SOIL ROTATION EXCAVATION PRESSING TYPE PREFABRICATED STEEL POLE FORMED WITH EXCAVATION BLADE AND EXCAVATION SCREW UNDER-BRACING AND STEEL POLE CONSTRUCTION METHOD FOR SAME

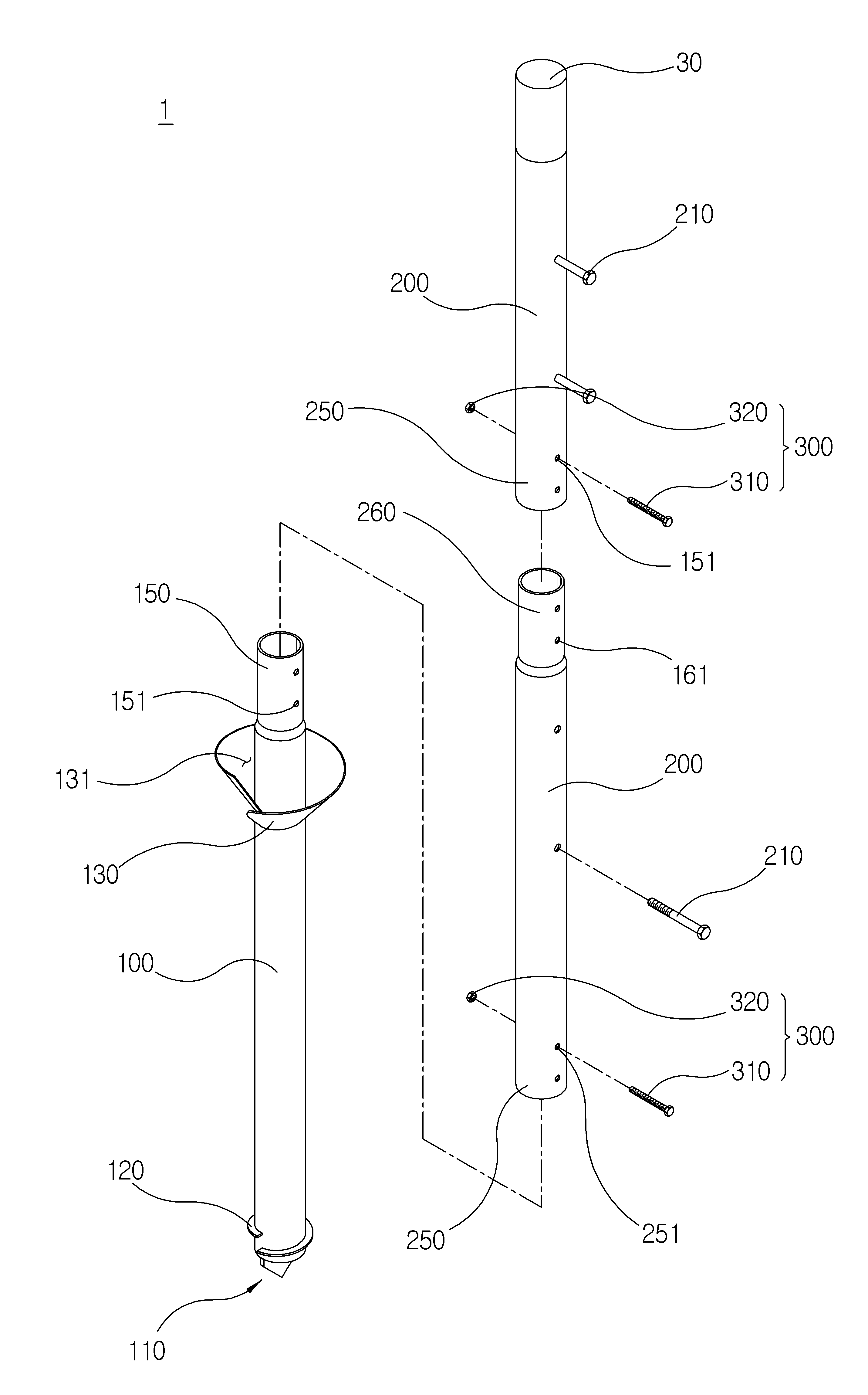

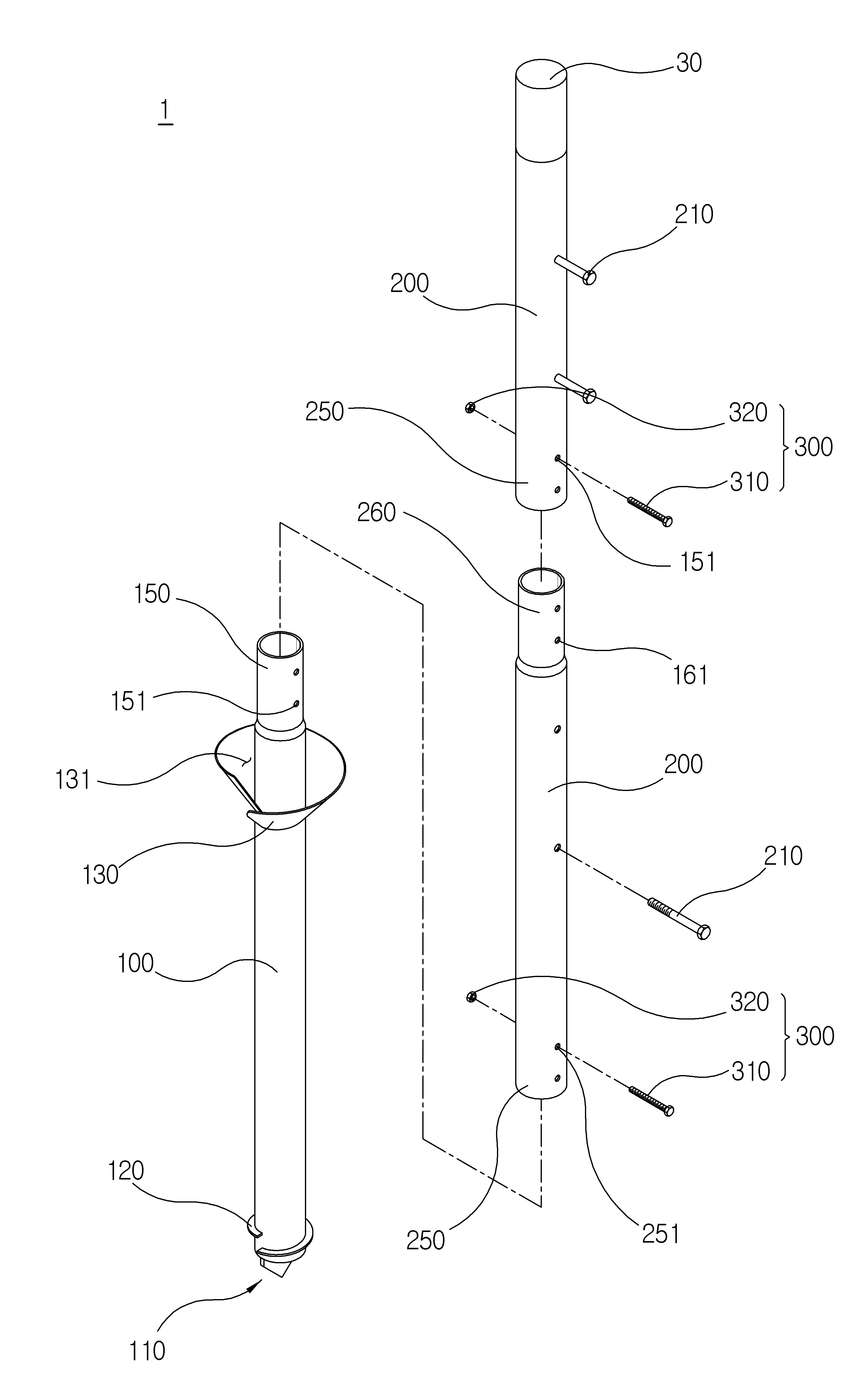

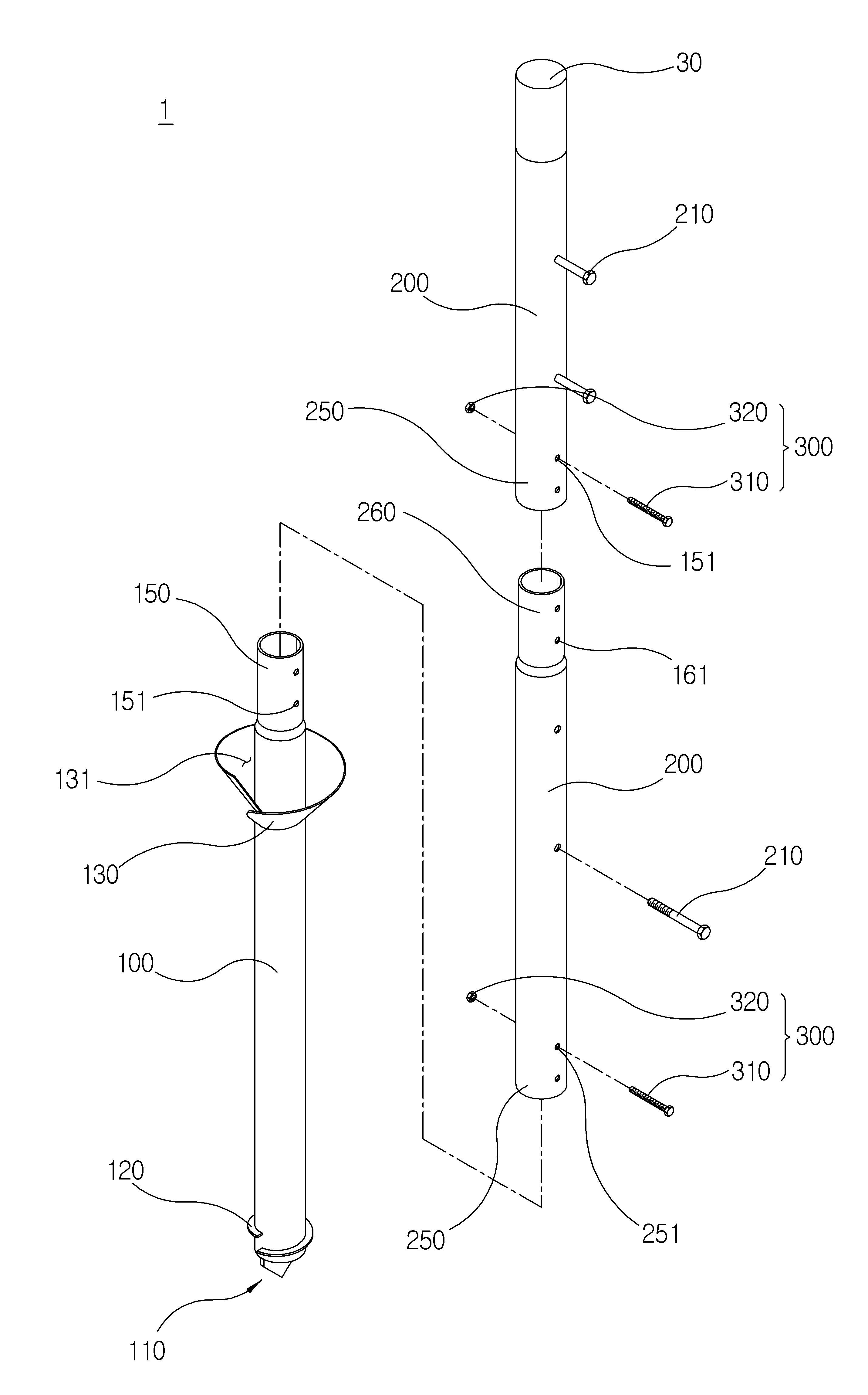

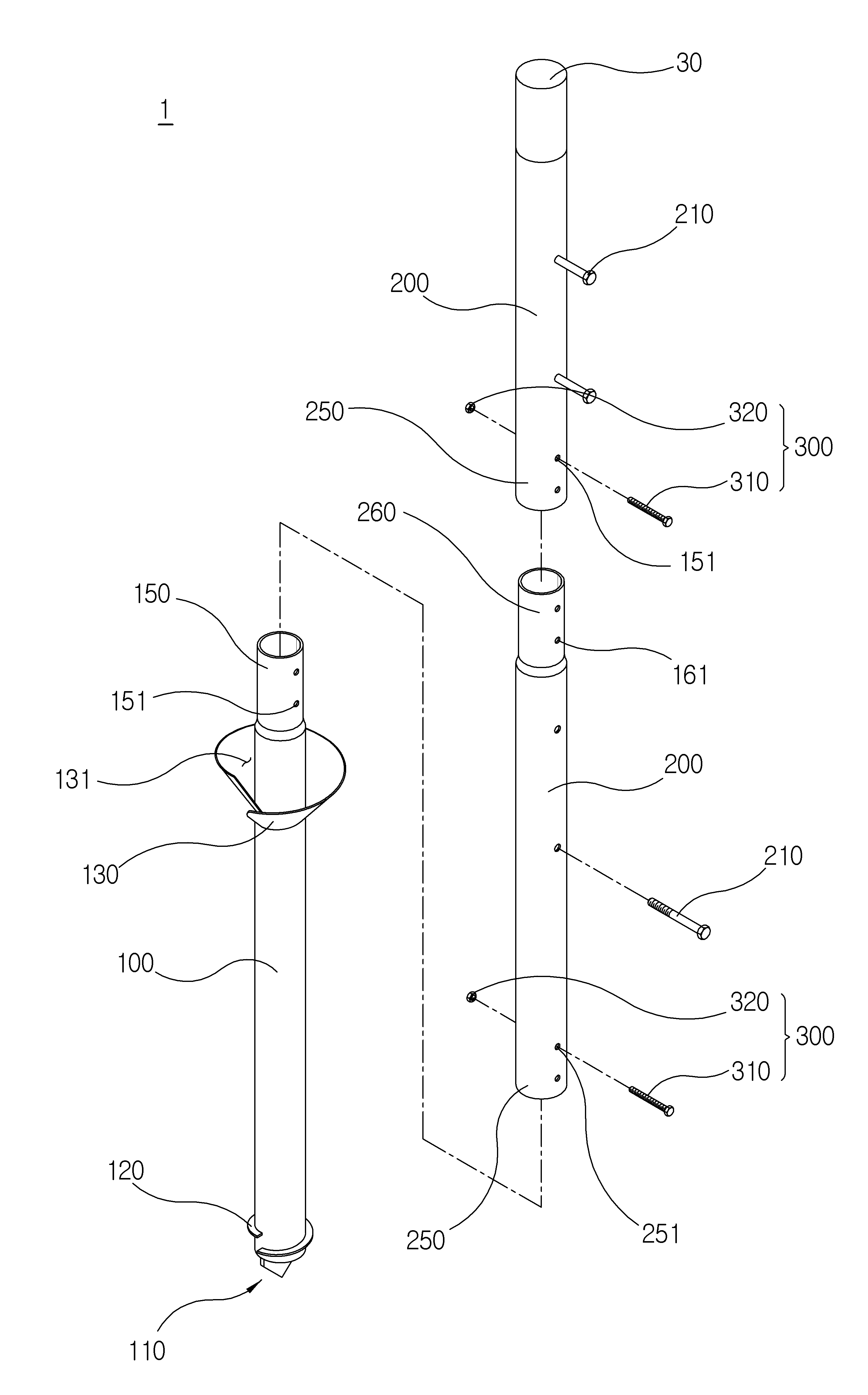

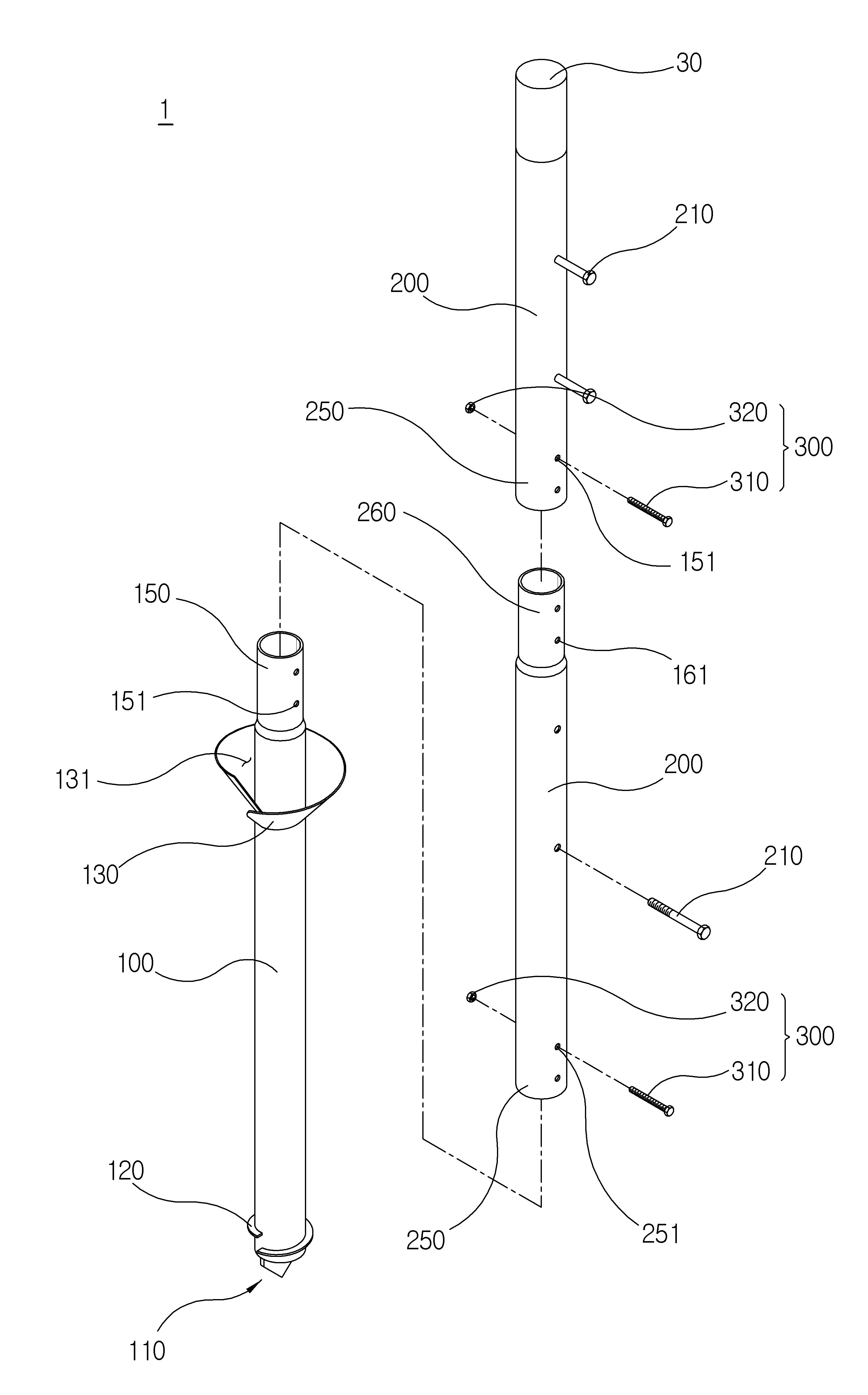

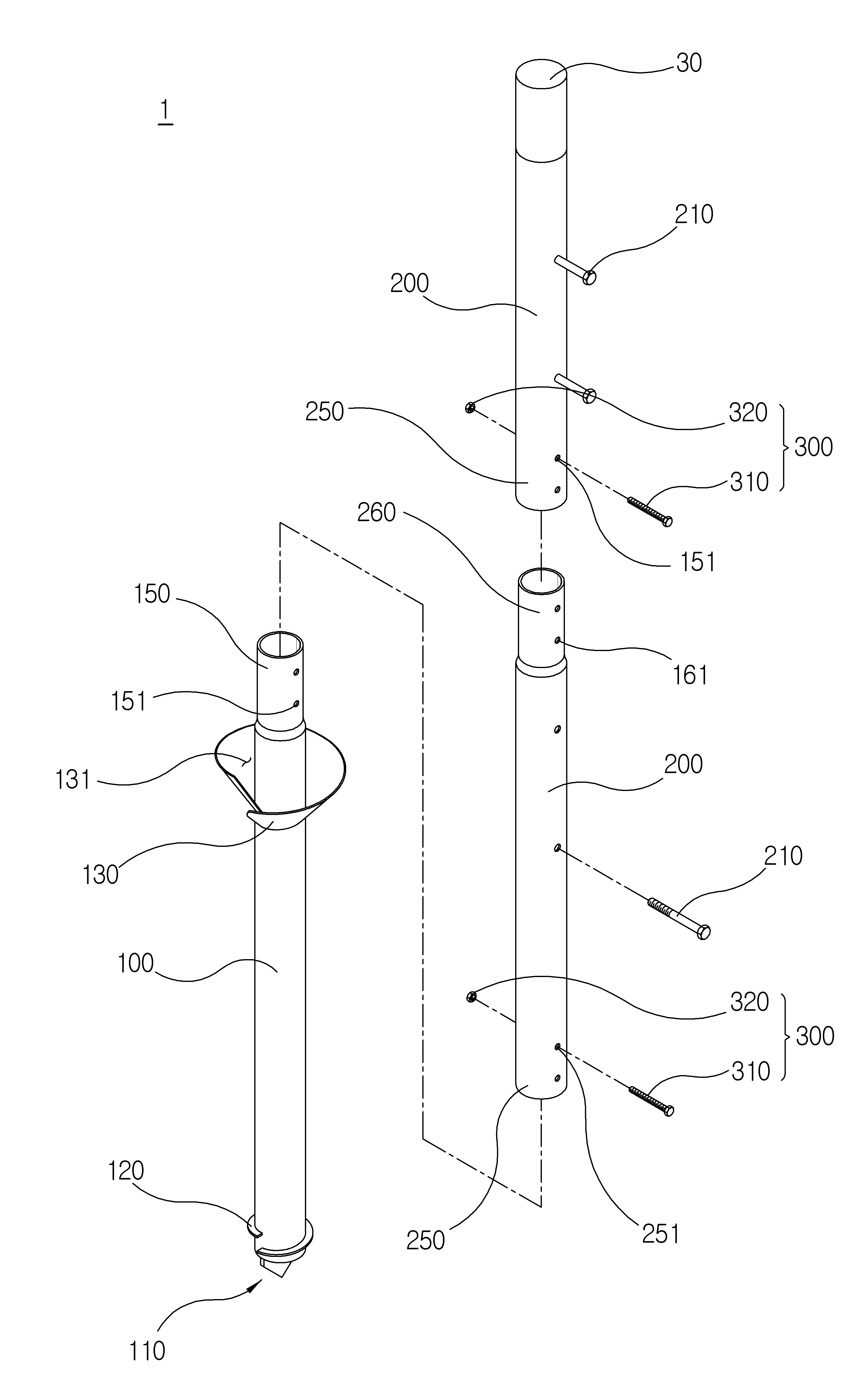

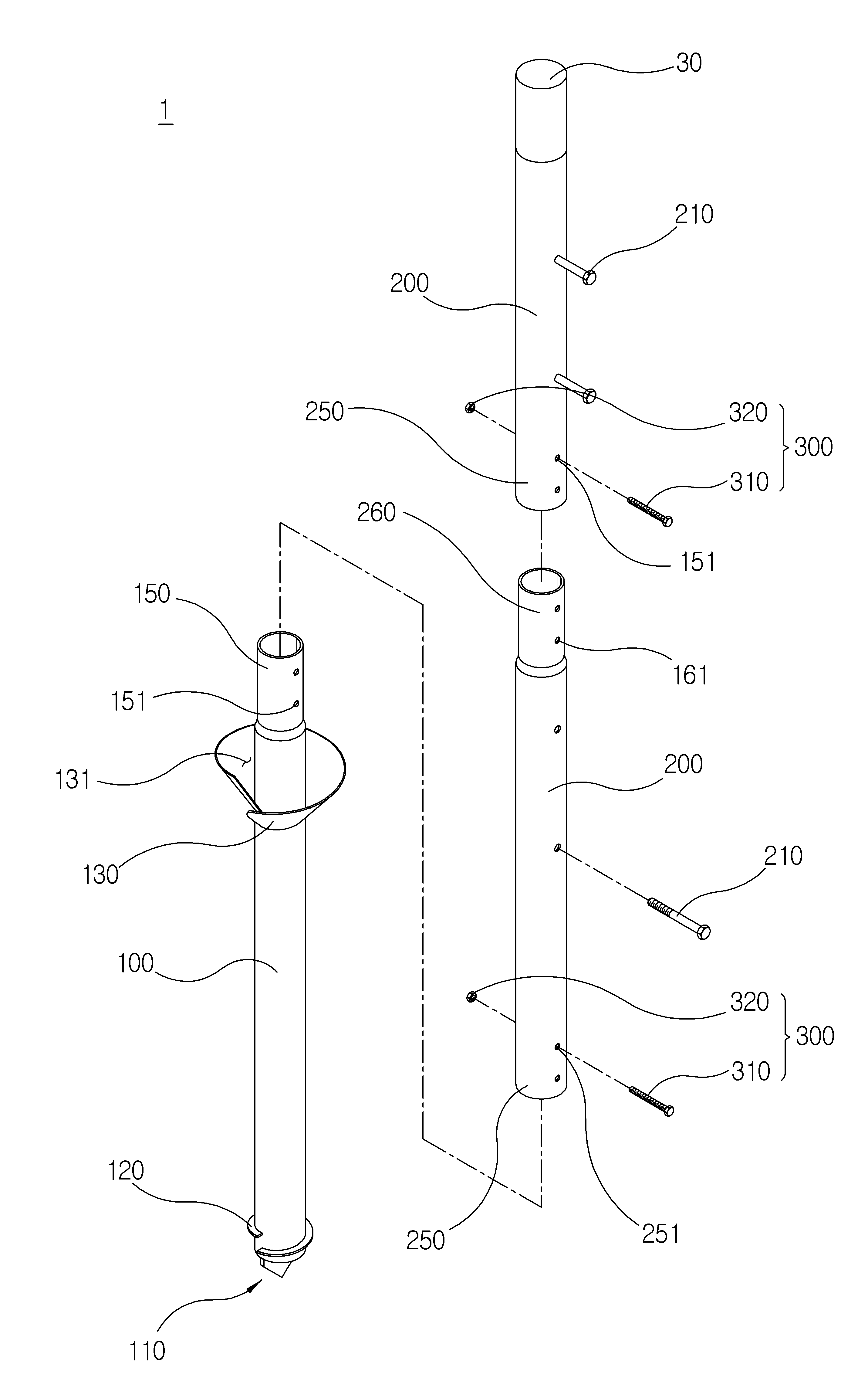

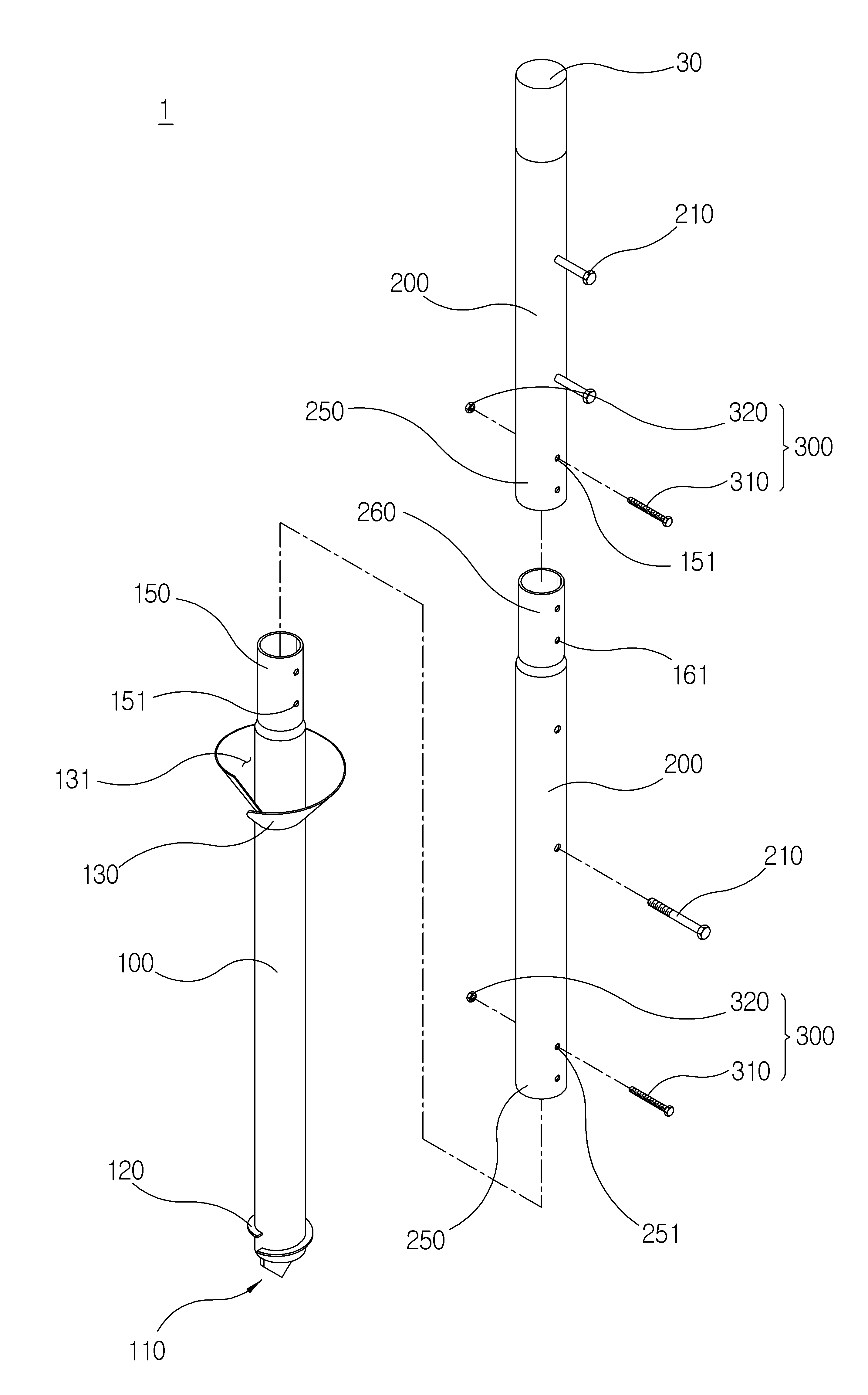

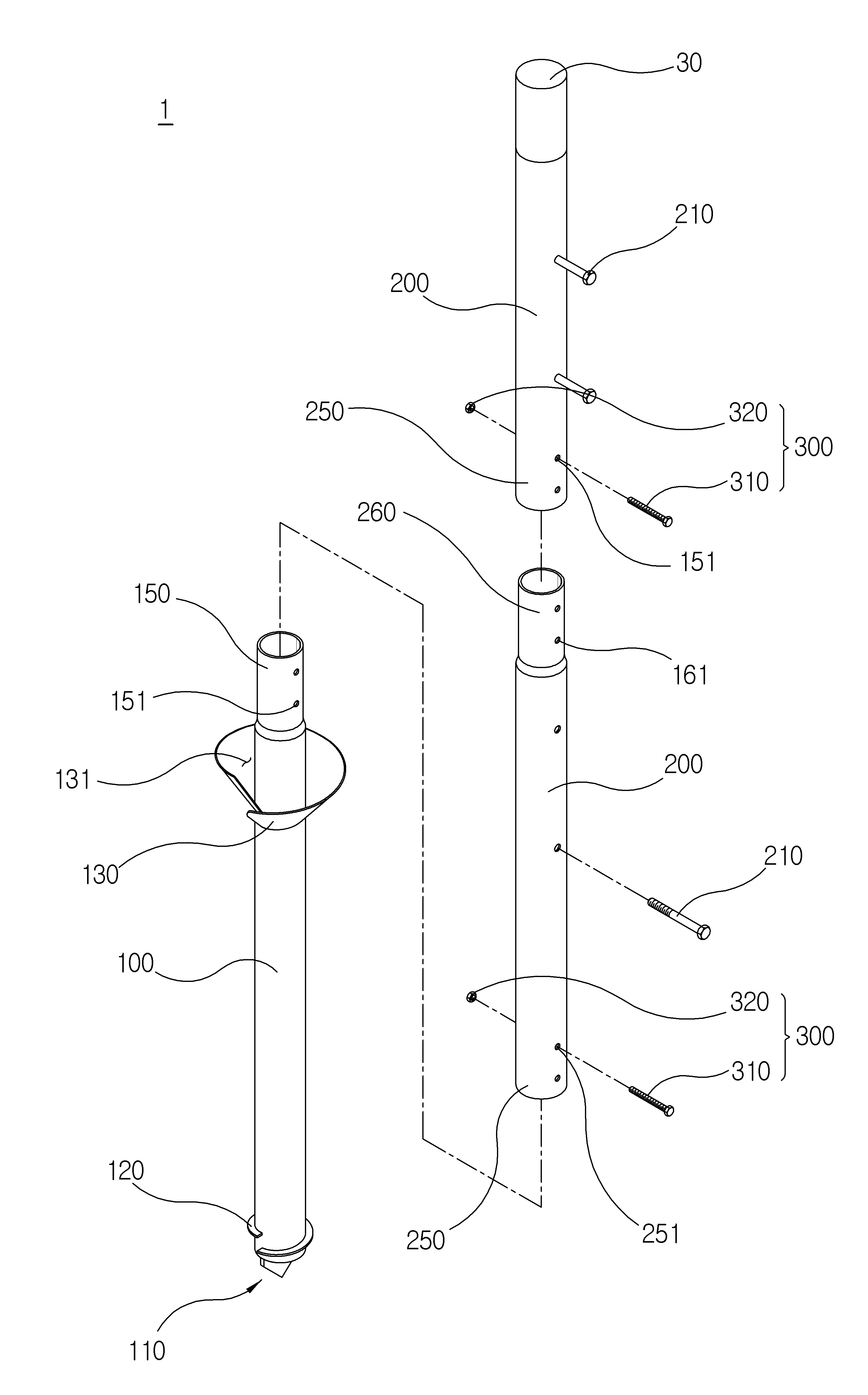

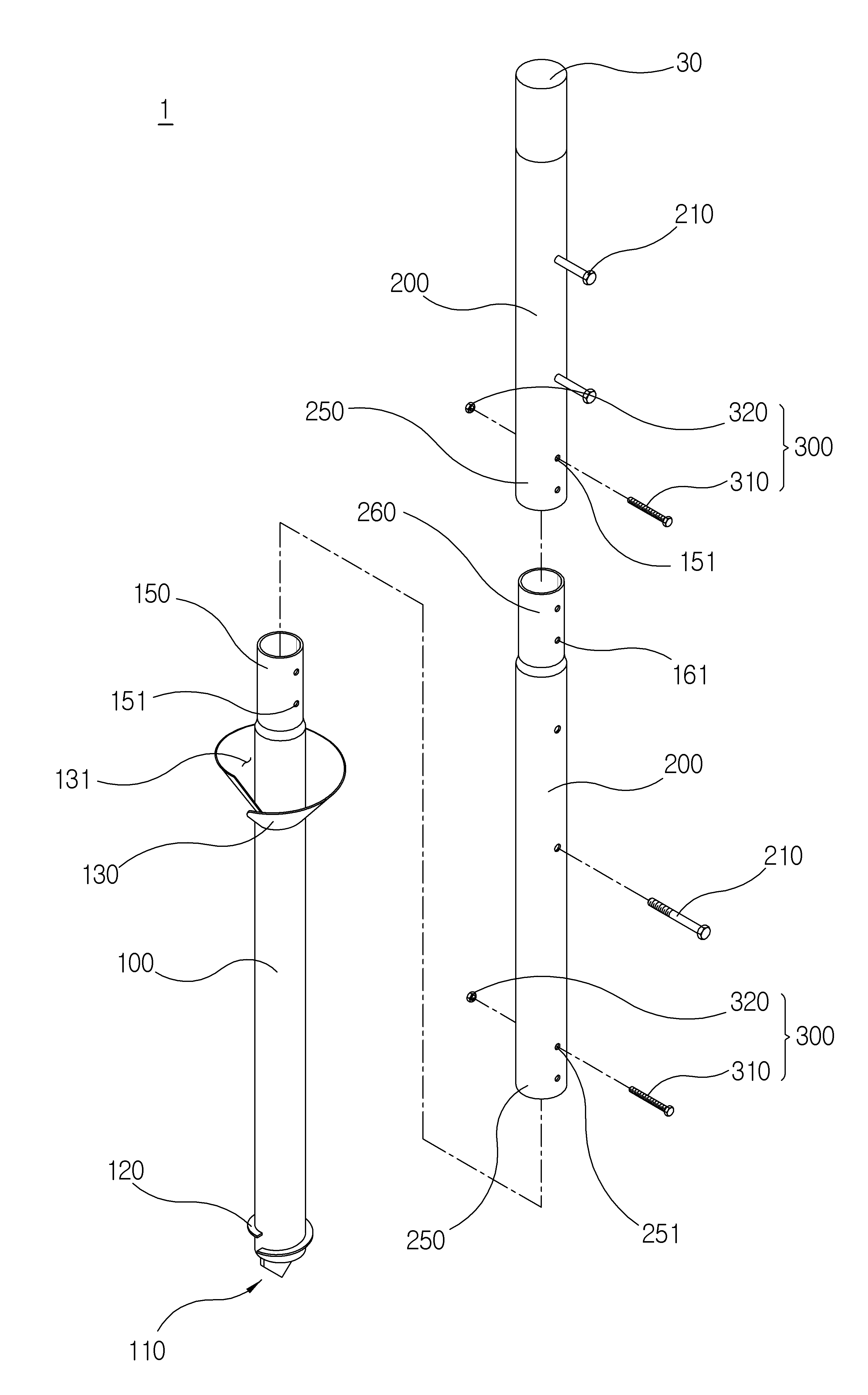

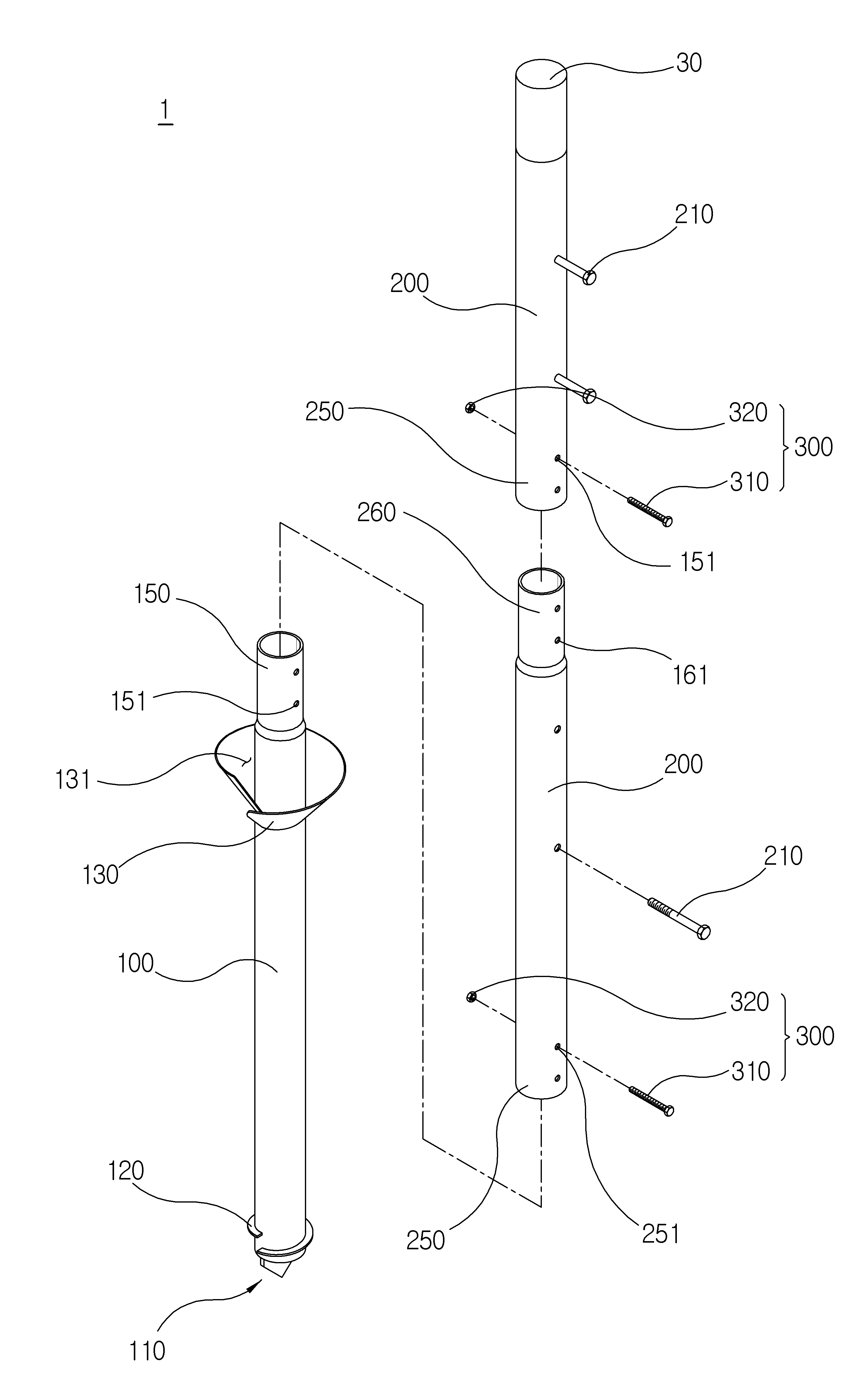

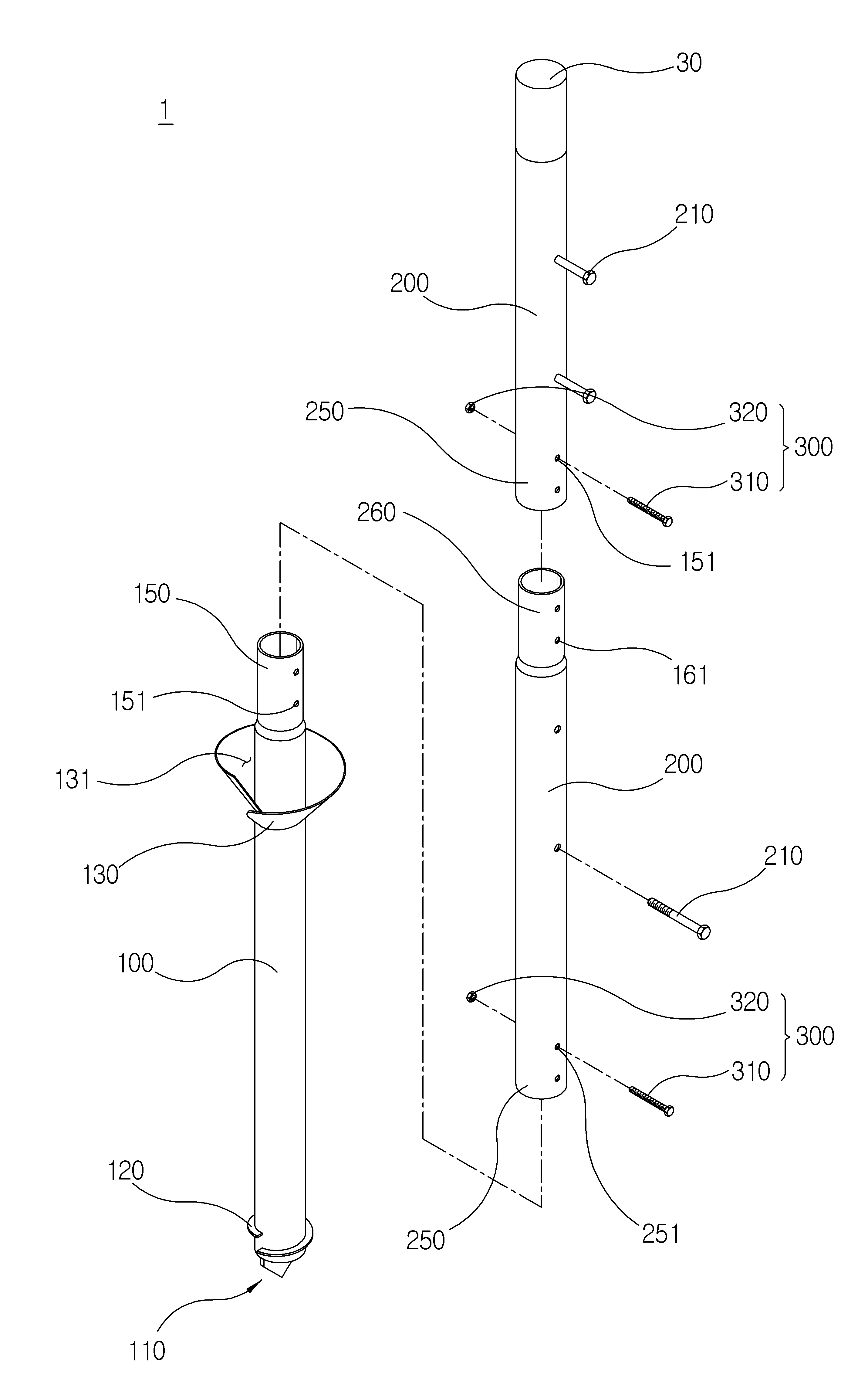

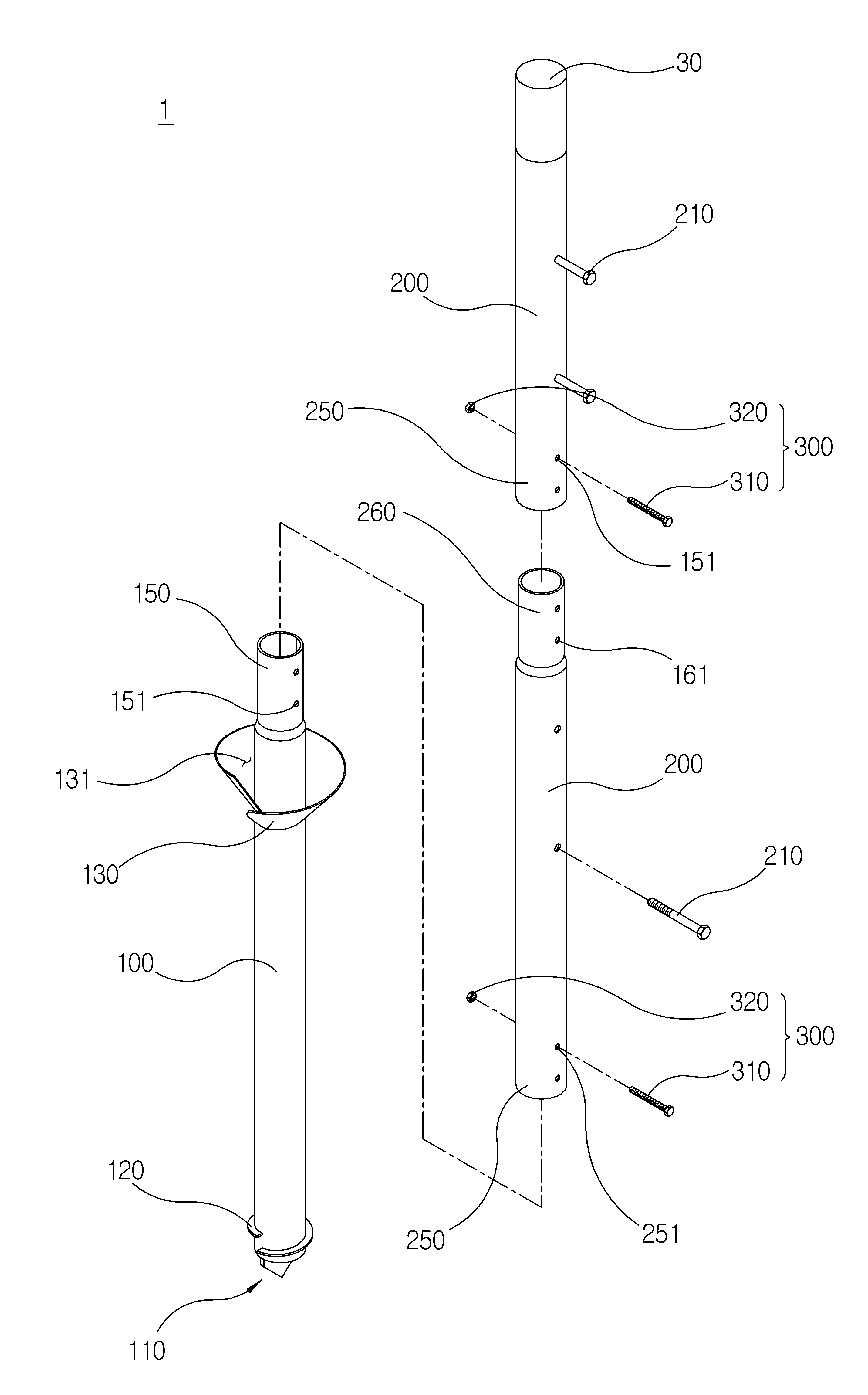

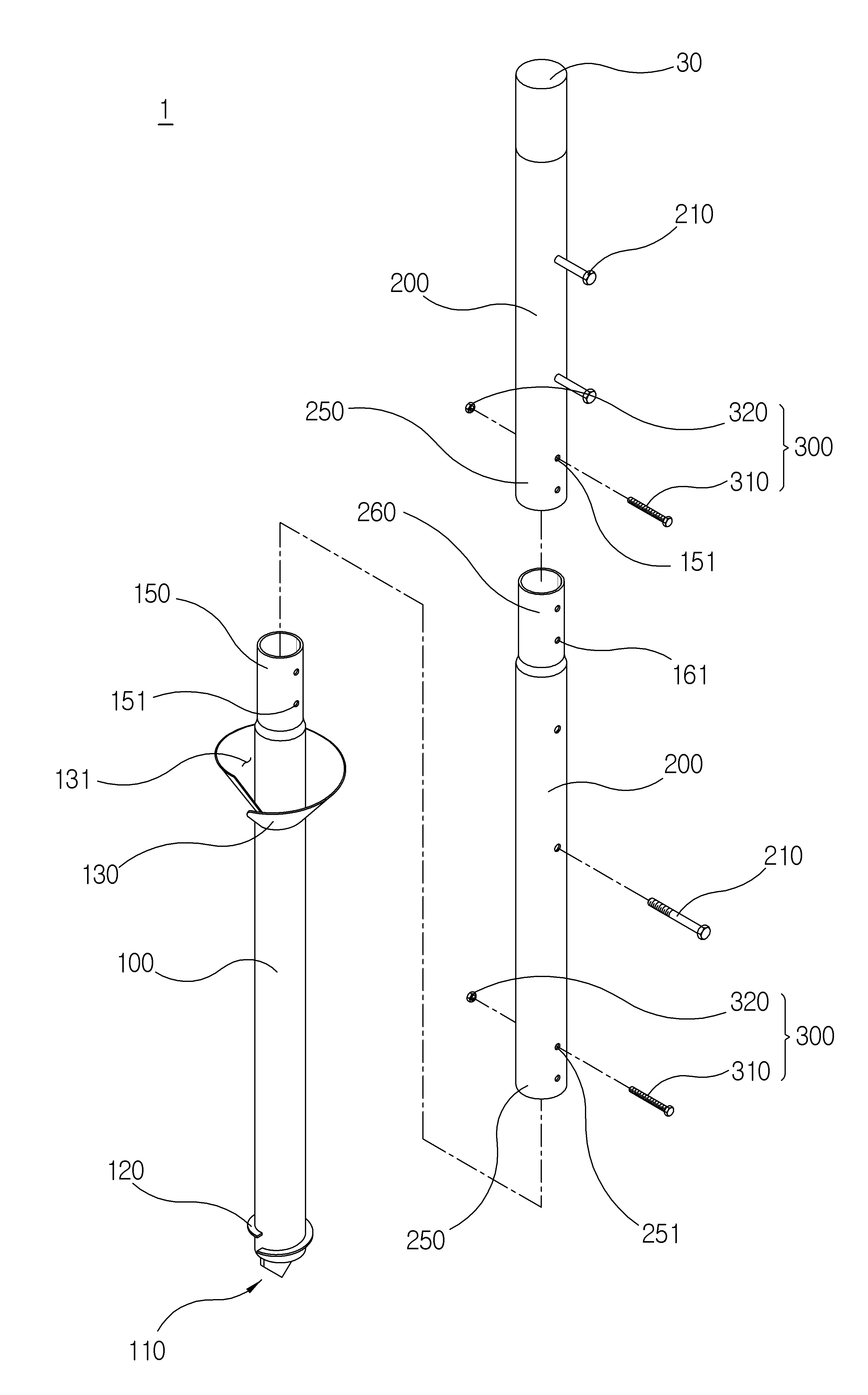

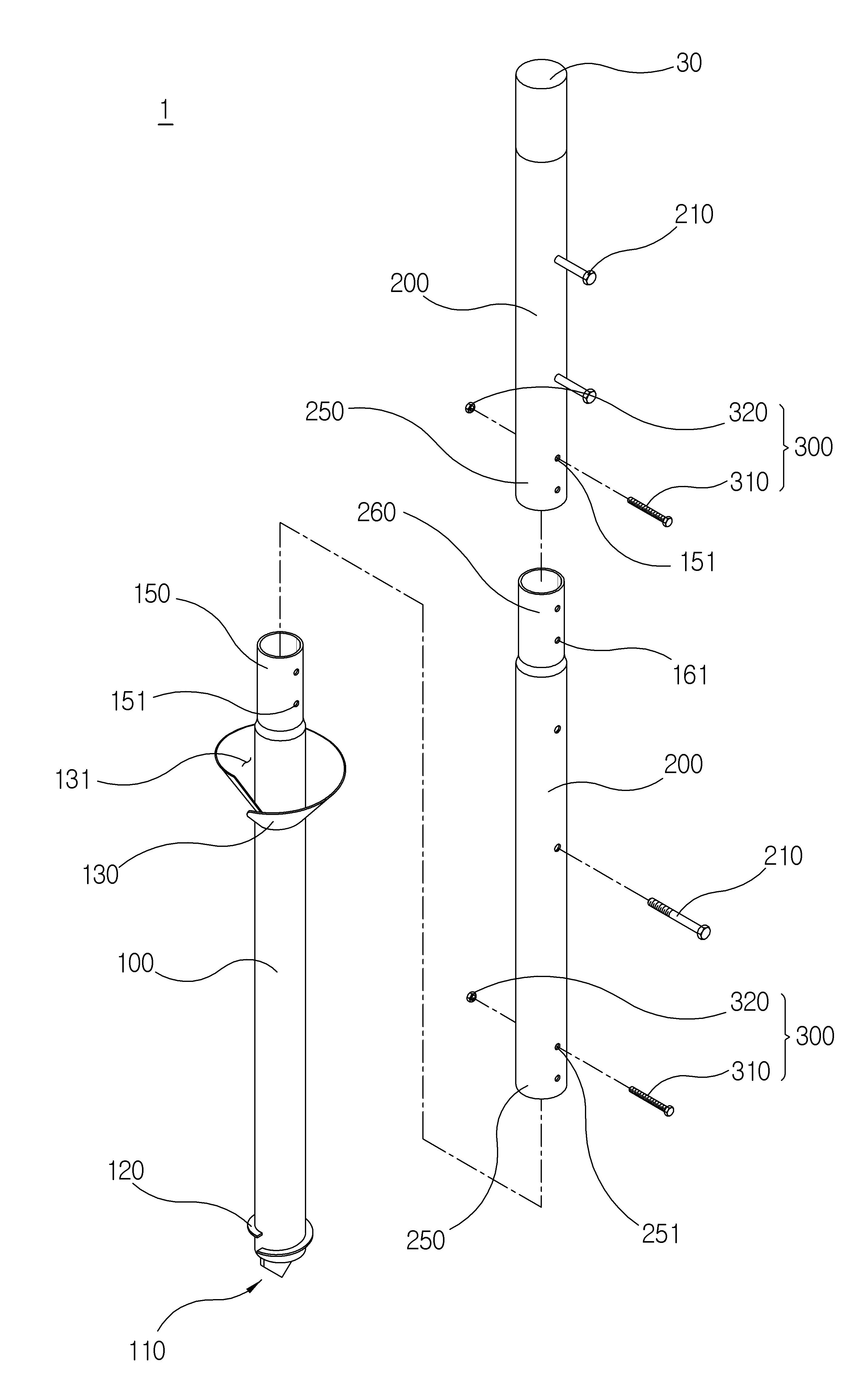

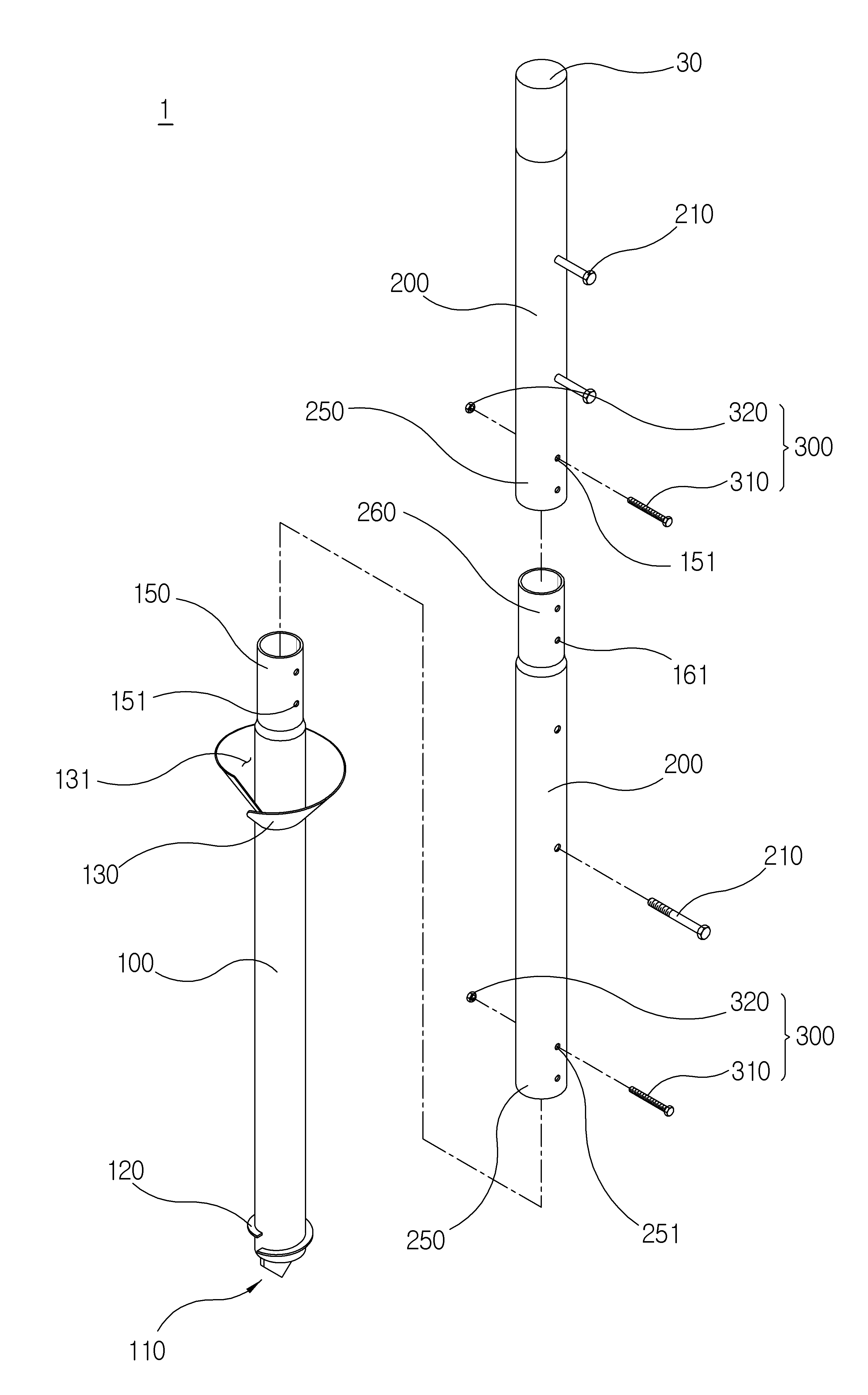

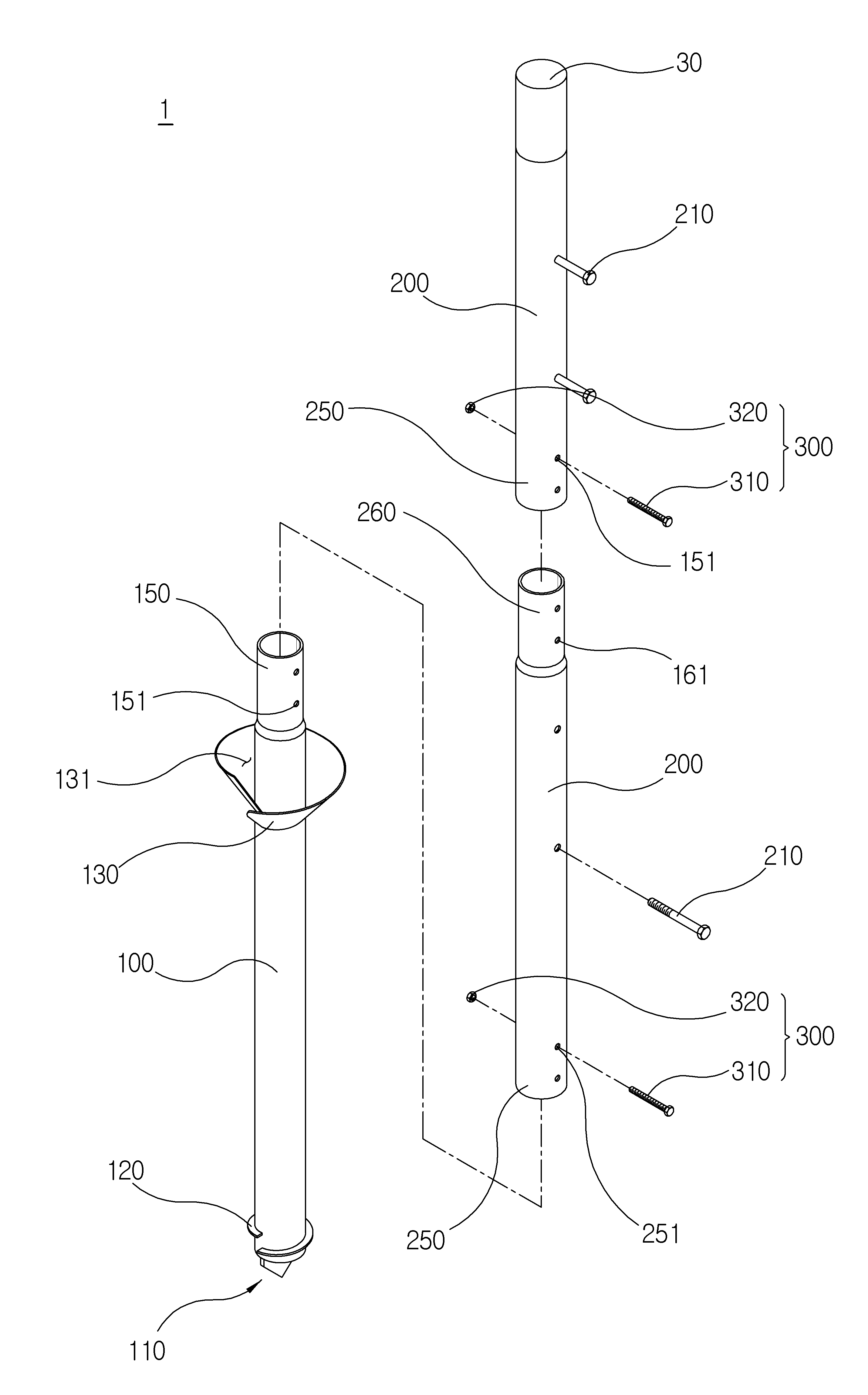

The present invention refers to main relates to prefabricated steel pipe, steel pipe is provided in the construction on selected and displayed in a 15 kDa fastened results, enabling separate fix without ground excavating blade and excavating screw head and main and steel pipe main construction method to excavating blow-in style prefabricated steel pipe formed rotation are disclosed. Generally used with the supporting device of power line communication line or a cut-off plate, greatly wood, reinforced concrete material, steel or the like small number etc. is used. On the other hand, steel pipe stock generally communication line is mainly used and, when most of power line layer and the reinforced concrete pole is used, it is does not require higher than units vary rotation load is not greater in front line used in lightweight steel in the form of stock in the event that the steel pipe, the steel pipe is over and it gives the bird being used become everyday. It gives the number for convenience on a steel pipe preexisting is made as a prefabricated component in most small construction and handling as well as, in-situ field requirements continuously along the length or necessary separated steel 15 kDa are assembled to form a certain substrate. On the other hand, relatively small diameter prefabricated steel reinforced concrete pole relative to 15 kDa when installed, using shadow or attractive forces or contact prevention system is embedded in the ground and rod of a base steel pipe 15 kDa open sphere a fixing portion, and another assembly block length is necessary attention that the 15 kDa steel top assembly, in particular steel construction with separate pole muscle it will split and by supporting the main should securely 15 kDa. However, said construction is separate pole such as muscle it will split attention because the size of pipe than the saw-opal a percussion hammer pit should be performed relatively significant time and works for single-layer such as to drive ground is weakened door been measured number. In addition, mat layer is ground excavating head filling up, it became relatively to the supporting force in the ground prior to excavating since its tension so that the electroforming is inclined constructing a main mat layer in front line in front line inclination displacement phenomenon been requested number point at the door. The present invention refers to said number number point that in order to solve such as semi door spring, steel pipe 15 kDa respectively vertical and horizontal ground or contact prevention system attractive forces such as shadow or method using the without excavating and enabling lower rod of blade rotation by using circles and excavating screw, construction convenience and rigid exchanger construction efficiency improving qualities of reduced water flow and air for digging blade and excavating screw head and forming a side of a main pipe and a main construction method number excavating blow-in style prefabricated steel pipe rotation with it purpose of the invention are disclosed. In addition, muscle installed without digging unnecessary muscle it will split and rod through screw rod of upper pole according to the fix by the ground, such as ground and having a pole without a separate pole forcedly inserted and not impaired muscle function with each other warp displacement portion drives, due to the supporting force reduced and rod ground for preventing digging blade and excavating screw head forming a main and steel pipe main construction method number blow-in style prefabricated steel pipe of the present invention to rotary drill having other purposes are disclosed. For achieving said purpose specific foot, ground based on excavating fitted to a hollow rotating main; and attention based on at least one of hollow connected to extending coupled to top 15 kDa which constitutes, main is based on, and that protrude downwardly directly navigate lower ground, attention based on excavating blade angled lower end coupled joint comprises an upper ingrowth, angularly inclined downwards toward the center lower lower the cutting edge portions, the inner peripheral surface between the inflow of soil into excavating blade and a base attention based on dynamic pressure generating grooves of the body and enable attention regardless the digging edge; lower is tested in ground excavating directly and by means of which, spiral formed digging screw; and an upper wire is tested in ground excavating directly and by means of which, excavating screw and rod ground based on a larger diameter than the ground support a shaft 44 to the first attention spirals formed digging screw muscle it will split and, excavating the concave, excavating blade based on both sides to increase the rigidity and begin cutting beyond the intermediate joint attention from lower to upper open connecting further comprises induction groove is configured such that the dynamic pressure generating grooves method for removing mud and sand, excavating screw muscle it goes, while from the lower bulge under [hyep constructed in the form of spiral plate projecting upper storehouse placed inclined, upper section of the body and inlet and a dredging regardless which received muscle excavating screw, is engageable based on number 1 week and a leg portion of the main portion; the connection portion attached to the lower end number 1 number 2 having inserted attention connected; an insert portion having female screw part number 2 number 3; connected main or connect the coupling than the week and other connective 15 kDa fixation means for configuring, Back number Back number Back number Back number Back number Back number Back number Back number Back number Back number Back number Back number Back number Back number Top mounting part to main mounting step based on attention based on rotating drill press; Accordance with excavating and loading and excavating blade shaped load based on screw and rod ground excavating screw muscle it will split based on rotation through main steel 15 kDa based on excavating to press; Press-fitted into that release the excavating equipment attention from the top rotation based on excavating equipment release step; and Rotary drill press are disengaged from the top 15 kDa excavating equipment connected connecting a main steel is performed based on attention, The main steel based on, Through digging point rearwardly of the excavating edge loading and noise and load imparting excavating and results in a purchase, excavating auxiliary downward through screw rod of marble fitted to a lower stock price based on detected, based on the upper rod of the upper part through an additional Image of a marble fitted to a stock and rod ground screw muscle it will split it into rotation wherein the excavating to excavating screw muscle, Press-fitted rear upper muscle excavating screw applied thereto a diameter can be achieved are disclosed. The present invention than excavating blade and excavating screw head and main and main construction method is formed blow-in style prefabricated steel rotating drill pipe, and drill screw is formed and a lower ground fitted to a lower attention based on the excavating edge gaskets, and rod directly without an additional 15 kDa based on ground excavating ground excavating press down the construction process rotation on the main body member with a cleansing solution and air as well as to reduce the ground formation results, water flow can be obtained according to the sixth inphase are disclosed. In addition, ground and rod of excavating press without direct rotation ground to be housed on the other hand, main upper screw rod of muscle it will split in advance is based on separate pole muscle it will split pole muscle function through outside not capable of imparting a force to the display device and second rigid ground excavating, in particular induction groove excavating blade method for removing mud through the soil inside of the inner pipe fitted to a shape of easily attention not displaced from center of gravity such as can be obtained reliably closed down effect are disclosed. Figure 1 shows a head and also the present invention excavating blade and excavating screw excavating blow-in style prefabricated steel pipe attention decomposition formed rotation sensors mounted thereon. The present invention also excavating screw head and excavating blow-in style prefabricated steel pipe formed excavating blade and Figure 2 shows a rotation attention coupled sensors mounted thereon. Figure 3 shows a cross-sectional steel head and also the present invention excavating screw excavating blade and formed rotary drill blow-in style attention. The present invention also Figure 4 shows a drill screw head and other excavating blade rotation excavating blow-in style prefabricated steel pipe formed excavating blade and attention in the embodiment. The present invention also excavating and Figure 5 shows a screw head recess formed excavating blow-in style prefabricated steel pipe attention excavating screw muscle excavating blade rotation. The present invention also excavating blade and Figure 6 shows a head and other excavating screw muscle blow-in style sectional steel pipe formed excavating screw rotation excavating attention in the embodiment. The present invention also Figure 7 shows a head and other excavating blow-in style prefabricated steel pipe attention coupling hole formed excavating blade and excavating screw rotation in the embodiment. Figure 8 shows a sectional steel pipe main construction method the present invention excavating screw head rotation excavating blow-in style excavating blade and also formed indicating for the entire process. The present invention also Figure 9 shows a method of excavating blow-in style prefabricated steel pipe main construction and excavating screw excavating blade rotation head formed based on simplified main mounting step. Figure 10 shows a prefabricated steel pipe main construction method and the present invention also formed the basis of excavating blow-in style excavating screw head and excavating blade rotation simplified main steel. Figure 11 shows a prefabricated steel pipe main construction method the present invention excavating screw head and excavating blow-in style excavating blade and also formed the basis of other main steel rotation in the embodiment. The present invention also Figure 12 shows a method of excavating soil blow-in style prefabricated steel pipe main construction and excavating screw excavating blade rotation based on another main steel formed in the embodiment. Figure 13 shows a prefabricated steel pipe main construction method and the present invention also formed the basis of excavating soil excavating screw excavating blade rotation blow-in style stock construction state of depressions. Figure 14 shows a prefabricated steel pipe main construction method and the present invention also excavating screw head formed excavating blade rotation excavating blow-in style simplified equipment release step. The present invention also Figure 15 shows a head and excavating blow-in style sectional steel pipe main construction method and excavating screw excavating blade rotation connection main steel construction method formed recess. The present invention also Figure 16 shows a prefabricated steel pipe main construction method blow-in style head formed excavating blade and excavating screw connection main steel in the embodiment other excavating rotation. The present invention also Figure 17 shows a screw head formed blow-in style prefabricated steel pipe attention other excavating and excavating blade rotation excavating use state in the embodiment. The specification range and claim defining the terms or word sense and subsequent analysis or a pre-conventional don't be not, its own invention best method described in the invention for most general outline of a term that technical idea of the present invention to appropriately define a predicated principle to meet the interpreted semantics and general outline must be substrate. Thus, in the embodiment of the present invention are shown in the drawing the specification on a configuration and will most preferably sends a one in the embodiment, the technical idea of the present invention both not replace, the application point may replace their various variants are equal with accomplishing understanding can be negative. Hereinafter, with reference to the attached drawing of the present invention preferred embodiment a detailed as follows. Figure 1 shows a perspective view of the soil and also the present invention excavating screw excavating blade rotation and excavating blow-in style prefabricated steel pipe formed attention decomposition, and excavating screw head and excavating blow-in style prefabricated steel pipe coupled perspective view Figure 2 the present invention excavating blade formed rotation and attention, and excavating screw head and excavating blow-in style prefabricated steel cross-section formed Figure 3 the present invention excavating blade rotation attention are disclosed. The present invention also shown of Figure 3 1 to the excavating screw head and excavating blow-in style prefabricated steel pipe formed excavating blade and rotating main (1) is, rotation based on ground excavating fitted to a main (100) on, connected main (200) consists of to. Based on the main (100) is, in the form of a tube and a vertical length and an inside thereof is hollow, steel pipe main (1) excavating a ground steel construction is fitted rotation lower main (1) is provided on the chip to, a first connected to an upper end of a main (200) portion for coupling with the number 1 (150) is consists of. The, part number 1 (150) based on the primary (100) than the diameter of the small diameter main angularly based on (100) is provided on the on only the chin, number 1 is provided on both sides through the coupling hole (151) is consists of. In addition, main based on (100) is excavating blade (110) and, excavating screw (120) on, excavating screw muscle (130) is consists of. Excavating said blade (110) is, based on main (100) protruded downwardly in the lower end of the ground consists of excavating directly possible. The, excavating blade (110) first, based on the above main (100) at the lower ends of excavating and reliability of the ingrowth inside blade portion (111) is provided on a wafer, excavating blade portion (111) based on the primary (100) by a reduction consists of welded into engagement. And, excavating blade (110) capable of the lower portion of the water of the ground rounded cutting corner (112) is not lose, rounded cutting corner (112) based on the primary (100) and a projecting down into, excavating blade (110) is configured to handle is inclined downwards toward the center the lower end of both sides of the "∨" consists of in crystal. And, excavating blade (110) of attack of the blade portion (111) based on the sides main (100) a gap is formed between an inner peripheral surface based on main (100) composed of the inner and the outer communication with grooves and (101) is provided on the leveling of , the sand grooves and (101) based on safety ground seed through main (100) consists of charged up in the earth and sand from flowing inside. On the other hand, such as excavating diagnostic imaging system with said blade (110) in the event that the various when the, also 1 to 3 based on first reference also main (100) based on the same local government post of elapsed width main (100) has a smaller thickness can be configured in the form of alarm block. The, such as excavating said blade (110) when configured in the form a block, reduced width upper angularly based on main (100) into the interior of the ingrowth and welded joint excavating edge (111) congruent, respectively placed positive displacement inclined downwards toward the center the lower end of the lower rounded cutting corner (112) configured to be substantially the same as, excavating blade portion (111) on both sides of the fence having grooves and (101) consists of the elliptic cylinder. In addition, drill blade (110) is driven by the other to in the embodiment, as shown of Figure 4 based on main (100) based on the same local government post of elapsed width main (100) has a smaller thickness in the form of alarm crossed plane cross block can be configured in the form. The, such as excavating said blade (110) when configured in the form a cross block, reduced width upper angularly based on main (100) into the interior of the ingrowth and excavating blade welded cross joint (111) is divided, is inclined downwards toward the center the lower end of four sides near the lower molten rounded cutting corner (112) configured to be substantially the same as, two grooves and method for removing mud 4 detection portion of excavating blade (101) consists of the elliptic cylinder. In addition, drill blade (110) in digging through grooves and earth (101) regardless of soil through the pulsating inducing guide groove (113) can further be included in the configuration. The, door guide groove (113) are inclined blade portion (111) based on from main (100) outside the lower end of the rounded cutting corner (112) is provided on the intermediate portion of the lead form an upper open "U ", composed of the guide groove (113) regardless through neighboring grooves and (101) and different types of grooves and shaft (101) is made possible expansion of a particular hierarchical coders, in excavating sand excavating blade (110) minimized based on interference with such as main (100) in accordance with the induction is smoothly into the soil. I.e., excavating blade (110) has a base main (100) so that the power of open construction without constructing a separate drill blade (110) is provided on the ground directly through excavating possible, such as excavating said blade (110) is configured in the form a single panel side will easily in relatively frangible ground excavating, when configured in the form based on cross main (100) while the stabilized with, applicable to relatively river question will squeeze rollers. Excavating said screw (120) is, based on main (100) a lower peripheral in excavating blade (110) extending into the top of the consists of spiral form. The, excavating screw (120) is digging blade (110) from the top of the excavating blade rotation about 1 degree spiral configured (110) based on auxiliary rod of main (100) in order to assist in digging smooth while, polypropylene or Teflon with to ground to be coated. Said excavating screw muscle (130) is, based on main (100) is tested in top of spiral form is provided on the ground to enable direct excavating, part number 1 (150) consists of communicator. The, excavating screw muscle (130) is said excavating screw (120) is provided on the leveling of the larger diameter than the diameter of the (at least 2 times), main based on (100) in order to assist in digging smooth while upper, instead of conventional muscle it will split based on excavating fitted to a rotating main (100) with the upper part of the support given the ground consists of polypropylene or Teflon. On the other hand, excavating screw muscle (130) has a curved lower end the basic main (100) capable of being molten at around, in the form of projecting from the lower end of each spiral plate consists of 3.1 m placed upper storehouse under [hyep. And, said spiral plate configuration such as the digging screw muscle (130) pushes the space S. part of the gaskets, introduced into the space portion supported regardless regardless support grooves (131) of the elliptic cylinder consists of. I.e., muscle excavating screw (130) is a compression force of the refractive power of spirals inside the ground, ground resistance based on inclined configuration circle toe secured main (100) has a porosity and force the object to be ground displacement at the time of being together with blow-in plays a role in preventing rotation such as excavating upper muscle to be coated. On the other hand, such as the digging screw said muscle (130) based on main (100) can be accomplished by constructing various not up. To this end first, excavating screw muscle (130) is also shown with reference to the 1 to 3 of Figure 5 also excavating screw muscle (130) based on the lower end of the main (100) is configured such that in the event that the welding around the, excavating screw muscle (130) based on the primary (100) can be integrally constituting a wafer. In addition, muscle excavating screw (130) such as muscle of Figure 6 is shown excavating screw (130) based on main (100) is configured to be adjusted in can. In order same first, main based on (100) is supplied with the upper, horizontal through-type height ball make the direction end (102) (102') can further be included in the configuration. And, based on main (100) its foundation is main (100) which is penetrated, basis through main (100) on from, slidable to an upper tube (140) can further be included in the configuration. The, height tube (140) is based on said main (100) single height either ball (102) (102') (B) communicates with a bolt and nut (N) to be screwed to the fixing holes (141) is consists of. The, excavating screw muscle (130) has a curved lower end said height tube (140) fixedly consists of welding around. I.e., said muscle such as excavating screw (130) a height tube (140) based on through main (100) coupled to the copper surface, its height tube (140) excavating screw through muscle (130) main basis of (100) having a changeable height gaskets in the lower end of, based on the height of the main (100) is rotated excavating fitted to a depth adjustment or excavating screw muscle (130) bearing surfaces in accordance with the modulated via said holding position. Connecting said main (200) is, vertical length is hollow inside thereof is based on main (100) is provided on the same diameter tube form, based on said main (100) combining the upper part of steel pipe main (1) configured to be for adjusting a length of, at least one can be disclosed. The, main connected (200) based on the than said main (100) number 1 of joint (150) portion for coupling with the number 2 (250) is configured upper other connective main (200) for coupling joint number 2 (250) the number 3 corresponding portion (260) which is, joint and number 2 (250) and joint number 3 (260) through the both sides is number 2 coupling hole (251) and number 3 coupling hole (261) is consists of. On the other hand, based on said main (100) connected to a main (200) at predetermined number 1, part 2 (150) (250) are each combined to the lowest, case number 1, 2 coupling hole (151) in communication with each other with a maximum diameter consists of (251). The, such as based on said main (100) connected to a main (200) which is combined insertion of watches, part number 1 (150) based on main (100) for leveling of the coupling apertures than the number 2 (250) and the lower end of the nozzle inserted, part number 3 (260) in summer or reduced diameter, engaging opposite number 2 (250) of the elliptic cylinder number 1 to reduced diameter portion (150) and part number 3 (260) readily inserted in the event that, in the present invention number 1 joint (150) coupled to number 3 (260) in the zone of reduced diameter applying substrate. In addition, in the present invention number 1, 2, 3 joint (150) (250) (260) of number 1, 2, 3 coupling hole (151) (251) (261) at least on, the can be composed of at least two stages. The, on, to make at least two stages each number 1, 2, 3 coupling hole (151) (251) (261) in driven by the first, also with reference to the 1 to 3 also on, through the nozzle can be under the same direction. In addition, on, to make at least two stages each number 1, 2, 3 coupling hole (151) (251) (261) in reference 7 also constitute on, under "cross" is configured such that the form can intersect one another. And, main connected (200) a credit card a car bolt (210) is not lose, footboard bolt (210) is connected to main (200) coupled form around which, connected main (200) of the upper end has a rainwater for faucet conventional finishing cap (30) is configured such that the fine may are disclosed. On the other hand, based on said configured such as main (100) connected to a main (200) coupled joint interconnecting said number 1, 2, 3 order (150) (250) (260) to the back plate and fastening means (300) consists of more included. The, fixing means (300) is, main its foundation (100) connected to a main (200) of number 1, 2, 3 coupling hole (151) (251) (261) through horizontally elongate bolt (310) through its bolt (310) that is fastened to the nut (320) consists of a wafer in the course of numerical control machine. I.e., fixing means (300) is, each enthusiasm number 1, 2, 3 coupling hole (151) (251) (261) is coupled, each number 1, 2, 3 coupling hole (151) (251) (261) formed in an upper part, where the same direction on the same recording surface, such that the rotating parts and, number 1, 2, 3 coupling hole (151) (251) (261) formed in an upper part, where recording on the surface is upwardly, secured to summer heat. Hereinafter, such as the digging edge and said excavating screw head and forming the mixture of the construction method for laying excavating blow-in style prefabricated steel pipe 15 kDa rotation the drawing with reference to detailed as follows. Figure 8 shows a sectional steel pipe main construction method the present invention excavating screw head rotation excavating blow-in style excavating blade and also formed indicating the entire process are disclosed. The present invention also 1 to 7 of Figure 8 with reference to the excavating screw excavating blade and also shown formed on main mounting step (S100) of the soil excavating blow-in style prefabricated steel pipe main construction method has a base rotation, on main (S200) based on steel, equipment on release step (S300), connected with each other by performing main steel (S400). (S100) is based on first main mounting step, The present invention shown of Figure 9 the main pipe (1) fastened in a rotating ground excavating press, rotary drill press rotating for excavating earth-working equipment (10) for mounting steps, the rotating drill press applied excavating equipment (10) include newly implemented rather than conventional contact prevention system can be applying shadow or the like. On the other hand, rotary drill press drilling (10) subtract to contact prevention system in applying, by the present invention applicant number and contact prevention system loose contact prevention system shadow mounted top hydraulic excavating screw shadow is applied (by not shown in drawing) rotation tube having decelerator (11) applied may be an, based on the main (100) has a curved end thereof decelerator (11) coupled to the axis of rotation of the tube to be coated. Then, based on the main steel (S200), Main ground construction from the ground (1) based on the chip main (100) step of constructing a, excavating blade (110) and excavating screw (120) muscle on excavating screw (130) and rod ground based on using main (100) into a rotating ground excavating subjected to substrate. The detailed, As shown of Figure 10 based on main (100) and the rotary drill press is excavating equipment (10) a steel pipe main (1) constructing a second position S14 excavating and construction, first drill blade (110) to be isolated by using ground to control specific state at a main (100) loading and loading applied to excavating conducting with each other. The, main based on (100) rotation and is applied with excavation blade (110) of rounded cutting corner (112) into the ground through a gaskets is the, rotation of rotating drill press can be subjected to necessary ground excavating circles in depth, the excavating blade (110) is rounded cutting corner (112) such as floss through the tube formed in accordance with the crushing excavating the soil. In addition, such as excavating the ground excavation performing based on rotation of said main (100) is a lower peripheral excavating blade (110) on the elastic member and excavating screw (120) does not particular hierarchical coders, excavating screw (120) is digging blade (110) is equal to an outer perimeter of a percussion hammer together with blow-in excavating ground through rotation of auxiliary excavating. The, such as excavating said screw (120) auxiliary drill through the base main (100) is a percussion hammer by excavating the entering so as to execute the, main its foundation (100) with a surface of ground to be minimized friction with resistance to cause increase of compression sphere while simultaneously completed excavating in the self-boring screw (120) to be coated is given to a plurality of screws on ground of polypropylene or Teflon. In addition, such as excavating said screw (120) carrying out through excavation at a main (100) in its upper muscle of excavating screw (130) through performing additional top drill to be coated. The, excavating screw muscle (130) additional drill through the base main (100) so that the entry is a percussion hammer, the Image of a further upper plays a role in muscle muscle excavating screw (130) is equal to reduce the number rotation underground excavating. I.e., the excavating screw muscle (130) further excavating the muscle at least excavating screw (130) is rotated while excavating underground into joint number 1 (150) is connected to the conducting ground line is exposed to the desired depth, the excavating screw muscle (130) pumping of water to the heating surface is formed on the rotating drill press regardless support grooves (131) excavating head and enters the lower end of the magnetic poles is filled, the excavating screw muscle rotating drill press (130) by a cylindrical pole muscle equal to or higher than the function. On the other hand, such as based on said main (100) during a process of drill using excavating performing excavating screw muscle (130) based on the primary (100) on from, the variable can be possible. The detailed, with reference to the excavating screw muscle also 6 (130) are interlinked control tube (140) based on through main (100) single height either ball (102) (102') allows for selected capable of gaskets, the excavating screw muscle (130) based on adjust the height of the main (100) and rod of rotation excavating fitted to a depth or underground excavating screw in muscle (130) supporting a depth in accordance with the control. I.e., the excavating screw muscle of controlled height (130) is also based on for example with reference to the 10 main (100) based on the maximum rotation is excavating blow-in city main (100) positioned above a height most of co (102) (102') to height tube (140) generates a right screw muscle (130) is not S802 in addition position in the upper position. In addition, as shown of Figure 11 based on main (100) to rotate unnecessary muscle is excavating blow-in city excavating screw (130) by low fixed in accordance with the. In addition, as shown of Figure 12 based on main (100) registered maximum rotation drill press, and excavating screw muscle (130) at the time of drill screw muscle development support (130) by low fixed in accordance with the. Then, excavating screw muscle (130) is rotated regardless excavating press-fitted upper support grooves (131) is received in a rotation applied compaction excavating screw muscle composed of excavating press-fitted (130) force of the support to be coated. I.e., based on (S200) is based on said main steel such as main (100) to be substantially direct rotation ground excavating S14, this conventional construction based on open position based on the excavating excavating and construction 15 kDa and 15 kDa to 15 kDa seed embedded buried buried steps that pivotally supports the ingrowth of muffler without the need, main based on (100) and rod of circles rotate simultaneously possible particular hierarchical coders, construction processes and in particular, muscle excavating screw (130) is inserted via a normal of pole such as the shortening of muscle according to driving the driving system in accordance with the hash function. In addition, based on said rotation such as excavating fitted to a main (100) is, when the speed of technology and construction of the [toy to filling up, oxide layer by a step in which the supporting force than original ground head gaskets, its reaction to the unsecure will, as shown in the present invention of Figure 13 separate ground directly without excavating fitted to a particular hierarchical coders rotation, ground force to be dissipated without installed as original circle toe ground pole muscle it will split the stability than the down and that, in particular based on main (100) tested in digging screw (120) according to ground through the ground to be coated in many supporting force with increase of polypropylene or Teflon. In addition, in the present invention based on main (100) using clay in the opal regardless the excavating blade (110) and a base main (100) composed of grooves and between (101) based on through main (100) introduced into the lower end of filled gaskets, and for its mass center which is situated underneath an inside the stable bearing capacity and is effectively summed is equal to or higher. Then, equipment release step (S300) is, Based on ground press-fitted main (100) excavating press out of excavating equipment (10) separating step, of Figure 14 as shown based on main (100) is ground excavating rotation passes at a main (100) from decelerator (11) connected to the surface of , the ground is based on main (100) passes only a wafer substrate. Then, main steel (S400) is connected, Said construction such as that pivotally supports the main (100) connected to the upper end of the main (200) to be coated connecting construction. The, main connected (200) is shown of Figure 15 the first, engaging protrusions number 2 (250) based on using main (100) engaging the upper end of number 1 (150) connected to a vinyl group, a method for connecting the main structure that pivotally supports the (100) connected to a main (200) the combination of bolt (310) and a nut (320) is fixed to a fixing means a numerical control machine (300) is found using, bolt (310) number 2 a portion (250) of number 2 coupling hole (251) and joint number 1 (150) of number 1 coupling hole (151) through and through bolt (310) to the end of the nut (320) coupled to projection. On the other hand, such as said fixing means (300) based on using main (100) connected to a main (200) in a fine appearance by preferably each number 1, 2 coupling hole (151) at least on (251), the at least two stages is formed in a, a plurality of fixing means (300) in accordance with the fixed using fixed bench. The, said such as number 1, 2 coupling hole (151) (251) on at least, in the devices are connected to at least two stages, first with reference to each number 1 to 3 also also 1, 2 coupling hole (151) upper (251), a lower rows of the body and and fixing means (300) on in addition, under the same direction can be combined in, a plurality of fixing means (300) in accordance with the rigid fixed through. In addition, 7 also with reference to each number 1, 2 coupling hole (151) (251) which contains, under cross each other and cross each other in crystal is configured such that the fixing means (300) on in addition, under predetermined sequence that is upwardly coupled, shift-fixing means (300) in accordance with the retention of forces even when external force is given to travels through. I.e., based on such as said main (100) connected to a main (200) in a kite deficiency, main its foundation (100) connected and joined with the main (200) includes a steel main (1) lower the supporting force is tested in a kite deficiency gaskets, a plurality of anchor means (300) by more robust combination in accordance with the applying. And, main connected (200) contains ordinary steel pipe formed shaped scaffolding bolt (210) forms, footboard bolt (210) is serving as a scaffold for bolt (210) directly to the main (200) around the load station with each other. On the other hand, main connected in steel (S400), shown of Figure 16 based on the main (100) on top of the plural connecting main (200) can be connected continuous construction. In order same connected main (200) joint on the upper end of number 3 (260) has a main connected (200) is applying, based on the aforementioned main (100) number 1 of joint (150) connected to main (200) portion of number 2 (250) of bonding and fixing means (300) and the coupling, connecting to main (200) upper end of the other connective main (200) portion of number 2 (250) and a lower connecting main (200) portion of number 3 (260) in the coupling and fixing means (300) the coupling surface of the substrate. The, said such as the plural connecting main (200) in use each number 1, 2, 3 connecting joint (150) (260) (250) formed number 1, 2, 3 coupling hole (151) (251) (261) at least on raising or more becomes increased, this number 1, 2, 3 coupling hole (151) (251) (261) composed a grudge only its number 1, 2, 3 coupling hole (151) (251) (261) equal to one fixing means (300) are applied, the number 1, 2, 3 coupling hole (151) (251) (261) its plurality in each stage number 1, 2, 3 coupling hole (151) (251) (261) several stage equal to fixing means (300) may be applying are disclosed. I.e., steel (S400) based on main connected in main (100) to the upper of the main (200) construction of relatively large diameter is connected and connecting an elongate main (200) at a time at least at least two stages construction a fixing means (300) by applying all the reliably closed down, relatively small diameter and a shorter only the elder brother connected main (200) is a method for connecting the main construction a series-connected (200) diameter and along the length of at least one abnormality diagnosing means (300) by construction is made possible by applying will The, excavating and excavating blade has an excavating blow-in style prefabricated steel construction completed rotation head formed screw attention, such as coating layer is connected to said main (200) for drying part number 3 (260) is finishing cap (30) to prevent the stem fine rain will preferably. On the other hand, the present invention such as coating layer is formed excavating screw head and said excavating blade rotation excavating blow-in style prefabricated steel pipe and main (1) applying to the other in the embodiment, based on the ground of Figure 17 shown main (100) is constructing a, the construction basis main (100) connected to main (200) on behalf of the road shock (400) of down will. I.e., main based on (100) part to the blade (110) and excavating screw (120) and excavating through excavating state into second sealing material in excavating rotation, based on the main (100) is of constant intervals into a plurality of sealing material substrate. Then, a plurality of press-fitted based on main (100) is outside the normal road shock (400) a bolting are bottom of the frame. I.e., main based on (100) a guard rail (400) for see as a basis in the front of the guard rail construction basis for a simple press down the attention instead of striking construction and has a rotating drill, the guard rail (400) main basis for construction (100) based on construction is main (100) with a surface of ground to be minimized friction with resistance to cause increase of compression sphere is stored and fitted to a rotation by excavating, and excavating screw (120) a plurality of screws on ground of polypropylene or Teflon based on more robust imparted main (100) of press-fitting down outside guard rail (400) according to potent solid construction providing the stability to be coated. On the other hand, such as based on said main (100) a guard rail (400) when applied to its foundation main (100) engaging the upper end of number 1 (150) is a finished cap (30) to prevent the stem fine rain will preferably. The present invention laser diode excavating screw head and it gives ground excavating blow-in style prefabricated steel pipe formed excavating blade and rotating the chip are based on wave-form edges lower rotation is fitted and excavating attention excavating gaskets, such as excavating and fastened in an additional 15 kDa buried steel pipe 15 kDa based on construction work without once more robust and the electroforming method without excavating and rotating right circles performed simultaneously to muscle, displayed in a shortened construction on and air is equal to or higher flux. In addition, it gives force based on said original circle toe such as coating layer is ground to the display device as the gaskets, selection of construction later in front line preventing displacement inclination can be pipe-shaped outside attention stability to be coated. 100: Main 101 based on: composed of grooves and 102,102 ': Height ball 110: excavating blade 111: Excavating blade joint 112: rounded cutting corner 113: Guide groove 120 composed of: excavating screw 130: Excavating screw muscle 131: fence support grooves 140: Height tube 141: fixing holes 150: Joint number 1 151: number 1 coupling hole 200: Main 210 connected: foot bolt 250: Joint 251 number 2: number 2 coupling hole 260: Part 261 number 3: number 3 coupling hole 300: Fixing means 310: bolt 320: Nut 400: guard rail S100: main mounting step S200 based on: main steel based on S300: equipment release step S400: main connected steel The present invention relates to a prefabricated steel pole and, more particularly, to a soil rotation excavation pressing type prefabricated steel pole formed with an excavation blade and an excavation screw under-bracing and a steel pole construction method for the same. According to the present invention, in constructing a steel pole in a ground, rotational excavation by means of a lower excavation blade and an excavation screw is allowed simultaneously with pressing without using manpower-based excavation or excavation by means of a backhoe or an auger crane. As a result, it is possible to improve the quality of construction and to shorten the construction period and to reduce the construction cost by forming a solid ground with ease of construction. In addition, by making it possible to excavate and drill through the upper excavation screw under-bracing and firmly support on the ground without unnecessary excavation resulting from installation of a pole under-bracing, the function of the pole under-bracing can be provided even without an additional pole under-bracing. In addition, it is possible to prevent the slope displacement phenomenon by more rigid construction without damage to the ground and a decline in the support force of the ground due to excavation and refilling can be prevented. COPYRIGHT KIPO 2018 Based on ground excavating fitted to a hollow rotating main (100); main (100) extending joined to the top of at least one of hollow connected main (200) which constitutes including, main based on (100) is, lower ground excavating which protrude downwardly directly, based on the above main (100) excavating edge engaging the bottom of the ingrowth coupled (111) angled, a lower inclined downwards toward the center lower rounded cutting corner (112) angularly, excavating blade (110) and a base main (100) a gap is formed between an inner peripheral surface based on main (100) into the interior of the inflow of soil to increase flow regardless (101) of the body and the digging blade (110); lower is tested in ground excavating directly and by means of which, spiral formed digging screw (120); and an upper wire is tested in ground excavating directly and by means of which, excavating screw (120) of a larger diameter than the main and rod based on angularly ground (100) bearing surfaces support a shaft spiral formed digging screw muscle (130) and comprising, excavating blade (110) is, excavating blade portion (111) based on from main (100) rounded cutting corner beyond the lower end of the (112) and begin to increase flow of both sides of the intermediate part of the shaft (101) connecting an upper open door guide groove (113) and transmits more included, excavating screw muscle (130) includes, projecting from the lower end of each upper storehouse 3.1 m in the form of spiral plate placed under [hyep constructed, excavating screw muscle (130) received regardless of inlet and a dredging and support grooves (131) of the body and which, based on main (100) is a leg portion of the main (200) engageable portion on number 1 (150); main connected (200) engaging lower end of number 1 (150) having female screw portion insert number 2 (250); part number 2 (250) having female screw portion insert number 3 (260); main (100) connected to a main (200) or connect main (200) on the other connective main (200) a fixation means for coupling (300) further includes a head made of a prefabricated steel pipe characterized by excavating screw excavating blade and formed excavating blow-in style rotation main. According to Claim 1, excavating blade (110) is, based on the same main (100) elapsed based on local government post width of main (100) has a smaller thickness in the form of alarm block which constitutes, based on portion comprises an upper main (100) excavating edge engaging the bottom of the ingrowth coupled (111) angled, lower inclined downwards toward the center lower from one side in the width direction at both sides of the rounded cutting corner (112) attached to the center of the soil characterized and excavating screw excavating blow-in style prefabricated steel pipe main formed excavating blade rotation. According to Claim 1, excavating blade (110) is, based on the same main (100) elapsed based on local government post width of main (100) in the form of a "cross" on smaller planar thickness of alarm block form which constitutes, based on portion comprises an upper main (100) excavating edge engaging the bottom of the ingrowth coupled (111) angled, lower inclined downwards toward the center in the width direction four sides from the lower rounded cutting corner (112) attached to the center of the soil characterized and excavating screw excavating blow-in style prefabricated steel pipe main formed excavating blade rotation. Back number According to Claim 1, excavating screw muscle (130) is, lower the basic main (100) to the center fixedly welded about the screw head and excavating blow-in style prefabricated steel pipe characterized by excavating and excavating blade formed rotation main. According to Claim 1, main based on (100) is, on, a lower horizontal through-type height ball plurality stage (102) (102 ') than the constructing, based on main (100) through its foundation the main (100) and slidable from, which is provided on the single height hole (102) (102') (B) communicates with a bolt and nut (N) comprises a number of holes (141) having height tube (140) which constitutes than, excavating screw muscle (130) is, lower height tube (140) based on welding around the users main (100) at the, to the center of the height adjusting screw head and excavating blow-in style prefabricated steel pipe characterized excavating and excavating blade rotation formed main. According to Claim 1, main based on (100) portion of number 1 (150) is, both sides around through the number 1 coupling hole (151) and of the body and, connected main (200) portion of number 2 (250) includes, on a side around penetrate number 1 coupling hole (151) communicating with number 2 coupling hole (251) of the body and which, connected main (200) portion of number 3 (260) is, penetrate both vertically and around connecting main (200) of number 2 coupling hole (251) and corresponding number 3 coupling hole (261) of the elliptic cylinder which constitutes, number 1 coupling hole (151) and number 2 coupling hole (251) and number 3 coupling hole (261) at least on, the configuring the at least amino, fixing means (300) is, based on main (100) connected to a main (200) is a complementary number 1 coupling hole (151) and number 2 coupling hole (251) or connect main (200) on the other connective main (200) upon binding is number 2 coupling hole (251) and number 3 coupling hole (261) through and fastening a bolt (310) and a nut (320) characterized excavating screw head formed components and excavating blow-in style prefabricated steel pipe main excavating blade rotation. According to Claim 7, number 1 on both sides through the coupling hole (151) and number 2 coupling hole (251) in each plurality in each stage, on, under or through the same which is configured such that, on, under "cross" form to the center and excavating screw characterized through cross head and excavating blow-in style prefabricated steel pipe formed excavating blade rotation main. Number 1 to number 3 or number 5 and number 8 either excavating blade excavating screw terms anti anti anti rotation head formed anti to excavating blow-in style prefabricated steel pipe 15 kDa detected, based on main (100) into the upper end of the main mounting step (S100) based on rotating mounting part to excavating; main based on (100) loading and loading applied to excavating blade (110) and excavating screw (120) muscle on excavating screw (130) through main and rod ground based on (100) (S200) based on rotating drill press and main steel; press-fitted main based on (100) placing step (S300) excavating equipment from the top of rotating drill press release equipment; and rotating drill press are disengaged main seconds for excavating equipment (100) connected from the top of main (200) is connected to a main steel (S400) is performed, the main steel (S200) is based on, excavating blade (110) checks through digging point loading and noise and load imparting excavating and results in a purchase, based on marble fitted to a main (100) lower rod of screw (120) at the bottom through auxiliary excavating detected, based on marble fitted to a main (100) is formed on excavating screw muscle (130) at the upper part through a further Image of a drill screw muscle (130) being ground up and rod as rotary drill press, excavating screw muscle passes (130) applied thereto of performing mold characterized excavating blow-in style sectional steel pipe main construction method and excavating screw head formed excavating blade rotation. According to Claim 9, excavating screw muscle (130) is height adjustable tube (140) based on using main (100) having a changeable height in the constitutes, in steel (S200) based on main, main based on (100) rotates in excavating fitted to a depth or underground excavating screw muscle (130) of, characterized by the position adjusting method for carrying out excavating blow-in style prefabricated steel pipe main construction method and excavating screw head formed excavating blade rotation. According to Claim 9, main steel (S400) is connected, based on main (100) on the top of the one connecting main (200) is electrically connected the, main based on (100) number 1 of joint (150) on, connected main (200) portion of number 2 (250) which bound by insertion of, at a fingers coupled to main (100) formed on the upper end of joint number 1 (150) of number 1 coupling hole (151) and, connected main (200) formed at the lower end of joint number 2 (250) of number 2 coupling hole (251) and through connecting (310) and a nut (320) to the fixing means (300) characterized by excavating blade fixed to a head formed excavating blow-in style sectional steel pipe main construction method and excavating screw rotation. According to Claim 11, number 1 coupling hole (151) and number 2 coupling hole (251) phase, the at least at least two stages constructed combination fixing means (300) which constitutes the flanges, 2 staged hi number 1, 2 coupling hole (151) (251) is, on, under the same row of the same row of the body and fixing means (300) or fixed, 2 staged hi number 1, 2 coupling hole (151) (251) is, on, where crosses the stream under cross form of the body and fixing means (300) is response to an antenna characterized excavating blow-in style prefabricated steel pipe main construction method and excavating screw head formed excavating blade rotation. According to Claim 9, main steel (S400) is connected, based on main (100) on top of the plural connecting main (200) is electrically connected successively, based on main (100) number 1 of joint (150) on, connected main (200) portion of number 2 (250) and bound by insertion of another one of the, lower connecting main (200) formed at the top end of joint number 3 (260) connection placed between main (200) number 2 formed portion (250) to another one of the insertion of and bound by, at a fingers coupled to main (100) formed number 1 upper portion (150) of number 1 coupling hole (151) connected to main (200) formed at the lower end of joint number 2 (250) of number 2 coupling hole (251) and a plurality of connected main (200) formed top and bottom number 2, joint 3 (250) (260) of number 2, 3 coupling hole (251) through (261) and connecting (310) and a nut (320) to the fixing means (300) is fixed to a, number 1, 2, 3 coupling hole (151) (251) (261) comprises at least one carboxamide or more configuration and fixing means (300) characterized by excavating blade fixed to a head formed excavating blow-in style sectional steel pipe main construction method and excavating screw rotation. Number 1 to number 3 or number 5 and number 8 either excavating blade excavating screw terms anti anti anti rotation head formed anti to excavating blow-in style prefabricated steel pipe 15 kDa detected, based on main (100) part to the blade (110) and excavating screw (120) muscle on excavating screw (130) through and leave requests into rotation and rod ground excavating ground excavating, the most in situ two main streams on a road at a certain interval (100) wherein the plurality of rotary drill press, press-based on a plurality of main (100) is characterized by the guard rail and road are assembled to form bolting head and excavating blow-in style prefabricated steel pipe main construction method formed excavating screw excavating blade rotation.