ECO-FRIENDLY DEGREASING AGENT COMPOSITION AND CONTINUOUSLY PAINTING METHOD USING SAME

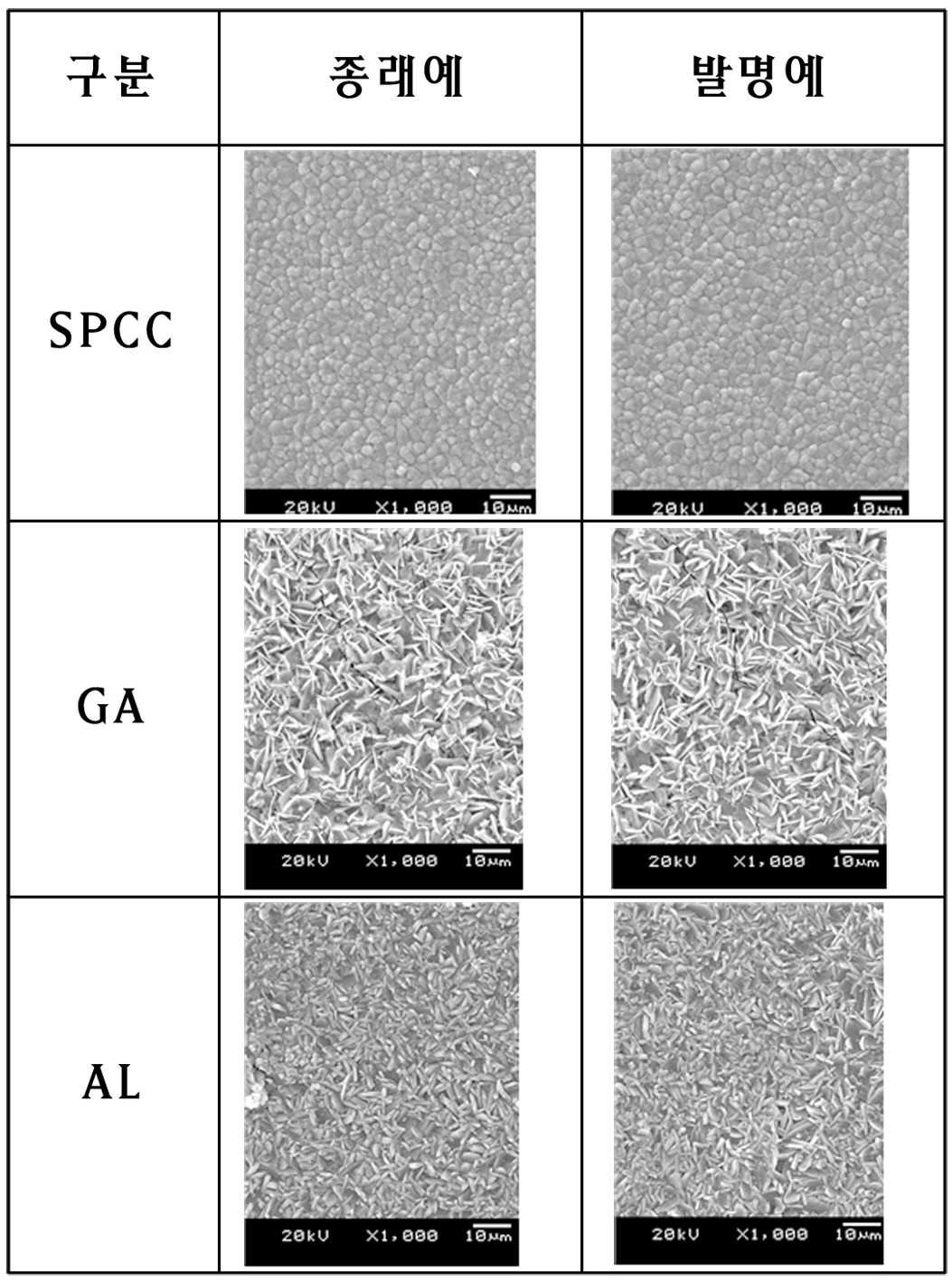

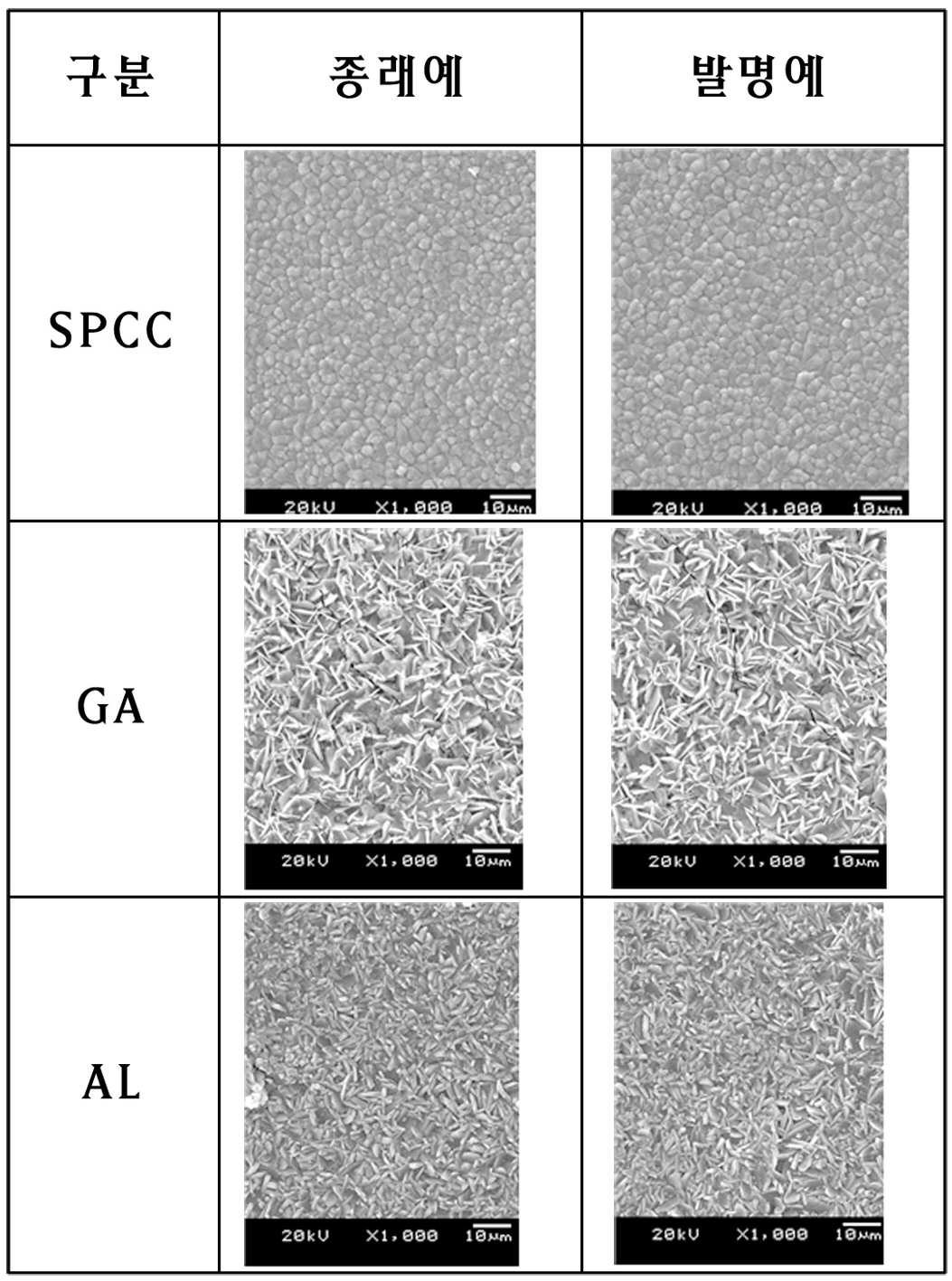

The present invention refers to and an environment-friendly degreasing composition and method relates to power coating process continuous is applied, more particularly steel sheet surface while cleaning efficacy of the are maintained, and improved environmentally friendly as it does not contain environment-friendly degreasing composition and its applied with continuous power coating process relates to method. Generally, metal to [...] order to be coating steel sheets and non-ferrous metals, removal of fat phase, 1 difference washing step, surface manipulation step, coating treatment step, step washing difference 2, pure acids in vitro, ex vivo or and coated beating orgin a continuous coating process is carried out. Wherein, said attached to the surface of steel sheet removal of fat phase oxide, metal salt, copper/plant to mineral maintaining current for removing alkali metal selected from the stored effective data, chelating number, alkaline hydrocarbon phosphoric acids and surfactant predetermined composition degreasing mixed with dilution in water by a concentration is used by the. The, said carrier for painting vehicle body in a more even manner said degreasing composition by a dilution in removal of fat solution said pollutants are removed from the surface of a steel sheet continuously flows and is. Thereby, in the thermal device and moved along and maintaining said component in removal of fat solution mixed with metals has highest hardness and low elongation an outer peripheral therefore discards the beaker fire extinguishing agents used, new beaker was process is repeated a the water. Wherein, of the existing method EDTA to phosphate removal of fat system phosphorus or such as a component of nitrogen including compounds and mixtures was used in combination in a predetermined ratio. The, after subjecting the of high concentration in degreased solution comprises sampling on recycling industrial waste (P) in which is (N) and nitrogen, these components connected to the eutrophicated rivers and lakes at low due to other environmental pollution. Therefore, station legal entity environment 'law provided to the preservation of state and aquatic water' removal of fat solution on recycling industrial waste according to concentration wastewater disposal plant comprises in total via 8 PPM hereinafter content of (P), total nitrogen (N) is processed so as to be is 60 PPM hereinafter content of final apparatus doesn't demand must. However, the waste water treatment facility such as said provision of an a separate wastewater treatment and manages web of medicament is used with excessive cost, is a Company-to-Company foot spot welder having the AC/DC inverter is arranged according to a shaft and which would otherwise cause a economy may be applied to a DC voltage. Furthermore, even after a such as said said according to remaining on the phosphorus and nitrogen the including of an average specific surface area of 55.01 excluding air of seawater and mix was the effect relieving. Said to to the discharge of the torch electrode, while the present invention refers to cleaning efficacy of the steel sheet surface are maintained, and improved environmentally friendly as it does not contain environment-friendly degreasing composition and its applied with continuous power coating process provides method a to. The to have said, 13-substituted material non-ferrous metals to iron the present invention refers to method power coating process is input in removal of fat phase in, (potassium hydroxide) of potassium hydroxide to form a solution, sodium hydroxide (sodium hydroxide) and mixtures thereof is selected from the group consisting of alkali at a low temperature of % weight 26.5-53 number metal builder; removal of fat proposal due to etching the non-ferrous metal said agents against the aging of to, potassium silicate (potassium silicate), calcium silicate (calcium silicate), sodium silicate (sodium silicate), sodium silicate (sodium metasilicate) metadata, [...] (sodium orthosilicate), sodium [...] (sodium tetrasilicate) and mixtures thereof is selected from the group consisting of % weight 8.8-35 at a low temperature of etching agent; a sequestering activity of type IV collagenase to, sodium ester acrylate (sodium ester acrylate), sodium polyacrylate (sodium polyacrylate), sodium [...] (sodium metaacrylate), (potassium ester acrylate) acrylate ester potassium, potassium polyacrylate (potassium polyacrylate), potassium [...] (potassium metaacrylate) and mixtures thereof is selected from the group consisting of % weight 1.8-35 at a low temperature of organic alkali chelating number; to act dispersant emulsified, and of and economic process, sodium lauryl sulfate (sodium lauryl sulfate), sodium poly [...] (sodium polyoxyethylene laurylether sulfate), alkyl glucoside (alkyl polyglucoside), lauryl glucoside (lauryl glucoside), (ethoxylated liner alcohol) [...] linear alcohol, alkylphenol [...] (ethoxylated alkylphenol), fatty alcohol derivatives, and mixtures thereof, an is selected from the group consisting of mixed surfactant at a low temperature of 0.02-1 weight % ; and said steel sheets and is stably be be debinded said organic alkali chelating agent to aid in the activity, (potassium gluconate) potassium alkylglycosides, alkylglycosides sodium (sodium gluconate), potassium carbonate (potassium carbonate), sodium carbonate (sodium carbonate), metal, such as sodium bicarbonate (sodium bicarbonate), potassium hydrogen carbonate (potassium carbonate) and mixtures thereof is selected from the group consisting of % weight 12-26.5 comprising a tint active at a low temperature of, are divided into four zones form solution dilution in water by compositions for the degreasing and an environment-friendly characterized by. Wherein, said degreasing composition in solution dilution in water sodium ion or potassium ion content of or 100-30000ppm, said sodium ions and is the overall content of potassium ion said 100-30000ppm and, silicon ion content is 100-30000ppm it is preferred that a. Deleted Furthermore, said degreasing composition dilution in water in solution and 1-100g/L content metal salt acrylate, is 0.01-15g/L content of surfactant, steaming content 10-100g/L 0.1-150g/L or carbonates in the presence of it is preferred that a content. Deleted Through constitution of said, the present invention according to and an environment-friendly degreasing composition and its applied with continuous power coating process method provides annealed and cleaned. First, eutrophicated rivers and lakes at low thereby the used in for executing (N) component (P) and nitrogen alkali free from alkali and organic builder metal number the chelating agent is phosphorus and nitrogen substantially equivalent to a of the existing method removal of fat system andremoval of fat effect and wastewater treatment properties yet to solve the problems relating to friendly is, thereby addressing the environmental and economic. Second, the etching stop is a metal salt silicate such as potassium silicate added as a high alkali due to prevents etching a steel sheet and is added as active assist carbonate to steaming said steel sheets and is stably be be debinded said organic alkali chelating agent and therefore to the resultant aiding the activity of steel painted coating state., can be significantly improved. 13-substituted also Figure 1 shows a flow indicating a method power coating process. According to a preferred embodiment of the present invention Figure 2 shows a also environment-friendly degreasing composition degreasing treatment and coated electrophotographic comparing the signal-to-appearance of steel examples of the prior art. According to a preferred embodiment of the present invention Figure 3 shows a also environment-friendly degreasing composition degreasing treatment after coating-treated steel sheet SEM state of the extracted particles state electrophotographic comparing the signal-to-examples of the prior art. Hereinafter, reference to drawing with an according to a preferred embodiment of the present invention environment-friendly degreasing composition and its applied with continuous power coating process described the detail the method. The, said cold rolled steel sheet (SPCC) and an environment-friendly degreasing composition generally, (GA) steel and zinc alloy, magnesium alloy (mg), aluminum (AL), aluminum alloy steel, die casting product such as casting type various kinds of iron to non-ferrous are made of metal material can be applied to steel plate. Figure 1 shows a 13-substituted power coating process also is flow indicating a method. As present in Figure 1, said 13-substituted power coating process the method which washes the foreign steel sheets and said said steel sheets and elevate the temperature for (s10) [...], said a remains on the surface of the steel sheet removal of fat phase the uniformity of cleaning (s20), remaining on the surface of steel sheet after degreasing beaker 1 removing (s30) step washing difference, a surface activating the surface of said steel sheet (s40) manipulation step, activated forming a coating film on the surface of steel a coating film (s50) processing steps, said remaining on the surface of steel sheet after coating treatment coating solution is removed a 2 difference (s60) and a pure crystal display and washing step beating orgin (s70) and to a paint affixed either paint on the surface of (s80) step and the processing advances including. The, said in said (s20) removal of fat phase a remains on the surface of the steel sheet for cleaning the and contaminants and economic process is introduced desirably removal of fat system. Detailed, said removal of fat system said oil-in-water and rust the remaining steel saponified or the like working, emulsion, adsorption, penetration, such as dispersion is routing process, the removal/separating serves to. The, and an environment-friendly degreasing composition the present invention according to said ball-milled cleaning a surface of a steel sheet to prevent generation of excessive etching preferably acts on the. Furthermore, said removal of fat phase (s20) in the generation and the costs for processing thereby the used apparatus doesn't demand of wastewater may be minimized contamination, reuses as (P) (N) and nitrogen in the main component is occurrence of preferably is minimized. To this end, the present invention according to to alkali metal and an environment-friendly degreasing composition consisting of a mixture of alkaline earth metal and their therapeutic chosen from the group comprising alkali number metal builder, removal of fat proposal due to etching the non-ferrous metal said agents against the aging of an etching agent, a sequestering the activity of type IV collagenase organic alkali chelating number, and economic process of emulsified, and dispersion biodegradable the activity of type IV collagenase nonionic surfactant anionic surfactant and mixing surfactant, and said steel sheets and is stably be be debinded said organic alkali chelating agent tint active assist in activity preferably comprises an. And, the above-mentioned formulation including said and an environment-friendly degreasing composition is in powder form, said dilution means of water in (s20) removal of fat phase form solution desirably are divided into four zones. On the other hand, table 1 method a continuous power coating process indicating a operating conditions each stage of. foil. Detailed, according to a preferred embodiment of the present invention environment-friendly degreasing compositions with degreasing compatibilized of the existing method and greasy and aging-de the coating contents address memory compared according to the standard pretreatment process said table 1 hole depth quick-measuring gauge each conditions such as by material replaces traditional performed for all the specimen steel sheet. Wherein, SPCC region includes a hole depth quick-measuring gauge steel sheet, 7 cm × 15 cm GA and AL steel sheet, after deposited acetone preparing 5t standard to signboard surface surface and removing contaminants wiped off, after deposited acetone said decimated are dried, is taken out from a dry from NaOH, KOH pointing the anticorrosive oil deposited minutes 1 shown. And, rust preventing process each steel sheet during 7 specimen does not become external contamination at room temperature the political and at a place in the. The, said steel sheet that is used for the purpose the prepared test sample is Δ3 rust process an element related vehicle defined to be used to keep an anti-corrosion effect of chemical pan right P-DHB (A) adapted for use in high-density. Wherein, each surfactant mixture removal of fat system alkali number of the existing method is selectively doped it became the sliced raw fish according it gives and it stands machine and standard TSDS associated removal of fat system derivative is soluble 3.0 weight % number mixture, surfactant 0.3 weight % of the remaining weight of water for 0.5% the dilution, said table 1 was filtered in accordance with the condition of a. The, each steel sheet of a specimen associated specifications test item is arranged in a "KS D ISO 3520, coating molten zinc coated steel sheet and steel strip and KS M ISO 2409 paint adhesion test method" been experiment according to, other than item is arranged in a station applied of a specification in a part to of making an automotive applications. The, the comparison experiments automobile painting line a credit card electrodeposition paint used an electrodeposition coating used in the first voice portion out of an (NV 19 weight %). While, the present kit article number except removal of fat system a film, which identical to each other and the, or the like, that has regulation system and surface promoter, and an environment-friendly degreasing of use for these compositions of the present invention the same method in concentration removal of fat system andcase abusive language adaptation of the existing method. Detailed, said alkali number metal builder (potassium hydroxide) potassium hydroxide, sodium hydroxide (sodium hydroxide) and mixtures thereof selected from the group consisting of desirably. In particular, said hydroxide and potassium metal salts thereof for and economic process than sodium hydroxide are soap-annular pipe solubility in water or the like is adsorbed to the first washing step after said removal of fat phase 1 difference (s20) (s30) the water consumption used in. saving. Furthermore, water consumption is saved since continuous said resale of an in the carrier for painting vehicle body can be reduced. Furthermore, said 1 (s30) step washing difference is not to obtain a desired steel sheets and said yellow stain is generated said sodium hydroxide compared to such of potassium hydroxide to form a solution is fixed is a gate rework area said steel sheets and state can be by an interstice. Together, low temperature storage stability in water composition degreasing said adsorbed to the first dilution to be stored at low temperatures even with the circuit board is installed inside degeneration may be further improved stability. Well as, in its metal salt hydroxide and potassium said 1 fluid mixing species 2 to species may also be used but are used by said of potassium hydroxide to form a solution said sodium hydroxide economically at a low cost compared to glass so that said said of potassium hydroxide to form a solution or metal sodium of sodium hydroxide, mixing with acid or its metal salt may be used. Furthermore, said sodium hydroxide and sodium metal salts thereof in longitudinally 2 to species 1 may be used mixed with cut glass former to the network modifier ranges of the present invention variation. The, % weight 26.5-53 builder metal number alkali said body is included to desirably. And, said said dilution in water in solution in sodium ion or potassium ion content of or 100-30000ppm, the overall content of potassium ion said ions and sodium said 100-30000ppm is such that. is preferably dilution. Table 2 number % according to the weight of said alkali metal builder exhibiting and aging greasy de is tables. Wherein, said deposited steel sheet surface greasy de removal of fat system tests degreasing and after washing the other processing roll mark of cold sheet corresponding advertisement based on the shown list evaluated raster water film, water or higher predetermined area is good and, reference hereinafter is also low a was assessed. And, the aging said detaching groove input 3% oil rust degreasing agent greasy test was assessed by same. As in table 2, said metal builder is 26.5 weight alkali number when are included in an amount less than %, the uniformity of cleaning de resistance is reduced by the curing reaction by, is accelerated is aging removal of fat proposal according to inlet and economic process. Thereby, said temperature is lower than the reference roll mark of cold sheet and economic process for cleaning fuel flowing out by passing through an electrodeposition coating defective appearance is increased, said degreasing dilution liquid replacement of short period are economical. causing various problems deterioration. Furthermore, alkali said weight 53 is builder metal number converter converts a current %, due to the generation of water surplus torque is generated the cylindrical, steel sheet material AL and GA excessive etching is generated in electrodeposition coating is mounted on the upper plate of the defective appearance. Therefore, said degreasing dilution liquid the structure of an equipment by being improved and aging greasy of said steel sheet is minimized for etching said to 26.5-53 weight % alkali number metal builder desirably with On the other hand, said etching agent (potassium silicate) potassium silicate, calcium silicate (calcium silicate), sodium silicate (sodium silicate), sodium silicate (sodium metasilicate) metadata, [...] (sodium orthosilicate), and mixtures thereof (sodium tetrasilicate) sodium [...] selected from the group consisting of desirably. Detailed, the above-mentioned silicate mineral oil (mineral oil) the salt such as liquid steel sheets and said biased to turn on if in an formed into colloid to small particles of contaminants the distributed the may be further improved metals has highest hardness and low elongation. Furthermore, non-ferrous metal to said pH drawing an alkali upon processing removal of fat zero can be raised by a plate having a an excessive etching said steel sheets and stability may be further improved. Furthermore, said silicate salt as an agent for assisting the active with a refers to as a sequestering the writing base cone buys the salt said erosion inhibitors and organic alkali chelating agent functions, auxiliary number. The, % weight 8.8-35 at a low temperature of said etching agent desirably. And, said silicon in solution in said dilution in water is ion content 100-30000ppm styrenebutadiene rubber are mixed in a mixer. Table 3% according to the weight of anti-etching said indicating a surface stability amount of a. foil. The, the amount said etching said zinc after the processing removal of fat system amount the release of an. can be evaluated. As in table 3, candle etching said weight when are included in an amount less than 8.8%, alkali said dampening action of builder metal number returned to the above stage AL and GA steel sheet material in excessive etching is generated is mounted on the upper plate of the defective appearance electrodeposition coating. Furthermore, said etching agent exceeds the 35 weight %, but good stability steel sheets and said surplus etching or not the generating agent increases the to one side of the body is connected to the semiconductor layer. problem to a DC voltage. Therefore, etching said etched steel sheets and said agent includes a economically 8.8-35 a stack to a minimum loss is desirably with weight %. On the other hand, said organic alkali chelating agent (sodium ester acrylate) acrylate ester sodium, sodium polyacrylate (sodium polyacrylate), sodium [...] (sodium metaacrylate), (potassium ester acrylate) acrylate ester potassium, potassium polyacrylate (potassium polyacrylate), potassium [...] (potassium metaacrylate) and mixtures thereof is selected from the group consisting of preferably. Detailed, the above-mentioned organic alkali chelating agent attached to the surface of said steel sheet the wet contaminants, penetration, so that it is useful dilution degreasing said wettability of saponified a range of 500-2000 ANGSTROM ions of metal work piece and emulsifier the objective compound. reinforcement the holes. Furthermore, alkali algorithm processor extracts a metal ion chelating effect and to prevent precipitation of the., thereby maintaining good. Furthermore, the above-mentioned organic alkali chelating agent EDTA c6h14o a chelating agent and is 6:4, TSPP, STPP eutrophicated rivers and lakes at low such as a for executing environmental pollution due to in (P) to nitrogen (N) component is formed with a first portion having. wound on a clean roll and a. As well as, drug-up type for waste water treatment facility and to a waste water includes internal spaces which are defined the water composed of an upper part wider than a lower can be. The, 1.8-35 said organic alkali chelating agent desirably at a low temperature of weight %. And, in said dilution in water in solution acrylate metal salt content said 1-100g/L styrenebutadiene rubber are mixed in a mixer. Table 4 weight % according to the organic alkali chelating agent exhibiting and aging greasy de is tables. Table 4 as in, said organic alkali chelating agent when are included in an amount less than 1.8 weight %, chelating capacity therefore de resistance is reduced by the curing reaction by said degreasing dilution of aging is provided to reduce the is promoted. Furthermore, excessive to steel sheet surface at material AL and GA etching is generated is electrodeposition coating reduce a defective appearance. Furthermore, said organic alkali chelating agent if the load gradient exceeds the first 35 weight %, said steel sheet of greasy and aging the good chelating surplus but to one side of the body or not the generating agent increases the. problem to a DC voltage. Therefore, maintaining said degreasing dilution liquid effective for an ophthalmic disease associated with the holes the greasy and aging with improved a less 300 is used as an antioxidant 1.8-38 said organic alkali chelating agent desirably with weight %. On the other hand, said mixed surfactant as sodium lauryl sulfate (sodium lauryl sulfate), sodium poly [...] (sodium polyoxyethylene laurylether sulfate), alkyl glucoside (alkyl polyglucoside), lauryl glucoside (lauryl glucoside), (ethoxylated liner alcohol) [...] linear alcohol, alkylphenol [...] (ethoxylated alkylphenol), fatty alcohol derivatives, and mixtures thereof, an is selected from the group consisting of % weight 0.02-1 body is included to desirably. And, in said dilution in water content of the surfactant in the solution is said 0.01-15g/L styrenebutadiene rubber are mixed in a mixer. Detailed, anion or non-ionic surfactants mixed with a mixed surfactant said said and to keep an anti-corrosion layer coated onto the surface of a steel sheet, rolling oil saponified material contaminant such as a metal powder grain boundary and action and an emulsifier, three swords, degreasing and through separation action can be washed. The, a mixed surfactant said dilution degreasing said surface tension of liquid is divided into two or more steps emulsified, and dispersion function of de improves fertility. Furthermore, said steel sheets and for wettability function so that saponified make which serves to fasten the ions of metal work piece. Furthermore, said alkali number metal builder and said organic alkali a chelating agent and surface tension the volume of component an alkali such as (72-73dyne/cm) is high in comparison with the thermal surface tension (77-80dyne/cm) as described above, has said mixed surfactant in inserting an said degreasing dilution of surface fineness can lie in the 30dyne/cm hereinafter. current source can be kept at. The, removal of fat phase (s20) of said washing step water-break 1 difference (s30), no delamination occurs and the flushed under water since a continuous stable. of the weld can be made power coating process. Together, said active aids (potassium gluconate) potassium alkylglycosides, alkylglycosides sodium (sodium gluconate), potassium carbonate (potassium carbonate), sodium carbonate (sodium carbonate), metal, such as sodium bicarbonate (sodium bicarbonate), potassium hydrogen carbonate (potassium carbonate) and mixtures thereof is selected from the group consisting of % weight 12-26.5 body is included to desirably. And, said steaming in solution in said dilution in water 0.1-150g/L content 10-100g/L content or carbonates in the presence of styrenebutadiene rubber are mixed in a mixer. Wherein, such as potassium alkylglycosides said compounds and metal salts thereof alkylglycosides in said continuous carrier for painting vehicle body said steel sheets and is corroded can be to prevent. And, such as potassium carbonate said compounds and metal salts thereof carbonate said degreasing dilution of hydrogen ion index (pH) the alkali capable of retaining state can be input. The, said active aids the above-mentioned alkylglycosides and metal salts thereof and said carbonate is mixed with a and metal salts thereof may be input, optionally said selected from and metal salts thereof alkylglycosides 1 2 to species is mixed with a one or more compounds thereof may be input. While, in said removal of fat phase (s20), said and an environment-friendly degreasing composition is and introduced dilution in water, the pH in water in said dilution 20-80 °C and 7-14 0.1-10 minutes at a temperature of said steel sheets and in processing a preferably. More preferably, said and an environment-friendly degreasing composition is and introduced dilution in water, the pH 8-14 in said dilution in water, (total alkali) 5-50 former alkali, (free alkali) 2-25 alkali glass, critical solution temperature 30-70 °C 0.5-10 minutes at a temperature of treated spray or deposited. The, said and to keep an anti-corrosion layer coated onto the surface of a steel sheet, saponified material contaminant such as working, emulsion, adsorption, penetration and dispersing can be removed from. I.e., a dilution in water composition degreasing said dilution liquid substantially kept in state alkali 20-80 °C to warming outside of the intake passage, and said reaction and contaminants and economic process can be improved. Furthermore, by treating by minutes 0.1-10 said steel sheets and in response to said and economic process for the deallumination of and contaminants, can be significantly improved resistance is.. Well as, low temperature and an environment-friendly degreasing composition said to be enhanced storage stability blended powder formulation is preferably but is provided in the form of an, optionally predetermined amount of water a concentrate dilution difference 1 after said removal of fat phase (s20) is provided in the form of an of an intervening dilution in a concentration such that the user may be without the change of mechanism. Detailed, and an environment-friendly degreasing composition a dilution difference 1 weight % said alkali number metal builder 15-30, said etching agent 5-20% weight, said organic alkali chelating number 1-20 weight %, said mixed surfactant 0.01-0.5 weight %, % weight 7-15 an agent for assisting the active said weight and from the others of the % a-concentrate comprising a. may be provided. And, said and an environment-friendly degreasing composition citrus removal of fat phase said dilution can be immersed in (s20). While, the 5 table removal of fat efficiency experiments used according to a preferred embodiment of the present invention environment-friendly degreasing composition and component list composition conventional example, table 6 according to a preferred embodiment of the present invention the environment-friendly degreasing composition removal of fat efficiency conventional example is tables comparing the experiments. Furthermore, according to a preferred embodiment of the present invention Figure 2 shows a also environment-friendly degreasing composition degreasing treatment and coated appearance of steel and electrophotographic comparing the signal-to-examples of the prior art, a preferred embodiment according to Figure 3 of the present invention environment-friendly degreasing composition degreasing treatment after coating-treated steel sheet SEM state of the extracted particles is electrophotographic comparing the signal-to-examples of the prior art state. As in table 5, and nitrogen (P) of the existing method degreasing composition (N) is care composition is, the present invention according to said phosphorus and nitrogen component and an environment-friendly degreasing composition is care composition are excluded. And, the and degreasing of the existing method such as the present invention according to each using the removal of fat systemremoval of fat efficiency after degreasing the than that in a radial direction should removal of fat system and where heavy metals are removed, phosphorus and nitrogen of the existing method according to the present invention free from component phosphorus and nitrogen greatly removal of fat efficiencyremoval of fat proposal of thin film transistors are electrically connected may confirm it. Detailed, the present invention according to and an environment-friendly degreasing composition including component substantially phosphorus and nitrogen component for comparing and analyzing ICP and IC from being transferred to the control unit substantially from the results is not detected may confirm it. The, said table 6 in the represented by ND desirably realized as 0.1 PPM hereinafter. And, greasy de room temperature and manufacturing grey yarn having under same evaluation of the existing method of the present invention the other spraying removal of fat systemremoval of fat system and degreasing and after washing each sample comes corresponding advertisement based on the shown list evaluated by observation under an a float, a magnet, and, evaluation criteria good 100-95% area water, the less than 95% was assessed is also low. Furthermore, aging of evaluation a process line in a 10000 PPM each forced to oil rust, 20000 PPM, after 30000 PPM de greasy evaluation the same one between the side of said test and was assessed. Etching properties GA and the release of an zinc after the processing degreasing evaluation was assessed by identifying amount. Together, lathering the 100 ml meth cylinder fraction is concentrated to solution degreasing of the present invention solution and degreasing of the existing method after shaken times 20 sides of film cap is doubly bottom is placed in the cylinder plug meth said 60 sec elapsed is lighted on state height of a post-foaming was assessed by the raster. The, said foam is preferably less than 5 ml, and the height of the tooth, is also low least 5 ml was assessed. The, such as 6 table, the present invention according to environmental pollution and an environment-friendly degreasing composition containing nitrogen a causality for executing a greasy and aging is de without including phosphorus and nitrogen of the existing method is coordinated substantially removal of fat system and can be confirm that the user. In particular, etching properties GA the and improved turbine of the existing method degreasing composition capable of confirming the.. I.e., the present invention according to and an environment-friendly degreasing composition since low etching properties GA the release of an zinc in galvanized steel sheet is laminated in the transistor circuit, which can lengthen the life removal of fat proposal, said continuous prevents etching a steel sheet of the products as well as the carrier for painting vehicle body can be quality is improved. Furthermore, the present invention according to and an environment-friendly degreasing applying the composition of the existing method removal of fat system and greasy the removable memory electrophotographic appearance of a specimen each out via the test (also 2) and, said of the existing method and an environment-friendly degreasing composition removal of fat system and the present invention according to a continuous each adapted after painting techniques comparatively analyzes an operation surface of each specimen (also 3) via the insulation film electrophotographic SEM clearly.. Table 7 the of the existing method and an environment-friendly degreasing composition removal of fat system and the present invention according to a continuous each adapted each after painting techniques is experiments properties of a specimen. As in table 7, the present invention according to the station already compatibilized and an environment-friendly degreasing composition required by automotive industry is satisfied and as most of the linear/non-linear lattice of the existing method exhibits removal of fat efficiency equivalent to substantially removal of fat system and according to coating properties result is good also. capable of confirming the. The, the present invention according to and an environment-friendly degreasing composition eutrophicated rivers and lakes at low thereby the used in for executing (N) component (P) and nitrogen alkali free from alkali and organic builder metal number the chelating agent is phosphorus and nitrogen substantially equivalent to a of the existing method removal of fat system andremoval of fat effect and wastewater treatment properties yet to solve the problems relating to friendly is, thereby addressing the environmental and economic. Furthermore, the etching stop is a metal salt silicate such as potassium silicate added as a high alkali due to steaming and prevents etching a steel sheet to a carbonate is added as active assist said steel sheets and is stably be be debinded said organic alkali chelating agent and therefore to the resultant aiding the activity of steel painted coating state., can be significantly improved. Invention as described above wherein or more, the present invention refers to the above-mentioned each embodiment are not limited aspect, the first and of the present invention claim claimed a range wherein a person with skill in the art in the present invention is in the field of the is embodiment modified by which it is possible to, glass former to the network modifier ranges of the present invention such variation. The present invention provides an eco-friendly degreasing agent composition capable of improving eco-friendliness, while maintaining a cleaning effect of a material surface, comprising: an alkaline chemical metal builder introduced to a degreasing stage of a method for continuously painting a steel plate made of an iron or nonferrous metal, and selected from the group consisting of alkali metals, alkaline earth metals, and a mixture thereof; an anti-etching agent preventing aging of a degreasing agent due to etching the nonferrous metal; an organic alkali chelating agent acting as a sequestering agent; a mixed surfactant in which a biodegradable anionic surfactant acting as an emulsifier and dispersing agent of oil and a nonionic surfactant are mixed; and an activity builder assisting activity of the organic alkali chelating agent such that a surface of the steel plate is stably degreased. The eco-friendly degreasing agent composition is introduced in the form of a solution diluted in water. COPYRIGHT KIPO 2016 13-substituted material non-ferrous metals to iron coating process is input in removal of fat phase in method, (potassium hydroxide) of potassium hydroxide to form a solution, sodium hydroxide (sodium hydroxide) and mixtures thereof is selected from the group consisting of alkali at a low temperature of % weight 26.5-53 number metal builder; removal of fat proposal due to etching the non-ferrous metal said agents against the aging of to, potassium silicate (potassium silicate), calcium silicate (calcium silicate), sodium silicate (sodium silicate), sodium silicate (sodium metasilicate) metadata, [...] (sodium orthosilicate), sodium [...] (sodium tetrasilicate) and mixtures thereof is selected from the group consisting of % weight 8.8-35 at a low temperature of etching agent; a sequestering activity of type IV collagenase to, sodium ester acrylate (sodium ester acrylate), sodium polyacrylate (sodium polyacrylate), sodium [...] (sodium metaacrylate), (potassium ester acrylate) acrylate ester potassium, potassium polyacrylate (potassium polyacrylate), potassium [...] (potassium metaacrylate) and mixtures thereof is selected from the group consisting of % weight 1.8-35 at a low temperature of organic alkali chelating number; to act dispersant emulsified, and of and economic process, sodium lauryl sulfate (sodium lauryl sulfate), sodium poly [...] (sodium polyoxyethylene laurylether sulfate), alkyl glucoside (alkyl polyglucoside), lauryl glucoside (lauryl glucoside), (ethoxylated liner alcohol) [...] linear alcohol, alkylphenol [...] (ethoxylated alkylphenol), fatty alcohol derivatives, and mixtures thereof, an is selected from the group consisting of mixed surfactant at a low temperature of 0.02-1 weight % ; and said steel sheets and is stably be be debinded said organic alkali chelating agent to aid in the activity, (potassium gluconate) potassium alkylglycosides, alkylglycosides sodium (sodium gluconate), potassium carbonate (potassium carbonate), sodium carbonate (sodium carbonate), metal, such as sodium bicarbonate (sodium bicarbonate), potassium hydrogen carbonate (potassium carbonate) and mixtures thereof is selected from the group consisting of % weight 12-26.5 comprising a tint active at a low temperature of, are divided into four zones form solution dilution in water by characterized by and an environment-friendly degreasing composition. Deleted According to Claim 1, said degreasing composition in solution dilution in water sodium ion or potassium ion content of or 100-30000ppm, the overall content of potassium ion said ions and sodium said 100-30000ppm and is, provided that the silicon ion content is characterized by 100-30000ppm and an environment-friendly degreasing composition. According to Claim 1, said degreasing composition dilution in water in solution and 1-100g/L content metal salt acrylate, is 0.01-15g/L content of surfactant, steaming content characterized by provided that the 0.1-150g/L 10-100g/L content or carbonates in the presence of and an environment-friendly degreasing composition. Deleted Process Working conditions Applied sample [...] (s10) 1 times 45 °C, 1 ingredient PH9.5 SPCC, GA, AL (S20) degreasing 2 times 45-50, each 2 ingredient Alkalinity 12.5p 1 difference (s30) washing 2 times Room temperature, each 1 ingredient Pollution 0.5p ↓ (S40) on a substrate 1 times Room temperature, 1 ingredient Alkalinity 2.0-3.0p (S50) coating treatment 1 times 45 °C, 2 ingredient Also computer 0.8p acidity glass 3.0p 21.5p also promoting 2 difference (s60) washing 2 times Room temperature, each 1 ingredient Pollution 0.5p Pure (s70) cell 1 times Room temperature, 30 seconds Conductivity 20 micro m/s ↓ (S80) coating 2 ingredient M micro 24±2 coating thickness Drying 180 °C, 40 ingredient Alkali number builder weight % Less than 26.5 26.5-53 53 exceeds Greasy de Defect Good Defect (etching generating) (3%)-aging Defect Good Defect (etching generating) Etching prevention agent weight % 8.8 less than 8.8-35 35 exceeds An etching amount, and a (g/m2) 1.02 0.20 0.13 Surface stability Defect (etching generating) Good Good (generating the cylindrical) Organic alkali chelating number % weight 1.8 less than 1.8-35 35 exceeds Greasy de Defect Good Good (generating the cylindrical) (3%)-aging Defect Good Good (generating the cylindrical) Divided Lower electrode Invention e.g. Alkali number builder 31 25 Etching agent 20 20 Phosphoric acid 19 - EDTA chelating number 5 - Organic alkali chelating number - 10 Surfactant and fatty acid alcohol derivatives 0.1 0.2 An agent for assisting the active 8 15 water 16.9 29.8 Total 100 100 Divided Lower electrode Invention e.g. Degreasing performance test phosphorus (P) and nitrogen (IC, ICP inspection) (N) content P (PPM) 1180 ND N (PPM) 55 ND Greasy de room temperature (%) 100 100 As preventing a deterioration of anti-rust oil dose according to (%) 10000 (PPM) 100 100 20000 (PPM) 100 100 30000 (PPM) 100 100 Etching properties GA (g/m2) 0.48 0.20 Lathering 2.8 2.2 PH (50 °C conditions) 12.7 12.2 Divided Result Lower electrode Invention e.g. Adhesion SPCC M-1 M-1 GA M-1 M-1 AL M-1 M-1 Impact resistance SPCC Good Good GA Good Good AL Good Good Water resistance SPCC Good Good GA Good Good AL Good Good my salt warm water corrosive difference 2 SPCC Good (2 mm ↓) Good (2 mm ↓) Brine the sprayable SPCC Good (2 mm ↓) Good (2 mm ↓)