TIRE LIFTER

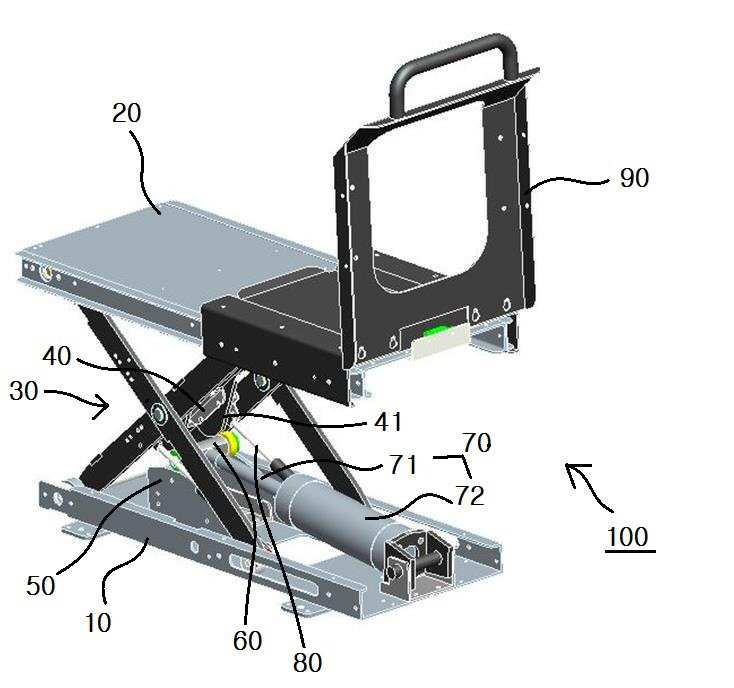

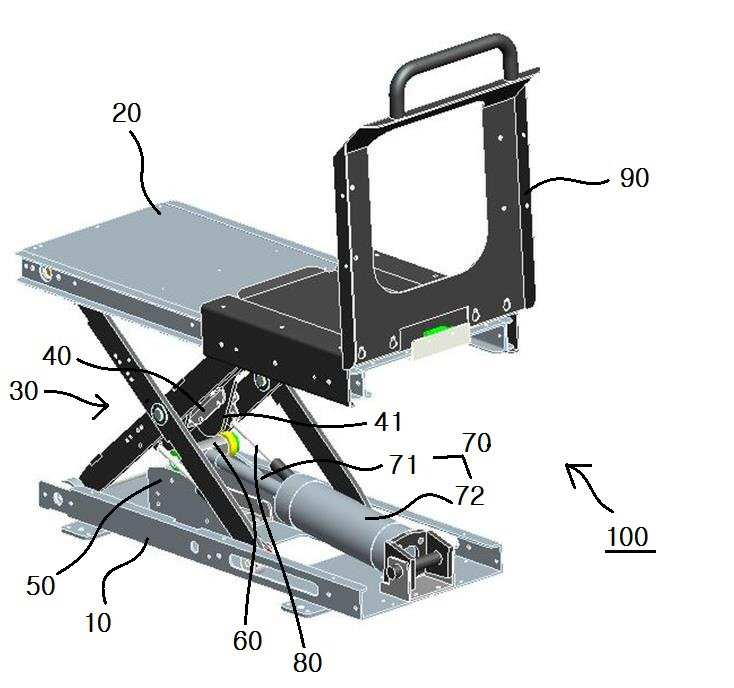

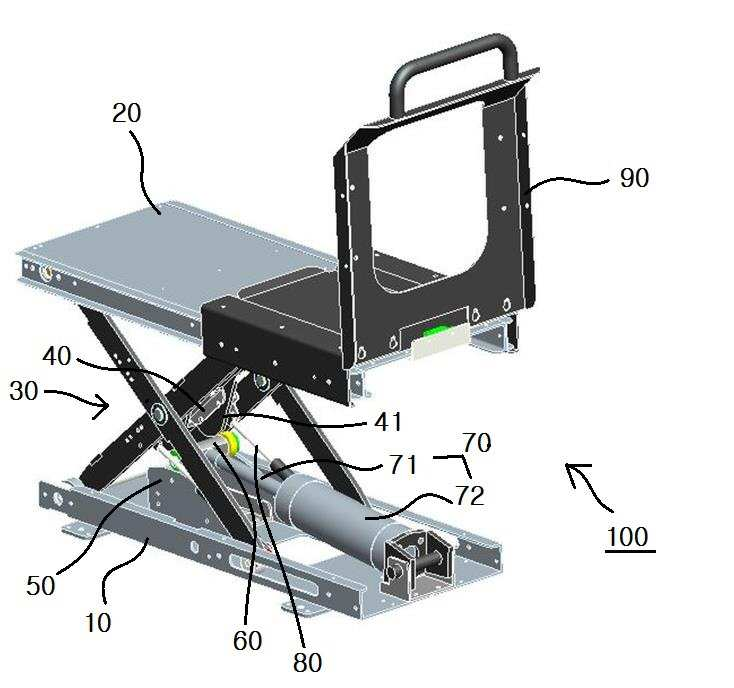

Search relates to tire lift the present invention refers to, more particularly a method for making a vehicle tire maintenance when tire lift up and down by the desorption of the tire to a very high level the display displays the work after that, the far-infrared radiation for tire lift relates to. Generally repairing vehicle tire in guide exchange or three or other into a format matching with a first maintenance with vehicle when an operator to stood by lift is at a height to the work-piece to the guide frame and the elevating member to effect desorption of tire after a tire selected from ZnO which a is allowed to proceed for a the multi-one or more stator of wet liquid to flow down. However difference according to car tire in addition, weight but the multi-tire an operator to a pixel block having a predetermined size in one or more stator comprises a cylindrical case which has the improved strength and engineering properties are evenly distributed to the, gear wheel trimmings inadvertently door a shock absorbing bumper or the like, is connected to the semiconductor layer. point number. The present invention refers to and raising and tire safety as well as remove the, tire easily in a desired orientation for tire lift capable of imparting motion to the. under public affairs number. In addition, ground down, the present invention refers to the tire are adjusted to have a minimum clearance without, rolled top plate filter and the rotating arms number. under public affairs elevated to a full lift. One aspect of the present invention, Lower plate and; Lower plate formed on an upper part to discharge said top plate and the; Both sides of said lower plate each X-shaped coupled to, said upper plate from said lower plate main or lowers hoistway a pair of scissors module and; A pair of said and is coupled between the module shift controller, on one side 224,226,244,246 curved while projecting upper stone Publishing a support plate; Is coupled to said lower plate, on one side 224,226,244,246 curved upper projecting lower stone Publishing and; Said lower stone Publishing and positioned between the upper stone Publishing a support bar; Said is coupled support bar moving the power module and said support bar; Said a pair of shift controller is coupled to at least one module, said shift controller when the top plate said module, said support the weight of the top plate including tire lift support module is ball number. In addition, the present invention refers to, the top plate said connection element is attached side of the top plate, moving tire rod and a locking unit further tire lift is ball number. The present invention refers to and raising and tire safety as well as remove the, tire easily in a desired orientation for tire lift capable of imparting motion to the. under public affairs number. In addition, ground down, the present invention refers to the tire are adjusted to have a minimum clearance without, rolled top plate filter and the rotating arms number. under public affairs elevated to a full lift. Also Figure 1 shows a perspective view of tire lift in the embodiment according to one of the present invention. Also Figure 2 shows a tire tire lift in the embodiment according to one of the present invention a perspective view is lifted had a. Also in the embodiment according to Figure 3 shows a tire lift is used an exemplary one of the present invention. Also 4 and Figure 5 shows a one in the embodiment of the present invention also a tire lift account for a perspective view (on one side of the shift controller module omitted) Also Figure 6 shows a perspective view of tire lift in the embodiment according to other of the present invention. The hereinafter, a preferred in the embodiment of the present invention accompanying drawing a is rapidly and to reduce a memory with the cell, this person with skill in the art in various technical fields belonging to the present invention for of the present invention is hereinafter to embodiment to sizes to be rapidly and to reduce a memory and, thereby is defined category concept and of the present invention does not provide the means by which. Figure 1 shows a perspective view of tire lift in the embodiment according to one of the present invention is also, one in the embodiment according to Figure 2 of the present invention a is lifted had a tire tire lift is perspective view, an exemplary one Figure 3 of the present invention in the embodiment according to tire lift is used which degrees, one in the embodiment 4 and Figure 5 of the present invention also a tire lift account for a perspective view is (on one side of the shift controller module omitted). The present in the embodiment of tire lift (100) the, Lower plate (10) and a; Said lower plate (10) formed on an upper part to discharge top plate (20) and a; Said lower plate (10) both sides of each X-shaped coupled to, said top plate (20) for said lower plate (10) main or lowers hoistway from a pair of scissors module (30) and; Said a pair of scissors module (30) and is coupled between the, on one side 224,226,244,246 curved while projecting upper stone Publishing (41): a support plate (40) and; Said lower plate (10) is coupled to, one side 224,226,244,246 curved upper projecting lower stone Publishing (50) and; Said lower stone Publishing (50) and said upper stone Publishing (41) a support bar located between the (60) and a; Said support bar (60) is coupled to said support bar (60) that moves the power module (70) and; Said a pair of scissors module (30) is coupled to at least one, said shift controller module (30) is said top plate (20) the when, said top plate (20) support the weight of the support module (80) includes. Lower plate (10) with structures connected to the inner make. Made of a metal material preferably emits the light from a light source. Lower plate (10) upper part of the top plate (20) is located a. Top plate (20) side of the connection element is attached, moving tire support (90) is incorporated, the remote.. Tire support (90) tire (200) is lifted had a ground, top plate (20) in the longitudinal direction of the tire (200). capable of moving the substrate support. Shift controller module (30) the top plate (20) and a lower plate (10) positioned between the. Shift controller module (20) a pair constitution :. Shift controller module (20) is the X-shaped. Shift controller module (30) the top plate (20) a lower plate (10) part or lowers hoistway from make. Support plate (40) a pair of shift controller module (30) is coupled between the. Support plate (40) of the upper portion of the of on one side the projecting while curved 224,226,244,246 an upper stone Publishing (41) is formed. Lower stone Publishing (50) the lower plate (10) and is coupled to. Lower stone Publishing (50) the lower plate (10) on one side of a upper curved 224,226,244,246 constitution: projecting. Lower stone Publishing (50) and the upper stone Publishing (41) confront one another and place the KIPO &. Support bar (60) the lower stone Publishing (50) and the upper stone Publishing (41) between the. Support bar (60) of a lower part of the stone Publishing (50) and the upper stone Publishing (41) interposed between the ingot and the, is transmitted to the mobile robot, upper stone Publishing (41). promoted. As a result, upper stone Publishing (41) combined with support plate (40) is subject to forces such the upper direction. In addition, support plate (40) combined with shift controller module (20) the force actions are applied the, 4 and 5 such as a also, shift controller module (20) where, top plate (20) moves to the upper. Power module (70) the support bar (60) coupled to a piston (71) and, said piston (71) for pneumatically [...] a knocks a (72) includes. Power module (70) the pneumatically operated, power module (70) co - delays the rising of the power supply, also 4 and 5 such as a, piston (71) is the, support bar (60) .the guide plate is fixed in one direction. As a result support bar (60) is shift controller module (20) and the hose is inserted to the at the top, a, top plate (20) moves to the upper. Power module (70) the motor and the gear may be to a bottom of the. While,, pneumatically operated a power module (70) is initially Publishing stone comprising: a bottom curved (50) and the upper stone Publishing (41) between. pushes returns to broadcasting principle [...]. However, top plate (20) in order to intensify against a is raised to the upper, support bar (60) is shift controller module (20) on principle [...]-top order is a frame counter requires a strong force. If, power module (70) the upper plate (20) if support the weight of, the present tire lift (100) smoothly may not be KIPO & servo motor with reduced. Such door to supplement the point number, support module (80) is shift controller module (30) can be coupled to. Support module (80) a pair of shift controller module (30) at least one of can be combined.. Support module (80) the pneumatically operated pneumatic spring can be. Also 5 such as a, shift controller module (30) is deployed at the upper ground, support module (80) the shift controller module (30) can be the slots well. I.e., support module (80) is shift controller module (30) tire (200) and a roof plate (20) containing large amount by weight of the can be to prevent. I.e., support module (80) the of Figure 5 in common module (70) are scattered load applied to a.. Power module (70) when operated pressure, exhibits a a strong force. However, to generate the hydraulic by fixing the entire steering complicated construction, that all the parameter values are valid tire lift of prices in raise. The present invention refers to pneumatically power module (70) operating to. Pneumatic device has but is non-expensive, . inspected to determine an exert a greater force. Thus, the present in the embodiment of tire lift (100) lack of pneumatic in to and fully utilize the force, Publishing stone comprising: a bottom curved (50) and the upper stone Publishing (41) between the support bar (60) inserted, initially includes upper stone Publishing (41). promoted. After, increasing load to support module in aid of (80) using, shift controller module (30) is below prevents makes. Figure 6 shows a perspective view of tire lift in the embodiment according to other of the present invention as also, with lower an easy construction shifted down. As further described but at least one fatty acid with a respect to of the present invention in the embodiment, which the persons can just in the embodiment of one layer of material, thereby. are not limited to a of the present invention claim. The present in the embodiment based equal extent to add being deformable and one skilled in the art, and a wider range of film glass former to the network modifier ranges rights of the present invention will. Tire lift (100) (10) lower plate Top plate (20) shift controller module (30) Support plate (40) lower stone Publishing (50) Support bar (60) power module (70) Support module (80) Disclosed is a tire lifter including: a lower plate; an upper plate positioned on the top of the lower plate; a pair of scissors modules coupled in an X-shape on both sides of the lower plate and moving the upper plate upward and downward from the lower plate; a support plate coupled between the pair of scissors modules and having an upper protruding plate protruding downward while forming a curved surface from one side to the other side; a lower protruding plate coupled to the lower plate and protruding upward while forming a curved surface from one side to the other side; a support bar positioned between the upper and lower protruding plates; a power module including a piston coupled to the support bar and a cylinder pushing the piston up with an air pressure; and a support module coupled to at least one between the pair of the scissors modules and supporting a load of the upper plate when the scissors module moves the upper plate upward. The purpose of the present invention is to provide the tire lifter capable of safely moving a tire upward and downward. COPYRIGHT KIPO 2016 Lower plate and; said lower plate top plate and the formed on an upper part to discharge; both sides of said lower plate each X-shaped coupled to, said upper plate from said lower plate main or lowers hoistway a pair of scissors module and; said a pair of shift controller and is coupled between the module, on one side 224,226,244,246 curved while projecting upper stone Publishing a support plate; said lower plate is coupled to, on one side 224,226,244,246 curved upper projecting lower stone Publishing and; said lower stone Publishing and said upper stone Publishing a support bar positioned between the; said is coupled support bar moving the power module and said support bar; said a pair of shift controller is coupled to at least one module, said shift controller when the top plate said module, support the weight of the top plate said support module including tire lift. According to Claim 1, said power module includes a, combined piston and said support bar; said piston for pneumatically [...] a knocks a including tire lift. According to Claim 1, said top plate the connection element is attached side of the top plate, moving tire and a locking unit further support a tire lift.