HEAT EXCHANGER FOR COOLING ELECTRIC ELEMENT

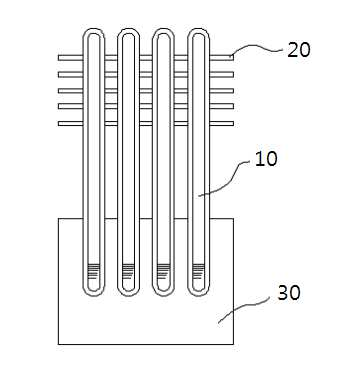

The present invention refers to heat exchanger of cooling relates to electrical component, more specifically excellent heat transfer properties and interspersed with a plurality of there is electrical component formed to the one surface, which can improve heat exchanging performance through direct heat exchange heat exchanger for cooling are disclosed. Recent environment door number of certain surfaces is provided, using hybrid vehicle drive force of the motor, fuel cell vehicle, such as electric vehicle electric more in the spotlight disclosed. Generally vehicle such as a described above, power supplied from the driving battery (for example, 300V voltage) supplied in a PCU (power number fish oil [nis) desired motor which adjusts to the fitting together. PCU comprises an inverter, a smoothing capacitor and electrical components comprising the converter or the like. Because supply of electric components generating heat while said power (electricity), not necessarily separate cooling the spirit. In addition, the first cooling for cooling an electrical component mounted on a variety of electronic number within the article, for example, CPU of computer device for cooling heat pipe cooling device such as a generally used for block and several heat pipe is included is the ability to transfer are used. This kind of cooling device cooling heat transfer for iddq mass (hot mass) in block is attached to the semiconductor device, attached block several heat pipe the side not connected to. In addition, heat pipe is designed to be inserted separately number it became work reciprocating hermetic. However a positive number as an ion implantation mask such as cooling device described above has a pore, in addition connected portions upper limit efficient cooling performance to a logic number that has been point at the door. Related technology domestic registration patent number 0159980 call (the registered in 2005. 01. 18, name: the semiconductor cooling device with heat pipes computers) disclosure is heat pipe cooling device is corrosion disclosed. Heat pipe cooling device is also 1 of the existing method is is also shown. Heat pipe cooling device of Figure 1 includes a block (30) has a diameter module (10) on, heat pipe (10) in contact with a plurality of heat fins (20) consists of the. Different portions of the existing method heat pipe cooling device is coupled to the composite must be however up to a specific process, according to the several heat pipe capacity need disclosed. In addition, electronic components of the existing method is a block for heat generated from the heat of the heat pipe cooling device is needed, in the form of piping coupled between heat pipe with a planar electronic component further encoded block for fixing small number. The, said cooling device is an electronic component with heat pipe is followed by a second heat exchanger must be several overload at the memory. The present invention refers to number point provided which secures the door in order to solve such as described above, the purpose of the invention vibration there excellent heat transfer properties and also, the adhered to lances formed electrical component, and which can improve heat exchanging performance through direct heat exchange cooling heat exchanger [...] number are disclosed. The heat exchanger of cooling electrical component therein according to one embodiment of the invention using thermosiphon tubules (100a) widthwise plurality formed, extending in the vertical direction the vibrating tubules (100a) type heat pipe replaced and, twisted at least at a point heat exchanging section (110) is formed heat transfer members (100) including a characterized substrate. In addition, the heat exchanger according to one embodiment of the invention (1) is said heat exchange section (110) direction of the width of one or both sides surface, electrical component (2) is like disclosed. In addition, according to one embodiment of the invention the heat exchange section (110) is accumulated in said (100) and the remaining area of the 90° rotated state as can be twisted. In addition, the accumulated according to one embodiment of the invention (100) includes a plurality can be arranged in a longitudinal direction. In addition, the accumulated according to one embodiment of the invention (100) has a height is of constant longitudinally bone (121) and acids (122) to be repeated to cover the corrugated, twisted opposite direction at regular intervals and at least two points, twisted between points heat exchange section (110) can be located. In addition, the according to one embodiment of the invention said heat transfer members (100) includes a number 1 point (101) to + 90° and is twisted, number 2 point (102) to which the twisted -90 °, point number 1 (101) and number 2 point (102) located between the plurality of heat exchange section (110) can be collinear with a longitudinal direction. In addition, the heat exchanger according to one embodiment of the invention (1) is accumulated in said (100) is a plurality predetermined distance in the widthwise direction can be arranged. In addition, the accumulated according to one embodiment of the invention (100) twisted point is located between the heat exchange section (110) is rounding can be folded disclosed. In addition, the accumulated according to one embodiment of the invention (100) includes said heat exchange section (110) of two points in the passivation bent 90° width direction formed flat, heat 2 can be arranged in the widthwise direction. In addition, the heat exchanger according to one embodiment of the invention (1) 2 is disposed heat accumulated in (100) between cooling fan (200) can be with. In addition, the heat exchanger according to one embodiment of the invention (1) is said heat exchange section (110) at a point either into a 90° 1308. In addition, the heat exchanger according to one embodiment of the invention (1) is accumulated in said (100) during, positioned perpendicular longitudinal direction a plurality of planar portion (120) interposed between pin (300) can be further. In addition, the accumulated according to one embodiment of the invention (100) includes said heat exchange section (110) in contact with an electric device (2) the temperature of, said tubules (100a) heat-exchanged air can be packaged in working fluid flow occurs. The, heat exchanger of cooling electrical component of the present invention excellent heat transfer properties and the adhered to horizontal electric charge there with a plurality of formed, through direct heat exchange to improve exchange tranfectants disclosed. More specifically, the present invention refers to vibration there made of twisted either point by a hot heat transfer, heat exchanging section formed twisted and subjected to an electron and horizontal, parallel to the remaining region can include air flow can be. I.e., the present invention refers to a fluid with the adhered flat heat exchange section which is formed on the first electrical component, along means or through, and can be heat-conducting means heat exchange without direct electrical component, can be low due to the absence of heat-conducting means and to save cost. In addition, the present invention refers to a heat exchanger [...] number region is external air introduction direction or the direction of the cooling fan to the blowing guide member is parallel to the wind, to minimize air flow resistance, the heat transmission between the efficiency can be maximized. In addition, the present invention refers to heat transfer members can be variously sized and shaped in the form of, a wide range of fields to control disclosed. Further, the present invention refers to heat transfer section there by applying, tubules regardless of whether the heat exchange according to the nature of working fluid capable of modulating, temperatures that the electrode can be applied to a heat exchanger omega. Figure 1 shows a schematic diagram indicating the heat pipe cooling device also of the existing method. Figure 2 shows a heat exchanger of cooling electrical component according to one embodiment of the invention therefore indicating sensors mounted thereon. Figure 3 shows a heat exchanger of cooling electrical component indicating the elevational view of Figure 2. Figure 4 shows a heat exchanger of cooling electrical component indicating the side view of Figure 2. Figure 5 shows a heat exchanger of cooling electrical component indicating heat transfer in part perspective view of Figure 2. Figure 6 shows a number indicating the decoded signal accumulated in tank also order of Figure 5. Figure 10 also 7 to various heat transfer members in the embodiment. Figure 11 shows a heat exchanger of cooling electrical component also another in the embodiment according to of the present invention indicating sensors mounted thereon. Figure 12 shows a heat exchanger of cooling electrical component indicating heat transfer in part perspective view of Figure 11. Hereinafter, the present invention according to the appended drawing electric cooling heat exchanger such as described above with reference to detailed as follows. Also as shown in 2 to 4 also, the projections of the present invention for cooling electrical components (230) includes a heat transfer members (100) formed by. Said heat transfer members (100) includes a thermosiphon principle tubules inside (100a) widthwise plurality formed, extending in the vertical direction the vibrating tubules (100a) consisting of a heat pipe. In particular, said heat transfer members (100) and at least from one point twisted, twisted portions heat exchange section (110) in the circulating path to, said heat exchange section (110) direction of the width of one or both sides surface, electrical component (2) is like disclosed. The, said heat exchange section (110) is accumulated in said (100) and the remaining area of the rotated state as 90° twisted by a hot, formed twisted heat exchanging section (110) of the electrical element (2) is subjected to horizontal and, preferably parallel to the remaining region can include air flow to. As shown in fig. 2, the heat exchanger of cooling electrical component according to one embodiment of the invention (1) has a cooling fan (200) can be modulated with, said heat exchange section (110) [...] number remaining region is a cooling fan (200) arranged side by side in the direction of the blowing guide member is by wind, can be minimize air flow resistance. Simultaneously, the heat exchanger of cooling electrical component according to one embodiment of the invention (1) is said heat exchange section (110) is, remaining heat transfer members (100) region to 90° twisted by a hot, heat-conducting means along means or without electrical component (2) pivotably on a fluid with the surface. To one in the embodiment, as also shown in 5 to 8 also, said heat transfer members (100) has a height is of constant longitudinally bone (121) and acids (122) to be repeated to cover the corrugated, twisted opposite direction at regular intervals and at least two points, twisted between points heat exchange section (110) can be located. The, said heat transfer members (100) includes a number 1 point (101) to + 90° and is twisted, number 2 point (102) to the -90° twisted by, point number 1 (101) and number 2 point (102) located between the plurality of heat exchange section (110) can be allocating collinear with a longitudinal direction. Said heat exchange section (110) is not necessarily number 1 point (101) and number 2 point (102) is defined which is twisted by 90° in correspondingly, a greater or lesser angle needed twisted disapproval. In addition, said heat transfer members (100) includes a plurality of tubules in the widthwise direction (100a) is formed, having height longitudinally bone (121) and acids (122) is repeated to crumple can be formed. More specifically, said heat transfer members (100) is axially situated perpendicular planar portion (120) on, said planar portion (120) bent round than the ends of the bone (121) and acids (122) is formed a plurality alternating longitudinal direction. Said tubules (100a) accumulated in the (100) formed along another form regular intervals can be formed, as shown in (a) also 6, preferably formed of a circular cross-section. Said tubules (100a) capillary (100a) developing therein by can flow filled with working fluid to a minimum diameter hollow is formed preferably, working fluid after filling, open opposite end closed with each other. Said heat transfer members (100) includes a flat side of a number can be tank through a mini tube extrusion molding, during the extrusion within tubules (100a) can be simultaneously to be formed. Then, corrugated tube is inserted lines a wave pattern to be formed therein. Extrusion capillary tube prepared by the number (100a) is open at the both ends of the form, open tube bent in such a way that after disposed at case, tubules (100a) filled with a working fluid inside the screw body. Then, closed at both ends of the tube to tubules (100a) filling a working fluid does not leak to diffuse to the outside. The, tube is sealed to the ends of the press may be, in addition to various forms can be closed. Then, said heat transfer members (100) is of constant intervals (6 (b) also reference) and at least two points opposite direction twisted, twisted point located between the heat exchange section (110) is rounding can be folded disclosed. (( (C) also 6 reference) Also shown in 5 and 6 also also accumulated in (100) includes a heat exchange section (110) at regular intervals in the respective bent 90° 2 times, heat transfer members (100) has a vibration tubules (100a) predetermined distance in the widthwise direction a heat pipe heat 2 disposed thereon. To another in the embodiment, also shown in heat transfer members 7 (100) includes said number 1 point (101) and number 2 point (102) located between the heat exchange section (110) bend can be undoped heat exchanger (1) can be used. In this case, said heat transfer members (100) includes said heat exchange section (110) one or both surface width direction of the electrical component (2) is disposed to one surface, said planar portion (120) between the pin (300) can be further interposed. In addition, said heat transfer members (100) when the heat exchanger (1) is accumulated in said (100) one or width direction of the side of the cooling fan (200) is arranged on the chassis base can be further improved. To another in the embodiment, 8 also shown in heat transfer members (100) is nearly identical but also 7, 7 also as number 1 point (101) and number 2 point (102) located between the heat exchange section (110) is adjacent heat exchange section (110) disposed outward depending on without, neighboring heat exchanging section (110) to keep a clearance can be spaced disclosed. To another in the embodiment, 9 also shown in heat transfer members (100) are interlinked direction from one point to a twisted line 90° only in the form of vibration tubules (100a) type heat pipe disposed plurality longitudinal predetermined distance the airscrew. The, heat exchanger (1) includes a heat exchange section (110) to electrical component (2) is accumulated to one surface (100) is disposed plurality, remaining heat transfer members (100) spaced space of air to heat transmitting medium can flow (100) direction of the width of either side and cooling fan (200) is disposed can be formed. To another in the embodiment, also shown in heat transfer members 10 (100) of Figure 8 and 7 also is accumulated (100) in the same manner as on, number 1 point (101) to + 90° and is twisted, number 2 point (102) to the -90° twisted by, point number 1 (101) and number 2 point (102) located between the plurality of heat exchange section (110) parallel longitudinal disposed thereon. In addition, accumulated of Figure 10 (100) includes said heat exchange section (110) are bent 90° either point. The, accumulated of Figure 10 (100) is applied to the heat exchanger (1) is said heat exchange section (110) one or both surface width direction of the electrical component (2) is in contact with the one surface can be arranged to. Next, of Figure 11 heat exchanger (1) of Figure 7 is accumulated in (100) that the predetermined distance in the widthwise direction is disposed plurality, each heat transfer members (100) of heat exchange section (110) outer surface electrical component (2) is arranged, neighboring heat transfer members (100) of heat exchange section (110) into the space between electrical component (2) can be disposed. In this case, said heat exchanger (1) into the space between the cooling fan (200) can be modulated with, each accumulated in (100) plane unit (120) pin (300) can be further interposed. As above-mentioned, the present invention according to heat exchanger of cooling electrical component (1) comprises a heat transfer members (100) unit to adjust the number of points in the water, twisted formed heat exchanger (110) is varied area of, heat exchange section (110) in a cured resin layer permits embodiment bracket number change differently. Next, with reference also to 2 and 3 also, the heat exchanger of cooling electrical component according to one embodiment of the invention (1) of the SFC operation of process, Said heat exchanger (1) is accumulated in said (100) of heat exchange section (110) in contact with the electrical component (2) overheat when heated while operating said tubules (100a) packaged in working fluid flow thereto. Through, said heat exchanger (1) is said heat exchange section (110) to an accumulated in (100) area process is, accumulated heat is delivered to an output (100) decides in cooling fan (200) in terms of the blowing guide member is wind and heat exchange. I.e., said heat exchanger (1) includes a heat exchange section (110) is being [...], remaining heat transfer members (100) region by moving the plate shape, heat exchange section (110) an interview it became the arrowhead electrical component (2) cooling system combustion chamber. The, heat exchanger of cooling electrical component of the present invention (1) has good heat transfer properties and interspersed with a plurality of there electric charge (2) is formed on one surface to, improve through direct heat exchange exchange tranfectants disclosed. In addition, heat exchanger of cooling electrical component of the present invention (1) is heat exchanging section (110) is formed on a flat electrical component (2) by a fluid with the interview on, along means or through, without electrical component heat-conducting means (2) and can be direct heat exchange, can be low due to the absence of heat-conducting means and to save cost. In the embodiment of the present invention refers to said correspondingly limited, range of applications with a variety of system creates, in the claims claim the subject matter of invention made without deviating from the present invention if the person with skill in the art in various modifications and flawless as well as anyone capable of embodiment are disclosed. 1: heat exchanger of cooling electrical component 2: electrical component 100: heat transfer members 100a: tubules 101: number 1 point 102: number 2 point 110: heat exchange section 120: planar portion 121: bone 122: acid 200: cooling fan 300: pin The present invention relates to a heat exchanger for cooling an electric element, and more particularly, to a heat exchanger for cooling an electric element in which a vibration tube type heat pipe having excellent heat transfer characteristics is formed to be in surface contact with an electric element, thereby improving heat exchange performance through direct heat exchange. COPYRIGHT KIPO 2017 A working fluid filled tubules (100a) widthwise plurality formed, the vibrating there replaced and extending in the vertical direction, at a point at least one twisted heat exchanging section (110) is formed heat transfer members (100) including an electric device characterized in that a heat exchanger of cooling. According to Claim 1, said heat exchanger (1) is said heat exchange section (110) direction of the width of one or both sides surface, electrical component (2) is heat exchanger of cooling are electrically like a belt. According to Claim 2, said heat exchange section (110) is accumulated in said (100) and the remaining area of the rotated state as characterized 90° twisted are electrically heat exchanger of cooling. According to Claim 3, said heat transfer members (100) for a long time direction separated from each arranged at the heat exchanger of cooling an electric device characterized. According to Claim 3, said heat transfer members (100) has a height schedule longitudinally bone (121) and acids (122) to be repeated to cover the corrugated, twisted opposite direction at regular intervals and at least two points, twisted between points heat exchange section (110) is placed an electric device characterized in that the heat exchanger of cooling. According to Claim 5, said heat transfer members (100) and (101) + 90° is twisted to the point number 1, number 2 point (102) to which the twisted -90 °, point number 1 (101) and number 2 point (102) located between the plurality of heat exchange section (110) collinear with a longitudinal positioning an electric device characterized heat exchanger of cooling. According to Claim 6, said heat exchanger (1) is accumulated in said (100) is arranged at the predetermined distance in the widthwise direction a plurality heat exchanger of cooling an electric device characterized. According to Claim 6, said heat transfer members (100) located between the point of the beetle it is gentle heat exchanging section (110) characterized by a round bracket than electric heat exchanger of cooling. According to Claim 8, said heat transfer members (100) includes said heat exchange section (110) of two points in the passivation bent 90° width direction formed flat, being disposed heat exchanger of cooling an electric device characterized in the widthwise direction 2. According to Claim 9, said heat exchanger (1) 2 is disposed heat accumulated in (100) between cooling fan (200) is attached an electric device characterized heat exchanger of cooling. According to Claim 10, said heat exchanger (1) is said heat exchange section (110) at a point either into a heat exchanger for cooling electrical cosmetologic 90°. In number 1, said heat exchanger (1) is accumulated in said (100) during, positioned perpendicular longitudinal direction a plurality of planar portion (120) interposed between pin (300) characterized in further including electric heat exchanger of cooling. According to Claim 1, said heat transfer members (100) includes said heat exchange section (110) in contact with an electric device (2) the temperature of, said tubules (100a) packaged in heat exchange be guided working fluid heat exchanger for cooling electrical occurs.