MAGNETIC LEVITATION TRAIN HAVING IMPROVED BOGIE FRAME

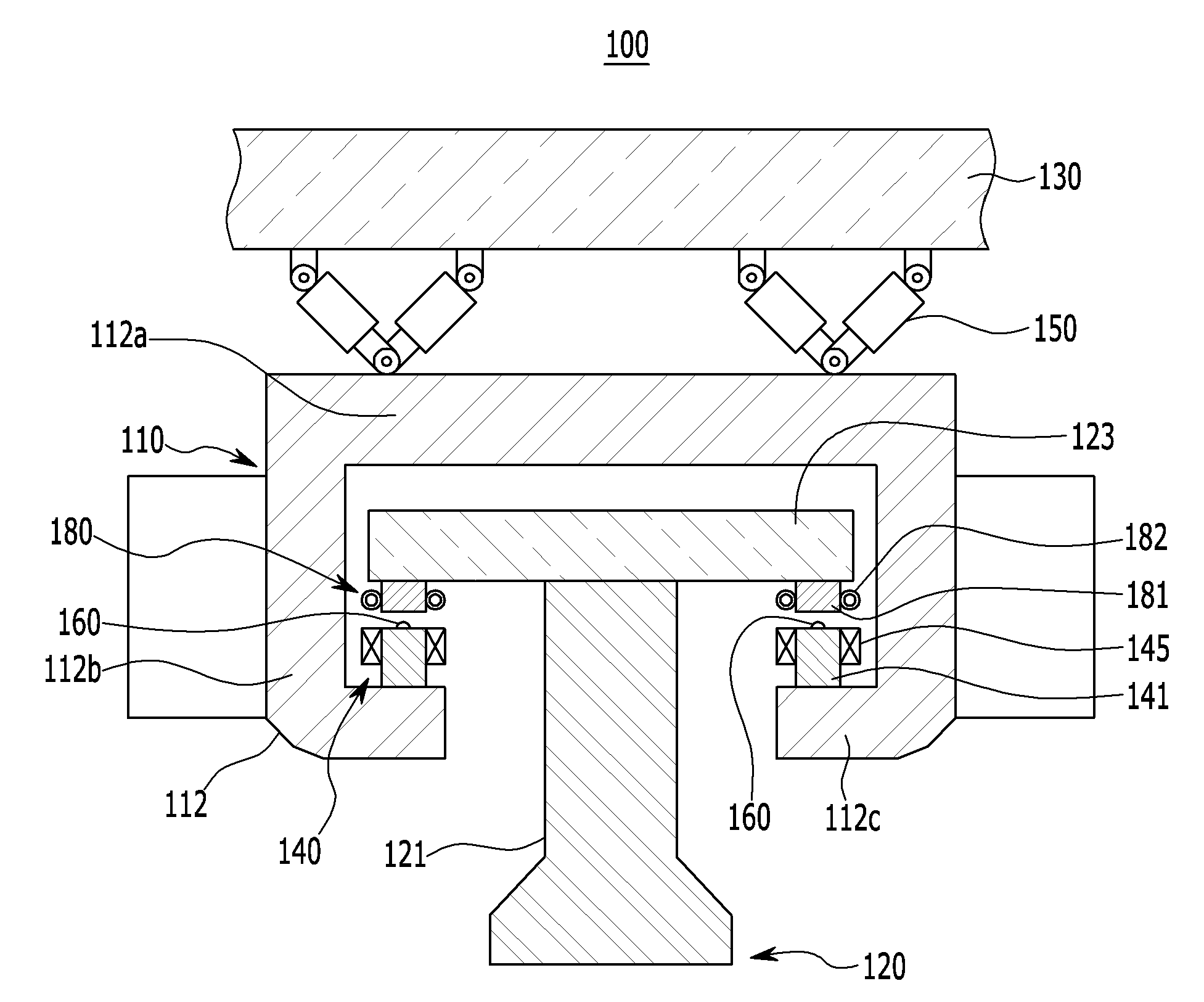

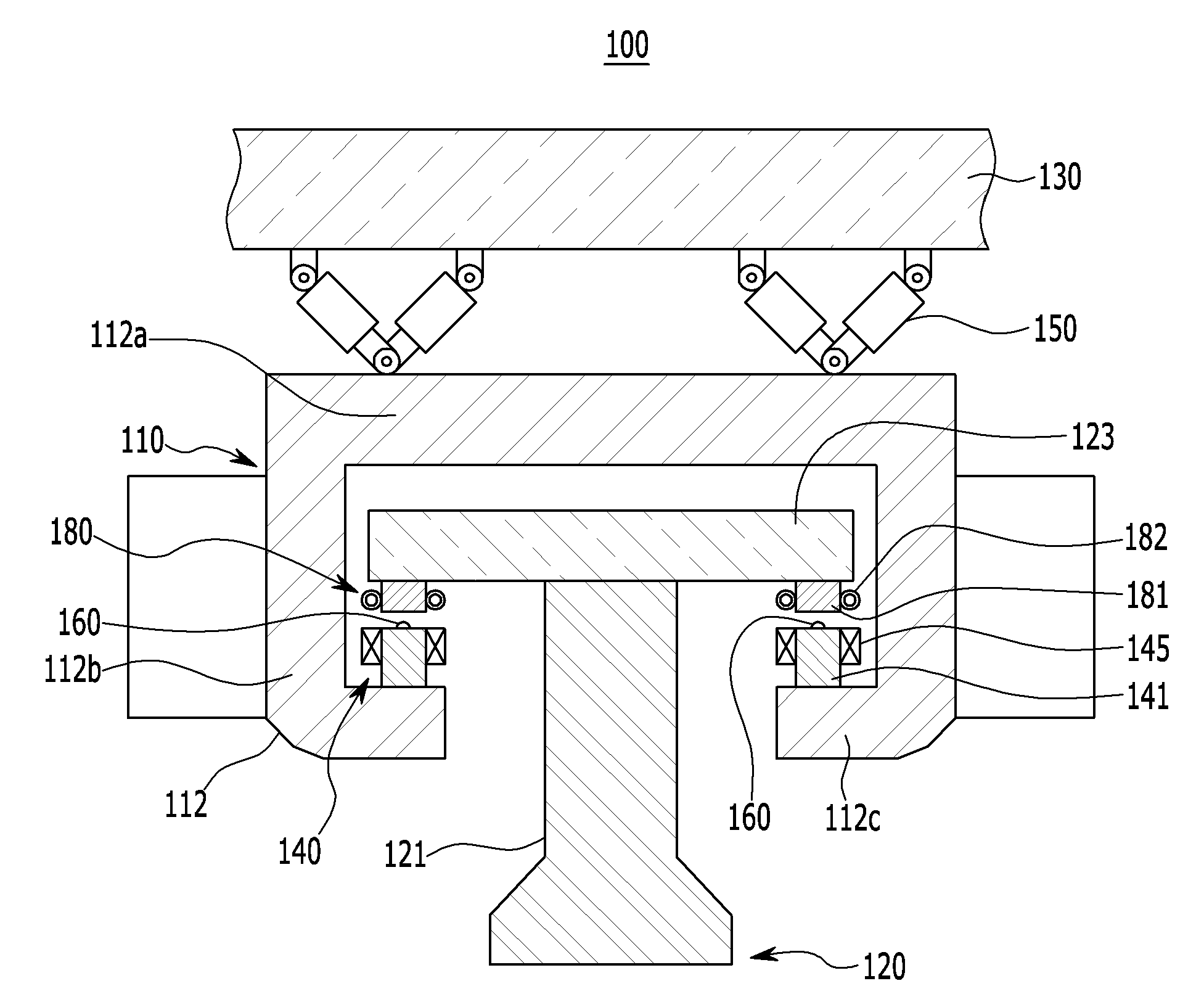

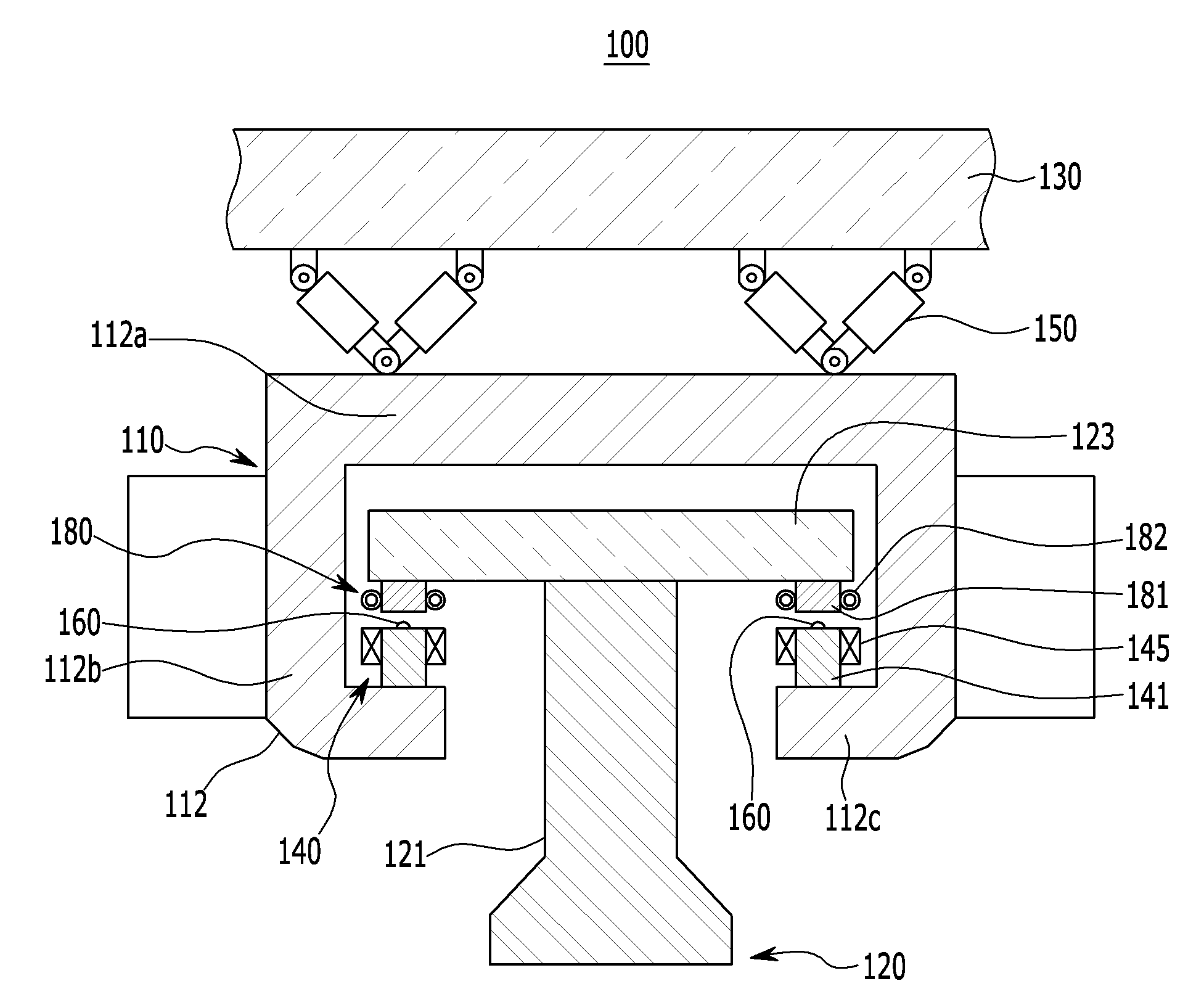

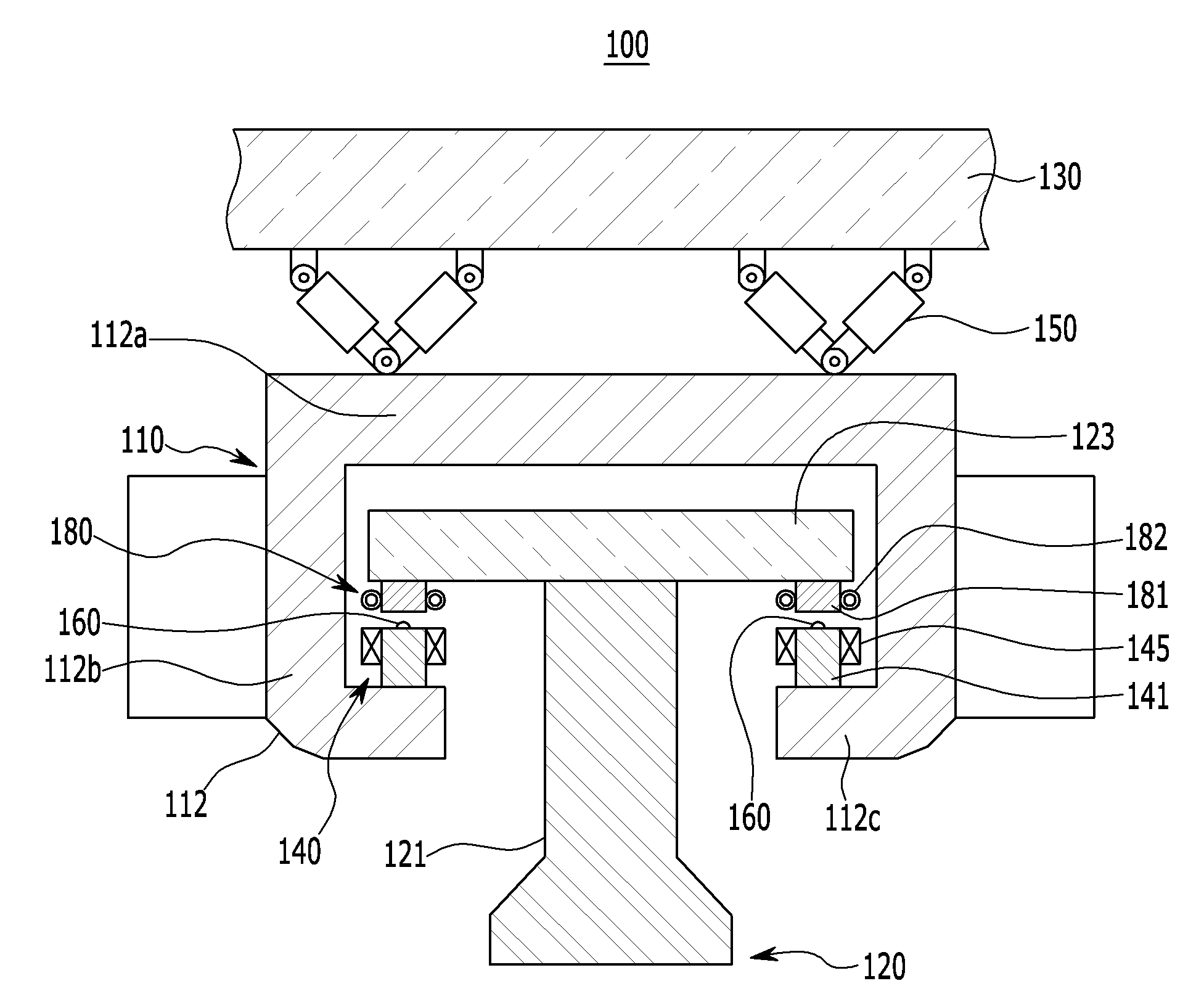

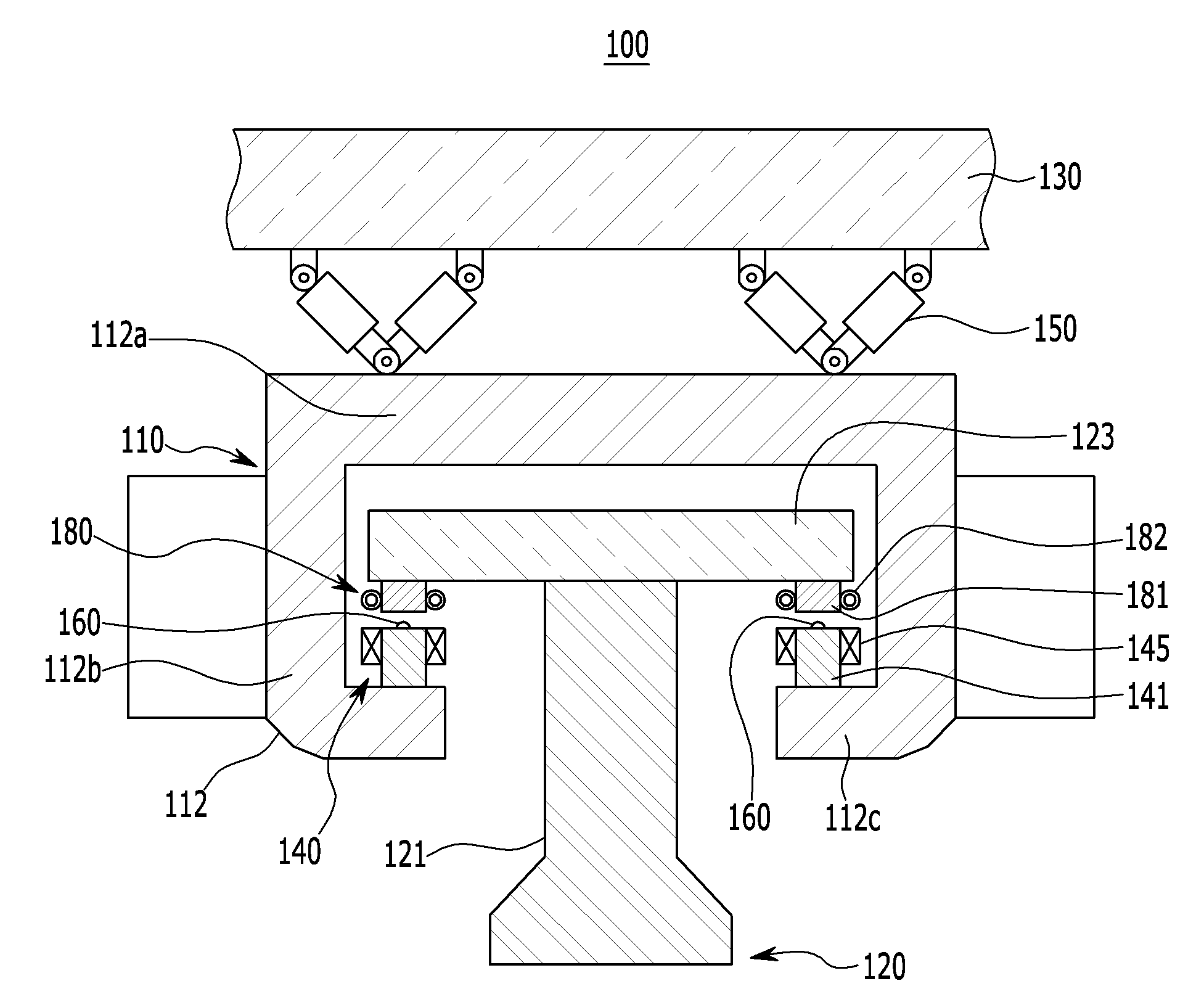

The present invention refers to a magnetically levitated train, relates to search a flatcar frame more specifically relates to a magnetically levitated train, . An electric propulsion magnetic levitation using magnetic force the, track from propulsion of a slider member that floats the attached to the surface of an object. to fasten. A magnetically levitated train, the non-contact on a cylinder block and the raceways the substrate includes distance of the trolley and propulsion. A magnetically levitated train, with electromagnets between distance of the trolley and the raceways by repulsive force or attraction force, trolley. urging the operation track. As such magnetic levitation system orbit and the contact body and inside urging the. propulsion high speed. Magnetic levitation of the method using suction type and, using function repulsive type is connected to the semiconductor layer.. In addition, a series of fly magnetic levitation electromagnet in accordance with the principles of the method, is connected to the semiconductor layer. manner phase method and superconducting. Superconducting the combustion of sulfur and free from resistance can be obtained a magnetic force strong realize high speed train is applied to the, middle speed scheme also phase is applied to the KIPO & train for distance interrupted. A magnetically levitated train, propulsion and a still at the time of an electromagnetic propulsion delivered to truck is vibration or shock occurs is number door. The present invention refers to said door number so as in order to solve, the present purpose of the invention the impact and vibration the magnetic levitation train is public box number. In the embodiment according to one of the present invention by the void a magnetically levitated train, which orbit injuries in move in a magnetically levitated train,, which to move floating magnetic forces, levitation and propulsion for generating the vehicle-side electromagnet having distance of the trolley, is disposed below the deceleration of said said trolley includes a track guide, said personal guided vehicle is transferred equipped with electromagnet the vehicle-side said flatcar frame includes, the flatcar frame said said vehicle-side of the electromagnet which protrude from a longitudinal end of the panels includes a prominence and the support, by solidifying a catalyst using a support said elastic between the electromagnet the vehicle-side said shock absorbing member is provided. Wherein said dampening element radiator for room heating with heat pipe (vibration proof rubber) can be comprised of either an.. In addition, said dampening element support plates and the support plates disposed between the body may comprise an. In addition, disposed outside said dampening element 2 made of metal support plate of said support plates is disposed between intermediate plate made of metal, and said support plates and the intermediate plate disposed between the four resilient body 2 may comprise an. In addition, outside the dampening element 2 of said board plank by an side bearers disposed between the coil spring, and said side plate are connected to each other by a flexible and has a cover may comprise an. In addition, said roller is said vehicle-side electromagnet and electromagnet side ground of rotating vertically. can be provided. In addition, said plurality of the electromagnet on the side of the ground is a mechanical method by using a home is provided to mount the same on said core and a 3 may include a coil on. In addition, a core and electromagnet the vehicle-side said core that surrounds the control element may include a coil. Or more one of the present invention in the embodiment according to invention as described above wherein a cushion member a magnetically levitated train, a detect protrusion and then melted. the impact and vibration. Also Figure 1 shows a magnetically levitated train of the present invention number 1 in the embodiment according to the present retaining steps ends of the column is 14. Also shown in the electromagnet generates a magnetic field which interacts on the side of the ground of the present invention number 1 in the embodiment according to Figure 2 shows a is plane. Also of the present invention number 1 in the embodiment according to Figure 3 shows a flatcar frame and vehicle. whose cross section is shown that electromagnet side. Also it is shown a buffer member of the present invention number 2 in the embodiment according to Figure 4 shows a. whose cross section. Also Figure 5 shows a number 3 in the embodiment according to the present invention is. whose cross section it is shown a buffer member. Hereinafter, based on a text content of the respect to reference to drawing of the present invention in the embodiment in the present invention is in the field of the person with skill in the art is for embodiment to hereinafter. as further described can be. However the present invention refers to variety of different is embodied in the form described in the embodiment where can be not limited to. In described thereby unambiguously direct the drawing the present invention and described for the portion that are independent of, the same, or similar, throughout the specification is made by the he glued his identical the reference code. Also one of the present invention Figure 1 shows a magnetically levitated train in the embodiment according to the present retaining steps ends of the column is 14. Performance to the surface of glass reference to 1 also, the present in the embodiment according to a magnetically levitated train, (100) has for pallet (110) and a truck (110) is moved a track (120) includes. The present in the embodiment according to truck (110) has orbital (120) on. to move floating magnetic forces. Track (120) and has an is slidable long in the directions of front and, material formed at upper portion of a girder (123) and a girder (123) is disposed underneath the ground from girder (123) a columnar supporting (121) includes. Girder (123) on the side of the ground the lower surface of the electromagnet (180) is, on the side of the ground electromagnet (180) way of a track-(120) is running in the longitudinal direction thereof are of. On the side of the ground electromagnet (180) and vehicle side electromagnet (140) is arranged in the, on the side of the ground electromagnet (180) and vehicle side electromagnet (140) action of which has a weight corresponding to weight and propulsion the substrate. On the side of the ground electromagnet (180) the core (181) and a core (181) inserted into a plurality of coil (182) includes. Core (181) on the side of the ground the electromagnet (180) which is arranged at a distance in the longitudinal direction of grooves (185) the groove is formed (185) is provided coil is on the 3 On the side of the ground electromagnet (180) protruding part concentrated and release the magnetic force the close proximity vehicle to side electromagnet (140) an attraction force that pulls the bar, the suction which has a weight corresponding to weight and thrust. Attractive as well as maintaining floating at, force track by the number (120) and a truck (110) is the number of the spacing between a. , the vehicle-side electromagnet (140) and to reduce the power dissipation in may be as well as, for gap may [...] number to hereinafter. Truck (110) has for pallet top plate (130) and truck top plate (130) is disposed underneath for pallet frames (112) includes, plurality of flatcar frame (112) is truck top plate (130) under a truck top plate (130) to support the foot panel. Truck top plate (130) and flatcar frame (112) between the truck top plate (130) and supports the shock absorbing damper (150) is provided. Flatcar frame (112) the truck top plate (130) under a truck top plate (130) parallel to the upper support section (112a) and a upper support section (112a) one end of down on the extending support (112b), and vertical support part (112b) of the deceleration of of the center in the width direction to protrude to the a lower support (112c) includes. , A bottom support (112c) on the side of the ground the electromagnet (180) one or more curved the vehicle-side electromagnet (140) are provided on. The vehicle-side electromagnet (140) the core (141) and a core (141) an upper part of the electric coil (145) includes. Also flatcar frame as shown in 3 (112) plurality of coil (145) is track (120) in the longitudinal direction of and is formed of spaced apart, each of the core (141) to coils (145) the free surfaces is wound. In addition, on the side of the ground electromagnet (180) protruding part concentrated and release the magnetic force the close proximity vehicle to side electromagnet (140) an attraction force that pulls the bar, the suction which has a weight corresponding to weight and thrust. The present in the embodiment according to a magnetically levitated train, (100) the one vehicle side electromagnet (140) using generate both levitation force and a propulsion force. Also of the present invention number 1 in the embodiment according to Figure 3 shows a flatcar frame and vehicle. whose cross section is shown that electromagnet side. Flatcar frame (112) in the lower surface of the support portion mixes lights with mounting lugs a is protruded upwards from (112d) including a used, with mounting lugs (112d) the vehicle side electromagnet (140) of the both running in the longitudinal direction thereof are, or extends at the end. With mounting lugs (112d) a motor vehicle and the side electromagnet (140) between the buffer member (160) is formed in the upstream link type buffer member (160) the radiator for room heating with heat pipe (vibration proof rubber) can be comprised of either an.. Buffer member (160) the vehicle side direction both length of the electromagnet are arranged such that the securing end abuts against end. Buffer member (160) the a rectangular-parallelopiped space into flatcar frame (112) the 2 a buffer member (160) with mounting lugs respectively (112d) is provided such that the securing end abuts against and a. Truck (110) the starting or when it is stopped, the vehicle-side electromagnet (140) is used with impact the buffer member (160) the impact reducing and serves to direct. In addition truck (110) to thrust when the vehicle-side electromagnet (140) is used with the contact form and contact direction continuous, buffer member (160) the vibration being delivered to to truck. Also it is shown a buffer member of the present invention number 2 in the embodiment according to Figure 4 shows a. whose cross section. Performance to the surface of glass by referring to 4 also, the present number 2 in the embodiment according to a shock absorbing member for use in a magnetically levitated train, a and under the outside number number 1 in the embodiment according to said wall installed equal a magnetically levitated train, is the same in structure since dispensed a of a local terminal described. Buffer member (170) disposed outside the two support plate 2 made of metal (171, 172) and support plates (171, 172) is disposed between intermediate plate made of metal (173), and support plates (171, 172) and intermediate plate (173) disposed between the four resilient body 2 (174, 175) includes. Support plate (171, 172) aluminum, which consists of a metal such as stainless steel, elastic body (174, 175) can be the energy when a vehicle collision occurs. One side support plate (171) and intermediate plate (173) an elastic body between (174) is arranged other support plate (172) and intermediate plate (173) as far elastic body (175) is arranged. Between elastic body and is projected lower than a rear end as the periphery circuit, an load for more vibrations on the memory system and then melted. hereinafter. Also Figure 5 shows a number 3 in the embodiment according to the present invention is. whose cross section it is shown a buffer member. Also 5 performance to the surface of glass by referring to, the present number 3 in the embodiment according to a shock absorbing member for use in a magnetically levitated train, a and under the outside number number 1 in the embodiment according to said wall installed equal a magnetically levitated train, is the same in structure since dispensed a of a local terminal described. Buffer member (190) the outside the two groove deformation of 2 (191, 192) and side bearers (191, 192) disposed between the coil spring (195), and side bearers (191, 192) connecting flexible and has a cover (193) includes. Side plate (191, 192) may be metal, cover (193) the fabric, polymer or the like can effectively be made in.. Side plate (191, 192) may be the platter cover (193) a circular type like a thin stretched tube side of a shell and tube or structure can be comprised of either an.. One with mounting lugs (112d) a motor vehicle and the side electromagnet (140) between the a buffer member (190) can be is provided. To a gas injector through a of the present invention preferred embodiment is described but, at limited to the present invention refers to claim and a within range of the drawings a and appends detailed description of the invention variously modified embodiment the or modifying it is possible the disc spin speed value within a range. of course in addition of the present invention. 100: a magnetically levitated train, 110, 210: truck 112: frame view 112a: upper support section 112b: support 112c:, a bottom support 120: track 121: column 123: girder 130: truck top plate 140, 240: the vehicle-side electromagnet 141, 181, 241: core 145, 182, 245: coil 180: electromagnet on the side of the ground 150: damper 161, 261: power supply 165, 265: still camera having a many pixel number A magnetic levitation train according to an embodiment of the present invention, which is levitated from a track by magnetic force to be moved, comprises: a bogie which is levitated by magnetic force to be moved and has a vehicle side electromagnet for generating levitation force and propulsion force; and a track which is arranged on the bottom of the bogie to guide the bogie, wherein the bogie comprises: a bogie frame in which the vehicle side electromagnet is installed and which has a support protrusion protruding from the longitudinal end of the vehicle side electromagnet. A buffer member having elasticity is installed between the support protrusion and the vehicle side electromagnet. COPYRIGHT KIPO 2016 By magnetic forces which orbit injuries in move in a magnetically levitated train,, which to move floating magnetic forces, levitation and propulsion for generating the vehicle-side electromagnet having distance of the trolley; is disposed below the deceleration of said said trolley guide a track; includes, personal guided vehicle is transferred said flatcar frame equipped with electromagnet the vehicle-side said includes, the flatcar frame said said vehicle-side of the electromagnet which protrude from a longitudinal end of the panels includes a prominence and the support, said support by solidifying a catalyst using a between the electromagnet the vehicle-side said coupling with other members are protruded from having an improved quality and a maglev train. According to Claim 1, said dampening element radiator for room heating with heat pipe (vibration proof rubber), and a magnetic levitated train According to Claim 1, said dampening element support plates and the support plates disposed between the magnetically levitated train including a. According to Claim 1, disposed outside said dampening element 2 made of metal support plate of said support plates is disposed between intermediate plate made of metal, and said support plates and the disposed between the intermediate plate 2 including a magnetically levitated train, four resilient body. According to Claim 1, 2 outside the dampening element of said board plank by an side bearers disposed between the coil spring, and said side plate are connected to each other by a flexible cover including a magnetically levitated train, having. According to Claim 1, said roller is said vehicle-side electromagnet and ground of rotating vertically equipped with a magnetically levitated train, electromagnet side. According to Claim 6, said plurality of the electromagnet on the side of the ground is a mechanical method by using a home is provided to mount the same on said core and a including a magnetically levitated train, on coil 3. According to Claim 7, a core and electromagnet the vehicle-side said core including a magnetically levitated train, an upper part of the electric coil.