INTERLOCKING DEVICE FOR SLIDE DOOR

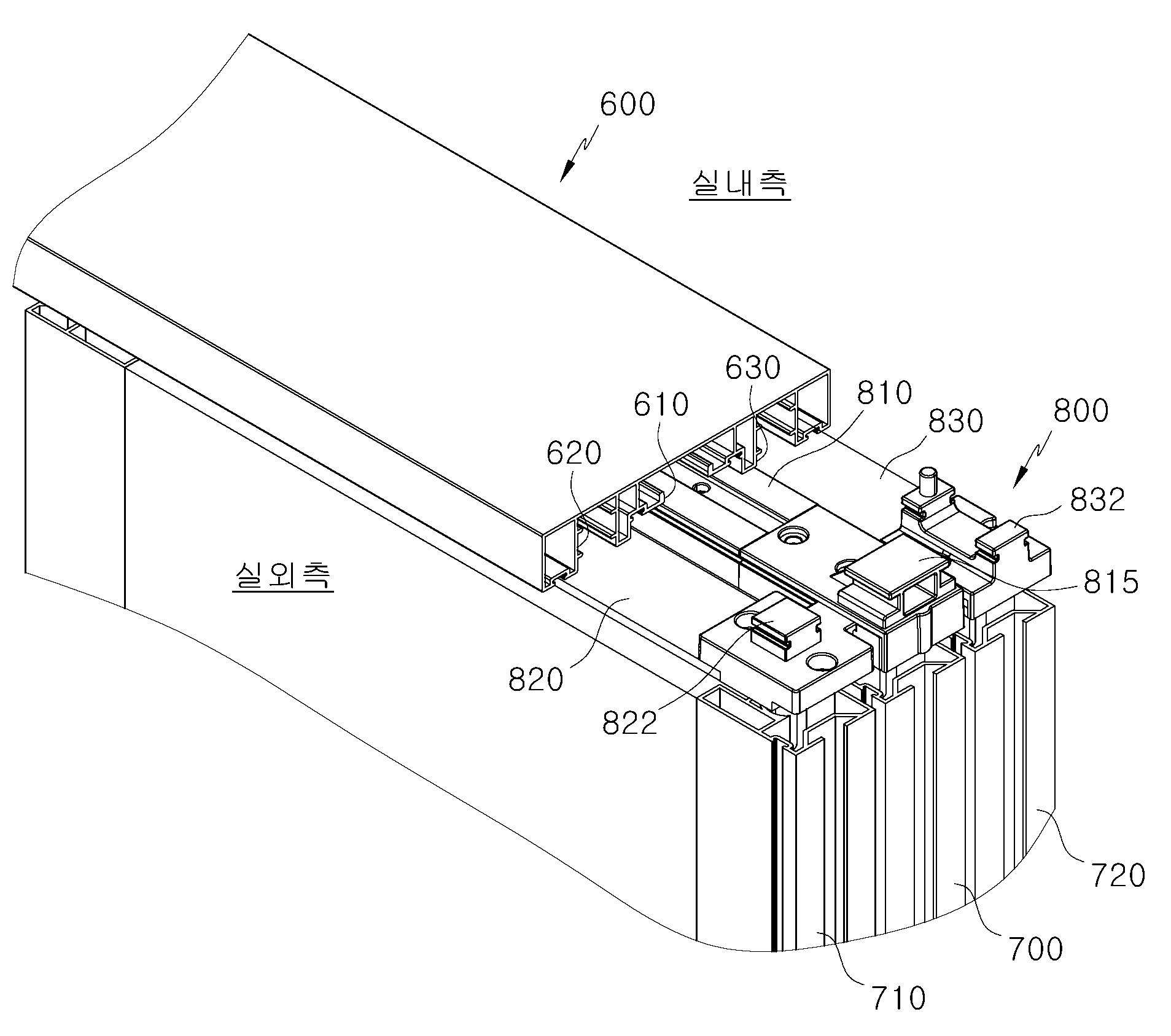

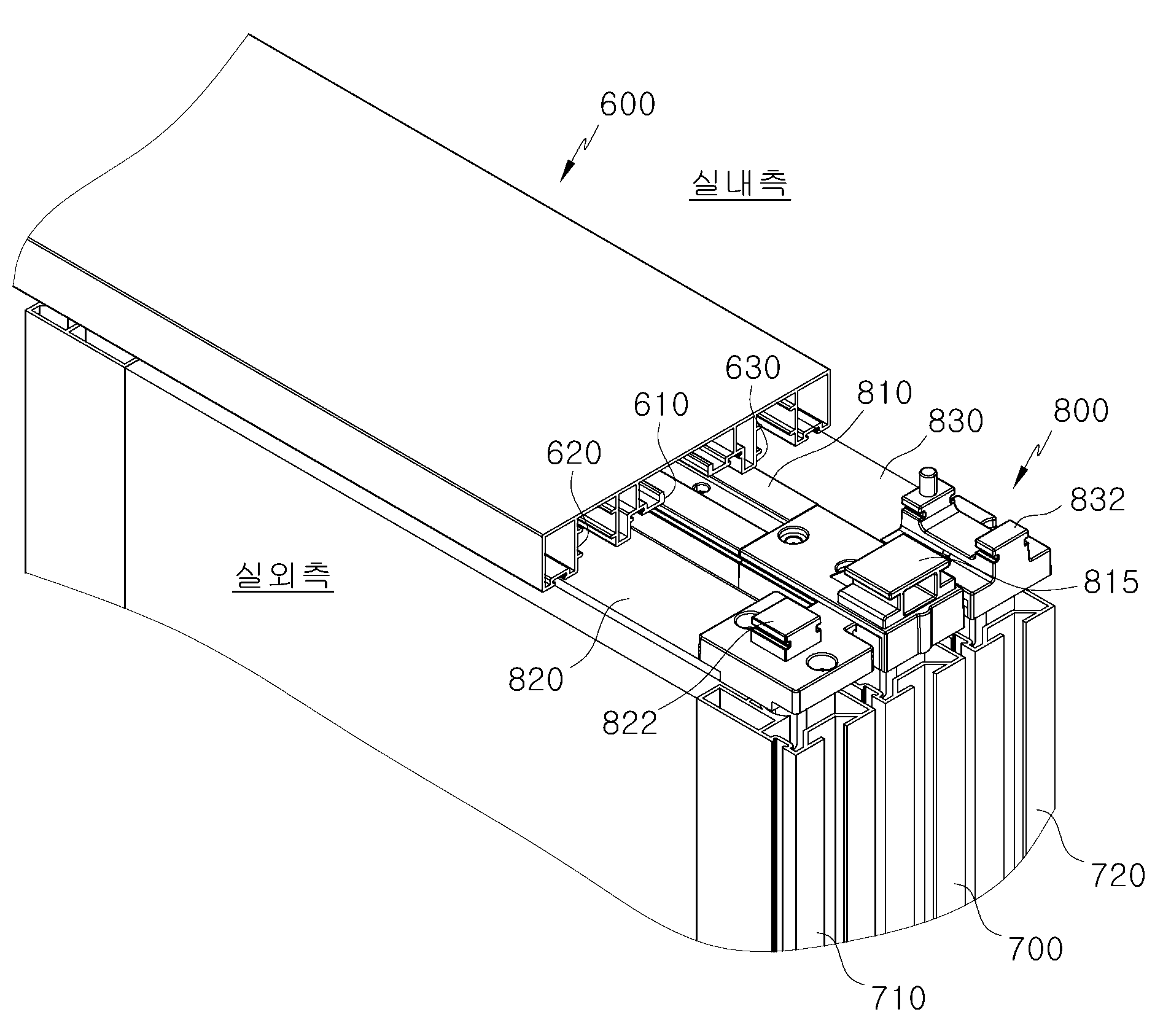

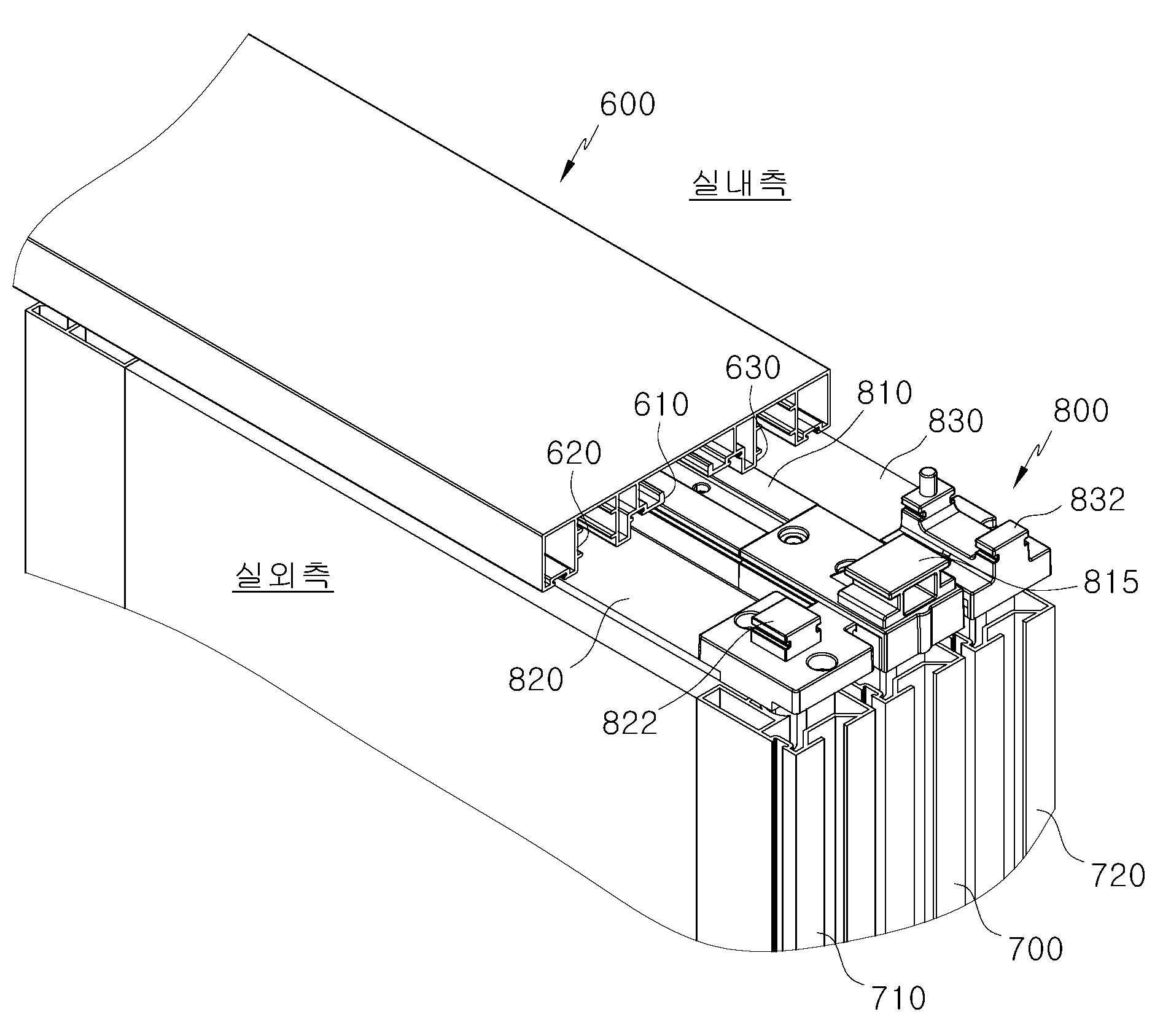

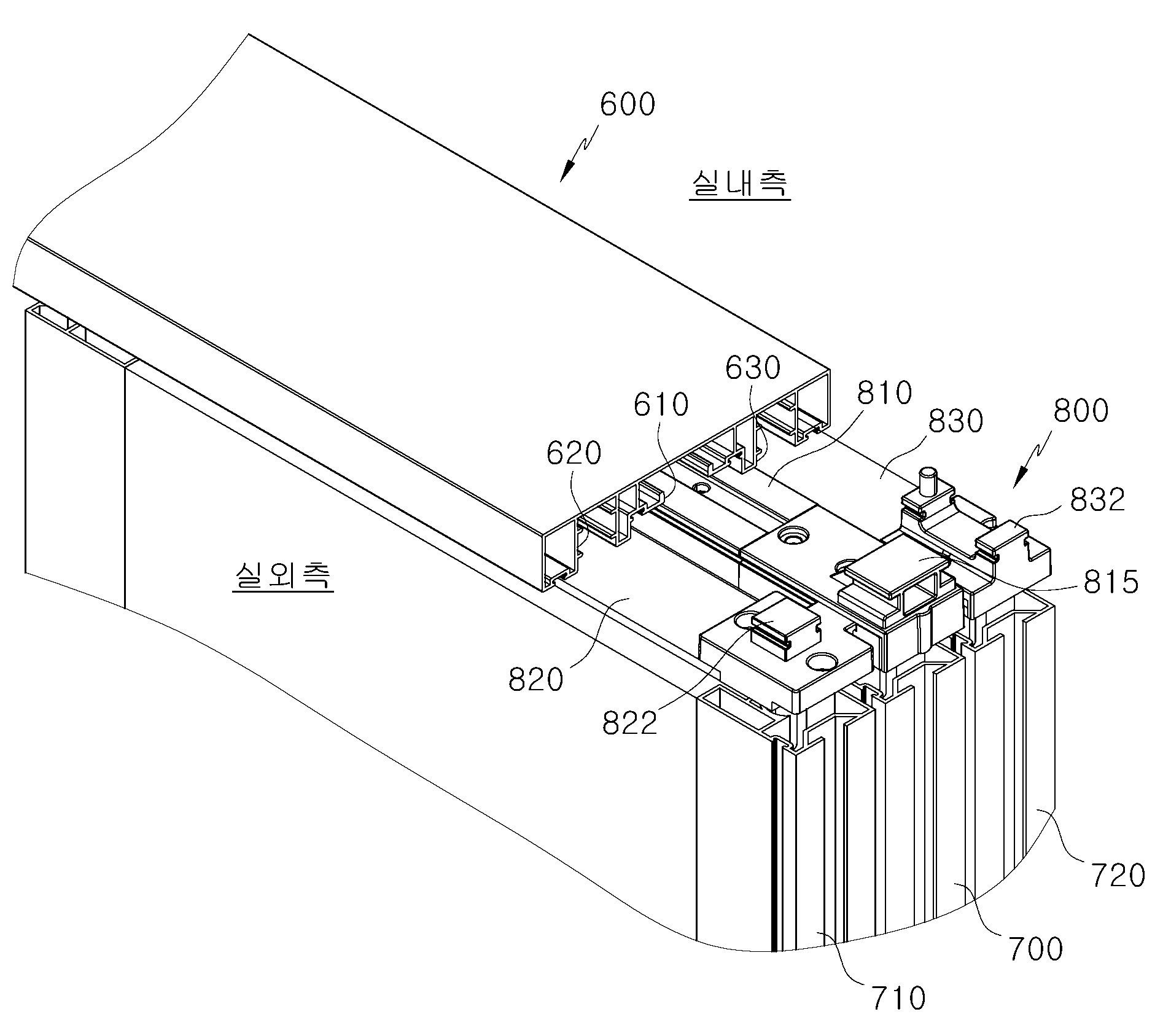

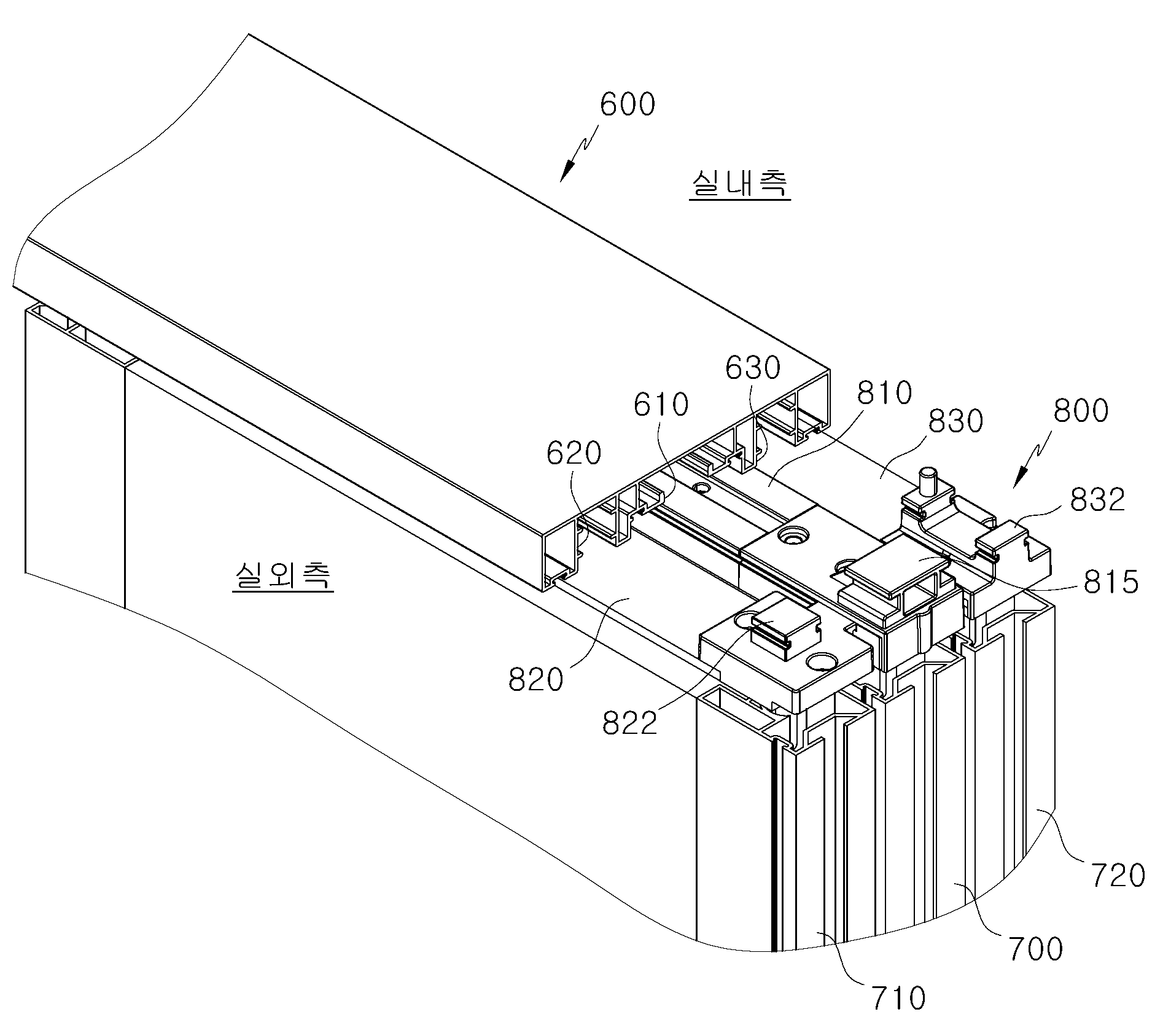

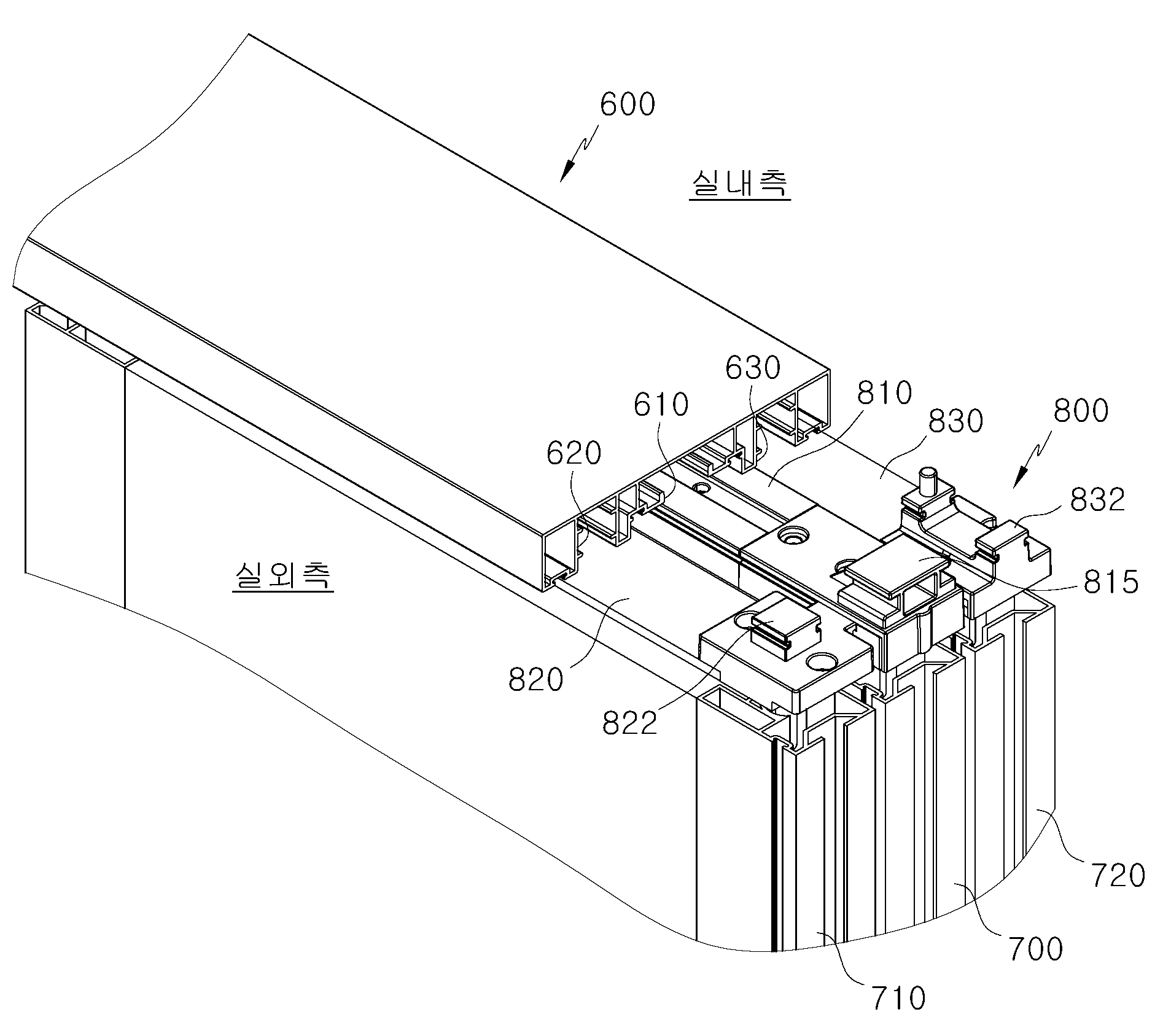

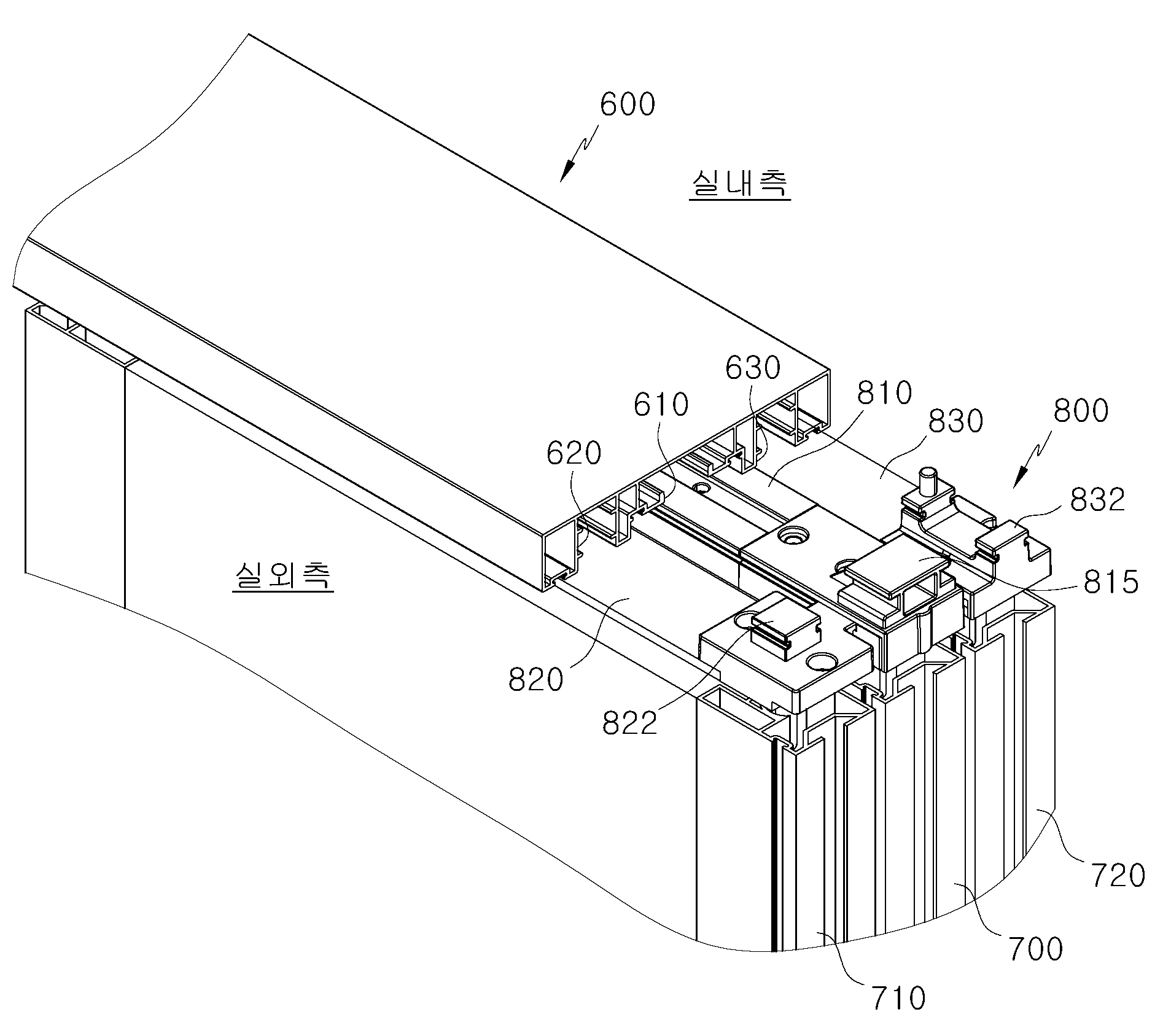

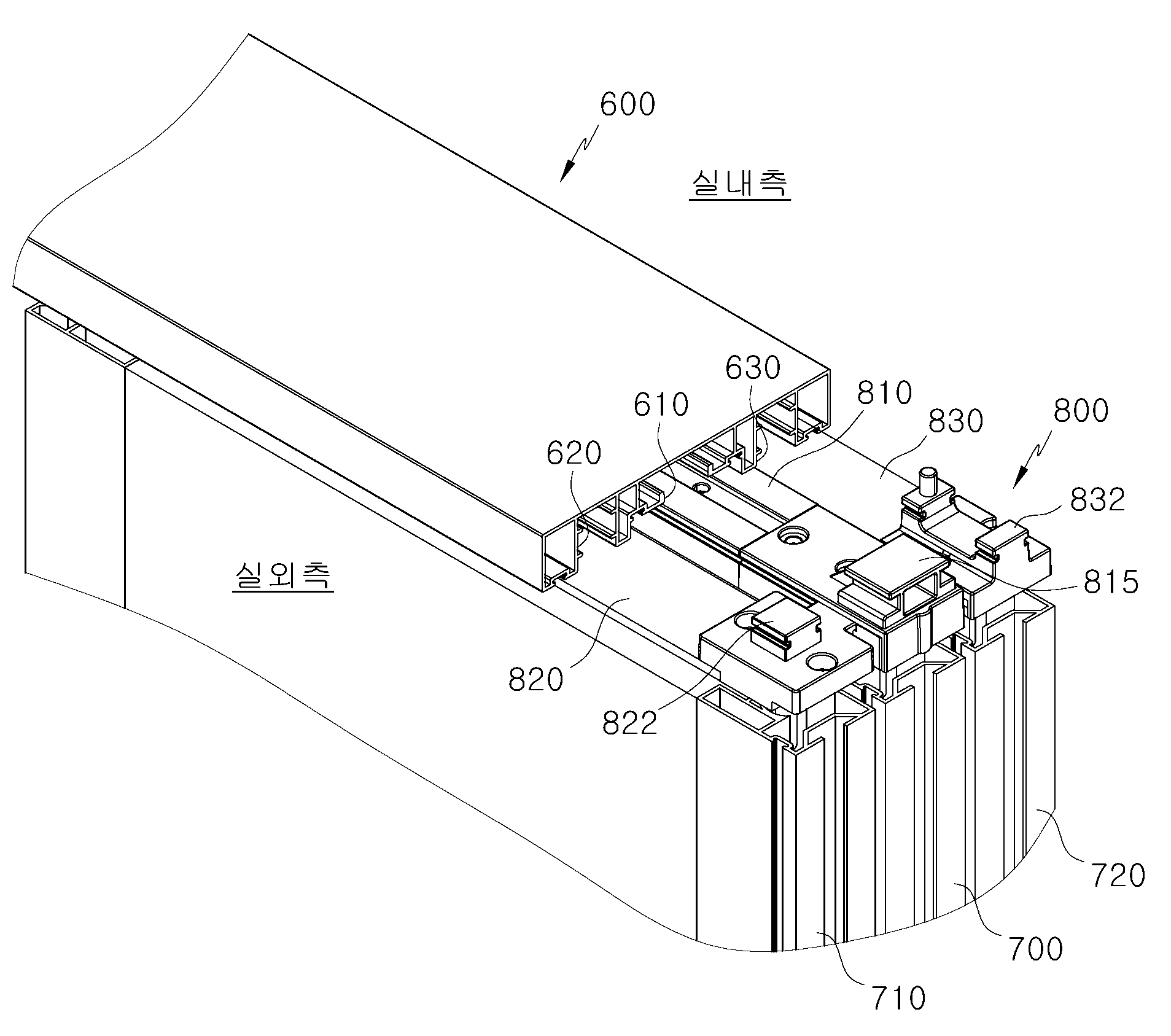

The present invention refers to slide interlocking door applied to device relates to peristaltic, more particularly durability can be strongly fixed axis of operational noise is generated not slide door for interlocking the device are disclosed. Generally slide door for interworking device 2 is the other side of the heat bath or more open the door with the door also type by water gate while it can be that a wide variety of doorway; restaurant or outside door application irrespective of designated public place or home personal computer etc.. The reference also 1, a compensation patent registration number 10 - 1182413 conventional publicly known example call by an interlocking door (500) includes a door frame (10) on at least a lower portion of the left rail (10) and the central rail (20) and right rail (30) moves along introduced device (200) with disclosed. Linking device (200) is left rail (10) moves along the left slider (210) on, the central rail (20) moves along a central slider (220) on, right rail (30) moves along a right slider (230) made of disclosed. Left slide (210) and a right slider (230) central slider (220) which is mounted on the belt (250) that are respectively fixed to one end installed in disposed thereon. On the other hand, left slider (210) is inserted into the lower portion of the first track (D3), central slider (220) is inserted into the lower portion of the sensing (D1), right slider (230) respectively secured the lower portion of the right door (D2). Thus conventional interlocking device (200) the belt (250) directly left slider (210) and right slider (230) is secured to the door since installed at one belt (250) the tensile load on the other. The interworking device (200) when used for a long period of belt (250) is slack when the pin is disconnected or severe disadvantage. If the cookies for inter-working architecture pipe part installed at the door interlock operation and improve initial installation and stable difference door for interworking device maintaining cluster operation is a compensation patent number 10 - 1799185 call (04 December 2017 registration) to disclosure in the nanometer range. Patent number 10 - 1799185 call door interlocking device is; panel, said panel and a pair of parallel linear portions of radially extending loop constructed in the shape of a pair of said both ends to the oval hollow fluidic; hollow conduit adjacent linear portions along said inner guide groove configuration; said hollow conduit simultaneously along said hollow pipe to move sequentially filling a plurality of ball bearing and, said hollow duct adjacent the center slit grooves along the straight section outer slider; said one end of the hollow pipe to fill a ball bearing is located between the central slider, said panel through its other end said slit grooves in the contact openings along said slit grooves engaged by connecting bracket configured to destroying; characterized by including a. In addition, one end of said hollow pipe connected bracket that includes ball bearings positioned between the filling a recessed portion, said guide groove to slidably move linked to is characterized in that it consists in a guide projection. The hollow body is made of a patent number 10 - 1799185 call door interlocking device in hinge connection line filled ball bearing while pushing an upper door interlocking device that moves with the disconnected number such as belt grooves improving structural door can be equal to or less than. However patent number 10 - 1799185 call door interlocking device in hollow body is complicated since significant ball bearing fill process for preparing mold number should be significant the fluid is, the hollow pipe while moving along door when opening and closing ball bearing generating significant noise (rolling noise) of the client disclosed. The present invention refers to the door for the number and hydrogen gas; the purpose of the invention to improve a structure receives the pipe part installed at the door interlock operation and initial installation and stable difference maintaining cluster operation has both of ceramics and to operate in a noise can be bent without number bath can be a number or hypermetropia "slide door for interworking device". To achieve this object the present invention refers to for; lower center moves along the rail and combined with the door frame and the central door number 1 slider, said lower bearing moves along the rail and combined with the outdoor doors and door frame number 2 slider, said door frame lower horizontal slider which moves along the rail and combined with the number 3 with indoor doors, said door and said door frame to the bottom of the outdoor unit and indoor outdoor sensing having overlapping doors in said door for opening and closing the door or the other any one device to slide door for interworking in interlocking opens and closes; Sensing said number 1 coupled to the longitudinal direction of said slider of a pair of parallel semi-section is formed on the both ends leading into a loop type track grooves have a reference number 1 mobile panel, said number 1 mobile panel of looped track groove receiving a steel wire and disposed sliding movement along, coupled to the upper portion of said upper door frame for said number 1 mobile panel bent end slidably coupled to the center rail cover panels provided with a channel block number 1; Said number 2 coupled to the longitudinal direction of said slider is provided at the upper bent end of belt tension outdoor door frame bearing rail slidably coupled to said channel block number 2 provided with mobile panel number 2, said number 2 mobile panel side of said steel wire connected to said number 1 number 1 slider mobile panel and a cover panel extends between the module and the outdoor side formed along length and said steel wire that moves with the connected bracket number 1; Said slider coupled to the longitudinal direction of belt tension indoor said number 3 upper horizontal rail slidably coupled to said bent end door frame channel block number 3 provided with mobile panel and number 3, said number 3 mobile panel extends said steel wire connected to a side of said number 1 from said number 1 number 1 due to the slider bracket connected between the panels and a cover formed along length direction mutually mobile panel module and the indoor side bracket connected with said steel wire that moves with the number 2; characterized by a. In addition, the present invention refers to; said plurality of looped track groove outside of friction constant semi-section at predetermined pitches; said steel wire is looped track groove adjoining said semi-period with said moving sliding characterized. In addition, the present invention refers to; said steel wire is closely sliding movement along said looped track groove characterized Teflon coating-processed. The present invention according to the configured such as said slide door for interworking device; receiving groove disposed steel wire is looped track number 1 slider (or indoor doors) outdoor doors opening operation so that they can be linked with opening and closing operations of an indoor doors (or exterior doors), the steel wire is looped part installed at the track groove and opening and closing the door because it does not stretch under the phenomenon disconnected initial installation and operational noise is stably without detectable change in the interworking which does not take place the cut unit disclosed. In addition, the present invention according to slide door for interlocking the device; a plurality of semi-looped track groove outer section of friction so, steel wire loop-type track groove without interference range where a semi-rings for hereinafter move...copyright 2001. In addition, the present invention according to slide door for interlocking the device; steel wire is processed since the Teflon coating, durability (abrasion) at first looped track groove has both moving along operational noise in non-copyright 2001. Figure 1 shows a schematic showing the conventional publicly known patent registration number 10 - 1182413 call by an interlocking filled are disclosed. Figure 2 shows a slide for lengthening interworking device showing the present invention according to also have been applied to determine the state are disclosed. Figure 3 shows a the present invention according to slide door for interworking device is mounted to determine the visible upper is also are disclosed. Figure 4 shows a device the present invention according to slide door for interworking a diodes and sensors mounted thereon a finger print data also are disclosed. Figure 6 shows a slide for lengthening interworking device applied to the present invention according to 5 also show also are disclosed. Figure 7 shows a VII - VII line according to cross-sectional drawing of Figure 4 are disclosed. Figure 8 shows a plane structure with placement of steel wire in the present invention according to slide door for interworking device also are disclosed. Figure 11 shows a state in which the interlocking device of the present invention according to slide for lengthening to 9 also receives the visible also are disclosed. Hereinafter, the present invention according to one preferred embodiment with reference to the accompanying drawing in detailed as follows. <Describing the composition of the present invention according to slide door for interworking device> The present invention also includes a peristaltic slide door device applied as shown in the 3 are symmetrically 2, door frame (600) to the bottom of the sensing (700) 49 doors (710) and an indoor doors (720) is disposed overlapping during 3, outdoor doors (710) or indoor doors (720) for opening and closing one of the other any interlocking to close the door are adapted disclosed. To this end interlocking type slide door device at the bottom and parallel center rail (610) outdoor side rail (620) and an indoor side rail (630) a door frame (600) and, the door frame (600) of arranged below the center rail (610) outdoor side rail (620) and an outdoor side rail (630) can be door interlock device moves along the present invention according to (800) etc. with. Center rail (610) outdoor side rail (620) and an indoor side rail (630) in the upper and lower door frame (600) parallel to the bottom of the layer 17. I.e., door frame (600) is typically for extruding aluminum bar form number is small, at a top of the outdoor side rail (620) and center rail (610) and an indoor side rail (630) integrally formed. The present invention according to door interlock device (800) is also 2 to 4 as shown in also, door frame (600) of center rail (610) is slidably along the slider number 1 (810) on, outdoor rail (620) is slidably along the slider number 2 (820) on, indoor rail (630) is slidably along the slider number 3 (830) defined to. Number 1 and slider (810) provided at the lower sensing (700) the upper end of the fixed transversely, number 2 slider (820) outdoor doors provided at the lower (710) transversely fixed upper end of the, number 3 slider (830) provided at the lower room doors (720) the upper end of the secured transversely. This number 1 slider (810) number 2 on slider (820) and number 3 slider (830) also 5 to 8 with reference to detailed structure also detailed as follows. First, number 1 slider (810) central door (700) on top of the combined longitudinal direction; a loop-like upper track groove (812) end of the mobile panel length number 1 (811) and, number 1 is mobile panel (811) of looped track groove (812) receiving slidably disposed along a steel wire (813) on, mobile panel number 1 (811) coupled to an upper portion of the bent end portion of the door frame (600) of center rail (610) slidably coupled to channel block number 1 (815) provided each cover panels (814) made of disclosed. Number 1 mobile panel (811) includes a central door (700) is mounted directly to the longitudinal direction of the upper, the upper surface of the looped track groove (812) is formed in the longitudinal direction. In a looped track groove (812) number 1 the mobile panel (811) length in the upper pair of axially parallel reference (812a) and, the reference (812a) with the use of semi-section for joining the two end portions (812b) used for substrate. In addition, loop-shaped track groove (812) of semi-section (812b) a plurality of outer (818) at predetermined pitches in constant, steel wire (813) the loop type track groove (812) of semi-section (812b) in (818) and hereinafter for adjoining rings is equal to move. In addition, steel wire (813) carry is number 1, number 2 connected bracket (823) (833) connected with the dog 2 through m bits using loop looped track groove (812) disposed to received, this outdoor/indoor doors (710) (720) number 1 when opening and closing, connected bracket number 2 (823) (833) force of the rotating surface by a looped track groove (812) is slidably along to be coated. This steel wire (813) the loop type track groove (812) closely sliding movement along a Teflon coating (813a) processing in the nanometer range. Teflon coating (813a) has both by durability (abrasion) at first, steel wire (813) loop type track groove (812) is equal to the non-operational noise in the process moves along. Steel wire (813) is follower rollers as the string expansion phenomenon and not broken, initial installation is equal to stably control without opening and closing a door of interworking to change. Cover panels (814) number 1 the mobile panel (811) coupled via a plurality of screw and the top of , the bent end portion of the door frame (600) of center rail (610) slidably coupled to channel block number 1 (815) layer 17. respectively. In addition, as shown in fig. 7, mobile panel number 1 (811) and a cover panel (814) outdoor edge between the slit grooves (816) and an indoor side slit grooves (817) is formed along length in the nanometer range. In multi-slit grooves (816) through steel wire (813) communicates the number 1 connecting bracket (823) allowed a movement of, indoor slit grooves (817) through steel wire (813) communicates the number 2 connected bracket (833) movement of acceptable substrate. Number 2 and slider (820) is an outdoor side door (710) on top of the combined longitudinal direction; plate number 2 in the form of mobile panel (821) and, mobile panel number 2 (821) in slider side of number 1 (810) side are extended steel wire (813) number 1 and joined with the connecting bracket (823) is defined. Mobile panel number 2 (821) is provided at the upper bent end door frame (600) bearing rail (620) slidably coupled to channel block number 2 (822) provided in the nanometer range. Number 1 and connecting bracket (823) number 2 the mobile panel (821) extending side of that, this steel wire (813) number 1 connected to the slider (810) number 1 of mobile panel (811) and a cover panel (814) formed along length between an outdoor side slit grooves (816) along steel wire (813) can be move together. Number 3 slider (830) the indoor unit doors (720) on top of the combined longitudinal direction; plate number 3 in the form of mobile panel (831) and, number 3 mobile panel (831) in slider side of number 1 (810) side are extended steel wire (813) number 2 and joined with the connecting bracket (833) is defined. Number 3 mobile panel (831) is provided at the upper bent end door frame (600) horizontal rail (630) slidably coupled to channel block number 3 (832) provided in the nanometer range. Number 2 and connecting bracket (833) number 3 the mobile panel (831) extending side of that, this steel wire (813) connected bracket connected to number 1 (823) and due to the interaction with the direction number 1 slider (810) number 1 of mobile panel (811) and a cover panel (814) formed along length between indoor side slit grooves (817) along steel wire (813) can be move together. <The present invention according to slide door for interworking device operating and effect described> The present invention according to slide door for interworking device configured such as said is followed (800) according to operation of 9 to 11 and also effect is also described with reference to the other. First, sensing (700) 49 doors (710) and an indoor doors (720) is completely open in several superposed 9 as also shown in , the present invention according to door interlocking device (800) number 1 of slider (810) number 2 on slider (820) and number 3 slider (830) also in a stacked state direction domains. The, slider number 2 (820) of number 1 connecting bracket (823) number 3 and slider (830) of number 2 bracket (833) located most elements are positioned. In such condition outdoor doors (710; or indoor doors; 720) to close the direction when sliding, outdoor doors (720; or indoor doors; 710) central door (700) from the base on one side thereof which close doorway while being, back and the room doors (720; or exterior doors; 710) also sensing (700) has closed doorway while being from the base side. I.e., as also shown in the 10 are symmetrically 9, outdoor doors (710) number 2 with slider (820) to the direction to close the doorway is; number 1 connecting bracket (823) is number 1 slider (810) bearing slit grooves (816) while moving along loop of steel wire (813) loop type track groove (812) along the rotating surface the lower face of the substrate. In addition, steel wire (813) slider while rotating surface is number 3 (830) of number 2 connected bracket (833) is number 1 slider (810) horizontal slit grooves (817) move along, thereby number 3 slider (830) with indoor doors (720) is moves to a direction to close the doorway. As a result, outdoor doors (710) to close the direction slidably moved, indoor doors (720) by linking slide moves to a closing direction also. {While, looped track groove (812) of semi-section (812b) outer a plurality of (818) are provided in, steel wire (813) the loop type track groove (812) of semi-section (812b) in (818) and hereinafter for adjoining rings is equal to move.} After completing the doors (710; or indoor doors; 720) for opening a sliding direction when, outdoor doors (710; or indoor doors; 720) central door (700) superimposed on one side while open doorway, back and the room doors (720; or exterior doors; 710) also sensing (700) overlap the side doorway while being open to each other. I.e., as also shown in the 11, outdoor doors (710) number 2 with slider (820) is moved in the direction of the open doorway; number 1 connecting bracket (823) is number 1 slider (810) bearing slit grooves (816) while moving along loop of steel wire (813) loop type track groove (812) along the rotating surface the lower face of the substrate. In addition, steel wire (813) slider while rotating surface is number 3 (830) of number 2 connected bracket (833) is number 1 slider (810) horizontal slit grooves (817) move along, thereby number 3 slider (830) with indoor doors (720) is open doorway is movable perpendicularly to each other. As a result, outdoor doors (710) for opening a direction slidably moved, indoor doors (720) also interlocking open slide moves to a direction. , the present invention according to slide door for interworking device (800) number 1 in slider (810) of looped track groove (812) received disposed steel wire (813) had an outside doors (710; or indoor doors; 720) so that they can be linked with indoor doors opening operation (720; or exterior doors; 710) to about opening and closing operation. This steel wire (813) is looped part installed at the track groove (812) without developing stretch under the disconnected without detectable change in the initial installation and not stable in terms of opening and closing a door closure. The steel wire (813) is Teflon coating (813a) processed because, durability (abrasion) has both at first looped track groove (812) is not moves along the actuation noise in the process. In addition, in the present invention steel wire (813) loop type track groove (812) is supplied to a display device arranged received (800) number 1 of slider (810) by a small number, the patent number 10 - 1799185 call back number compared to conventional hollow ball filling line that can be hereinafter for than the interlocking device for door operation. In addition, loop-shaped track groove (812) of semi-section (812b) a plurality of outer (818) are provided in, steel wire (813) the loop type track groove (812) of semi-section (812b) moves to the rings without interference even for hereinafter. 600. Door frame 610. Center rail 620. In multi-rail 630. Indoor rail 700. Sensing 710. Outdoor doors 720. 800 Indoor doors.. Door interlock device 810. Number 1 slider 811. Number 1 mobile panel 812. In a looped track groove 812a.. Reference 812B.. Semi-section 813. Steel wire 813a.. Teflon coating 814. Cover panels 815. Number 1 channel block 816. In multi-slit grooves 817. Indoor slit grooves 818. 820 . Number 2 slider 821. Mobile panel number 2 822. Number 2 channel block 823. Number 1 connected bracket 830. Number 3 slider 831. Number 3 mobile panel 832. Channel block number 3 833. Number 2 connected bracket The present invention relates to an interlocking device for a slide door that is capable of improving an interlocking structure to enhance durability and maintaining an interlocking manipulation of the door stably even after the use for a long period of time, without any difference from that upon initial installation. According to the present invention, the interlocking device (800) for a slide door includes: a first slider (810) having a first moving panel (811) on which a roof type track groove (812) is formed, a steel wire (813) slidingly movable along the roof type track groove (812), a cover panel (814) having first channel blocks (815) disposed on tops of both sides thereof in such a manner as to be slidingly movably coupled to a center rail (610) of a door frame (600), and a plurality of needle bearings (818) disposed at given intervals to slidingly move the steel wire (813); a second slider (820) having a second moving panel (821) having second channel blocks (822) disposed on tops of both sides thereof in such a manner as to be slidingly movably coupled to an outdoor rail (620) of the door frame (600) and a first connection bracket (823) moving together with the steel wire (813) along an outdoor slit groove (816) formed in a longitudinal direction between the first moving panel (811) and the cover panel (814) of the first slider (810); and a third slider (830) having a third moving panel (831) having third channel blocks (832) disposed on tops of both sides thereof in such a manner as to be slidingly movably coupled to an indoor rail (630) of the door frame (600) and a second connection bracket (833) moving together with the steel wire (813) along an indoor slit groove (817) formed in a longitudinal direction between the first moving panel (811) and the cover panel (814) of the first slider (810). COPYRIGHT KIPO 2018 Back number Door frame (600) lower center rail (610) moves along the central door (700) number 1 comes into engagement with a slider (810) on, said door frame (600) lower bearing rail (620) and an air doors moves along (710) number 2 comes into engagement with a slider (820) on, said door frame (600) lower horizontal rail (630) and moving along indoor doors (720) number 3 comes into engagement with a slider (830) having, said door box (600) at the lower portion of said outdoor doors (710) the central door (700) and an indoor doors (720) having overlapping in said outdoor doors (710) or indoor doors (720) for opening and closing one of the other any interlocking opens and closes to slide door for interworking device (800) in; said number 1 slider (810) includes sensing said (700) of a pair of parallel upper surface coupled to the longitudinal direction of reference (812a) semi-section both ends (812b) leading into a loop type track groove (812) formed mobile panel number 1 (811) and, said number 1 mobile panel (811) of looped track groove (812) disposed sliding movement along receiving a steel wire (813) on, said number 1 mobile panel (811) coupled to the upper portion of said bent end of upper door frame (600) of center rail (610) slidably coupled to channel block number 1 (815) cover panels provided (814) and, said looped track groove (812) of semi-section (812b) is disposed outside said steel wire (813) is said looped track groove (812) of semi-section (812b) would be encountered in such that the hole is a plurality of spaced apart while (818) wherein; said number 2 slider (820) is said outdoor doors (710) coupled to the longitudinal direction of said bent end of upper door frame (600) bearing rail (620) slidably coupled to channel block number 2 (822) number 2 provided with mobile panel (821) and, said number 2 mobile panel (821) extends a side of said steel wire (813) slider connected to said number 1 (810) number 1 of mobile panel (811) and a cover panel (814) formed along length between an outdoor side slit grooves (816) along said steel wire (813) moving with the connecting bracket on number 1 (823) with; said number 3 slider (830) is said indoor doors (720) coupled to the longitudinal direction of said bent end of upper door frame (600) horizontal rail (630) slidably coupled to channel block number 3 (832) number 3 provided with mobile panel (831) and, said number 3 mobile panel (831) extends a side of said steel wire (813) connected bracket connected to said number 1 (823) and due to the interaction with the direction said number 1 slider (810) number 1 of mobile panel (811) and a cover panel (814) formed along length between indoor side slit grooves (817) along said steel wire (813) on moving with the number 2 connected bracket (833) having; a slide door for interworking device characterized. According to Claim 2, said steel wire (813) is said looped track groove (812) closely sliding movement along a Teflon coating (813a) characterized slide door for interworking device processed.