PORTABLE APPARATUS FOR MACHINING FLAT SURFACE

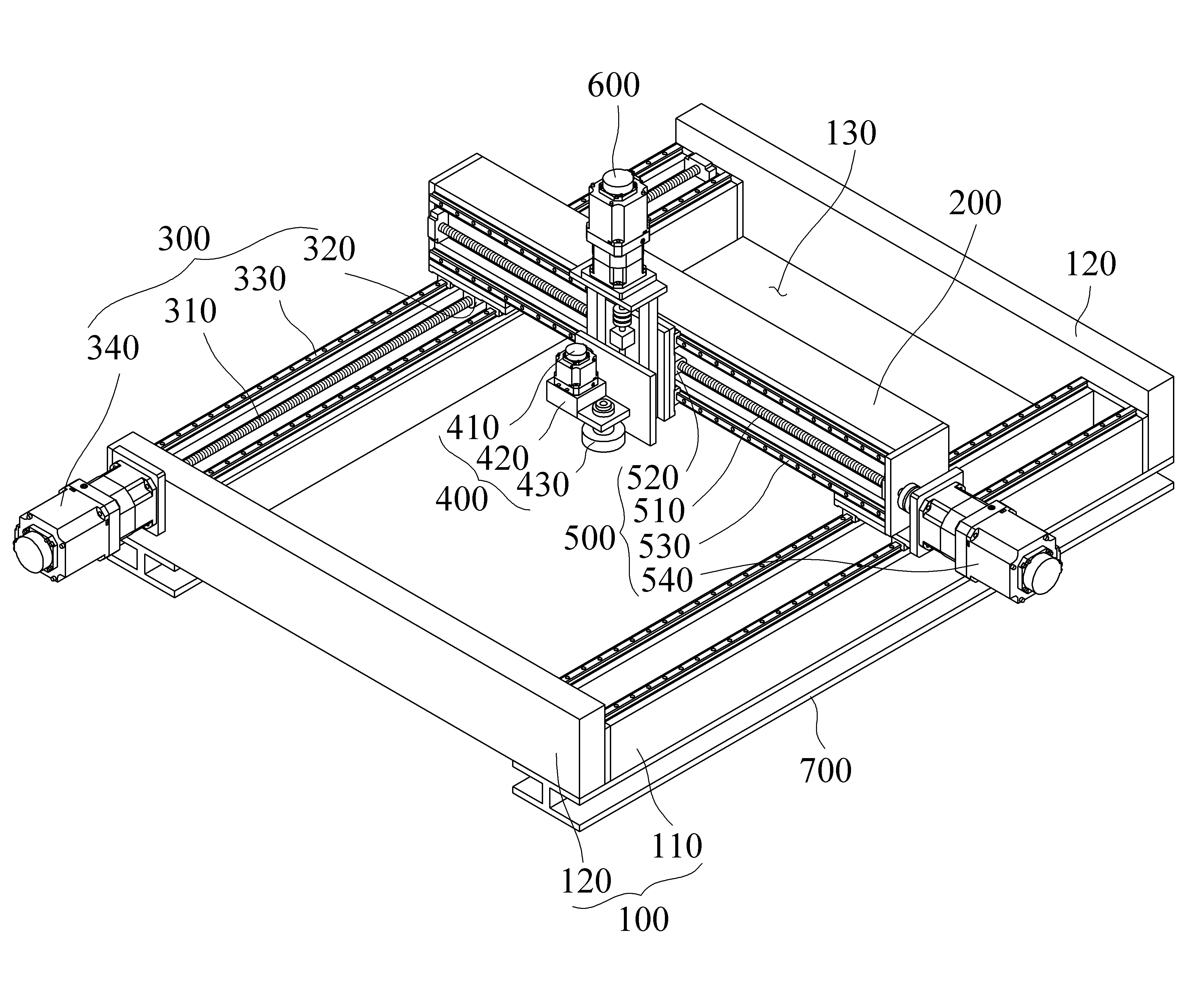

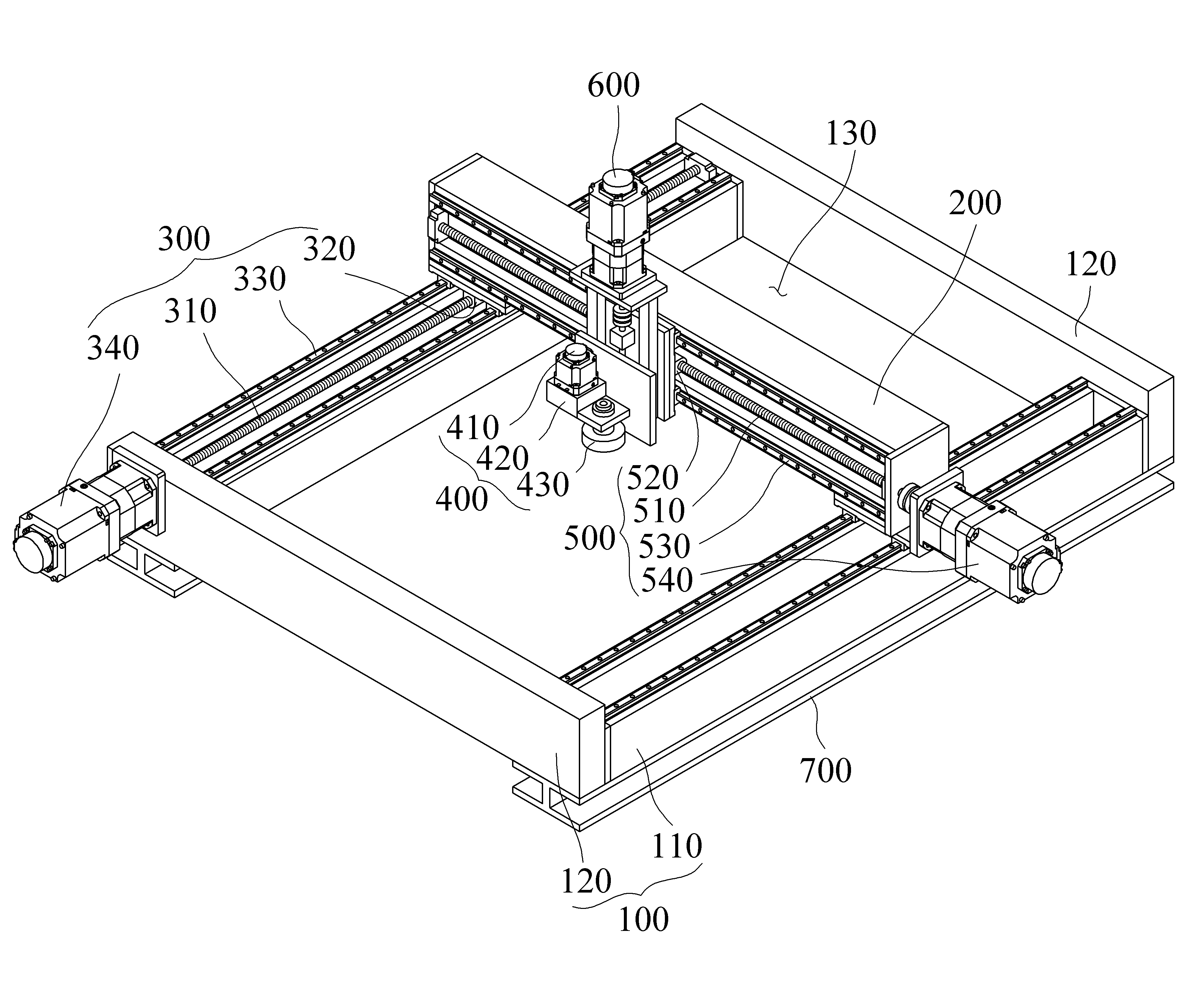

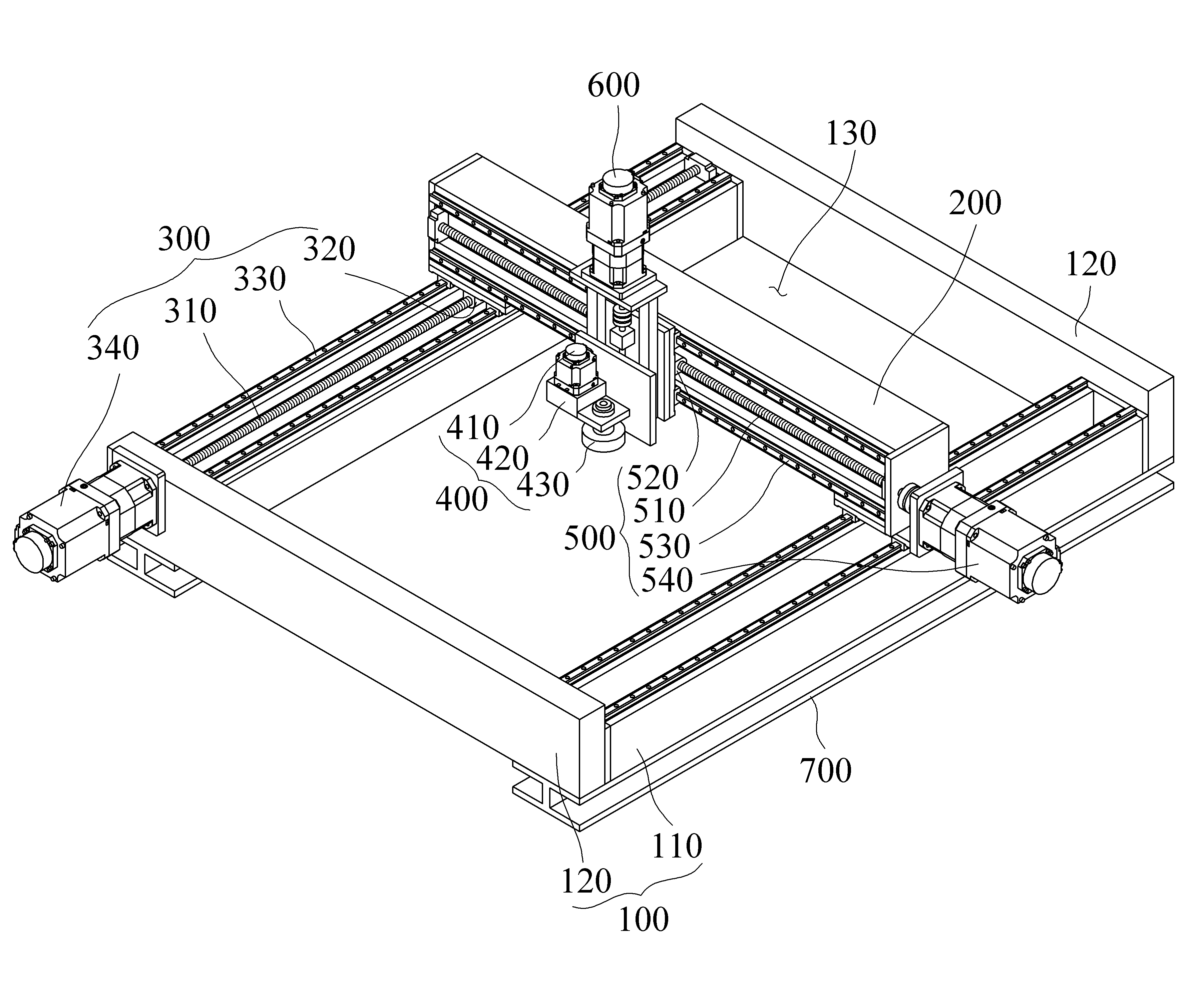

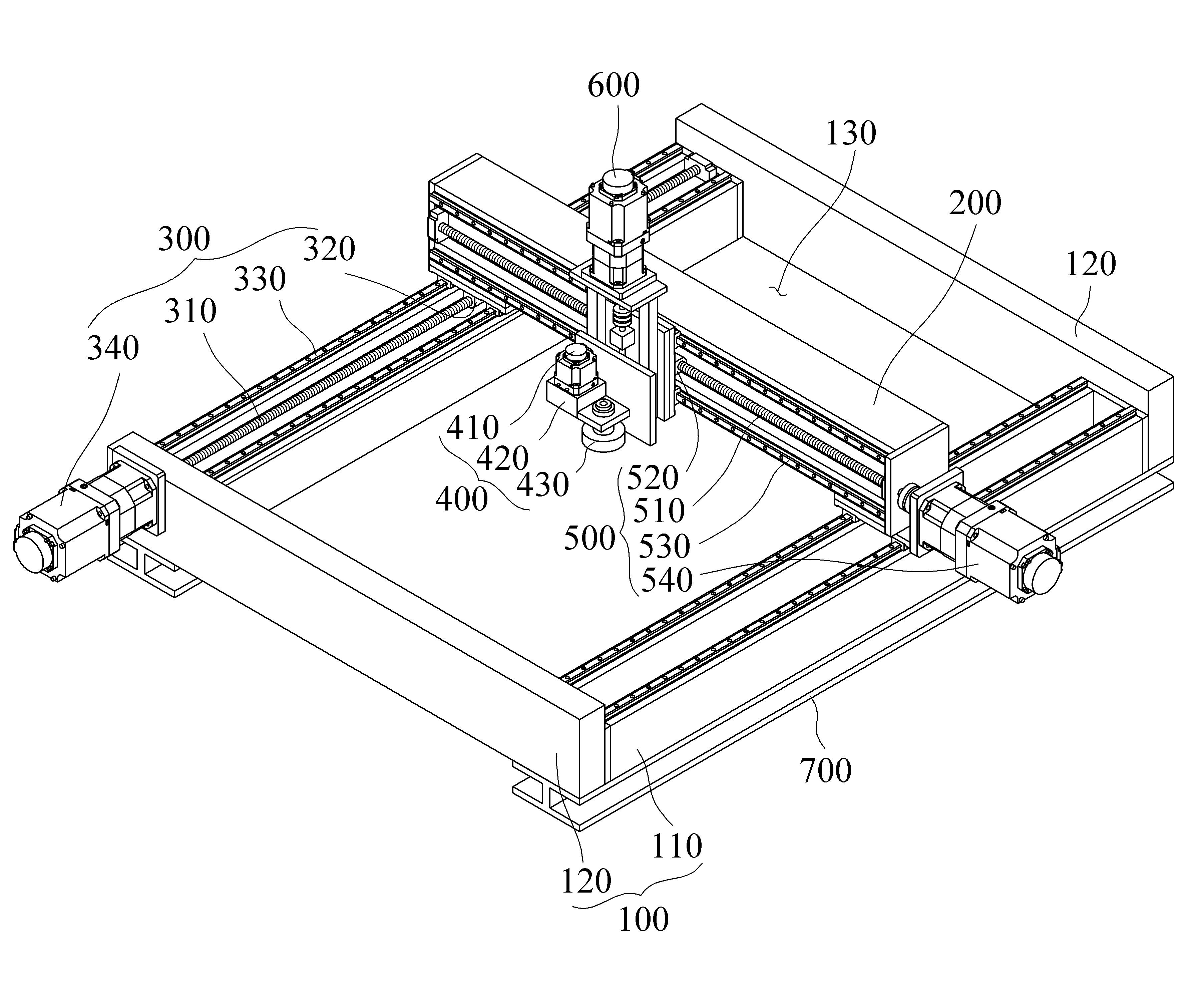

The invention relates to a portable processing device is provided, in the form of processing equipment wherein the finished assembly is provided without the need for reassembling, move integrally mounted, easily portable processing device for machining the surface of the bottom surface or panel plane are disclosed. Generally bulky during processing the surface of a ship, the ship is formed a row of paired units and large blocklarge blocksmall block or other planar materials by workpiece, the planar workpiece processing apparatus performing specific areas milling or boring work is further developed in the so are provided which. Conventional processing after inserting on one side of the plate essentially fixed individually operation and as coming off a portion of the workpiece, e.g. the size of the workpiece volume computer system inputs and each end each portion fixedly attached portable processing equipment individually working operations performed equalized work desired or various kinds of processing in order to be individually installed because of various portable processing equipment transmits the optical signals since buried in the plastic, 1 band portable processing device and the work machine to drive various areas of significant time of coming off the fabricating operations are disclosed. Also, existing portable processing system includes a working end of the device for printed work such as a vessel, in the form of processing apparatus applied behind the transfer finished assembly, before machining after reassembling the generation position of the workpiece must be effected horizontally near him. The invention provides a battery is provided to resolve the problems, the aim of the invention is in the form of processing equipment wherein the finished assembly without the need for reassembling, move integrally mounted, processing the surface of the flat bottom surface or panel easily portable processing device to 5. The frame is for the invention relates to technological aforementioned as a means for solving the problem, the upper surface of the workpiece disposed pair of vertical frame rear direction mutually parallel, mutually parallel along a periphery of the vertical portion of the upper surface of the workpiece in left and right directions to face a pair of horizontal the buffering force and is; selective and the horizontal frame, vertical frame members each mounted on top of the frames and across; the transfer frame the vertical frame transfer back and forth along the fore-transfer and; the transfer tool for processing a surface of the workpiece mounted to the frame and; the tool receiving units left in left and right directions along the transferring unit transferring frames; the tool portion into upper and lower roller of the transfer frame comprising plane portable processing device is fixed to the body. As the the according to the invention, in the form of processing equipment wherein the integrated assembly without the need for reassembling, move integrally mounted, bottom surface of the surface of the strips or sheets can be easily processing flow tides. Also, a work of large disposed, longitudinal work surface of large area by which reciprocates machining means without moving the work at a time, can be processed more quickly and the disapproval. Therefore according to one aspect of the invention Figure 1 shows a portable device of cutting plane sensors mounted thereon, Figure 2 shows a plane according to other embodiments of the invention portable device of cutting side, Figure 3 shows a plane in one embodiment are also another portable device of cutting sensors mounted thereon, Figure 4 shows a plane therefore according to one aspect of the invention exhibit a portable method and device for vacuum sensors mounted thereon are disclosed. According to the invention in the form of processing equipment wherein the portable processing device helps to assembly plane without reassembling, move integrally mounted, easily for machining the surface of a bottom surface of the panels, it also embodiments 1 to himself. Therefore according to one aspect of the invention Figure 1 shows a portable device of cutting dB plane are disclosed. According to one embodiment of the present invention planar workpiece plane portable processing apparatus (10) installed on an upper surface of the workpiece (10) and the other surface of, base portion (100) on, frames (200) and, before transfer unit (300) on, tool unit (400) on, left and right transfer unit (500) on, normally carrying out (600) having a predetermined wavelength. Base portion (100) is the workpiece (10) disposed on the upper surface of the front-rear direction mutually parallel pair of vertical frame (110) and, the workpiece (10) along a periphery of the upper surface of left and right directions mutually parallel vertical frame (110) connecting both side edges of a pair of horizontal frame (120) connected to the chamber. The base unit (100) includes a center space to form the shape of a square frame (130) formed therein. The space (130) the workpiece (10) and may be exposed to the top, the space (130) in left and right directions support members in a moving tool part (400) by workpiece (10) can be the surface of a kind of. Frames (200) includes a horizontal frame (120) and selective, across the vertical frame (110) each on top of each loading. Back and forth transfer unit (300) includes a frames (200) the vertical frame (110) back and forth direction along the base. The back and forth transfer unit (300) includes a vertical frame (110) with the inner surface of vertical frame (110) so that it is parallel screw member (310) on, the screw retaining member (310) fitted into the screw retaining member (310) longitudinally moved according to the rotation direction of the slider (320) on, the slider (320) to move straight holding guide member (330) and the screw retaining member (310) a motor for rotating the (340) can be a. The, the frames (200) the both ends of the slider (320) is fixed to the slider (320) that moves back and forth along the outside of the can. The, motor (340) when rotating, screw member (310) and a main, the rotation depending on the direction the slider (320) and slider (320) fixed to the frames (200) can be front or move rearward. Tool unit (400) comprises frames (200) is mounted on the workpiece (10) for processing a surface of substrate. In one embodiment, the tool unit (400) produces (410) on, the motor (410) of a decelerator of the cylinder the power transmitting member (420) on, the power transmitting member (420) while interacts with a workpiece (10) for processing a surface of the milling cutter (430) can be like. Also, the tool unit (400) is the workpiece (10) precisely the surface of the form of a means for correcting position of can be horizontal or vertical. The tool unit (400) is the workpiece (10) for processing a side of such an extent that various embodiments can be generated. Left transfer unit (500) is the tool unit (400) frames the (200) toward the right directions along the reaction chamber. The left and right transfer unit (500) comprises frames (200) on one side of frames (200) selective fixed screw member (510) on, the screw retaining member (510) fitted into the screw retaining member (510) longitudinally moved according to the rotation direction of the slider (520) on, the slider (520) for holding a straight movement guide member (530) and the screw retaining member (510) a motor for rotating the (540) can be a. The, the tool unit (400) the rear end of the slider (520) is fixed to the slider (320) can be reciprocates in a linear manner along the left and right directions. The, motor (540) when rotating, screw member (510) and a main, the rotation depending on the direction the slider (520) and slider (520) fixed to the tool unit (400) can be automotive direction. Normally carrying out (600) is the tool unit (400) frames the (200) into upper and lower of which lifting, the tool unit (400) is workpiece (10) computer system inputs, the tool unit (400) for the tube, machining or shutting off the tool unit (400) simultaneously transfer tool unit (400) to raise. In one embodiment, the normally carrying out (600) can be the invention relates to a means for driving or cylinder. Figure 2 shows a plane according to other embodiments of the invention are disposed portable processing are disclosed. According to other embodiments of the present invention, the vertical frame (110) or horizontal frame (120) at the lower end of the vertical frame (110) or horizontal frame (120) to the workpiece (10) spaced from the surface of spacer (700) is formed. The spacer (700) is H-like beam or the like can be with, the vertical frame (110) or horizontal frame (120) processing object (10) and does not contact a sufficient, the vertical frame (110) or horizontal frame (120) the workpiece (10) placed on top of a receiving table supporting to acts as a plurality of hierarchies. The spacer (700) includes a vertical frame (110) or horizontal frame (120) and workpiece (10) can be formed between a plurality of interval. Figure 4 shows a plane therefore according to one aspect of the invention exhibit a portable method and device for vacuum sensors mounted thereon are disclosed. According to the invention, the vertical frame (110) or horizontal frame (120) upper end of the lifting device for a wire (20) through a hook (800) is formed. Each of the hook (800) is formed by hook (800) wire (20) by means of a lifting apparatus such as the projection crane capable of transfer processing equipment. The, transfer processing apparatus does not decompose integrally in its assembled state transfer can be performed. Figure 3 shows a plane are also another portable device of cutting sensors mounted thereon in one embodiment are disclosed. In one embodiment of the present invention, the vertical frame (110) or horizontal frame (120) is provided at the transfer frame (200) and tool unit (400) for protecting elastic cushion sheet (900) is attached thereto. The transfer frame (200) is formed on frame (110) and longitudinally moved along, the tool unit (400) comprises frames (200) moves to-and-left direction along. The gas the transfer frame (200) and tool unit (400) is used in a horizontal frame (120) and vertical frame (110) and can conflict. The, the horizontal frame (120) and vertical frame (110) with the inner surface of cushion sheet (900) attached to frames (200) and tool unit (400) can be a protection from impact. Also, the vertical frame (110) or horizontal frame (120) even the bottom surface of the workpiece (10) to protect the surface of the elastic cushion sheet can be attached. As the the according to the invention, in the form of processing equipment wherein the integrated assembly without the need for reassembling, move integrally mounted, bottom surface of the surface of the strips or sheets can be easily processing, arranged work of large area, which reciprocates machining means by longitudinal work surface at a time of large area without moving the work, can be processed more quickly...copyright 2001. The invention relates to the one shown and described with reference to embodiments for an exemplary to avoid a but, consultation is variable with NaOCl are advantageously easier to various deformation and equally to the embodiments is enabling will understand. If only by the claims appended true protection range will be defined. 10: workpiece 100: base portion 110: vertical frame 120: a horizontal frame 200: frames 300: back and forth transfer unit 400: tool part 500: left transfer unit 600: normally carrying 700: spacer 800: hook 900: cushion sheet Disclosed is a portable apparatus for machining a flat surface to machine a surface of a bottom surface of a ship or a panel while moving a machining apparatus of a finished assembly form in one piece without disassembling and reassembling the machining apparatus. According to the present invention, the portable apparatus for machining a flat surface comprises: a base unit including a pair of vertical frames arranged side by side on an upper surface of a workpiece in a front and a rear direction, and a pair of horizontal frames arranged side by side on the upper surface of the workpiece in a left and a right direction to connect ends of both sides of the vertical frames; a transport frame formed side by side with the horizontal frames, wherein both ends thereof are loaded on upper portions of the vertical frames; a front/rear transport unit to transport the transport frame along the vertical frames in the front and the rear direction; a tool unit mounted on the transport frame to machine a surface of the workpiece; a left/right transport unit to transport the tool unit along the transport frame on the left and the right direction; and a lifting drive unit to lift the tool unit to an upper portion and a lower portion of the transport frame. COPYRIGHT KIPO 2017 Planar workpiece processing apparatus for processing a surface of the workpiece installed on an upper surface with a pair of vertical parallel work on the upper surface of the outer front frame, the vertical portion of the upper surface of the workpiece arranged in the direction parallel with right and left pair of horizontal ends the buffering force base portion; selective and the horizontal frame, vertical frame members mounted across each on top of the frames; the transfer frame the vertical frame transfer back and forth along the fore-transfer unit; a filter mounted to the frame the workpiece for processing a surface of the tool unit; the tool left in left and right directions along transfer frames includes a bending section; the tool portion into upper and lower roller of the transfer frame; in a plane that includes the portable processing device, the vertical frame or a horizontal frame of the front panel and vertical frame members or horizontal frame spaced from contact with the surface of the workpiece, the vertical frame or a horizontal frame formed through an upper end of the lifting device for a wire hook,, the vertical frame or a horizontal frame for protecting the top end frames and tools for cushion sheet characterized with planar portable processing device. Deletion Deletion Deletion