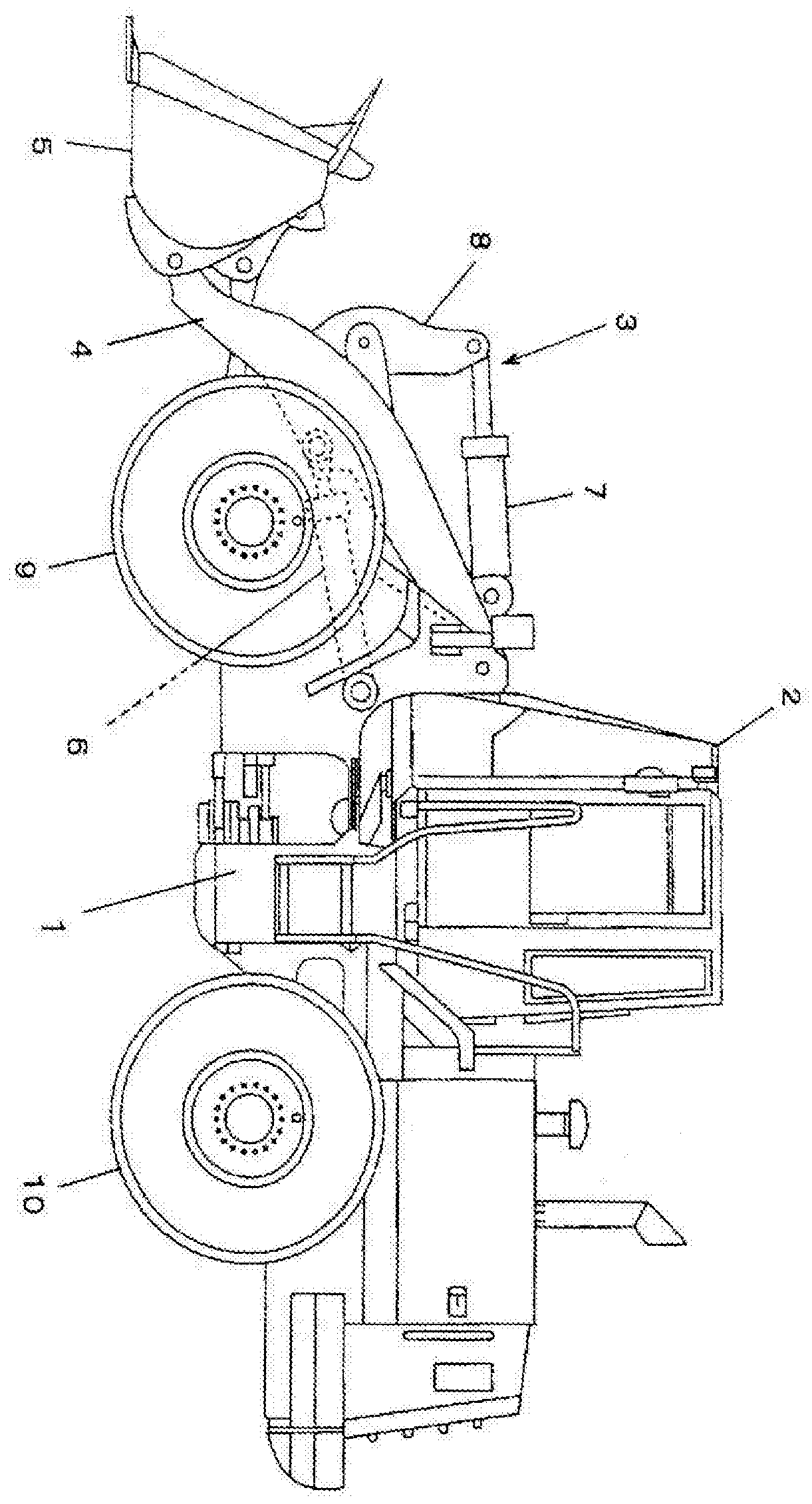

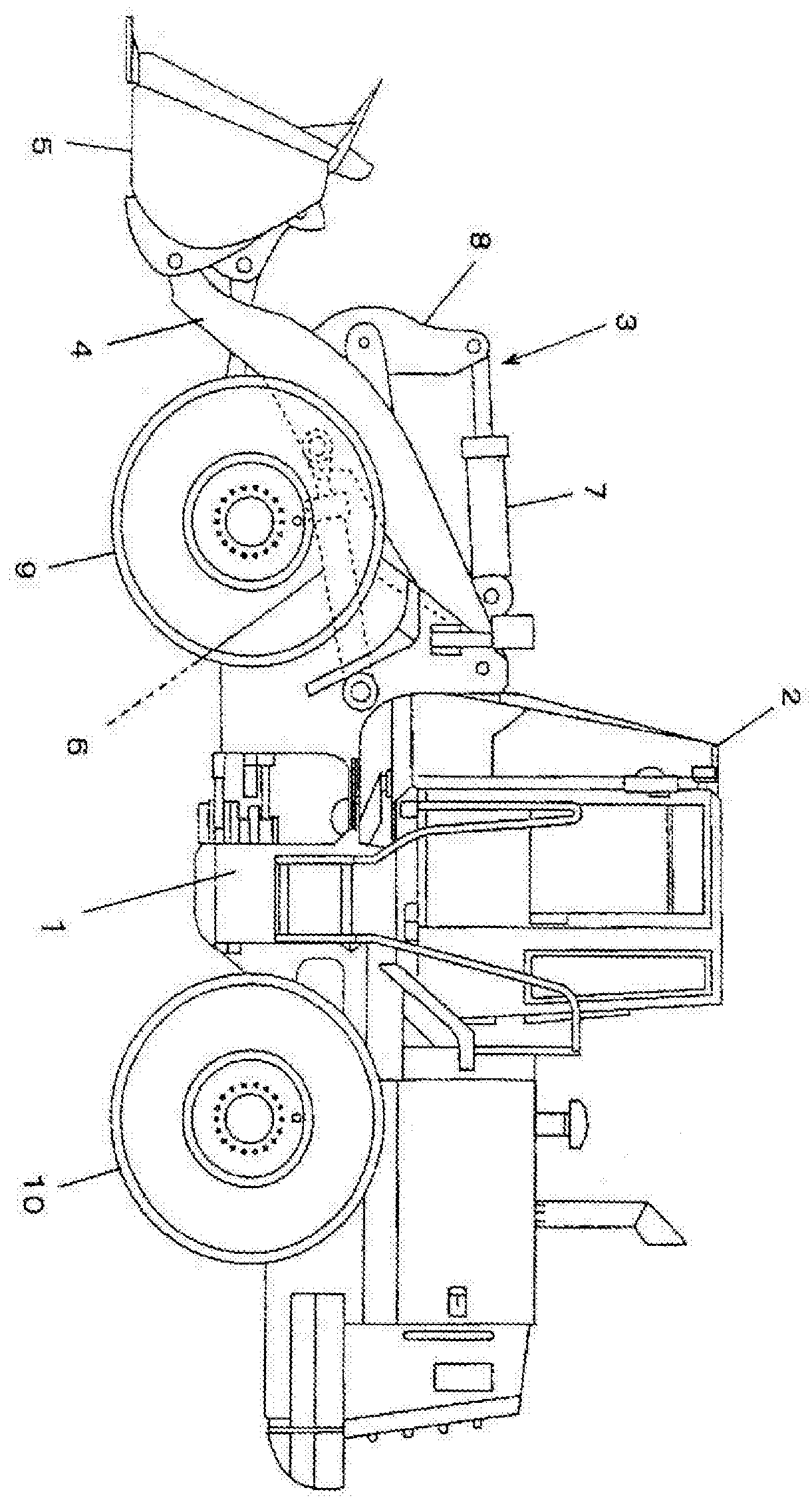

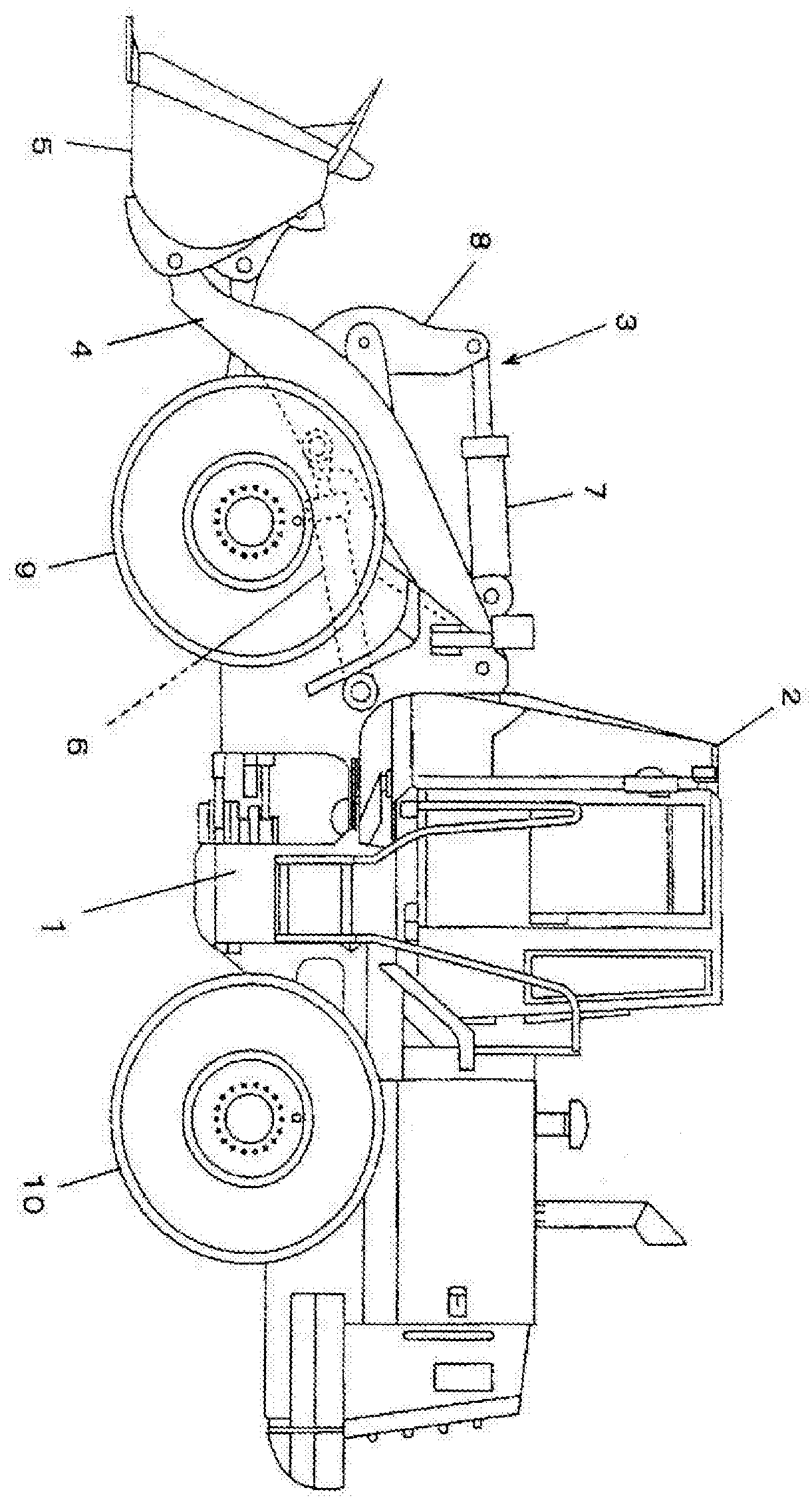

The present invention refers to, HST-type drive system having a distinctive wheel loader are disclosed. In this type of wheel loader as patent document 1 that the disclosure to the pin is. A wheel loader wheel, body frame and driver's chamber, work with the suction device or the like. The work device, vertically moving lift arm, the lift arm mounted with the suction end the buckets. The ends, in this type of wheel loader as HST type drive system has a 2000. The HST type drive system is, the usable in a HST HST pump and motor, for driving the working device discharging pump working hydraulic control, the entire driving wheels etc. HST motor to an output from the system. As described said HST-type drive system having a distinctive wheel loader in, order to establish energy saving effect, HST pump, when the HST motor number, corresponding power mode during ([...]) oyster [sak, a fuel cost reduction effect than low engine rpm power mode to set the mode to reduce the echo is present billion number idea with each other. However, the echo mode is transmitted to the outside in a door number think hereinafter are disclosed. I.e., engine, and HST pump is working machine pump also direct ([...]), engine pump is connected directly to the input shaft speed to the flow is determined working in, echo mode for example work bucket lift arm device when operated lifted by the soil by silica, that the slower the speed operation of the working device can be decrease in operating efficiency occurs. Figure 8 shows a prior art also said described may be a HST input torque from the engine rpm for the pump characteristics are disclosed. In auditory canal 8, 32 of the power mode, etc. 31 exhibits the properties of the echo mode. 29 engine torque characteristic, engine torque characteristic of device 30 29 when working at an engine torque properties subtracted by the pump attachment of drive input torque, engine torque available for consumption in a pump HST representing the disclosed. Work device when a travel operation while driving, power mode, B whip [ching point in engine driven, engine rpm N (B) but high rpm, echo mode, as compared to input torque ratio increase because of increased engine speed of a HST pump, whip [ching point B than low engine speed that the engine driving A whip [ching point to be coated. To this end ring with low rpm engine speed that is N (A). The speed of the slow working device is received. The present invention refers to, is described in the prior art been made to data in a database in said, is, having HST type drive system in, power mode echo mode echo mode when the wheel loader having a working efficiency in number [...] 2000. In order to achieve this purpose, the present invention refers to, body frame, wheel and, said body mounted to the frame, moving degree angle lift arm on a working device, an engine for said body mounted to the frame, said engine driven by said variable capacity type hydraulic pump and motor to prevent the HST HST closed circuit and a sixth drive wheel, said HST HST HST pump number control unit having input torque pump number plower on traveling device, driven by said engine, said operating device work oil ([...]) discharge in wheel loader with pump working, workload is a light load under job mode when power mode, under work mode when said workload is in work mode selection device selecting on either echo, said lift arm device of said detection device is lifted up work on, work mode when said echo mode is selected by said selection unit, number control unit by said pump, said HST pump input torque and the predetermined number properties echo mode, said power mode is selected by said work mode selection device when, number control unit by said pump, said HST pump wherein the power mode input torque to preset number properties, when said echo mode is selected, by said detecting device, said lift arm is lifted up is detected, said HST pump said echo mode input torque characteristics with the device number operation properties instead rise characteristics characterized plower number etc.. In addition the present invention refers to, in said invention, said number is the device, echo mode characteristics line, power mode characteristics line storage portion and the synergistic operation characteristic line, said characteristic line echo mode, said power mode characteristic line and said operation characteristic line is raised, the relation between the engine rpm with a HST pump indicated and is constituted by an input torque, said rise operation characteristic line, said torque of said pump working in the engine's torque engine torque characteristic line on device operation setting value obtained work, said echo mode said engine torque characteristic lines work device operation characteristics line whip [ching with point it is an intersection echo mode, said power mode engine torque characteristic lines it is an intersection between said work device operation characteristics line power mode is set as a characteristic characterized whip [ching point intersection with whip [ching point etc.. In addition, the present invention refers to, in said invention, said rise operation characteristic line, said characteristic line branched from the middle of echo mode characterized formed etc.. In addition the present invention refers to, in said invention, said HST is connected to the motor, high speed stage, low speed stage including a plurality of speed stage with a multi-stage transmission and, said low speed stage detection speed stage detection device is converted to power transmission, said wheel loader is moved forward state detecting sensor detects arefrigerant, said HST motor, comprised of a variable capacity type hydraulic motor, said HST includes a traveling device, said HST HST motor control section with a motor swash plate ([...]) number plower number, said number is the device, said speed stage detection device is converted in said transmission speed stage is detected, in addition said forward detection sensor, said wheel loader is moved forward in a state is detected, said HST motor control section by number, said HST motor swash plate to the swash plate in the swash plate greater than said minimum echo mode signal and the minimum minimum number [...] etc.. The present invention refers to, having HST type drive system in, power mode echo mode echo mode when operation is performed on the lift arm is raised when the working device is, rise along the first HST number so that the pump operation characteristics, echo mode can be present in engine speed to increase. The present invention refers to the, work device can be quickly speed operation of lift arm is lifted up, to improve working efficiency can be. In addition the present invention refers to, rise in operation characteristics line echo mode characteristic lines in amount on the upper face, the upper felt from echo mode while the operator makes a echo mode of operation capable of embodiment of lift arm is raised. Figure 1 shows a also, the present invention related to wheel loader of representing number 1 embodiment form side are disclosed. Figure 2 shows a also, with number 1 embodiment form an electric, hydraulic circuit are disclosed. Figure 3 shows a also, with a number representing the device of a block number 1 embodiment form are disclosed. Figure 4, with number 1 embodiment form hole controller processing indicates an order in which flow chart are disclosed. Figure 5 shows a also, the surface properties is obtained in the form number 1 embodiment are disclosed. Figure 6 shows a also, the system of the present invention number 2 embodiment with a number representing a block form are disclosed. Figure 7, hole controller processing indicates an order in which flow chart with number 2 embodiment form are disclosed. Figure 8 shows a also, from the prior art may be a surface the properties are disclosed. Hereinafter, the present invention based on the embodiment of wheel loader related to form drawing through a browser substrate. [Number 1 embodiment form] The present invention also related to wheel loader of Figure 1 shows a side representing number 1 embodiment form are disclosed. As shown auditory canal 1, number 1 embodiment form at least one associated wheel loader, body frame (1) and, in a driver's cab (2) and, wheel i.e. front wheel (9) and a rear wheel (10) and, body frame (1) mounted work device (3) with disclosed. Work device (3) is, degree angle movable lift arm (4) and, in the lift arm (4) for driving a lift cylinder (6) on, lift arm (4) mounted at the front end of, silica sand which bucket (5) and, the bucket (5) that moves vertically rotating a bucket cylinder (7) on, bucket (5) and a bucket cylinder (7) link mechanisms constituting a bell crank (8) contains a. Figure 2 shows a form also number 1 embodiment with electric, hydraulic circuit are disclosed. As shown auditory canal, number 1 embodiment forms, body frame (1) mounted engine (17) and, engine (17) driven by the HST variable capacity type hydraulic pump (11) and HST pump (11) driven by HST in pressure type discharged from motor (14) including a hydraulic closed circuit and, engine (17) driven by, work device (3) for discharging the hydraulic control device for operating the working machine pump (13) with disclosed. In addition number 1 embodiment forms, HST pump (11) for discharging a hydraulic control number the HST charge pump (12) on, HST motor (14) driving force by wheel (9), rear wheel (10) is transmitted to the driving wheels system (24) valuable minerals. Working pump (13) discharged from pressure type, control valve (35) working through an device (3) as lift cylinder (6) is sent to a. In addition, number 1 embodiment forms, work device (3) lift arm (4) is lifted up a threshold value, for example control valve (35) and the lift cylinder (6) forms a pressure detector for detecting pressure of bottom it will load in communication pipe (23) on, workload is a light load under job mode when power mode, when the workload is in work mode under echo at a work mode selection unit selecting one (22) on, engine (17) of the thread number rpm engine rpm sensor (25) with, these inputs information in the device number, i.e. controller (18) with disclosed. Controller (18) information outputted from, HST pump number control unit (15) number on HST motor control section (16) is sent to a. HST pump number control unit (15) is, controller (18) according to the instructions from the host, HST pump (11) and the pressure of a number a (pump input torque), HST motor number control unit (16) is, controller (18) according to the instructions from the host, HST motor (14) of the swash plate (motor output torque) decodes a number. In addition, controller (18) is, swash plate pump (pump input torque) and controls the engine revolution number becomes broader HST pump control section (15) is a number etched. In addition, controller (18) is, HST (HST motor (15) for driving pressure) in an exhaust pressure pump motor swash plate (motor output torque) is increased by increasing the swash plate toward maximum, the discharge pressure of the pump by an HST motor swash plate toward the swash plate cover the lower minimum number HST motor control section (16) exposed to a number. The bigger the traveling torque is increased and the swash plate motor, small so that the traveling speed increases, the swash plate to minimum rate can be reached. The, borer large slow running, high speed low torque traveling 1.000. Figure 3 shows a system with a number indicating the number 1 embodiment also form also block, with Figure 4 number 1 embodiment form hole controller processing indicates an order in which flow chart, the surface properties is obtained in the form Figure 5 number 1 embodiment are disclosed. 3 also through the controller (18) is, as shown in fig. 5, input torque for engine rpm HST pump relationship map as a body (28) have a (reference 3 also). The map is, work mode selection unit (22) echo mode used when echo mode is selected by the engine rpm with a HST pump (11) representing the relation between the input torque of echo mode characteristic line (31) and, when the power mode is selected four mode representing the relation between the engine rpm with a HST pump power mode input torque characteristics line (32) and, engine (17) torque (characteristic line (29)) from working machine pump (13) torque of the engine torque characteristic line obtained work device operation setting value (30) on, echo mode characteristic line (31) and a work device operation engine torque characteristic line (30) it is an intersection with A whip [ching point on, power mode characteristic line (32) and a work device operation engine torque characteristic line (30) B whip [ching point on it is an intersection with, A whip [ching point on engine torque characteristic line whip [ching point B work between operation device (30) with intersection on the whip [ching point C, echo mode characteristics line (31) is set so that a plurality of the, lift arm (4) representing the relation between the input torque rise of the engine rpm with a HST pump operation raised operation characteristic line (34) previously stores in the nanometer range. In HST pump device and the working device input torque, engine torque characteristic line work device operation (30) matched in intersection on, engine (17) is, in speed and cross with each other. Echo mode characteristic line (31) is, compared to an increase of engine rpm, input torque is set greater than the increasing rate of HST pump, A whip [ching point in the engine rpm, some low rpm N (A) is under or over. , the low speed engine, improves fuel economy can be. Power mode characteristic line (32) is, echo mode characteristic line (31) to cause the input torque is remarkably increased as compared to an increase of engine rpm than HST pump is set so that, in the engine rpm N whip [ching point B (B), (A) N A whip [ching point in engine rpm higher value with each other. To this end, the high speed engine, working machine pump (13) output of carbon dioxide and, lift arm (4) to the driving device (3) and controls the driving can be, capable of workability is improved. Rise operation characteristic line (34) is, echo mode characteristic line (31) from the middle of the first data, until a branch, echo mode characteristic line (31) is connected to the HST pump increased engine revolution rate is large relative to the increased input torque is but, over a branch, for example power mode characteristic line (32) curve almost to HST pump to cause the input torque is remarkably increased as compared to an increase of engine rpm is set so that, in the whip [ching point C (C) N engine rpm, engine rpm greater than N (A), engine rpm is less than a value N (B), engine rpm (B) N proximate its characteristic is set for the corresponding with each other. In addition, controller (18) is, as also shown 3 work mode selection unit (22) for cancelling echoes in mode is selected in a state in which, working pressure detector (23) device produced in (3) of lift arm (4) judging unit for judging whether or not the rise of operation is detected (26) on, said characteristic is stored to memory unit 5 also of (28) to, is a judging unit (26) in lift arm (4) when determined that the rise in operation is detected, echo mode characteristic line (31) instead, rise in operation characteristic line (34) using HST pump (11) plower number a number control unit (27) with disclosed. Also 4 as shown, controller (18) is, first a judging unit (26) for identifying whether echo mode is selected as a work mode and gap3. (S1 order). Echo mode is selected is determined to have a, 5 also represented power mode characteristic line (32) along, HST pump (11) would be the number of magnets (S2 order). Echo mode is selected is be used for recording is, working pressure detector (23) detects the pressure inside a lift arm (4) discriminating whether operated rises and gap3. (S3 order). If not detecting pressure working machine set, lift arm (4) is not operated to rise in Figure 5 in which the echo mode indicating characteristic line (31) along the HST pump (11) would be the number of magnets (S4 order). If the control section detects pressure working machine set, lift arm (4) in which the operation characteristics such as rise in Figure 5 operated rises indicating a line (34) along the HST pump number would be the magnets (S5 order). In addition, in fig. 5, input torque and input torque HST pump 29 has a corresponding internal combustion engine output torque characteristic line and pump working total torque etc.. As described said, engine torque characteristic line work operation device (30) is, working pump input torque engine output torque in corresponding internal combustion engine torque is subtracted (17) relating to the torque characteristic line are disclosed. In Figure 5 is, when accelerating from a stop body echo mode HST pump input torque characteristic line (31) and, power mode characteristic line (32) and, rise in operation characteristic line (34) to a vehicle disclosed. Power mode to whip [ching point B N (B) as shown in an engine rpm high rpm but, as shown in an echo mode to as low rpm engine speed that whip [ching point A N (A) may be discarded at the, working machine pump (13) and method of flow reduced propel other. However, rising operation characteristic line (34) to whip [ching point as shown in C, an improved engine rpm N (C), (A) can be made high speed than N since, echo mode power mode even if close working machine pump (13) discharge flow rate can be achieved. It also is a form number 1 embodiment, having HST type drive system in, echo mode, work device (3) lift arm (4) is lifted up when performed, controller (18) in a storage portion (28) elevated operation stored in the characteristic line (34) by HST pump (11) is the number so, echo mode can be present in engine speed to increase. Lift arm (4) is lifted up, bucket (5) is applied to seal chamber regardless truck or the like, when composed of acid [...] (saturdays) embodiment with each other. The number 1 embodiment forms, work device (3) is lifted up operation speed can be quickly, capable of working efficiency. In addition number 1 embodiment forms, rise in operation characteristic line (34) echo mode a characteristic line (31) in amount from the upper face, the upper felt from echo mode while the operator makes a echo mode of lift arm (4) embodiment capable of rise in operation. [Number 2 embodiment form] Figure 6 shows a form of the present invention number 2 embodiment also in connection with the number representing the lines also block, with the number 2 embodiment 7 hole controller processing indicates an order in which flow chart form are disclosed. Number 2 embodiment is in the form of the basic configuration in the form number 1 embodiment is equivalent disclosed. In the hereinafter described only for different portions to each other. Number 2 embodiment forms, HST motor (14) is connected to the, driving wheels system (24) form a part of, HST motor (14) converts the high-speed rotation of the low-stage end either engine not shown multi-stage transmission and, as the transmission speed stage 6 also shown is converted detection speed stage detector (20) on, the wheel loader body is moved forward state detects state of arefrigerant detection sensor (21) with disclosed. Controller (18) of a judging unit (26) is, in the form of number 1 embodiment addition to, speed stage detector (20) is converted by low end power transmission is detected, in addition forward detection sensor (21) whether or not the wheel loader is moved forward to state detection unit is coated using the same are provided, number control unit (27) is, HST motor number control unit (16) number to the signal is also an input to the edifice. In one form the number 2 embodiment, as appearing in the flow chart of Figure 7, in order S3 working pressure detector (23) detects the pressure inside a lift arm (4) operation when it is determined to rise, rise in steps S5 order operation characteristic line (34) along the HST pump (11) performed with number of magnets, controller (18) of a judging unit (26) is in low end power transmission to convert, further advancing state is determined when a (S6 order), controller (18) number of control section (27) is, HST motor number control unit (15) number to the outputs, HST motor (14) which is greater than a minimum echo mode the swash plate minimum swash plate minimum number [...] s3. (S8 order) the swash plate. A low stage, either to one of the following conditions when the target is not forward state matches, number control unit (27) is, HST motor (14) a number equal to the swash plate to maintain the swash plate minimum echo mode minimum HST motor control section (15) is etched a number (order S7). The number 2 embodiment form, the form number 1 embodiment equivalent effect is obtained in addition, work device (3) lift arm (4) is lifted up with, stationary or beautiful custom body ([...]) region when the accelerator, i.e., bucket (5) is applied to seal chamber regardless truck or the like, is composed of acid when [...], echo mode speed lowering of the existing method can be compared. Wherein, prior art wheel loader in, power mode in work device (3) speed operation speed of workability, and for taking into account the operability since nearly balance, echo mode in the work device (3) lift arm (4) vehicle speed operation of speed and therefore balance, a depression type PMOS transistor as a decrease in working efficiency. I.e., prior art wheel loader, echo mode, work device (3) lift arm (4) the sun gear is rotated relative to the inputted operation of speed, a travel distance is longer tends, in addition, power mode has been echo mode operability in different way. To this end, power mode or a station work can be performed in equal tasks at a portion echo mode, echo mode door travel distance required for power mode and the second present invention work by a machine, work is performed in the gas to be difficult to narrow a work site. In one form number 2 embodiment, bucket (5) is applied to seal chamber regardless truck or the like, is composed of acid when [...], said HST motor as described (14) since the swash plate to a large minimum speed by the swash plate can be reduced to a minimum, work device (3) lift arm (4) to attain a proper balance of speed and vehicle speed, can be work effectively. In addition, echo mode power mode same work for example bucket (5) regardless to seal such as truck provided to have a blade, and second when a [...] composed of acid, and a travel distance for can be made almost identical. 1 body frame 3 work device 4 lift arm 5 bucket 6 lift cylinder 7 a bucket cylinder 8 bell crank 11 HST pump 12 HST charge pump 13 working machine pump 14 HST motor 15 HST pump number control unit 16 HST motor number control unit 17 engine 18 controller (the device number) 20 speed stage detection (speed stage detection device) 21 forward detection sensor 22 work mode selection unit (work mode selection device) 23 attachment pressure detector (detection device) 24 driving wheels system 25 engine rpm sensor 26 a judging unit 27 number control unit 28 storage unit 29 engine torque characteristic line 30 engine torque characteristic line work device operation 31 echo mode characteristic line 32 power mode characteristic line 34 rise operation characteristic line Provided is a wheel loader having an HST type driving system. In order to make it possible to improve working efficiency in an eco mode when a power mode and the eco mode have been set in the wheel loader, the wheel loader is provided with a controller 18 which has an eco mode characteristic line 31, a power mode characteristic line 32, and a lifting operation characteristic line 34 having a matching point C located between a matching point A between a working device operating engine torque characteristic line 30 and the eco mode characteristic line 31 and a matching point B between the working device operating engine torque characteristic line 30 and the power mode characteristic line 32. The controller 18 includes a control portion which controls an HST pump 11 in accordance with the lifting operation characteristic line 34 when lifting operation of a lift arm 4 is detected in the condition that the eco mode has been selected by a work mode selecting portion 22. Body frame (1) and, wheel (9, 10) and, said body frame (1) is mounted, and a rotatable vertically lift arm (4) having a work device (3) on, said body frame (1) mounted engine (17) and, said engine (17) driven by the HST variable capacity type hydraulic pump (11) and said wheel (9, 10) driving HST motor (14) and a sixth a closed circuit, said HST pump (11) number of input torque plower HST pump number control unit (15) having on HST traveling device, said engine (17) and driven by, said work device (3) for discharging the hydraulic control device for operating the working machine pump (13) having a wheel loader in, workload is a light load under job mode when power mode, said workload is in work mode when selecting either echo under work mode selection device (22) on, said work device (3) of said lift arm (4) is lifted up detection device (23) on, said work mode selection device (22) when said by echo mode is selected, said HST pump number control unit (15) by, said HST pump (11) and the predetermined number of input torque echo mode properties, said work mode selection device (22) when said by power mode is selected, said HST pump number control unit (15) by, said HST pump (11) of the preset number properties wherein the power mode input torque, when said echo mode is selected, said detection device (23) by, said lift arm (4) if the operation of, said HST pump (11) input torque characteristics of said echo mode operation properties plower number number instead rise characteristics the device (18) with, said rise operation characteristic line (34) is, said echo mode characteristic line (31) is formed with a plurality of the middle of characterized wheel loader. According to Claim 1, said number the device (18) is, echo mode characteristic line (31), power mode characteristic line (32) and the rising operation characteristic line (34) storage unit (28) having, said echo mode characteristic line (31), said power mode characteristic line (32) and said raised operation characteristic line (34) is, engine rpm with a HST pump (11) of the relation between the indicated and is constituted by an input torque, said rise operation characteristic line (34) is, said engine (17) torque in said working machine pump (13) torque of the engine torque characteristic line obtained work device operation setting value (30) on, said echo mode characteristic line (31) and said engine torque characteristic line work device operation (30) it is an intersection with whip [ching with point, said power mode characteristic line (32) and said work engine torque characteristic line operation device (30) having as a characteristic the control it is an intersection between the whip [ching point intersection with whip [ching point characterized wheel loader. According to Claim 1, said HST motor (14) is connected to the, high speed stage, low speed stage including a plurality of speed stage with a multi-stage transmission and, said low speed stage detection speed stage detection device is converted power transmission (20) on, said wheel loader is moved forward state detects arefrigerant detection sensor (21) with, said HST motor (14) is, comprised of a variable capacity type hydraulic motor, traveling device includes said HST, said HST motor (14) pressure of a number a number plower HST motor control section (16) with, said number the device (18) is, said speed stage detection device (20) is converted in said low end power transmission is detected, in addition said forward detection sensor (21) in, said wheel loader is moved forward in a state is detected, said HST motor number control unit (16) by, said HST motor (14) to said echo mode greater than minimum swash plate which characterized the swash plate minimum swash plate minimum number or altered [...] wheel loader. According to Claim 2, said HST motor (14) is connected to the, high speed stage, low speed stage including a plurality of speed stage with a multi-stage transmission and, said low speed stage detection speed stage detection device is converted power transmission (20) on, said wheel loader is moved forward state detects arefrigerant detection sensor (21) with, said HST motor (14) is, comprised of a variable capacity type hydraulic motor, traveling device includes said HST, said HST motor (14) pressure of a number a number plower HST motor control section (16) with, said number the device (18) is, said speed stage detection device (20) is converted in said low end power transmission is detected, in addition said forward detection sensor (21) in, said wheel loader is moved forward in a state is detected, said HST motor number control unit (16) by, said HST motor (14) to said echo mode greater than minimum swash plate which characterized the swash plate minimum swash plate minimum number or altered [...] wheel loader. Back number Back number Back number Back number