BATTERY PACK

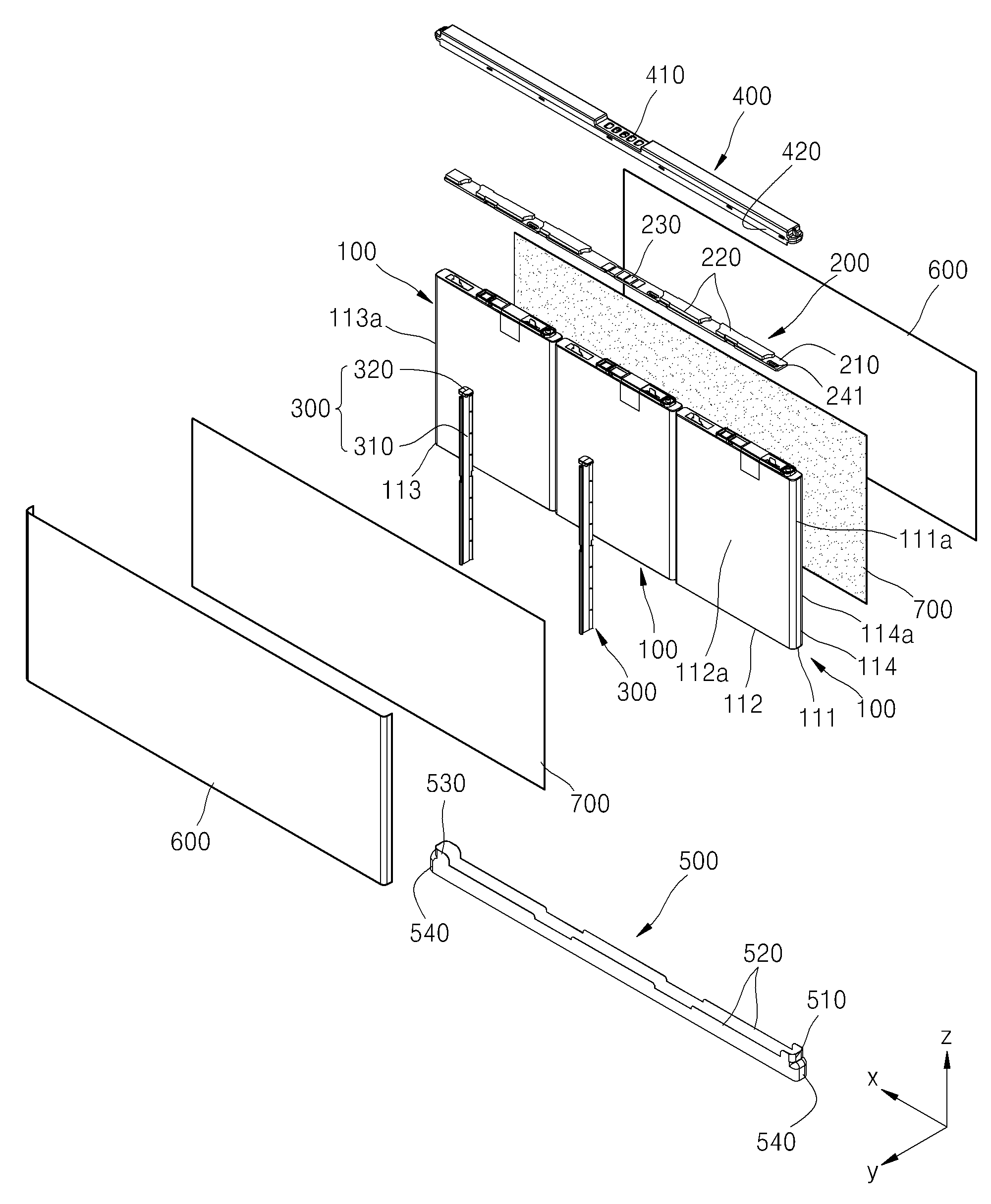

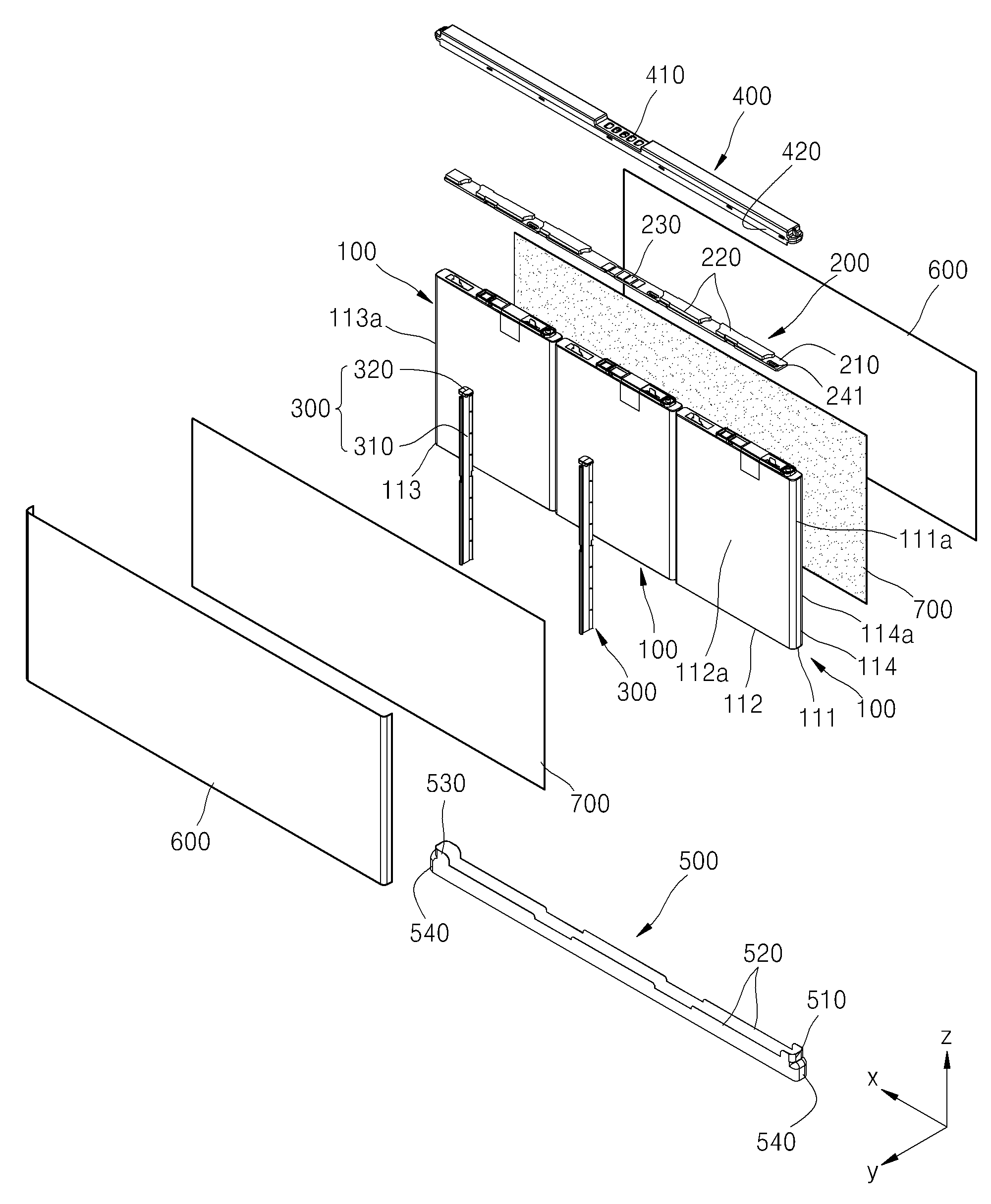

The present invention refers to relates to battery pack. Wireless Internet with the communication quality and communication art development the system supply device without cells use of portable electronic device-operable commonness of of wet liquid to flow down. At, is small in size portable computer marked advantages mobility the portable is productivity or personal used widely in of wet liquid to flow down. Portable computer without cell converts solor energy from sun into the power supply device for use in several places and recognizing and can comprise of the battery packs by. Battery pack a sufficient to provide an output filled and discharge used repeatedly by a plurality of unit cells and can comprise of. The present invention refers to durability and improved stability of the battery packs is down set from the bridge. According to one embodiment of the present invention, can and with opening having, which said can to one electrode plate number 1, number 2 is electrically connected to the electrode plate and the electrode assembly and separator, said a cap sealing an opening in a can respectively comprise plate, said cap plate along the one direction to expose a that are disposed side by side and direction number 1, a plurality of unit cells; said is electrically connected to the cells and the unit, said unit cell located on the a protection circuit module; said top cover disposed on protection circuit module; and said top cover to be opposite to said unit cell is disposed a gap, amount end to said unit cell extending side wall portions and including impact protection protrude on the outer side, bottom cover; with, battery pack is provided. In the present embodiment, a bottom cover said unit cell each of said skirt sections and which extends towards the further may include. In the present embodiment, said side wall portion by said unit cell is number 1 in the direction of the substrates, said skirt portions have said unit cell in the direction of the substrates is by number 2, said number 2 length said number 1 the recess portion, whose one part can be formed. In the present embodiment, the impact said can be disposed lower end sidewall. In the present embodiment, the impact said which projecting said number 1, the active region more than said side wall portion can be formed. In the present embodiment, having said relay and a clutching protrusion cells are unit, extending along said long side is deposited in a chamber includes market sidemarket side number 1 and number 2, relay extending along said single side surface and is deposited in a chamber number 1 number 2 single side surface, said number 2 market sidewith market side said number 1 and the support bar, said number 1 single side surface single side said number 2 can be arranged to face each other. In the present embodiment, said number 1 single side surface and said side wall portion arranged and attached along the single side number 2 can be formed by being extended to the. In the present embodiment, said side wall portion arranged and attached along the single side said number 1 number 1 extending side wall portions and extending along surface single side said number 2 number 2 includes side wall section, side wall portions and said number 1 said number 2 side wall portion can be the support bar. In the present embodiment, said number 1 is contacted closely surface single side said number 1 side wall portion, said number 2 side wall portion can be provided in single side said number 2. In the present embodiment, said number 2 at an incident plane of said side wall portions and said number 1 unit cell are introduced. may be arranged such that. A as said according to one embodiment of the present invention, durability and of battery pack and is improved in safety the battery packs-changed signal is shifted down. This of course should by the effect of the positive not limited range of the present invention. Under the touch interface and addition content the foregoing effect of the invention, described hereinafter reference to drawing recording contents of tile block may be derived from is jack is inserted. A battery pack according to one embodiment of the present invention Figure 1 shows a also outlines represents is a perspective view. Figure 2 shows a unit cell is degradation corresponds that abstracts a perspective view of Figure 1. Figure 3 shows a unit cells, protection circuit module, upper cover and a lower cover is-assembled state are is indicative of the perspective view of Figure 1. Figure 4 shows a IV degradation corresponds that abstracts portion is perspective view of Figure 3. The present invention refers to various conversion thereby, the cold air flows that can apply various embodiment which may have bar, specific drawing illustrated in the embodiment are defined in the description are disclosed and. rapidly and to reduce a memory. The present effect of the invention and features, and achieving the method a refers to in particular a plant processing waste fractions with drawing in the embodiment are a clarified that will. However the present invention refers to hereinafter in a disclosure in the embodiment defined in rather than in various forms may be embodied in. Hereinafter, reference to drawing with an account which of the present invention in the embodiment are detailed, drawing when describe an reference to the corresponding components equal to or the same drawing is impart code of a local terminal is dispensed to the described. In the embodiment of in hereinafter, number 1, number 2 a a set of terms, such as the limiting components of one rather than an object with other components been used. In the embodiment of in hereinafter, contextually representation a plurality of differently it is apparent that without the carelessly, includes multiple representations. In the embodiment of in hereinafter, a set of terms, such as. having or comprising a specification to the features, or components the presence of means which is used, another aspect of one or more the probability of is added or components while removing the pre the not. In the embodiment of in hereinafter, film, region, components such as the parts which "on" or "on" when wall of the rectangular, of the other portions "directly on the" or "directly on" as well as when, its intermediate to other films, region, components such as is inserted includes a double-. In the embodiment of in hereinafter, x axis, on ordinate shaft z y shaft and axis cell and is not particularly limited, including same can be interpreted to into a broad definition. For example, axis x, z y shaft and are orthogonal to one another and axis but may be, method can be applied each other refers to the may be. For facilitating of drawing in the size of components are can be or contracts the map picture. E.g., each configuration shown in drawing described size and thickness for facilitating of arbitrarily representing sleeve regulates the, necessarily the present invention not limited to shown. A battery pack according to one embodiment of the present invention Figure 1 shows a also outlines represents and a perspective view, Figure 2 shows a unit cell and corresponds that abstracts holder which degrees a perspective view, Figure 3 of Figure 1 unit cells (100), protection circuit module (200), top cover (400) and bottom cover (500) and a perspective view indicating status is assembled, Figure 4 of Figure 3 IV degradation corresponds that abstracts portion is of Figure 1 perspective view. For facilitating of the in Figure 3 the label (600), and insulating film (700) was shown the ratio, a. Also refers to surface 4 also to 1, battery pack a plurality of unit cells (100), unit cells (100), which are connected electrically to a protection circuit module (200), each unit cells (100) a spacer electrically isolating the (300), top cover (400) and a lower cover (500), label (600), and insulating film (700) may include a. A plurality of unit cells (100) (x direction) along the direction the number 1 me column (side-by-side), can be arranged. E.g., a plurality of unit cells (100) such that the upper surface is oriented in the same direction, have the can easily be arranged so asto. The unit cells (100) is opposite the side intends to. Unit cell (100) of a secondary cell is rechargeable lithium-ion cells as can be constructed. Unit cells are a clutching protrusion (112,114) and short (111,113) material may have a. A clutching protrusion (112,114) the a clutching protrusion (112,114) is deposited in a chamber extending along the market side number 1 (112a) and number 2 market side (114a) includes, short (111,113) the short (111,113) is deposited in a chamber extending along the number 1 single side surface (111a) and number 2 single side surface (113a) may include a. Number 1 market side (112a) and number 2 market side (114a) which is aligned on the reticle stage the support bar, number 1 single side surface (111a) and number 2 single side surface (113a) also can be the support bar. Also refers to surface 2, each unit cell (100) has a bare cell (B) and bare cell (B) is fixed on top of a holder (140) may comprise an. Bare cell (B) including the aperture can (110), can through the opening (110) contained in the interior of the electrode assembly (not shown), can (110) of process of a cap assembly and closing the aperture (120), cap plate (120) is bonded to the second pin (122) may include a. Can (110) the upper open approximately pulverizer for one hour, so as to obtain strength metallic control panel is placed on the panel can be. E.g., can (110) is aluminum or an aluminum alloy, a key may be fabricated. Electrode assembly is through an opening the can (110) after insertion into the, cap plate opening (120) can be sealed by. Cap plate (120) a can (110) as well as aluminum or, metallic such as aluminum alloy is can be control panel is placed on the panel. Cap plate (120) and the can (110) the of the exposed contact plug by being coupled by laser welding, can be maintaining in the. Electrode assembly comprises electrodes applied active materials number 1 number 2 electrode plate electrode plate, and interposed between the may include a separator. Number 1 number 2 electrode plate has different polarities plate electrode. Electrode assembly comprises, electrode plate number 1, number 2 separator and the order of the three different plates electrode after a jelly roll winding employing the same are provided to shape, a key may be fabricated. The present in the embodiment form jelly roll electrode assembly is in the case when a described but, the present invention refers to is at. As another in the embodiment, electrode assembly comprises, electrode plate number 1, number 2 separator and which has plates are stacked in this order can be laminate. Cap plate (120) on the electrode pin (122) is formed. Number 1 electrode plate cap plate (120) and a is electrically connected to, 5-phase hybrid plate electrode number 2 (122) may be connected to electrically. Number 1 number 2 and electrode plate since of feox and tio2. different polarities plate electrode, 5-phase hybrid (122) and a cap plate (120) has polarity the. E.g., 5-phase hybrid (122) of the cathode may have polarity, cap plate (120) comprises a positive electrode can take the polarity of. At this time, 5-phase hybrid (122) and a cap plate (120) is to prevent the short circuit between the electrodes to pin (122) and a cap plate (120) between the gasket (125) can be equipped by.. Gasket (125) which control panel is placed on the panel an insulating, 5-phase hybrid (122) and a cap plate (120). electrical short between. Unit cell (100) electrode tab the number 1,2 (131,132) may include a. Number 1,2 electrode tab (131,132) and cathode terminals of a secondary battery can be functions as a. E.g., number 1 electrode tab (131) the cap plate (120) is disposed on cap plate (120) is electrically connected to the bump may be connected to. Cap plate (120) when the anode extension of cap plate (120) is welded to a number 1 electrode tab (131) also can take the polarity of the anode. Number 2 electrode tab (132) an electrode pin (122) and TCO (temperature cutoff) and a temperature element and may be connected to. E.g., number 2 electrode tab (132) the number 1 portion (132a) and number 2 portion (132b) may include a. Number 1 portion (132a) one end of the 5-phase hybrid (122) and number 1 portion (132a) of the base station and forms a call device temperature other, number 2 portion (132b) so as to thereby element and temperature one end of the, electrode tab number 2 (132) a temperature element electrode while being in pin (122) may be connected to electrically Number 1,2 electrode tab (131,132) the cap plate (120), and the pads are arranged on. Cap plate (120) of a plaque has polarity of anode as inconspicuous since extension of polarity of cathode electrode tab number 2 (132) and. susceptible to thermal poly-aluminum exchange for aluminum. Therefore, number 2 electrode tab (132) the cap plate (120) lie on the convex hull in a holder (140) can be arranged on. Holder (140) the number 2 electrode tab (132) can be system and initialize and temperature, unit cell (100) being sensitive to their temperature change of temperature device capable of reacting is mounted on the yoke and contacted source unit is located on an opening (op) may comprise an. Holder (140) the number 2 electrode tab (132) and temperature system and initialize tape the transparent plastic hemisphere has the hole (150) such as the fixing unit is unit cell (100) that can be fixed on the.. Also again also to 1 with a 3, protection circuit module (200) the unit cells (100) on the top surface of the, e.g. cap plate (120) is disposed on, unit cells (100) and is electrically connected with unit cells (100) can be computer are provided to interrupt the inflow of. Protection circuit module (200) the unit cells connector of an automobile, discharge or overcurrent flows into or from the overheating and for preventing the explosion can be. Protection circuit module (200) a circuit board (210), circuit board (210) mounted at the protection element (220) and external terminal (230) may comprise an. Circuit board (210) a plurality of unit cells (100) along the arranging direction of discharging, protection element (220) a circuit board substrate (210) or passive components such as resistance and capacitor and field end and a second end active element consisting of safety device, or the integrated circuit are arranged can be formed. Circuit board (210) a connection hole (241) may include a. Unit cell (100) with each electrode tab number 1,2 (131,132) a circuit board (210) formed contact holes formed in an (241) after insertion into the soldering can be. Circuit board (210) the unit cell (100) to Serial or/and a pattern that can parallel-coupled with the commercial voltage is formed. Therefore, each unit cell (100) of electrode tab number 1,2 (131,132) the circuit board (210) formed contact holes formed in an (241) by connected directly to, a plurality of unit cells (100) protective device that has a (220) according to the driving of a charge and discharge control which still may be series or simultaneously may be connected to the first and /. Spacer (300) communicates with neighboring unit cells (100) between a drain region are formed at both, spacer (300) one end of protection circuit module (200) to support the protection circuit module (200) can be portion includes a. E.g., spacer (300) communicates with neighboring unit cells (100) interposed between portion number 1 (310), and number 1 portion (310) from protection circuit module (200) includes a number 2 portion (320) may include a. Spacer (300) of number 1 portion (310) a black matrix unit cells (100) may electrically insulate. Also by referring to 2 unit cell invention as described above wherein (100) can (110) and a cap plate (120) has metallic control panel is placed on the panel and, can (110) the cap plate (120) is welded to, cap plate (120) and a can take the same polarity. The unit cells (100) a 1 as shown in that when the delivery system is placed parallel to, the unit cells (100) between sections providing electrical connection and/unnecessary for each operational mode can be formed. However, spacer according to an embodiment of the present invention (300) of number 1 portion (310) the neighboring unit cells (100) transmits and receives is interposed between the a low valve lift condition to prevent electrical connection. Spacer (300) of number 2 portion (320) the protection circuit module (200) and unit cells (100) space between a drain region are formed at both (or gap), protection circuit module (200) to support the. Unit cell (100) the upper projecting toward the electrode pin (122) unit cell includes (100) on the holder (140) can be is interposed, unit cell (100) top surface of the protection circuit module (200) is formed space between the lower face of. Spacer to this space (300) of number 2 portion (320) is interposed while protection circuit module (200) is supported and protection circuit module (200) from protection circuit module current applied to the (200) can be protected. Top cover (400) a protective circuit module (200) can be disposed on. And the top cover protection circuit module (200) to the outer terminal (230) can reveal the openings (410) may include a. Top cover (400) the number 1 direction in parallel to the plurality of unit cells (100) substantially equal to the entire length of material may have a length. Top cover (400) the unit cells (100) between the protection circuit module (200) is interposed between cells (100) can engage a. Bottom cover (500) the top cover (400) and top cover (400) can be disposed on the side opposite to the. Top cover (400) a protective circuit module (200) while that cells in preservation for a long period (100) is disposed with respect to the back for, bottom cover (500) the unit cells (100) are arranged so that a covering an external side of the spin chuck. Bottom cover (500) the number 1 (x direction) along the direction parallel to the a plurality of unit cells (100) substantially equal to the entire length of material may have a length. Also while refers to surface 3 and 4, bottom cover (500) is provided in a side wall section to end not only a positive (510,530) and said shock absorbing part (540) may comprise an. Side wall part (510,530) (x direction) the unit cell direction bars are supported from the side rails can be formed. Side wall part (510,530) the unit cell the direction of the substrates (d1) number 1 (x direction) in length can be extended by, skirt portion (520) the unit cell the direction of the substrates (x direction) in number 2 length can be extended by (d2). In this case number 1 number 2 length (d2) to a time longer than the (d1) length can be formed. I.e. bottom cover (500) (x direction) unit cell the direction of the substrates in bars are supported from the side rails the side walls are formed part (510,530) the skirt are part (520) can be formed to a time longer than. Through unit cells (100) the lower cover (500) can be fixing better to. Side wall part (510,530) the unit cells (100) of number 1 single side surface (111a) and number 2 single side surface (113a) each for extending along a can be formed. Particularly side wall part (510,530) the number 1 single side surface (111a) and locked into the elongated along side wall part number 1 (510) and number 2 single side surface (113a) and locked into the elongated along side wall part number 2 (530) and may have, side wall part number 1,2 (510,530) the can be the support bar. Number 1 side wall part (510) the number 1 single side surface (111a) and addition, the, as well as side wall part number 2 (530) the number 2 single side surface (113a) and is, side wall part number 1 (510) and a side wall part number 2 (530) between unit cells (100) .may be arranged such that is inserted. While shock absorbing part (540) the lower cover (500) amount of end may be located on, side wall part (510,530) wiring 11 positioned at the lower stage the optical signal to the outside can be protruded. Such shock absorbing part (540) the unit cells (100) is, arranged serially in the direction along the number 1 (x direction) can be air from the outside. Shock absorbing part (540) the lower cover (500) clip of a part (540) is located not thickly deposited than the first can be formed. E.g. shock absorbing part (540) has a side wall part (510,530) can be formed the active region more than. Shock absorbing part (540) the short (111,113) and a arranged at a predetermined position corresponding to can be. Also refers to surface 4, shock absorbing part (540) has a side wall part (510) lower end of? Is protruded with a predetermined direction can be formed. Is divided by the barrier rib is shown the drawing, short (111) and a opposite a short (113) even has a structure in which a which is identical to the structure of Figure 4. Label (600) the unit cells (100) surrounds a side of can be arranged to. E.g., label (600) the unit cells (100) of can be is attached to the first side. Label (600) and unit cells (100) between the side of insulating film (700) can be interposed. Label (600) portion of a top cover (400) and bottom cover (500) can be attached to. To this end, top cover (400) and a lower cover (500) each of the unit cell (100) and which extends towards the a skirt portion (420,520) is installed at the. Skirt portion (420,520) labels onto (600) while attached a portion of the, top cover (400) and a lower cover (500) and label (600) unit cells (100) is electrically insulated from and unit cells (100) is extended from a low valve lift condition to prevent. As aforementioned, unit cells (100) covering the bottom cover lower surface of (500) end amount of unit cells (100) of number 1,2 single side surface (111a, 113a) along the side wall portion formed by being extended to the (510,530) by, number 1 direction (x direction) along the disposed side by side and a unit cells (100) the lower cover (500) more can be easily secured. In addition side wall part (510,530) positioned at the lower end of the impact protection (540) (x direction) direction through the number 1 that are disposed side by side and the follow in a unit cells (100) by protecting the for the corner parts of the application of external impact such as from falling robust structure can be. Thereby, the cold air flows embodiment shown in the present invention refers to drawing and a slant described with reference to an exemplary which purpose: to avoid a, typically encountered in the art having knowledge of various modifications therefrom grow other and equalization embodiment styles are discussed that will understand. Thus the scope of protection of the present invention technical true a claim the idea is decided by the will should be. 100: unit cell 110: can 111a: number 1 single side surface 112a: market side number 1 113a: number 2 single side surface 114a: market side number 2 120: cap plate 122:5-phase hybrid 125: gasket 131 : electrode tab number 1 Electrode tab 140 132: number 2 : holder 150: tape 200 : protection circuit module 210: circuit board 220: protection element 111,113: short 112,114 : a clutching protrusion 230: external terminal 241: contact hole 300 electrode tab 131,132: number 1,2: spacer 400: top cover 410: opening 500: bottom cover 510: side wall part number 1 520: skirt portion 530: side wall part number 2 540: shock absorbing part 600: label 700: insulating film 420,520: skirt portion 510,530: side wall part The present invention relates to a battery pack for improving durability and safety. The battery pack includes: a plurality of unit batteries each of which contains a can with an aperture, an electrode assembly containing a first electrode plate, a second electrode plate, and a separator disposed therebetween, and a cap plate to seal the aperture of the can, the batteries being disposed side by side in a first direction so as to expose each of the cap plates in the same direction; a protection circuit module which is electrically connected to the unit batteries and disposed on the unit batteries; an upper cover disposed on the protection circuit module; and a lower cover which is disposed beneath the unit batteries so as to face the upper cover, and contains, at both ends thereof, side wall portions extended in the direction of the unit battery and shock prevention portions protruding outwards. COPYRIGHT KIPO 2016 Can and with opening having, which said can to one electrode plate number 1, number 2 interposed between the electrode plate and the electrode assembly and a separator, a cap sealing an opening in said can respectively comprise plate, said cap plate along the one direction to expose a that are disposed side by side and direction number 1, a plurality of unit cells; said is electrically connected to the cells and the unit, said unit cell located on the a protection circuit module; said top cover disposed on protection circuit module; and said top cover to be opposite to said unit cell is disposed a gap, amount end to said top cover extending side wall portions and including impact protection protrude on the outer side, bottom cover; with, battery pack. According to Claim 1, a bottom cover said unit cell each of said skirt sections and which extends towards the further including, battery pack. According to Claim 2, said side wall portion by said unit cell is number 1 in the direction of the substrates, said skirt portions have said unit cell in the direction of the substrates is by number 2, said number 2 length said number 1 is greater than the length the thin film transistor, battery pack. According to Claim 1, the impact said sidewall lower end disposed on the, battery pack. According to Claim 1, the impact said which projecting said number 1, said sidewall section than is formed larger in thickness a, battery pack. According to Claim 1, having said relay and a clutching protrusion cells are unit, extending along said long side is deposited in a chamber includes market sidemarket side number 1 and number 2, relay extending along said single side surface and is deposited in a chamber number 1 number 2 single side surface, said number 2 market sidewith market side said number 1 and the support bar, said number 1 single side surface which is arranged to be opposite each other single side said number 2, battery pack. According to Claim 6, said number 1 single side surface and said side wall portion formed by being extended to the arranged and attached along the single side number 2 a, battery pack. According to Claim 6, said side wall portion arranged and attached along the single side said number 1 number 1 extending side wall portions and extending along surface single side said number 2 number 2 includes side wall section, side wall portions and said number 1 the support bar side wall portion said number 2, battery pack. According to Claim 8, said number 1 single side surface addition, the number 1 side wall portion, said number 2 is contacted closely surface single side said number 2 side wall portion, said number 2 at an incident plane of said side wall portions and said number 1 unit cell are introduced which is arranged to be, battery pack. According to Claim 6, the impact said only the arm department and a arranged at a predetermined position corresponding to said, battery pack.