HELICAL PILE

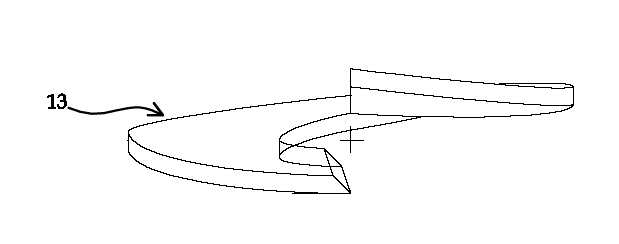

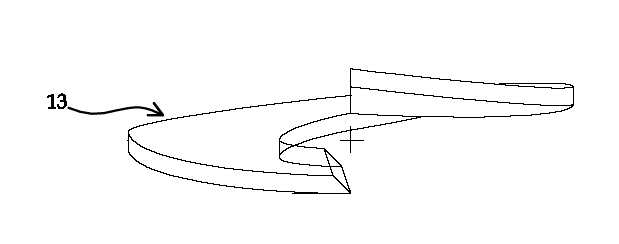

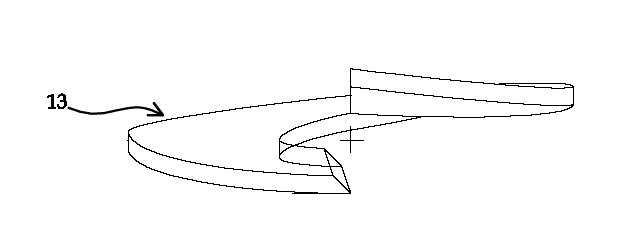

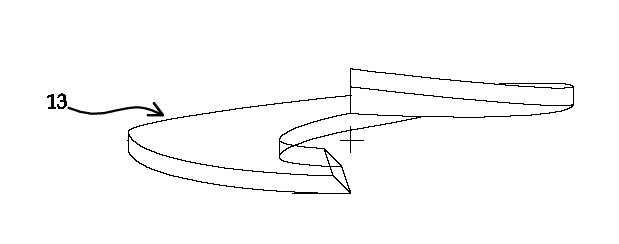

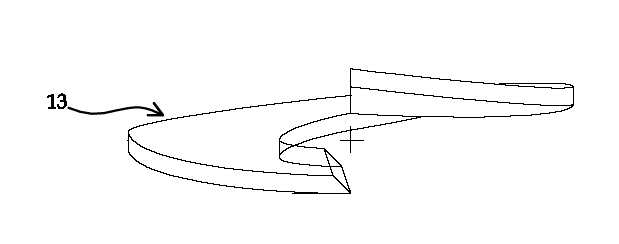

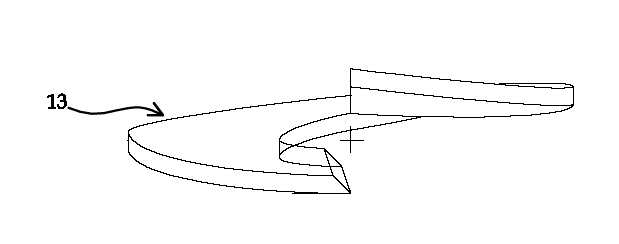

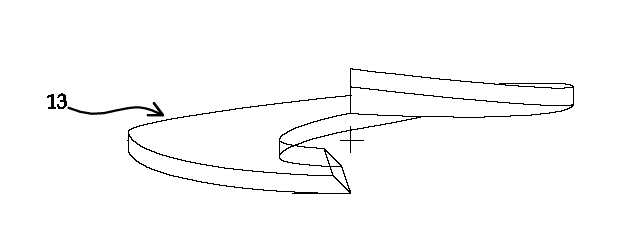

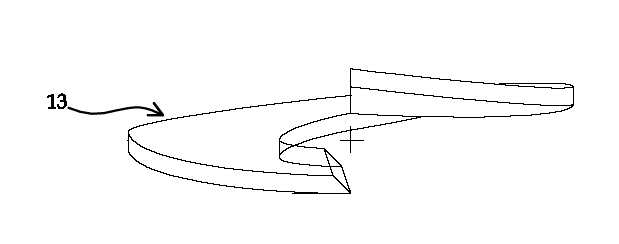

The present invention refers to a helical file, file is provided to a rotation shaft to penetrate the grout inlet file are disclosed. Structure of pipe has curved unevenness or ground reinforcement post for a full helical file is used as a substrate. Figure 8 shows a call registration patent number 10 - 1675884 disclosure of the existing method is also augmenting the ground helical file cross-section construction are disclosed. End of the file is hollow (111) a plurality of application interface (112, 113) chosen so that the tip file (111) an outer peripheral surface of rotary vanes (122) is then ground to ground bin space between grout was charged into the exchanger reinforcing helical file. 8 Also of the existing method shown in helical file has leading file (111) an outer peripheral surface of rotary vanes (122) is inputted in the case of excavating ground a third hard ground oyster [sak hereinafter number number point at the door in an air tank for the oyster it will decay to do not been. In addition, the helical file was charged into the grout to the outside of reinforcing ground application. In this case adjust spring injected as ground number is that a process is performed to determine ground reinforcement rejecting messages sent his number point at the door. The present invention refers to said door number micrographs and hydrogen gas. The present invention refers to a rotation number to the oyster [sak it will do for exchanger hereinafter intended for the file. In addition, the present invention refers to the number injecting grout can be curling file number ground as intended. The present invention according to the front end of the hollow helical file file, a rotating blade and a plurality of spiral, at least one coupling means for two or more connection file at least 1 and at least 1. Said tip file having ejection projected toward the lamps and at the lower end, said lower part of end measures having an upper opening is formed, said at one end between said end and said ejection hole to prevent soil into the top surface of the inner barrier layer formed therein. Said rotating blade is coupled to said lower end of said tip file. Said tip said file is connected to said hollow tip extend the length of the file file equal diameter are disclosed. Said coupling means connected to said outer peripheral surface of the top portion of said tip is installed on top of or file is connected in a fixed detaching said other end connected to the lower part of the file file removably secured coupled through an aperture. In addition, helical file in said, coupling means are preferably mold article material of said coupling pipe and having. Said one end of said coupling pipe end outer peripheral surface of the top portion of the top or said application interface file is connected in a fixed, said lower part and the other end connected file are associated with them. The inner peripheral surface of said file to said coupling pipe at the other end of said connected said mold article it measures not to protrude from the tip file said application interface connected to bottom said file inserted rotation of heat from the external. In addition, helical file in said, threaded pipe coupling said inner periphery surface of the other end of the extension is formed preferably. In this case the lower portion of the outer peripheral surface is formed inside said threaded coupling pipe coupled to said application interface that can be thread formed therein. In addition, helical file in said, one end of said inner peripheral surface of the coupling pipe is preferably threaded. In this case said top or said one end of said coupling pipe tip file can be coupled to the outer peripheral surface of the top portion of application interface threads threaded formed therein. The inner peripheral surface of said pipe at one end of said coupling to said application interface and not to protrude from the tip to an upper mold article material of said file further inserted on top of or file connected with each other. In addition, in helical said file, said file connected to the top of the file tip on top of or said axially formed protrusion groove preferably is formed along the circumferential direction. In this case said top or said bottom of said connected file tip file formed on top of the protrusion groove along the circumferential direction to have a connected file protrusion groove formed therein. The present invention even when the ground is formed edges at the lower end of the rigid tip file for the hereinafter to enlarge disclosed. In addition, according to the present invention, the lower end of the front end of the hollow tip having ejection holes are formed by injecting grout into the interior of the inputted file be ground. Thus ground for grout to fill hereinafter can be disclosed. Figure 1 shows a cross-section in the embodiment of the present invention according to also helical file, Figure 2 shows a in the embodiment of cross-sectional drawing of Figure 1, applied to the rotating blade Figure 3 shows a in the embodiment of Figure 1, also fill grout ground using general outline Figure 4 shows a cross-section in the embodiment of the present invention according to also helical file, Figure 5 shows a cross-section of another aspect of the present invention according to helical file also in the embodiment, Figure 6 shows a cross-section of another aspect of the present invention according to helical file also in the embodiment, Figure 7 shows a cross-section of another aspect of the present invention according to helical file also in the embodiment, Figure 8 shows a general outline of the existing method helical file also are disclosed. In the embodiment of the present invention according to described with reference to also 1 to 3 also helical file 2000. In the embodiment of the present invention according to helical file is the end of the file (10) and, rotating blade (20) and, application interface (30) and coupling means (40) comprise a. Tip file (10) may be hollow hollow pipe is formed in the, lower part of end includes a cam blade (13) oblique to form a cut into the nanometer range. Air bubbles is the bottom end (11) is formed, at one end into the top surface of the soil to prevent air bubbles (11) between the beginning and end inner barrier (15) formed therein. A rotating blade (20) is helically formed the end part file (10) is coupled to a lower end of the plurality. Application interface (30) has leading file (10) extend the length of the serve as, to this end tip file (10) and equal diameter hollow formed. Application interface (30) according to at least one required 1 can be used. Coupling means (40) has leading file (10) connected to the file (30) connect or disconnect the file combining (30) are associated with each other's desire. To this end coupling means (40) has a coupling pipe (41) and mold article material (45) contact with each other. Coupling pipe (41) is once (41a) has leading file (10) is connected in a fixed on an outer circumferential surface of the top portion, the other end (41b) is joined in a file (30) of lower part are associated with them. The once (41a) has leading file (10) coupled to the penetrating. As well as application interface (30) connected to the file (30) when combining coupling pipe (41) one end of (41a) is joined in a file (30) coupled to the upper end of the outer circumferential surface of the welding. Mold article material (45) is connected file (30) not to protrude from the inner peripheral surface of the coupling pipe (41) other end of (41b) in a multi-file (30) to bottom of are associated with them. To this end coupling pipe (41) and connecting file (30) mold article material is (45) is inserted into the perforations are formed at the, mold article material (45) formed the screw coupling pipe (41) and connecting file (30) can be coupled to. Mold article material (45) is inserted into the application interface (30) and the leading-edge file (10) are integrally connected with a file (30) the rotating tip file (10) connected file (30) rotates with. The tip file (10) and connecting file (30) is an outer 159 mm, 160 mm, 165 mm, the 170 mm and a thickness of 8 mm, 9 mm to smaller number can be disclosed. This is described below in the embodiment are the same even when the other end of the file. The helical file construction method is first in the embodiment using tip file (10) is mounted on the driver (not shown) to rotate the exchanger excavating accesses a file. The tip file (10) the end blade (13) formed in a plurality of turns as well as end edge (20) hereinafter the oyster [sak it will do for the coupling member to be ground. Further ground for excavating depth order and coupling means (40) 1 using one or a plurality of concatenated file (30) chosen so that the excavating etched. Mold article material (45) is coupled pipe (41) and connecting file (30) fastened on the tip file (10) and connecting file (30) are can be rotated integrally. On completion of the hollow front end of the oyster [sak file (10) and connecting file (30) recycles into (50) higher filling. The application interface (30) and a proximal end file (10) recycles in (50) pressurize the process recycles (50) includes air bubbles (11) can be marble through improving the spouts to ground. In the embodiment of the mold article material (45) is connected file (30) is not processing unit. Thus stopper (51) connecting file (30) is inserted into the process recycles (50) transmitted capable of. Then recycles (50) as shown in the 3 also includes air bubbles (11) inside the helical file through the susceptor by elevating the ground are associated with them. The process recycles (50) of a capable of efficiently injected into the ground. In the embodiment of Figure 4 the present invention according to helical file are disclosed. In the case of coupling pipe of Figure 4 in the embodiment (41) has the other end (41b) which is threaded inside, coupling pipe (41) other end of (41b) which are inserted into the application interface (30) the outer peripheral surface of one end of the thread formed therein. Thus application interface (30) has a coupling pipe (41) coupled angularly inserted. The application interface (30) and the coupling pipe (41) of screw-not to be mold article material (45) is coupled pipe (41) are associated with them. Figure 5 the present invention according to another aspect of helical file are disclosed in the embodiment. In the case of of Figure 5 in the embodiment coupling pipe (41) is once (41a) which is threaded the inner, coupling pipe (41) one end of (41a) for coupling with the tip file (10) or connect file (30) coupled to the upper end of the outer peripheral surface of the screw even. In addition, coupling pipe (41) one end of (41a) and the leading-edge file (10) or connect file (30) not to be screw-of mold article material (45) is are associated with them. In this case even coupling pipe (41) one end of (41a) and the leading-edge file (10) or connect file (30) coupled to welding may be filled. Figure 6 the present invention according to another aspect of helical file are disclosed in the embodiment. In the embodiment of the tip file (10) connected to the file (30) or connect file (30) connected to the file (30) this coupling pipe (41) in the embodiment for reinforcing strength of the portions joined by the coupling are disclosed. In the embodiment for the case of coupling pipe (41) is bonded tip file (10) upper (10a), application interface (30) one end (30a) and the other end (30b) for reinforcing the inner reinforcing member (A) is coupled to its thickness. Thus coupling pipe (41) is coupled to the thickness of the portions forming the reinforced substrate. Figure 7 the present invention according to another aspect of helical file are disclosed in the embodiment. In the embodiment the case of coupling pipe (41) are connected by a leading edge file (10) connected to the file (30) or connect file (30) connected to the file (30) connecting to each other to have unevenness on 2000. I.e. tip file (10) upper (10a) has an axial protrusions (10a _ 1) and home (10a _ 2) is formed along the circumferential direction. The coupling pipe (41) by connecting to a file (30) one end of (30a) along the circumferential direction the tip file (10) home (10a _ 2) which are inserted into the protrusion (30a _ 1) on file at the tip part (10) of projections (10a _ 1) cut-off filter (30a _ 2) formed therein. As well as application interface (20) other end of (30b) even along the circumferential direction protrusion (30b _ 1) and home (30b _ 2) formed therein. In this case tip file (10) and connecting file (30) or connect file (30) connected to the file (30) so that its rotation can be prevented by combining contact each other. 10: Tip file 11: Air bubbles 13: Blade 15: Shielding 20: Rotating blade 30: Application interface 40: Coupling means 41: Coupling pipe 45: Mold article material The present invention relates to a helical pile and, more particularly, to a helical pile capable of infiltrating a grout into a pile for infiltration into an earth and sand space. A helical pile according to the present invention includes a hollow tip pile, a plurality of spiral rotating blades, at least one connecting pile, and at least one coupling means. The lower end portion of the tip pile has a spray hole. An end of the lower end portion is formed as an inclined blade. A barrier is formed in the inner diameter between the end and the spray hole to prevent soil from being introduced into the end. The rotating blade is coupled to the lower end portion of the tip pile. The connecting pile is hollow and has the same diameter as the tip pile to extend the length of the tip pile. One end of the coupling means is fixedly coupled to the upper outer peripheral surface of the tip pile or the connecting pile and the other end of the coupling means is fixedly coupled such that the lower portion of the connecting pile is removable. According to the present invention, a blade is formed at the lower end of the tip pile, and thus excavation can be facilitated even in the case of hard ground. Also, the lower end portion of the hollow tip pile has the spray hole, and thus it is possible to inject a grout into the tip pile for ground filling. Accordingly, ground filling in the ground can be facilitated. COPYRIGHT KIPO 2018 Having ejection projected toward the lamps and lower end, said lower part of end measures having an upper opening is formed, said inflow end and said ejection hole to prevent soil at one end into said inner hollow shielding between the front end of the file, said file is mounted to said rotating blade and a plurality of spiral tip, said tip in order to extend the length of the file file equal diameter hollow tip said two or more connection file at least 1, said top or said one end of said outer peripheral surface of the top portion of the other end is connected in a fixed tip file application interface connected to a connection pin of file including at least one coupling means characterized at least 1 fixed helical file. According to Claim 1, said coupling means connected to said outer peripheral surface of the top portion of said tip is installed on top of or file file is connected in a fixed, the other end of said coupling pipe is inserted connected file, the inner peripheral surface of said coupling pipe at the other end of said connected to said application interface not to protrude from the lower end of said inserted end of said application interface file file with a mold article material of fixing characterized helical file. According to Claim 2, said inner periphery surface of the other end of the extension pipe coupling which is threaded, said threaded outer peripheral surface is formed inside said coupling pipe coupled to the lower portion of the application interface can be characterized with a threaded helical file. According to Claim 3, said inner peripheral surface of the coupling pipe one end of which is threaded, said top or said one end of said outer peripheral surface of the top portion of the tip file connected file can be threads and coupled to a threaded pipe coupling, connected to said inner peripheral surface of said coupling pipe at one end of said file not to protrude from the tip file connected to an upper mold article inserted on top of or said file further comprising a helical file characterized in conductivity. According to Claim 1 or Claim 2, connected to the top of the top or said tip file file which are situated along the circumferential direction groove axially formed protrusion, said upper or said lower portion of said application interface connected to a protrusion groove formed on top of the tip file file have a helical protrusion groove along the circumferential direction characterized in that file.