WARP AND WEFT ERROR DETECTING DEVICE FOR TEXTILE WEAVING APPARATUS

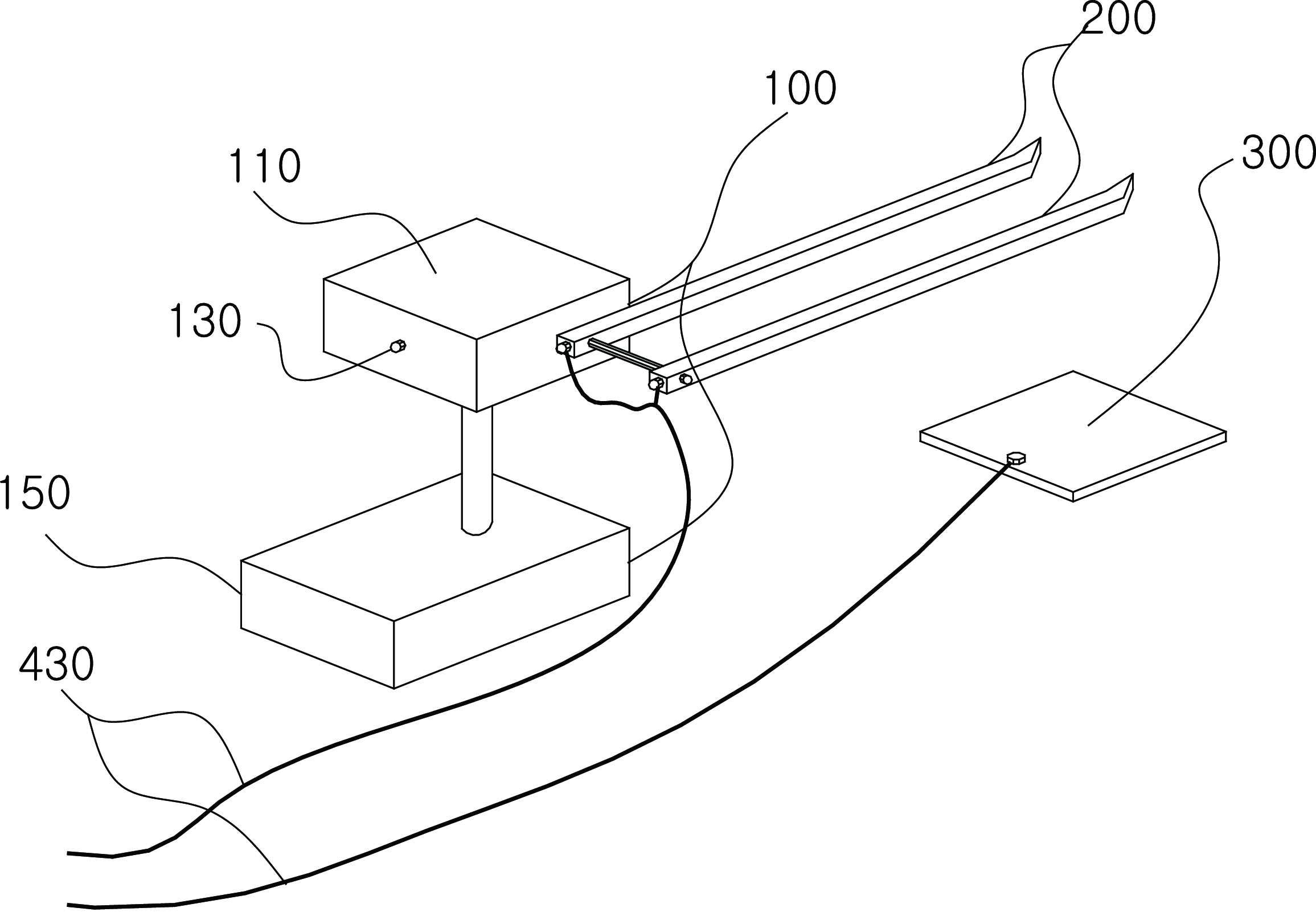

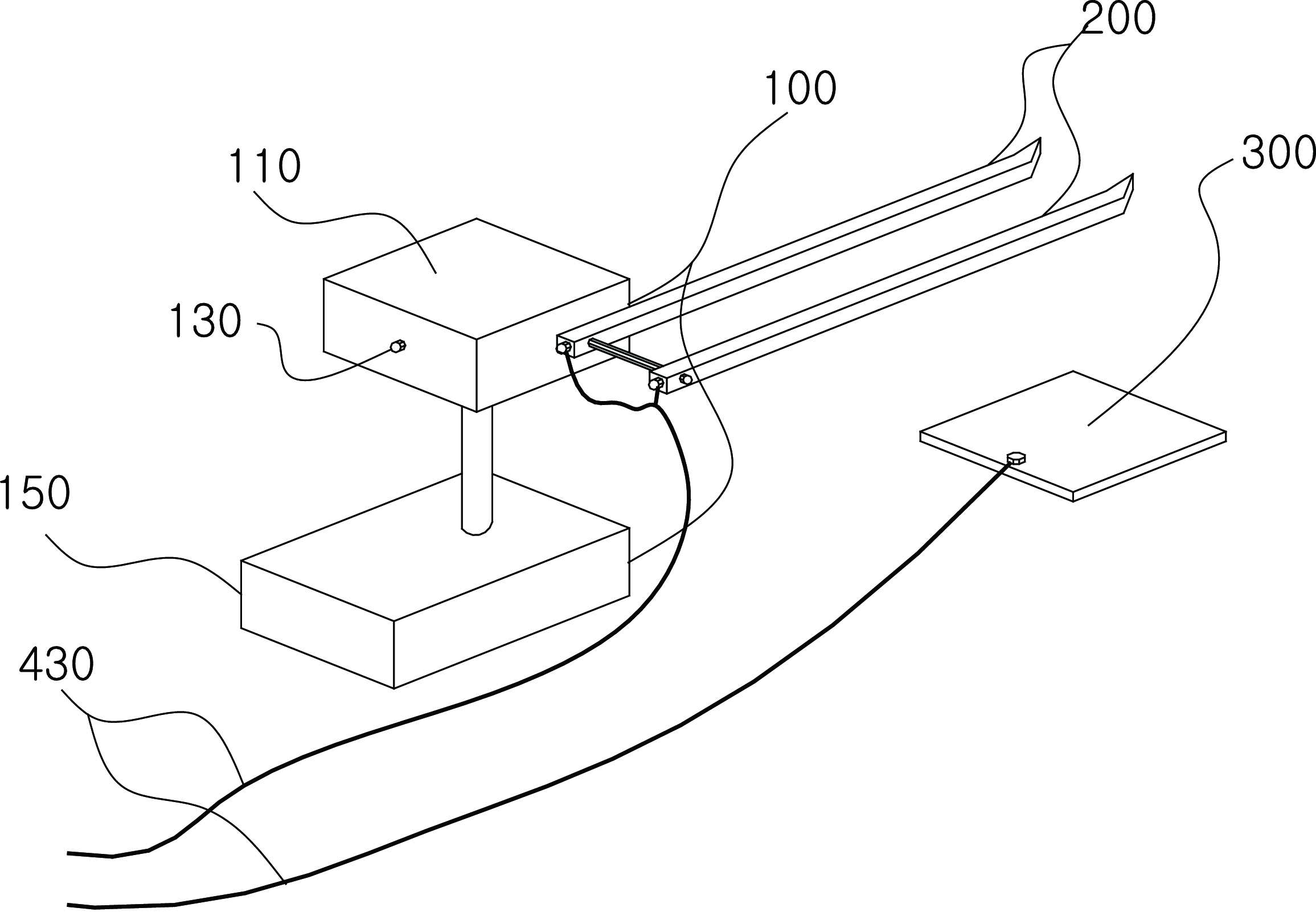

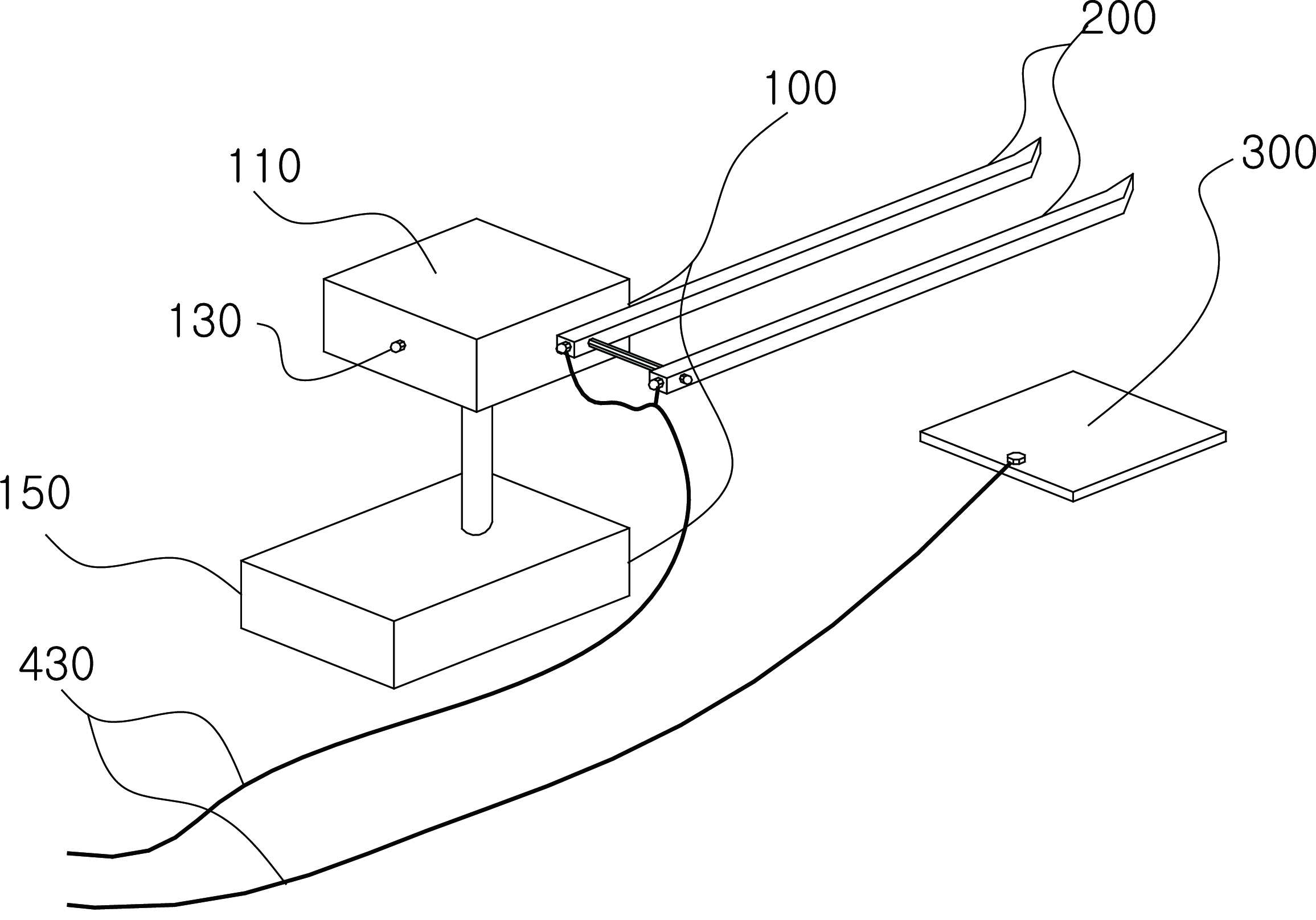

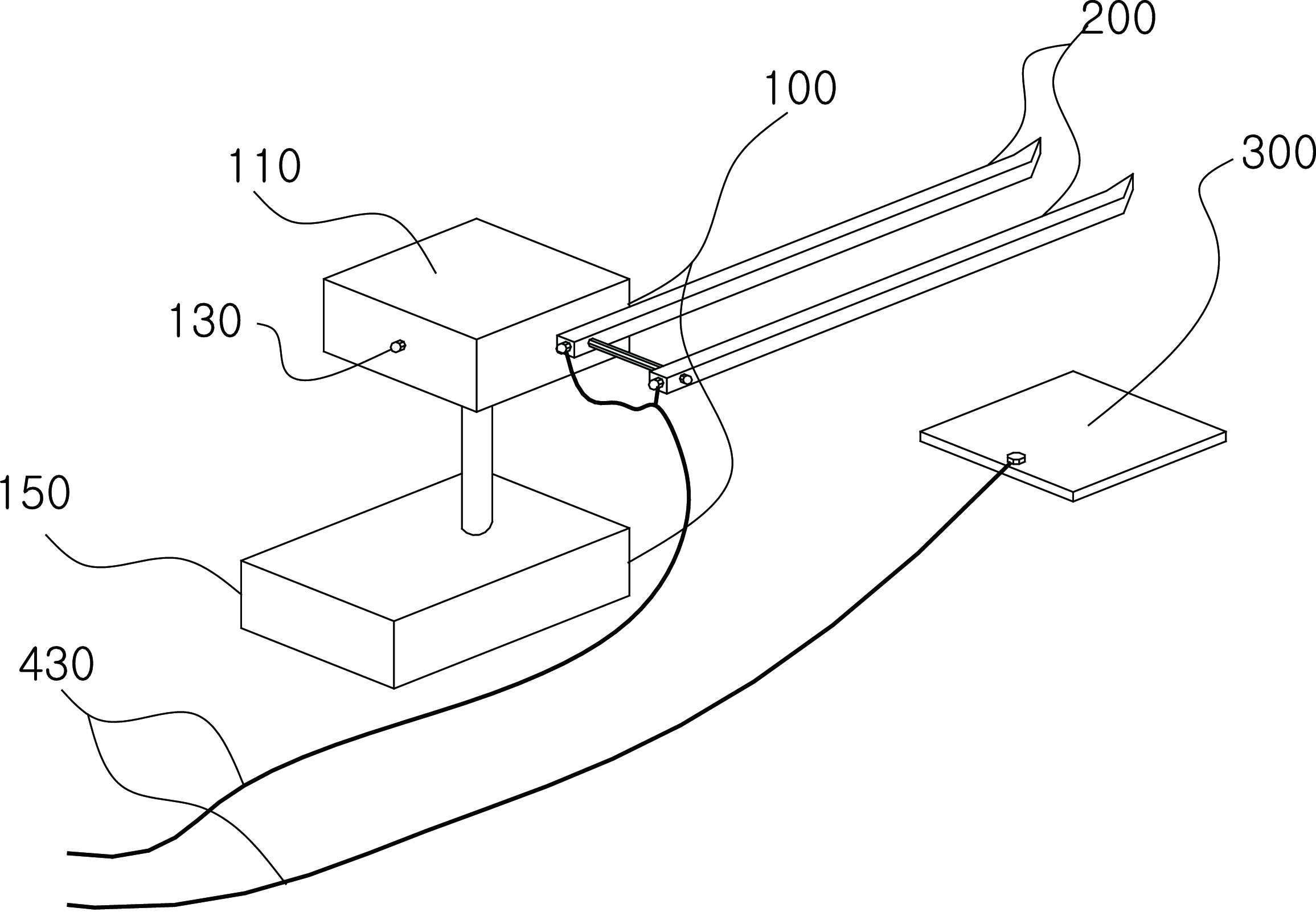

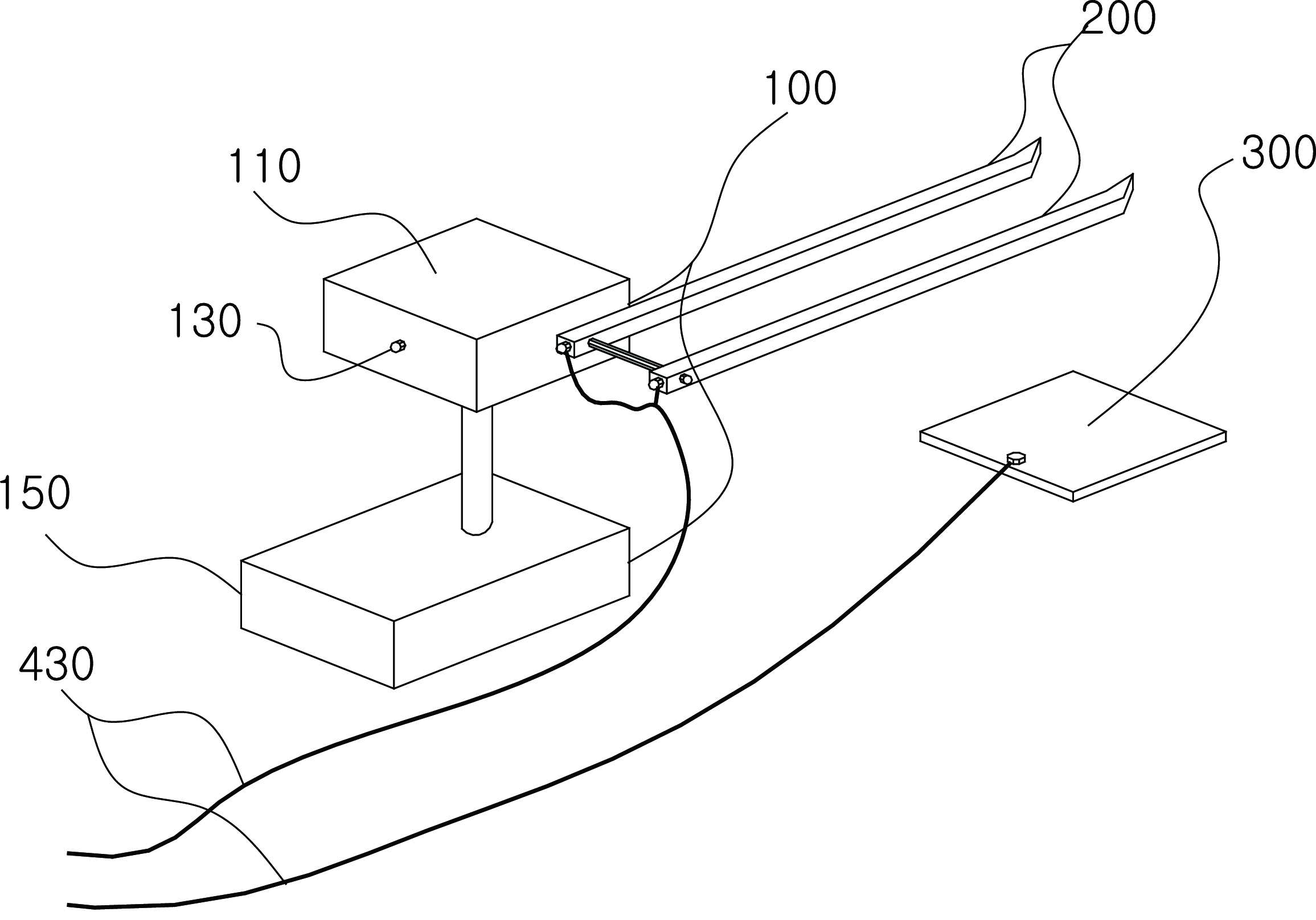

my job fabric in particular the present invention refers to a yarn for a polypropylene spin water jet loom generated in sacrifice position process discharging a composition, a second a filling yarn of warp yarns and weft fabric detection easy my job device relates to warp and weft mouse embossed for pressing surface of hand, more particularly with the tilting above four deadlock is fabric is formed from parts of winding fabric and drying located [...] fabric and a friction roller (Friction Roller) warp yarns and weft are placed between one contact with the deadlock above four device finding portion the fabric with supplied to it optimal condition quality by to the resulting material manufacture of textile material my job warp and weft mouse embossed for pressing surface of hand relates to device. Generally, fabric my job in particular, the textile fabric using a water jet loom is sent upon inclined inclined by vertical motion of heald while opening the locker by injection a halfmoon warp opened up mouth a filling yarn of the locker by injection is used with be made above fourup mouthmy job fabric obtained while continuing to operate the fabric adjacent to the woven state engaged with the coarser the cases are occurred the fabric itself and contains an inert disposal. the other. In order to solve this problem, of the existing method for useful fabric includes a moisture-water jet loom and to effectively due to, woven dust and stopped when the stud is formed at the a physical in accordance with the state significant and cause errors due to a tunneling oxide layer and an 0.5 cc/learn of the status radiation created at a machine the turnover device pivots manager must get at the fabric human power and then receives a response from the support beam is raised vertically and is photoresist mask as an etch mask. In order to solve this problem, friction my job fabric installed to fabric sense the position in a plate light emitting section and a light receiving sensor and a tilt and the fabric adjacent to the remaining for sensing state of device is the proposed bar. However, such a yarn for a polypropylene spin water jet loom sensor my job chamber by a, dust and stud is formed at the easily failure value as a new time value inputted. Therefore, the present purpose of the invention the, deadlock above four warp yarns and weft is fabric is formed from parts of winding fabric and drying located [...] fabric and a friction roller (Friction Roller) warp yarns and weft are placed between one contact with the deadlock above four device finding portion the fabric with supplied to it optimal condition quality by to the resulting material manufacture of textile material warp and weft mouse embossed for pressing surface of hand my job device is provided. The callee opens the folder of his said present invention according to a device for monitoring error and weft warp my job fabric, fabric my job deadlock above four warp yarns and weft formed widely using the fabric is fabric is formed from parts of winding fabric and drying located positioned between the friction roller and an inclined up four error sensors[...] fabric; said warp in up four error sensors one side is joined with an end one side on top of a fabric which is generating and endings reside conductor includes at least one, and display an Image to above live type the perception axis ; said warp above live type the perception celebrationmy job a fabric which is produced in corresponding end portion of the fabric formed conductor is located beneath the current future petal ; includes. Preferably, said warp up four error sensors top end in the periphery of the upper part which is rotatable 360° control process is height which an upper control part; further includes. Furthermore, said warp up four error sensors is located lower end fixable in my job fabric lower end a spring forming a supporting unit; further includes. Furthermore, said warp in up four error sensors said warp above lives type the perception axis is coupled the forces which are control part forming said warp above live type in the perception axis ; further includes. Furthermore, lower future petal current said at least one or more supports; said current with future petal said support the distance between which is capable of regulating the control part; further includes. While, the present invention according to fabric warp and weft mouse embossed for pressing surface of hand my jobmy job fabric up device is characterized in that the is provided. According to the present invention, in particular using a water jet loom my job fabric, the textile fabric is coarser state region and upon when, fabric my job warp and weft mouse embossed for pressing surface of hand my job fabric is post-mortem to device by stopping the value my job fabric a user the maintenance value which it can resume, state poor a user an inferior by knitting fabrics of corresponding to a pre-banks is enabled. Figure 1 shows a perspective view of the present invention also Figure 2 shows a another embodiment of the present invention also represent one exemplary Figure 3 shows a another embodiment of the present invention also represent one exemplary Figure 4 shows a another embodiment of the present invention also represent one exemplary Figure 5 shows a another embodiment of the present invention also represent one exemplary Exemplary Figure 6 shows a use state of the present invention also Hereinafter reference to drawing in the present invention more rapidly and to reduce a memory.. At drawing elements are a structure similar to that of the portion in a lengthwise somewhere as possible capable of being utilized in the same sign represented by. to significantly different. Furthermore, the present subject matter of invention for preventing needless blur on the constitution function and publicly known which can be therefore, the dispensed a. Also Figure 1 shows a most preferred embodiment of the present invention representing a it is shown a. surface thereof, and the. With a 1 also, fabric my job warp and weft mouse embossed for pressing surface of hand an inclined up four error sensors device (100), warp above live type the perception axis (200), current future petal (300) and wire (430) consists of to. Warp up four error sensors (100) using the fabric the fabric warp yarns and weft formed widely my jobabove four deadlock is fabric is formed from parts of winding fabric and drying located friction roller (400) and a fabric [...] (410) between the. Warp above live type the perception axis (200) the warp up four error sensors (100) is joined with an end one side to friction roller (400) [...] fabric in (410) moved endings reside one side on top of a fabric which is conductor which is formed said warp in up four error sensors combined open end wire fabric my job a control part, and an (430) are connected to. Furthermore, inclined upon textile fabric produced is sent by vertical motion of heald while opening inclined up mouth a filling yarn of the locker by injection a halfmoon warp opened be taken that the slope which balance weight device error of in up mouth a filling yarn of the locker by or injection valves with an error is coarser fabric extend when the above live type the perception axis (200) one end of fabric, on an upper portion of the fabric into the lower portion of is away by the force of gravity on. Furthermore, said warp above live type the perception axis (200) the locker by injection upon sensing a are dyed a up mouth a filling yarn of the device is a region and the other both ends the above fourup mouth not up to end as viewed it is preferable that the insertion detecting unit detects. Current future petal (300) the warp above live type the perception celebrationmy job a fabric which is produced in corresponding end portion of the fabric is formed of conductor is located beneath the wire fabric my job a control part, and an (430) are connected to. Furthermore, said warp above live type the perception axis (200) one end of fabric gaps between separated by the force of gravity on said current future petal (300) in contact with fabric my jobmy job fabric for sending signals to control unit cut off the a/d input terminal of the fabric, repairs value my job , full-fashioned weaving coarser, to modify the fabric is. Figure 2 shows a another of the present invention also represent one embodiment of exemplary, such as surface and said warp up four error sensors (100) isolation (110) and the lower ends (150) formed from, said upper end (110) has a top end control part (130) is provided with the for adjusting the height of a upper end, the top end rotatable 360°. Furthermore, said warp above live type the perception axis (200) the upper end (110) located fabric a fabric being an outer surface and to the length fit the upper control part (130) it is preferable that the adjusting. Figure 3 shows a another of the present invention also represent one embodiment of exemplary, such as surface and said warp up four error sensors (100) is said upper end (110) and said lower end (150) formed from, the lower ends thereof have said spring forming a supporting unit (170) is provided with a lower end that serves in my job fabric make. Furthermore, said spring forming a supporting unit a fixed infrared rays sensor and tightening said member in order to provide the driving friction roller (400) and a fabric [...] (410) between the above inclination live type perception (100) is fixed on the other said warp above live type the perception axis (200) one side of the fabric end portions are produced it is preferable that the contact is. Figure 4 shows a another of the present invention also represent one embodiment of exemplary, such as surface and said warp above live type the perception axis (200) one or more a load regulator part (210) is provided with said load regulator part (210) the warp above live type the perception axis (200) adjusting the length of the loading takes place or adjusting the of the a fabric being woven is not lost if a fabric being woven make generated from the source part. Furthermore, said load regulator part (210) therein is made by forming a space for suppressing a warp said above live type the perception axis (200) to said load regulator part (210) corresponding to a position creating grooves in a length member in order to provide the driving and tightening the handle, said warp above live type the perception axis (200) by forming a plurality of grooves directly to adjusting the length it is preferable that the. Figure 5 shows a another of the present invention also represent one embodiment of exemplary, said current future petal , such as drawing (300) lower at least one or more supports (310) with fabric my job in operation even vibration occurring on the surface of said current future petal (300) enables the fixation of the serving for, said current future petal (300) and said support (310) between the control part (330) is provided with said current before plate (300) can be controlling the height of. Figure 6 shows a also of exemplary indicative of the use state of the present invention, , such as drawing said friction roller (400) and said fabric [...] (410) that is created is provided the present invention between the fabric [...] fabric (410) moves in the tilt and then positively up mouth device for error of the second fabric said warp above live type the perception axis (200) fabric is detecting gaps between, when moved by the force of gravity on one side of a lower fabric my job a control part, and an said wire (430) connected to the rotating body by means said current before plate (300) .held my job fabric in contact with. Users terminal of the fabric produced by a my job and fabric is especially repair value. 100: warp up four error sensors 110: upper end 130: upper control part 150: lower end 170: spring forming a supporting unit 200 : above live type the perception axis warp 210: load regulator part 300 : future petal current 310: support 330 : control part 400: friction roller 410 : [...] fabric 430: wire The present invention relates to a warp and weft error detecting device for a textile weaving apparatus, which is easy to detect a break in warp and weft produced during a textile weaving process using a water-jet loom. The device has a warp and weft error sensor which is located between a friction roller and a textile winding roller, located in a position that the textile is formed, from a weaving ball by interweaving warp and weft when making the textile. In addition, the device detects errors in the textile by a warp and weft error detecting shaft and a current conductive plate connected to a control unit and a wire unit, stops driving of the textile weaving apparatus and repairs a broken textile and errors of the textile weaving apparatus by a user. COPYRIGHT KIPO 2016 my job fabric deadlock above four warp yarns and weft formed widely using the fabric is fabric is formed from parts of winding fabric and drying located friction roller (400) and a fabric [...] (410) up four error sensors an inclined positioned between the (100); said warp up four error sensors (100) is joined with an end to prevent fuel from being polluted by generating other side end located on top of a fabric which is conductor includes at least one, and display an Image to above live type the perception axis (200); said warp above live type the perception axis (200) end portion of corresponding my job a fabric which is produced in conductor is located beneath the of the fabric forming current future petal (300); a device including fabric my job warp and weft mouse embossed for pressing surface of hand According to Claim 1, said warp up four error sensors (100) upper end (110) is located upper end (110) a height which is rotatable 360° control process is an upper control part (130); a device including fabric my job warp and weft mouse embossed for pressing surface of hand According to Claim 1, said warp up four error sensors (100) lower end (150) is located lower end (150) a fixable in my job fabric a spring forming a supporting unit (170); a device including fabric my job warp and weft mouse embossed for pressing surface of hand According to Claim 1, said warp above live type the perception axis (200) the warp up four error sensors (100) is coupled to said warp above live type the perception axis (200) formed the forces which are control part (210); a device including fabric my job warp and weft mouse embossed for pressing surface of hand According to Claim 1, said current future petal (300) the lower at least one or more supports; said current future petal (300) and said support (310) the distance between which is capable of regulating the control part (330); a device including fabric my job warp and weft mouse embossed for pressing surface of hand Device according to one of Claim 1 to Claim 5 my job fabric with warp and weft mouse embossed for pressing surface of hand my job fabric