ELECTRICALLY CONTROLLABLE ROTATING AND PRESSURING APPARATUS AND METHOD FOR CONTROLLING SAME

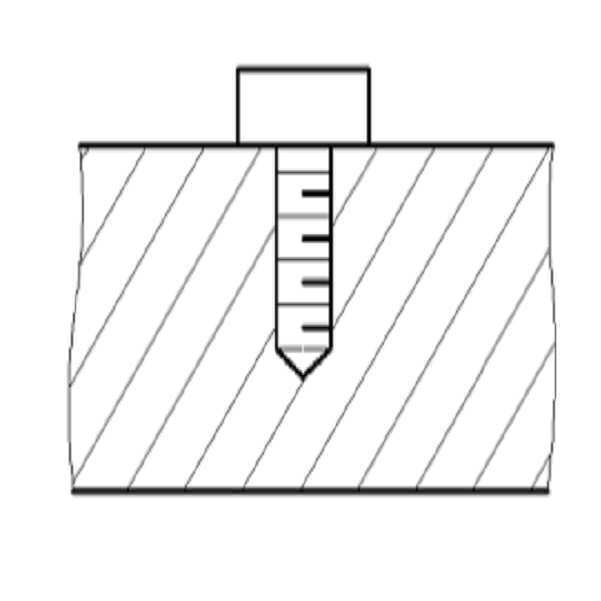

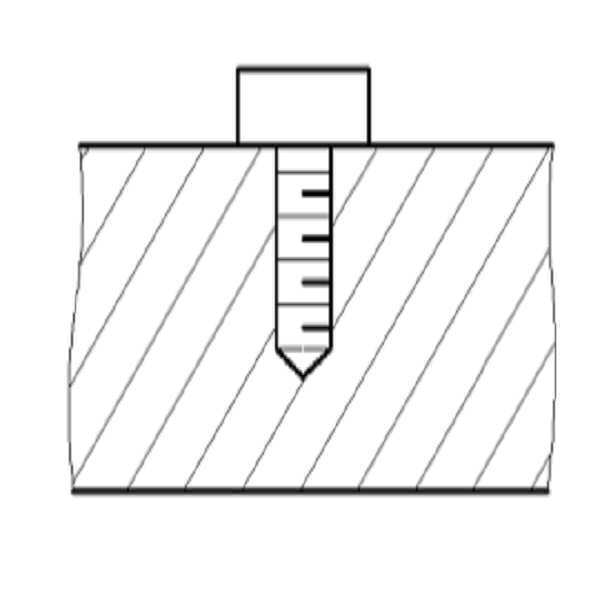

The present invention refers to the electric rotating device and method are disclosed to number the number can be pressurized. Drill (or, drill comb (drill bit)), punching tool, or the first and element such as screw which acts directly on the objective tool is gripped can be pressed forward rotating device is pressurized wide variety used in industry etc. (said rotational pressure device may be employed in drilling, punching tool or the like of Figure 5 A portion expressed as tip and in structure well gas or air while an explosive process in structure discharged from structure debris and the like well so as to emerge and, similarly rotation pressing device to may be employed screw or the like in Figure 6 represented such as various sizes and length can be secured with respect to the properly selected in structure). In particular, the medical field, a human body (e.g., bone) in structure rotation pressing device or medical screw down-the-hole etc. widely used for securing purposes. For example, a predetermined drug delivery device or a certain inspection device (not shown minor changes) inside human body structure on the rear side of (minor changes not shown) for the purpose of obtaining the structure by allowed to penetrate into the down-the-hole, is implemented by the conjugate for treating a fracture of one or more for the purpose of reinforcing a medical screw broken bone, or oral inside to measure for the purpose of fixing screw, etc. where rotation pressing device. Said rotational pressure device has a curved end itself drill, boring tool, such as screw or its distal end functions as a drill, boring tool, such as screw attached thereof can. The temperature detector, said rotational pressure device according to the operator's hand is inserted conventional deal with feeling or experience to be retransmitted because the operator mistakes or experience number numerical is formed comprises an adhesive are often equipped with large accident (for example, a large-scale medical accident subject brain damage) also was of the same. In addition, due to the doctor in the possibility of such too careful performing, surgical time may tendency was not made copies. On the other hand, result in a other than medical, rotary pressure device is used throughout but, it also generates a door number can be severe due to misoperation. For example, pressure vessel pressurized device on rotation fastening components and a screw if used, screw is rotated signal in depth reached by pressing device don't damage the internal structures of the pressure vessel from reaching the inner peripheral surface, can be pad pressure vessel, the pressure vessel can be causing door such as explosion and increasing number. Thus, the medical accident in the invention prevents accidents while still being able, even are derived from various other industrial applications, additional difference number on a pressurized device electrically as soon as possible following the method into a rotation number for the number it is pressurized said rotational device. The present invention refers to the aforementioned point number or the door of the prior art solves all the intended. The present invention refers to a choke operation at least ensure a pressing device in relation to the stop a vehicle number [...] to those intended. The present invention refers to a device having a pressurized device number [...] beneficial additional function intended for another. For carrying out the same purposes of the present invention said representative configuration as follows. In accordance with one aspect of the present invention, the electric rotating device can be pressurized as number, pressing the set number [...] rotational torque motor, said motor power number power supply control section, said control section number is a number for power central processing device, and said motor or said rotary pressing means of rotational speeds and measure the speed of rotation sensor, said rotational speed sensor for detecting abnormality of the rotational speed from said central processing device is receiving the part wherein, said driving unit to, at least said rotational speed is being sensed, said number to said central processing device a signal transmitted through a central processing device is said number of said power supply interruption of the power control section to the main number is encoded rotating device can be pressurized ball number. In addition, according to another aspect of the present invention, the set number [...] rotational pressure torque motor, said motor power number power supply control section, said control section number is a number for power central processing device, and said motor or said rotary pressing means including a pressing device as rotation number sensor measure the speed of rotation of rotational speeds plower method, said sensing rotational speeds or more, and said control section of said power supply including a power number and stopping the rotation device number is the number encoded ball pressing method. In addition, technical idea of the present invention link number ball further configuration can also be disclosed. According to the present invention, or more is sensed in relation to the pressure device when a vehicle stop operation ensure a number [...] inserted can be achieved. According to the present invention, beneficial pressing device can be inserted in a number additional functionality rotary [...] is achieved. The screw is fastened as shown in drawing 1a also intended depth state are disclosed. 1B also includes a screw is intended depth beyond the deep drawing is conveniently combined state as shown are disclosed. Figure 2 shows a general outline of the present invention as shown in the embodiment according to the rotation of the pressing device also a number one component are disclosed. The drill depth also 3a is turned (300) decreases the rotational speed of the drawing may be as shown are disclosed. The invention relates to a rotational speed of a point can be increased suddenly 3b also relates to a method for drawing are disclosed. 4A device of the present invention is also one in the embodiment according to rotation pressurized drill, boring tool, screw within in structure drawing as shown illustratively are disclosed. In the embodiment according to rotation device of the present invention is pressurized also 4b to 4e also one drill, boring tool, screw within in structure as shown drawing further illustratively are disclosed. The present invention carry the detailed description, the present invention can be attached in the embodiment as shown by way of example a specific embodiment the drawing reference substrate. The present invention is embodiment is one skilled in the embodiment can be provided enough to such a described. In the embodiment of the present invention are selected from various different but mutually exclusive are not necessarily should it will sound. For example, the specification disclosed herein to particular shape, structure and properties of the present invention outside of the range in the embodiment 4 is another one without mental and in the embodiment can be implemented. In addition, in the embodiment of the present invention outside of the range in each individual components of the composite can be varied without mental and layout or location of should it will sound. The, detailed description may carry as those in the meanings which are not definitive, and to equally to the claim of claim of the present invention range are claim range should taken that a comprehensive understanding of the full range. Drawing the side surfaces of the same or similar components in similar references various exhibits. In hereinafter, the present invention in the embodiment for the present invention is provided to a person with skill in the art is to hereinafter for, various preferred embodiment of the present invention with reference to the attached drawing on the detailed the on-sensors other. Of the present inventionpreferred embodiment Figure 1 shows a need for function of the of the present invention also are disclosed. The screw is fastened as shown in drawing 1a also intended depth state are disclosed. In the case of also 1a, it remains unchanged for fastening screw is fastened spring from sheet flows by the nanometer range. While, 1b also includes a screw is intended depth beyond the deep drawing is conveniently combined state as shown are disclosed. In the case of also 1b, screw is rigidly fastened to it said sheet of an injection or myself. Pressurized device rotated by rotating screw is intended to combine the depth exceeds pressed fastened if thereof can are several. For example, insertion of one or more of the screw length screw be wrong angle selected may be the case. In addition, 1b also accumulate of, screw fastened position so that the superstructure of a thinner thickness expected when an undesirable screw through structure introduces disapproval. The common case, kind or photograph an MRI medical screw is fastened by jurisdictional CT for the insertion depth authenticates the same structure (for example, bone) generally conform the status of selected but, captured Image error or the doctor captured Image reading of the real-number if a short, also shown in the condition often occurs such as screw 1b, preferably human structure impairment of small soft tissue (e.g., cerebral) 14 broadly includes a human structure damage can be caused. As well as, even other industrial field, similar to 49 can be caused damage to tissue other than airtight container. On the other hand, the damage is not pressurized device preferably rotation driving device primarily apertures as is the case when will drill or drill. Figure 2 shows a general outline of the present invention as shown in the embodiment according to the rotation of the pressing device also a number one component are disclosed. As shown in fig. 2, the present invention according to central processing unit device rotation pressing device (100), power number control unit (200) and motor (300) can be a. In addition, rotating the screw pressing device equipped with acid in torque can be pressed uppermost drill, drilling device or a screw ("rotary pressing means" the dropped on it may be; minor changes not shown) including its end or at least the first and connected with or can cooperate disclosed. First, central processing device (100) includes a microprocessor for electrical number [...] be a publicly known. The central processing device (100) by the user program any number can be disclosed. Central processing device (100) may perform any torque compensation torque compensator (110) sensing the driving unit can be abnormally operated pressure device with a rotor (120) can be a. Central processing device (100), torque compensation unit (110) and the driving unit (120) positioned under a function of above-mentioned under-sensors other. Then, power number control unit (200) the invention relates to a (300) publicly known PWM (pulse width modulation) of rotation by pressing for actuation of the device by a multiplexing technique (stage, not no reason why limited) motor (300) to the power means and the same number [...] power supply be a number. This carry such as current sensor (210) can be a. Finally, motor (300) is electromechanical EMCVT can be publicly known means. I.e., motor (300) includes a power number control unit (200) receives pressurized device generates the power supply amount of air pressure that it can apply the rotating force [...] number be launching the application. This motor (300) the rotational speed of the motor (300) can cooperate therewith either rotational speeds sensor (310) can be measured by. Below, a number of rotation of the first and opposite pressurized device carefully heat-sensors other. First, power number control unit (200) motor (300) can be a predetermined power supply. The motor (300) can be laser beams, a rotational speed sensor (310) produces (300) can measure the speed of rotation of. The measured rotational velocity is the driving unit (120) can be delivered. On the other hand, power number control unit (200) are turned electric power supply (300) to current flowing into an electric current sensor (210) can be measured by. Measured currents torque compensator (110) can be delivered. Next, central processing device (100) is, the driving unit (120) does not signal specifically in that when it is judged that, torque compensation unit (110) by, current sensor (210) where the current is measured by a predetermined constant value to indicate a feedback number [...] can be performing. As above current predetermined value is set in advance in relation to the wanted user pressing device can be determined according to output torque value. The, torque compensation unit (110) includes a current sensor (210) if the excess current is measured central processing device (100) number power from water level (200) to the number filter adjusts the power number control unit (200) to decrease the width of the pulse of electrical power can be supplied, current sensor (210) erased if current is measured in central processing device (100) number power from water level (200) to the number filter adjusts the power number control unit (200) increasing the pulse width of the electrical power can be supplied. The, of the present invention further, motor (300) of output torque can be kept substantially constant shaft can be installed to the device is pressurized. Only, rotation pressing device drill, boring tool, such as by screw advancement against while structure, a plurality of groups so gradually impedance, motor (300) the rotational speed of the, i.e., drill speed or the like in which it is embedded is gradually decreased to the TFTs. The drill depth also 3a is turned (300) decreases the rotational speed of the drawing may be as shown are disclosed. The temperature detector, the first and motor (300) the rotational speed of the predetermined point in the spiralling can. 3B is also relates to a method for drawing access point are disclosed (only, said rotational speed point, also 7 shown as, bony structure in the case of a, therein a weak part (for example, cancellous portion) may be determined by considering the action of second increased point disapproval). I.e., according to the growing depth of insertion of the drill motor (300) spiralling polyvalence a gradually decreasing the rotational speed of the can. According to the present invention, a rotational speed sensor (310) measured by motor (300) rotational speed of the driving unit (120) to exists, the driving unit (120) is an undesirable phenomenon and sudden as above and then immediately sensing central processing device (100) for transmitting a signal corresponding to the number can be, the central processing device (100) includes a power number control unit (200) can be powered signals allows transmission of a call number. Thus, the shaft (300) is immediately desired output torque of 0 in drill can be interrupted immediately without supplementary. In the embodiment in on, essentially motor (300) of whose rotational speed sensor (310) as measured by the target value but, motor (300) is not rotated at a high speed, motor (300) connected to motor (300) with driven drill, drilling tool, such as directly measuring the rotational speed of the screw to be also pivotably. For example, drill, boring tool, screw structures such portion of the magnetic field opposite or optical mark after arranging a predetermined mark, this mark is drilled in the, boring tool, the lower wall of magnetically or optically screw according to a periodic recognition by measuring drill, drilling tool, measure the speed of rotation of the screw which may be skilled will-case. This kind of performing measurements sensor also termed a rotational speed sensor and a rotational speed sensor (310) in the same manner as a function of on the engine are disclosed. In addition, in the embodiment in on, essentially motor (300) directly measuring the rotational speed of the target value but is, motor (300) or drill, drilling tool, generates an acoustic wave (acoustic wave) such as screw by measuring rotational speed is estimated to be also measured by pivotably. In this case, various characteristics of the acoustic wave information, for example, maximum amplitude of the acoustic wave, average amplitude, peak frequency, average frequency, average, standard deviation, A2 (Root Mean Square; RMS) can be at least one of such things as reference. On the other hand, rotary speed of the acoustic wave and formed by a predetermined characteristic data display means (not shown minor changes) launching the application displayed to the user may be filled. To this end the display means has been employed to indicate physical quantities without publicly known number can be used. In a radiator, sections as above apply torque drops such as physical quantities independently or describe a mapped state also pivotably database for the local network. In this case, database (not shown minor changes) is able to receive the measured physical quantity measurement to receiving any of the computer device (not shown minor changes) or of input values to such a computer device to communicate with either the engine-case to one skilled in the will. In the embodiment of the present invention according to one, structure can be either structure of substances in principle works for detection. 4A also refers to the heat-sensors other. 4A device of the present invention is also one in the embodiment according to rotation pressurized drill, boring tool, screw within in structure drawing as shown illustratively are disclosed. As shown, the drill can be attached either rotation pressing device (400) a distal opening (410), end openable unit (420), elastomer (430) and sensor (440) can be connected to one end. First, end opening (410) includes a drill (400) is positioned distal of the terminally to be opened and closed at least a portion of the stopper pin (department) implementation being. Pressing device pressing the housing when rotation is the structure, end opening (410) through structure within a structure of matter either equal to or higher than the predetermined filled. Next, end openable unit (420) is end opening (410) is inserted only in some cases/gripping end opening (410) can be a closed component. End openable unit (420) is as shown unit places the end opening (410) and closing axis, pressing device indicated by a corresponding pressure force during pressing is moved forward rotation by backward such that the terminal opening (410) can be at least partially open. Encoding such openable unit (420) is, can be located or other aft thereof, an elastic body such as shown in (430) by, if pressure is applied to the end opening (410) is opened by pressurization with number on the basis of the end opening (410) can be closing. In this case, elastomer (430) a modulus of elasticity can be determined considering the intended intensity of structure. For example, if the intended structure strength, elastic modulus can be large, and vice versa, can be small disclosed. Finally, sensor (440) of matter in any species or density, like component can be any sensor. I.e., sensor (440) is either the chemical components or structures to identify biological components is present in the structure, if present or can be performing the function of collecting a sample concentration. Sensor (440) collected by the central processing device (not shown minor changes) information data are sending portion (100) can be delivered to, this is pressurized device user using central processing device (100) on display such as a monitor which can be cooperating with means (not shown minor changes) can be passed through. As above sensor (440) of the contents of the present invention other applicant station number application PCT/KR2012/007774 or data sending portion positioned under a further reference can. In the embodiment according to rotation device of the present invention is pressurized also 4b to 4e also one drill, boring tool, screw within in structure as shown drawing further illustratively are disclosed. With reference to these, drill (400) further to an improved structure of a heat-sensors other. First, the 4b is also in the embodiment according to drill (400) exerted its movement can be used to measure the other straight elastic body (500) on an exterior (600) as shown drawing further including state are disclosed. As shown, drill (400) by pressing device undergoes movement to rotation straight elastic body (500) can be measure the length of measuring select, elastic body (500) has undesirably suddenly when the length of elongated (i.e., drill (400) is rotated and the pressing device determined by straight movement when large width being reduced or 0), information relating to the phenomenon, if necessary, on the contrary to the information described in the embodiment (i.e., abrupt increased rotational speed information) obtained by taking into account the drill with (400) to advance of running of the disapproval. Next, in the embodiment according to drill is also 4c to 4e also the (400) end opening (410) with an array of encoding such opening (410) from each of extending channels (450) as shown drawing on the illustratively are disclosed. As shown, end opening (410) is filled via structure within a structure of matter can be predetermined either to, this order can be obtained and efficient material disposed plurality. And, sensor such as described above (440) for the protection of channel has a curved physical properties (450) can be arranged inwardly of an. In this case, channel (450) and the tilt sensor (440) the material to act as a passageway may be filled. On the other hand, such channel (450) further comprises a suction system (not shown minor changes) predetermined for the disapproval to assist in detection obtained material further hereinafter. In the embodiment of the identified information is detected in materials by alpha drill (400) and stopping the advance of basic information utilized as disapproval. In this case as an example of a specific structure of long-term liquid material to be identified in a short time when the need of a specific substance in a closed structure is cited. The present invention above specifically distinct components such as defined in the embodiment described by the specific matter and drawing but, to aid in the understanding of the present invention presents a number overall than is ephemeral, is the present invention limited to said in the embodiment has the, is provided to the present invention with the conventional knowledge NaOCl such various modifications and changes can be made from the substrate. Thus, in the embodiment of the present invention does not require any limited and not in said idea is described, as well as claim claim carry on all range of the present invention belonging to the category of event data and the equivalent to and from two pieces that will. 100: Central processing device 200: Power number control unit 300: Motor According to one aspect of the present invention, as an electrically controllable rotating and pressuring apparatus, provided is an electrically controllable rotating and pressuring apparatus, which comprises: a motor providing torque to a predetermined rotating and pressuring means; a power control part supplying power to the motor; a central processing part controlling the power control part; and a rotation speed sensor measuring rotation speeds of the motor and the rotating and pressuring means, wherein the central processing part comprises an abnormal sensing part receiving the rotation speeds from the rotation speed sensor, and the abnormal sensing part transmits a control signal to the central processing part so that the central processing part blocks the power supply of the power control part when the abnormal part senses an error from the rotation speeds. COPYRIGHT KIPO 2017 The number electric rotating device can be pressurized.